Sol–Gel-Processed Y2O3 Multilevel Resistive Random-Access Memory Cells for Neural Networks

Abstract

:1. Introduction

2. Materials and Methods

- Cleaning the ITO-coated glass substrate: The substrate was immersed in acetone and sonicated for 10 min, followed by additional cleaning with deionized water. A UV/O3 treatment was then performed for 1 h to remove any remaining organic impurities.

- Y2O3 precursor solution preparation: A Y2O3 precursor solution (0.3 M) was created by dissolving yttrium (III) nitrate tetrahydrate (Y(NO3)34H2O) in 2-methoxymethanol. The solution was sonicated for an additional 10 min to achieve a clear solution.

- Coating Y2O3 on the ITO/glass substrate: A tiny Kapton tape was used to define the contact window for the ITO bottom electrodes. The Y2O3 precursor solution was then spin-coated onto the cleaned ITO/glass substrate at 3000 rpm for 50 s. The Kapton tape was removed before the heating process.

- Thermal annealing: To evaporate the solvent, the coated substrate was annealed on a hot plate at 100 °C for 10 min. The coated substrate was thermally annealed in a furnace at 500 °C for 3 h in the presence of air to convert the Y2O3 precursor into Y2O3.

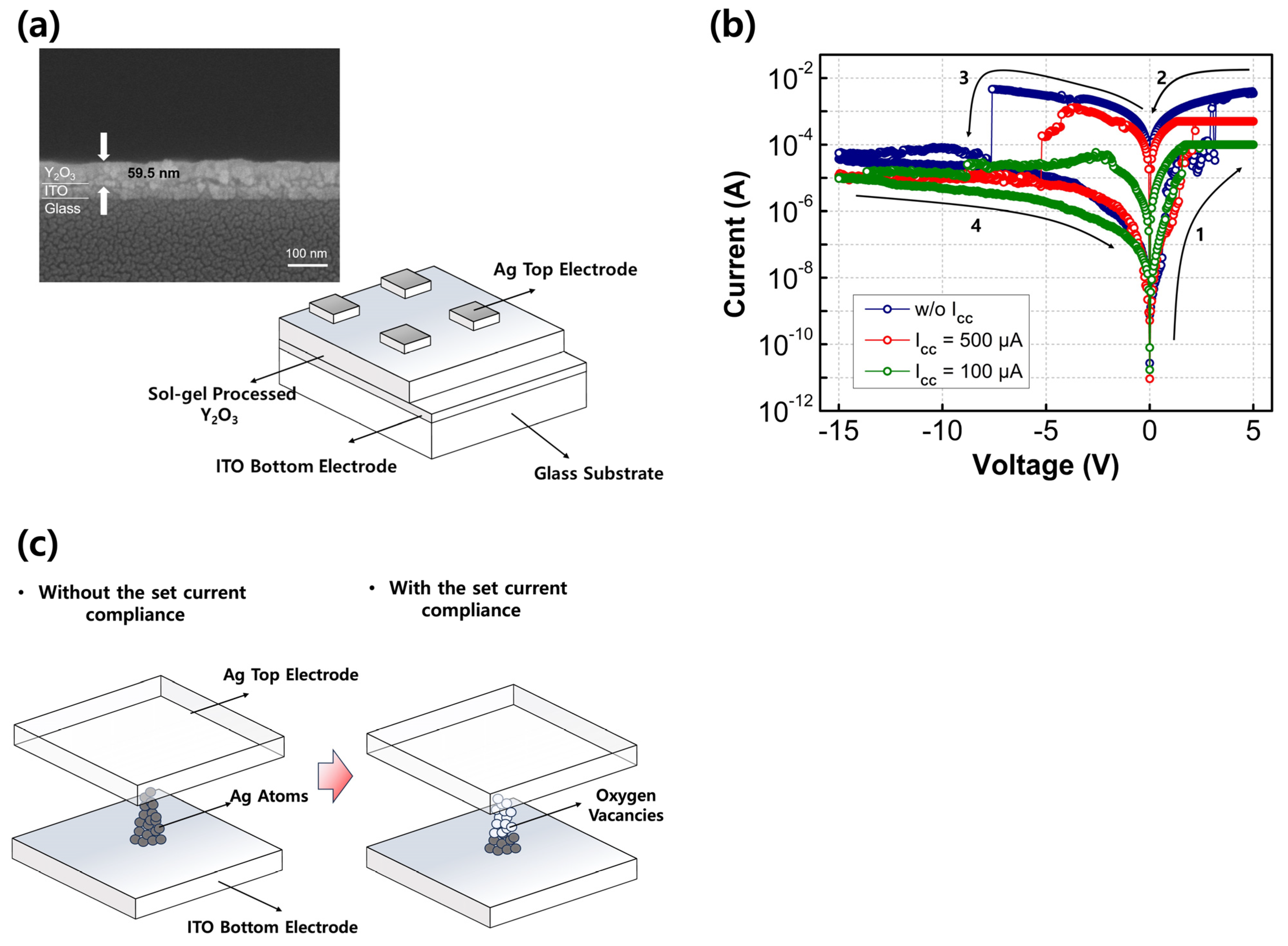

- Deposition of Ag TE: A shadow metal mask was placed in contact with the Y2O3 film to define the size of the electrode (30 μm × 30 μm). A 100-nm-thick layer of Ag was deposited onto the Y2O3 films using thermal evaporation at a rate of 1.8 Å/s under 5 × 10−6 torr.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Joshi, S.; Savel’ev, S.E.; Jiang, H.; Midya, R.; Lin, P.; Hu, M.; Ge, N.; Strachan, J.P.; Li, Z. Memristors with diffusive dynamics as synaptic emulators for neuromorphic computing. Nat. Mater. 2017, 16, 101–108. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.H.; Wang, Z.; Kim, K.M.; Wu, H.; Ravichandran, V.; Xia, Q.; Hwang, C.S.; Yang, J.J. An artificial nociceptor based on a diffusive memristor. Nat. Commun. 2018, 9, 417. [Google Scholar] [CrossRef] [PubMed]

