Natural Convection Water/Glycerin–CNT Fractionalized Nanofluid Flow in a Channel with Isothermal and Ramped Conditions

Abstract

1. Introduction

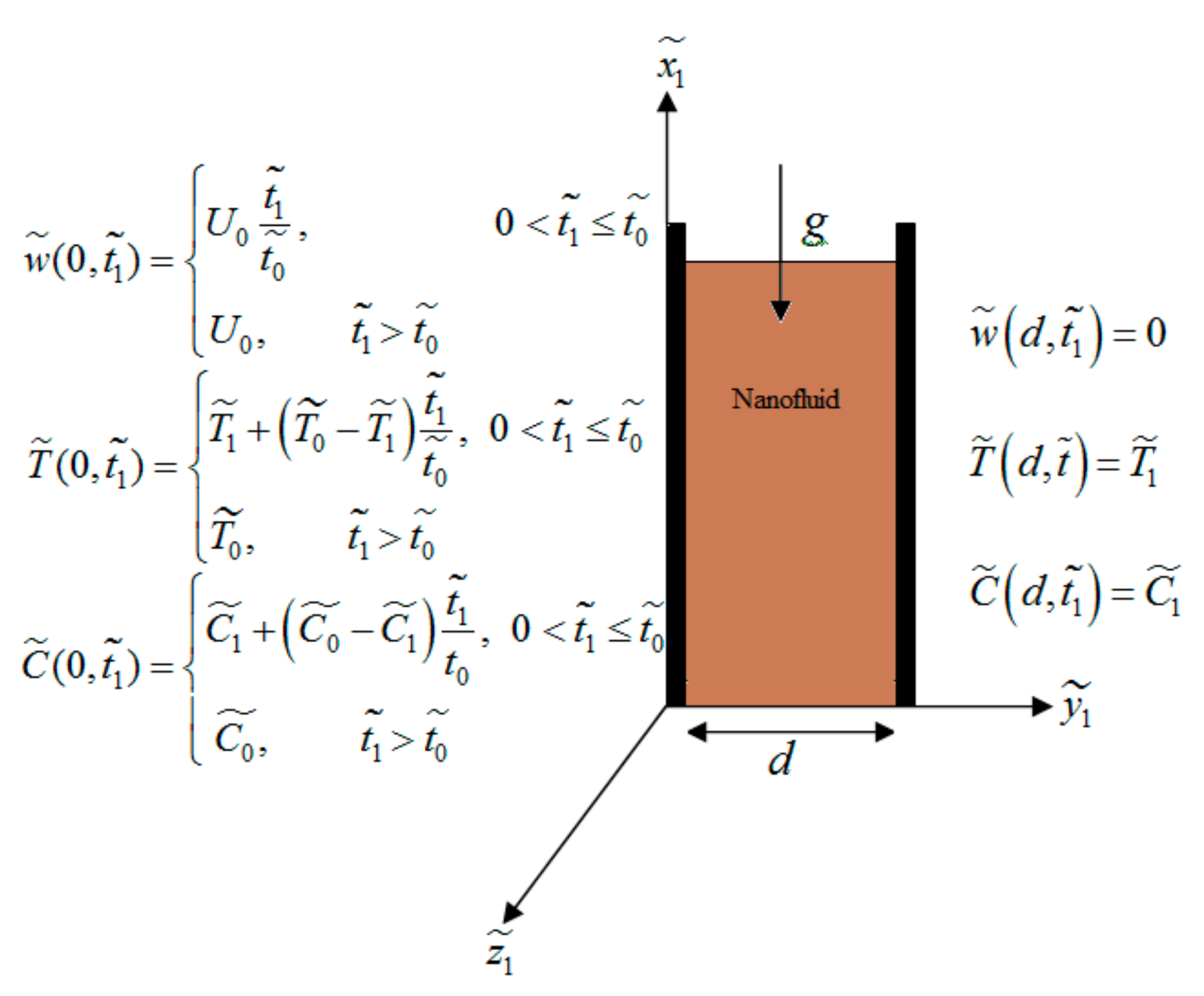

2. Mathematical Model

3. Solution of the Problem

4. Nusselt Numbers, Skin Frictions and Sherwood Numbers

5. Graphical Results and Discussions

6. Conclusions

- The temperature, concentration and velocity fields for isothermal boundary conditions are higher than ramped boundary conditions.

