Effect of Thermal Radiation on Three-Dimensional Magnetized Rotating Flow of a Hybrid Nanofluid

Abstract

:1. Introduction

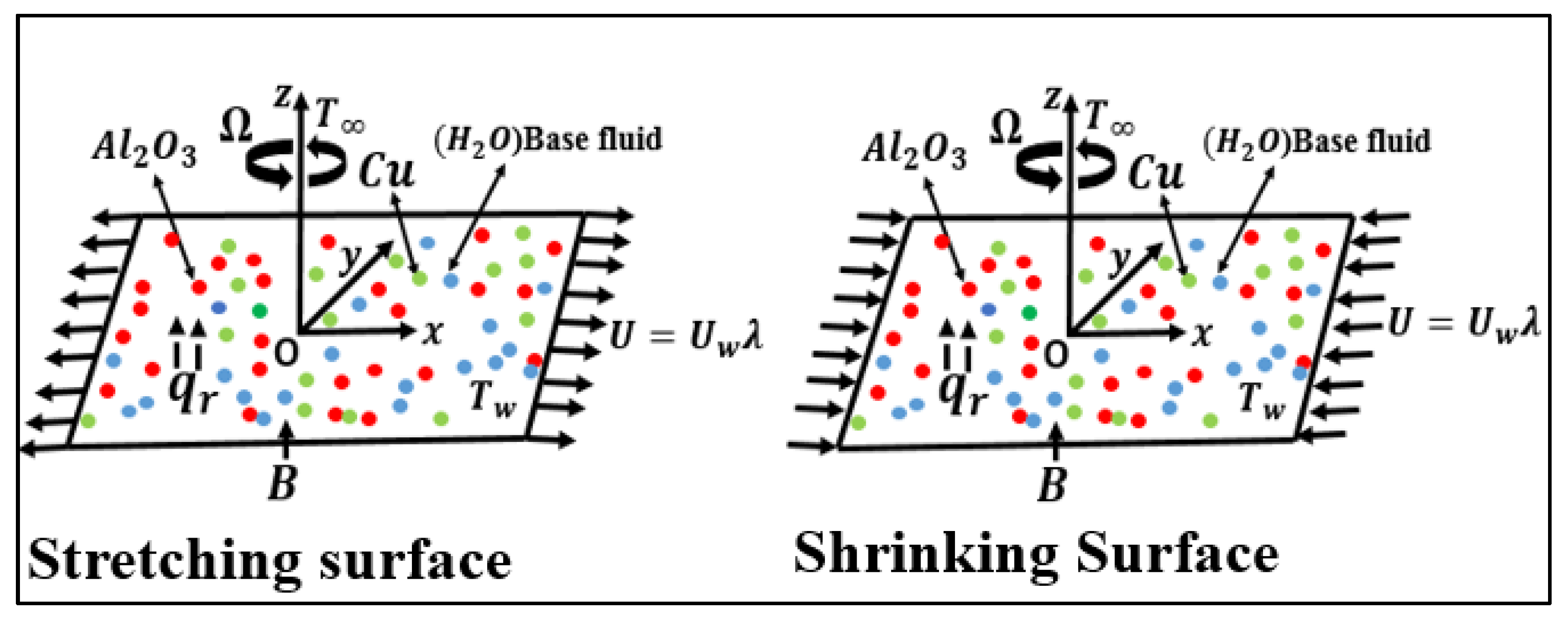

2. Materials and Methods

2.1. Mathematical Formulation

2.2. Stability Analysis

