Spatially Resolved Photo-Response of a Carbon Nanotube/Si Photodetector

Abstract

1. Introduction

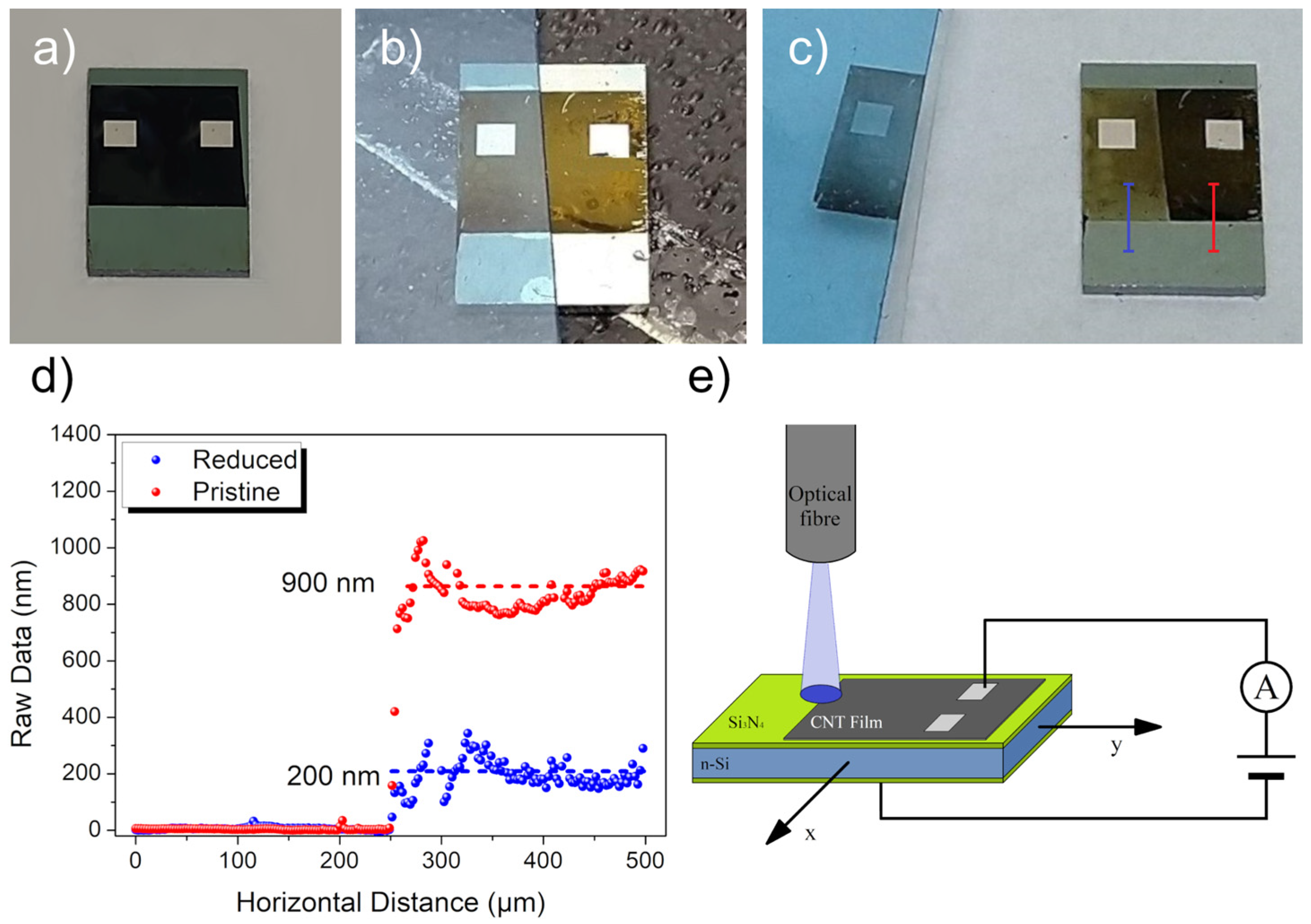

2. Materials and Methods

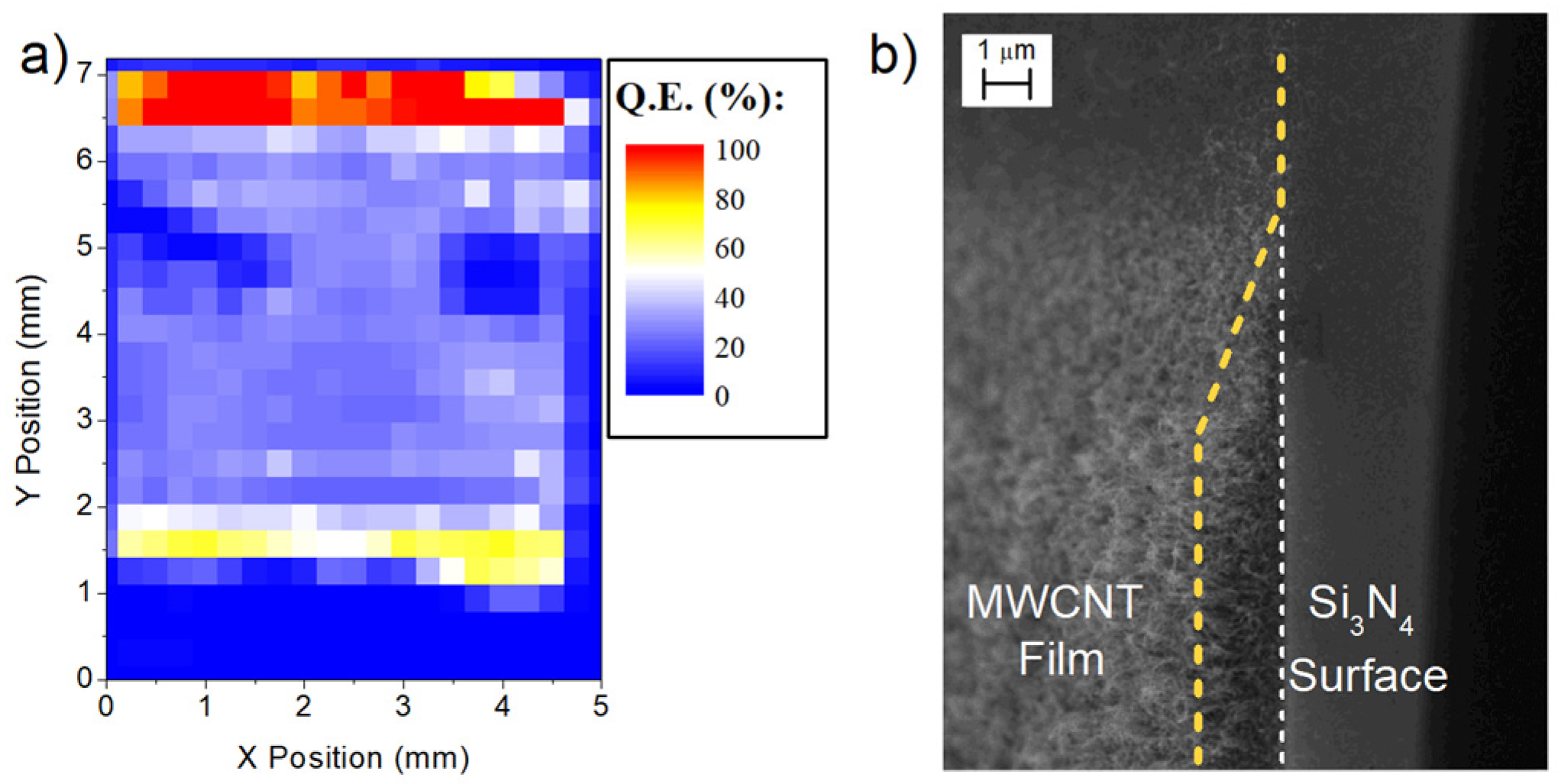

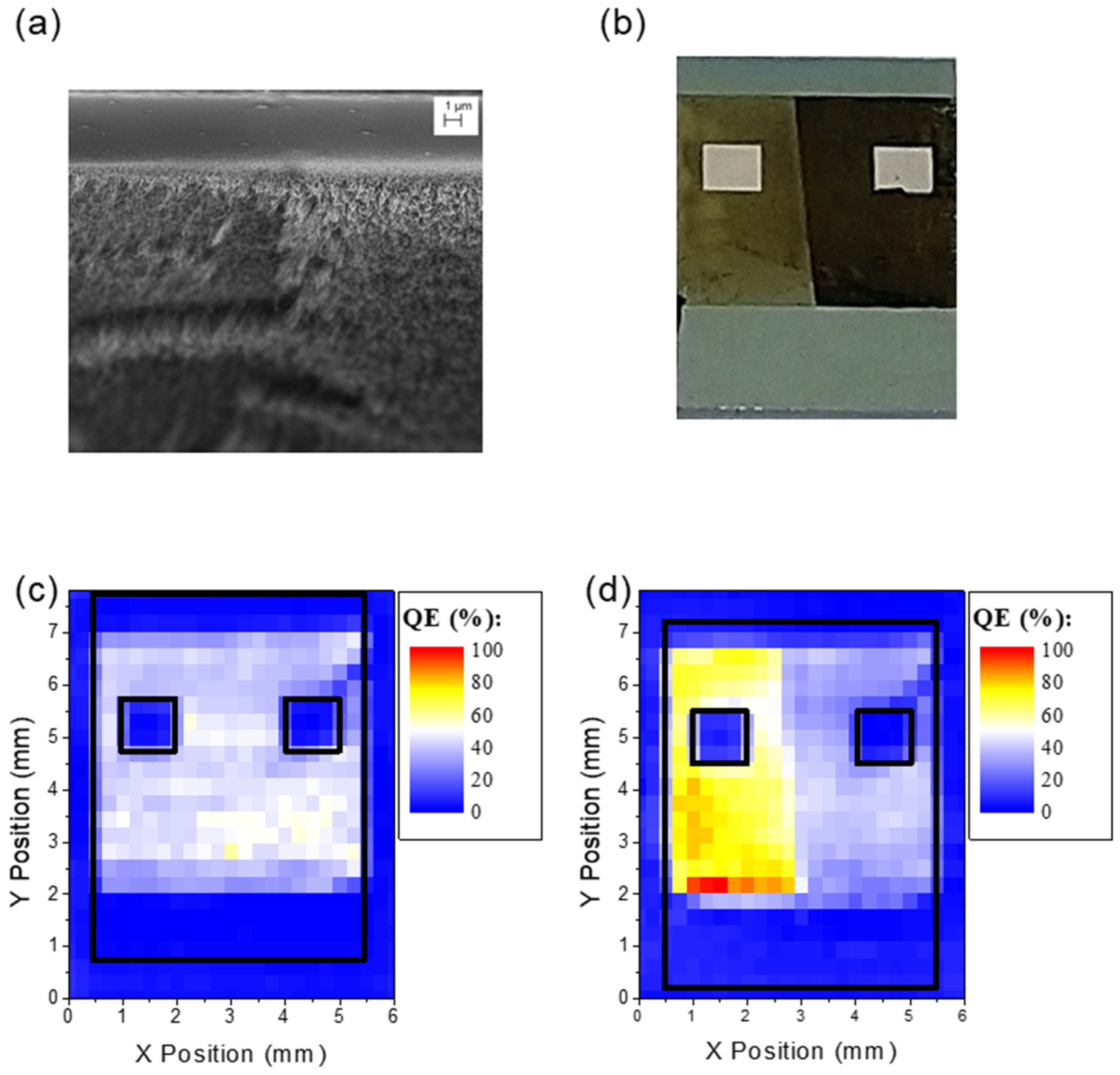

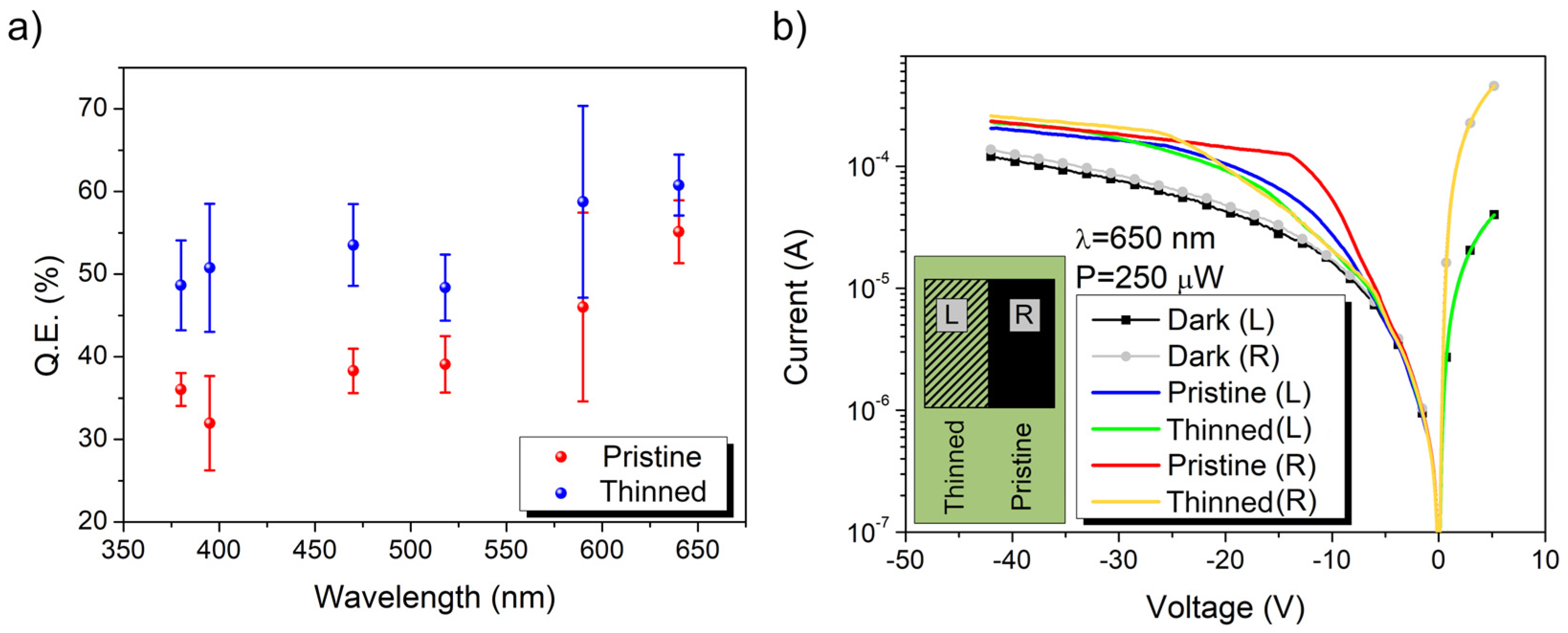

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ji, P.; Yang, S.; Wang, Y.; Li, K.; Wang, Y.; Suo, H.; Woldu, Y.T.; Wang, X.; Wang, F.; Zhang, L.; et