- Isothermal wall temperature and velocity increase by increasing while decreases occur in the case of ramped wall temperature and velocity. Contrastingly, concentration increases in both cases.

- Velocities decrease by increasing R, Q and increase by increasing Sr, Nr, φ.

- Temperatures decrease by increasing Q and increase by increasing Nr, φ.

- Concentrations decrease by increasing R, Nr, φ and increase by increasing Sr, Q.

- Ramped wall conditions help to manage deviations of temperature, concentration and velocity fields.

- Velocity profile of water–MWCNT is greater than the velocities of water–SWCNT, glycerin–SWCNT and glycerin–WMCNT.

- Temperature of water–SWCNT is higher than the temperatures of water–MWCNT, glycerin–SWCNT and glycerin–WMCNT.

- Concentration profile of glycerin–WMCNT is greater than the concentrations of water–SWCNT, water–MWCNT and glycerin–SWCNT.

- Water–MWCNT has the maximum velocity, while glycerin–SWCNT has the lowest velocity. Because of its increased thermal conductivity, the temperature profiles of water–SWCNT are higher than those of other fluids. Glycerin–MWCNT has a greater concentration than the other fluids under study.

- Skin frictions of water–SWCNT, water–MWCNT, glycerin–SWCNT and glycerin–WMCNT increases by increasing φ for both isothermal and ramped conditions on both walls of the channel.

- Nusselt numbers of water–SWCNT, water–MWCNT, glycerin–SWCNT and glycerin–WMCNT increases by increasing φ for both isothermal and ramped conditions on both walls of the channel.

- Sherwood numbers of water–SWCNT, water–MWCNT, glycerin–SWCNT and glycerin–WMCNT increase at y = 0 and decrease at y = 1 by increasing φ for both isothermal and ramped conditions on both walls of the channel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Concentration (kgm−3) | |

| Velocity (m s−1) | |

| Temperature (K) | |

| D | Mass diffusivity (m2 s−1) |

| k | Thermal conductivity (W m−1 K−1) |

| Gravitational acceleration(m s−2) | |

| cp | Specific heat (J kg−1 K−1) |

| Radiative heat flux | |

| Heat absorption (W m−3K−1) | |

| Mean fluid temperature | |

| Thermal diffusion ratio | |

| Chemical reaction (s−1) | |

| Rosseland absorption coefficient | |

| Gm | Mass Grashof number |

| Stefan-Boltzmann constant | |

| Pr | Prandtl number |

| Sc | Schmidt number |

| Gr | Thermal Grashof number |

| Sr | Soret effect |

| Nr | Thermal radiation |

| Nu | Nusselt number |

| R | Chemical reaction |

| Sr | Soret effect |

| Q | Heat absorption |

| Sk | Skin friction |

| Sh | Sherwood number |

| Greek Symbols | |

| φ | Nanoparticles volume fraction |

| ν | Kinematic viscosity (m2 s−1) |

| α | Fractional parameter |

| βT | Thermal expansion (K−1) |

| θ | Dimensionless temperature |

| βC | Mass volumetric (m3kg−1) |

| ρ | Density (kg m−3) |

| µ | Dynamic Viscosity (kg m−1 s−1) |

| Subscript | |

| f | Fluid |

| CNTs | Carbon nanotubes |

| ssnf | Nanofluid |

References

- Choi, S.U.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles; Argonne National Lab: Chicago, IL, USA, 1995. [Google Scholar]

- Gorji, T.B.; Ranjbar, A. A review on optical properties and application of nanofluids in direct absorption solar collectors (DASCs). Renew. Sustain. Energy Rev. 2017, 72, 10–32. [Google Scholar] [CrossRef]

- Sajid, M.U.; Ali, H.M. Recent advances in application of nanofluids in heat transfer devices: A critical review. Renew. Sustain. Energy Rev. 2019, 103, 556–592. [Google Scholar] [CrossRef]

- Babu, J.A.R.; Kumar, K.K.; Rao, S.S. State of art review on hybrid nanofluids. Renew. Sustain. Energy Rev. 2017, 77, 551–565. [Google Scholar] [CrossRef]

