Design of Surfaces with Persistent Antimicrobial Properties on Stainless Steel Developed Using Femtosecond Laser Texturing for Application in “High Traffic” Objects

Abstract

:1. Introduction

2. Materials and Methods

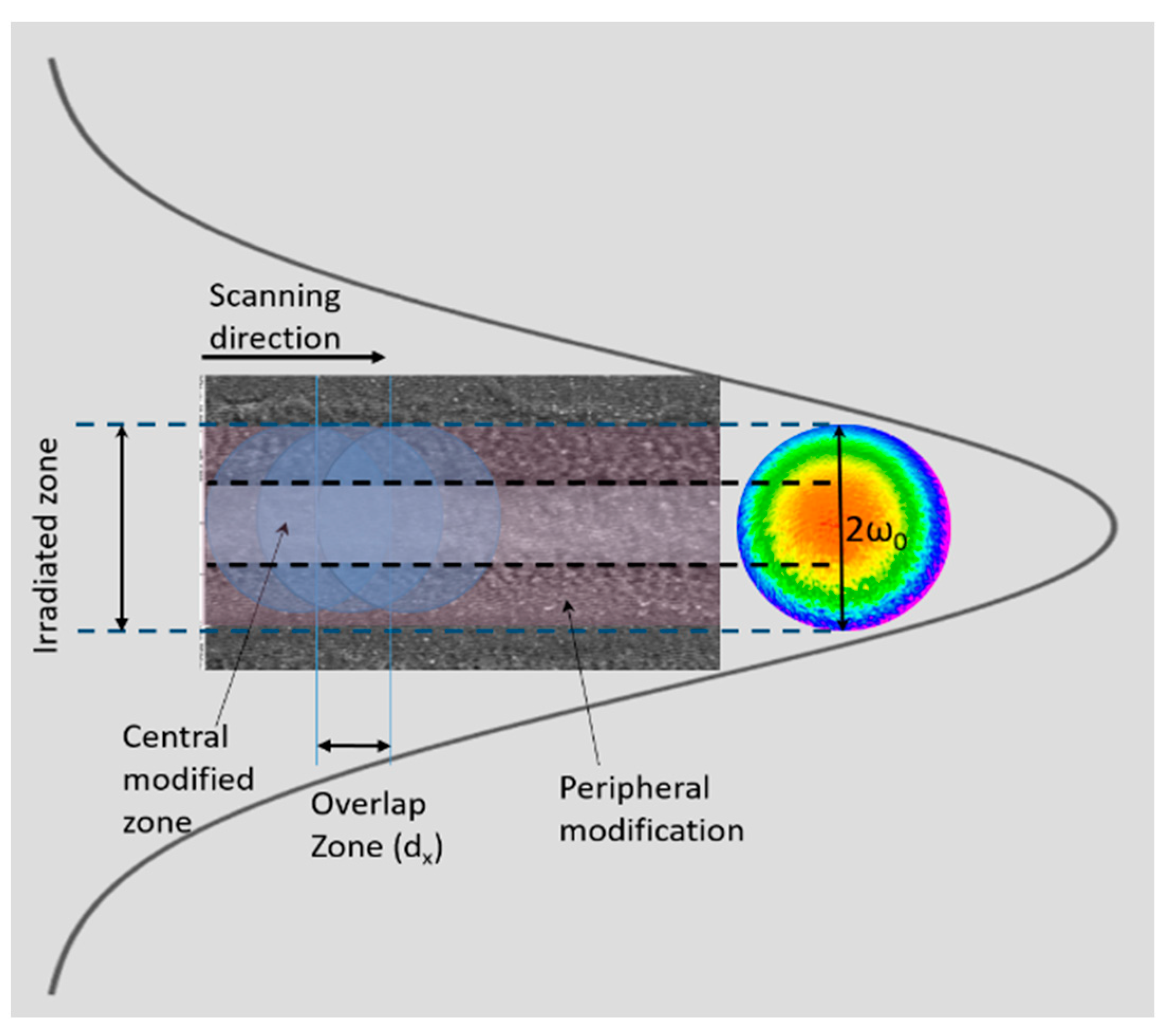

2.1. Femtosecond Laser Processing

