Systematically Study the Tensile and Compressive Behaviors of Diamond-like Carbon

Abstract

1. Introduction

2. Computational Details

3. Results and Discussion

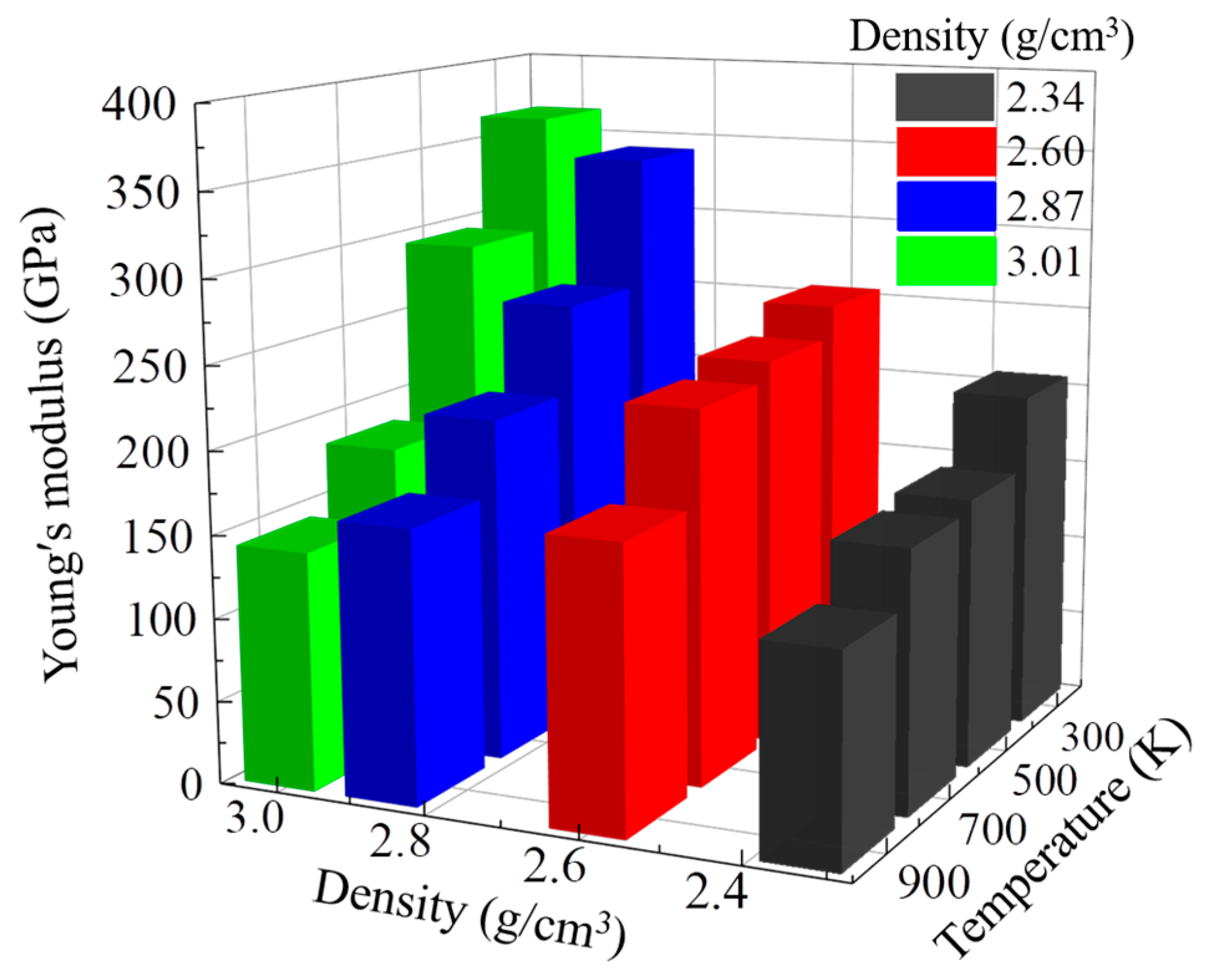

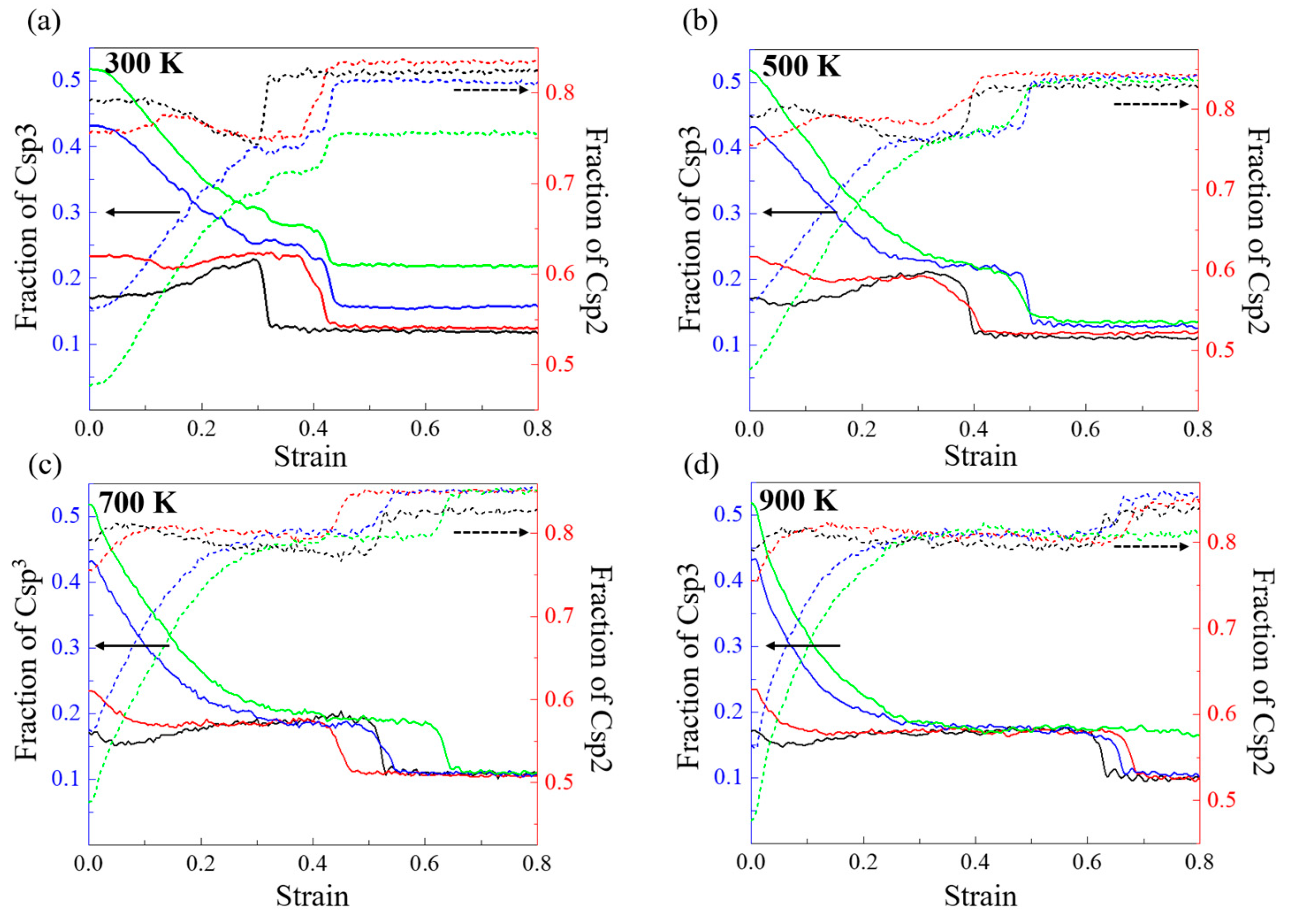

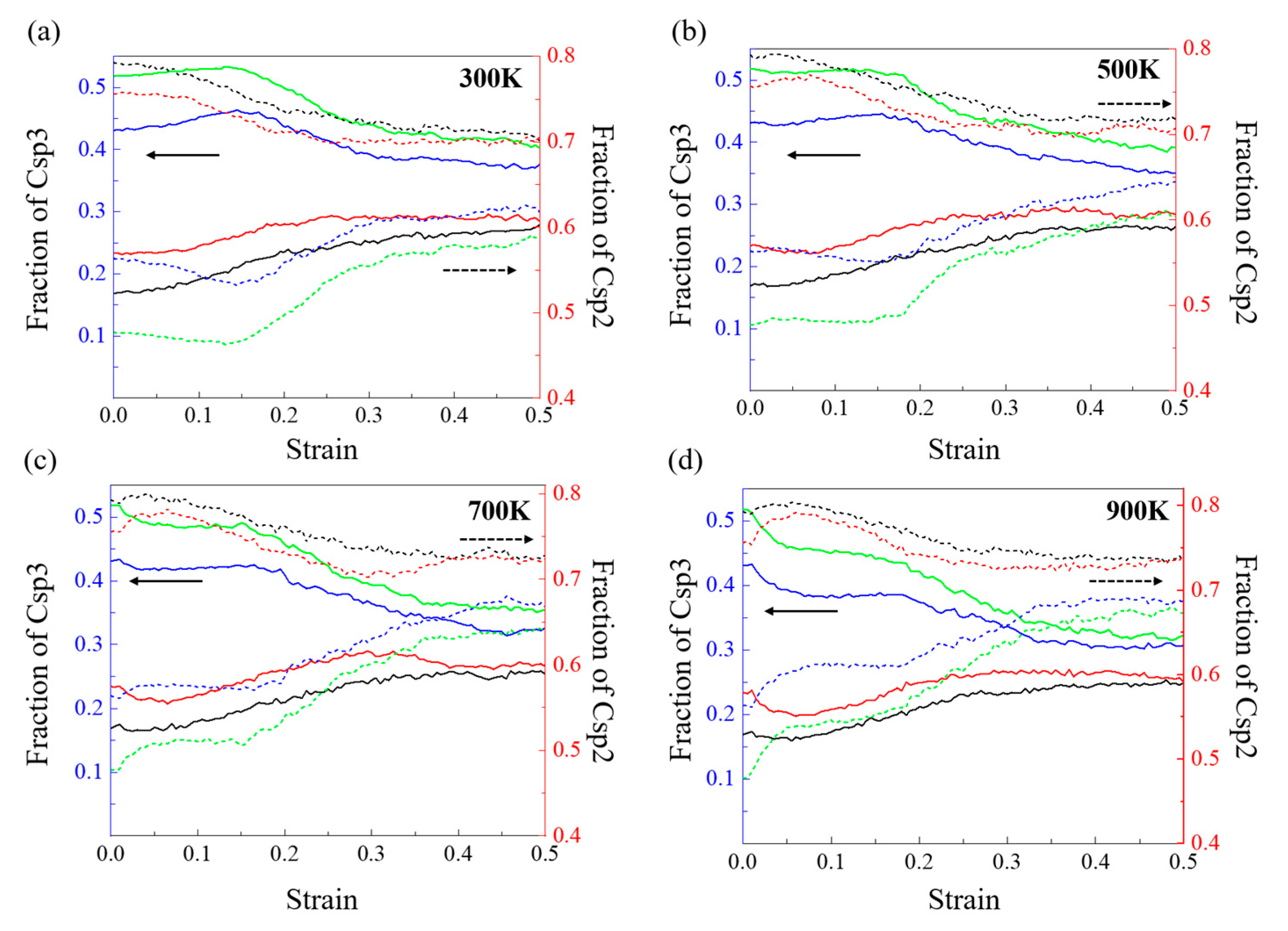

3.1. Tensile Properties of DLC

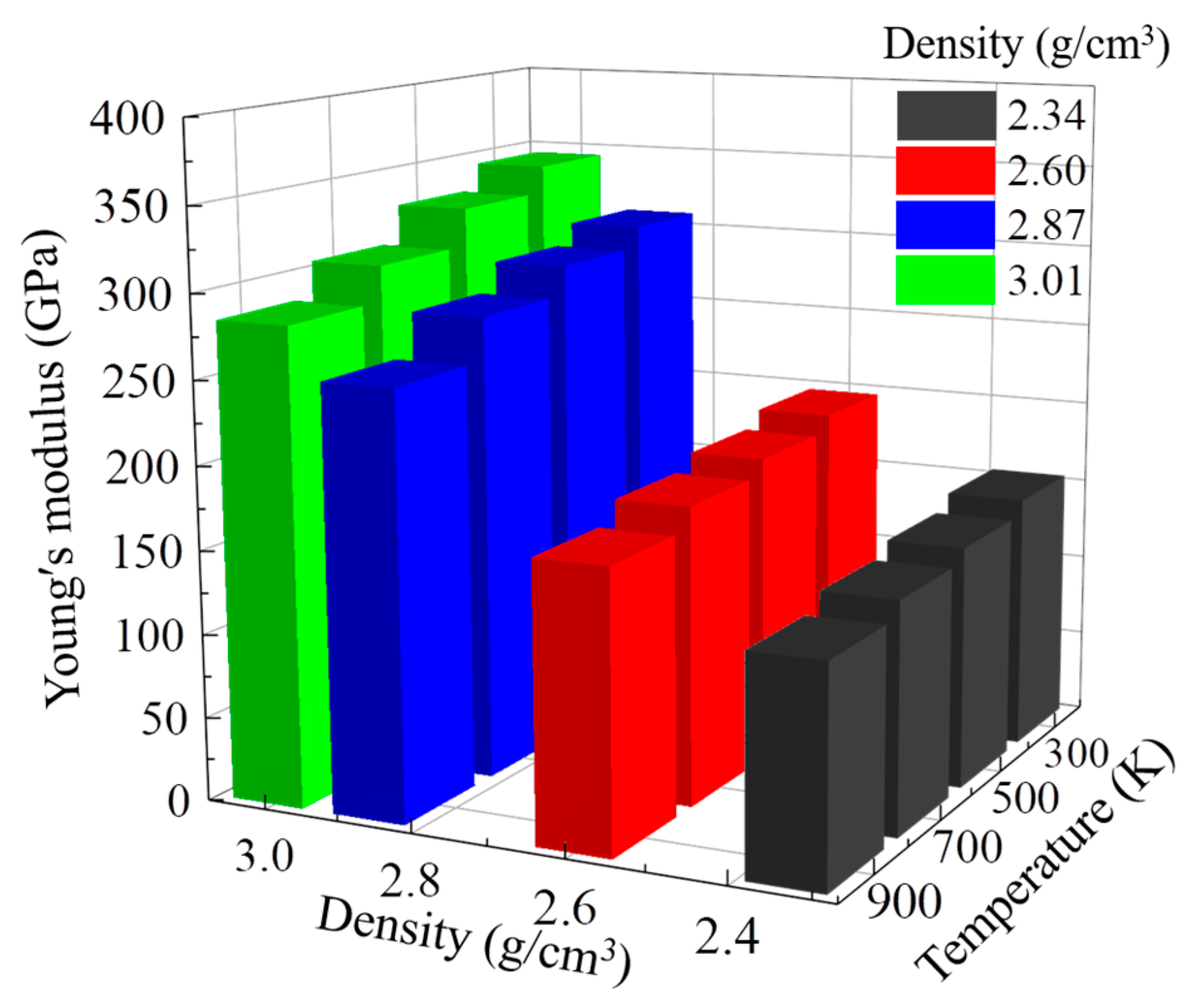

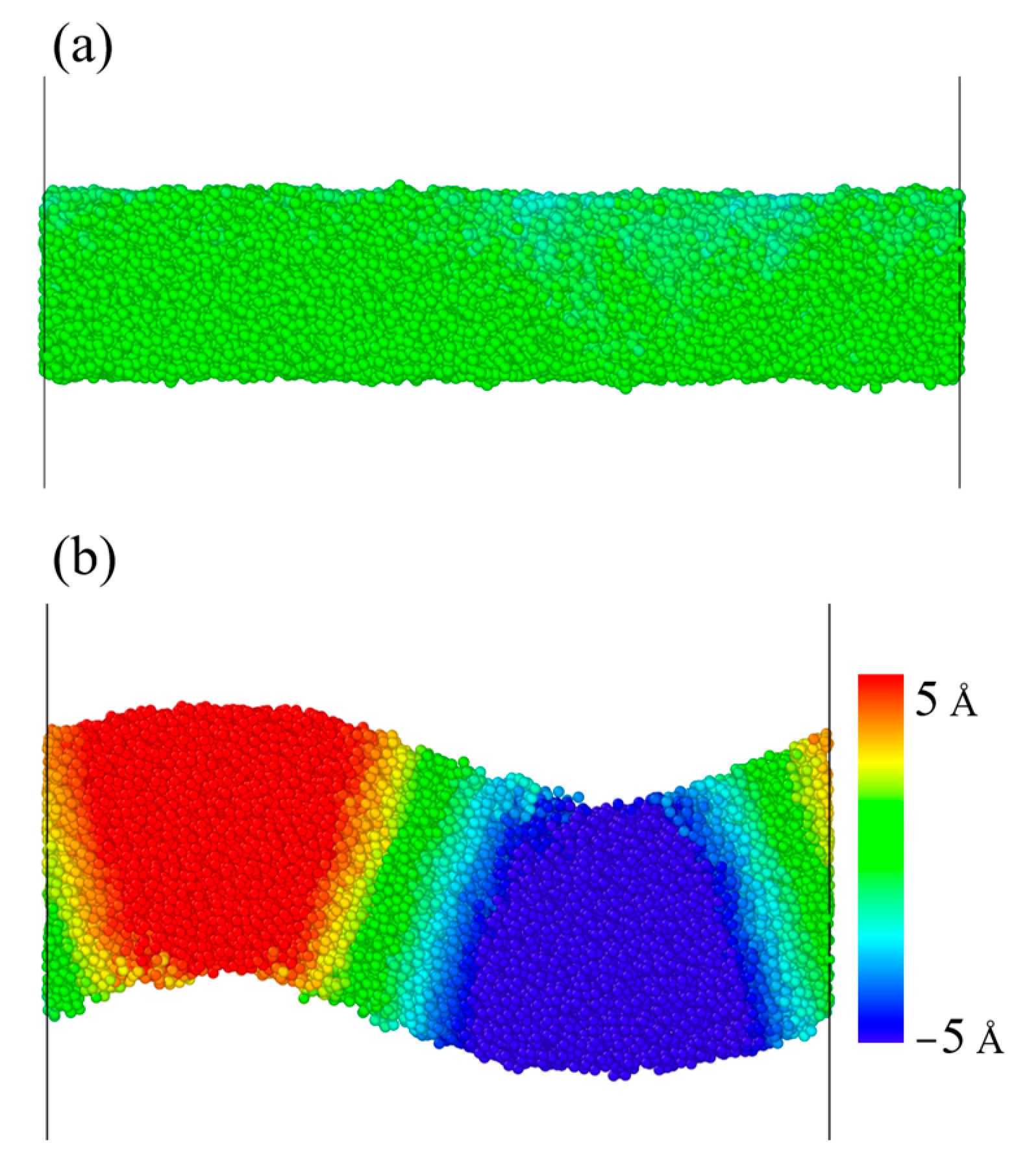

3.2. Compressive Properties of DLC and Schemes