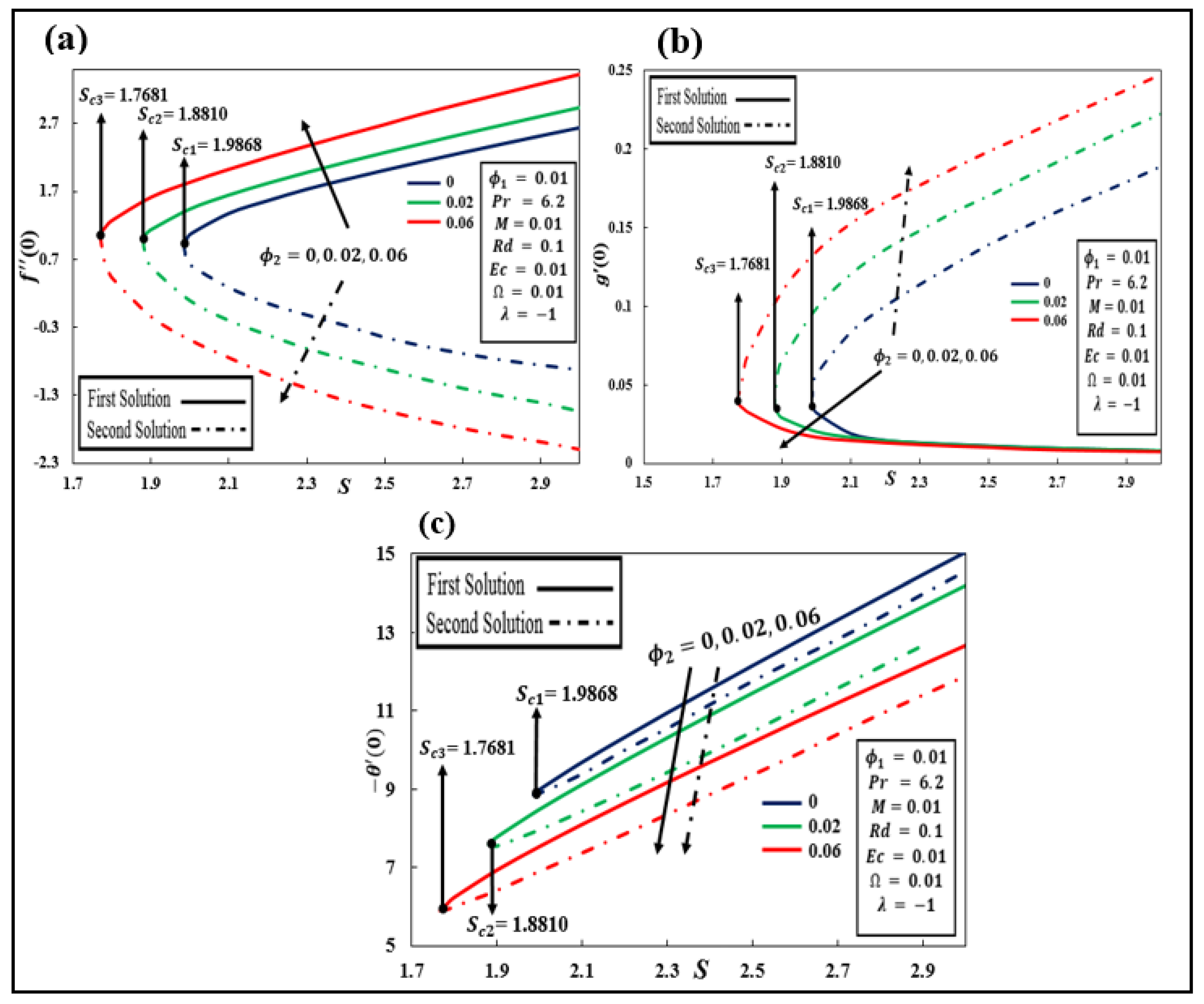

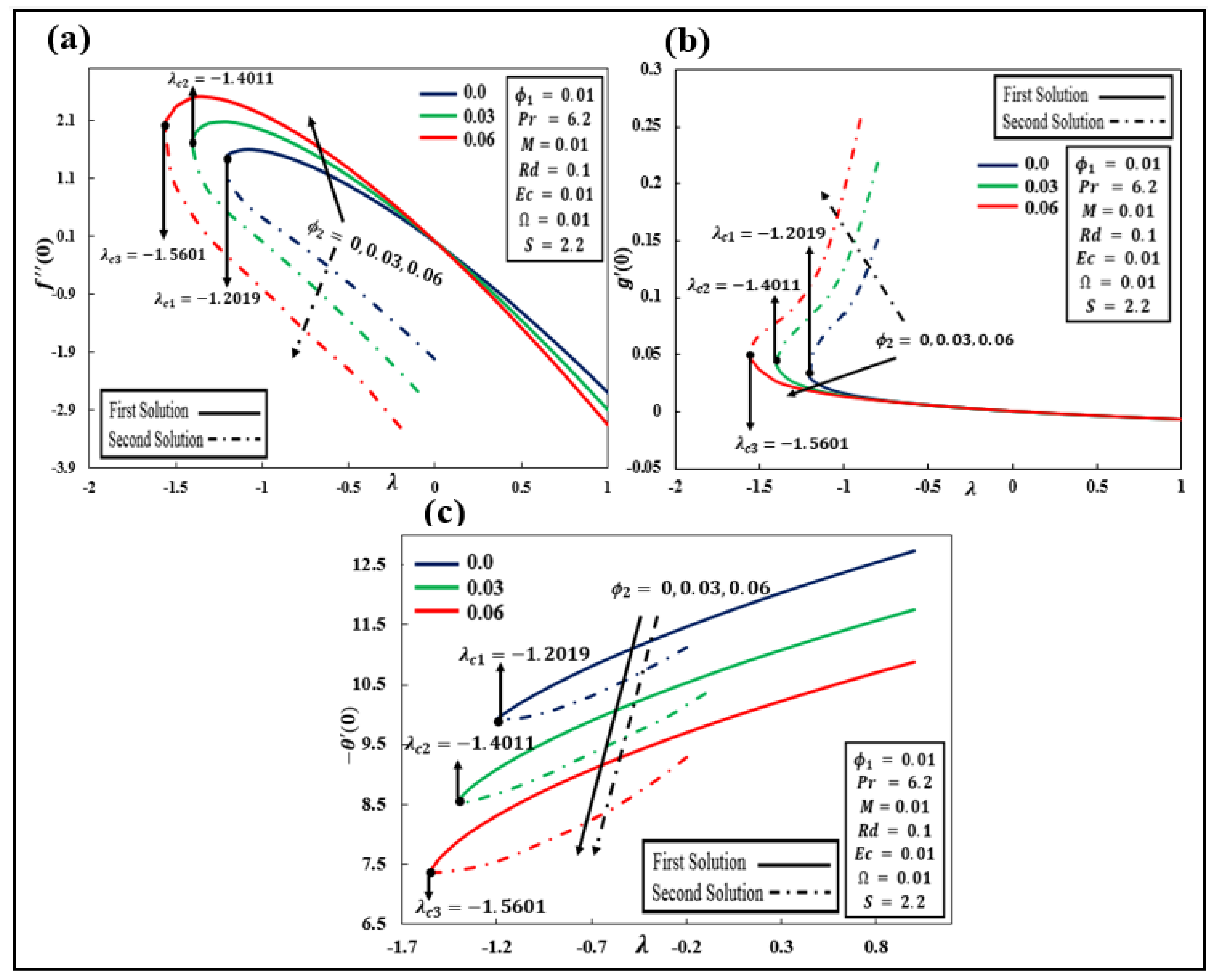

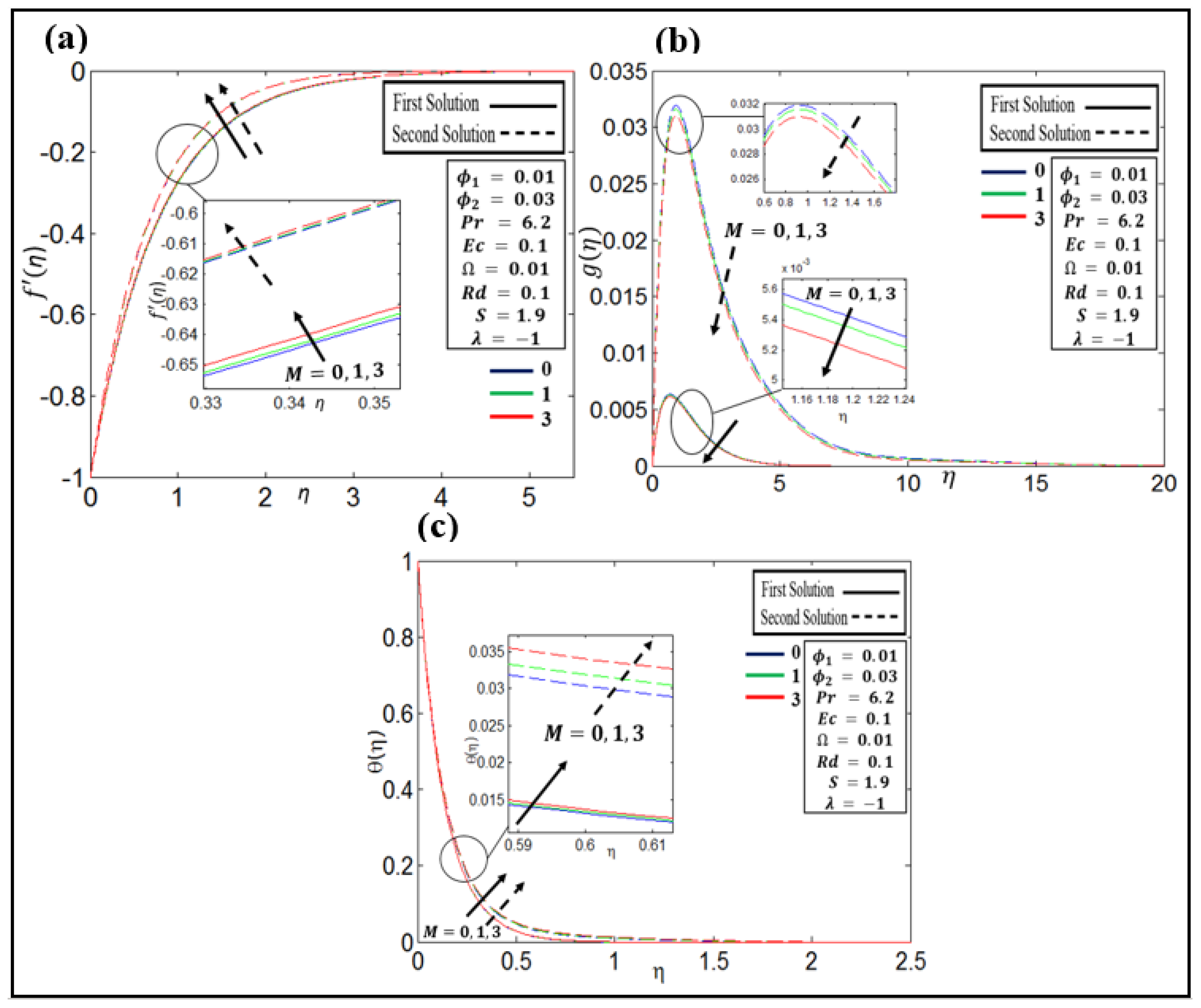

3. Results and Discussion

4. Conclusions

- The outcomes of Equations (2)–(5) are non-unique when and unique when . No solution exists when is noticed for a shrinking sheet.

- The presence of solutions is based on the values of the suction parameter for assumed parameter values.

- The intended model displays good heat transfer performance when nanoparticle sizes are less than 10%.

