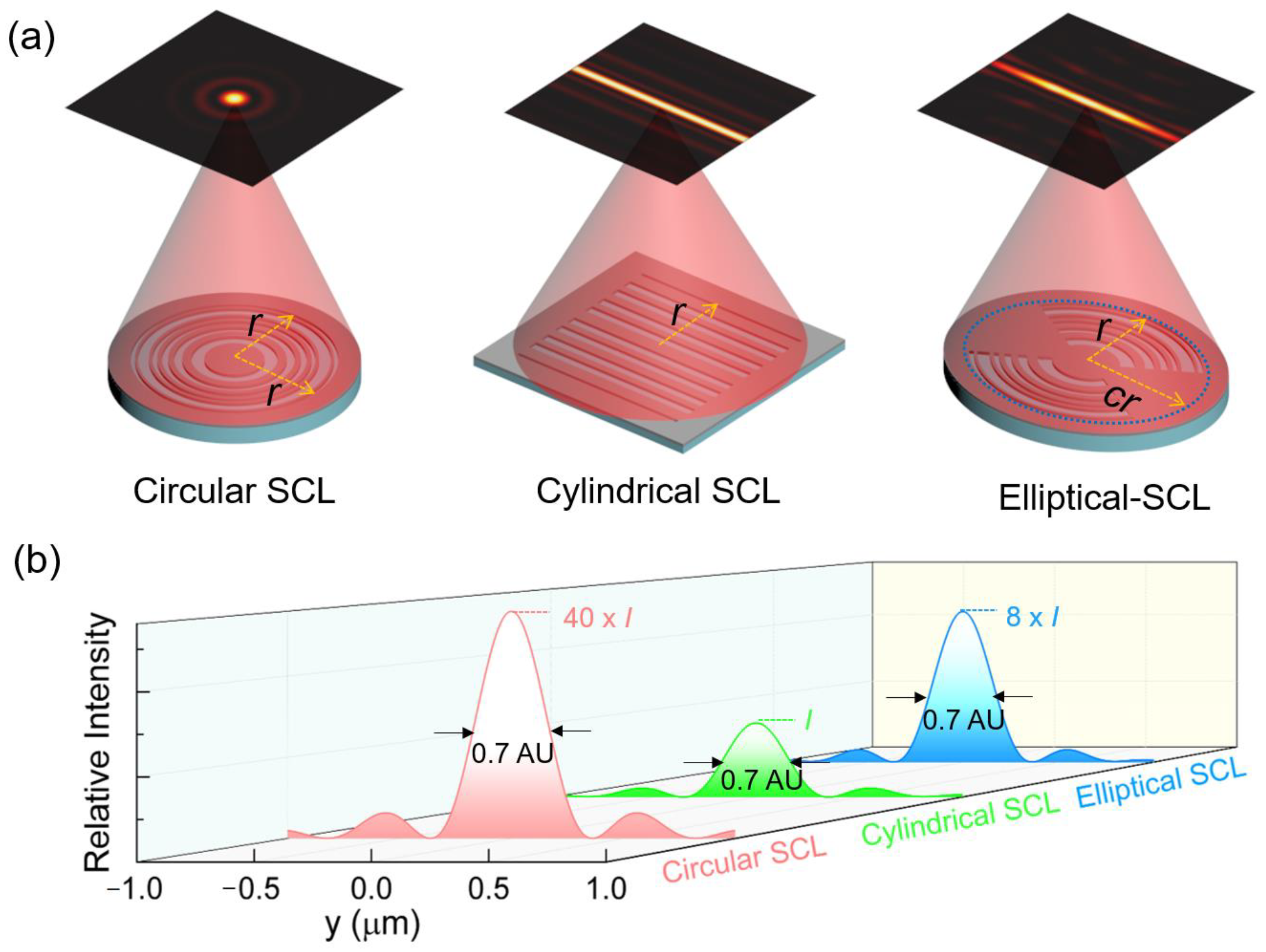

Elliptical Supercritical Lens for Shaping Sub-Diffractive Transverse Optical Needle