- Jeong, D.S.; Hwang, C.S. Nonvolatile memory materials for neuromorphic intelligent machines. Adv. Mater. 2018, 30, 1704729. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Wu, H.; Wu, R.; Zhang, Y.; Deng, N.; Yu, Z.; Qian, H. Study of Multi-level Characteristics for 3D Vertical Resistive Switching Memory. Sci. Rep. 2014, 4, 5780. [Google Scholar] [CrossRef]

- Ho, T.-L.; Ding, K.; Lyapunov, N.; Suen, C.-H.; Wong, L.-W.; Zhao, J.; Yang, M.; Zhou, X.; Dai, J.-Y. Multi-Level Resistive Switching in SnSe/SrTiO3 Heterostructure Based Memristor Device. Nanomaterials 2022, 12, 2128. [Google Scholar] [CrossRef]

- Park, J.; Park, E.; Yu, H.-Y. Active layer nitrogen doping technique with excellent thermal stability for resistive switching memristor. Appl. Surf. Sci. 2022, 603, 154307. [Google Scholar] [CrossRef]

- Wang, S.; Ning, X.; Hao, A.; Chen, R. Metal nanoparticles layer boosted resistive switching property in NiFe2O4-based memory devices. J. Alloys Compd. 2022, 908, 164569. [Google Scholar] [CrossRef]

- Jang, J.; Subramanian, V. Effect of electrode material on resistive switching memory behavior of solution-processed resistive switches: Realization of robust multi-level cell. Thin Solid Films 2017, 625, 87–92. [Google Scholar] [CrossRef]

- Smith, J.; Chung, S.; Jang, J.; Biaou, C.; Subramanian, V. Solution-processed complementary resistive switching arrays for associative memory. IEEE Trans. Electron Devices 2017, 64, 4310–4316. [Google Scholar] [CrossRef]

- Lee, S.; Kim, T.; Jang, B.; Lee, W.Y.; Song, K.C.; Kim, H.S.; Do, G.Y.; Hwang, S.B.; Chung, S.; Jang, J. Impact of device area and film thickness on performance of sol-gel processed ZrO2 RRAM. IEEE Electron. Device Lett. 2018, 39, 668–671. [Google Scholar] [CrossRef]

- Ha, S.; Lee, H.; Lee, W.Y.; Jang, B.; Kwon, H.J.; Kim, K.; Jang, J. Effect of annealing environment on the performance of sol-gel-processed ZrO2 RRAM. Electronics 2019, 8, 947. [Google Scholar] [CrossRef]

