Revisiting the Rate-Dependent Mechanical Response of Typical Silicon Structures via Molecular Dynamics

Abstract

:1. Introduction

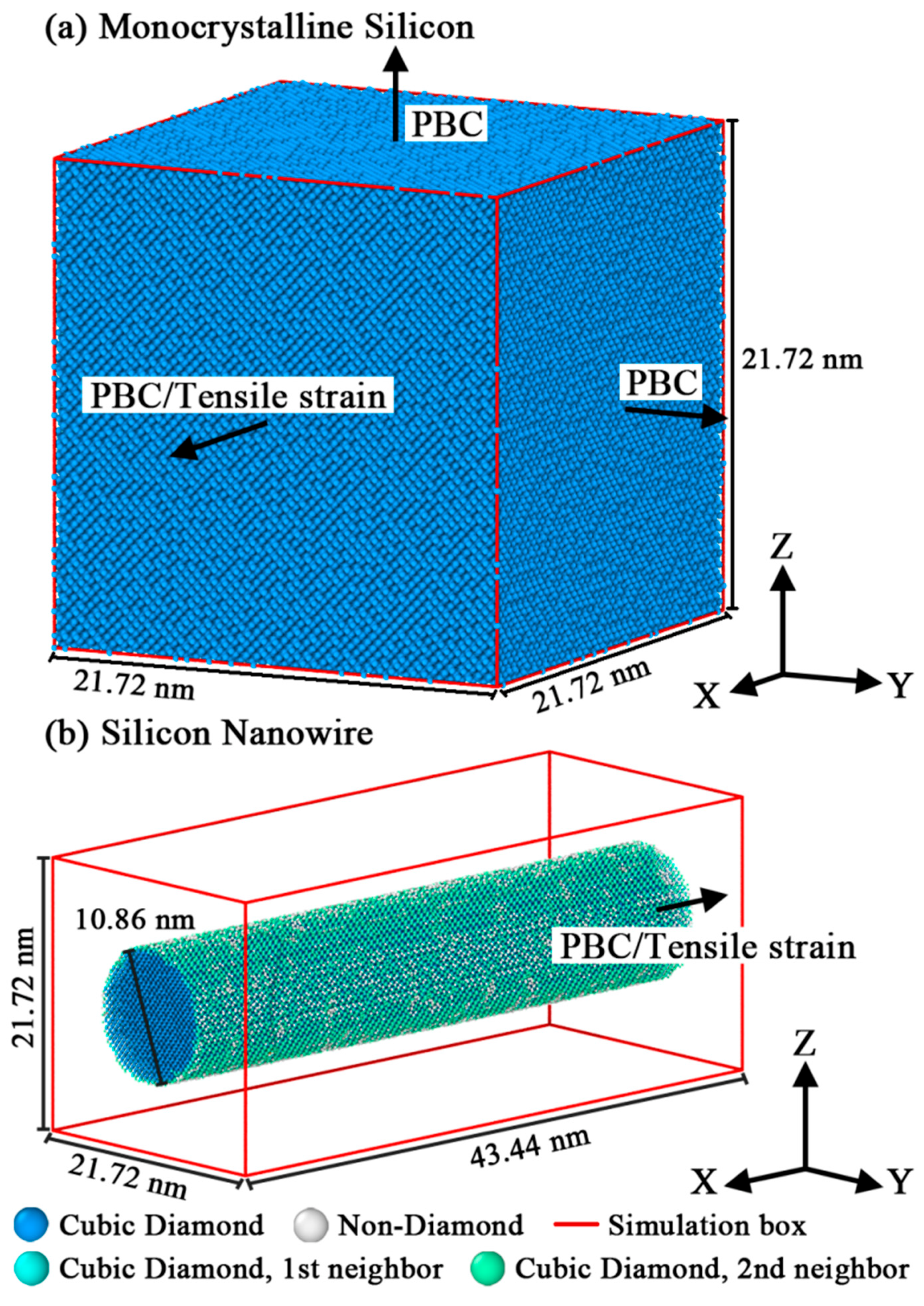

2. Methodologies

2.1. Model and Method

2.2. Relevant Theories

3. Results

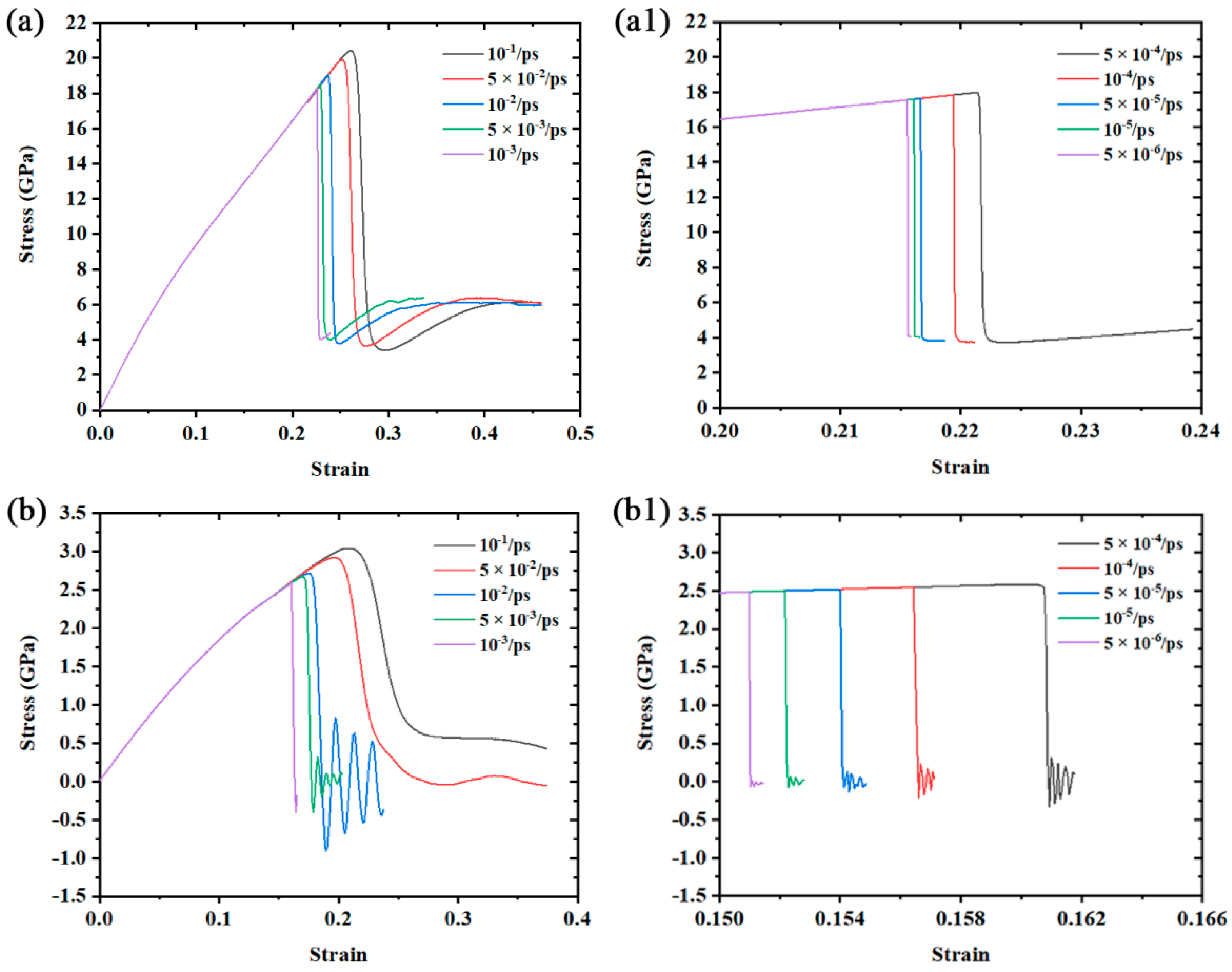

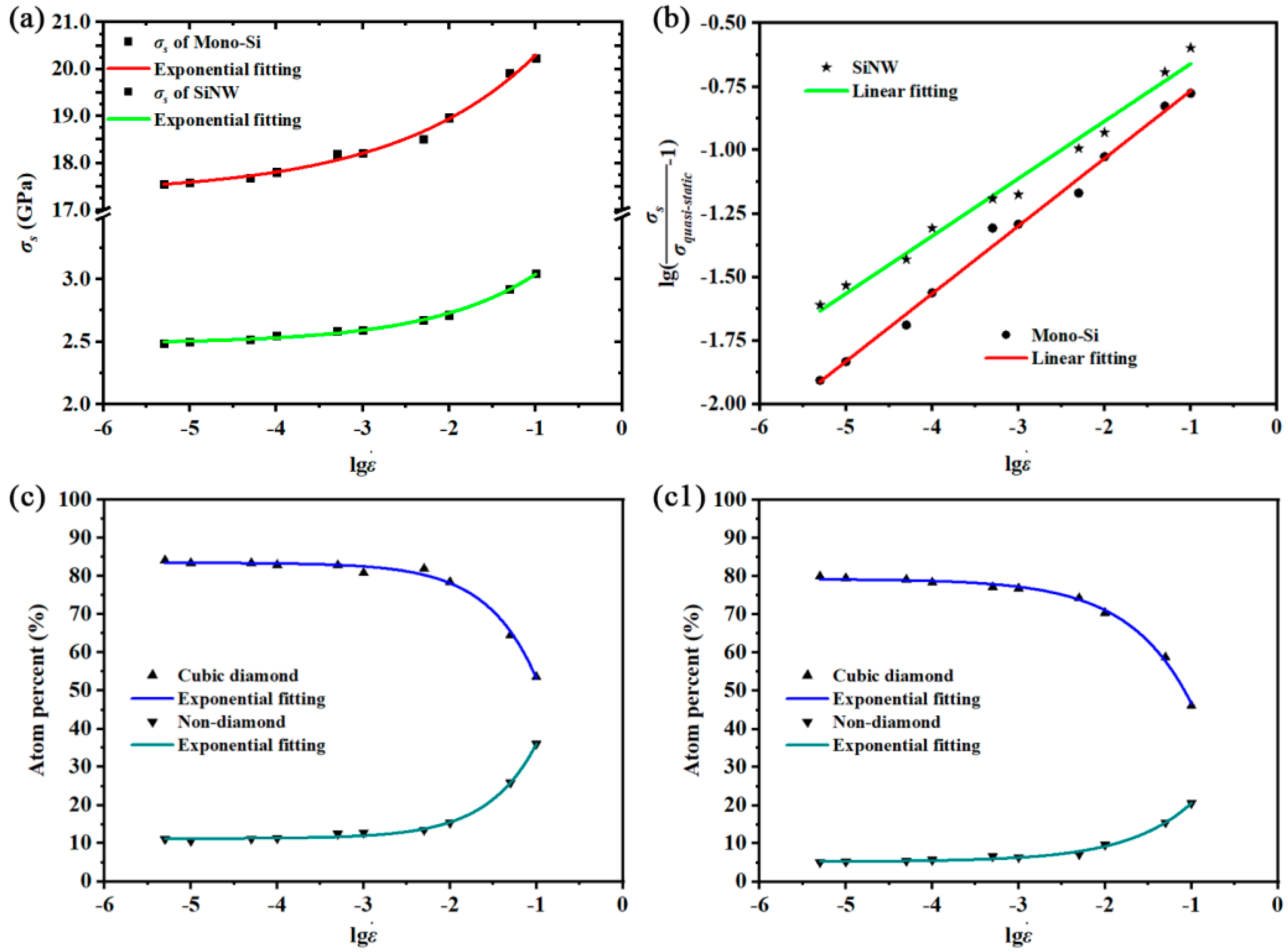

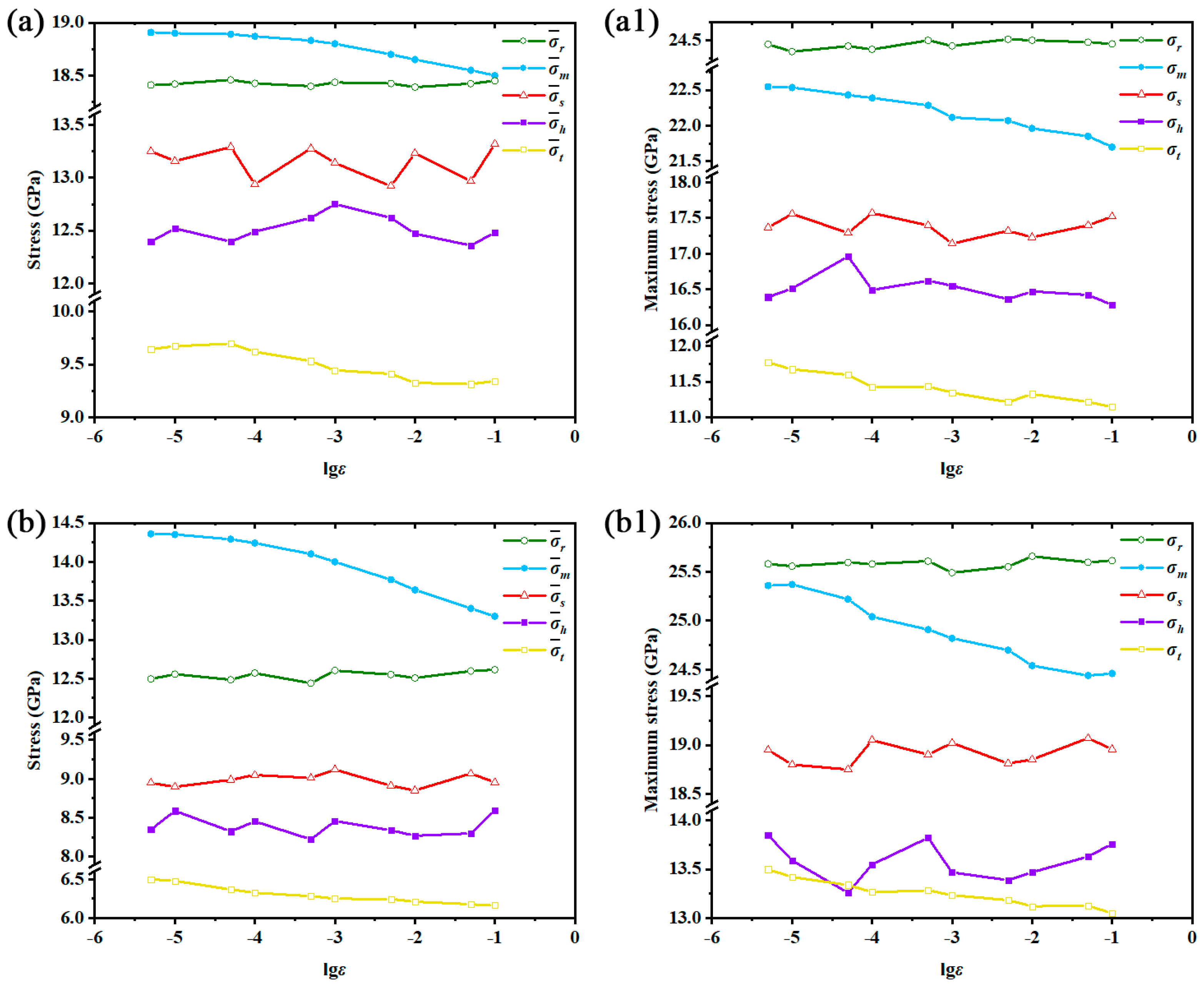

3.1. Strain Rate Sensitivity

