Passive Daytime Radiative Cooling of Silica Aerogels

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Silica Aerogels

2.3. Characterizations

2.4. Passive Radiative Cooling Performance of the Silica Aerogels

3. Results and Discussion

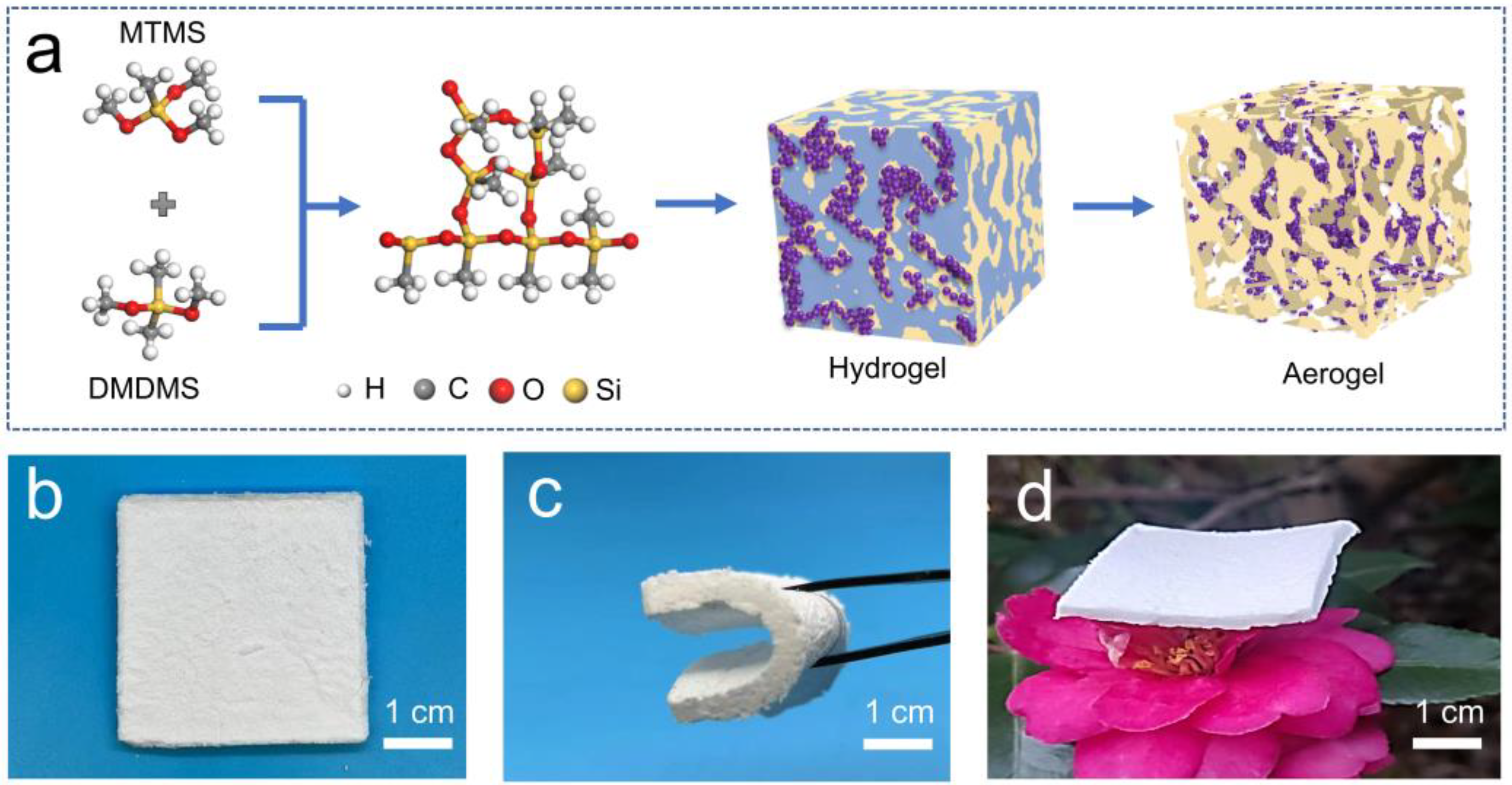

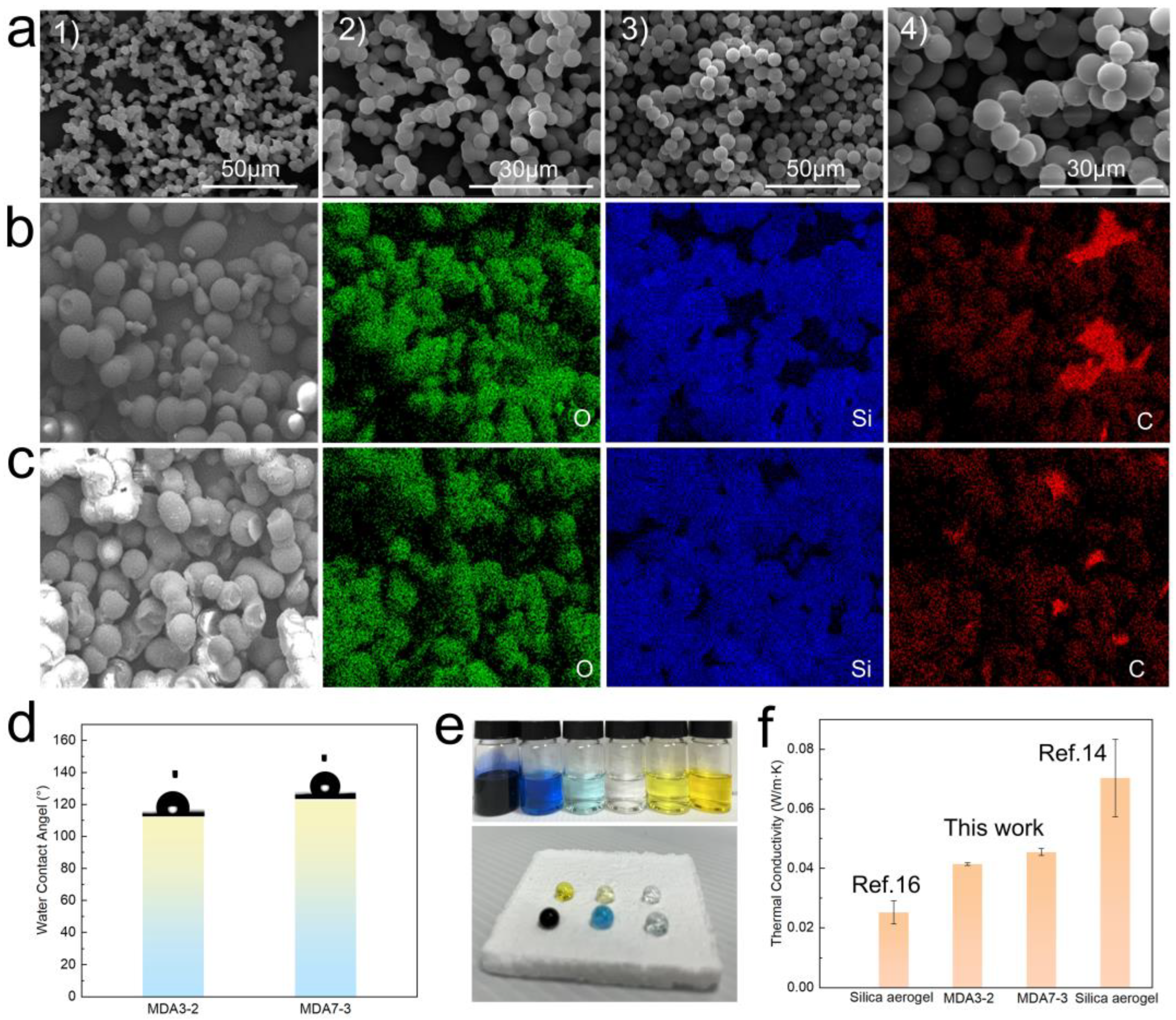

3.1. Synthesis and Characterization of the Silica Aerogels