- Kim, K.; Hong, W.; Lee, C.; Lee, W.Y.; Kim, H.J.; Kwon, H.J.; Kang, H.; Jang, J. Sol-gel-processed amorphous-phase ZrO2 Based resistive random-access memory. Mater. Res. Express 2021, 8, 116301. [Google Scholar] [CrossRef]

- Ding, Z.; Feng, Y.; Huang, P.; Liu, L.; Kang, J. Low-power resistive switching characteristic in HfO2/TiOx bi-layer resistive random-access memory. Nanoscale Res. Lett. 2018, 14, 157. [Google Scholar] [CrossRef]

- Kim, K.; Lee, C.; Lee, W.Y.; Kim, H.J.; Lee, S.H.; Bae, J.H.; Kang, I.M.; Jang, J. Enhanced switching ratio of sol–gel-processed Y2O3 RRAM device by suppressing oxygen-vacancy formation at high annealing temperature. Semicond. Sci. Technol. 2021, 37, 015007. [Google Scholar] [CrossRef]

- Kim, D.W.; Kim, H.J.; Lee, W.Y.; Kim, K.; Lee, S.H.; Bae, J.H.; Kang, I.M.; Kim, K.; Jang, J. Enhanced switching reliability of sol–gel-processed Y2O3 RRAM devices based on Y2O3 surface roughness-induced local electric field. Materials 2022, 15, 1943. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Kim, D.W.; Lee, W.Y.; Kim, K.; Lee, S.H.; Bae, J.H.; Kang, I.M.; Kim, K.; Jang, J. Flexible sol-gel-processed Y2O3 RRAM devices obtained via UV/Ozone-assisted photochemical annealing process. Materials 2022, 15, 1899. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.I.; Lee, T.; Lee, W.Y.; Kim, K.; Bae, J.H.; Kang, I.M.; Lee, S.H.; Kim, K.; Jang, J. Improved Environment Stability of Y2O3 RRAM Devices with Au Passivated Ag Top Electrodes. Materials 2022, 15, 6859. [Google Scholar] [CrossRef]

- Kim, K.; Kim, H.I.; Lee, T.; Lee, W.Y.; Bae, J.H.; Kang, I.M.; Lee, S.H.; Jang, J. Thickness dependence of resistive switching characteristics of the sol–gel processed Y2O3 RRAM devices. Semicond. Sci. Technol. 2023, 38, 045002. [Google Scholar] [CrossRef]

- Lee, C.; Lee, W.Y.; Kim, H.J.; Bae, J.H.; Kang, I.M.; Lim, D.; Kim, K.; Jang, J. Extremely bias stress stable enhancement mode sol–gel-processed SnO2 thin-film transistors with Y2O3 passivation layers. Appl. Surf. Sci. 2021, 559, 149971. [Google Scholar] [CrossRef]

- Lee, Y.W.; Kim, D.W.; Kim, H.J.; Kim, K.; Lee, S.H.; Bae, J.H.; Kang, I.M.; Kim, K.; Jang, J. Environmentally and electrically stable sol–gel-deposited SnO2 thin-film transistors with controlled passivation layer diffusion penetration depth that minimizes mobility degradation. ACS Appl. Mater. Interfaces 2022, 14, 10558–10565. [Google Scholar] [CrossRef]

- Jang, J.; Kang, H.; Chakravarthula, H.C.N.; Subramanian, V. Fully inkjet-printed transparent oxide thin film transistors using a fugitive wettability switch. Adv. Electron. Mater. 2015, 1, 1500086. [Google Scholar] [CrossRef]

- Scheideler, W.J.; Jang, J.; Karim, M.A.U.; Kitsomboonloha, R.; Zeumault, Z.; Subramanian, V. Gravure-Printed Sol-Gels on Flexible Glass: A Scalable Route to Additively Patterned Transparent Conductors. ACS Appl. Mater. Interfaces 2015, 7, 12679–12687. [Google Scholar] [CrossRef] [PubMed]

- Lim, D.G.; Kwak, D.J.; Yi, J. Improved interface properties of yttrium oxide buffer layer on silicon substrate for ferroelectric random access memory applications. Thin Solid Films 2017, 422, 150–154. [Google Scholar] [CrossRef]

- Yang, B.; Xu, N.; Li, C.; Huang, C.; Ma, D.; Liu, J.; Arumi, D.; Fang, L. A forming-free ReRAM cell with low operating voltage. IEICE Electron. Express 2020, 17, 20200343. [Google Scholar] [CrossRef]

