Aramid Nanofiber/XNBR Nanocomposite with High Mechanical, Thermal, and Electrical Performance

Abstract

1. Introduction

2. Experience

2.1. Materials

2.2. Preparation of ANF/XNBR Nanocomposites

2.3. Characterization

3. Results and Discussion

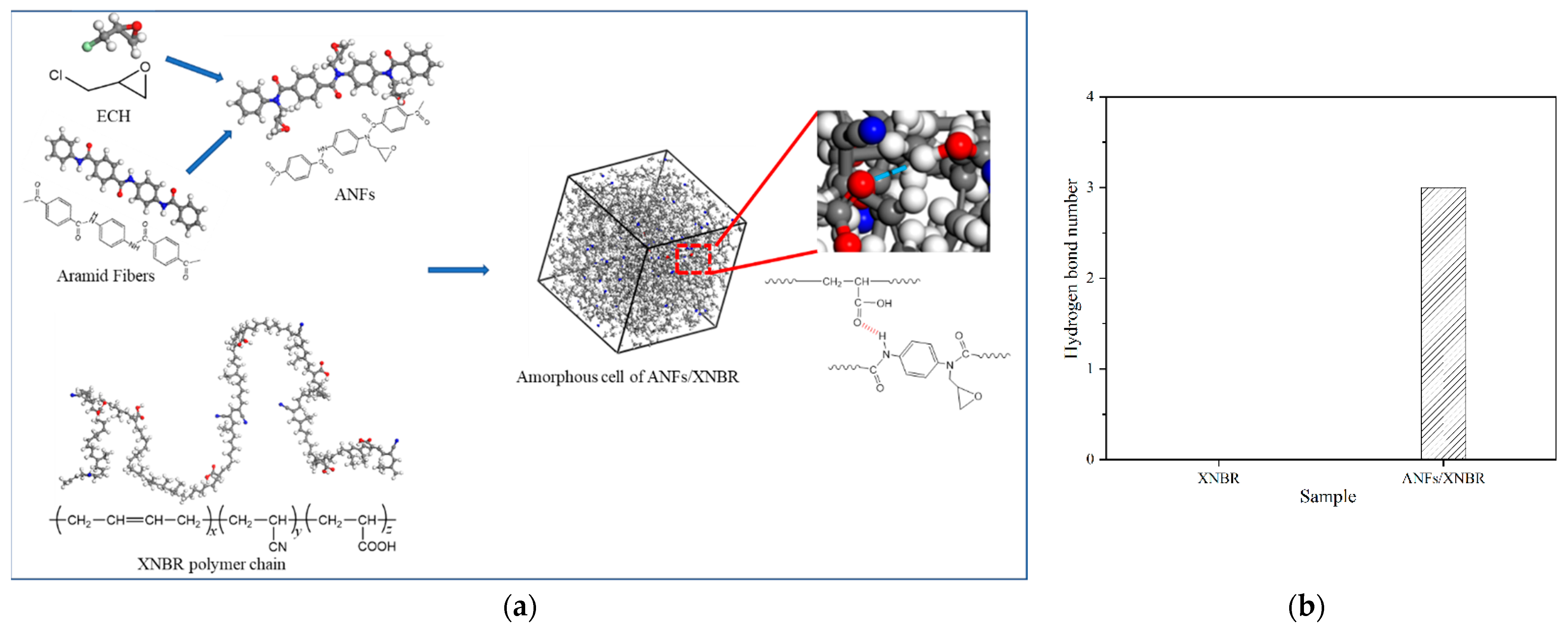

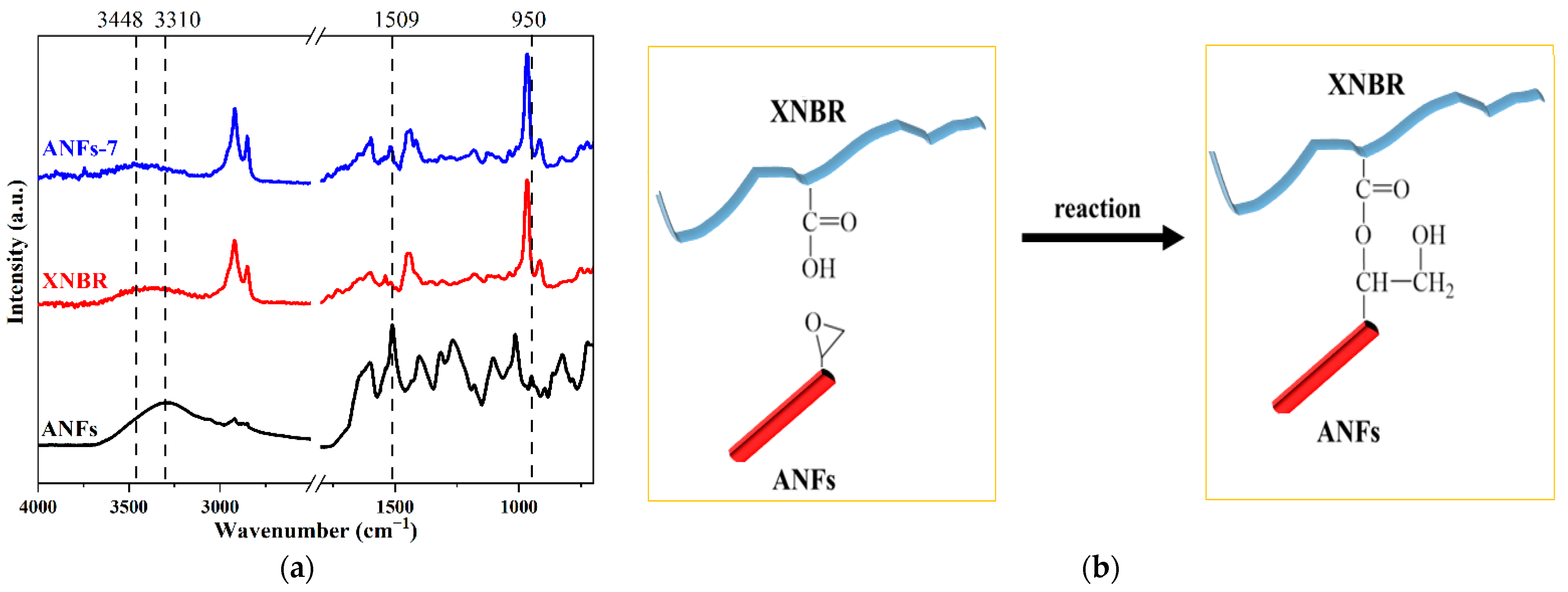

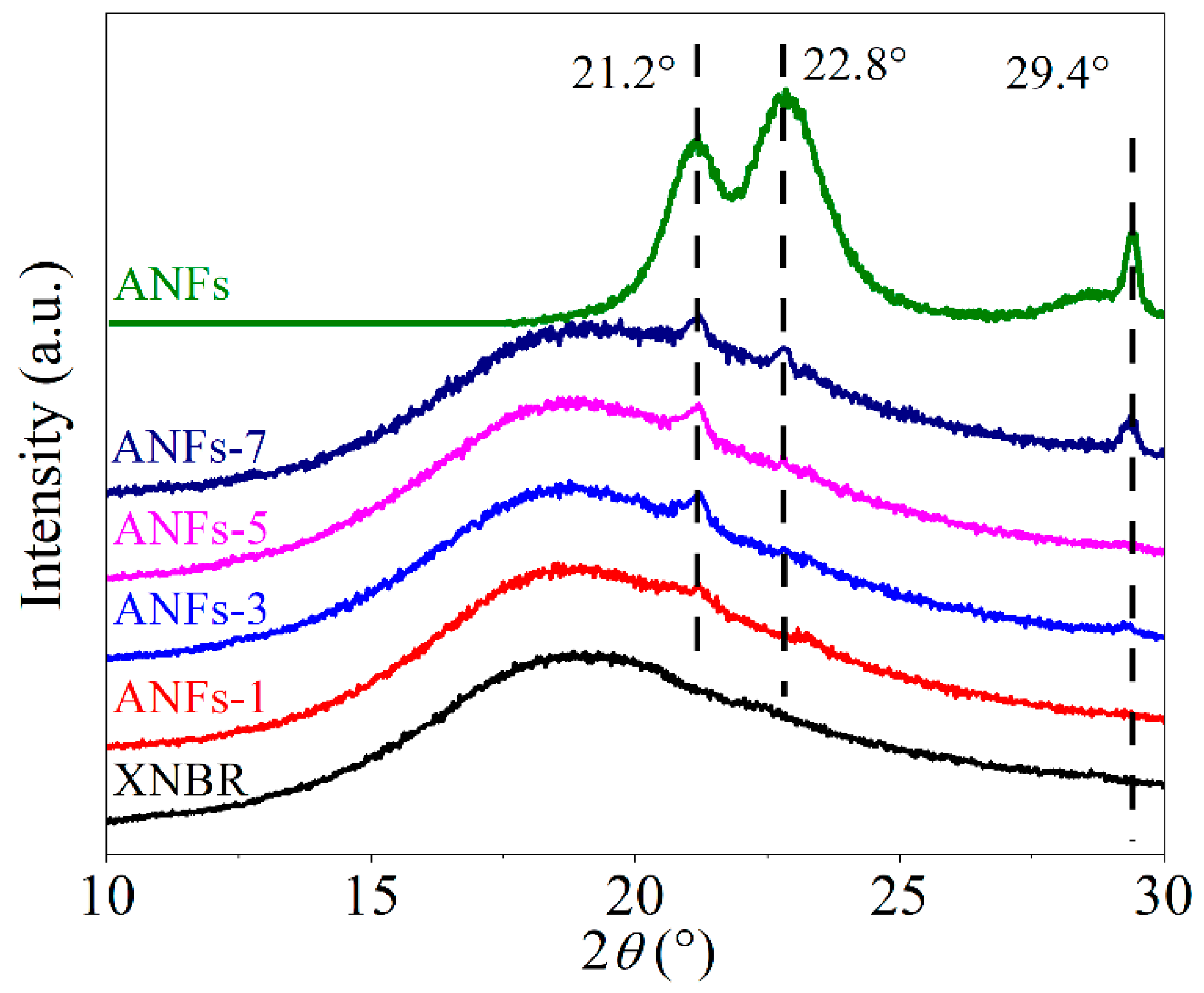

3.1. Interactions between XNBR and ANFs

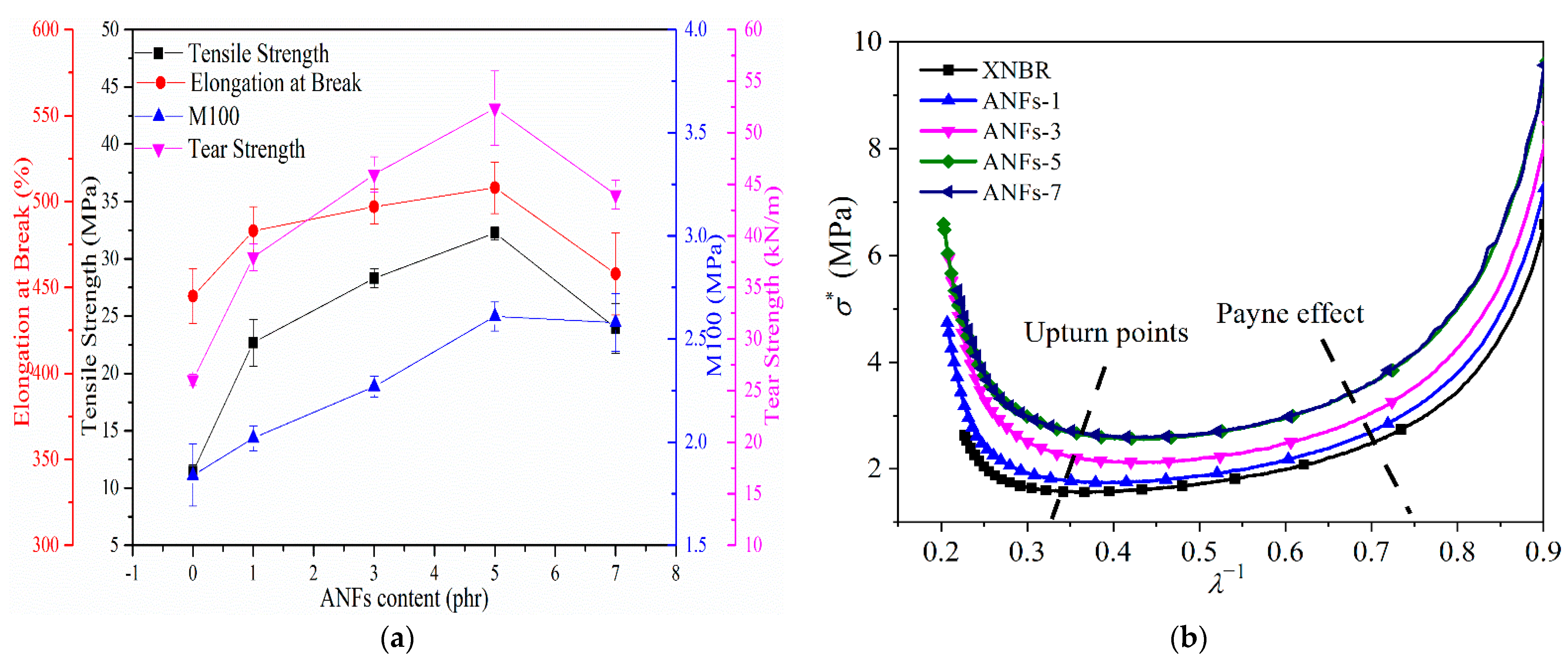

3.2. Mechanical Properties

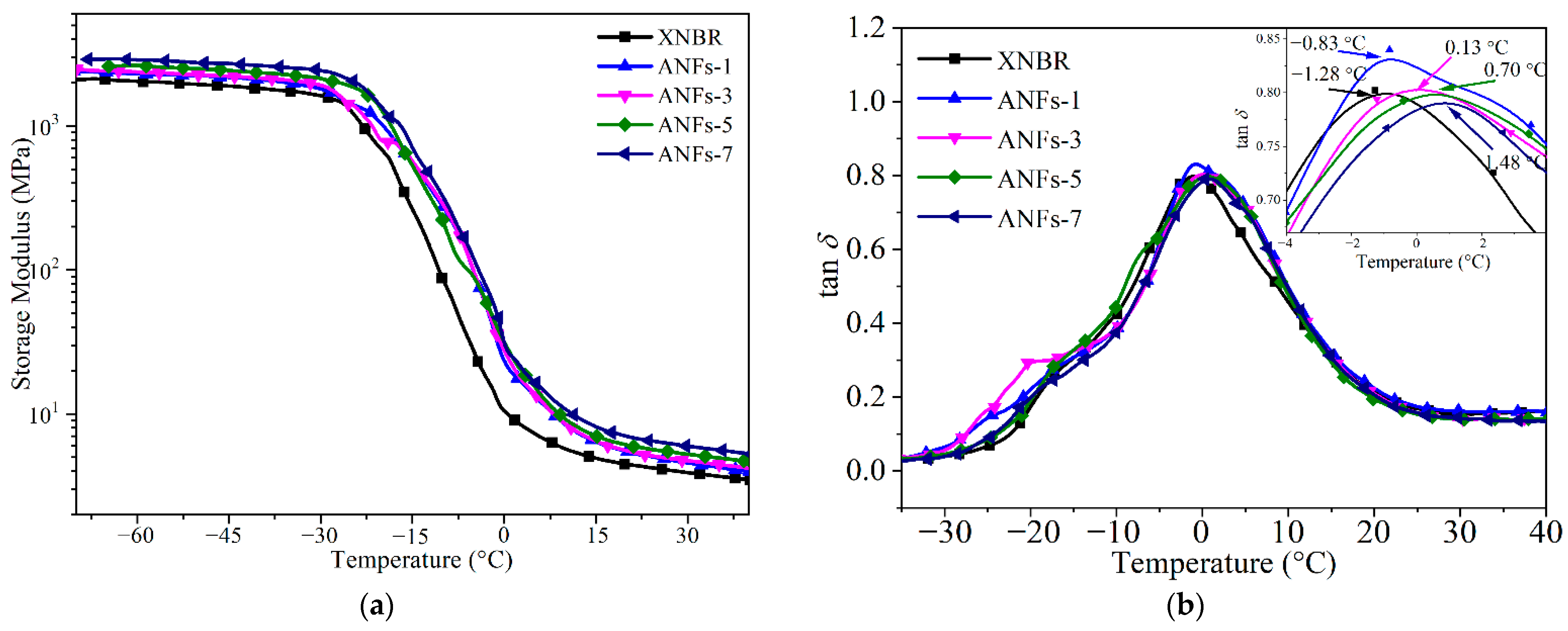

