Effect of Grain Refinement on the Comprehensive Mechanical Performance of W–Cu Composites

Abstract

1. Introduction

2. Experimental

2.1. Materials and Methods

2.2. Characterizations

3. Results and Discussion

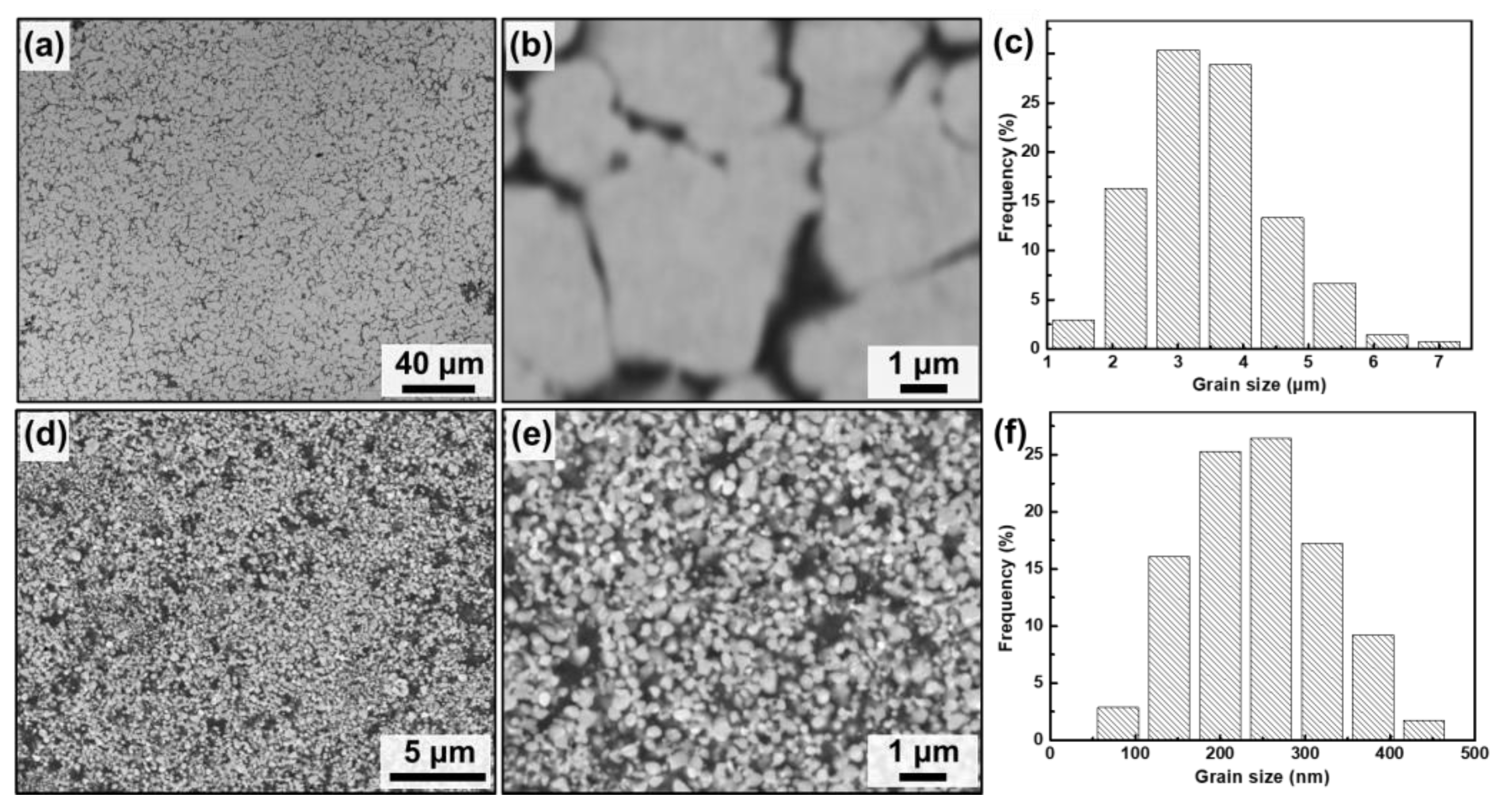

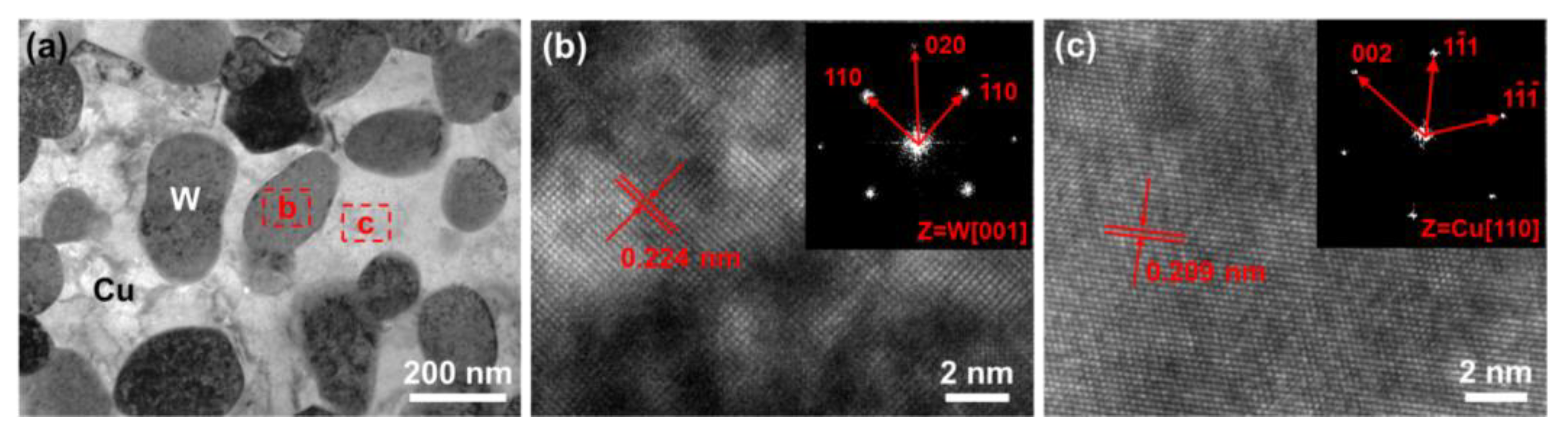

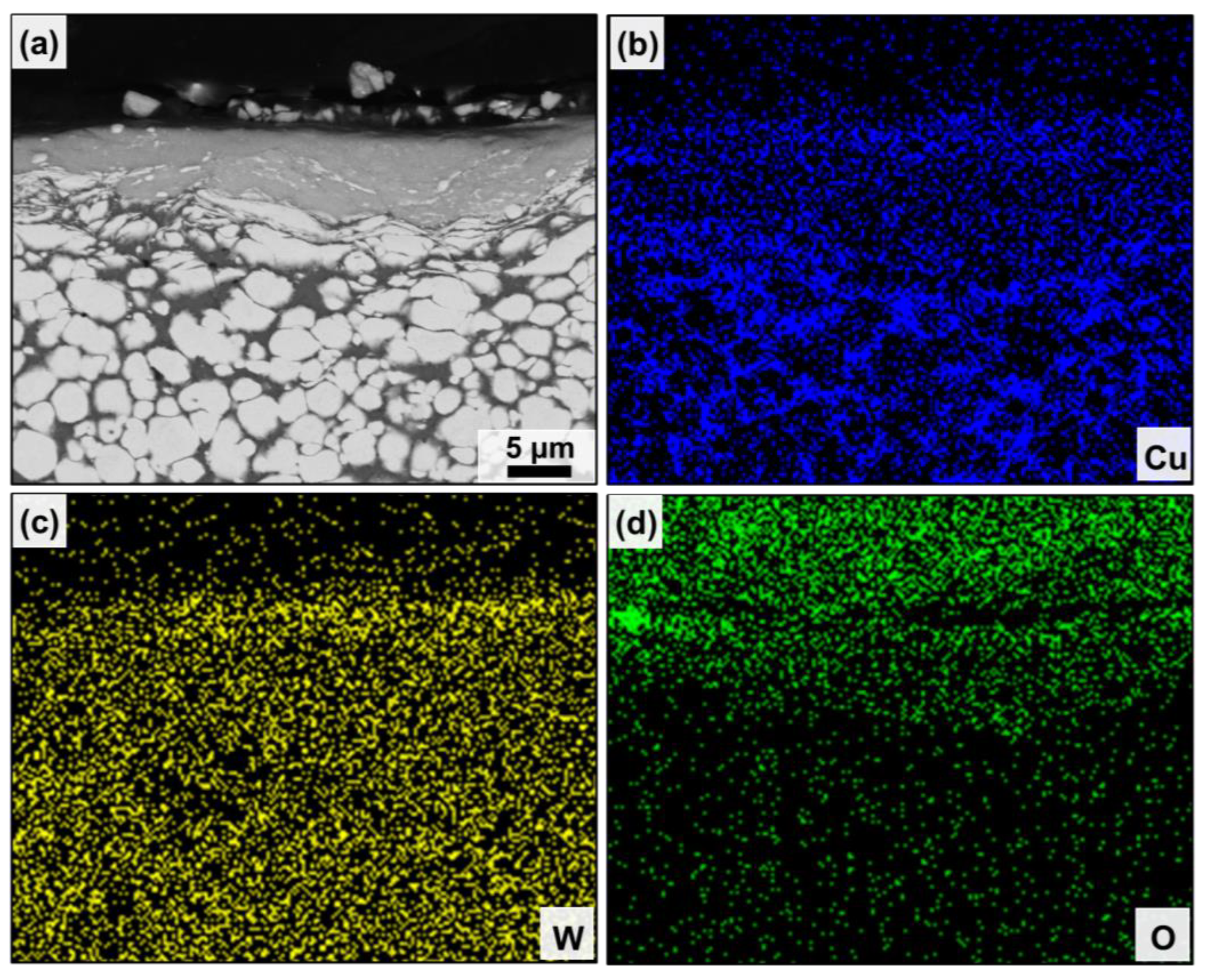

3.1. Microstructures and Properties

