Substrate Dependence of CdSe/ZnS Quantum-Dot Light-Emitting Diodes: A Comparative Study between Rigid Glass and Flexible Plastic Substrates

Abstract

1. Introduction

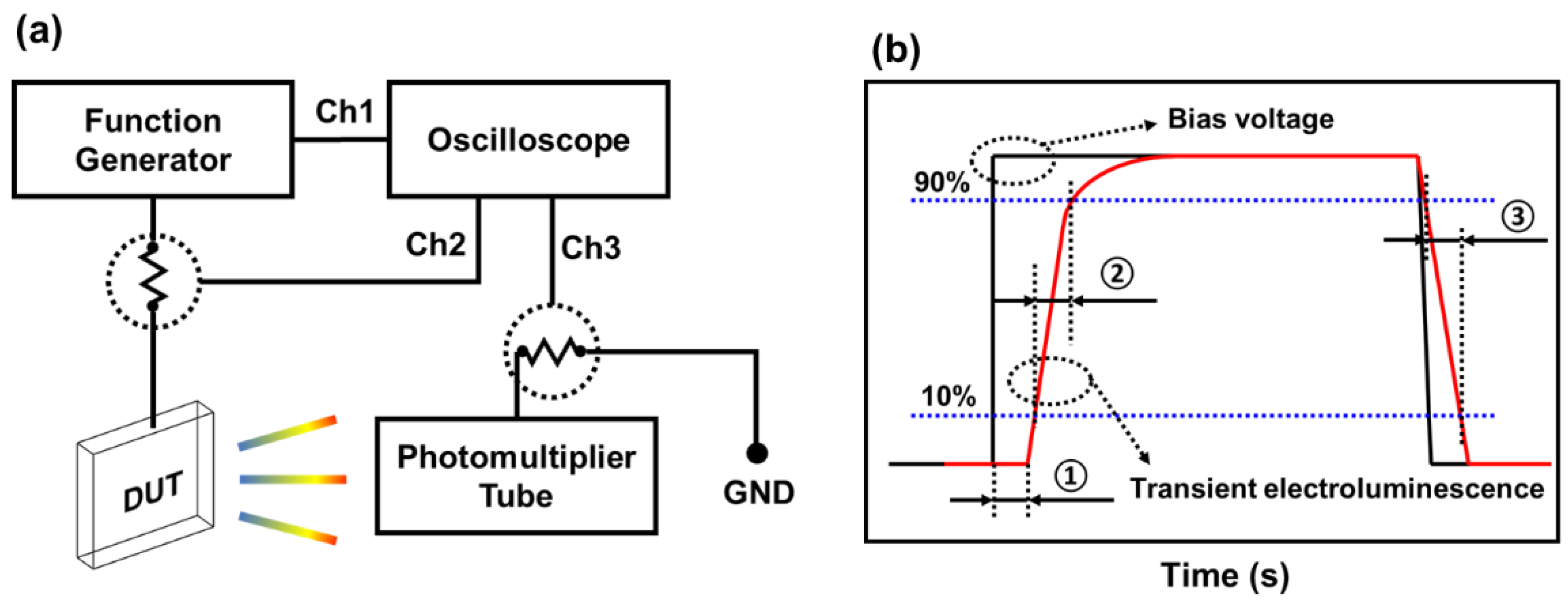

2. Experimental Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dabbousi, B.O.; Bawendi, M.G.; Onitsuka, O.; Rubner, M.F. Electroluminescence from CdSe Quantum-Dot/Polymer Composites. Appl. Phys. Lett. 1995, 66, 1316. [Google Scholar] [CrossRef]

- Chaudhary, S.; Ozkan, M.; Chan, W.C.W. Trilayer Hybrid Polymer-Quantum Dot Light-Emitting Diodes. Appl. Phys. Lett. 2004, 84, 2925–2927. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, J.; Jiang, C.; Bohnenberger, J.; Basché, T.; Mews, A. Electroluminescence from Isolated CdSe/ZnS Quantum Dots in Multilayered Light-Emitting Diodes. J. Appl. Phys. 2004, 96, 3206–3210. [Google Scholar] [CrossRef]

- Lee, H.; Kim, D. Quantum Mechanical Analysis Based on Perturbation Theory of CdSe/ZnS Quantum-Dot Light-Emission Properties. Nanomaterials 2022, 12, 3590. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Lee, H. Characteristics of Quantum-Dot Light-Emitting Diodes Fabricated Using a Sputtered Zinc Tin Oxide Electron-Transporting Layer. Jpn. J. Appl. Phys. 2018, 57, 03DC01. [Google Scholar] [CrossRef]

- Kim, D.; Kwon, O.; Kim, M.; Lee, H. Charge Carrier Analysis via Impedance Spectroscopy and the Achievement of High Performance in CdSe/ZnS:Di-[4-(N,N-Di-p-Tolyl-Amino)-Phenyl]Cyclohexane Hybrid Quantum Dot Light-Emitting Diodes. Org. Electron. 2022, 108, 106593. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, L.; Zhang, Q.; Zhang, Y.; Li, F.; Chang, C.; Sun, H.; Yang, M.; Yanto, S.; Zhang, Z. CdSe/ZnS Quantum-Dot Light-Emitting Diodes with Spiro-OMeTAD as Buffer Layer. IEEE Trans. Electron Devices 2019, 66, 4901–4906. [Google Scholar] [CrossRef]