3.3. Dynamic Mechanical Properties

3.4. Dielectric Properties

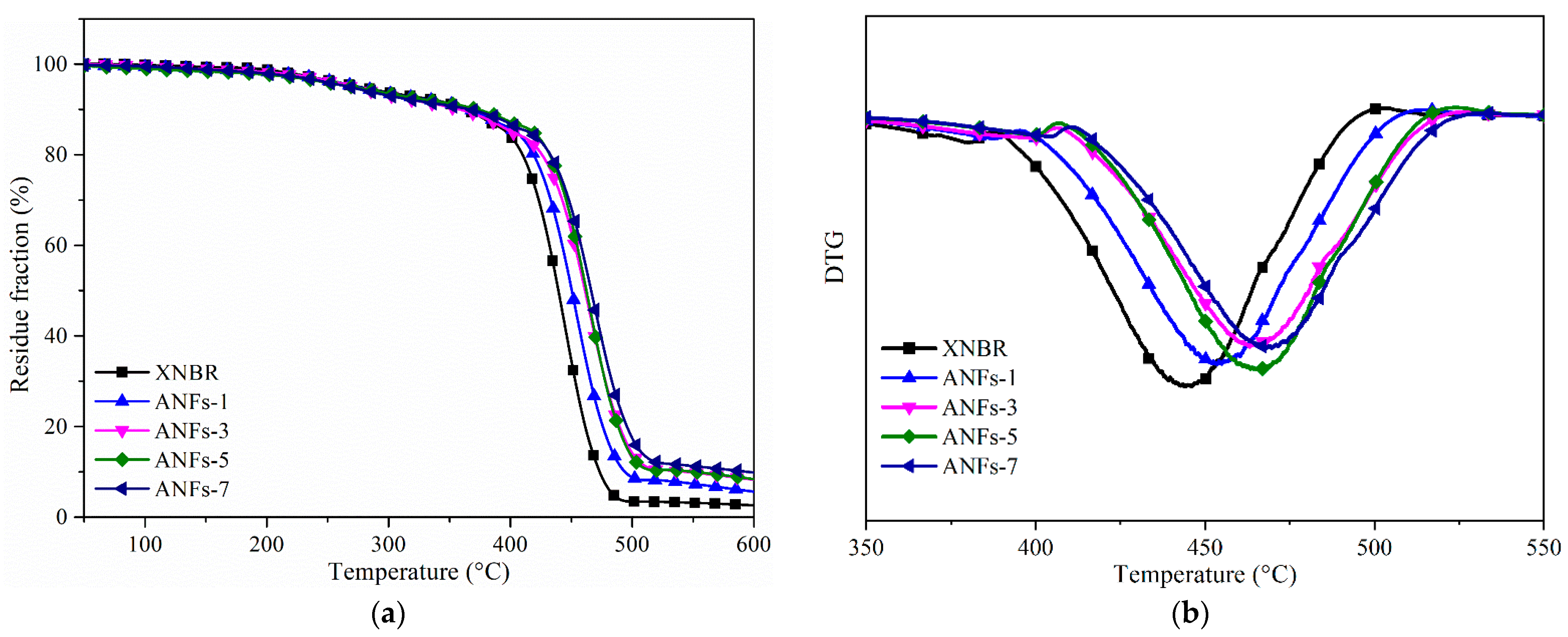

3.5. Thermal Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Jia, H. The Effects of Carbon-Silica Dual-Phase Filler on the Crosslink Structure of Natural Rubber. Polymers 2022, 14, 3897. [Google Scholar] [CrossRef]

- Lin, Y.; Yin, Q.; Wang, J.; Jia, H.; Yuan, G.; Wang, J. Sensitivity enhanced, highly stretchable, and mechanically robust strain sensors based on reduced graphene oxide-aramid