- Abbas, Y.; Ambade, R.B.; Ambade, S.B.; Han, T.H.; Choi, C. Tailored nanoplateau and nanochannel structures using solution-processed rutile TiO2 thin films for complementary and bipolar switching characteristics. Nanoscale 2019, 11, 13815. [Google Scholar] [CrossRef]

- Prakash, A.; Deleruyelle, D.; Song, J.; Bocquet, M.; Hwang, H. Resistance controllability and variability improvement in a TaOx-based resistive memory for multilevel storage application. Appl. Phys. Lett. 2015, 106, 233104. [Google Scholar] [CrossRef]

- Sedghi, N.; Li, H.; Brunell, I.F.; Dawson, K.; Potter, R.J.; Guo, Y.; Gibbon, J.T.; Dhanak, V.R.; Zhang, W.D.; Zhang, J.F.; et al. The role of nitrogen doping in ALD Ta2O5 and its influence on multilevel cell switching in RRAM. Appl. Phys. Lett. 2017, 110, 102902. [Google Scholar] [CrossRef]

- Kim, D.; Shin, J.; Kim, S. Resistive Switching Characteristics of ZnO-Based RRAM on Silicon Substrate. Metals 2021, 11, 1572. [Google Scholar] [CrossRef]

- Deng, Y.; Huang, P.; Chen, B.; Yang, X.; Gao, B.; Wang, J.; Zeng, L.; Du, G.; Kang, J.; Liu, X. RRAM crossbar array with cell selection device: A device and circuit interaction study. IEEE Trans. Electron. Devices 2013, 60, 719–726. [Google Scholar] [CrossRef]

- Mahata, C.; Kang, M.; Kim, S. Multi-level analog resistive switching characteristics in tri-layer HfO2/Al2O3/HfO2 based memristor on ITO electrode. Nanomaterials 2020, 10, 2069. [Google Scholar] [CrossRef]

- Tseng, H.T.; Hsu, T.H.; Tsai, M.H.; Huang, C.Y.; Huang, C.L. Resistive switching characteristics of sol-gel derived La2Zr2O7 thin film for RRAM applications. J. Alloys Compd. 2022, 899, 163294. [Google Scholar] [CrossRef]

- Zhu, X.; Zhuge, F.; Li, M.; Yin, K.; Liu, Y.; Zuo, Z.; Chen, B.; Li, R.W. Microstructure dependence of leakage and resistive switching behaviors in Ce-doped BiFeO3 thin film. J. Phys. D Appl. Phys. 2011, 44, 415104. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, T.; Kim, H.-I.; Cho, Y.; Lee, S.; Lee, W.-Y.; Bae, J.-H.; Kang, I.-M.; Kim, K.; Lee, S.-H.; Jang, J. Sol–Gel-Processed Y2O3 Multilevel Resistive Random-Access Memory Cells for Neural Networks. Nanomaterials 2023, 13, 2432. https://doi.org/10.3390/nano13172432

Lee T, Kim H-I, Cho Y, Lee S, Lee W-Y, Bae J-H, Kang I-M, Kim K, Lee S-H, Jang J. Sol–Gel-Processed Y2O3 Multilevel Resistive Random-Access Memory Cells for Neural Networks. Nanomaterials. 2023; 13(17):2432. https://doi.org/10.3390/nano13172432

Chicago/Turabian StyleLee, Taehun, Hae-In Kim, Yoonjin Cho, Sangwoo Lee, Won-Yong Lee, Jin-Hyuk Bae, In-Man Kang, Kwangeun Kim, Sin-Hyung Lee, and Jaewon Jang. 2023. "Sol–Gel-Processed Y2O3 Multilevel Resistive Random-Access Memory Cells for Neural Networks" Nanomaterials 13, no. 17: 2432. https://doi.org/10.3390/nano13172432

APA StyleLee, T., Kim, H.-I., Cho, Y., Lee, S., Lee, W.-Y., Bae, J.-H., Kang, I.-M., Kim, K., Lee, S.-H., & Jang, J. (2023). Sol–Gel-Processed Y2O3 Multilevel Resistive Random-Access Memory Cells for Neural Networks. Nanomaterials, 13(17), 2432. https://doi.org/10.3390/nano13172432