- Zubair, T.; Usman, M.; Nisar, K.S.; Khan, I.; Ghamkhar, M.; Ahmad, M. Crank Nicholson scheme to examine the fraction-al-order unsteady nanofluid flow of free convection of viscous fluids. PLoS ONE 2022, 17, e0261860. [Google Scholar] [CrossRef] [PubMed]

- Shahzad, F.; Jamshed, W.; Nisar, K.S.; Nasir, N.A.A.M.; Safdar, R.; Abdel-Aty, A.H.; Yahia, I.S. Thermal analysis for Al2O3–sodium alginate magnetized Jeffrey’s nanofluid flow past a stretching sheet embedded in a porous medium. Sci. Rep. 2022, 12, 3287. [Google Scholar] [CrossRef] [PubMed]

- Najim, F.T.; Mohammed, H.I.; Al-Najjar, H.M.T.; Thangavelu, L.; Mahmoud, M.Z.; Mahdi, J.M.; Tiji, M.E.; Yaïci, W.; Talebizadehsardari, P. Improved Melting of Latent Heat Storage Using Fin Arrays with Non-Uniform Dimensions and Distinct Patterns. Nanomaterials 2022, 12, 403. [Google Scholar] [CrossRef] [PubMed]

- Mehryan, S.A.M.; Ghalambaz, M.; Gargari, L.S.; Hajjar, A.; Sheremet, M. Natural convection flow of a suspension containing nano-encapsulated phase change particles in an eccentric annulus. J. Energy Storage 2020, 28, 101236. [Google Scholar] [CrossRef]

- Shahsavar, A.; Rashidi, M.; Monfared, M.M.; Sardari, P.T. A numerical investigation on the influence of nanoadditive shape on the natural convection and entropy generation inside a rectangle-shaped finned concentric annulus filled with boehmite alumina nanofluid using two-phase mixture model. J. Therm. Anal. Calorim. 2019, 141, 915–930. [Google Scholar] [CrossRef]

- Gul, H.; Ramzan, M.; Nisar, K.S.; Mohamed, R.N.; Ghazwani, H.A.S. Performance-based comparison of Yamada–Ota and Hamilton–Crosser hybrid nanofluid flow models with magnetic dipole impact past a stretched surface. Sci. Rep. 2022, 12, 29. [Google Scholar] [CrossRef]

- Ramzan, M.; Shahmir, N.; Ghazwani, H.A.S.; Nisar, K.S.; Alharbi, F.M.; Yahia, I.S. Hydrodynamic and heat transfer analysis of dissimilar shaped nanoparticles-based hybrid nanofluids in a rotating frame with convective boundary condition. Sci. Rep. 2022, 12, 436. [Google Scholar] [CrossRef]

- Redouane, F.; Jamshed, W.; Devi, S.S.U.; Prakash, M.; Nasir, N.A.A.M.; Hammouch, Z.; Eid, M.R.; Nisar, K.S.; Mahammed, A.B.; Abdel-Aty, A.H.; et al. Heat flow saturate of Ag/MgO-water hybrid nanofluid in heated trigonal enclosure with rotate cylindrical cavity by using Galerkin finite element. Sci. Rep. 2022, 12, 2302. [Google Scholar] [CrossRef]

- Saleem, S.; Animasaun, I.; Yook, S.-J.; Al-Mdallal, Q.M.; Shah, N.A.; Faisal, M. Insight into the motion of water conveying three kinds of nanoparticles shapes on a horizontal surface: Significance of thermo-migration and Brownian motion. Surf. Interfaces 2022, 30, 101854. [Google Scholar] [CrossRef]

- Animasaun, I.; Yook, S.-J.; Muhammad, T.; Mathew, A. Dynamics of ternary-hybrid nanofluid subject to magnetic flux density and heat source or sink on a convectively heated surface. Surf. Interfaces 2022, 28, 101654. [Google Scholar] [CrossRef]

- Lijima, S. Helical microtubules of graphitic carbon. Nature 1991, 54, 56–58. [Google Scholar]

- Ajayan, P.M.; Lijima, S. Capillarity-induced filling of carbon nanotubes. Nature 1993, 361, 333–334. [Google Scholar] [CrossRef]