nanofibers hybrid fillers. Chem. Eng. J. 2022, 443, 136468. [Google Scholar] [CrossRef]

- Yang, M.; Cao, K.; Sui, L.; Qi, Y.; Zhu, J.; Waas, A.; Arruda, E.M.; Kieffer, J.; Thouless, M.D.; Kotov, N.A. Dispersions of aramid nanofibers: A new nanoscale building block. Acs Nano 2011, 5, 6945. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Wang, F.; Huang, Y. Facile and simple fabrication of strong, transparent and flexible aramid nanofibers/bacterial cellulose nanocomposite membranes. Compos. Sci. Technol. 2018, 159, 70–76. [Google Scholar] [CrossRef]

- Wang, J.; Jia, H.; Zhang, J.; Ding, L.; Huang, Y.; Sun, D.; Gong, X. Bacterial cellulose whisker as a reinforcing filler for carboxylated acrylonitrile-butadiene rubber. J. Mater. Sci. 2014, 49, 6093–6101. [Google Scholar] [CrossRef]

- Chen, Y.; Yin, Q.; Zhang, X.; Zhang, W.; Jia, H.; Ji, Q.; Yang, F.; Rui, X. Rational design of multifunctional properties for styrene-butadiene rubber reinforced by modified Kevlar nanofibers. Compos. Part B Eng. 2019, 166, 196–203. [Google Scholar] [CrossRef]

- Wang, J.; Jia, H.; Tang, Y.; Ji, D.; Sun, Y.; Gong, X.; Ding, L. Enhancements of the mechanical properties and thermal conductivity of carboxylated acrylonitrile butadiene rubber with the addition of graphene oxide. J. Mater. Sci. 2013, 48, 1571–1577. [Google Scholar] [CrossRef]

- Xue, X.; Yin, Q.; Jia, H.; Zhang, X.; Wen, Y.; Ji, Q.; Xu, Z. Enhancing mechanical and thermal properties of styrene-butadiene rubber/carboxylated acrylonitrile butadiene rubber blend by the usage of graphene oxide with diverse oxidation degrees. Appl. Surf. Sci. 2017, 423, 584–591. [Google Scholar] [CrossRef]

- Costa, P.; Silva, J.; Anson-Casaos, A.; Martinez, M.T.; Abad, M.J.; Viana, J.; Lanceros-Mendez, S. Effect of carbon nanotube type and functionalization on the electrical, thermal, mechanical and electromechanical properties of carbon nanotube/styrene-butadiene-styrene composites for large strain sensor applications. Compos. Part B-Eng. 2014, 61, 136–146. [Google Scholar] [CrossRef]