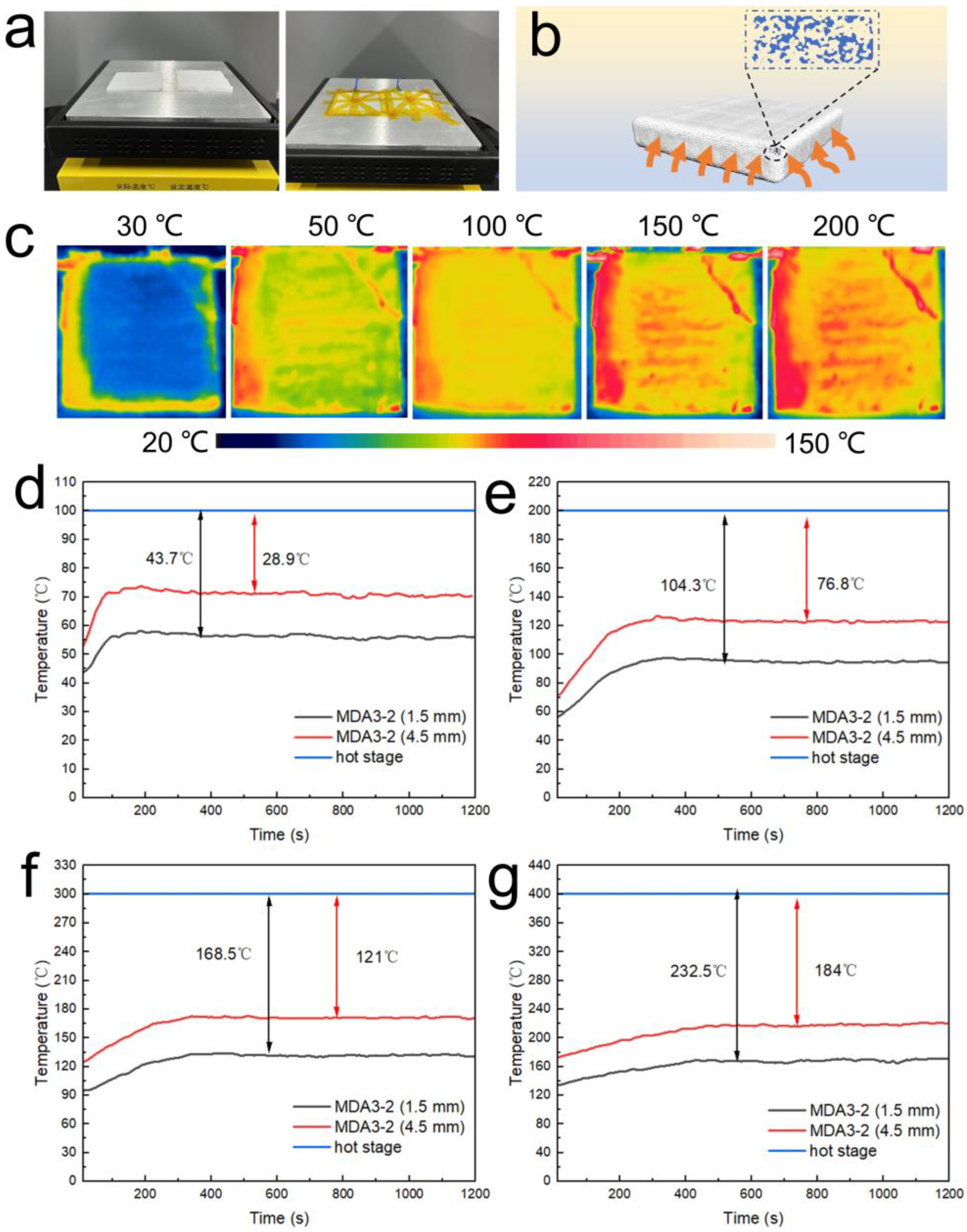

3.2. Thermal Insulation Behavior of the Silica Aerogel

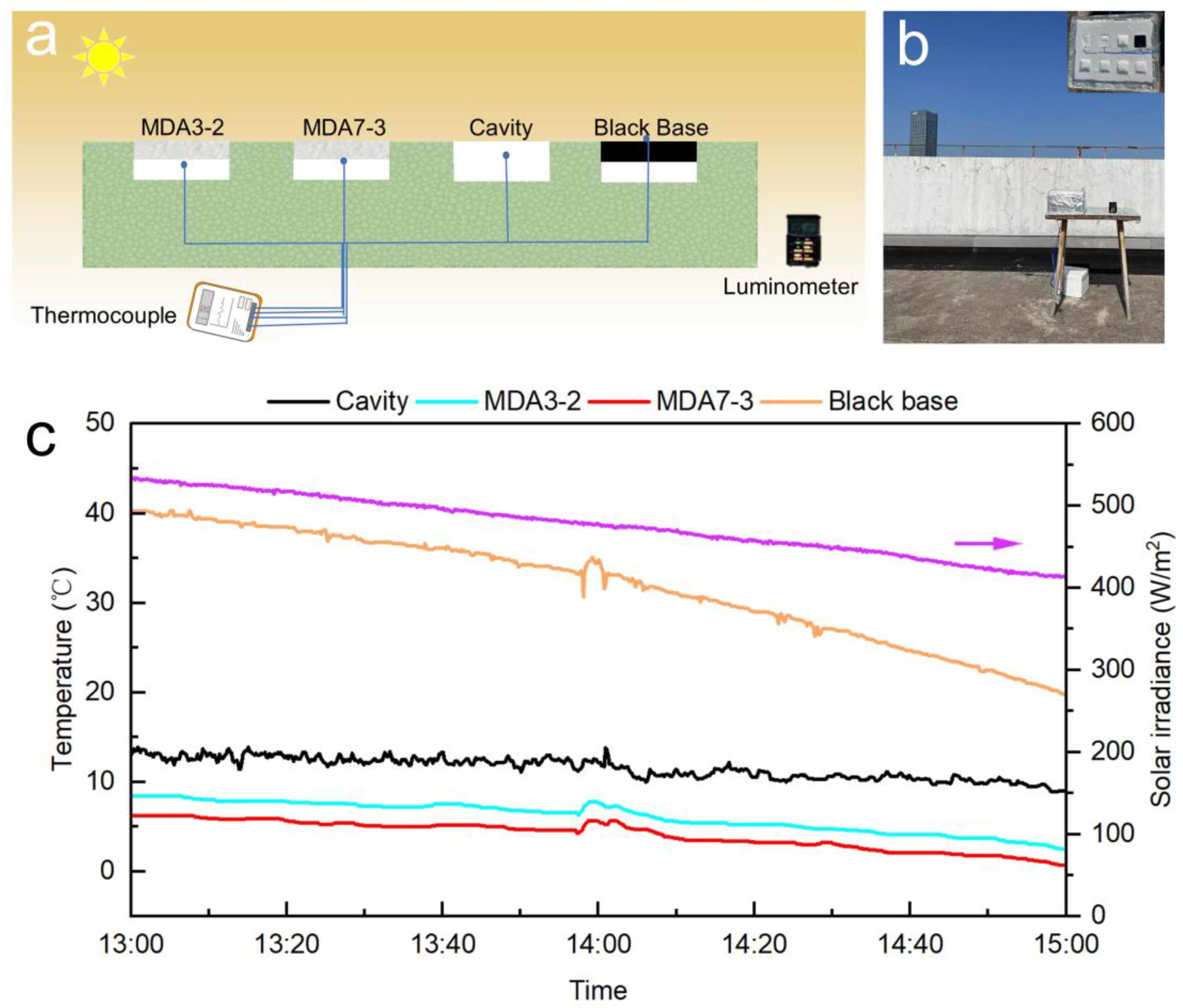

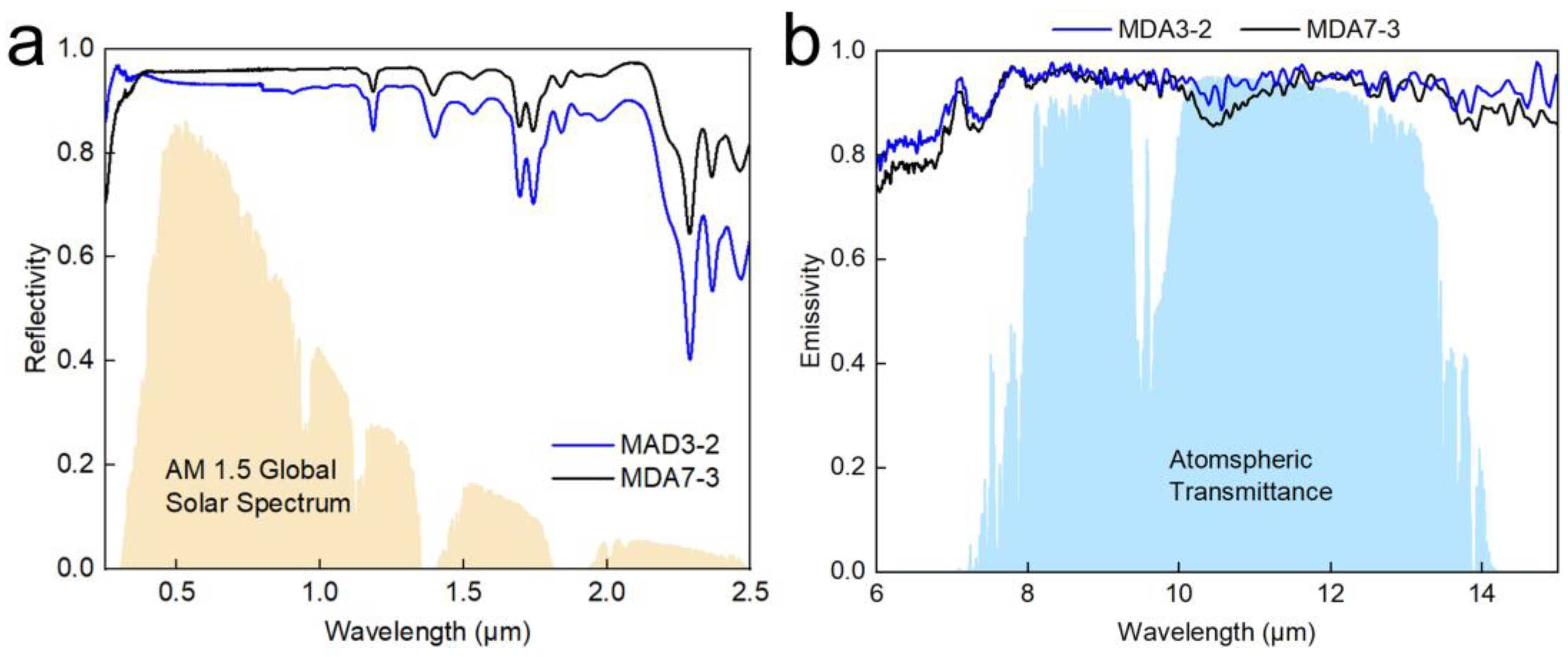

3.3. PDRC Performance of the Silica Aerogels

3.4. Reasons and Proposed Mechanism for PDRC

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lamy-Mendes, A.; Girão, A.V.; Silva, R.F.; Durães, L. Polysilsesquioxane-based silica