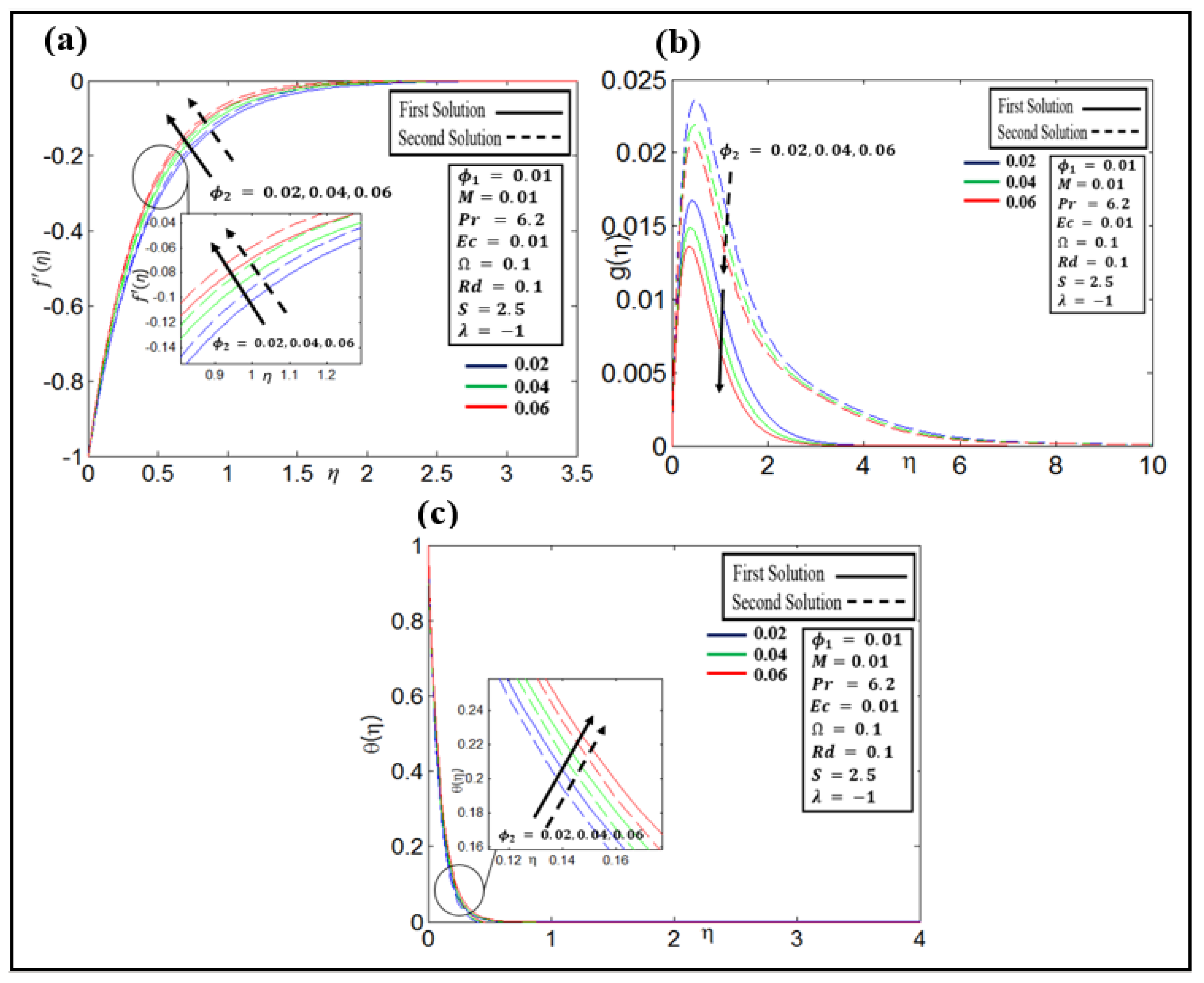

- The temperature and velocity profiles of the boundary layer can be changed by applying nanoparticles in the hybrid nanofluid.

- The profile is reduced when the magnetic parameter is enhanced.