Abstract

1. Introduction

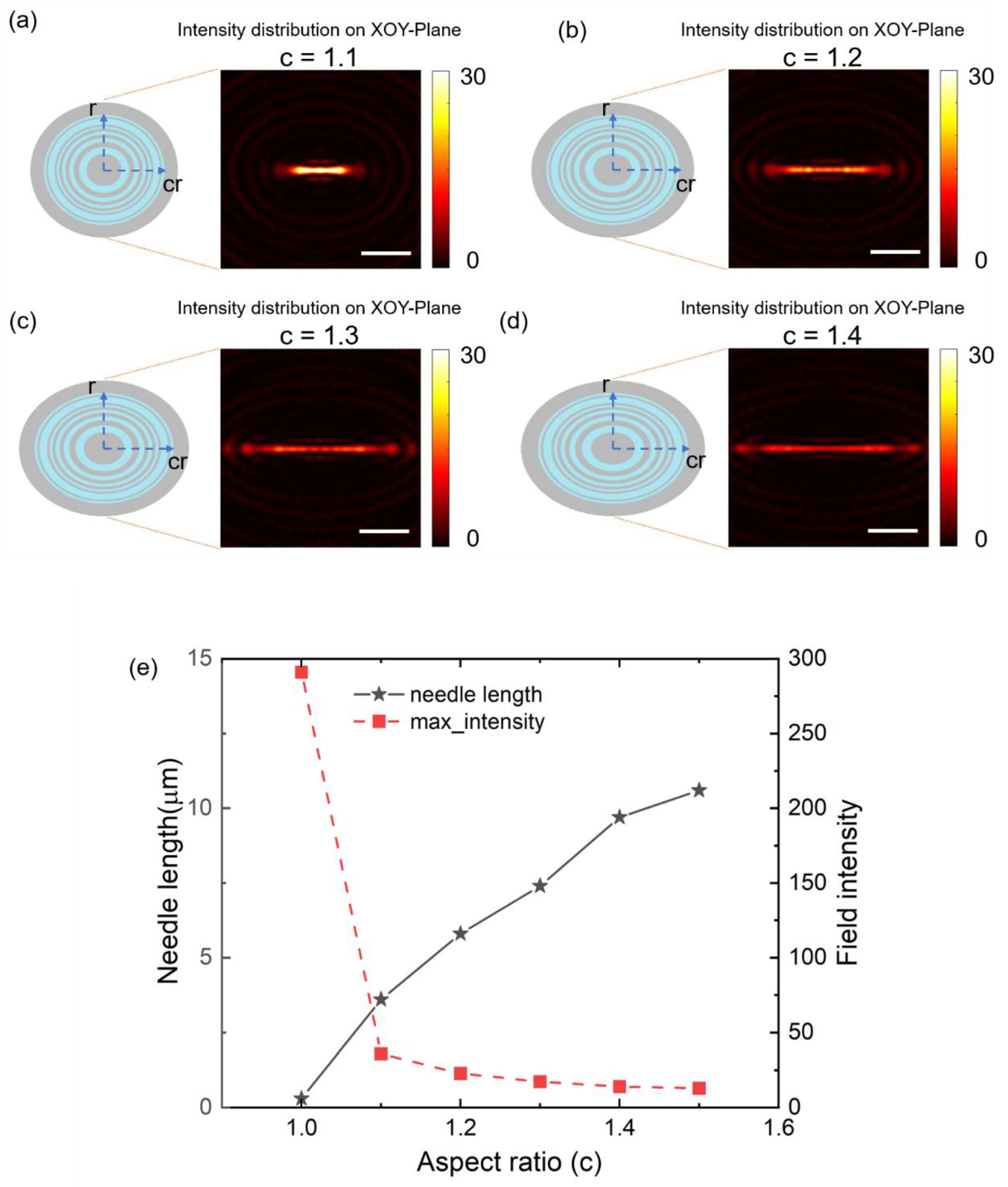

2. Results

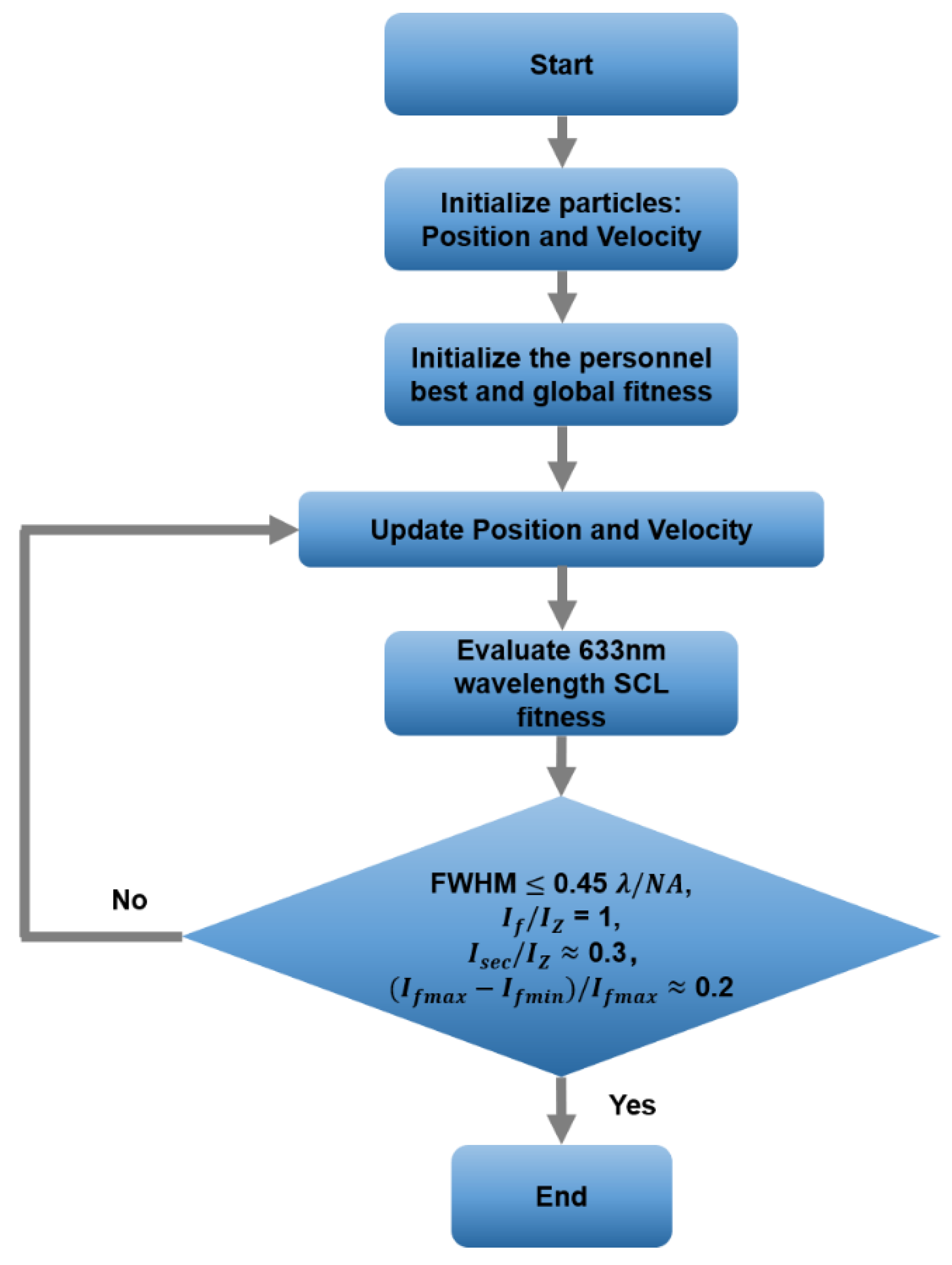

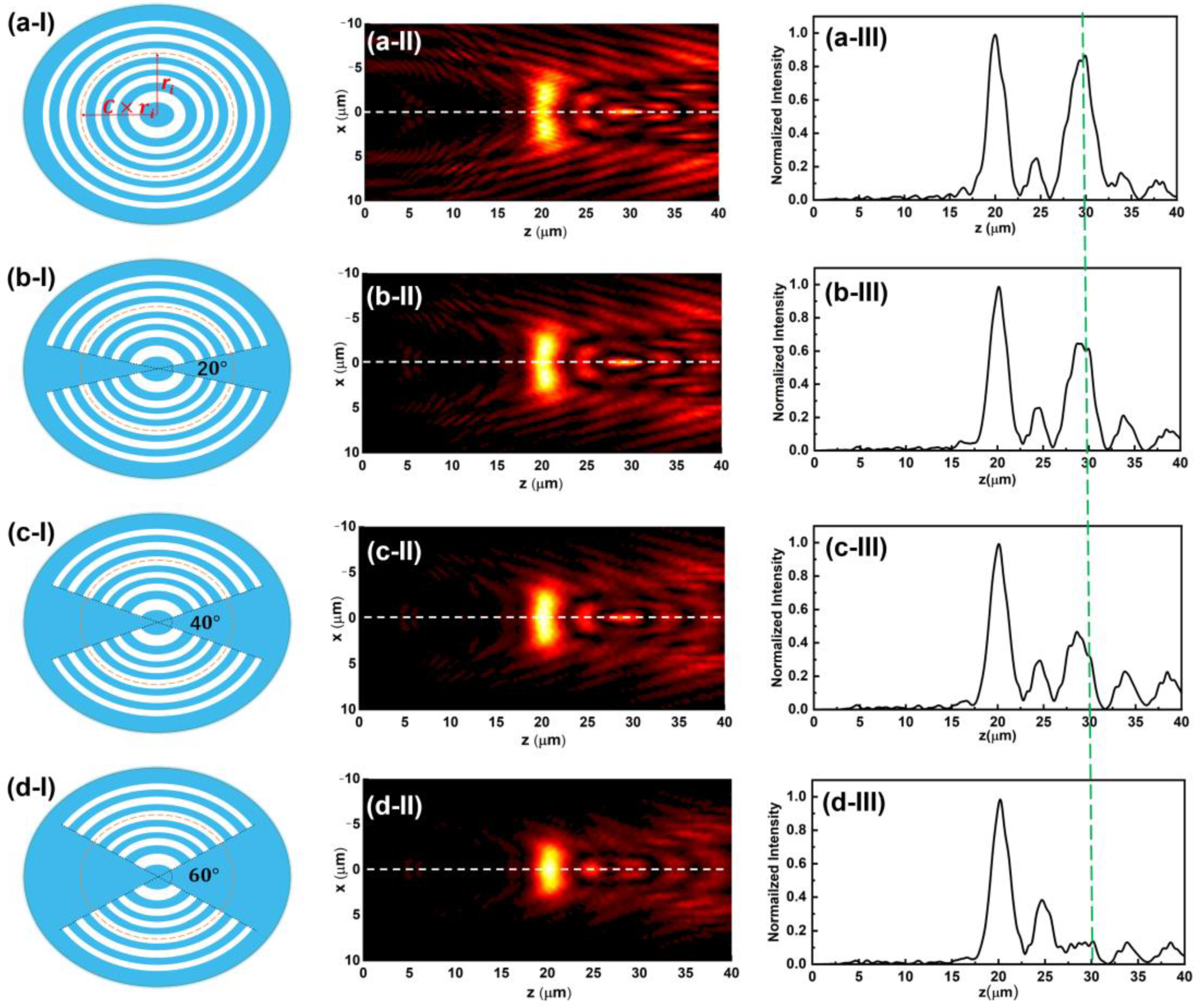

