Surface Degradation of Thin-Layer Al/MgF2 Mirrors under Exposure to Powerful VUV Radiation

Abstract

1. Introduction

2. Materials and Methods

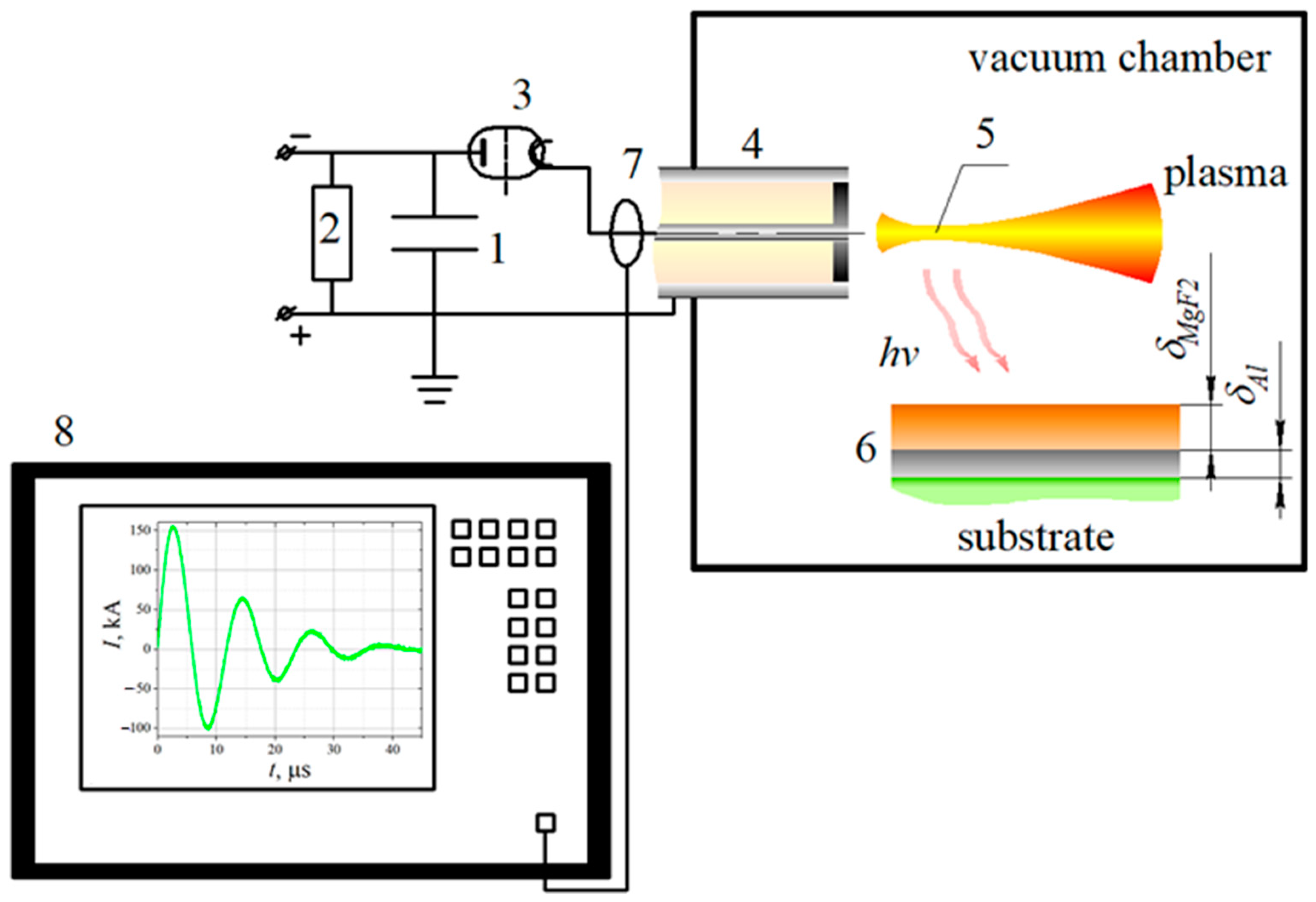

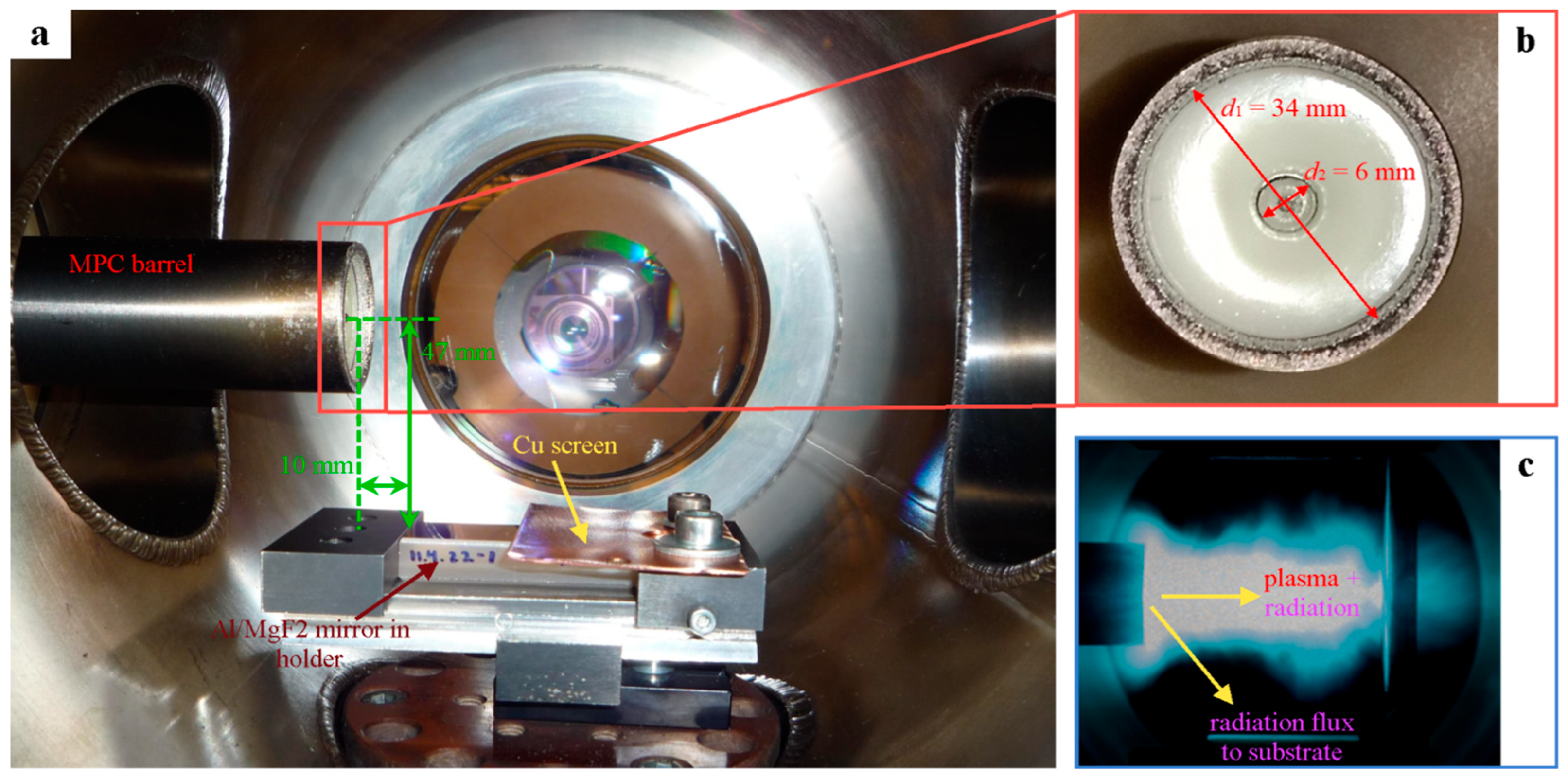