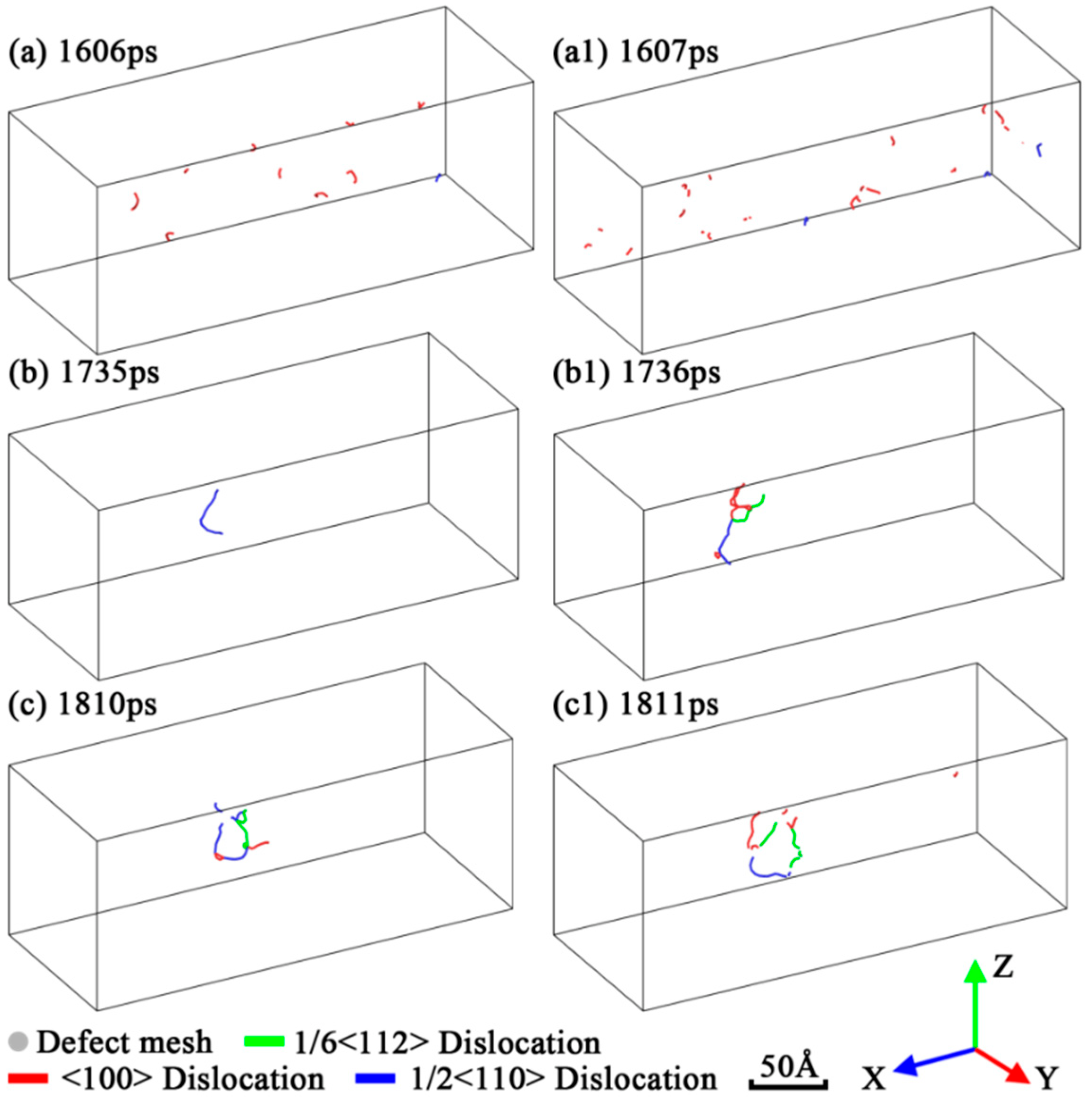

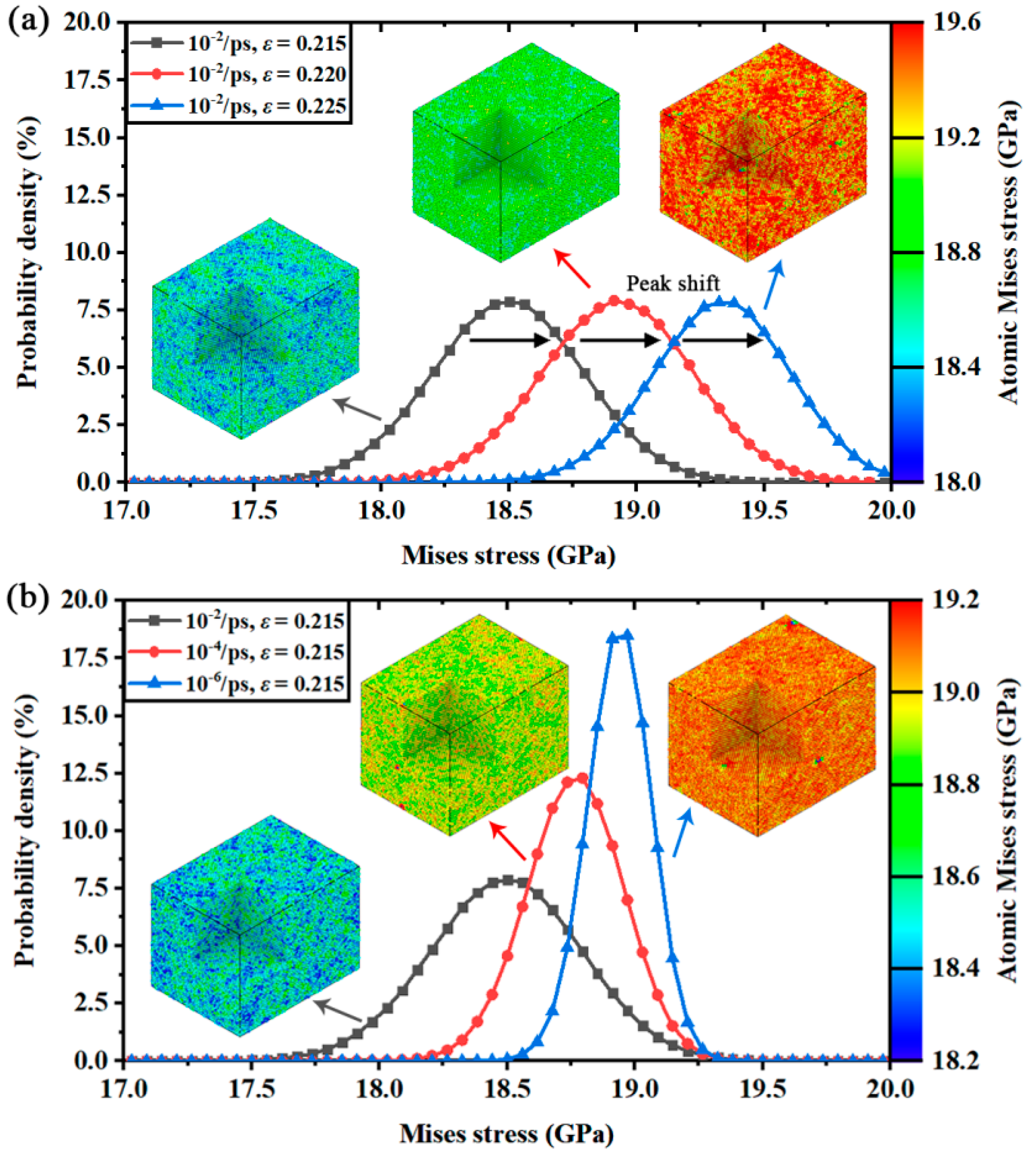

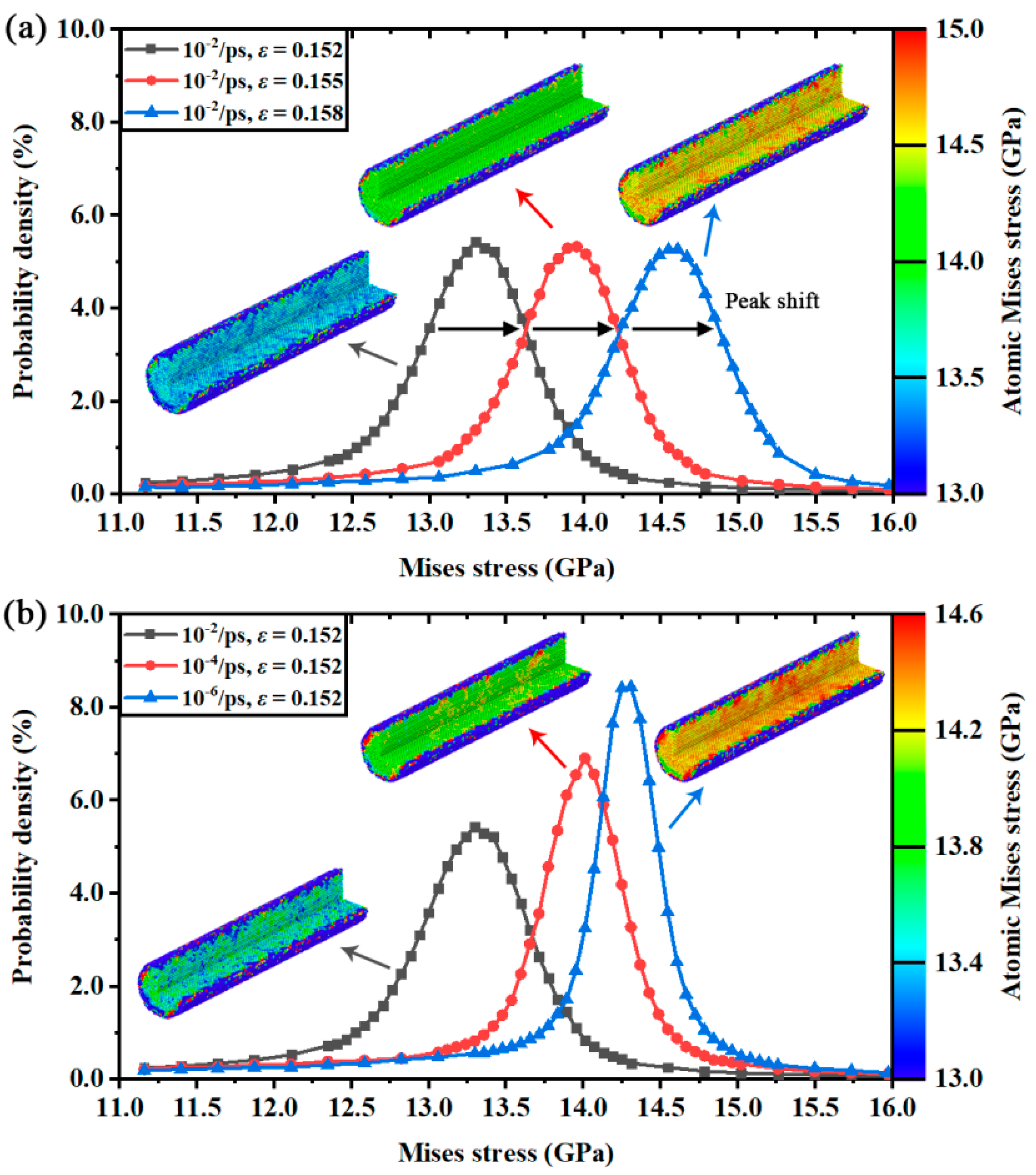

3.2. Rate-Dependent Dislocation Activities

3.3. Comparison of Equivalent Stresses

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Properties | Expt. | QM Methods | Analytical Potentials | ||||||

|---|---|---|---|---|---|---|---|---|---|

| DFT | TB | Tersoff T2 | Tersoff T3 | SW | EDIP | ABOP | DS | ||