2.1. Optimization Algorithm for Modified Elliptical SCL

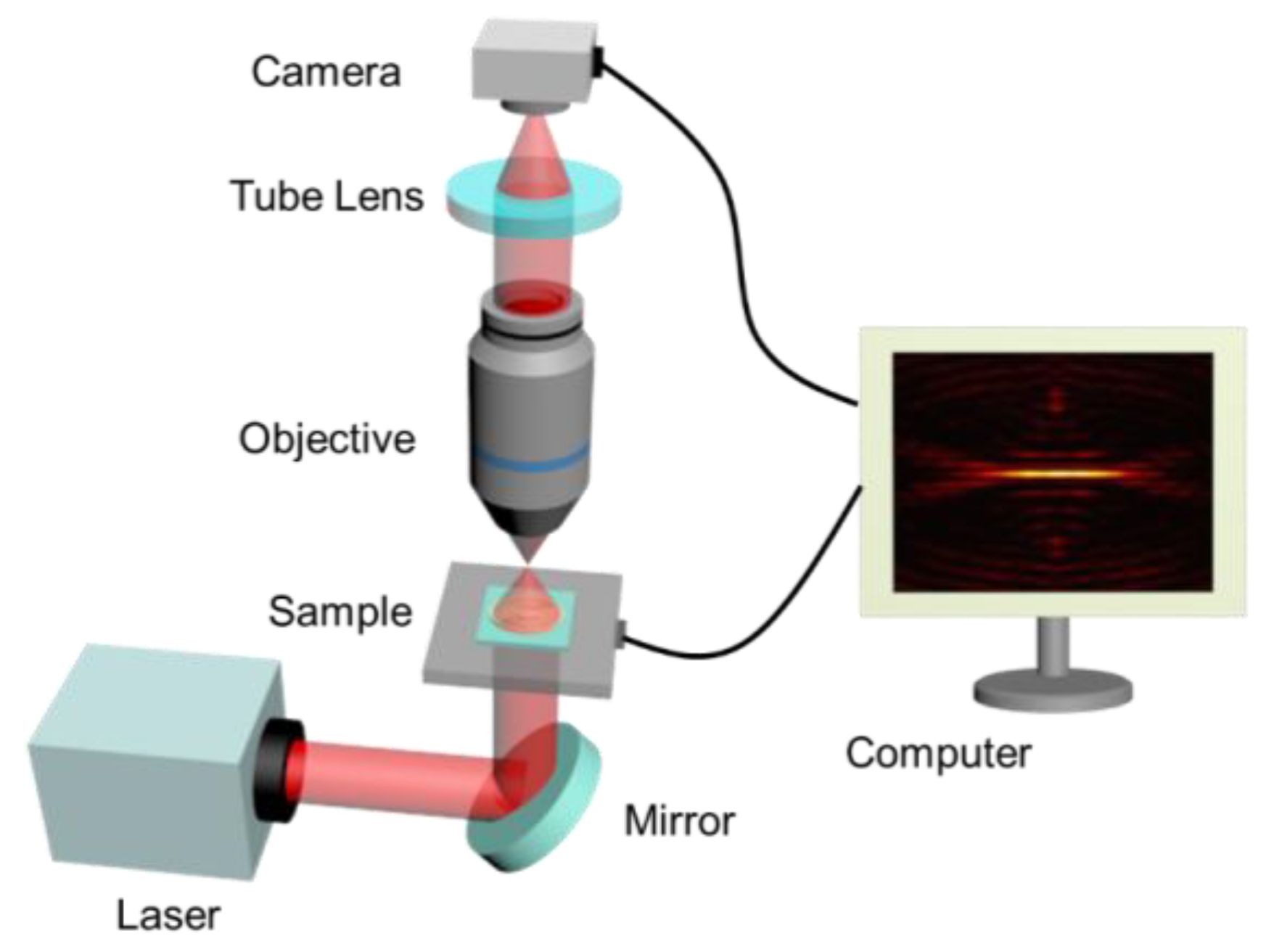

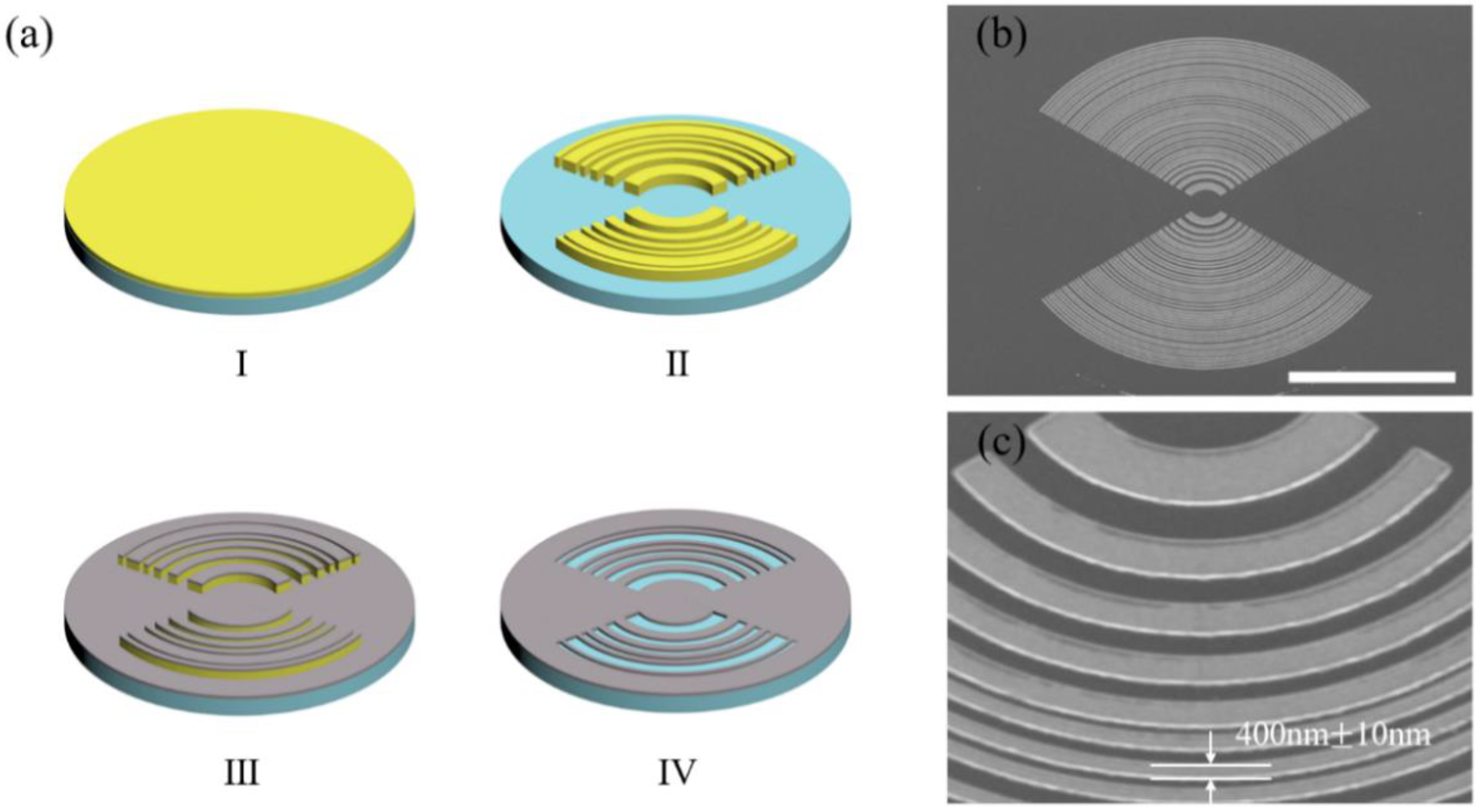