aerogel monoliths with embedded CNTs. Micropor. Mesopor. Mater. 2019, 288, 109575. [Google Scholar] [CrossRef]

- Kong, Y.; Shen, X.; Cui, S. Amine hybrid zirconia/silica composite aerogel for low-concentration CO2 capture. Micropor. Mesopor. Mater. 2016, 236, 269–276. [Google Scholar] [CrossRef]

- Tabata, M.; Adachi, I.; Kawai, H.; Kubo, M.; Sato, T. Recent progress in silica aerogel Chrenkov radiator. Phys. Procedia 2012, 37, 642–649. [Google Scholar] [CrossRef]

- Perego, D.L. Status of the LHCb silica aerogel Chrenkov radiator. Nuclear Phys. B 2007, 172, 308–310. [Google Scholar] [CrossRef]

- Liu, Z.; Ran, Y.; Xi, J.; Wang, J. Polymeric hybrid aerogels and their biomedical applications. Soft Matter 2020, 16, 9160–9175. [Google Scholar] [CrossRef]

- Qin, L.; He, Y.; Zhao, X.; Zhang, T.; Qin, Y.; Du, A. Preparation, characterization, and in vitro sustained release profile of resveratrol-loaded silica aerogel. Molecules 2020, 25, 2752. [Google Scholar] [CrossRef]

- Wei, W.; Hu, H.; Yin, S.; Li, Y.; Ji, X.; Xie, J. Rational fabrication of chitosan/alginate/silica ternary aerogel beads adsorbent with free separation. Micro Nano Lett. 2019, 14, 142–145. [Google Scholar] [CrossRef]