2.2. Surface Characterization: Morphological, Wettability, and Elemental Analysis

2.3. Antimicrobial Studies

3. Results

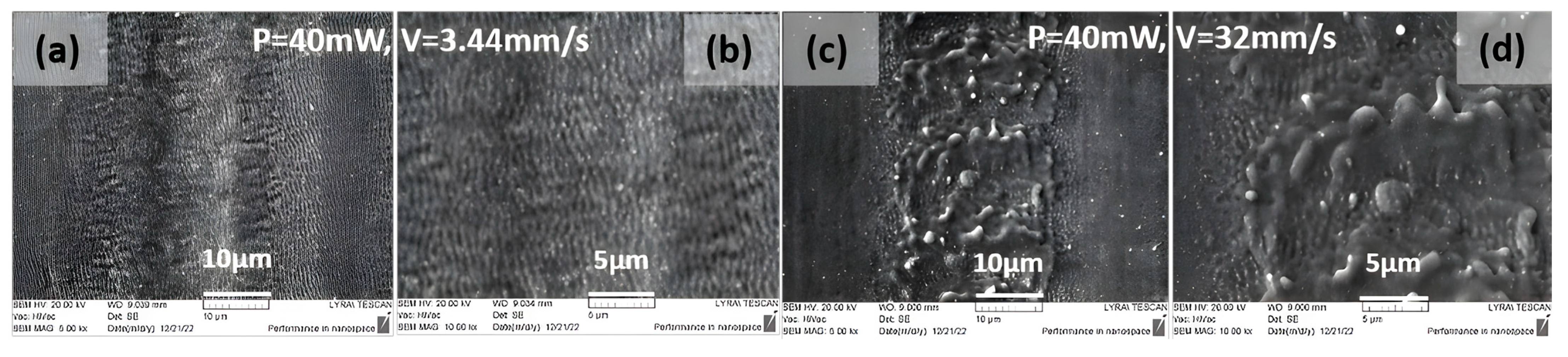

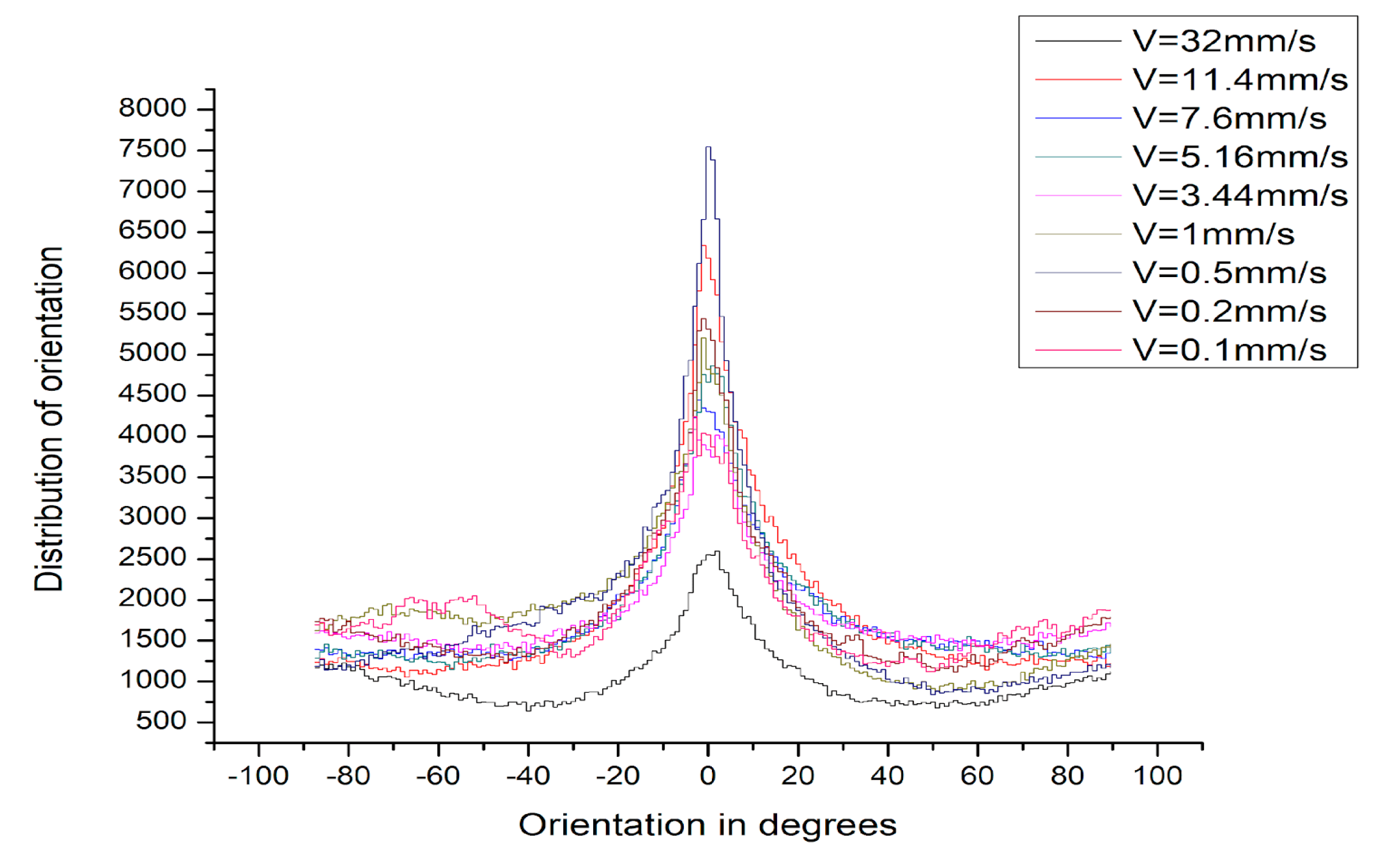

3.1. Evolution of Surface Morphology

3.2. Roughness Analysis