2.1. Plasma Radiation Emitter

2.2. Measuring of Discharge Energy Fluxes

2.3. Coating Deposition

2.4. Coating Characterization

3. Results

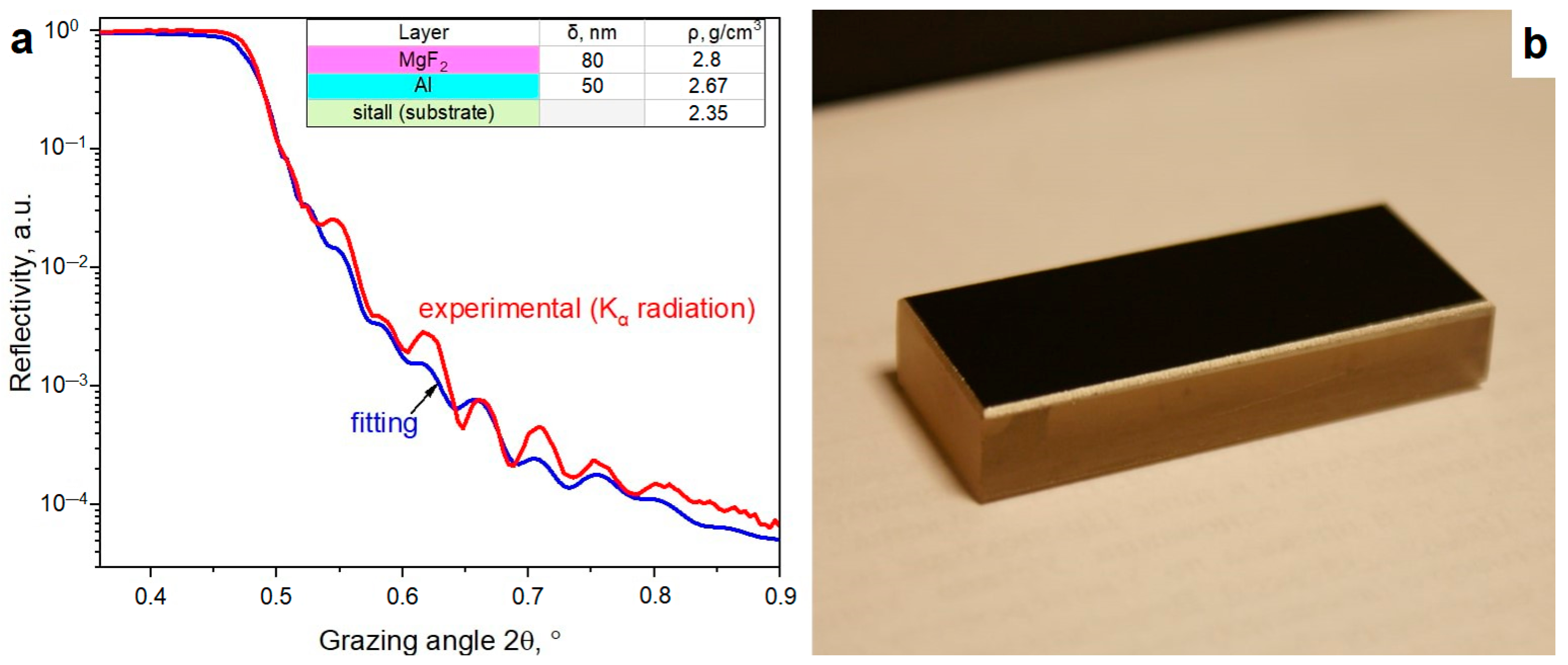