| a0 (Å) | 5.429 | 5.400 | 5.429 | 5.432 | 5.432 | 5.431 | 5.430 | 5.429 | 5.432 |

| EC (eV) | −4.63 | − | −4.62 | −4.63 | −4.62 | −4.63 | −4.65 | −4.63 | −4.63 |

| C11 (GPa) | 168 | 159 | 167 | 166 | 143 | 162 | 175 | 167 | 109 |

| C12 (GPa) | 65 | 61 | 67 | 65 | 75 | 82 | 62 | 65 | 93 |

| C44 (GPa) | 80 | 85 | 75 | 77 | 69 | 60 | 71 | 72 | 38 |

| B (GPa) | 99 | 93 | 100 | 98 | 98 | 108 | 99 | 99 | 98 |

| S (GPa) | − | 111 | − | 119 | 119 | 117 | 112 | 111 | 114 |

| EV (eV) | − | 3.17 | 3.68 | 3.72 | 3.70 | 2.82 | 3.22 | 3.20 | − |

| ζ | 0.54 | 0.53 | − | 0.67 | 0.67 | 0.63 | − | 0.52 | 0.91 |

Appendix B

References

- Popel, O.S.; Tarasenko, A.B. Modern development trends in photovoltaics. Therm. Eng. 2021, 68, 807–825. [Google Scholar] [CrossRef]