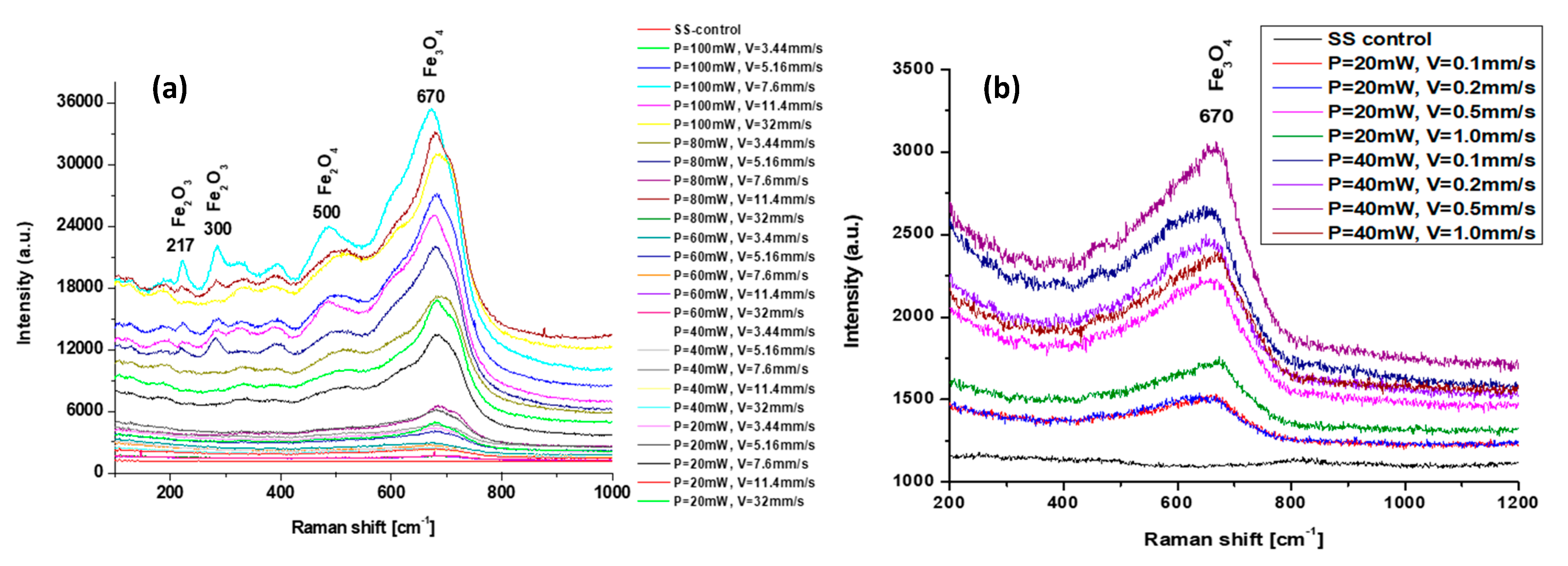

3.3. Chemical Analysis

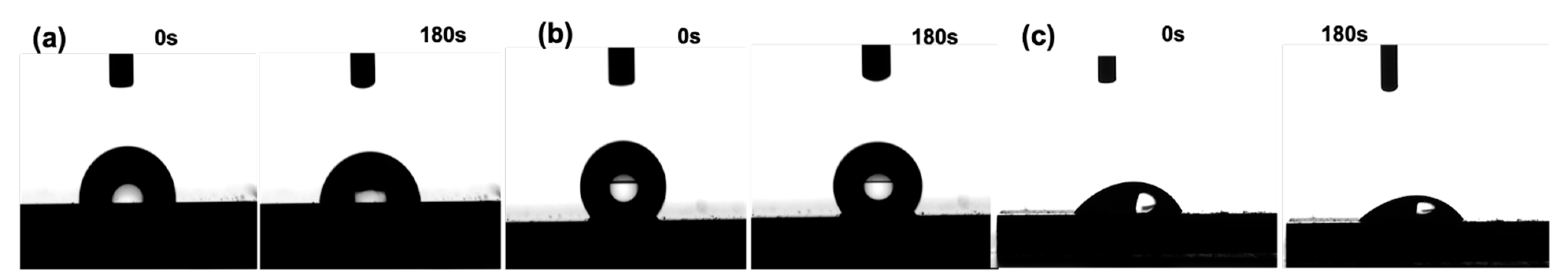

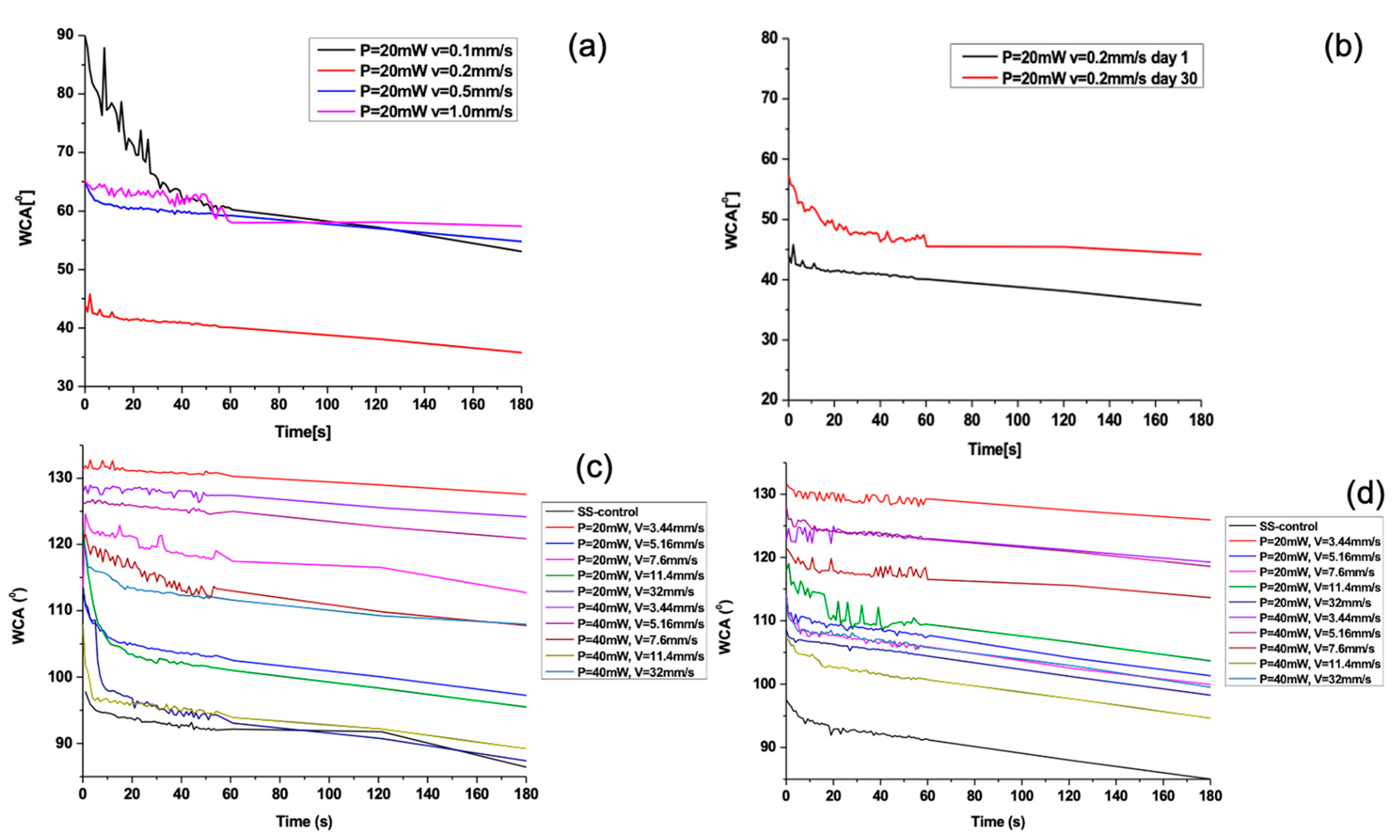

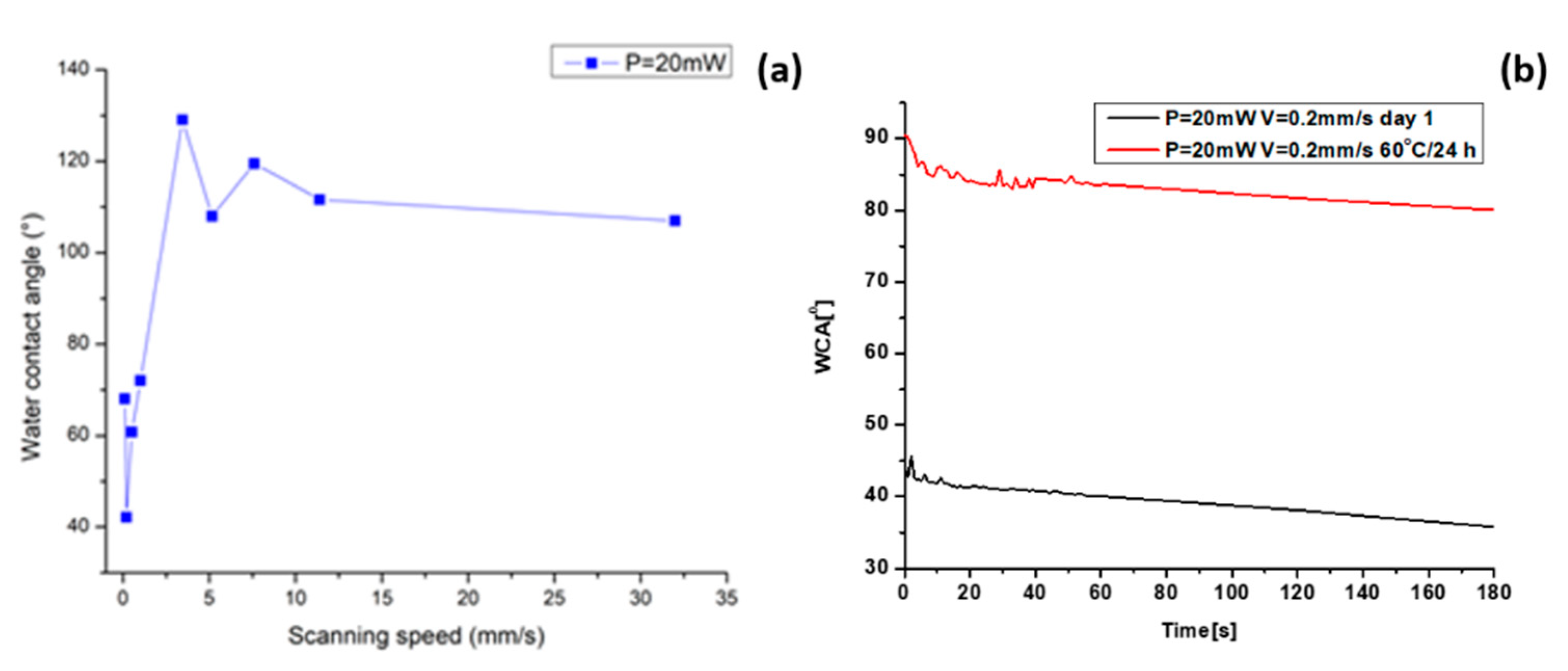

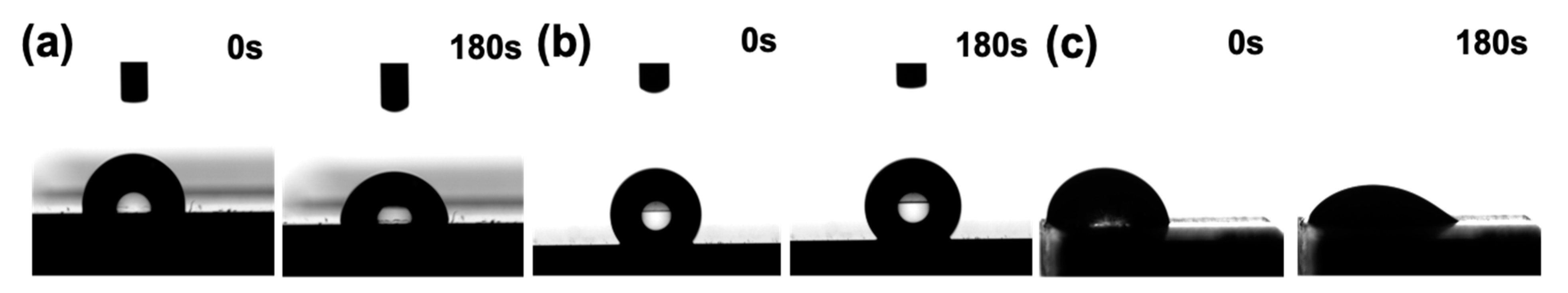

3.4. Wettability Analysis

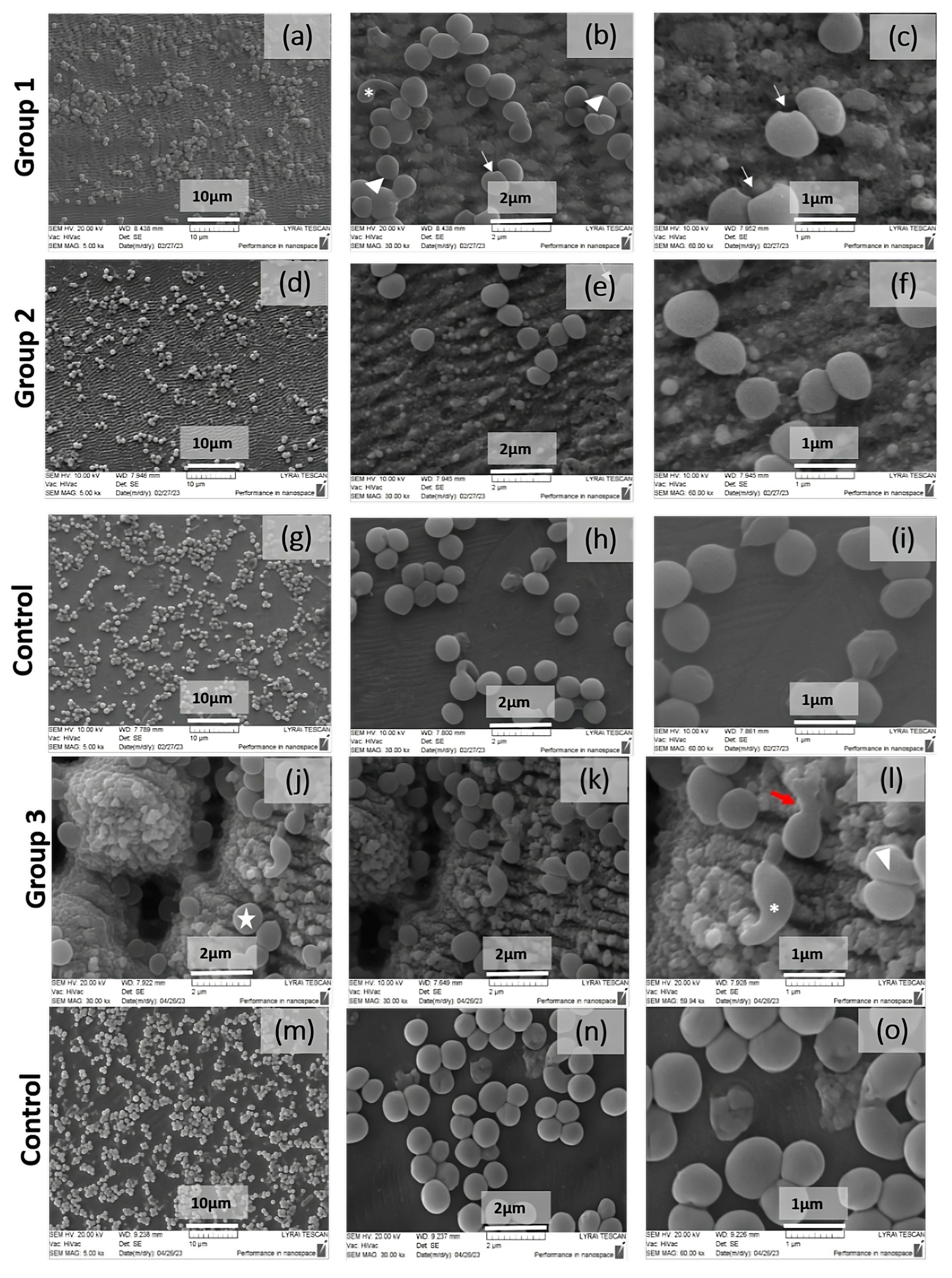