3.1. Inner Structure and Properties of As-Deposited Al/MgF2 Mirrors

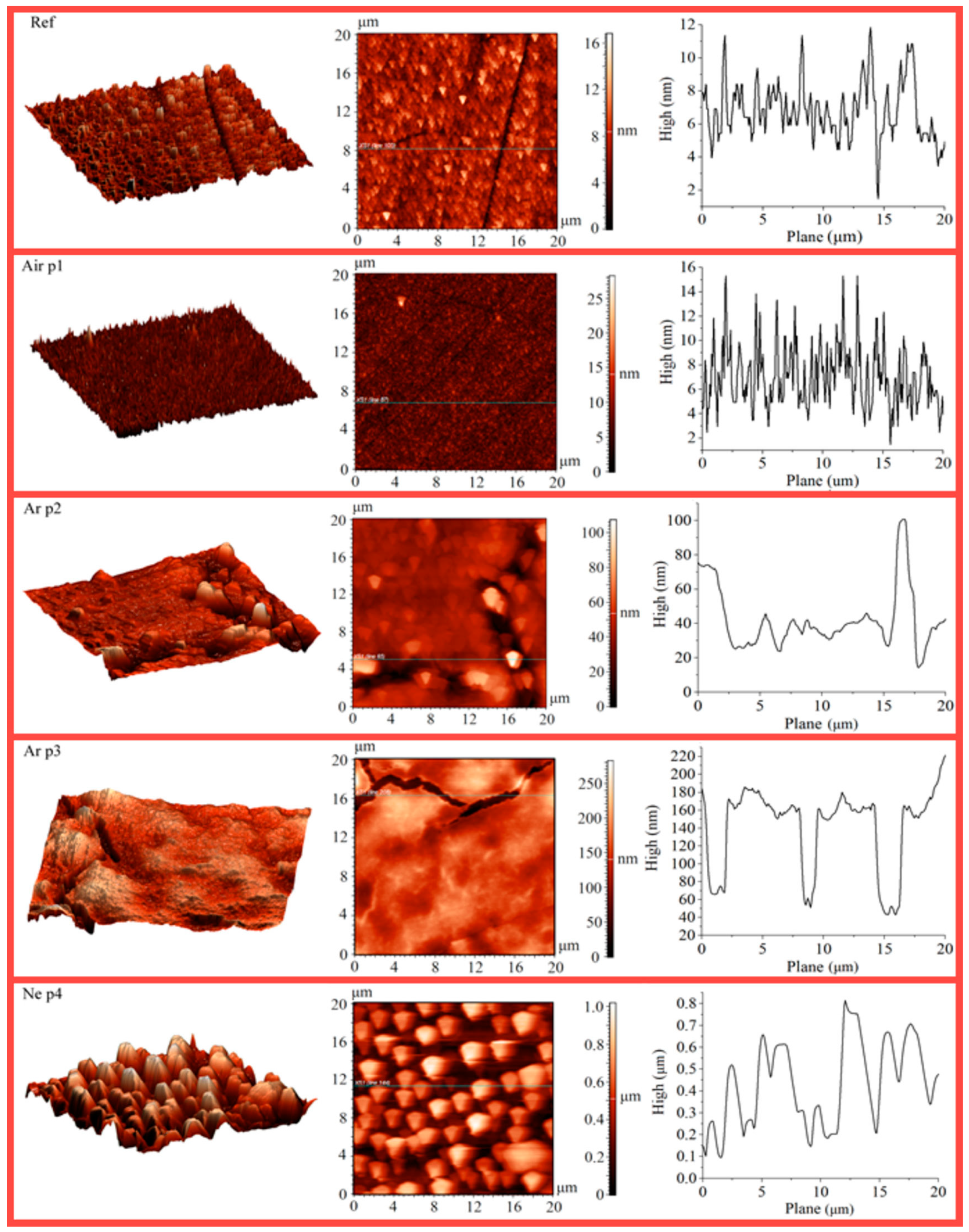

3.2. Surface Degradation of Irradiated Samples

3.3. Energy Fluxes from Discharges

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pencheva, T.; Nenkov, M.; Michev, J. Interference multilayer antireflection coatings for two wavelengths in the near infra red. Proc. SPIE 2001, 4397, 124–128. [Google Scholar] [CrossRef]