- Li, Y.; Du, A.; Shen, J.; Zhang, Z.; Wu, G.; Zhou, B. Temperature dependence of dynamic mechanical behaviors in low density MTMS-derived silica aerogel. J. Porous Mater. 2018, 25, 1229–1235. [Google Scholar] [CrossRef]

- Kistler, S.S. Coherent expanded aerogels and jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Karamikamkar, S.; Naguib, H.E.; Park, C.B. Advances in precursor system for silica-based aerogel production toward improved mechanical properties, customized morphology, and multifunctionality: A review. Adv. Colloid Interface Sci. 2020, 276, 102101. [Google Scholar] [CrossRef]

- Alves, P.; Dias, D.A.; Pontinha, A.D.R. Silica aerogel-rubber composite: A sustainable alternative for buildings’ thermal insulation. Molecules 2022, 27, 7127. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Wang, J.; Liao, J.; Zhang, X. Robust silica–polyimide aerogel blanket for water-proof and flame-retardant self-floating artificial island. Front. Mater. 2021, 8, 659655. [Google Scholar] [CrossRef]

- Yan, M.; Fu, Y.; Pan, Y.; Cheng, X.; Gong, L.; Zhou, Y.; Ahmed, H.; Zhang, H. Highly elastic and fatigue resistant wood/silica composite aerogel operated at extremely low temperature. Compos. B Eng. 2022, 230, 109496. [Google Scholar] [CrossRef]

- Liu, L.; Shan, X.; Hu, X.; Lv, W.; Wang, J. Superhydrophobic silica aerogels and their layer-by-layer structure for thermal management in harsh cold and hot environments. ACS Nano 2021, 15, 19771–19782. [Google Scholar] [CrossRef]

- Peng, F.; Jiang, Y.; Feng, J.; Cai, H.; Feng, J.; Li, L. Thermally insulating, fiber-reinforced alumina–silica aerogel composites with ultra-low shrinkage up to 1500 °C. Chem. Eng. J. 2021, 411, 128402. [Google Scholar] [CrossRef]

- Wang, J.; Shang, X.; Hu, P.; Zhang, C.; Yuan, D.; Hu, Y.; Wang, J. Bioinspired multilayer structures for energy-free passive heating and thermal regulation in cold environments. ACS Appl. Mater. Interfaces 2022, 14, 46569–46580. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Y.; Ma, Y.; David, S.N.; Zhao, D.; Lou, R.; Tan, G.; Yang, R.; Yin, X. Scalable-manufactured randomized glass-polymer hybrid metamaterial for daytime radiative cooling. Science 2017, 355, 1062–1066. [Google Scholar] [CrossRef]

- Ma, H.; Yao, K.; Dou, S.; Xiao, M.; Dai, M.; Wang, L.; Zhao, H.; Zhao, J.; Li, Y.; Zhan, Y. Multilayered SiO2/Si3N4 photonic emitter to achieve high-performance all-day radiative cooling. Sol. Energy Mater. Sol. Cells 2020, 212, 110584. [Google Scholar] [CrossRef]

- Jeon, S.; Son, S.; Lee, S.Y.; Chae, D.; Bae, J.H.; Lee, B.; Oh, S.J. Multifunctional daytime radiative cooling devices with simultaneous light-emitting and radiative cooling functional layers. ACS Appl. Mater. Interfaces 2020, 12, 54763–54772. [Google Scholar] [CrossRef]

- Ma, H.; Wang, L.; Dou, S.; Zhao, H.; Huang, M.; Xu, Z.; Zhang, X.; Xu, X.; Zhang, A.; Yue, H.; et al. Flexible daytime radiative cooling enhanced by enabling three-phase composites with scattering interfaces between silica microspheres and hierarchical porous coatings. ACS Appl. Mater. Interfaces 2021, 13, 19282–19290. [Google Scholar] [CrossRef]

- Li, X.; Peoples, J.; Yao, P.; Ruan, X. Ultrawhite BaSO4 paints and films for remarkable daytime subambient radiative cooling. ACS Appl. Mater. Interfaces 2021, 13, 21733–21739. [Google Scholar] [CrossRef]

- Li, X.; Peoples, J.; Huang, Z.; Zhao, Z.; Qiu, J.; Ruan, X. Full daytime sub-ambient radiative cooling in commercial-like paints with high figure of merit. Cell Rep. Phys. Sci. 2020, 1, 100221. [Google Scholar] [CrossRef]