- Baghban, A.; Kahani, M.; Nazari, M.A.; Ahmadi, M.H.; Yan, W.-M. Sensitivity analysis and application of machine learning methods to predict the heat transfer performance of CNT/water nanofluid flows through coils. Int. J. Heat Mass Transf. 2018, 128, 825–835. [Google Scholar] [CrossRef]

- Saqib, M.; Khan, I.; Shafie, S. Application of Atangana–Baleanu fractional derivative to MHD channel flow of CMC-based-CNT’s nanofluid through a porous medium. Chaos Solitons Fractals 2018, 116, 79–85. [Google Scholar] [CrossRef]

- Aman, S.; Khan, I.; Ismail, Z.; Salleh, M.Z.; Alshomrani, A.S.; Alghamdi, M.S. Magnetic field effect on Poiseuille flow and heat transfer of carbon nanotubes along a vertical channel filled with Casson fluid. AIP Adv. 2017, 7, 015036. [Google Scholar] [CrossRef]

- Khalid, A.; Khan, I.; Khan, A.; Shafie, S.; Tlili, I. Case study of MHD blood flow in a porous medium with CNTS and thermal analysis. Case Stud. Therm. Eng. 2018, 12, 374–380. [Google Scholar] [CrossRef]

- Khan, I.; Saqib, M.; Alqahtani, A.M. Channel flow of fractionalized H2O-based CNTs nanofluids with Newtonian heating. Discret. Contin. Dyn. Syst. S 2020, 13, 769–779. [Google Scholar] [CrossRef]

- Saqib, M.; Khan, I.; Chu, Y.M.; Qushairi, A.; Shafie, S. Multiple fractional solutions for magnetic bio-nanofluid using Ol-droyd-B model in a porous medium with ramped wall heating and variable velocity. Appl. Sci. 2020, 10, 3886. [Google Scholar] [CrossRef]

- Saqib, M.; Kasim, A.R.M.; Mohammad, N.F.; Ching, D.L.C.; Shafie, S. Application of Fractional Derivative without Singular and Local Kernel to Enhanced Heat Transfer in CNTs Nanofluid over an Inclined Plate. Symmetry 2020, 12, 768. [Google Scholar] [CrossRef]

- Saqib, M.; Shafie, S.; Khan, I.; Chu, Y.M.; Nisar, K.S. Symmetric MHD channel flow of non-local fractional model of BTF containing hybrid nanoparticles. Symmetry 2020, 12, 663. [Google Scholar] [CrossRef]

- Omowaye, A.; Fagbade, A.; Ajayi, A. Dufour and soret effects on steady MHD convective flow of a fluid in a porous medium with temperature dependent viscosity: Homotopy analysis approach. J. Niger. Math. Soc. 2015, 34, 343–360. [Google Scholar] [CrossRef]

- Raju, S.S.K.; Narahari, M.; Pendyala, R. Soret and chemical reaction effects on unsteady two-dimensional natural convection along a vertical plate. Arab. J. Basic Appl. Sci. 2014, 27, 344–357. [Google Scholar] [CrossRef]

- Reddy, G. Soret and Dufour Effects on MHD Free Convective Flow Past a Vertical Porous Plate in the Presence of Heat Generation. Int. J. Appl. Mech. Eng. 2016, 21, 649–665. [Google Scholar] [CrossRef]

- Sadiq, K.; Jarad, F.; Siddique, I.; Ali, B. Soret and Radiation Effects on Mixture of Ethylene Glycol-Water (50%-50%) Based Maxwell Nanofluid Flow in an Upright Channel. Complexity 2021, 2021, 5927070. [Google Scholar] [CrossRef]

- Srinivas, D.R.; Sreedhar, G.S.; Govardhan, K. Effect of viscous dissipation, Soret and Dufour effect on free convection heat and mass transfer from vertical surface in a porous medium. Procedia Mater. Sci. 2015, 10, 563–571. [Google Scholar]

- Tippa, S.; Narahari, M.; Pendyala, R. Dufour effect on unsteady natural convection flow past an infinite vertical plate with constant heat and mass fluxes. AIP Conf. Proc. 2014, 1621, 470. [Google Scholar] [CrossRef]