- Yin, B.; Li, G.; Wang, D.; Wang, L.; Wang, J.; Jia, H.; Ding, L.; Sun, D. Enhanced mechanical properties of styrene-butadiene rubber with low content of bacterial cellulose nanowhiskers. Adv. Polym. Technol. 2018, 37, 1323–1334. [Google Scholar] [CrossRef]

- Zhao, J.-Y.; Xu, F.-F.; Li, Z.-Q.; Gong, Z.-L.; Zhong, Y.-W.; Yao, J. Molecular Cocrystals with Hydrogen-Bonded Polymeric Structures and Polarized Luminescence. Materials 2022, 15, 7247. [Google Scholar] [CrossRef]

- Bredikhin, A.A.; Fayzullin, R.R.; Gubaidullin, A.T.; Bredikhina, Z.A. Intermolecular Hydrogen Bonding in Alpha-Hydroxy Carboxylic Acids Crystals: Connectivity, Synthons, Supramolecular Motifs. Crystals 2022, 12, 1479. [Google Scholar] [CrossRef]

- Rocks, J.; Rintoul, L.; Vohwinkel, F.; George, G. The kinetics and mechanism of cure of an amino-glycidyl epoxy resin by a co-anhydride as studied by FT-Raman spectroscopy. Polymer 2004, 45, 6799–6811. [Google Scholar] [CrossRef]

- Fan, J.; Shi, Z.; Zhang, L.; Wang, J.; Yin, J. Aramid nanofiber-functionalized graphene nanosheets for polymer reinforcement. Nanoscale 2012, 4, 7046–7055. [Google Scholar] [CrossRef]

- Wen, Y.; Yin, Q.; Jia, H.; Yin, B.; Zhang, X.; Liu, P.; Wang, J.; Ji, Q.; Xu, Z. Tailoring rubber-filler interfacial interaction and multifunctional rubber nanocomposites by usage of graphene oxide with different oxidation degrees. Compos. Part B Eng. 2017, 124, 250–259. [Google Scholar] [CrossRef]

- Gatos, K.G.; Sawanis, N.S.; Apostolov, A.A.; Thomann, R.; Karger-Kocsis, J. Nanocomposite Formation in Hydrogenated Nitrile Rubber (HNBR)/Organo-Montmorillonite as a Function of the Intercalant Type. Macromol. Mater. Eng. 2004, 289, 1079–1086. [Google Scholar] [CrossRef]

- Yin, Q.; Wen, Y.; Jia, H.; Hong, L.; Ji, Q.; Xu, Z. Enhanced mechanical, dielectric, electrical and thermal conductive properties of HXNBR/HNBR blends filled with ionic liquid-modified multiwalled carbon nanotubes. J. Mater. Sci. 2017, 52, 10814–10828. [Google Scholar] [CrossRef]

- Zhang, X.; Xue, X.; Yin, Q.; Jia, H.; Wang, J.; Ji, Q.; Xu, Z. Enhanced compatibility and mechanical properties of carboxylated acrylonitrile butadiene rubber/styrene butadiene rubber by using graphene oxide as reinforcing filler. Compos. Part B Eng. 2017, 111, 243–250. [Google Scholar] [CrossRef]

- Ponnamma, D.; Ramachandran, R.; Hussain, S.; Rajaraman, R.; Amarendra, G.; Varughese, K.T.; Thomas, S. Free-volume correlation with mechanical and dielectric properties of natural rubber/multi walled carbon nanotubes composites. Compos. Part A-Appl. Sci. Manuf. 2015, 77, 164–171. [Google Scholar] [CrossRef]

