A Simple Method for Fabricating an External Light Extraction Composite Layer with RNS to Improve the Optical Properties of OLEDs

Abstract

:1. Introduction

2. Materials and Methods

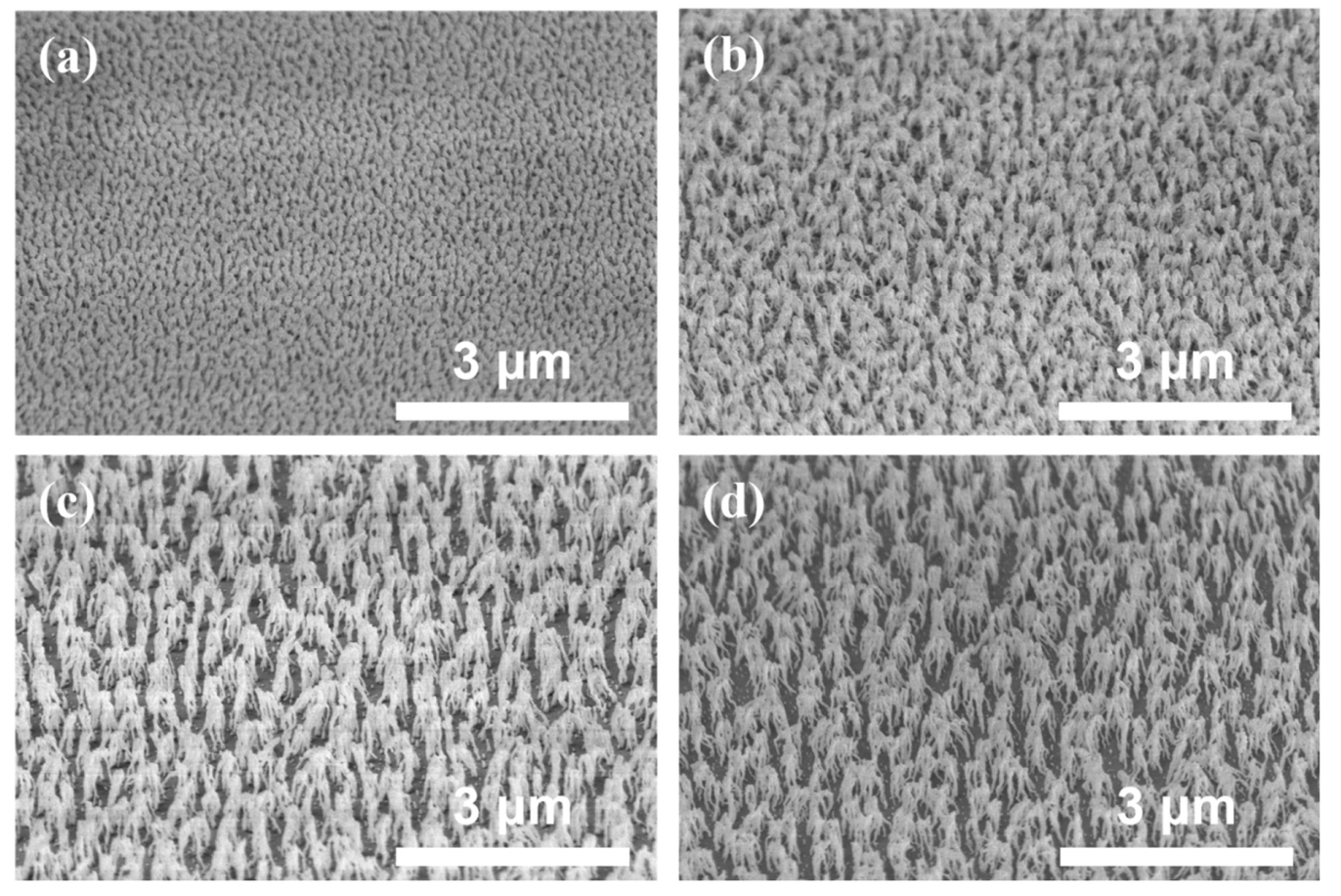

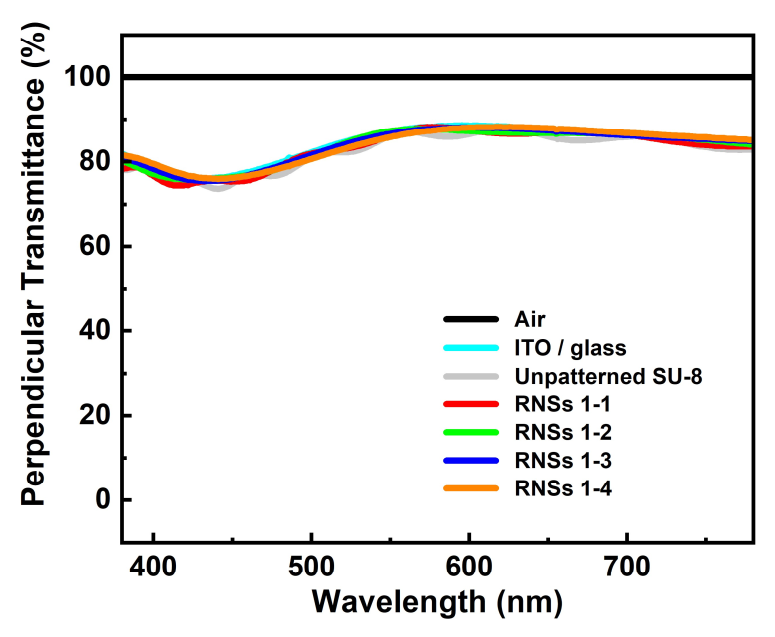

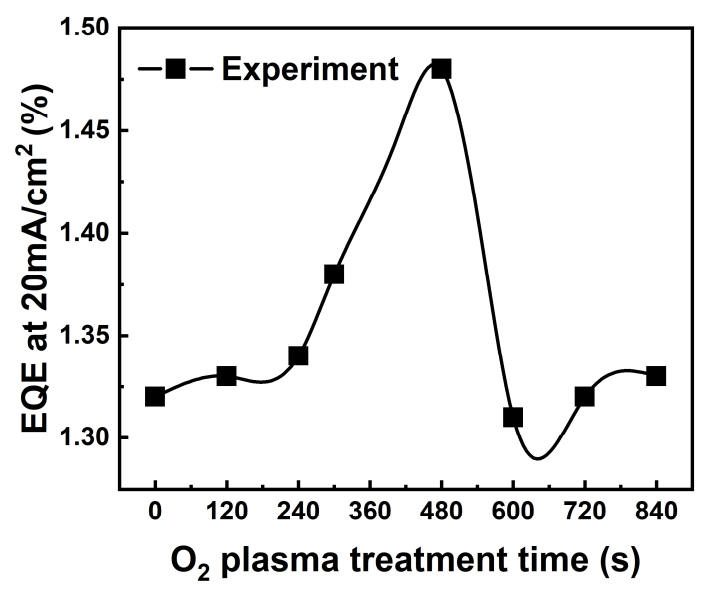

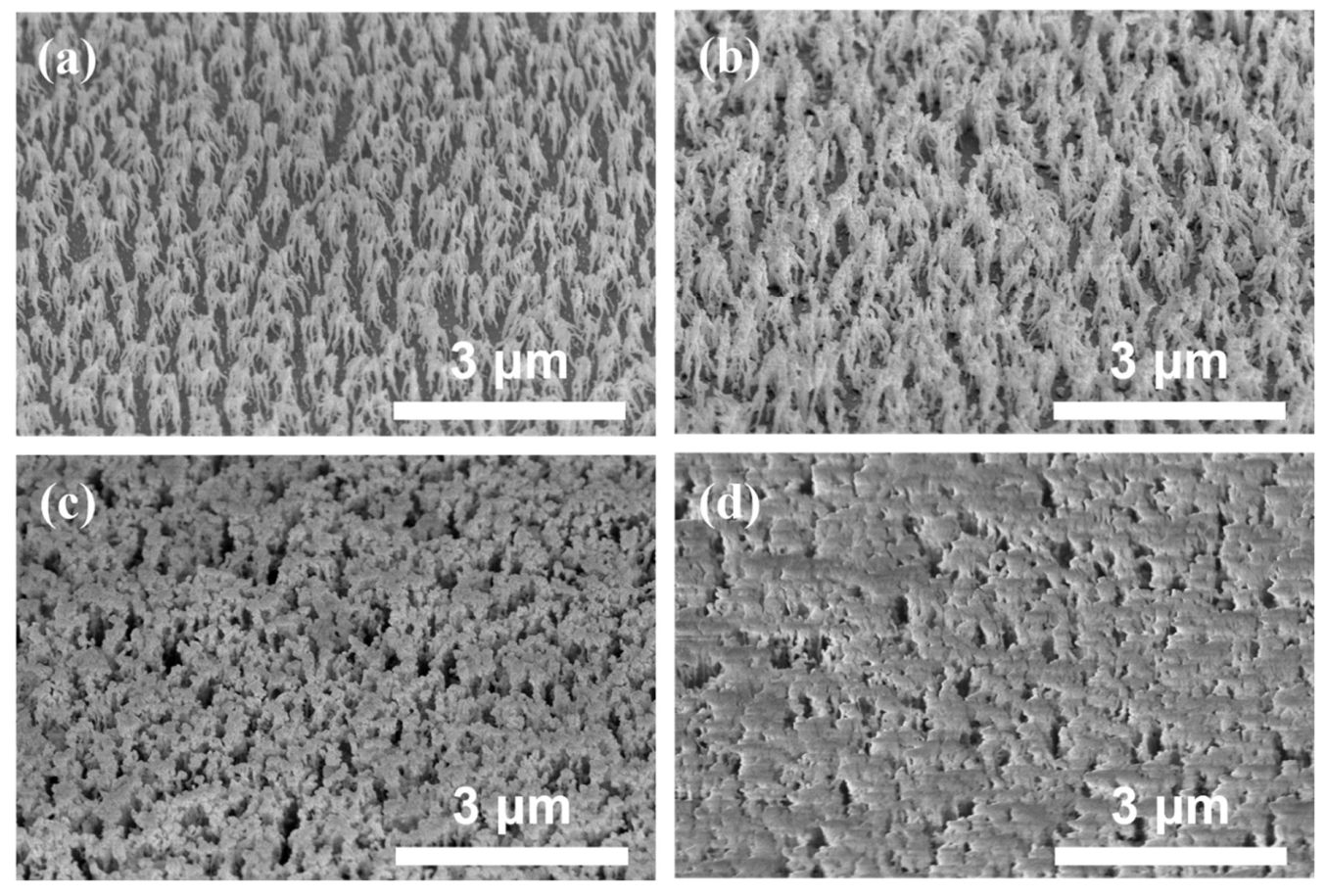

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mann, V.; Rastogi, V. Dielectric nanoparticles for the enhancement of OLED light extraction efficiency. Opt. Commun. 2017, 387, 202–207. [Google Scholar] [CrossRef]

- Kim, J.-B.; Lee, J.-H.; Moon, C.-K.; Kim, S.-Y.; Kim, J.-J. Highly Enhanced Light Extraction from Surface Plasmonic Loss Minimized Organic Light-Emitting Diodes. Adv. Mater. 2013, 25, 3571–3577. [Google Scholar] [CrossRef]

- Shim, Y.S.; Kim, K.N.; Hwang, J.H.; Park, C.H.; Jung, S.-G.; Park, Y.W.; Ju, B.-K. Spectral-distortion-free light extraction from organic light-emitting diodes using nanoscale photonic crystal. Nanotechnology 2016, 28, 45301. [Google Scholar] [CrossRef]

- Lee, J.S.; Shim, Y.S.; Park, C.H.; Hwang, H.; Park, C.H.; Joo, C.W.; Park, Y.W.; Lee, J.; Ju, B.K. Enhanced light extraction from organic light-emitting diodes using a quasi-periodic nano-structure. Nanotechnology 2018, 30, 085302. [Google Scholar] [CrossRef]