- Uwanta, I.J.; Usman, H. On the Influence of Soret and Dufour Effects on MHD Free Convective Heat and Mass Transfer Flow over a Vertical Channel with Constant Suction and Viscous Dissipation. Int. Sch. Res. Not. 2014, 2014, 639159. [Google Scholar] [CrossRef][Green Version]

- Raju, C.S.K.; Babu, M.J.; Sandeep, N.; Sugunamma, V.; Reddy, J.V.R. Radiation and Soret effects of MHD nanofluid flow over a moving vertical moving plate in porous medium. Chem. Process Eng. Res. 2015, 30, 9–23. [Google Scholar]

- RamReddy, C.; Murthy, P.; Chamkha, A.J.; Rashad, A. Soret effect on mixed convection flow in a nanofluid under convective boundary condition. Int. J. Heat Mass Transf. 2013, 64, 384–392. [Google Scholar] [CrossRef]

- Pal, D.; Talukdar, B. Perturbation analysis of unsteady magnetohydrodynamic convective heat and mass transfer in a boundary layer slip flow past a vertical permeable plate with thermal radiation and chemical reaction. Commun. Nonlinear Sci. Numer. Simul. 2010, 15, 1813–1830. [Google Scholar] [CrossRef]

- Chamkha, A.J. MHD flow of a uniformly stretched vertical permeable surface in the presence of heat genera-tion/absorption and a chemical reaction. Int. Commun. Heat Mass Transf. 2003, 30, 413–422. [Google Scholar] [CrossRef]

- Uwanta, I.J.; Omokhuale, E. Viscoelastic fluid flow in a fixed plane with heat and mass transfer. Res. J. Math. Stat. 2012, 4, 63–69. [Google Scholar]

- Das, K.; Jana, S.; Kundu, P.K. Unsteady MHD free convection flow near a moving vertical plate with ramped wall tem-perature. Int. J. Fluid Mech. Res. 2014, 41, 71–90. [Google Scholar] [CrossRef]

- Seth, G.S.; Ansari, S.; Nandkeolyar, R. MHD natural convection flow with radiative heat transfer past an impulsively moving plate with ramped wall temperature. Heat Mass Transf. 2010, 47, 551–561. [Google Scholar] [CrossRef]

- Das, K. Effects of heat and mass transfer on MHD free convection flow near a moving vertical plate of a radiating and chemically reacting fluid. J. Sib. Fed. Univ. Math. Phys. 2011, 4, 18–31. [Google Scholar]

- Makinde, O.D. Free convection flow with thermal radiation and mass transfer past a moving vertical porous plate. Int. Commun. Heat Mass Transf. 2005, 32, 1411–1419. [Google Scholar] [CrossRef]

- Gireesha, B.J.; Mahanthesh, B. Perturbation solution for radiating viscoelastic fluid flow and heat transfer with convective boundary condition in non-uniform channel with hall current and chemical reaction. Int. Sch. Res. Not. 2013, 81, 9354. [Google Scholar]

- Turkyilmazoglu, M.; Pop, I. Soret and heat source effects on the unsteady radiative MHD free convection flow from an impulsively started infinite vertical plate. Int. J. Heat Mass Transf. 2012, 55, 7635–7644. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Ganji, D.D.; Rashidi, M.M. Ferrofluid flow and heat transfer in a semi annulus enclosure in the presence of magnetic source considering thermal radiation. J. Taiwan Inst. Chem. Eng. 2015, 47, 6–17. [Google Scholar] [CrossRef]

- Jha, B.K.; Gambo, Y.Y. Dufour Effect with Ramped Wall Temperature and Specie Concentration on Natural Convection Flow Through A Channel. Physics 2019, 1, 111–130. [Google Scholar] [CrossRef]

- Qiang, X.; Siddique, I.; Sadiq, K.; Shah, N.A. Double diffusive MHD convective flows of a viscous fluid under influence of the inclined magnetic field, source/sink and chemical reaction. Alex. Eng. J. 2020, 59, 4171–4181. [Google Scholar] [CrossRef]

- Siddique, I.; Sadiq, K.; Khan, I.; Nisar, K.S. Nanomaterials in convection flow of nanofluid in upright channel with gradients. J. Mater. Res. Technol. 2021, 11, 1411–1423. [Google Scholar] [CrossRef]