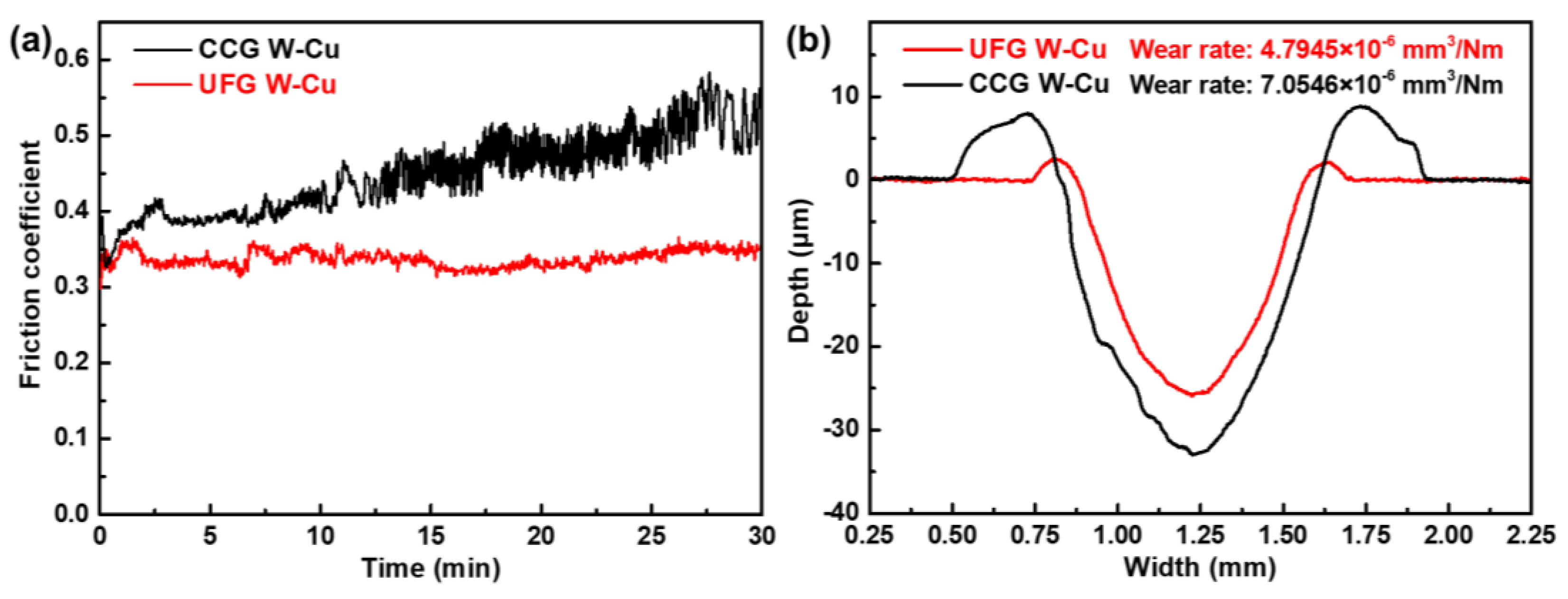

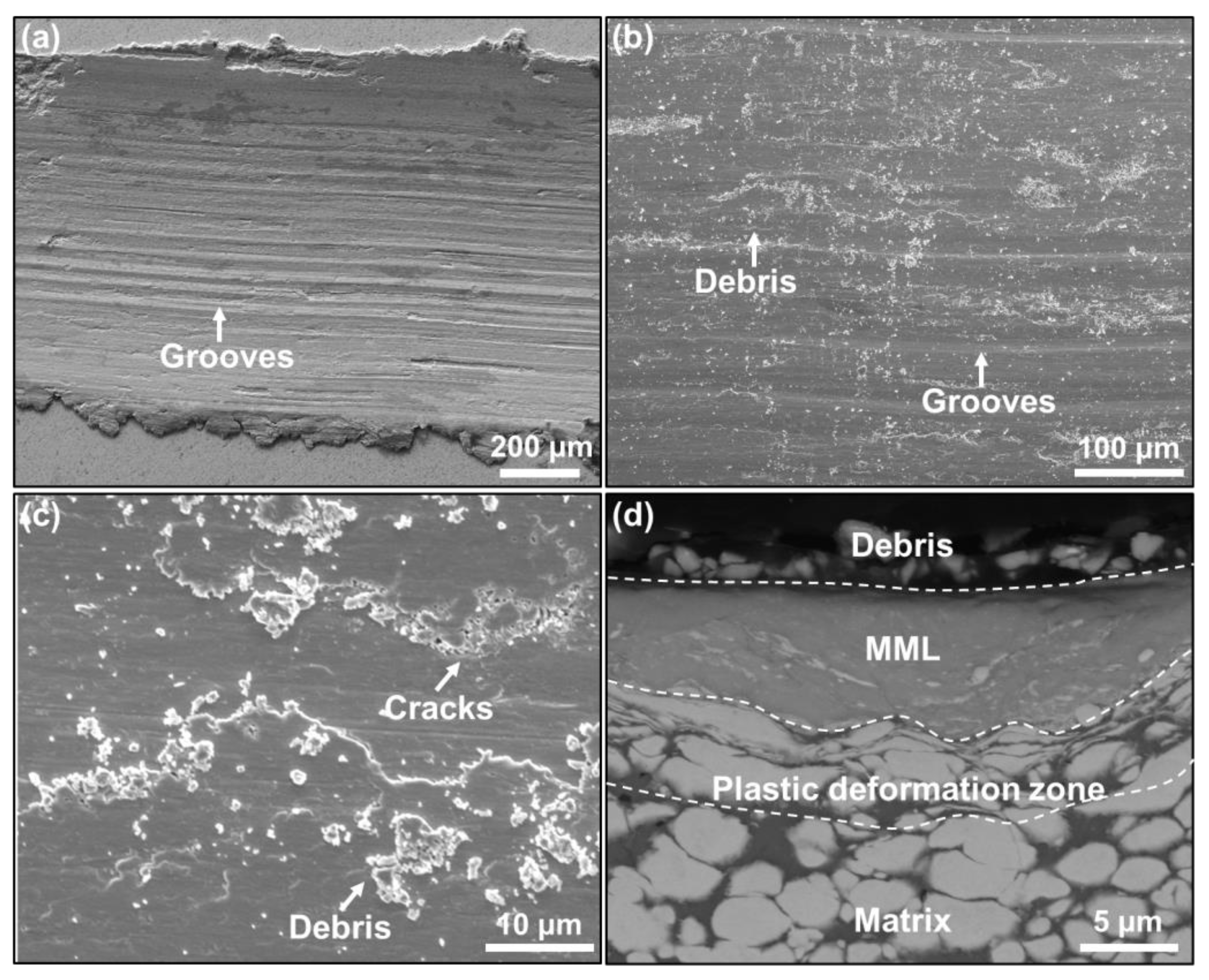

3.2. Friction and Wear Resistance

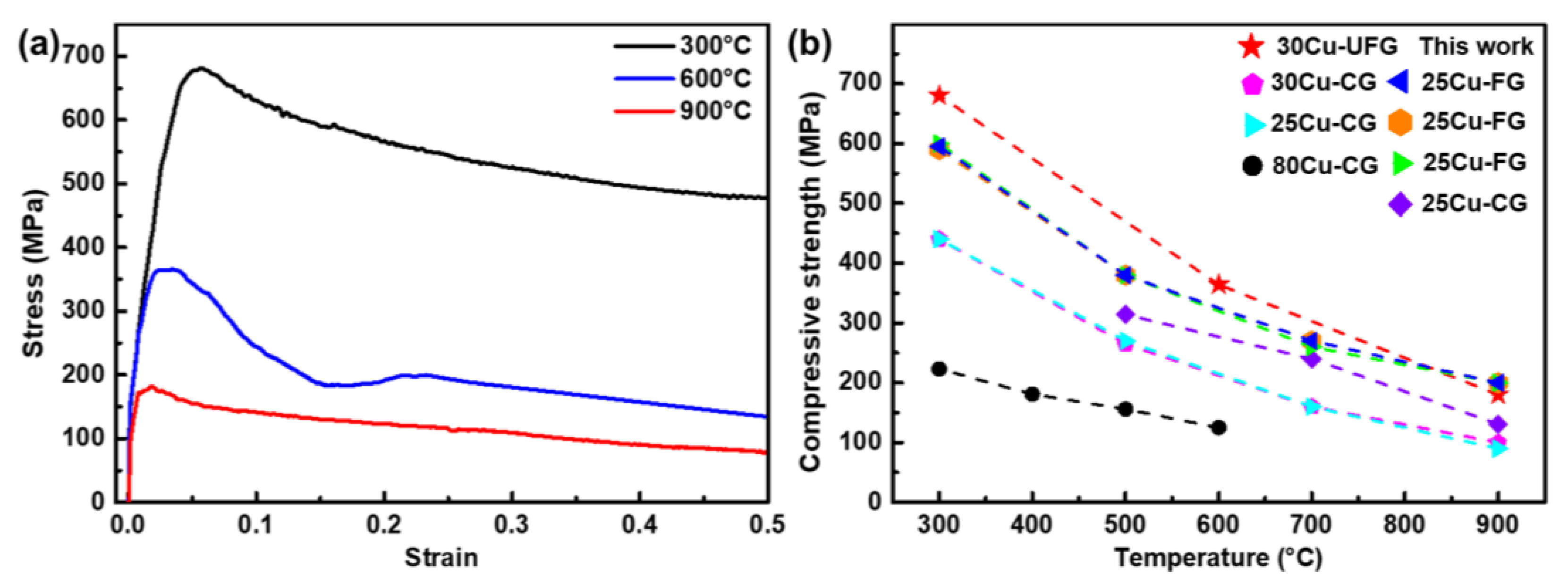