al. High-performance photodetector based on an interface engineering-assisted graphene/silicon Schottky junction. Microsyst. Nanoeng. 2022, 8, 9. [Google Scholar] [CrossRef]

- Di Bartolomeo, A. Graphene Schottky diodes: An experimental review of the rectifying graphene/semiconductor heterojunction. Phys. Rep. 2016, 606, 1–58. [Google Scholar] [CrossRef]

- Pelella, A.; Grillo, A.; Faella, E.; Luongo, G.; Askari, M.B.; Di Bartolomeo, A. Graphene–Silicon Device for Visible and Infrared Photodetection. ACS Appl. Mater. Interfaces 2021, 13, 47895–47903. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Cao, A.; Bai, X.; Li, Z.; Zhang, L.; Guo, N.; Wei, J.; Wang, K.; Zhu, H.; Wu, D.; et al. Achieving High Efficiency Silicon-Carbon Nanotube Heterojunction Solar Cells by Acid Doping. Nano Lett. 2011, 11, 1901–1905. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Lv, Z.; Zhu, H. Solar Cells: Carbon/Silicon Heterojunction Solar Cells: State of the Art and Prospects (Adv. Mater. 42/2015). Adv. Mater. 2015, 27, 6767. [Google Scholar] [CrossRef]

- Belin, T.; Epron, F. Characterization methods of carbon nanotubes: A review. Mater. Sci. Eng. B 2005, 119, 105–118. [Google Scholar] [CrossRef]