- Kim, G.; Park, K.; Hwang, K.; Jin, S. Highly sunlight reflective and infrared semi-transparent nanomesh textiles. ACS Nano 2021, 15, 15962–15971. [Google Scholar] [CrossRef]

- Zhang, Q.; Lv, Y.; Wang, Y.; Yu, S.; Li, C.; Ma, R.; Chen, Y. Temperature-dependent dual-mode thermal management device with net zero energy for year-round energy saving. Nat. Commun. 2022, 13, 4874. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhu, L.; Raman, A.; Fan, S. Radiative cooling to deep sub-freezing temperatures through a 24-h day–night cycle. Nat. Commun. 2016, 7, 13729. [Google Scholar] [CrossRef] [PubMed]

- Shan, X.; Liu, L.; Wu, Y.; Yuan, D.; Wang, J.; Zhang, C.; Wang, J. Aerogel-functionalized thermoplastic polyurethane as waterproof, breathable freestanding films and coatings for passive daytime radiative cooling. Adv. Sci. 2022, 9, 2201190. [Google Scholar] [CrossRef]

- Hayase, G.; Kanamori, K.; Nakainshi, K. New flexible aerogels and xerogels derived from methyltrimethoxysilane/dimethyldimethoxysilane co-precursors. J. Mater. Chem. 2011, 21, 17077–17079. [Google Scholar] [CrossRef]

- Hayase, G.; Kanamori, K.; Fukuchi, M.; Kaji, H.; Nakanishi, K. Facile synthesis of marshmallow-like macroporous gels usable under harsh conditions for the separation of oil and water. Angew. Chem. Int. Ed. 2013, 52, 1986–1989. [Google Scholar] [CrossRef] [PubMed]

- Hasegawa, G.; Shimizu, T.; Kanamori, K.; Maeno, A.; Kaji, H.; Nakanishi, K. Highly flexible hybrid polymer aerogels and xerogels based on resorcinol-formaldehyde with enhanced elastic stiffness and recoverability: Insights into the origin of their mechanical properties. Chem. Mater. 2017, 29, 2122–2134. [Google Scholar] [CrossRef]

- Kanamori, K.; Aizawa, M.; Nakanishi, K.; Hanada, T. New Transparent Methylsilsesquioxane Aerogels and Xerogels with Improved Mechanical Properties. Adv. Mater. 2007, 19, 1589–1593. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Zhang, X. Reversible superhydrophobic coatings on lifeless and biotic surfaces via dry-painting of aerogel microparticles. J. Mater. Chem. A 2016, 4, 11408–11415. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Wei, Y.; Zhang, X. Fast and one-pot synthesis of silica aerogels via a quasi-solvent-exchange-free ambient pressure drying process. Micropor. Mesopor. Mater. 2015, 218, 192–198. [Google Scholar] [CrossRef]

- Zu, G.; Kanamori, K.; Maeno, A.; Kaji, H.; Nakanishi, K. Superflexible multifunctional polyvinylpolydimethylsiloxane-based aerogels as efficient absorbents, thermal superinsulators, and strain sensors. Angew. Chem. Int. Ed. 2018, 57, 9722–9727. [Google Scholar] [CrossRef] [PubMed]

- Zu, G.; Shimizu, T.; Kanamori, K.; Zhu, Y.; Maeno, A.; Kaji, H.; Shen, J.; Nakanishi, K. Transparent, superflexible doubly cross-linked polyvinylpolymethylsiloxane aerogel superinsulators via ambient pressure drying. ACS Nano 2018, 12, 521–532. [Google Scholar] [CrossRef] [PubMed]

- Aizawa, M. How elastic moduli affect ambient pressure drying of poly(methylsilsesquioxane) gels. J. Sol-Gel Sci. Technol. 2022, 104, 490–496. [Google Scholar] [CrossRef]

- Lu, Z.; Strobach, E.; Chen, N.; Ferralis, N.; Grossman, J.C. Passive sub-ambient cooling from a transparent evaporation-insulation bilayer. Joule 2020, 4, 2693–2701. [Google Scholar] [CrossRef]