- Sadiq, K.; Siddique, I.; Ali, R.; Jarad, F. Impact of Ramped Concentration and Temperature on MHD Casson Nanofluid Flow through a Vertical Channel. J. Nanomater. 2021, 2021, 3743876. [Google Scholar] [CrossRef]

- Shafiq, A.; Rasool, G.; Alotaibi, H.; Aljohani, H.; Wakif, A.; Khan, I.; Akram, S. Thermally Enhanced Darcy-Forchheimer Casson-Water/Glycerine Rotating Nanofluid Flow with Uniform Magnetic Field. Micromachines 2021, 12, 605. [Google Scholar] [CrossRef]

- Narahari, M.; Tippa, S.; Pendyala, R.; Fetecau, C. Soret, heat generation, radiation and porous effects on MHD free con-vection flow past an infinite plate with oscillating temperature. J. Therm. Anal. Calorim. 2020, 143, 2525–2543. [Google Scholar] [CrossRef]

- Loganathan, P.; Chand, P.N.; Ganesan, P. Radiation Effects on An Unsteady Natural Convective Flow of A Nanofluid Past an Infinite Vertical Plate. Nano 2013, 8, 1350001. [Google Scholar] [CrossRef]

- Das, S.; Jana, R. Natural convective magneto-nanofluid flow and radiative heat transfer past a moving vertical plate. Alex. Eng. J. 2015, 54, 55–64. [Google Scholar] [CrossRef]

- Xue, Q.Z. Model for thermal conductivity of carbon nanotube-based composites. Phys. B Condens. Matter 2005, 368, 302–307. [Google Scholar] [CrossRef]

- Arif, M.; Kumam, P.; Kumam, W.; Khan, I.; Ramzan, M. A fractional model of Casson fluid with ramped wall temperature: Engineering applications of engine oil. Comput. Math. Methods 2021, 3, e1162. [Google Scholar] [CrossRef]

- Ali, F.; Aamina, B.; Khan, I.; Sheikh, N.A.; Saqib, M. Magnetohydrodynamic flow of Brinkman-type engine oil based MoS2-nanofluid in a rotating disk with Hall Effect. Int. J. Heat Technol. 2017, 35, 893–902. [Google Scholar]