- Liang, H.; Hsu, H.-C.; Wu, J.; He, X.; Wei, M.-K.; Chiu, T.-L.; Lin, C.-F.; Lee, J.-H.; Wang, J. Corrugated organic light-emitting diodes to effectively extract internal modes. Opt. Express 2019, 27, A372–A384. [Google Scholar] [CrossRef]

- Lee, K.; Shin, J.-W.; Park, J.-H.; Lee, J.; Joo, C.W.; Lee, J.-I.; Cho, D.-H.; Lim, J.T.; Oh, M.-C.; Ju, B.-K.; et al. A Light Scattering Layer for Internal Light Extraction of Organic Light-Emitting Diodes Based on Silver Nanowires. ACS Appl. Mater. Interfaces 2016, 8, 17409–17415. [Google Scholar] [CrossRef]

- Sajeev, A.K.; Agarwal, N.; Soman, A.; Gupta, S.; Katiyar, M.; Ajayaghosh, A.; Unni, K. Enhanced light extraction from organic light emitting diodes using a flexible polymer-nanoparticle scattering layer. Org. Electron. 2021, 100, 106386. [Google Scholar] [CrossRef]

- Song, J.; Kim, K.-H.; Kim, E.; Moon, C.-K.; Kim, Y.-H.; Kim, J.-J.; Yoo, S. Lensfree OLEDs with over 50% external quantum efficiency via external scattering and horizontally oriented emitters. Nat. Commun. 2018, 9, 3207. [Google Scholar] [CrossRef]

- Choi, J.; Kim, S.; Park, C.H.; Kwack, J.H.; Park, C.H.; Hwang, H.; Im, H.S.; Park, Y.W.; Ju, B.K. Light extraction enhancement in flexible organic light-emitting diodes by a light-scattering layer of dewetted Ag nanoparticles at low temperatures. ACS Appl. Mater. Interfaces 2018, 10, 32373–32379. [Google Scholar] [CrossRef]

- Qu, Y.; Kim, J.; Coburn, C.; Forrest, S.R. Efficient, Nonintrusive Outcoupling in Organic Light Emitting Devices Using Embedded Microlens Arrays. ACS Photon. 2018, 5, 2453–2458. [Google Scholar] [CrossRef]

- Choi, G.S.; Bae, E.J.; Jang, E.B.; Seo, G.E.; Jang, S.M.; Ju, B.K.; Park, Y.W. Enhanced light out-coupling efficiency of OLEDs: Fabrication of an external light extraction composite layer. Domest. J. 2022, in press.

- Tsougeni, K.; Vourdas, N.; Tserepi, A.; Gogolides, E.; Cardinaud, C. Mechanisms of Oxygen Plasma Nanotexturing of Organic Polymer Surfaces: From Stable Super Hydrophilic to Super Hydrophobic Surfaces. Langmuir 2009, 25, 11748–11759. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.-W.; Cho, D.-H.; Moon, J.; Joo, C.W.; Park, S.K.; Lee, J.; Han, J.-H.; Cho, N.S.; Hwang, J.; Huh, J.W.; et al. Random nano-structures as light extraction functionals for organic light-emitting diode applications. Org. Electron. 2014, 15, 196–202. [Google Scholar] [CrossRef]

- Salehi, A.; Fu, X.; Shin, D.; So, F. Recent advances in OLED optical design. Adv. Funct. Mater. 2019, 29, 1808803. [Google Scholar] [CrossRef]

- Bae, B.H.; Jun, S.; Kwon, M.S.; Park, Y.W.; Han, C.J.; Kim, S.-I.; Ju, B.-K. Highly efficient flexible OLEDs based on double-sided nano-dimpled substrate (PVB) with embedded AgNWs and TiO2 nanoparticle for internal and external light extraction. Opt. Mater. 2019, 92, 87–94. [Google Scholar] [CrossRef]