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Robertson, J. Diamond-like Amorphous Carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Grill, A. Diamond-like Carbon: State of the Art. Diam. Relat. Mater. 1999, 8, 428–434. [Google Scholar] [CrossRef]

- Matthews, A.; Eskildsen, S.S. Engineering Applications for Diamond-like Carbon. Diam. Relat. Mater. 1994, 3, 902–911. [Google Scholar] [CrossRef]

- Zhang, L.; Wei, X.; Lin, Y.; Wang, F. A Ternary Phase Diagram for Amorphous Carbon. Carbon N. Y. 2015, 94, 202–213. [Google Scholar] [CrossRef]

- Ferrari, A.C. Diamond-like Carbon for Magnetic Storage Disks. Surf. Coat. Technol. 2004, 180–181, 190–206. [Google Scholar] [CrossRef]

- Tung, S.C.; McMillan, M.L. Automotive Tribology Overview of Current Advances and Challenges for the Future. Tribol. Int. 2004, 37, 517–536. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global Energy Consumption Due to Friction in Passenger Cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Fontaine, J. Towards the Use of Diamond-like Carbon Solid Lubricant Coatings in Vacuum and Space Environments. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2008, 222, 1015–1029. [Google Scholar] [CrossRef]

- Yu, L.; Ma, Y.; Zhou, C.; Xu, H. Damping Efficiency of the Coating Structure. Int. J. Solids Struct. 2005, 42, 3045–3058. [Google Scholar] [CrossRef]

- Rongong, J.A.; Goruppa, A.A.; Buravalla, V.R.; Tomlinson, G.R.; Jones, F.R. Plasma Deposition of Constrained Layer Damping Coatings. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2004, 218, 669–680. [Google Scholar] [CrossRef]

- Catania, G.; Strozzi, M. Damping Oriented Design of Thin-Walled Mechanical Components by Means of Multi-Layer Coating Technology. Coatings 2018, 8, 73. [Google Scholar] [CrossRef]