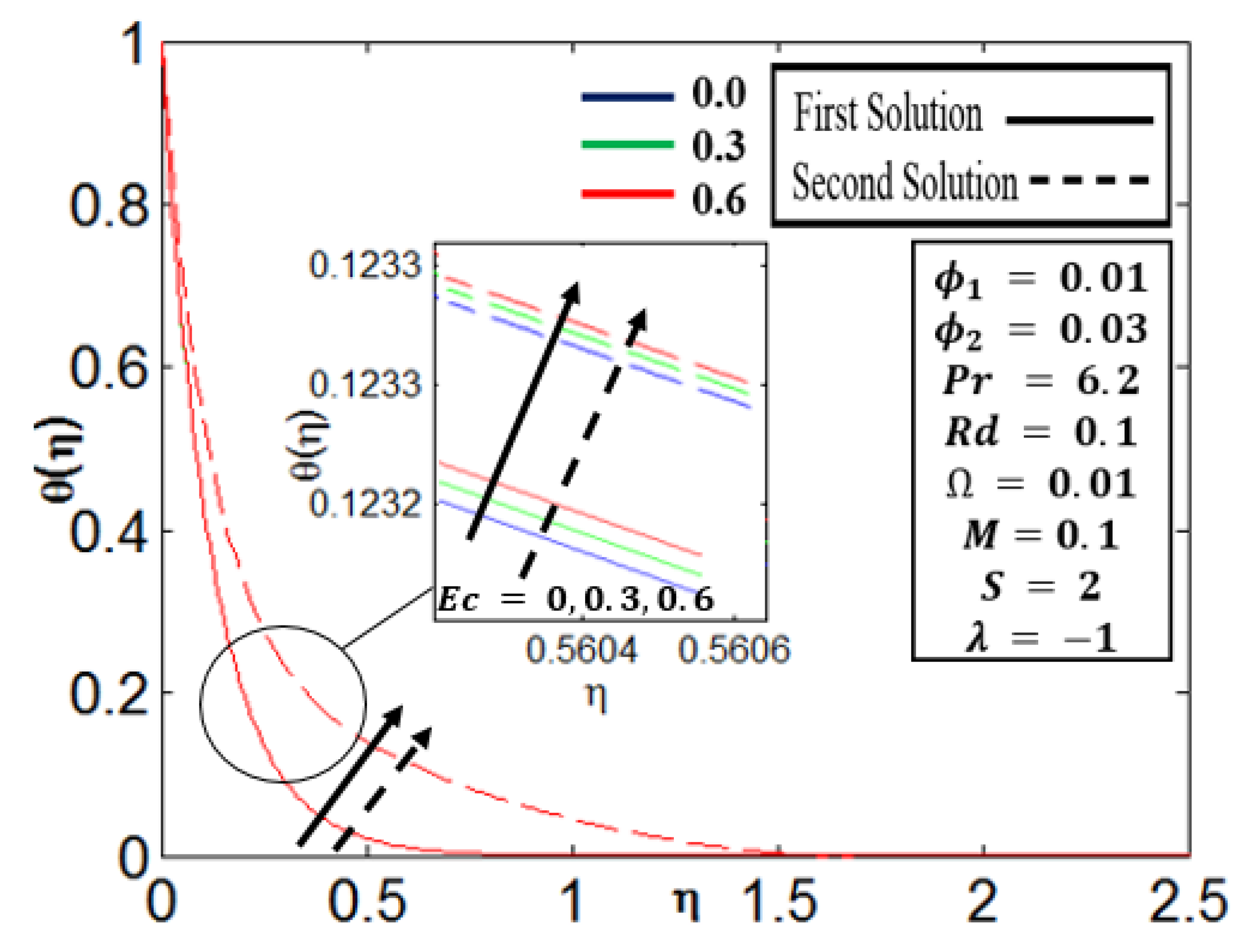

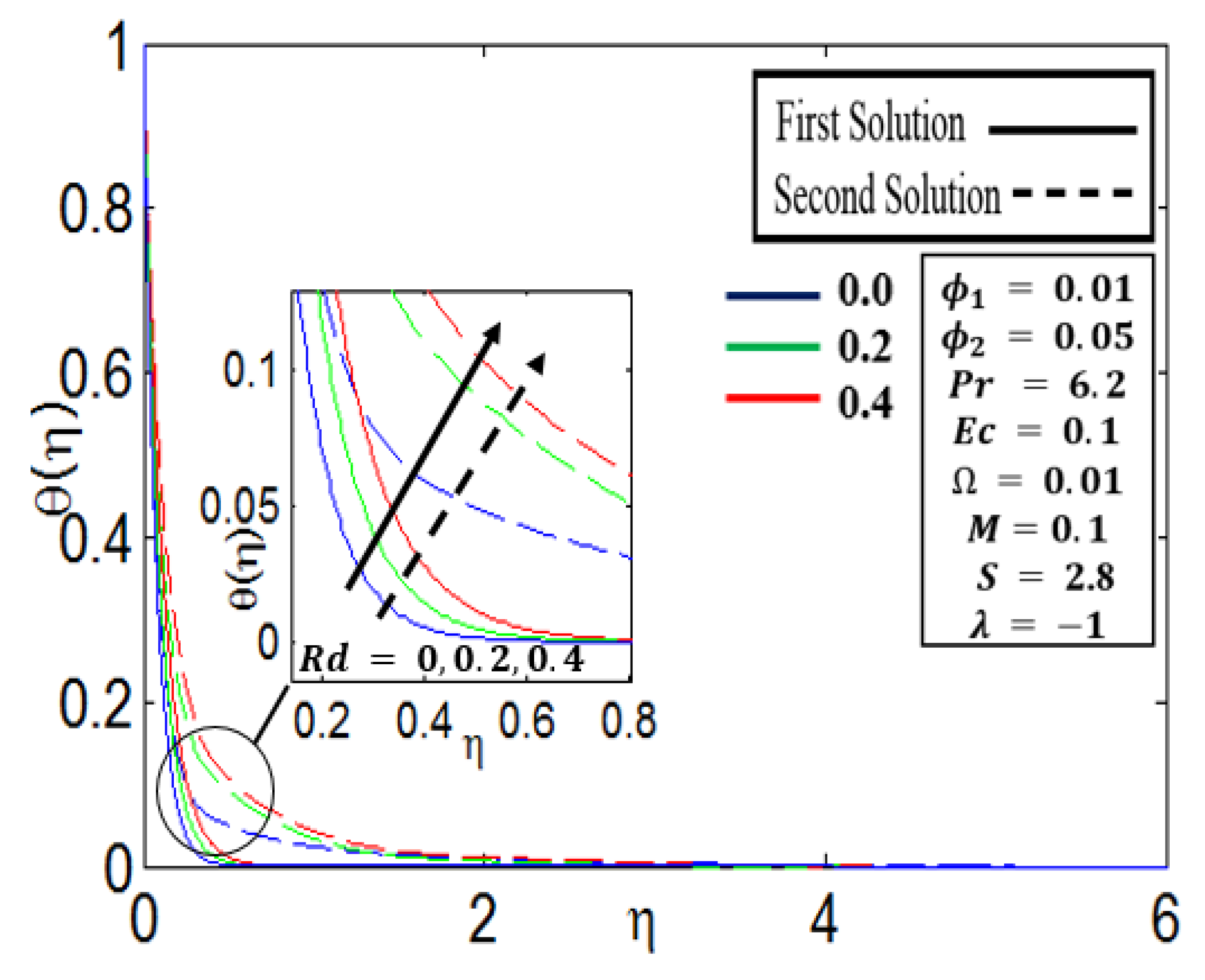

- and values are directly proportional to temperature profiles in both solutions.