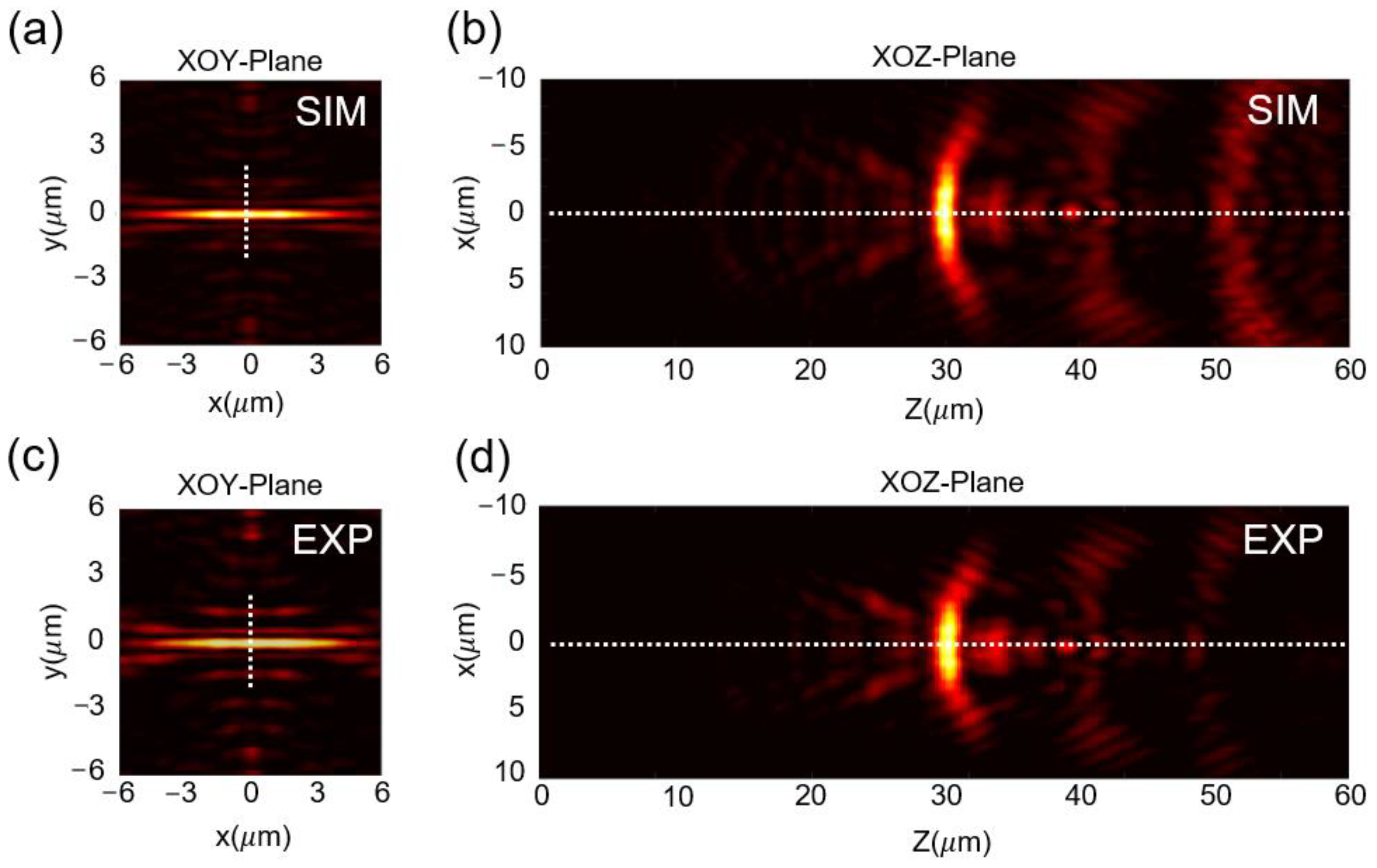

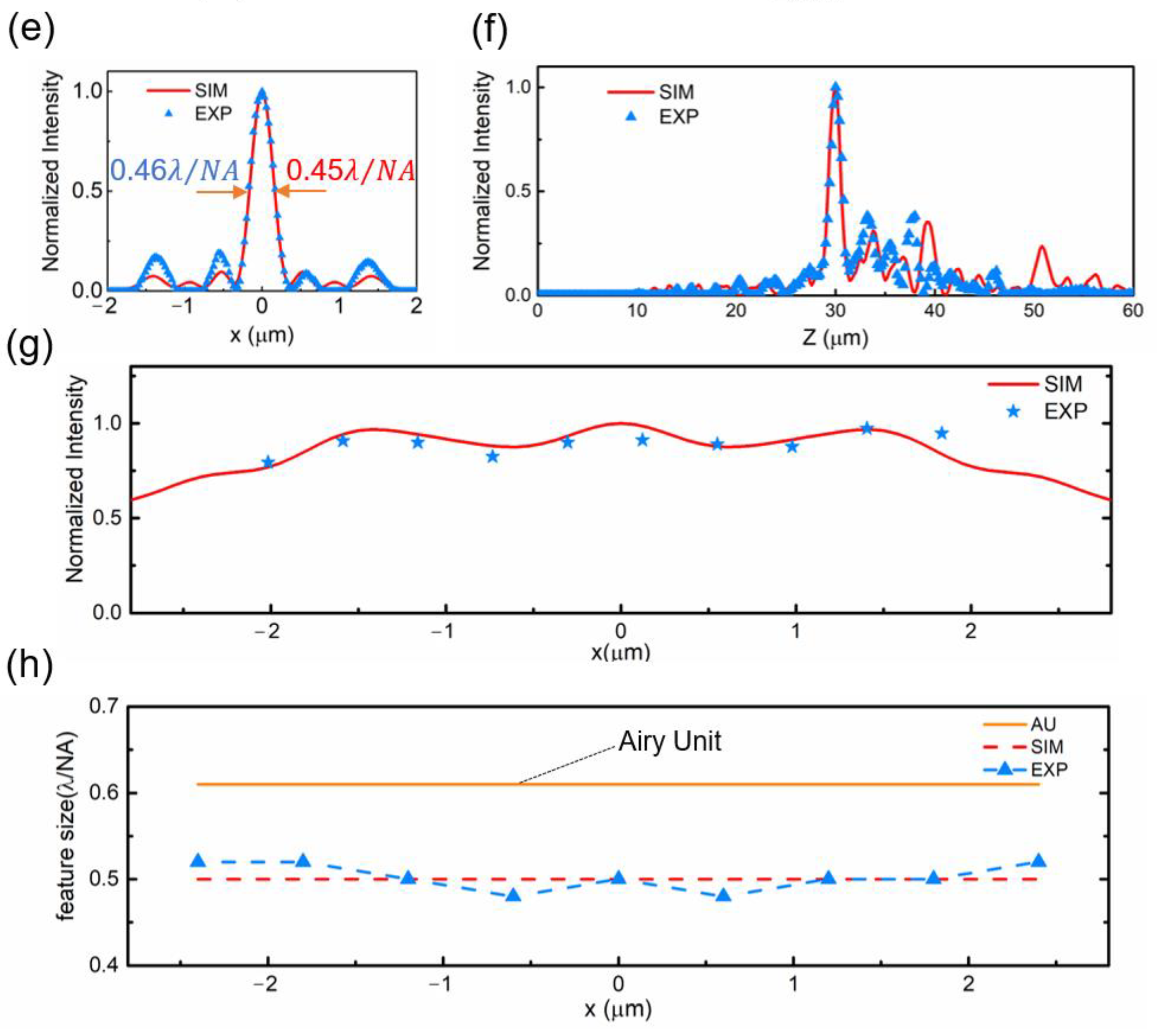

2.2. Fabrication and Optical Characterization