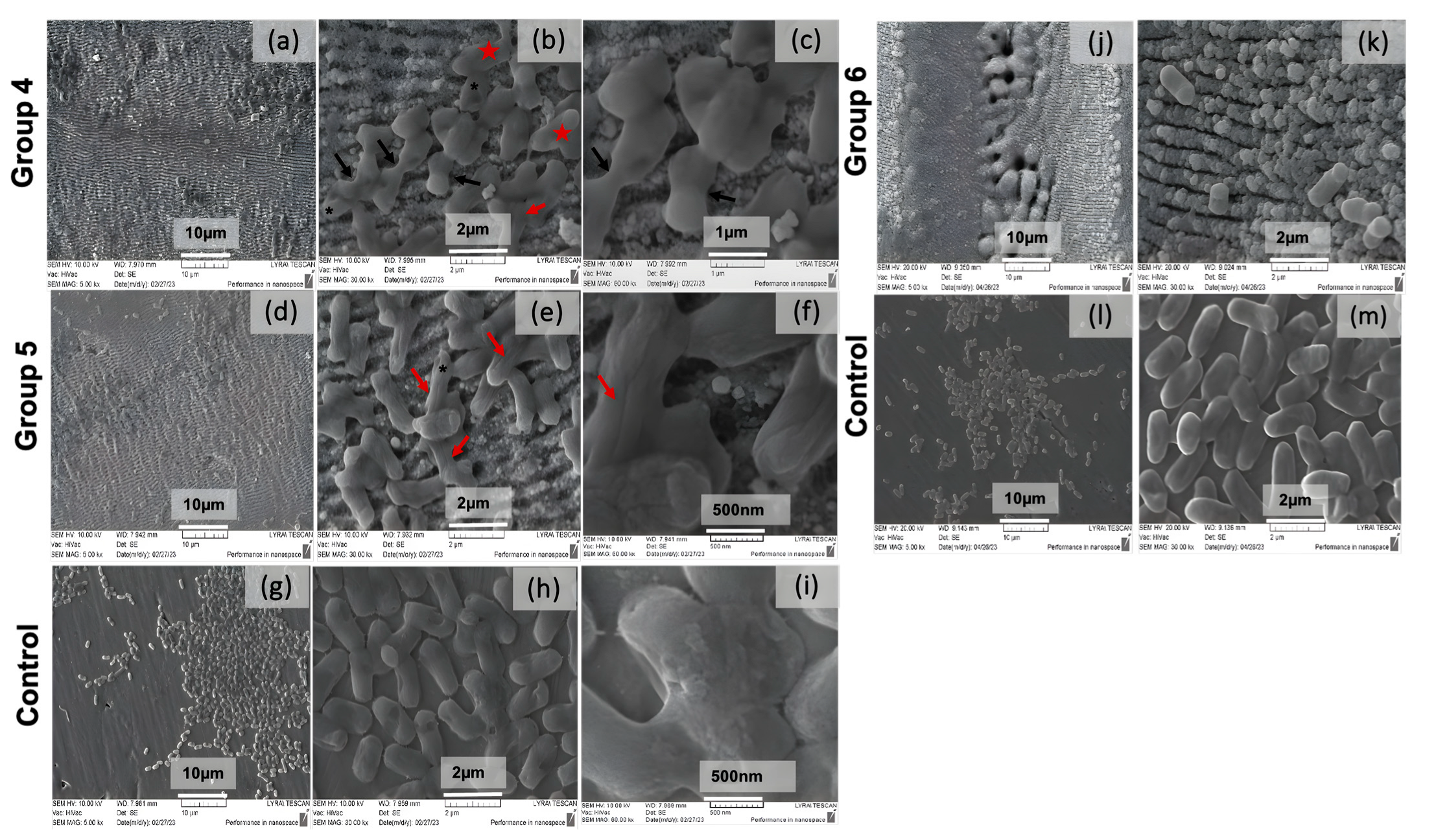

3.5. Bacteria Adhesion on Laser-Structured Stainless Steel

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jalil, S.; Akram, M.; Bhate, J.; Hayese, J.; Singh, S.; ElKabbash, M.; Guo, C. Creating superhydrophobic and antibacterial surfaces on gold by femtosecond laser pulses. Appl. Surf. Sci. 2020, 506, 144952. [Google Scholar] [CrossRef] [PubMed]

- Haque, M.; Sartelli, M.; McKimm, J.; Abu Bakar, M. Health care-associated infections—An overview. Infect. Drug Resist. 2018, 11, 2321–2333. [Google Scholar] [CrossRef]

- McFee, R.B. Nosocomial or Hospital-acquired Infections: An Overview. Dis. A Mon. 2009, 55, 422–438. [Google Scholar] [CrossRef] [PubMed]

- Villapún, V.M.; Dover, L.G.; Cross, A.; González, S. Antibacterial Metallic Touch Surfaces. Materials 2016, 9, 736. [Google Scholar] [CrossRef]