- Uzoma, P.C.; Shabbir, S.; Hu, H.; Okonkwo, P.C.; Penkov, O.V. Multilayer reflective coatings for BEUV lithography: A review. Nanomaterials 2021, 11, 2782. [Google Scholar] [CrossRef]

- Garoli, D.; Rodriguez De Marcos, L.V.; Larruquert, J.I.; Corso, A.J.; Proietti Zaccaria, R.; Pelizzo, M.G. Mirrors for Space Telescopes: Degradation Issues. Appl. Sci. 2020, 10, 7538. [Google Scholar] [CrossRef]

- Rodríguez-de Marcos, L.; Gutiérrez-Luna, N.; Espinosa-Yáñez, L.; Honrado-Benítez, C.; Chavero-Royán, J.; Perea-Abarca, B.; Larruquert, J.I. Enhanced far-UV reflectance of Al mirrors protected with hot-deposited MgF2. In Proceedings of the Advances in Optical Thin Films VI, Frankfurt, Germany, 14–17 May 2018; Volume 10691. [Google Scholar] [CrossRef]

- Hennessy, J.; Balasubramanian, K.; Moore, C.; Jewell, A.D.; Nikzad, S.; France, K.; Quijada, M. Performance and prospects of far ultraviolet aluminum mirrors protected by atomic layer deposition. J. Astron. Telesc. Instrum. Syst. 2016, 2, 041206. [Google Scholar] [CrossRef]

- Johnson, B.I.; Avval, T.G.; Turley, S.R.; Linford, M.R.; Allred, D.D. Oxidation of aluminum thin films protected by ultrathin MgF2 layers measured using spectroscopic ellipsometry and X-ray photoelectron spectrometry. OSA Contin. 2021, 4, 879–895. [Google Scholar] [CrossRef]

- Shustov, B.; Gómez de Castro, A.I.; Sachkov, M.; Vallejo, J.C.; Marcos-Arenal, P.; Kanev, E.; Savanov, I.; Shugarov, A.; Sichevskii, S. The World Space Observatory Ultraviolet (WSO–UV), as a bridge to future UV astronomy. Astrophys. Space Sci. 2018, 363, 62. [Google Scholar] [CrossRef]

- Kerr, J.B. Understanding the factors that affect surface ultraviolet radiation. Opt. Eng. 2005, 44, 041002-1–041002-9. [Google Scholar] [CrossRef]

- Rodríguez De Marcos, L.V.; Larruquert, J.I.; Méndez, J.A.; Gutiérrez-Luna, N.; Espinosa-Yáñez, L.; Honrado-Benítez, C.; Chavero-Royán, C.; Perea-Abarca, B. Optimization of MgF2-deposition temperature for far UV Al mirrors. Opt. Express 2018, 26, 9363–9372. [Google Scholar] [CrossRef] [PubMed]

- Zhupanov, V.; Vlasenko, O.; Sachkov, M.; Fedoseev, V. New facilities for Al+MgF2 coating for 2-m class mirrors for UV. In Proceedings of the SPIE 9144, Space Telescopes and Instrumentation 2014: Ultraviolet to Gamma Ray, Montréal, QC, Canada, 22–26 June 2014; Volume 9144, pp. 979–986. [Google Scholar] [CrossRef]

- Fernández-Perea, M.; Larruquert, J.I.; Aznárez, J.A.; Pons, A.; Méndez, J.A. Vacuum ultraviolet coatings of Al protected with MgF2 prepared both by ion-beam sputtering and by evaporation. Appl. Opt. 2007, 46, 4871–4878. [Google Scholar] [CrossRef]

- Pelizzo, M.G.; Corso, A.J.; Santi, G.; Hubner, R.; Garoli, D.; Doyle, D.; Lubin, P.; Cohen, A.N.; Erlikhman, J.; Favaro, G.; et al. Dependence of the damage in optical metal/dielectric coatings on the energy of ions in irradiation experiments for space qualification. Sci. Rep. 2021, 11, 3429. [Google Scholar] [CrossRef]