- Hauert, R.; Patscheider, J. From Alloying to Nanocomposites—Improved Performance of Hard Coatings. Adv. Eng. Mater. 2000, 2, 247–259. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Lin, H.-D.; Liu, C.-K.; Huang, M.-W.; Chen, Y.-C.; Chen, J.-R.; Shih, H.C. Annealing Effect on the Structural, Mechanical and Electrical Properties of Titanium-Doped Diamond-like Carbon Films. Thin. Solid Film. 2009, 518, 1503–1507. [Google Scholar] [CrossRef]

- Xu, Z.; Zheng, Y.J.; Jiang, F.; Leng, Y.X.; Sun, H.; Huang, N. The Microstructure and Mechanical Properties of Multilayer Diamond-like Carbon Films with Different Modulation Ratios. Appl. Surf. Sci. 2013, 264, 207–212. [Google Scholar] [CrossRef]

- Peter, S.; Günther, M.; Gordan, O.; Berg, S.; Zahn, D.R.T.; Seyller, T. Experimental Analysis of the Thermal Annealing of Hard A-C:H Films. Diam. Relat. Mater. 2014, 45, 43–57. [Google Scholar] [CrossRef]

- Wang, L.; Nie, X.; Hu, X. Effect of Thermal Annealing on Tribological and Corrosion Properties of DLC Coatings. J. Mater. Eng. Perform. 2013, 22, 3093–3100. [Google Scholar] [CrossRef]

- Baimova, J.A.; Rysaeva, L.K.; Rudskoy, A.I. Deformation Behavior of Diamond-like Phases: Molecular Dynamics Simulation. Diam. Relat. Mater. 2018, 81, 154–160. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, X.; Yin, S.; Bai, L.; Liu, Z. The Sp2-Sp3 Transition and Shear Slipping Dominating the Compressive Deformation of Diamond-like Carbon. J. Non Cryst. Solids 2022, 577, 121318. [Google Scholar] [CrossRef]

- Bai, L.; Srikanth, N.; Wu, H.; Liu, Y.; Liu, B.; Zhou, K. Investigation on Tensile Behaviors of Diamond-like Carbon Films. J. Non Cryst. Solids 2016, 443, 8–16. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Y.; Cen, Y.; Xing, B.; Zheng, X.; Ootani, Y.; Kubo, M. Prediction of Macroscopic Properties of Diamond-like Carbon from Atomic-Scale Structure. J. Phys. Chem. C 2019, 123, 24609–24614. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, S.F.; Zhang, Y.; Gao, Y.N. Simulation and Application of Molecular Dynamics in Materials Science. Adv. Mat. Res. 2012, 572, 232–236. [Google Scholar] [CrossRef]

- Hollingsworth, S.A.; Dror, R.O. Molecular Dynamics Simulation for All. Neuron 2018, 99, 1129–1143. [Google Scholar] [CrossRef] [PubMed]

- Rapaport, D.C. The Art of Molecular Dynamics Simulation; Cambridge University Press: Cambridge, UK, 2004; ISBN 9780521825689. [Google Scholar]

- Chen, L.; Luo, H.; Li, Z.; Sha, A. Effect of Al Doping on the Early-Stage Oxidation of Ni-Al Alloys: A ReaxFF Molecular Dynamics Study. Appl. Surf. Sci. 2021, 563, 150097. [Google Scholar] [CrossRef]

- Mortazavi, B.; Ostadhossein, A.; Rabczuk, T.; van Duin, A.C.T. Mechanical Response of All-MoS2 Single-Layer Heterostructures: A ReaxFF Investigation. Phys. Chem. Chem. Phys. 2016, 18, 23695–23701. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.M.; Strachan, A. Role of Dynamical Compressive and Shear Loading on Hotspot Criticality in RDX via Reactive Molecular Dynamics. J. Appl. Phys. 2020, 128, 065101. [Google Scholar] [CrossRef]

- Senftle, T.P.; Hong, S.; Islam, M.M.; Kylasa, S.B.; Zheng, Y.; Shin, Y.K.; Junkermeier, C.; Engel-Herbert, R.; Janik, M.J.; Aktulga, H.M.; et al. The ReaxFF Reactive Force-Field: Development, Applications and Future Directions. NPJ Comput. Mater. 2016, 2, 15011. [Google Scholar] [CrossRef]