- Wan, Y.-J.; Zhu, P.-L.; Yu, S.-H.; Yang, W.-H.; Sun, R.; Wong, C.-P.; Liao, W.-H. Barium titanate coated and thermally reduced graphene oxide towards high dielectric constant and low loss of polymeric composites. Compos. Sci. Technol. 2017, 141, 48–55. [Google Scholar] [CrossRef]

- Tian, C.; Du, Y.; Xu, P.; Qiang, R.; Wang, Y.; Ding, D.; Xue, J.; Ma, J.; Zhao, H.; Han, X. Constructing Uniform Core-Shell PPy@PANI Composites with Tunable Shell Thickness toward Enhancement in Microwave Absorption. Acs Appl. Mater. Interfaces 2015, 7, 20090–20099. [Google Scholar] [CrossRef]

- Jamal, E.M.A.; Joy, P.A.; Kurian, P.; Anantharamana, M.R. Synthesis of nickel-rubber nanocomposites and evaluation of their dielectric properties. Mater. Sci. Eng. B-Adv. Funct. Solid-State Mater. 2009, 156, 24–31. [Google Scholar] [CrossRef]

- Psarras, G.C.; Sofos, G.A.; Vradis, A.; Anastassopoulos, D.L.; Georga, S.N.; Krontiras, C.A.; Karger-Kocsis, J. HNBR and its MWCNT reinforced nanocomposites: Crystalline morphology and electrical response. Eur. Polym. J. 2014, 54, 190–199. [Google Scholar] [CrossRef]

- Agrebi, F.; Ghorbel, N.; Ladhar, A.; Bresson, S.; Kallel, A. Enhanced dielectric properties induced by loading cellulosic nanowhiskers in natural rubber: Modeling and analysis of electrode polarization. Mater. Chem. Phys. 2017, 200, 155–163. [Google Scholar] [CrossRef]

- Ning, N.; Ma, Q.; Liu, S.; Tian, M.; Zhang, L.; Nishi, T. Tailoring Dielectric and Actuated Properties of Elastomer Composites by Bioinspired Poly(dopamine) Encapsulated Graphene Oxide. Acs Appl. Mater. Interfaces 2015, 7, 10755–10762. [Google Scholar] [CrossRef] [PubMed]

| Sample | T5/°C | T50/°C | Tmax/°C | R600/wt.% |

|---|---|---|---|---|

| XNBR | 276 | 439 | 445 | 2.61 |

| ANFs-1 | 274 | 450 | 453 | 5.54 |

| ANFs-3 | 271 | 461 | 463 | 7.78 |

| ANFs-5 | 270 | 462 | 467 | 7.90 |

| ANFs-7 | 267 | 466 | 469 | 9.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhang, X.; Wen, Y.; Chen, Y.; Fu, Q.; Wang, J.; Jia, H. Aramid Nanofiber/XNBR Nanocomposite with High Mechanical, Thermal, and Electrical Performance. Nanomaterials 2023, 13, 335. https://doi.org/10.3390/nano13020335

Wang J, Zhang X, Wen Y, Chen Y, Fu Q, Wang J, Jia H. Aramid Nanofiber/XNBR Nanocomposite with High Mechanical, Thermal, and Electrical Performance. Nanomaterials. 2023; 13(2):335. https://doi.org/10.3390/nano13020335

Chicago/Turabian StyleWang, Jingyi, Xumin Zhang, Yanwei Wen, Yang Chen, Quansheng Fu, Jing Wang, and Hongbing Jia. 2023. "Aramid Nanofiber/XNBR Nanocomposite with High Mechanical, Thermal, and Electrical Performance" Nanomaterials 13, no. 2: 335. https://doi.org/10.3390/nano13020335

APA StyleWang, J., Zhang, X., Wen, Y., Chen, Y., Fu, Q., Wang, J., & Jia, H. (2023). Aramid Nanofiber/XNBR Nanocomposite with High Mechanical, Thermal, and Electrical Performance. Nanomaterials, 13(2), 335. https://doi.org/10.3390/nano13020335