3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

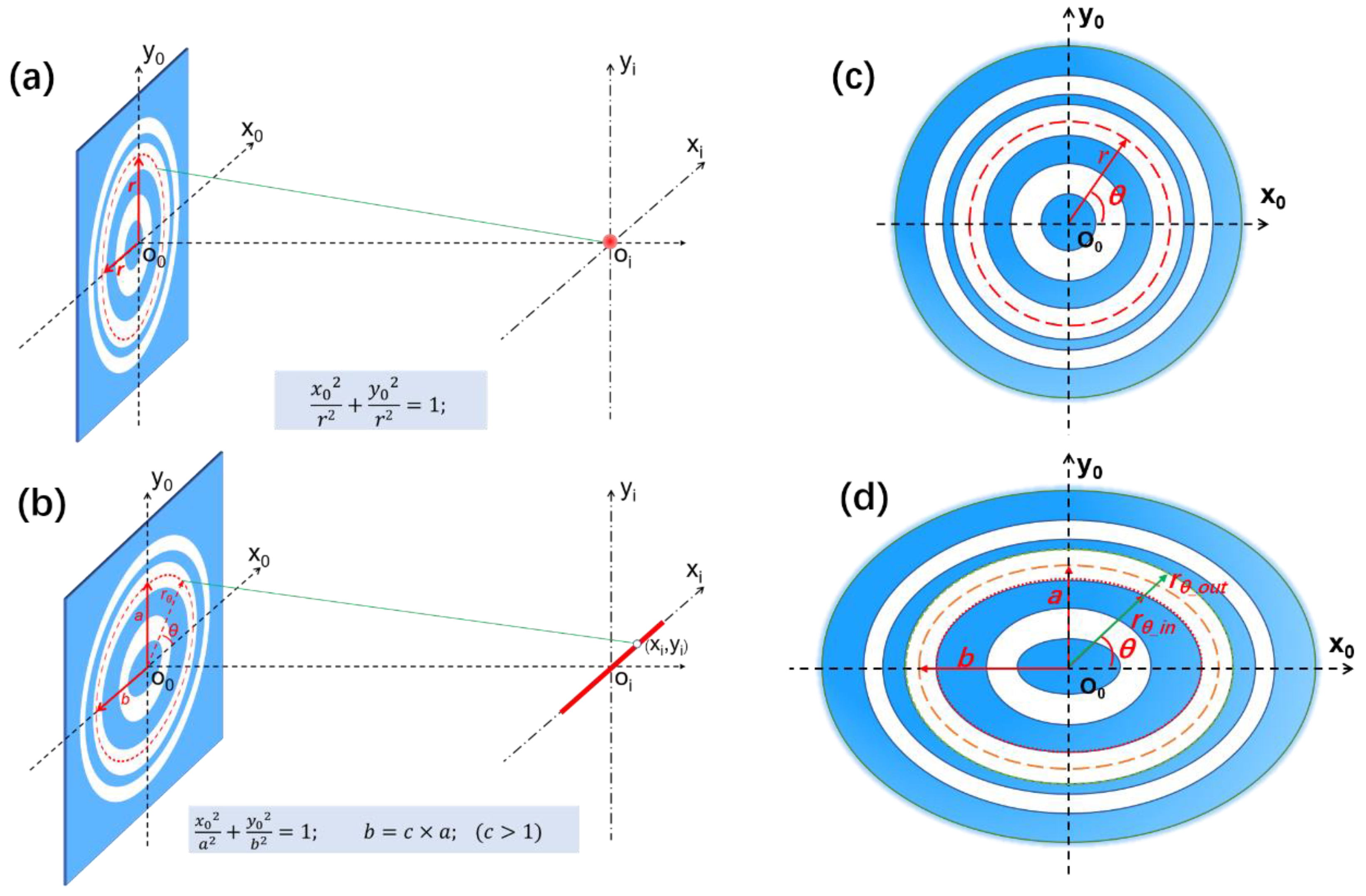

Appendix A.1. Design of Binary Amplitude Elliptical Super-Critical Lens

| No | Opaque | Transparent | No | Opaque | Transparent | ||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 0 | 1 | ||||||