- Punturat, J.; Tangwarodomnukun, V.; Dumkum, C. Surface characteristics and damage of monocrystalline silicon induced by wire-EDM. Appl. Surf. Sci. 2014, 320, 83–92. [Google Scholar] [CrossRef]

- Ciszek, T.F.; Wang, T.H. Silicon defect and impurity studies using float-zone crystal growth as a tool. J. Cryst. Growth 2002, 237–239, 1685–1691. [Google Scholar] [CrossRef]

- Moore, R.M. Czochralski silicon solar cell modules: Present cost and future prospects. Sol. Cells 1982, 5, 313–329. [Google Scholar] [CrossRef]

- Arif, M.; Rahman, M.; San, W.Y. A state-of-the-art review of ductile cutting of silicon wafers for semiconductor and microelectronics industries. Int. J. Adv. Manuf. Tech. 2012, 63, 481–504. [Google Scholar] [CrossRef]

- Shen, J.Y.; Zhu, X.; Chen, J.B.; Tao, P.; Wu, X. Investigation on the Edge Chipping in Ultrasonic Assisted Sawing of Monocrystalline Silicon. Micromachines 2019, 10, 616. [Google Scholar] [CrossRef] [Green Version]

- Ramachandramoorthy, R.; Schwiedrzik, J.; Petho, L.; Guerra-Nuñez, C.; Frey, D.; Breguet, J.M.; Michler, J. Dynamic plasticity and failure of microscale glass: Rate-dependent ductile-brittle-ductile transition. Nano Lett. 2019, 19, 2350–2359. [Google Scholar] [CrossRef]