- Han, Y.; Moon, C.-K.; Kim, K.; Lee, H.; Kim, J.-J. Random organic nano-textured microstructures formed by photoexcitation for light extraction of blue OLEDs. Org. Electron. 2020, 87, 105892. [Google Scholar] [CrossRef]

- Kwack, J.H.; Choi, J.; Park, C.H.; Hwang, H.; Park, Y.W.; Ju, B.-K. Simple method for fabricating scattering layer using random nanoscale rods for improving optical properties of organic light-emitting diodes. Sci. Rep. 2018, 8, 14311. [Google Scholar] [CrossRef] [Green Version]

- Kwack, J.H.; Hwang, H.; Choi, J.; Choi, Y.; Park, Y.W.; Ju, B.-K. Improving the optical properties of organic light-emitting diodes using random nanoscale rods with a double refractive index. Nanotechnology 2020, 31, 335205. [Google Scholar] [CrossRef]

- Park, C.H.; Kang, S.W.; Jung, S.-G.; Lee, D.J.; Park, Y.W.; Ju, B.-K. Enhanced light extraction efficiency and viewing angle characteristics of microcavity OLEDs by using a diffusion layer. Sci. Rep. 2021, 11, 3430. [Google Scholar] [CrossRef]

- Chang, H.-W.; Tien, K.-C.; Hsu, M.-H.; Huang, Y.-H.; Lin, M.-S.; Tsai, C.-H.; Tsai, Y.-T.; Wu, C.-C. Organic light-emitting devices integrated with internal scattering layers for enhancing optical out-coupling. J. Soc. Inf. Disp. 2011, 19, 196–204. [Google Scholar] [CrossRef]

- Riedel, D.; Wehlus, T.; Reusch, T.C.; Brabec, C.J. Polymer-based scattering layers for internal light extraction from organic light emitting diodes. Org. Electron. 2016, 32, 27–33. [Google Scholar] [CrossRef]

- Choi, H.; Kim, C.; Chae, H.; Cho, S.M. Efficiency enhancement of organic light-emitting diodes using mesoporous titanium-oxide scattering nanoparticles. Mater. Lett. 2018, 214, 1–5. [Google Scholar] [CrossRef]