- Lazzini, G.; Romoli, L.; Lutey, A.H.A.; Fuso, F. Modelling the interaction between bacterial cells and laser-textured surfaces. Surf. Coat. Technol. 2019, 375, 8–14. [Google Scholar] [CrossRef]

- Cheng, Y.; Feng, G.; Moraru, C.I. Micro- and Nanotopography Sensitive Bacterial Attachment Mechanisms: A Review. Front. Microbiol. 2019, 10, 191. [Google Scholar]

- Dhyani, A.; Taylor Repetto, D.; Bartikofsky, C.; Mirabelli, Z.; Gao, S.A.; Snyder, C.; Snyder, G.; Mehta, C.; Wobus, E.; VanEpps, J.S.; et al. Surfaces with instant and persistent antimicrobial efficacy against bacteria and SARS-CoV-2. Matter 2022, 5, 4076–4091. [Google Scholar]

- Lutey, A.; Gemini, L.; Romoli, L.; Lazzini, G.; Fuso, F.; Faucon, M.; Kling, R. Towards Laser-Textured Antibacterial Surfaces. Sci. Rep. 2018, 8, 10112. [Google Scholar] [CrossRef]

- Sarbada, S.; Shinm, Y.C. Superhydrophobic contoured surfaces created on metal and polymer using a femtosecond laser. Appl. Surf. Sci. 2017, 405, 465–475. [Google Scholar] [CrossRef]

- Cunha, A.; Serroc, A.; Oliveira, V.; Almeida, A.; Vilar, R.; Durrieu, M. Wetting behaviour of femtosecond laser textured Ti–6Al–4V surfaces. Appl. Surf. Sci. 2013, 265, 688–696. [Google Scholar]

- Li, Y.; Cui, Z.; Wang, W.; Lin, C.; Tsai, H. Formation of linked nanostructure-textured mound-shaped microstructures on stainless steel surface via femtosecond laser ablation. Appl. Surf. Sci. 2015, 324, 775–783. [Google Scholar] [CrossRef]

- Sugioka, K. Progress in ultrafast laser processing and future prospects. Nanophotonics 2017, 6, 393–413. [Google Scholar]

- Peter, A.; Lutey, A.H.A.; Faas, S.; Romoli, L.; Onuseit, V.; Graf, T. Direct laser interference patterning of stainless steel by ultrashort pulses for antibacterial surfaces. Opt. Laser Technol. 2020, 123, 105954. [Google Scholar]

- Winter, J.; Sellauge, M.; Hermann, J.; Eulenkamp, C.; Huber, H.P.; Schmidt, M. Ultrashort single-pulse laser ablation of stainless steel, aluminium, copper and its dependence on the pulse duration. Opt. Express 2021, 29, 14561–14581. [Google Scholar] [CrossRef] [PubMed]

- Sciancalepore, C.; Gemini, L.; Romolic, L.; Bondiolia, F. Study of the wettability behavior of stainless steel surfaces after ultrafast laser texturing. Surf. Coat. Technol. 2018, 352, 370–377. [Google Scholar] [CrossRef]

- Indrišiūnas, S.; Gedvilas, M. Control of the wetting properties of stainless steel by ultrashort laser texturing using multi-parallel beam processing. Opt. Laser Technol. 2022, 153, 108187. [Google Scholar] [CrossRef]

- Rukosuyev, M.V.; Lee, J.; Jin, S.; Cho, G.; Lim, M.; Jun, B.G. One-step fabrication of superhydrophobic hierarchical structures by femtosecond laser ablation. Appl. Surf. Sci. 2014, 313, 411–417. [Google Scholar] [CrossRef]

- Richter, A.M.; Buchberger, G.; Stifter, D.; Duchoslav, J.; Hertwig, A.; Bonse, J.; Heitz, J.; Schwibbert, K. Spatial Period of Laser-Induced Surface Nanoripples on PET Determines Escherichia coli Repellence. Nanomaterials 2021, 11, 3000. [Google Scholar] [CrossRef]

- Gnilitskyi, I.; Derrien, T.J.-Y.; Levy, Y.; Bulgakova, N.M.; Mocek, T.; Orazi, L. High-speed manufacturing of highly regular femtosecond laserinduced periodic surface structures: Physical origin of regularity. Sci. Rep. 2017, 7, 8485. [Google Scholar] [CrossRef]

- Song, Y.; Wang, C.; Dong, X.; Yin, K.; Zhang, F.; Xie, Z.; Chu, D.; Duan, J. Controllable superhydrophobic aluminum surfaces with tunable adhesion fabricated by femtosecond laser. Opt. Laser Technol. 2018, 102, 25–31. [Google Scholar] [CrossRef]

- Cai, Y.; Luoa, X.; Macleanb, M.; Qina, Y.; Duxburyd, M.; Ding, F. A single-step fabrication approach for development of antimicrobial surfaces. J. Mater. Process. Technol. 2019, 271, 249–260. [Google Scholar] [CrossRef]

- Amulevicius, A.; Mazeika, K.; Sipavicius, C. Oxidation of Stainless Steel by Laser Cutting. Acta Phys. Pol. A 2009, 115, 880–885. [Google Scholar] [CrossRef]

- Dywel, P.; Szczesny, R.; Domanowski, P.; Skowronski, L. Structural and Micromechanical Properties of Nd:YAG Laser Marking Stainless Steel (AISI 304 and AISI 316). Materials 2020, 13, 2168. [Google Scholar] [CrossRef] [PubMed]