- The first solution is a stable solution.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sakiadis, B.C. Boundary-layer behavior on continuous solid surfaces: I. Boundary-layer equations for two-dimensional and axisymmetric flow. AIChE J. 1961, 7, 26–28. [Google Scholar] [CrossRef]

- Crane, L.J. Flow past a stretching plate. Z. Angew. Math. Phys. 1970, 21, 645–647. [Google Scholar] [CrossRef]

- Reddy, M.G.; Prasannakumara, B.; Makinde, O.D. Cross Diffusion Impacts on Hydromagnetic Radiative Peristaltic Carreau-CassonNanofluids Flow in an Irregular Channel. Defect Diffus. Forum 2017, 377, 62–83. [Google Scholar] [CrossRef]

- Moghimi, S.M.; Hunter, A.; Murray, J.C. Nanomedicine: Current status and future prospects. FASEB J. 2005, 19, 311–330. [Google Scholar] [CrossRef] [Green Version]

- Godin, B.; Sakamoto, J.H.; Serda, R.E.; Grattoni, A.; Bouamrani, A.; Ferrari, M. Emerging applications of nanomedicine for the diagnosis and treatment of cardiovascular diseases. Trends Pharmacol. Sci. 2010, 31, 199–205. [Google Scholar] [CrossRef] [Green Version]

- Reddy, M.G.; Makinde, O.D. Magnetohydrodynamic peristaltic transport of Jeffrey nanofluid in an asymmetric channel. J. Mol. Liq. 2016, 223, 1242–1248. [Google Scholar] [CrossRef]

- Shahzadi, I.; Bilal, S. A significant role of permeability on blood flow for hybrid nanofluid through bifurcated stenosed artery: Drug delivery application. Comput. Methods Programs Biomed. 2020, 187, 105248. [Google Scholar] [CrossRef]

- Choi, S.U.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles. In Proceedings of the 1995 International Mechanical Engineering Congress and Exhibition, San Francisco, CA, USA, 12–17 November 1995. No. ANL/MSD/CP-84938; CONF-951135-29, 1 October 1995. [Google Scholar]

- Abu-Nada, E.; Oztop, H.F. Effects of inclination angle on natural convection in enclosures filled with Cu–water nanofluid. Int. J. Heat Fluid Flow 2009, 30, 669–678. [Google Scholar] [CrossRef]

- Wang, X.-Q.; Mujumdar, A.S. Heat transfer characteristics of nanofluids: A review. Int. J. Therm. Sci. 2007, 46, 1–19. [Google Scholar] [CrossRef]

- Lund, L.A.; Omar, Z.; Dero, S.; Baleanu, D.; Khan, I. Rotating 3D Flow of Hybrid Nanofluid on Exponentially Shrinking Sheet: Symmetrical Solution and Duality. Symmetry 2020, 12, 1637. [Google Scholar] [CrossRef]

- Khan, W.A.; Pop, I. Boundary-layer flow of a nanofluid past a stretching sheet. Int. J. Heat Mass Transfer. 2010, 53, 2477–2483. [Google Scholar] [CrossRef]

- Miklavčič, M.; Wang, C. Viscous flow due to a shrinking sheet. Q. Appl. Math. 2006, 64, 283–290. [Google Scholar] [CrossRef] [Green Version]

- Bachok, N.; Ishak, A.; Pop, I. Unsteady boundary-layer flow and heat transfer of a nanofluid over a permeable stretching/shrinking sheet. Int. J. Heat Mass Transf. 2012, 55, 2102–2109. [Google Scholar] [CrossRef]

- Dero, S.; Rohni, A.M.; Saaban, A. Stability analysis of Cu−C6H9NaO7 and Ag−C6H9NaO7 nanofluids with effect of viscous dissipation over stretching and shrinking surfaces using a single-phase model. Heliyon 2020, 6, e03510. [Google Scholar] [CrossRef]

- Devi, S.A.; Devi, S.S.U. Numerical investigation of hydromagnetic hybrid Cu–Al2O3/water nanofluid flow over a permeable stretching sheet with suction. Int. J. Nonlinear Sci. Numer. Simul. 2016, 17, 249–257. [Google Scholar] [CrossRef]

- Huminic, G.; Huminic, A. Hybrid nanofluids for heat transfer applications—A state-of-the-art review. Int. J. Heat Mass Transf. 2018, 125, 82–103. [Google Scholar] [CrossRef]

- Waini, I.; Ishak, A.; Pop, I. Hybrid nanofluid flow and heat transfer over a nonlinear permeable stretching/shrinking surface. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 3110–3127. [Google Scholar] [CrossRef]

- Waini, I.; Ishak, A.; Pop, I. Transpiration effects on hybrid nanofluid flow and heat transfer over a stretching/shrinking sheet with uniform shear flow. Alex. Eng. J. 2020, 59, 91–99. [Google Scholar] [CrossRef]

- Hayat, T.; Nadeem, S. Heat transfer enhancement with Ag–CuO/water hybrid nanofluid. Results Phys. 2017, 7, 2317–2324. [Google Scholar] [CrossRef]

- Hayat, T.; Nadeem, S.; Khan, A.U. Rotating flow of Ag-CuO/H2O hybrid nanofluid with radiation and partial slip boundary effects. Eur. Phys. J. E 2018, 41, 1–9. [Google Scholar] [CrossRef]

- Anuar, N.S.; Bachok, N.; Pop, I. Radiative hybrid nanofluid flow past a rotating permeable stretching/shrinking sheet. Int. J. Numer. Methods Heat Fluid Flow 2020, 31, 914–932. [Google Scholar] [CrossRef]

- Lund, L.A.; Omar, Z.; Khan, I. Darcy-Forchheimer porous medium effect on rotating hybrid nanofluid on a linear shrinking/stretching sheet. Int. J. Numer. Methods Heat Fluid Flow 2021, 21, 716. [Google Scholar] [CrossRef]