3.3. High-Temperature Compressive Properties

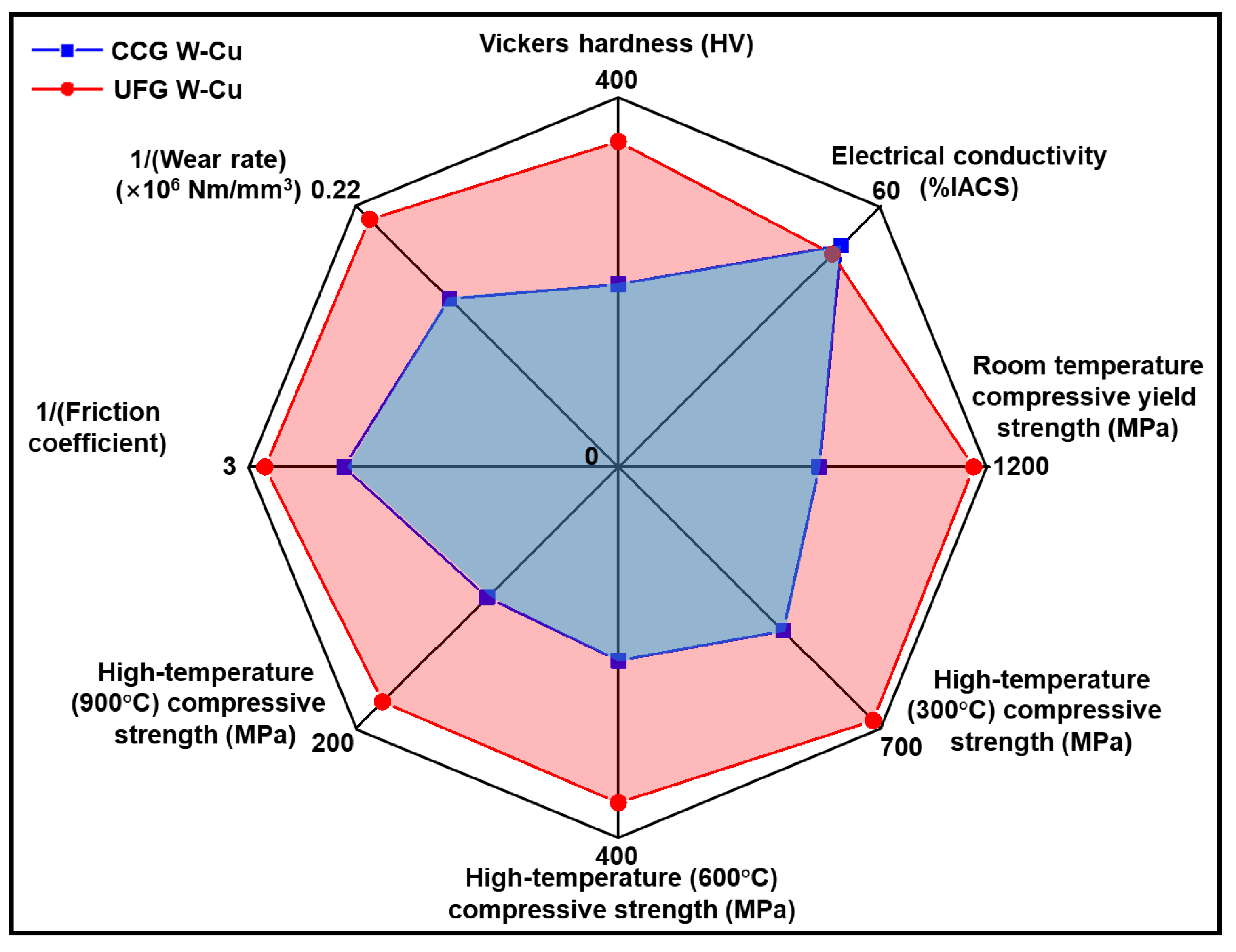

3.4. Evaluation of Overall Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hou, C.; Song, X.; Tang, F.; Li, Y.; Cao, L.; Wang, J.; Nie, Z. W–Cu composites with submicron- and nanostructures: Progress and challenges. NPG Asia Mater. 2019, 11, 74. [Google Scholar] [CrossRef]