- Stoian, R.; Colombier, J. Advances in ultrafast laser structuring of materials at the nanoscale. Nanophotonics 2020, 9, 4665–4688. [Google Scholar] [CrossRef]

- Terekhin, P.; Oltmanns, J.; Blumenstein, A.; Ivanov, D.; Martin, K.; Garcia, E.; Rethfeld, B.; Ihlemann, J.; Simon, P. Key role of surface plasmon polaritons in generation of periodic surface structures following single-pulse laser irradiation of a gold step edge. Nanophotonics 2022, 11, 359–367. [Google Scholar] [CrossRef]

- Lickschat, P.; Metzner, D.; Weißmante, S. Burst mode ablation of stainless steel with tunable ultrashort laser pulses. J. Laser Appl. 2021, 33, 022005. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Q.; Long, M.; Han, R.; Cao, K.; Zhang, S.; Feng, D.; Jia, T.; Sun, Z.; Qiu, J.; et al. Femtosecond laser-induced periodic structures: Mechanisms, techniques, and applications. Opto-Electron. Sci. 2022, 1, 220005. [Google Scholar] [CrossRef]

- Zhang, D.; Li, X.; Yao, F.; Yao, Q.; Li, Z.; Sugioka, K. Liquid vortexes and flows induced by femtosecond laser ablation in liquid governing formation of circular and crisscross LIPSS. Opto-Electron. Adv. 2022, 5, 210066. [Google Scholar] [CrossRef]

| Group № | Scanning Velocity V (mm/s) | Laser Power (mW) |

|---|---|---|

| G1 | 0.1, 0.2, 0.5, 1, 3.44, 5.16, 7.6, 11.4, 32 | 20 |

| G2 | 0.1, 0.2, 0.5, 1, 3.44, 5.16, 7.6, 11.4, 32 | 40 |

| Irradiation Conditions | Ra—Averaged (Rpm) (µm) | Sa—Averaged (µm) | Distance b/n Heights Averaged (µm) | Distance b/n Rows Averaged (µm) | Depth of Grooves Averaged (µm) |

|---|---|---|---|---|---|

| Reference SS sample | - | 0.04839 | - | - | - |

| P = 20 mW, V = 0.1 mm/s | 4.429 | 3.791 | 35.57 | 39.63 | 17.48 |

| P = 20 mW, V = 0.2 mm/s | 3.652 | 1.603 | 49.58 | 52.15 | 8.831 |

| P = 20 mW, V = 0.5 mm/s | 0.873 | 1.039 | 53.26 | 67.93 | 4.97 |

| P = 20 mW, V = 1 mm/s | 0.377 | 0.482 | 62.08 | 42.11 | 2.36 |

| P = 20 mW, V = 3.44 mm/s | 0.2459 | 0.1254 | 24.84 | 29.65 | 1.08 |

| P = 20 mW, V = 5.16 mm/s | 0.2592 | 0.1838 | 21.2 | 32.01 | 1.04 |

| P = 20 mW, V = 7.6 mm/s | 0.272 | 0.1717 | 20.43 | 37.69 | 0.98 |

| P = 20 mW, V = 11.4 mm/s | 0.2737 | 0.1925 | 16.49 | 40.25 | 0.81 |

| P = 20 mW, V = 32 mm/s | 0.2801 | 0.2412 | 13.92 | 42.66 | 0.69 |

| P = 40 mW, V = 3.44 mm/s | 0.2306 | 0.1983 | 17.53 | 37.95 | 1.2 |

| P = 40 mW, V = 5.16 mm/s | 0.2089 | 0.1334 | 16.4 | 39.18 | 1.01 |

| P = 40 mW, V = 7.6 mm/s | 0.2449 | 0.1594 | 14.8 | 40.12 | 0.97 |

| P = 40 mW, V = 11.4 mm/s | 0.2742 | 0.1755 | 11.01 | 42.02 | 0.89 |

| P = 40 mW, V = 32 mm/s | 0.2994 | 0.1945 | 9.96 | 43.97 | 0.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daskalova, A.; Angelova, L. Design of Surfaces with Persistent Antimicrobial Properties on Stainless Steel Developed Using Femtosecond Laser Texturing for Application in “High Traffic” Objects. Nanomaterials 2023, 13, 2396. https://doi.org/10.3390/nano13172396

Daskalova A, Angelova L. Design of Surfaces with Persistent Antimicrobial Properties on Stainless Steel Developed Using Femtosecond Laser Texturing for Application in “High Traffic” Objects. Nanomaterials. 2023; 13(17):2396. https://doi.org/10.3390/nano13172396

Chicago/Turabian StyleDaskalova, Albena, and Liliya Angelova. 2023. "Design of Surfaces with Persistent Antimicrobial Properties on Stainless Steel Developed Using Femtosecond Laser Texturing for Application in “High Traffic” Objects" Nanomaterials 13, no. 17: 2396. https://doi.org/10.3390/nano13172396

APA StyleDaskalova, A., & Angelova, L. (2023). Design of Surfaces with Persistent Antimicrobial Properties on Stainless Steel Developed Using Femtosecond Laser Texturing for Application in “High Traffic” Objects. Nanomaterials, 13(17), 2396. https://doi.org/10.3390/nano13172396