- Lund, L.A.; Omar, Z.; Khan, I.; Sherif, E.M. Dual Branches of MHD Three-Dimensional Rotating Flow of Hybrid Nanofluid on Nonlinear Shrinking Sheet. Comput. Mater. Contin. 2020, 66, 127–139. [Google Scholar] [CrossRef]

- Kolsi, L.; Dero, S.; Lund, L.A.; Alqsair, U.F.; Omri, M.; Khan, S.U. Thermal stability and performances of hybrid nanoparticles for convective heat transfer phenomenon with multiple solutions. Case Stud. Therm. Eng. 2021, 28, 101684. [Google Scholar] [CrossRef]

- Saeed, A.; Khan, N.; Gul, T.; Kumam, W.; Alghamdi, W.; Kumam, P. The Flow of Blood-Based Hybrid Nanofluids with Couple Stresses by the Convergent and Divergent Channel for the Applications of Drug Delivery. Molecules 2021, 26, 6330. [Google Scholar] [CrossRef]

- Yashkun, U.; Zaimi, K.; Ishak, A.; Pop, I.; Sidaoui, R. Hybrid nanofluid flow through an exponentially stretching/shrinking sheet with mixed convection and Joule heating. Int. J. Numer. Methods Heat Fluid Flow 2020, 31, 1930–1950. [Google Scholar] [CrossRef]

- Devi, S.S.U.; Devi, S.A. Numerical investigation of three-dimensional hybrid Cu–Al2O3/water nanofluid flow over a stretching sheet with effecting Lorentz force subject to Newtonian heating. Can. J. Phys. 2016, 94, 490–496. [Google Scholar] [CrossRef]

- Devi, S.U.; Devi, S.A. Heat transfer enhancement of cu−al2o3/water hybrid nanofluid flow over a stretching sheet. J. Niger. Math. Soc. 2017, 36, 419–433. [Google Scholar]

- Aly, E.H.; Pop, I. MHD flow and heat transfer over a permeable stretching/shrinking sheet in a hybrid nanofluid with a convective boundary condition. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 3012–3038. [Google Scholar] [CrossRef]

- Waini, I.; Ishak, A.; Pop, I. Hybrid nanofluid flow induced by an exponentially shrinking sheet. Chin. J. Phys. 2020, 68, 468–482. [Google Scholar] [CrossRef]

- Lund, L.A.; Omar, Z.; Khan, I.; Sherif, E.-S.M. Dual Solutions and Stability Analysis of a Hybrid Nanofluid over a Stretching/Shrinking Sheet Executing MHD Flow. Symmetry 2020, 12, 276. [Google Scholar] [CrossRef] [Green Version]

- Teh, Y.Y.; Asghar, A. Three Dimensional MHD Hybrid Nanofluid Flow with Rotating Stretching/Shrinking Sheet and Joule Heating. CFD Lett. 2021, 13, 1–19. [Google Scholar]

- Khashi’Ie, N.S.; Arifin, N.M.; Nazar, R.; Hafidzuddin, E.H.; Wahi, N.; Pop, I. Magnetohydrodynamics (MHD) axisymmetric flow and heat transfer of a hybrid nanofluid past a radially permeable stretching/shrinking sheet with Joule heating. Chin. J. Phys. 2020, 64, 251–263. [Google Scholar] [CrossRef]

- Yan, L.; Dero, S.; Khan, I.; Mari, I.A.; Baleanu, D.; Nisar, K.S.; Sherif, E.-S.M.; Abdo, H.S. Dual Solutions and Stability Analysis of Magnetized Hybrid Nanofluid with Joule Heating and Multiple Slip Conditions. Processes 2020, 8, 332. [Google Scholar] [CrossRef] [Green Version]

- Khan, U.; Shafiq, A.; Zaib, A.; Baleanu, D. Hybrid nanofluid on mixed convective radiative flow from an irregular variably thick moving surface with convex and concave effects. Case Stud. Therm. Eng. 2020, 21, 100660. [Google Scholar] [CrossRef]

- Sreedevi, P.; Reddy, P.S.; Chamkha, A. Heat and mass transfer analysis of unsteady hybrid nanofluid flow over a stretching sheet with thermal radiation. SN Appl. Sci. 2020, 2, 1–15. [Google Scholar] [CrossRef]

- Dero, S.; Lund, L.A.; Shah, Z.; Bonyah, E.; Deebani, W. Numerical Analysis of Cu + Al2O3/H2O Hybrid Nanofluid of Streamwise and Cross Flow with Thermal Radiation Effect: Duality and Stability. Math. Probl. Eng. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Roşca, N.C.; Roşca, A.V.; Pop, I. Axisymmetric flow of hybrid nanofluid due to a permeable non-linearly stretching/shrinking sheet with radiation effect. Int. J. Numer. Methods Heat Fluid Flow 2021, 31, 2330–2346. [Google Scholar] [CrossRef]

- Shoaib, M.; Raja, M.A.Z.; Sabir, M.T.; Islam, S.; Shah, Z.; Kumam, P.; Alrabaiah, H. Numerical investigation for rotating flow of MHD hybrid nanofluid with thermal radiation over a stretching sheet. Sci. Rep. 2020, 10, 1–15. [Google Scholar] [CrossRef]

- Eid, M.R.; Nafe, M.A. Thermal conductivity variation and heat generation effects on magneto-hybrid nanofluid flow in a porous medium with slip condition. Waves Random Complex Media 2020, 1–25. [Google Scholar] [CrossRef]