| Rin/μm | Rout/μm | Rin/μm | Rout/μm | Rin/μm | Rout/μm | Rin/μm | Rout/μm | ||

| 1 | 0.00 | 4.37 | 4.37 | 6.20 | 21 | 29.38 | 30.17 | 30.17 | 30.57 |

| 2 | 6.20 | 7.61 | 7.61 | 8.81 | 22 | 30.57 | 31.28 | 31.28 | 31.68 |

| 3 | 8.81 | 9.87 | 9.87 | 10.84 | 23 | 31.68 | 32.43 | 32.43 | 32.83 |

| 4 | 10.84 | 11.74 | 11.74 | 12.58 | 24 | 32.83 | 33.33 | 33.33 | 33.73 |

| 5 | 12.58 | 13.38 | 13.38 | 14.14 | 25 | 33.73 | 34.20 | 34.20 | 34.60 |

| 6 | 14.14 | 14.57 | 14.57 | 14.97 | 26 | 34.60 | 35.09 | 35.09 | 35.49 |

| 7 | 14.97 | 15.58 | 15.58 | 15.98 | 27 | 35.49 | 35.99 | 35.99 | 36.39 |

| 8 | 15.98 | 16.46 | 16.46 | 16.86 | 28 | 36.39 | 37.00 | 37.00 | 37.40 |

| 9 | 16.86 | 17.72 | 17.72 | 18.12 | 29 | 37.40 | 38.14 | 38.14 | 38.54 |

| 10 | 18.12 | 18.76 | 18.76 | 19.16 | 30 | 38.54 | 39.04 | 39.04 | 39.44 |

| 11 | 19.16 | 20.00 | 20.00 | 20.40 | 31 | 39.44 | 40.01 | 40.01 | 40.41 |

| 12 | 20.40 | 20.93 | 20.93 | 21.33 | 32 | 40.41 | 40.93 | 40.93 | 41.33 |

| 13 | 21.33 | 22.16 | 22.16 | 22.56 | 33 | 41.33 | 42.22 | 42.22 | 42.62 |

| 14 | 22.56 | 23.16 | 23.16 | 23.56 | 34 | 42.62 | 43.07 | 43.07 | 43.47 |

| 15 | 23.56 | 24.34 | 24.34 | 24.74 | 35 | 43.47 | 44.16 | 44.16 | 44.56 |

| 16 | 24.74 | 25.14 | 25.14 | 25.54 | 36 | 44.56 | 45.08 | 45.08 | 45.48 |

| 17 | 25.54 | 26.13 | 26.13 | 26.53 | 37 | 45.48 | 46.11 | 46.11 | 46.51 |

| 18 | 26.53 | 27.17 | 27.17 | 27.57 | 38 | 46.51 | 47.00 | 47.00 | 47.40 |

| 19 | 27.57 | 28.07 | 28.07 | 28.47 | 39 | 47.40 | 47.99 | 47.99 | 48.39 |

| 20 | 28.47 | 28.98 | 28.98 | 29.38 | 40 | 48.39 | 49.04 | 49.04 | 49.44 |

Appendix A.2. Introduction of the Sector-Shape Cutting Region

Appendix A.3. Nanofabrication Process of the Binary Amplitude Supercritical Lens

Appendix A.4. Optical Characterization of the Patterned Supercritical Lenses

References

- Gareau, D.S.; Krueger, J.G.; Hawkes, J.E.; Lish, S.R.; Dietz, M.P.; Mulberger, A.G.; Mu, E.W.; Stevenson, M.L.; Lewin, J.M.; Meehan, S.A.; et al. Line scanning, stage scanning confocal microscope (LSSSCM). Biomed. Opt. Express 2017, 8, 3807–3815. [Google Scholar] [CrossRef]

- Tsang, J.M.; Gritton, H.J.; Das, S.L.; Weber, T.D.; Chen, C.S.; Han, X.; Mertz, J. Fast, multiplane line-scan confocal microscopy using axially distributed slits. Biomed. Opt. Express 2021, 12, 1339–1350. [Google Scholar] [CrossRef]

- Mei, E.; Fomitchov, P.A.; Graves, R.; Campion, M. A line scanning confocal fluorescent microscope using a CMOS rolling shutter as an adjustable aperture. J. Microsc. 2012, 247, 269–276. [Google Scholar] [CrossRef]

- Im, K.-B.; Han, S.; Park, H.; Kim, D.; Kim, B.-M. Simple high-speed confocal line-scanning microscope. Opt. Express 2005, 13, 5151–5156. [Google Scholar] [CrossRef]

- Zhang, P.; Phipps, M.E.; Goodwin, P.M.; Werner, J.H. Light-sheet microscopy by confocal line scanning of dual-Bessel beams. J. Biomed. Opt. 2016, 21, 100502. [Google Scholar] [CrossRef][Green Version]

- Zhong, Q.; Li, A.; Jin, R.; Zhang, D.; Li, X.; Jia, X.; Ding, Z.; Luo, P.; Zhou, C.; Jiang, C.; et al. High-definition imaging using line-illumination modulation microscopy. Nat. Methods 2021, 18, 309–315. [Google Scholar] [CrossRef]

- Yuan, G.; Rogers, E.T.; Zheludev, N.I. Achromatic super-oscillatory lenses with sub-wavelength focusing. Light Sci. Appl. 2017, 6, e17036. [Google Scholar] [CrossRef] [PubMed]

- Yuan, G.; Rogers, E.T.; Roy, T.; Adamo, G.; Shen, Z.; Zheludev, N.I. Planar super-oscillatory lens for sub-diffraction optical needles at violet wavelengths. Sci. Rep. 2014, 4, 6333. [Google Scholar] [CrossRef] [PubMed]

- Tang, D.; Wang, C.; Zhao, Z.; Wang, Y.; Pu, M.; Li, X.; Gao, P.; Luo, X. Ultrabroadband superoscillatory lens composed by plasmonic metasurfaces for subdiffraction light focusing. Laser Photon. Rev. 2015, 9, 713–719. [Google Scholar] [CrossRef]

- Qin, F.; Huang, K.; Wu, J.; Jiao, J.; Luo, X.; Qiu, C.; Hong, M. Shaping a subwavelength needle with ultra-long focal length by focusing azimuthally polarized light. Sci. Rep. 2015, 5, 9977. [Google Scholar] [CrossRef]

- Qin, F.; Liu, B.; Zhu, L.; Lei, J.; Fang, W.; Hu, D.; Zhu, Y.; Ma, W.; Wang, B.; Shi, T.; et al. pi-phase modulated monolayer supercritical lens. Nat. Commun. 2021, 12, 32. [Google Scholar] [CrossRef] [PubMed]

- Fang, W.; Lei, J.; Zhang, P.; Qin, F.; Jiang, M.; Zhu, X.; Hu, D.; Cao, Y.; Li, X. Multilevel phase supercritical lens fabricated by synergistic optical lithography. Nanophotonics 2020, 9, 1469–1477. [Google Scholar] [CrossRef]

- Zhu, X.; Fang, W.; Lei, J.; Li, Z.; Xie, F.; Cao, Y.; Zhang, Y.; Qin, F.; Li, X. Supercritical lens array in a centimeter scale patterned with maskless UV lithography. Opt. Lett. 2020, 45, 1798–1801. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Tang, D.; Wang, Y.; Zhao, Z.; Wang, J.; Pu, M.; Zhang, Y.; Yan, W.; Gao, P.; Luo, X. Super-resolution optical telescopes with local light diffraction shrinkage. Sci. Rep. 2015, 5, 18485. [Google Scholar] [CrossRef]

- Yuan, G.; Zheludev, N.I. Detecting nanometric displacements with optical ruler metrology. Science 2019, 364, 771–775. [Google Scholar] [CrossRef]

- Qin, F.; Huang, K.; Wu, J.; Teng, J.; Qiu, C.W.; Hong, M. A Supercritical Lens Optical Label-Free Microscopy: Sub-Diffraction Resolution and Ultra-Long Working Distance. Adv. Mater. 2017, 29, 1602721. [Google Scholar] [CrossRef]

- Rogers, E.T.F.; Quraishe, S.; Rogers, K.S.; Newman, T.A.; Smith, P.J.S.; Zheludev, N.I. Far-field unlabeled super-resolution imaging with superoscillatory illumination. APL Photonics 2020, 5, 066107. [Google Scholar] [CrossRef]

- Rogers, E.T.; Lindberg, J.; Roy, T.; Savo, S.; Chad, J.E.; Dennis, M.R.; Zheludev, N.I. A super-oscillatory lens optical microscope for subwavelength imaging. Nat. Mater. 2012, 11, 432–435. [Google Scholar] [CrossRef]