- Heaney, J.B.; Kauder, L.R.; Freese, S.C.; Quijada, M.A. Preferred mirror coatings for UV, visible, and IR space optical instruments. In Earth Observing Systems XVII, Proceedings of the SPIE Optical Engineering + Applications, San Diego, CA, USA, 12–16 August 2012; Butler, J.J., Xiong, X., Gu, X., Eds.; SPIE: Bellingham, WA, USA, 2012; p. 85100F. [Google Scholar] [CrossRef]

- Sheikh, D.A.; Connell, S.J.; Dummer, R.S. Durable silver coating for Kepler Space Telescope primary mirror. In Space Telescopes and Instrumentation 2008: Optical, Infrared, and Millimeter, Proceedings of the SPIE Astronomical Telescopes + Instrumentation, Marseille, France, 23–28 June 2008; SPIE: Bellingham, WA, USA, 2008; p. 70104E. [Google Scholar] [CrossRef]

- Canfield, L.R.; Hass, G.; Waylonis, J.E. Further Studies on MgF2-Overcoated Aluminum Mirrors with Highest Reflectance in the Vacuum Ultraviolet. Appl. Opt. 1966, 5, 45. [Google Scholar] [CrossRef]

- Areda, E.E.; Cordova-Alarcon, J.R.; Masui, H.; Cho, M. Development of Innovative CubeSat Platform for Mass Production. Appl. Sci. 2022, 12, 9087. [Google Scholar] [CrossRef]

- Huang, T.; Wu, Z.; Sun, G.; Liu, X.; Ling, W.Y.L. Study and modeling of propellant ablation in coaxial ablative pulsed plasma thrusters. Acta Astronaut. 2020, 173, 69–75. [Google Scholar] [CrossRef]

- Protasov, Y.S.; Protasov, Y.Y. A Pulsed Source of Short-Wave UV Radiation of High Power Density. Instrum. Exp. Tech. 2003, 46, 206–210. [Google Scholar] [CrossRef]

- Giovannini, A.Z.; Barendregt, I.; Haslinde, T.; Hubbs, C.; Abhari, R.I. Self-confined plasma in a magneto-plasma compressor and the influence of an externally imposed magnetic field. Plasma Sources Sci. Technol. 2015, 24, 025007. [Google Scholar] [CrossRef]

- Anevsky, S.; Vernyi, A.; Kozlov, N.; Konev, I.; Malaschenko, V.; Morozov, O.; Tsygankov, P. Use of synchrotron radiation for calibration of a working measuring instrument based on plasma focus. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 1989, 282, 714–715. [Google Scholar] [CrossRef]

- Telekh, V.D.; Pavlov, A.V.; Kirillov, D.V.; Vorob’ev, E.V.; Turyanskiy, A.G.; Senkov, V.M.; Tsygankov, P.A.; Parada-Becerra, F.F.; Vesnin, V.R.; Skriabin, A.S. Experimental Study of Irradiation of Thin Oxide and Mo/Si Multilayers by High Brightness Broadband VUV/UV Radiation and Their Degradation. Coatings 2022, 12, 290. [Google Scholar] [CrossRef]

- Skriabin, A.S.; Telekh, V.D.; Pavlov, A.V.; Chesnokov, D.A.; Zhupanov, V.G.; Novikov, P.A. Modification and optical degradation of thin multilayers under VUV/UV radiation from compressed plasma flows. J. Phys. Conf. Ser. 2021, 2064, 012069. [Google Scholar] [CrossRef]

- Couprie, M. New generation of light sources: Present and future. J. Electron. Spectrosc. Relat. Phenom. 2014, 196, 3–13. [Google Scholar] [CrossRef]