- Dong, L.; Chen, W.; Hou, L.; Deng, N.; Zheng, C. W–Cu system: Synthesis, modification, and applications. Powder Metall. Met. Ceram. 2017, 56, 171–184. [Google Scholar] [CrossRef]

- Chen, H.; Zheng, F.; Cheng, W.; Tao, P.; Song, C.; Shang, W.; Fu, B.; Deng, T. Low thermal expansion metal composite-based heat spreader for high temperature thermal management. Mater. Des. 2021, 208, 109897. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhuo, L.; Zhao, Z.; Zhang, Q.; Zhang, J.; Liang, S.; Luo, B.; Chen, Q.; Wang, H. The influence of pre-sintering temperature on the microstructure and properties of infiltrated ultrafine-grained tungsten-copper composites. J. Alloy. Compd. 2020, 823, 153761. [Google Scholar] [CrossRef]

- Ding, F.; Fan, J.; Cao, L.; Wang, Q.; Li, J.; Li, P. Effect of microstructure refinement on surface morphology and dynamic mechanical properties of W-Cu alloys. Materials 2021, 14, 4615. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Guo, H.; Gao, B.; Wang, X.; Hu, Y.; Shi, Z. Rapid consolidation of ultrafine grained W-30wt.% Cu composites by field assisted sintering from the sol-gel prepared nanopowders. J. Alloy. Compd. 2017, 724, 155–162. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, Q.; Zhang, J.; Luo, G.; Liu, Y.; Sun, Y.; Li, Y. Improved parallelism of graded W–Cu–SiC materials by adjusting the coefficient of thermal expansion. Ceram. Int. 2020, 46, 9714–9721. [Google Scholar] [CrossRef]

- Müller, A.V.; Böswirth, B.; Cerri, V.; Greuner, H.; Neu, R.; Siefken, U.; Visca, E.; You, J.H. Application of tungsten–copper composite heat sink materials to plasma-facing component mock-ups. Phys. Scripta. 2020, T171, 14015. [Google Scholar] [CrossRef]

- Li, X.; Zhang, M.; Zhang, G.; Wei, S.; Wang, Q.; Lou, W.; Liang, J.; Chen, L.; Xu, L.; Zhou, Y.; et al. Influence evaluation of tungsten content on microstructure and properties of Cu-W composite. Metals 2022, 12, 1668. [Google Scholar] [CrossRef]

- Yang, X.; Zou, J.; Xiao, P.; Wang, X. Effects of Zr addition on properties and vacuum arc characteristics of Cu-W alloy. Vacuum 2014, 106, 16–20. [Google Scholar] [CrossRef]

- He, G.; Xu, K.; Guo, S.; Qian, X.; Yang, Z.; Liu, G.; Li, J. Preparation of tungsten fiber reinforced-tungsten/copper composite for plasma facing component. J. Nucl. Mater. 2014, 455, 225–228. [Google Scholar] [CrossRef]

- Zhang, Q.; Cheng, Y.; Chen, B.; Liang, S.; Zhuo, L. Microstructure and properties of W-25wt% Cu composites reinforced with tungsten carbide produced by an in situ reaction. Vacuum 2020, 177, 109423. [Google Scholar] [CrossRef]

- Wu, W.Z.; Hou, C.; Cao, L.J.; Liu, X.M.; Wang, H.B.; Lu, H.; Song, X.Y. High hardness and wear resistance of W-Cu composites achieved by elemental dissolution and interpenetrating nanostructure. Nanotechnology 2019, 31, 135704. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Li, X.; Zha, Y.; Zhou, X.; Peng, D.; Hua, N.; Chen, W. Fabrication and high temperature tribological properties of WC reinforced W-Cu composites. Mater. Today Commun. 2021, 28, 102550. [Google Scholar] [CrossRef]

- Liang, S.; Chen, L.; Yuan, Z.; Li, Y.; Zou, J.; Xiao, P.; Zhuo, L. Infiltrated W–Cu composites with combined architecture of hierarchical particulate tungsten and tungsten fibers. Mater. Charact. 2015, 110, 33–38. [Google Scholar] [CrossRef]

- Ji, K.; Zhang, Y.; Chen, B.; Zhang, Q.; Xi, A.; Zhao, Z.; Liu, C.; Sun, J.; Fang, D.; Wang, Q.; et al. Effects of reinforcing tungsten fibers and skeleton pre-sintering temperature on microstructure, mechanical and electrical properties of ultrafine-grained tungsten-copper composites. Int. J. Refract. Met. Hard Mater. 2022, 108, 105929. [Google Scholar] [CrossRef]