- Klar, T.A.; Jakobs, S.; Dyba, M.; Egner, A.; Hell, S.W. Fluorescence microscopy with diffraction resolution barrier broken by stimulated emission. Proc. Natl. Acad. Sci. USA 2000, 97, 8206–8210. [Google Scholar] [CrossRef]

- Westphal, V.; Rizzoli, S.O.; Lauterbach, M.A.; Kamin, D.; Jahn, R.; Hell, S.W. Video-rate far-field optical nanoscopy dissects synaptic vesicle movement. Science 2008, 320, 246–249. [Google Scholar] [CrossRef]

- Denk, W.; Strickler, J.; Webb, W. Two-photon laser scanning fluorescence microscopy. Science 1990, 248, 73–76. [Google Scholar] [CrossRef]

- Gissibl, T.; Thiele, S.; Herkommer, A.; Giessen, H. Two-photon direct laser writing of ultracompact multi-lens objectives. Nat. Photonics 2016, 10, 554–560. [Google Scholar] [CrossRef]

- Wang, J.; Qin, F.; Zhang, D.; Li, D.; Wang, Y.; Shen, X.; Yu, T.; Teng, J. Subwavelength superfocusing with a dipole-wave-reciprocal binary zone plate. Appl. Phys. Lett. 2013, 102, 061103. [Google Scholar] [CrossRef]

- Zheng, X.; Jia, B.; Lin, H.; Qiu, L.; Li, D.; Gu, M. Highly efficient and ultra-broadband graphene oxide ultrathin lenses with three-dimensional subwavelength focusing. Nat. Commun. 2015, 6, 8433. [Google Scholar] [CrossRef]

- Wang, H.; Shi, L.; Lukyanchuk, B.; Sheppard, C.; Chong, C.T. Creation of a needle of longitudinally polarized light in vacuum using binary optics. Nat. Photonics 2008, 2, 501–505. [Google Scholar] [CrossRef]

- Wang, H.; Hao, C.; Lin, H.; Wang, Y.; Lan, T.; Qiu, C.; Jia, B. Generation of super-resolved optical needle and multifocal array using graphene oxide metalenses. Opto-Electron. Adv. 2021, 4, 20003101–20003115. [Google Scholar] [CrossRef]

- Dai, X.; Dong, F.; Zhang, K.; Liao, D.; Li, S.; Shang, Z.; Zhou, Y.; Liang, G.; Zhang, Z.; Wen, Z.; et al. Holographic Super-Resolution Metalens for Achromatic Sub-Wavelength Focusing. ACS Photonics 2021, 8, 2294–2303. [Google Scholar] [CrossRef]

- Kim, J.; Seong, J.; Yang, Y.; Moon, S.-W.; Badloe, T.; Rho, J. Tunable metasurfaces towards versatile metalenses and metaholograms: A review. Adv. Photonics 2022, 4, 024001. [Google Scholar] [CrossRef]

- Yoon, G.; Kim, K.; Huh, D.; Lee, H.; Rho, J. Single-step manufacturing of hierarchical dielectric metalens in the visible. Nat. Commun. 2020, 11, 2268. [Google Scholar] [CrossRef]

- Yoon, G.; Jang, J.; Mun, J.; Nam, K.T.; Rho, J. Metasurface zone plate for light manipulation in vectorial regime. Comms. Phys. 2019, 2, 156. [Google Scholar] [CrossRef]

- Huang, K.; Liu, H.; Garcia-Vidal, F.J.; Hong, M.; Luk’yanchuk, B.; Teng, J.; Qiu, C.W. Ultrahigh-capacity non-periodic photon sieves operating in visible light. Nat. Commun. 2015, 6, 7059. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Qin, F.; Liu, H.; Ye, H.; Qiu, C.; Hong, M.; Yanchuk, B.L.; Teng, J. Planar Diffractive Lenses: Fundamentals, Functionalities, and Applications. Adv. Mater. 2018, 30, 1704556. [Google Scholar] [CrossRef]

- Jin, Z.; Janoschka, D.; Deng, J.; Ge, L.; Dreher, P.; Frank, B.; Hu, G.; Ni, J.; Yang, Y.; Li, J.; et al. Phyllotaxis-inspired nanosieves with multiplexed orbital angular momentum. eLight 2021, 1, 5. [Google Scholar] [CrossRef]

- Ye, H.; Qiu, C.-W.; Huang, K.; Teng, J.; Luk’yanchuk, B.; Yeo, S.P. Creation of a longitudinally polarized subwavelength hotspot with an ultra-thin planar lens: Vectorial Rayleigh–Sommerfeld method. Laser Phys. Lett. 2013, 10, 065004. [Google Scholar] [CrossRef]

- Yuan, G.; Vezzoli, S.; Altuzarra, C.; Rogers, E.T.; Couteau, C.; Soci, C.; Zheludev, N.I. Quantum super-oscillation of a single photon. Light Sci. Appl. 2016, 5, e16127. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, J.; Wang, M.; Wu, J.; Duan, H.; Zhang, K.; Wang, S.; Cao, Y.; Li, X.; Qin, F. Elliptical Supercritical Lens for Shaping Sub-Diffractive Transverse Optical Needle. Nanomaterials 2023, 13, 242. https://doi.org/10.3390/nano13020242

Lei J, Wang M, Wu J, Duan H, Zhang K, Wang S, Cao Y, Li X, Qin F. Elliptical Supercritical Lens for Shaping Sub-Diffractive Transverse Optical Needle. Nanomaterials. 2023; 13(2):242. https://doi.org/10.3390/nano13020242

Chicago/Turabian StyleLei, Jian, Minghui Wang, Jin Wu, Hui Duan, Kun Zhang, Sicong Wang, Yaoyu Cao, Xiangping Li, and Fei Qin. 2023. "Elliptical Supercritical Lens for Shaping Sub-Diffractive Transverse Optical Needle" Nanomaterials 13, no. 2: 242. https://doi.org/10.3390/nano13020242

APA StyleLei, J., Wang, M., Wu, J., Duan, H., Zhang, K., Wang, S., Cao, Y., Li, X., & Qin, F. (2023). Elliptical Supercritical Lens for Shaping Sub-Diffractive Transverse Optical Needle. Nanomaterials, 13(2), 242. https://doi.org/10.3390/nano13020242