- van Duin, A.C.T.; Dasgupta, S.; Lorant, F.; Goddard, W.A. ReaxFF: A Reactive Force Field for Hydrocarbons. J. Phys. Chem. A 2001, 105, 9396–9409. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, Y.; Sun, Q.; Lu, K.; Kubo, M.; Xu, J. Development of a Transferable ReaxFF Parameter Set for Carbon- and Silicon-Based Solid Systems. J. Phys. Chem. C 2020, 124, 10007–10015. [Google Scholar] [CrossRef]

- Xu, J.; Higuchi, Y.; Ozawa, N.; Sato, K.; Hashida, T.; Kubo, M. Parallel Large-Scale Molecular Dynamics Simulation Opens New Perspective to Clarify the Effect of a Porous Structure on the Sintering Process of Ni/YSZ Multiparticles. ACS Appl. Mater. Interfaces 2017, 9, 31816–31824. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, J.; Ootani, Y.; Bai, S.; Higuchi, Y.; Ozawa, N.; Adachi, K.; Martin, J.M.; Kubo, M. Tight-Binding Quantum Chemical Molecular Dynamics Study on the Friction and Wear Processes of Diamond-Like Carbon Coatings: Effect of Tensile Stress. ACS Appl. Mater. Interfaces 2017, 9, 34396–34404. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, J.; Zhang, J.; Chen, Q.; Ootani, Y.; Higuchi, Y.; Ozawa, N.; Martin, J.M.; Adachi, K.; Kubo, M. Tribochemical Reactions and Graphitization of Diamond-like Carbon against Alumina Give Volcano-Type Temperature Dependence of Friction Coefficients: A Tight-Binding Quantum Chemical Molecular Dynamics Simulation. Carbon N. Y. 2018, 133, 350–357. [Google Scholar] [CrossRef]

- Safina, L.R.; Krylova, K.A.; Baimova, J.A. Molecular Dynamics Study of the Mechanical Properties and Deformation Behavior of Graphene/Metal Composites. Mater. Today Phys. 2022, 28, 100851. [Google Scholar] [CrossRef]

- Aral, G.; Wang, Y.-J.; Ogata, S.; van Duin, A.C.T. Effects of Oxidation on Tensile Deformation of Iron Nanowires: Insights from Reactive Molecular Dynamics Simulations. J. Appl. Phys. 2016, 120, 135104. [Google Scholar] [CrossRef]

- Schultrich, B.; Scheibe, H.-J.; Grandremy, G.; Drescher, D.; Schneider, D. Elastic Modulus as a Measure of Diamond Likeness and Hardness of Amorphous Carbon Films. Diam. Relat. Mater. 1996, 5, 914–918. [Google Scholar] [CrossRef]

- Bai, L.; Zhang, G.; Wu, Z.; Wang, J.; Yan, P. Effect of Different Ion Beam Energy on Properties of Amorphous Carbon Film Fabricated by Ion Beam Sputtering Deposition (IBSD). Nucl. Instrum. Methods Phys. Res. B 2011, 269, 1871–1877. [Google Scholar] [CrossRef]

- Chung, J.-W.; Ko, D.-H.; Eun, K.Y.; Lee, K.-R. Elastic Modulus and Structural Evolution of Diamond-like Carbon Films Deposited by RF-PACVD. Diam. Relat. Mater. 2002, 11, 1441–1446. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Geng, Y.; Chu, Z.; Hu, Q.; Lei, Y.; Wang, Y. Systematically Study the Tensile and Compressive Behaviors of Diamond-like Carbon. Nanomaterials 2023, 13, 1772. https://doi.org/10.3390/nano13111772

Xu J, Geng Y, Chu Z, Hu Q, Lei Y, Wang Y. Systematically Study the Tensile and Compressive Behaviors of Diamond-like Carbon. Nanomaterials. 2023; 13(11):1772. https://doi.org/10.3390/nano13111772

Chicago/Turabian StyleXu, Jingxiang, Yina Geng, Zhenhua Chu, Qingsong Hu, Yanhua Lei, and Yang Wang. 2023. "Systematically Study the Tensile and Compressive Behaviors of Diamond-like Carbon" Nanomaterials 13, no. 11: 1772. https://doi.org/10.3390/nano13111772

APA StyleXu, J., Geng, Y., Chu, Z., Hu, Q., Lei, Y., & Wang, Y. (2023). Systematically Study the Tensile and Compressive Behaviors of Diamond-like Carbon. Nanomaterials, 13(11), 1772. https://doi.org/10.3390/nano13111772