- Li, J.; Deng, N.; Wu, P.; Zhou, Z. Elaborating the Cu-network structured of the W–Cu composites by sintering intermittently electroplated core-shell powders. J. Alloy. Compd. 2019, 770, 405–410. [Google Scholar] [CrossRef]

- Li, X.; Hu, P.; Wang, J.; Chen, S.; Zhou, W. In situ synthesis of core-shell W-Cu nanopowders for fabricating full-densified and fine-grained alloys with dramatically improved performance. J. Alloy. Compd. 2021, 853, 156958. [Google Scholar] [CrossRef]

- Hao, Z.; Liu, J.; Cao, J.; Li, S.; Liu, X.; He, C.; Xue, X. Enhanced ductility of a W-Cu composite by improving microstructure homogeneity. Metals 2019, 9, 646. [Google Scholar] [CrossRef]

- Tishkevich, D.I.; Zubar, T.I.; Zhaludkevich, A.L.; Razanau, I.U.; Vershinina, T.N.; Bondaruk, A.A.; Zheleznova, E.K.; Dong, M.; Hanfi, M.Y.; Sayyed, M.I.; et al. Isostatic hot pressed W–Cu composites with nanosized grain boundaries: Microstructure, structure and radiation shielding efficiency against gamma rays. Nanomaterials 2022, 12, 1642. [Google Scholar] [CrossRef]

- Madhur, V.; Srikanth, M.; Annamalai, A.R.; Muthuchamy, A.; Agrawal, D.K.; Jen, C. Effect of nano copper on the densification of spark plasma sintered W–Cu composites. Nanomaterials 2021, 11, 413. [Google Scholar] [CrossRef] [PubMed]

- Zhuo, L.; Zhao, Z.; Qin, Z.; Chen, Q.; Liang, S.; Yang, X.; Wang, F. Enhanced mechanical and arc erosion resistant properties by homogenously precipitated nanocrystalline fcc-Nb in the hierarchical W-Nb-Cu composite. Compos. Part B 2019, 161, 336–343. [Google Scholar] [CrossRef]

- Li, Y.; Hou, C.; Cao, L.; Liu, C.; Liang, S.; Tang, F.; Song, X.; Nie, Z. Excellent wear resistance of multicomponent nanocrystalline W–Cu based composite. J. Alloys Compd. 2021, 861, 158627. [Google Scholar] [CrossRef]

- Chen, Q.; Li, L.; Man, X.; Sui, H.; Liu, J.; Guo, S.; Zhang, J. In-situ synthesis of core-shell structure W(WC) composite grains in W-Cu composites fabricated by infiltration. J. Alloy. Compd. 2021, 864, 158633. [Google Scholar] [CrossRef]

- Zhang, Q.; Liang, S.; Zhuo, L. Microstructure and properties of ultrafine-grained W-25 wt.%Cu composites doped with CNTs. J. Mater. Res. Technol. 2019, 8, 1486–1496. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, B.; Zhao, B.; Liang, S.; Zhuo, L. Microstructure and properties of W-30wt.%Cu composites reinforced with WC particles prepared by vapor deposition carbonization. JOM 2019, 71, 2541–2548. [Google Scholar] [CrossRef]

- Zhang, Q.; Liang, S.; Zhuo, L. Ultrafine-grained W-25 wt-%Cu composite with superior high-temperature characteristics. Mater. Sci. Tech. 2017, 33, 2071–2077. [Google Scholar] [CrossRef]

- Cao, L.; Hou, C.; Tang, F.; Liang, S.; Luan, J.; Jiao, Z.; Liu, C.; Song, X.; Nie, Z. Thermal stability and high-temperature mechanical performance of nanostructured W–Cu–Cr–ZrC composite. Compos. Part B 2021, 208, 108600. [Google Scholar] [CrossRef]

- Hou, C.; Cao, L.; Li, Y.; Tang, F.; Song, X. Hierarchical nanostructured W-Cu composite with outstanding hardness and wear resistance. Nanotechnology 2020, 31, 84003. [Google Scholar] [CrossRef]

- Han, T.; Hou, C.; Zhao, Z.; Huang, X.; Tang, F.; Li, Y.; Song, X. W–Cu composites with excellent comprehensive properties. Compos. Part B Eng. 2022, 233, 109664. [Google Scholar] [CrossRef]

- Guo, W.; Liu, J.; Li, S.; Wang, Y.; Ji, W. Microstructural evolution and deformation mechanism of the 80W-20Cu alloy at ultra-high strain rates under explosive loading. Mater. Sci. Eng. A 2013, 572, 36–44. [Google Scholar] [CrossRef]

- Chen, W.; Shi, Y.; Dong, L.; Wang, L.; Li, H.; Fu, Y. Infiltration sintering of WCu alloys from copper-coated tungsten composite powders for superior mechanical properties and arc-ablation resistance. J. Alloy. Compd. 2017, 728, 196–205. [Google Scholar] [CrossRef]