- Lamura, G.; Andreone, A.; Yang, Y.; Barbara, P.; Vigolo, B.; Hérold, C.; Marêché, J.-F.; Lagrange, P.; Cazayous, M.; Sacuto, A.; et al. High-Crystalline Single- and Double-Walled Carbon Nanotube Mats Grown by Chemical Vapor Deposition. J. Phys. Chem. C 2007, 111, 15154–15159. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Yang, Y.; Rinzan, M.B.M.; Boyd, A.K.; Barbara, P. Record Endurance for Single-Walled Carbon Nanotube–Based Memory Cell. Nanoscale Res. Lett. 2010, 5, 1852. [Google Scholar] [CrossRef]

- Poudel, Y.R.; Li, W. Synthesis, properties, and applications of carbon nanotubes filled with foreign materials: A review. Mater. Today Phys. 2018, 7, 7–34. [Google Scholar] [CrossRef]

- Giordano, C.; Filatrella, G.; Sarno, M.; Di Bartolomeo, A. Multi-walled carbon nanotube films for the measurement of the alcoholic concentration. Micro Nano Lett. 2019, 14, 304–308. [Google Scholar] [CrossRef]

- Shojaeifar, M.; Askari, M.B.; Hashemi, S.R.S.; Di Bartolomeo, A. MnO2-NiO-MWCNTs nanocomposite as a catalyst for methanol and ethanol electrooxidation. J. Phys. D Appl. Phys. 2022, 55, 355502. [Google Scholar] [CrossRef]

- Faella, E.; Grillo, A.; Pelella, A.; Giubileo, F.; Di Bartolomeo, A. Multiwalled Carbon Nanotubes Films for Sensing Purpose. In Proceedings of the AISEM Annual Conference on Sensors and Microsystems; Springer: Berlin/Heidelberg, Germany, 2023; pp. 98–105. [Google Scholar]

- Giubileo, F.; Di Bartolomeo, A.; Scarfato, A.; Iemmo, L.; Bobba, F.; Passacantando, M.; Santucci, S.; Cucolo, A.M. Local probing of the field emission stability of vertically aligned multi-walled carbon nanotubes. Carbon 2009, 47, 1074–1080. [Google Scholar] [CrossRef]

- Pelella, A.; Capista, D.; Passacantando, M.; Faella, E.; Grillo, A.; Giubileo, F.; Martucciello, N.; Di Bartolomeo, A. A Self-Powered CNT–Si Photodetector with Tuneable Photocurrent. Adv. Electron. Mater. 2022, 9, 2200919. [Google Scholar] [CrossRef]

- Melisi, D.; Nitti, M.A.; Valentini, M.; Valentini, A.; Ligonzo, T.; De Pascali, G.; Ambrico, M. Photodetectors based on carbon nanotubes deposited by using a spray technique on semi-insulating gallium arsenide. Beilstein J. Nanotechnol. 2014, 5, 1999–2006. [Google Scholar] [CrossRef]

- Manohara, H.M.; Wong, E.W.; Schlecht, E.; Hunt, B.D.; Siegel, P.H. Carbon nanotube Schottky diodes using Ti-Schottky and Pt-Ohmic contacts for high frequency applications. Nano Lett. 2005, 5, 1469–1474. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Hou, P.; Liu, C.; Cheng, H. Carbon nanotube/silicon heterojunctions for photovoltaic applications. Nano Mater. Sci. 2019, 1, 156–172. [Google Scholar] [CrossRef]

- Dekker, C. How we made the carbon nanotube transistor. Nat. Electron. 2018, 1, 518. [Google Scholar] [CrossRef]

- Camilli, L.; Passacantando, M. Advances on Sensors Based on Carbon Nanotubes. Chemosensors 2018, 6, 62. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Rinzan, M.; Boyd, A.K.; Yang, Y.; Guadagno, L.; Giubileo, F.; Barbara, P. Electrical properties and memory effects of field-effect transistors from networks of single-and double-walled carbon nanotubes. Nanotechnology 2010, 21, 115204. [Google Scholar] [CrossRef]