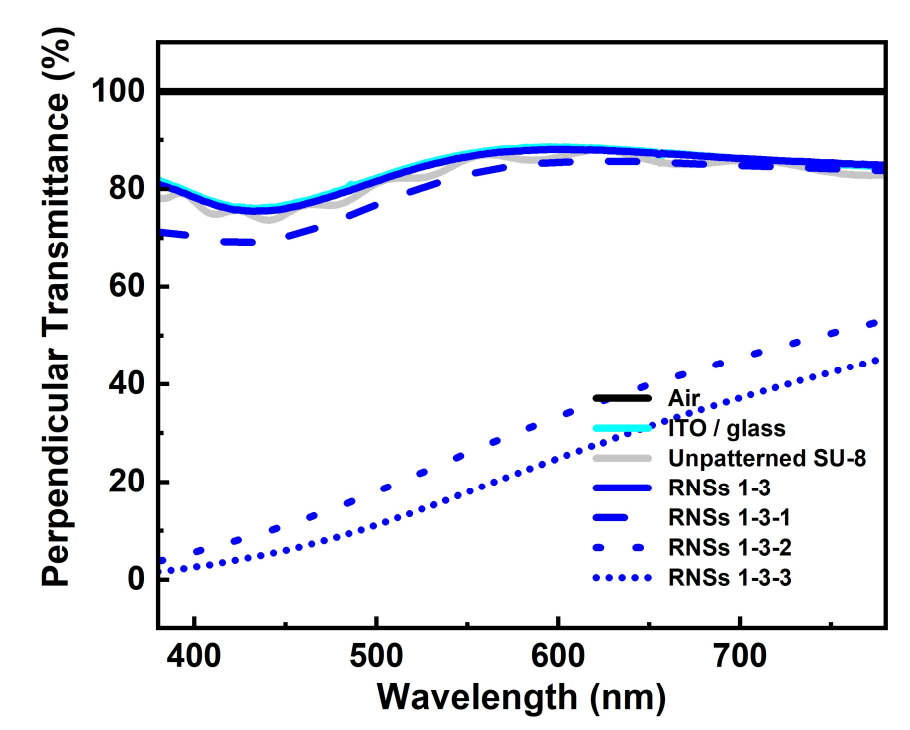

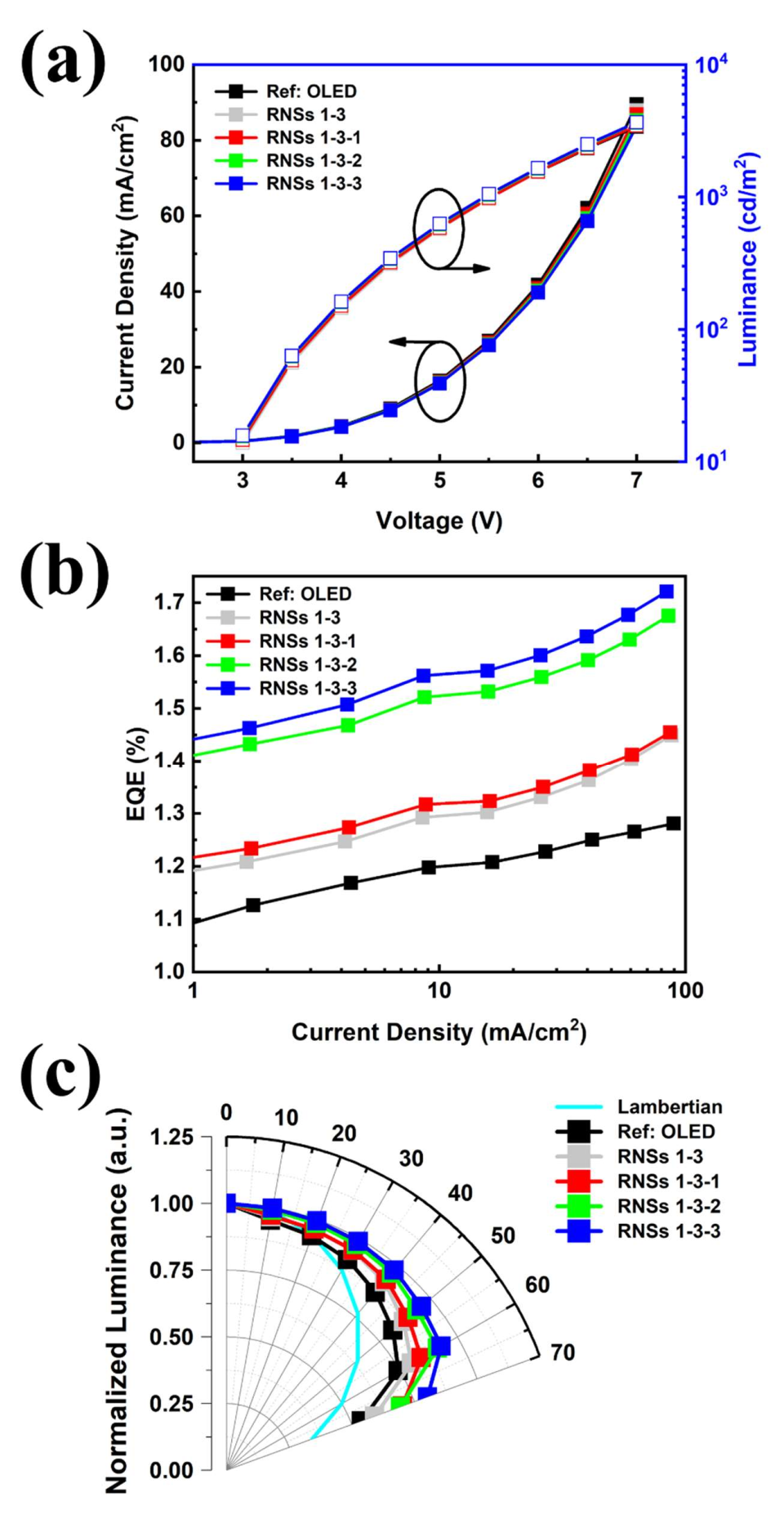

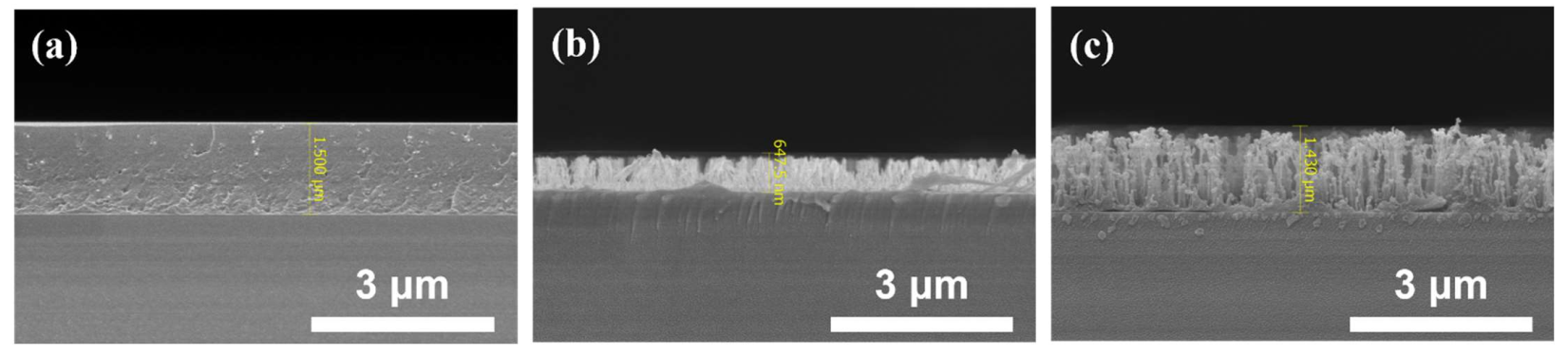

| Unpatterned SU-8 | RNSs 1-3 | RNSs 1-3-2 | |

|---|---|---|---|

| Average height of film (nm) | 1500 | 647.5 | 1430 |

| Perpendicular transmittance at 550 nm (%) | 86.1 | 86.5 | 25.9 |

| Enhancement in EQE (%) | 0 | 12.9 | 28.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, G.-S.; Kang, S.-W.; Bae, E.-J.; Jang, E.-B.; Baek, D.-H.; Ju, B.-K.; Park, Y.-W. A Simple Method for Fabricating an External Light Extraction Composite Layer with RNS to Improve the Optical Properties of OLEDs. Nanomaterials 2022, 12, 1430. https://doi.org/10.3390/nano12091430

Choi G-S, Kang S-W, Bae E-J, Jang E-B, Baek D-H, Ju B-K, Park Y-W. A Simple Method for Fabricating an External Light Extraction Composite Layer with RNS to Improve the Optical Properties of OLEDs. Nanomaterials. 2022; 12(9):1430. https://doi.org/10.3390/nano12091430

Chicago/Turabian StyleChoi, Geun-Su, Shin-Woo Kang, Eun-Jeong Bae, Eun-Bi Jang, Dong-Hyun Baek, Byeong-Kwon Ju, and Young-Wook Park. 2022. "A Simple Method for Fabricating an External Light Extraction Composite Layer with RNS to Improve the Optical Properties of OLEDs" Nanomaterials 12, no. 9: 1430. https://doi.org/10.3390/nano12091430

APA StyleChoi, G.-S., Kang, S.-W., Bae, E.-J., Jang, E.-B., Baek, D.-H., Ju, B.-K., & Park, Y.-W. (2022). A Simple Method for Fabricating an External Light Extraction Composite Layer with RNS to Improve the Optical Properties of OLEDs. Nanomaterials, 12(9), 1430. https://doi.org/10.3390/nano12091430