- Cao, L.; Hou, C.; Tang, F.; Han, T.; Huang, X.; Li, Y.; Wu, G.; Liu, C.; Liang, S.; Luan, J.; et al. Wear-resistance enhancement of nanostructured W-Cu-Cr composites. Int. J. Refract. Met. Hard Mater. 2021, 101, 105673. [Google Scholar] [CrossRef]

- Hashempour, M.; Razavizadeh, H.; Rezaie, H. Investigation on wear mechanism of thermochemically fabricated W–Cu composites. Wear 2010, 269, 405–415. [Google Scholar] [CrossRef]

- Li, X.; Zhang, M.; Zhang, G.; Zhang, Q.; Wang, Q.; Wei, S.; Xu, L.; Zhou, Y. Research on the hot deformation behavior of Cu-20wt%W composite under different temperatures. Mater. Sci. Eng. A 2022, 830, 142326. [Google Scholar] [CrossRef]

- Tian, B.; Liu, P.; Song, K.; Li, Y.; Liu, Y.; Ren, F.; Su, J. Microstructure and properties at elevated temperature of a nano-Al2O3 particles dispersion-strengthened copper base composite. Mater. Sci. Eng. A 2006, 435–436, 705–710. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, L.; Wei, S.; Pan, K.; Wu, X.; Li, Q. Effect of ZrO2 content on microstructure and mechanical properties of W alloys fabricated by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2019, 79, 79–89. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, L.; Wei, S.; Pan, K.; Wu, X.; Li, Q. Preparation, microstructure, and constitutive equation of W-0.25 wt% Al2O3 alloy. Mater. Sci. Eng. A 2019, 744, 79–85. [Google Scholar] [CrossRef]

- Hu, H.; Liu, X.; Hou, C.; Wang, H.; Tang, F.; Song, X. How hard metal becomes soft: Crystallographic analysis on the mechanical behavior of ultra-coarse cemented carbide. Acta Crystallogr. Sect. B 2019, 75, 1014–1023. [Google Scholar] [CrossRef]

- Zhang, Q.; Liang, S.; Zhuo, L. Fabrication and properties of the W-30wt%Cu gradient composite with W@WC core-shell structure. J. Alloy. Compd. 2017, 708, 796–803. [Google Scholar] [CrossRef]

- Liu, J.; Wang, X.; Liu, J.; Liu, Y.; Li, H.; Wang, C. Hot deformation and dynamic recrystallization behavior of Cu-3Ti-3Ni-0.5Si alloy. J. Alloy. Compd. 2019, 782, 224–234. [Google Scholar] [CrossRef]

- Wen, D.; Lin, Y.C.; Chen, J.; Chen, X.; Zhang, J.; Liang, Y.; Li, L. Work-hardening behaviors of typical solution-treated and aged Ni-based superalloys during hot deformation. J. Alloy. Compd. 2015, 618, 372–379. [Google Scholar] [CrossRef]

- Atashparva, M.; Hamedi, M. Investigating mechanical properties of small scale resistance spot welding of a nickel based superalloy through statistical DOE. Exp. Tech. 2018, 42, 27–43. [Google Scholar] [CrossRef]

- Xie, H.; Yang, H.; Yu, J.; Gao, M.; Shou, J.; Fang, Y.; Liu, J.; Wang, H. Research progress on advanced rail materials for electromagnetic railgun technology. Def. Technol. 2021, 17, 429–439. [Google Scholar] [CrossRef]

| W–Cu | Hardness/HV30 | Compressive Yield Strength/MPa | Electrical Conductivity/%IACS |

|---|---|---|---|

| CCG | 198 ± 4 | 650 ± 10 | 51 ± 0.5 |

| UFG | 353 ± 3 | 1150 ± 8 | 49 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, T.; Hou, C.; Sun, Y.; Li, Y.; Song, X. Effect of Grain Refinement on the Comprehensive Mechanical Performance of W–Cu Composites. Nanomaterials 2023, 13, 386. https://doi.org/10.3390/nano13030386

Han T, Hou C, Sun Y, Li Y, Song X. Effect of Grain Refinement on the Comprehensive Mechanical Performance of W–Cu Composites. Nanomaterials. 2023; 13(3):386. https://doi.org/10.3390/nano13030386

Chicago/Turabian StyleHan, Tielong, Chao Hou, Yaochuan Sun, Yurong Li, and Xiaoyan Song. 2023. "Effect of Grain Refinement on the Comprehensive Mechanical Performance of W–Cu Composites" Nanomaterials 13, no. 3: 386. https://doi.org/10.3390/nano13030386

APA StyleHan, T., Hou, C., Sun, Y., Li, Y., & Song, X. (2023). Effect of Grain Refinement on the Comprehensive Mechanical Performance of W–Cu Composites. Nanomaterials, 13(3), 386. https://doi.org/10.3390/nano13030386