- Zhao, L.; Bhatia, B.; Yang, S.; Strobach, E.; Weinstein, L.A.; Cooper, T.A.; Chen, G.; Wang, E.N. Harnessing heat beyond 200 °C from unconcentrated sunlight with nonevacuated transparent aerogels. ACS Nano 2019, 13, 7508–7516. [Google Scholar] [CrossRef]

- August, A.; Kneer, A.; Reiter, A.; Wirtz, M.; Sarsour, J.; Stegmaier, T.; Barbe, S.; Gresser, G.T.; Nestler, B. A bionic approach for heat generation and latent heat storage inspired by the polar bear. Energy 2019, 168, 1017–1030. [Google Scholar] [CrossRef]

- Bhagat, S.D.; Oh, C.; Kim, Y.; Ahn, Y.; Yeo, J. Methyltrimethoxysilane based monolithic silica aerogels via ambient pressure drying. Micropor. Mesopor. Mater. 2007, 100, 350–355. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X. Binary crystallized supramolecular aerogels derived from host-guest inclusion complexes. ACS Nano 2015, 9, 11389–11397. [Google Scholar] [CrossRef]

- Fang, Q.; Shan, X.; Liu, L.; Hu, X.; Wang, J. Design and Synthesis of Phase-Change-Material Aerogels for Personal Thermal Management. Acta Polym. Sin. 2022, 53, 165–173. [Google Scholar]

- Xu, B.; Cai, J.; Finn, N.; Cai, Z. An improved method for preparing monolithic aerogels based on methyltrimethoxysilane at ambient pressure Part I: Process development and macrostructures of the aerogels. Micropor. Mesopor. Mater. 2012, 148, 145–151. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, J.; Sun, Q.; Ye, X.; Ma, X.; Wang, J. Sol–gel routes toward ceramic nanofibers for high-performance thermal management. Chemistry 2022, 4, 1475–1497. [Google Scholar] [CrossRef]

- Mandal, J.; Fu, Y.; Overvig, A.C.; Jia, M.; Sun, K.; Shi, N.N.; Zhou, H.; Xiao, X.; Yu, N.; Yang, Y. Hierarchically porous polymer coatings for highly efficient passive daytime radiative cooling. Science 2018, 362, 315–319. [Google Scholar] [CrossRef]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef]

- Chen, M.; Pang, D.; Chen, X.; Yan, H.; Yang, Y. Passive daytime radiative cooling: Fundamentals, material designs, and applications. EcoMat 2022, 4, e12153. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, S.; Wang, X.; Jiang, Y.; Li, J.; Xu, W.; Zhu, B.; Zhu, J. Recent progress in daytime radiative cooling: Advanced material designs and applications. Small Methods 2022, 6, 2101379. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.; Peng, H. Making passive daytime radiative cooling metafabrics on a large scale. Adv. Fiber Mater. 2022, 4, 3–4. [Google Scholar] [CrossRef]

- Chen, M.; Pang, D.; Yan, H. Colored passive daytime radiative cooling coatings based on dielectric and plasmonic spheres. Appl. Thermal Eng. 2022, 216, 119125. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Q.; Song, Y.; Zhu, B.; Zhu, J. Fundamentals, materials, and applications for daytime radiative cooling. Adv. Mater. Technol. 2020, 5, 1901007. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, B.; Cheng, Y.; Hu, P.; Fang, D.; Wang, J. Passive Daytime Radiative Cooling of Silica Aerogels. Nanomaterials 2023, 13, 467. https://doi.org/10.3390/nano13030467

Ma B, Cheng Y, Hu P, Fang D, Wang J. Passive Daytime Radiative Cooling of Silica Aerogels. Nanomaterials. 2023; 13(3):467. https://doi.org/10.3390/nano13030467

Chicago/Turabian StyleMa, Bingjie, Yingying Cheng, Peiying Hu, Dan Fang, and Jin Wang. 2023. "Passive Daytime Radiative Cooling of Silica Aerogels" Nanomaterials 13, no. 3: 467. https://doi.org/10.3390/nano13030467

APA StyleMa, B., Cheng, Y., Hu, P., Fang, D., & Wang, J. (2023). Passive Daytime Radiative Cooling of Silica Aerogels. Nanomaterials, 13(3), 467. https://doi.org/10.3390/nano13030467