| Material | |||||

|---|---|---|---|---|---|

| Glycerin | 48 | 0.286 | 1259.9 | 2427 | 6.78 |

| Water (H2O) | 21 | 0.613 | 997 | 4179 | 6.2 |

| SWCNTs | 27 | 6600 | 2600 | 427 | - |

| MWCNTs | 44 | 3000 | 1600 | 796 | - |

| φ | t | Water | Glycerin | ||||||

|---|---|---|---|---|---|---|---|---|---|

| y = 0 | y = 1 | y = 0 | y = 1 | ||||||

| SWCNT | MWCNT | SWCNT | MWCNT | SWCNT | MWCNT | SWCNT | MWCNT | ||

| 0.01 | 0.6 | 0.132 | 0.268 | 0.26 | 0.744 | 0.284 | 0.282 | 0.737 | 0.738 |

| 0.02 | 0.6 | 0.133 | 0.267 | 0.268 | 0.768 | 0.297 | 0.293 | 0.754 | 0.756 |

| 0.03 | 0.6 | 0.135 | 0.267 | 0.277 | 0.792 | 0.312 | 0.306 | 0.772 | 0.775 |

| 0.04 | 0.6 | 0.138 | 0.268 | 0.286 | 0.816 | 0.327 | 0.319 | 0.79 | 0.795 |

| 0.01 | 1.2 | 0.081 | 0.074 | 0.507 | 1.447 | 0.112 | 0.111 | 1.433 | 1.434 |

| 0.02 | 1.2 | 0.081 | 0.076 | 0.523 | 1.489 | 0.131 | 0.129 | 1.465 | 1.465 |

| 0.03 | 1.2 | 0.083 | 0.08 | 0.539 | 1.532 | 0.151 | 0.148 | 1.496 | 1.498 |

| 0.04 | 1.2 | 0.086 | 0.084 | 0.555 | 1.576 | 0.174 | 0.17 | 1.529 | 1.531 |

| φ | t | Water | Glycerin | ||||||

|---|---|---|---|---|---|---|---|---|---|

| y = 0 | y = 1 | y = 0 | y = 1 | ||||||

| SWCNT | MWCNT | SWCNT | MWCNT | SWCNT | MWCNT | SWCNT | MWCNT | ||

| 0.01 | 0.6 | 2.716 | 2.697 | 0.107 | 0.103 | 2.735 | 2.716 | 0.11 | 0.107 |

| 0.02 | 0.6 | 2.917 | 2.882 | 0.15 | 0.142 | 2.953 | 2.918 | 0.158 | 0.15 |

| 0.03 | 0.6 | 3.109 | 3.058 | 0.201 | 0.187 | 3.161 | 3.111 | 0.214 | 0.2 |

| 0.04 | 0.6 | 3.294 | 3.229 | 0.258 | 0.237 | 3.36 | 3.296 | 0.278 | 0.256 |

| 0.01 | 1.2 | 3.786 | 3.759 | 0.293 | 0.285 | 3.812 | 3.786 | 0.301 | 0.939 |

| 0.02 | 1.2 | 4.075 | 4.023 | 0.393 | 0.374 | 4.125 | 4.074 | 0.411 | 0.392 |

| 0.03 | 1.2 | 4.352 | 4.278 | 0.505 | 0.474 | 4.225 | 4.351 | 0.534 | 0.503 |

| 0.04 | 1.2 | 4.62 | 4.525 | 0.627 | 0.583 | 4.713 | 4.62 | 0.67 | 0.624 |

| φ | t | Water | Glycerin | ||||||

|---|---|---|---|---|---|---|---|---|---|

| y = 0 | y = 1 | y = 0 | y = 1 | ||||||

| SWCNT | MWCNT | SWCNT | MWCNT | SWCNT | MWCNT | SWCNT | MWCNT | ||

| 0.01 | 0.6 | 0.131 | 0.126 | 0.69 | 0.69 | 0.136 | 0.095 | 0.689 | 0.694 |

| 0.02 | 0.6 | 0.185 | 0.176 | 0.676 | 0.677 | 0.192 | 0.152 | 0.675 | 0.68 |

| 0.03 | 0.6 | 0.228 | 0.218 | 0.662 | 0.664 | 0.238 | 0.198 | 0.661 | 0.667 |

| 0.04 | 0.6 | 0.265 | 0.253 | 0.648 | 0.651 | 0.275 | 0.237 | 0.647 | 0.654 |

| 0.01 | 1.2 | 0.352 | 0.344 | 1.176 | 1.177 | 0.308 | 0.302 | 1.183 | 1.185 |

| 0.02 | 1.2 | 0.422 | 0.411 | 1.15 | 1.152 | 0.387 | 0.377 | 1.157 | 1.159 |

| 0.03 | 1.2 | 0.479 | 0.465 | 1.125 | 1.128 | 0.45 | 0.439 | 1.131 | 1.134 |

| 0.04 | 1.2 | 0.529 | 0.511 | 1.1 | 1.105 | 0.502 | 0.489 | 1.106 | 1.111 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadiq, K.; Siddique, I.; Awrejcewicz, J.; Bednarek, M. Natural Convection Water/Glycerin–CNT Fractionalized Nanofluid Flow in a Channel with Isothermal and Ramped Conditions. Nanomaterials 2022, 12, 1255. https://doi.org/10.3390/nano12081255

Sadiq K, Siddique I, Awrejcewicz J, Bednarek M. Natural Convection Water/Glycerin–CNT Fractionalized Nanofluid Flow in a Channel with Isothermal and Ramped Conditions. Nanomaterials. 2022; 12(8):1255. https://doi.org/10.3390/nano12081255

Chicago/Turabian StyleSadiq, Kashif, Imran Siddique, Jan Awrejcewicz, and Maksymilian Bednarek. 2022. "Natural Convection Water/Glycerin–CNT Fractionalized Nanofluid Flow in a Channel with Isothermal and Ramped Conditions" Nanomaterials 12, no. 8: 1255. https://doi.org/10.3390/nano12081255

APA StyleSadiq, K., Siddique, I., Awrejcewicz, J., & Bednarek, M. (2022). Natural Convection Water/Glycerin–CNT Fractionalized Nanofluid Flow in a Channel with Isothermal and Ramped Conditions. Nanomaterials, 12(8), 1255. https://doi.org/10.3390/nano12081255