- Kwon, O.; Kim, D.; Kim, M.; Lee, H. High-Performance Tandem CdSe/ZnS Quantum-Dot Light-Emitting Diodes with a Double-Layer Interconnecting Layer Composed of Thermally Evaporated and Sputtered Metal Oxides. J. Inf. Disp. 2022, 23, 213–219. [Google Scholar] [CrossRef]

- Kim, D.-J.; Lee, H.-N. The Dependence of QD-LED Properties on the RF-Sputtering and Plasma Treatment Conditions of the Electron-Transporting Layer. Mol. Crys. Liq. Crys. 2017, 651, 155–162. [Google Scholar] [CrossRef]

- Kim, M.; Kim, D.; Kwon, O.; Lee, H. Flexible CdSe/ZnS Quantum-Dot Light-Emitting Diodes with Higher Efficiency than Rigid Devices. Micromachines 2022, 13, 269. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, T.; Duan, L. Emerging Self-Emissive Technologies for Flexible Displays. Adv. Mater. 2020, 32, 1902391. [Google Scholar] [CrossRef] [PubMed]

- Su, Q.; Zhang, H.; Chen, S. Flexible and Tandem Quantum-Dot Light-Emitting Diodes with Individually Addressable Red/Green/Blue Emission. NPJ Flex. Electron. 2021, 5, 8. [Google Scholar] [CrossRef]

- Choi, M.K.; Yang, J.; Hyeon, T.; Kim, D.-H. Flexible Quantum Dot Light-Emitting Diodes for next-Generation Displays. NPJ Flex. Electron. 2018, 2, 10. [Google Scholar] [CrossRef]

- Tsukagoshi, K.; Tanabe, J.; Yagi, I.; Shigeto, K.; Yanagisawa, K.; Aoyagi, Y. Organic Light-Emitting Diode Driven by Organic Thin Film Transistor on Plastic Substrates. J. Appl. Phys. 2006, 99, 064506. [Google Scholar] [CrossRef]

- Sugimoto, A.; Ochi, H.; Fujimura, S.; Yoshida, A.; Miyadera, T.; Tsuchida, M. Flexible OLED Displays Using Plastic Substrates. IEEE J. Sel. Top. Quantum Electron. 2004, 10, 107–114. [Google Scholar] [CrossRef]

- Chuang, T.K.; Troccoli, M.; Kuo, P.C.; Jamshidi-Roudbari, A.; Hatalis, M.; Voutsas, A.T.; Afentakis, T. Process Technology for High-Resolution AM-PLED Displays on Flexible Metal-Foil Substrates. Electrochem. Solid-State Lett. 2007, 10, J92. [Google Scholar] [CrossRef]

- Yoo, J.S.; Jung, S.H.; Kim, Y.C.; Byun, S.C.; Kim, J.M.; Choi, N.B.; Yoon, S.Y.; Kim, C.D.; Hwang, Y.K.; Chung, I.J. Highly Flexible AM-OLED Display with Integrated Gate Driver Using Amorphous Silicon TFT on Ultrathin Metal Foil. IEEE/OSA J. Disp. Technol. 2010, 6, 565–570. [Google Scholar] [CrossRef]

- Kim, S.; Lee, J.-L. Design of Dielectric/Metal/Dielectric Transparent Electrodes for Flexible Electronics. J. Photonics Energy 2012, 2, 021215. [Google Scholar] [CrossRef]

- Cattin, L.; Jouad, E.; Stephant, N.; Louarn, G.; Morsli, M.; Hssein, M.; Mouchaal, Y.; Thouiri, S.; Addou, M.; Khelil, A.; et al. Dielectric/Metal/Dielectric Alternative Transparent Electrode: Observations on Stability/Degradation. J. Phys. D Appl. Phys. 2017, 50, 375502. [Google Scholar] [CrossRef]

- Kinner, L.; Bauch, M.; Wibowo, R.A.; Ligorio, G.; List-Kratochvil, E.J.W.; Dimopoulos, T. Polymer Interlayers on Flexible PET Substrates Enabling Ultra-High Performance, ITO-Free Dielectric/Metal/Dielectric Transparent Electrode. Mater. Des. 2019, 168, 107663. [Google Scholar] [CrossRef]

- Kim, D.; Lee, S.; Kim, J.; Lee, H. Understanding the Electroluminescence Mechanism of CdSe/ZnS Quantum-Dot Light-Emitting Diodes with a Focus on Charge Carrier Behavior in Quantum-Dot Emissive Layers. IEEE Electron. Device Lett. 2023, 44, 959–962. [Google Scholar] [CrossRef]