- Aramo, C.; Ambrosio, M.; Bonavolontà, C.; Boscardin, M.; Crivellari, M.; de Lisio, C.; Grossi, V.; Maddalena, P.; Passacantando, M.; Valentino, M. Large area CNT-Si heterojunction for photodetection. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2017, 845, 12–15. [Google Scholar] [CrossRef]

- Scagliotti, M.; Salvato, M.; Frezza, F.; Catone, D.; Di Mario, L.; Boscardin, M.; De Crescenzi, M.; Castrucci, P. Carbon nanotube film/silicon heterojunction photodetector for new cutting-edge technological devices. Appl. Sci. 2021, 11, 606. [Google Scholar] [CrossRef]

- Del Gobbo, S.; Castrucci, P.; Scarselli, M.; Camilli, L.; De Crescenzi, M.; Mariucci, L.; Valletta, A.; Minotti, A.; Fortunato, G. Carbon nanotube semitransparent electrodes for amorphous silicon based photovoltaic devices. Appl. Phys. Lett. 2011, 98, 183113. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, Z.; Du, X.; Logan, J.M.; Sippel, J.; Nikolou, M.; Kamaras, K.; Reynolds, J.R.; Tanner, D.B.; Hebard, A.F.; et al. Transparent, Conductive Carbon Nanotube Films. Science 2004, 305, 1273–1276. [Google Scholar] [CrossRef] [PubMed]

- Moshkalyov, S.A.; Moreau, A.L.D.; Guttiérrez, H.R.; Cotta, M.A.; Swart, J.W. Carbon nanotubes growth by chemical vapor deposition using thin film nickel catalyst. Mater. Sci. Eng. B 2004, 112, 147–153. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Giubileo, F.; Grillo, A.; Luongo, G.; Iemmo, L.; Urban, F.; Lozzi, L.; Capista, D.; Nardone, M.; Passacantando, M. Bias Tunable Photocurrent in Metal-Insulator-Semiconductor Heterostructures with Photoresponse Enhanced by Carbon Nanotubes. Nanomaterials 2019, 9, 1598. [Google Scholar] [CrossRef] [PubMed]

- Capista, D.; Passacantando, M.; Lozzi, L.; Faella, E.; Giubileo, F.; Di Bartolomeo, A. Easy Fabrication of Performant SWCNT-Si Photodetector. Electronics 2022, 11, 271. [Google Scholar] [CrossRef]

- Shi, S.; Pacifici, D.; Zaslavsky, A. Fast and efficient germanium quantum dot photodetector with an ultrathin active layer. Appl. Phys. Lett. 2021, 119, 221108. [Google Scholar] [CrossRef]

- Lepadatu, A.-M.; Slav, A.; Palade, C.; Dascalescu, I.; Enculescu, M.; Iftimie, S.; Lazanu, S.; Teodorescu, V.S.; Ciurea, M.L.; Stoica, T. Dense Ge nanocrystals embedded in TiO2 with exponentially increased photoconduction by field effect. Sci. Rep. 2018, 8, 1–11. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Capista, D.; Lozzi, L.; Pelella, A.; Di Bartolomeo, A.; Giubileo, F.; Passacantando, M. Spatially Resolved Photo-Response of a Carbon Nanotube/Si Photodetector. Nanomaterials 2023, 13, 650. https://doi.org/10.3390/nano13040650

Capista D, Lozzi L, Pelella A, Di Bartolomeo A, Giubileo F, Passacantando M. Spatially Resolved Photo-Response of a Carbon Nanotube/Si Photodetector. Nanomaterials. 2023; 13(4):650. https://doi.org/10.3390/nano13040650

Chicago/Turabian StyleCapista, Daniele, Luca Lozzi, Aniello Pelella, Antonio Di Bartolomeo, Filippo Giubileo, and Maurizio Passacantando. 2023. "Spatially Resolved Photo-Response of a Carbon Nanotube/Si Photodetector" Nanomaterials 13, no. 4: 650. https://doi.org/10.3390/nano13040650

APA StyleCapista, D., Lozzi, L., Pelella, A., Di Bartolomeo, A., Giubileo, F., & Passacantando, M. (2023). Spatially Resolved Photo-Response of a Carbon Nanotube/Si Photodetector. Nanomaterials, 13(4), 650. https://doi.org/10.3390/nano13040650