- Tiwari, R.K.; Das, M.K. Heat transfer augmentation in a two-sided lid-driven differentially heated square cavity utilizing nanofluids. Int. J. Heat Mass Transf. 2007, 50, 2002–2018. [Google Scholar] [CrossRef]

- Lund, L.A.; Omar, Z.; Khan, I.; Kadry, S.; Rho, S.; Mari, I.A.; Nisar, K.S. Effect of Viscous Dissipation in Heat Transfer of MHD Flow of Micropolar Fluid Partial Slip Conditions: Dual Solutions and Stability Analysis. Energies 2019, 12, 4617. [Google Scholar] [CrossRef] [Green Version]

- Sajid, M.; Javed, T.; Hayat, T. MHD rotating flow of a viscous fluid over a shrinking surface. Nonlinear Dyn. 2008, 51, 259–265. [Google Scholar] [CrossRef]

- Ishak, A. MHD boundary layer flow due to an exponentially stretching sheet with radiation effect. Sains Malays. 2011, 40, 391–395. [Google Scholar]

- Merkin, J.H. On dual solutions occurring in mixed convection in a porous medium. J. Eng. Math. 1986, 20, 171–179. [Google Scholar] [CrossRef]

- Harris, S.D.; Ingham, D.B.; Pop, I. Mixed Convection Boundary-Layer Flow Near the Stagnation Point on a Vertical Surface in a Porous Medium: Brinkman Model with Slip. Transp. Porous Media 2009, 77, 267–285. [Google Scholar] [CrossRef]

- Hale, N.; Moore, D.R. A sixth-order extension to the MATLAB package bvp4c of J. Kierzenka and L. Shampine. Comput. Sci. 2008. [Google Scholar]

- Nazar, R.; Amin, N.; Pop, I. Unsteady boundary layer flow due to a stretching surface in a rotating fluid. Mech. Res. Commun. 2004, 31, 121–128. [Google Scholar] [CrossRef]

| Names | Properties |

|---|---|

| Dynamic viscosity | |

| Density | |

| Thermal conductivity | |

| Heat capacity | |

| Electrical conductivity |

| Fluids | (kg/m3) | k (W/m K) | |||

|---|---|---|---|---|---|

| Copper (Cu) | 8933 | 385 | 400 | - | |

| 3970 | 765 | 40 | - | ||

| ) | 997.1 | 0.05 | 4179 | 0.613 | 6.2 |

| Nazar et al. [49] | Anuar et al. [22] | Current Results | ||||

|---|---|---|---|---|---|---|

| 0.5 | −1.1384 | −0.5128 | −1.13838 | −0.51276 | −1.138374 | −0.512760 |

| 1.0 | −1.3250 | −0.8371 | −1.35503 | −0.83710 | −1.325028 | −0.837098 |

| 2.0 | −1.6523 | −1.2873 | −1.65235 | −1.28726 | −1.65235 | −1.287258 |

| 0 | 8.247357 (8.476272) |

| 0.3 | 8.247162 (8.476187) |

| 0.6 | 8.246967 (8.476103) |

| First Solution | Second Solution | ||

|---|---|---|---|

| 0 | 3 | 0.2042 | −0.2233 |

| 2.5 | 0.1584 | −0.2093 | |

| 2 | 0.0806 | −0.1003 | |

| 1.9868 | 0.0071 | −0.0251 | |

| 0.02 | 3 | 0.8668 | −0.8978 |

| 2.8 | 0.7704 | −0.7929 | |

| 2.6 | 0.5954 | −0.5988 | |

| 2.4 | 0.3723 | −0.4012 | |

| 2.2 | 0.1912 | −0.0853 | |

| 1.8810 | 0.0108 | −0.0071 | |

| 0.06 | 3 | 1.1380 | −1.0836 |

| 2.8 | 1.0230 | −0.9651 | |

| 2.6 | 0.8186 | −0.7554 | |

| 2.4 | 0.6591 | −0.5691 | |

| 2.2 | 0.3532 | −0.2856 | |

| 2 | 0.0993 | −0.1003 | |

| 1.7681 | 0.0080 | −0.0006 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asghar, A.; Lund, L.A.; Shah, Z.; Vrinceanu, N.; Deebani, W.; Shutaywi, M. Effect of Thermal Radiation on Three-Dimensional Magnetized Rotating Flow of a Hybrid Nanofluid. Nanomaterials 2022, 12, 1566. https://doi.org/10.3390/nano12091566

Asghar A, Lund LA, Shah Z, Vrinceanu N, Deebani W, Shutaywi M. Effect of Thermal Radiation on Three-Dimensional Magnetized Rotating Flow of a Hybrid Nanofluid. Nanomaterials. 2022; 12(9):1566. https://doi.org/10.3390/nano12091566

Chicago/Turabian StyleAsghar, Adnan, Liaquat Ali Lund, Zahir Shah, Narcisa Vrinceanu, Wejdan Deebani, and Meshal Shutaywi. 2022. "Effect of Thermal Radiation on Three-Dimensional Magnetized Rotating Flow of a Hybrid Nanofluid" Nanomaterials 12, no. 9: 1566. https://doi.org/10.3390/nano12091566

APA StyleAsghar, A., Lund, L. A., Shah, Z., Vrinceanu, N., Deebani, W., & Shutaywi, M. (2022). Effect of Thermal Radiation on Three-Dimensional Magnetized Rotating Flow of a Hybrid Nanofluid. Nanomaterials, 12(9), 1566. https://doi.org/10.3390/nano12091566