- Liu, R.; Gan, Z.; Shinar, R.; Shinar, J. Transient Electroluminescence Spikes in Small Molecular Organic Light-Emitting Diodes. Phys. Rev. B Condens Matter Mater. Phys. 2011, 83, 245302. [Google Scholar] [CrossRef]

- Kim, J.; Hahm, D.; Bae, W.K.; Lee, H.; Kwak, J. Transient Dynamics of Charges and Excitons in Quantum Dot Light-Emitting Diodes. Small 2022, 18, 2202290. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Greco, T.; Ippen, C.; Wedel, A.; Kim, J. Indium Phosphide (InP) Colloidal Quantum Dot Based Light-Emitting Diodes Designed on Flexible PEN Substrate. In Proceedings of the 2013 IEEE 5th International Nanoelectronics Conference (INEC), Singapore, 2–4 January 2013; pp. 425–427. [Google Scholar] [CrossRef]

- Forsythe, E.W.; Shi, J.; Liu, S.; Morton, D.C.; Loy, D.; Lee, Y.K.; Bell, C.; Richards, M.; Bawolek, E.; Ageno, S.; et al. Future Flexible OLED Displays for Army Applications. In Proceedings of the 2009 Conference on Lasers and Electro-Optics and 2009 Conference on Quantum Electronics and Laser Science Conference, Baltimore, MD, USA, 2–4 June 2009; pp. 8–9. [Google Scholar] [CrossRef]

- Fonrodona, M.; Escarré, J.; Villar, F.; Soler, D.; Asensi, J.M.; Bertomeu, J.; Andreu, J. PEN as Substrate for New Solar Cell Technologies. Sol. Energy Mater. Sol. Cells 2005, 89, 37–47. [Google Scholar] [CrossRef]

- Dunbar, E.; Leone, M.; Lukes, S.; Dickensheets, D.L. Polymer Deformable Membrane Mirrors for Focus Control Using SU-8 2002. In Proceedings of the 2008 IEEE/LEOS International Conference on Optical MEMs and Nanophotonics, Freiburg, Germany, 11–14 August 2008; pp. 138–139. [Google Scholar]

- Hasnidawani, J.N.; Azlina, H.N.; Norita, H.; Bonnia, N.N.; Ratim, S.; Ali, E.S. Synthesis of ZnO Nanostructures Using Sol-Gel Method. Procedia Chem. 2016, 19, 211–216. [Google Scholar] [CrossRef]

- Kim, D.-J.; Lee, H.-N. Improving the Charge Balance and Performance of CdSe/ZnS Quantum-Dot Light-Emitting Diodes with a Sputtered Zinc-Tin-Oxide Electron-Transport Layer and a Thermally Evaporated Tungsten-Oxide Charge-Restricting Layer. Jpn. J. Appl. Phys. 2019, 58, 106502. [Google Scholar] [CrossRef]

- Kim, J.C.; Cakmak, M.; Zhou, X. Effect of Composition on Orientation, Optical and Mechanical Properties of Bi-Axially Drawn PEN and PEN/PEI Blend Films. Polymer 1998, 39, 4225–4234. [Google Scholar] [CrossRef]

- Girtan, M.; Negulescu, B. A Review on Oxide/Metal/Oxide Thin Films on Flexible Substrates as Electrodes for Organic and Perovskite Solar Cells. Opt. Mater. X 2022, 13, 100122. [Google Scholar] [CrossRef]

- Xue, Z.; Liu, X.; Zhang, N.; Chen, H.; Zheng, X.; Wang, H.; Guo, X. High-Performance NiO/Ag/NiO Transparent Electrodes for Flexible Organic Photovoltaic Cells. ACS Appl. Mater. Interfaces 2014, 6, 16403–16408. [Google Scholar] [CrossRef]

- Wenda, E. High Temperature Reactions in The MoO3-Ag2O System. J. Them. Anal. 1998, 53, 861–870. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Kim, J.; Lee, H. Substrate Dependence of CdSe/ZnS Quantum-Dot Light-Emitting Diodes: A Comparative Study between Rigid Glass and Flexible Plastic Substrates. Nanomaterials 2023, 13, 1780. https://doi.org/10.3390/nano13111780

Lee S, Kim J, Lee H. Substrate Dependence of CdSe/ZnS Quantum-Dot Light-Emitting Diodes: A Comparative Study between Rigid Glass and Flexible Plastic Substrates. Nanomaterials. 2023; 13(11):1780. https://doi.org/10.3390/nano13111780

Chicago/Turabian StyleLee, Seyoung, Jimyoung Kim, and Honyeon Lee. 2023. "Substrate Dependence of CdSe/ZnS Quantum-Dot Light-Emitting Diodes: A Comparative Study between Rigid Glass and Flexible Plastic Substrates" Nanomaterials 13, no. 11: 1780. https://doi.org/10.3390/nano13111780

APA StyleLee, S., Kim, J., & Lee, H. (2023). Substrate Dependence of CdSe/ZnS Quantum-Dot Light-Emitting Diodes: A Comparative Study between Rigid Glass and Flexible Plastic Substrates. Nanomaterials, 13(11), 1780. https://doi.org/10.3390/nano13111780