- Yoshino, K.; Freeman, D.E.; Parkinson, W.H. Atlas of the Schumann–Runge Absorption Bands of O2 in the Wavelength Region 175–205 nm. J. Phys. Chem. Ref. Data 1984, 13, 207–227. [Google Scholar] [CrossRef][Green Version]

- Kamrukov, A.S.; Kozlov, N.P.; Kuznetsov, S.G.; Protasov, Y.S. High-brightness ultraviolet radiation source based on a cumulative plasmadynamic discharge. Sov. J. Quantum Electron. 1982, 12, 910–914. [Google Scholar] [CrossRef]

- Available online: https://refractiveindex.info/ (accessed on 14 August 2023).

- Popov, N.L.; Uspenskii, Y.A.; Turyanskii, A.G.; Pirshin, I.V.; Vinogradov, A.V.; Platonov, Y.Y. Determination of the parameters of multilayer nanostructures using two-wave X-ray reflectometry. Semiconductors 2003, 37, 675–680. [Google Scholar] [CrossRef]

- Available online: https://www.icdd.com/pdf-2/ (accessed on 14 August 2023).

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/72226.html (accessed on 1 August 2023).

- Available online: https://www.schott.com/en-cz/products/zerodur-p1000269/technical-details (accessed on 14 August 2023).

- Available online: https://www.polymtl.ca/larfis/en/links (accessed on 14 August 2023).

- Dessemond, C.; Soucy, G.; Harvey, J.-P.; Ouzilleau, P. Phase Transitions in the α–γ–β Spodumene Thermodynamic System and Impact of γ-Spodumene on the Efficiency of Lithium Extraction by Acid Leaching. Minerals 2020, 10, 519. [Google Scholar] [CrossRef]

- Heaney, J.B.; Herzig, H.; Osantowski, J.F. Auger spectroscopic examination of MgF2-coated Al mirrors before and after uv irradiation. Appl. Opt. 1977, 16, 1886–1889. [Google Scholar] [CrossRef] [PubMed]

- Bityurin, N.; Luk’yanchuk, B.S.; Hong, M.H.; Chong, T.C. Models for Laser Ablation of Polymers. Chem. Rev. 2003, 103, 519–552. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skriabin, A.; Telekh, V.; Pavlov, A.; Pasynkova, D.; Podlosinskaya, A.; Novikov, P.; Zhupanov, V.; Chesnokov, D.; Senkov, V.; Turyanskiy, A. Surface Degradation of Thin-Layer Al/MgF2 Mirrors under Exposure to Powerful VUV Radiation. Nanomaterials 2023, 13, 2819. https://doi.org/10.3390/nano13212819

Skriabin A, Telekh V, Pavlov A, Pasynkova D, Podlosinskaya A, Novikov P, Zhupanov V, Chesnokov D, Senkov V, Turyanskiy A. Surface Degradation of Thin-Layer Al/MgF2 Mirrors under Exposure to Powerful VUV Radiation. Nanomaterials. 2023; 13(21):2819. https://doi.org/10.3390/nano13212819

Chicago/Turabian StyleSkriabin, Andrei, Victor Telekh, Aleksei Pavlov, Daria Pasynkova, Anastasiya Podlosinskaya, Pavel Novikov, Valery Zhupanov, Dmitry Chesnokov, Viacheslav Senkov, and Alexander Turyanskiy. 2023. "Surface Degradation of Thin-Layer Al/MgF2 Mirrors under Exposure to Powerful VUV Radiation" Nanomaterials 13, no. 21: 2819. https://doi.org/10.3390/nano13212819

APA StyleSkriabin, A., Telekh, V., Pavlov, A., Pasynkova, D., Podlosinskaya, A., Novikov, P., Zhupanov, V., Chesnokov, D., Senkov, V., & Turyanskiy, A. (2023). Surface Degradation of Thin-Layer Al/MgF2 Mirrors under Exposure to Powerful VUV Radiation. Nanomaterials, 13(21), 2819. https://doi.org/10.3390/nano13212819