- Ramachandramoorthy, R.; Gao, W.; Bernal, R.; Espinosa, H. High strain rate tensile testing of silver nanowires: Rate-dependent brittle-to-ductile transition. Nano Lett. 2016, 16, 255–263. [Google Scholar] [CrossRef]

- Hu, Z.Q.; Shao, J.L.; Xie, Y.F.; Mei, Y. Atomistic study on tensile fracture of densified silica glass and its dependence on strain rate. Chin. Phys. B 2020, 29, 580–587. [Google Scholar] [CrossRef]

- Sansa, M. Frequency fluctuations in silicon nanoresonators. Nat. Nanotechnol. 2016, 11, 552. [Google Scholar] [CrossRef] [Green Version]

- Xu, T.; Wu, W.K.; Luo, X.; Guo, L.J. Plasmonic nanoresonators for high-resolution colour filtering and spectral imaging. Nat. Commun. 2010, 1, 59. [Google Scholar] [CrossRef] [PubMed]

- Darbaniyan, F.; Yan, X.; Sharma, P. An atomistic perspective on the effect of strain rate and lithium fraction on the mechanical behavior of silicon electrodes. J. Appl. Mech. 2020, 87, 031011. [Google Scholar] [CrossRef] [Green Version]

- Pharr, M.; Suo, Z.G.; Vlassak, J.J. Variation of stress with charging rate due to strain-rate sensitivity of silicon electrodes of Li-ion batteries. J. Power Sources 2014, 270, 569–575. [Google Scholar] [CrossRef]

- Steinberg, D.J.; Cochran, S.G.; Guinan, M.W. A constitutive model for metals applicable at high-strain rate. J. Appl. Phys. 1980, 51, 1498–1504. [Google Scholar] [CrossRef] [Green Version]

- Johnson, G.R. A constitutive model and data for materials subjected to large strains, high strain rates, and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, the Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Bodner, S.R.; Partom, Y. Constitutive equations for elastic-viscoplastic strain-hardening materials. J. Appl. Mech. 1975, 42, 385–389. [Google Scholar] [CrossRef]

- Zerilli, F.J.; Armstrong, R.W. Dislocation-mechanics-based constitutive relations for material dynamics calculations. J. Appl. Phys. 1987, 61, 1816–1825. [Google Scholar] [CrossRef] [Green Version]

- Hansen, B.L.; Beyerlein, I.J.; Bronkhorst, C.A.; Cerreta, E.K.; Dennis-Koller, D. A dislocation-based multi-rate single crystal plasticity model. Int. J. Plasticity 2013, 44, 129–146. [Google Scholar] [CrossRef]

- Guo, Y.; Zhuang, Z.; Li, X.Y.; Chen, Z. An investigation of the combined size and rate effects on the mechanical responses of FCC metals. Int. J. Solids Struct. 2007, 44, 1180–1195. [Google Scholar] [CrossRef] [Green Version]

- Kulshreshtha, P.K.; Youssef, K.M.; Rozgonyi, G. Nano-indentation: A tool to investigate crack propagation related phase transitions in PV silicon. Sol. Energy Mater. Sol. Cells 2012, 96, 166–172. [Google Scholar] [CrossRef]

- Wang, F.; Huang, P.; Xu, K. Strain rate sensitivity of nanoindentation creep in polycrystalline Al film on Silicon substrate. Surf. Coat. Tech. 2006, 201, 5216–5218. [Google Scholar] [CrossRef]

- Jarzbek, D.M.; Milczarek, M.; Nosewicz, S.; Bazarnik, P.; Schift, H. Size effects of hardness and strain rate sensitivity in amorphous silicon measured by nanoindentation. Metall. Mater. Trans. A 2020, 51, 1625–1633. [Google Scholar] [CrossRef] [Green Version]

- Yue, Y.; Zheng, K. Strong strain rate effect on the plasticity of amorphous silica nanowires. Appl. Phys. Lett. 2014, 104, 231906. [Google Scholar] [CrossRef]

- Smith, R.F.; Minich, R.W.; Rudd, R.E.; Eggert, J.H.; Collins, G.W. Orientation and rate dependence in high strain-rate compression of single-crystal silicon. Phys. Rev. B 2012, 86, 6536–6541. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Melkote, S.N.; Wang, P.Z.; Saraogi, S. Effect of speed on material removal behavior in scribing of monocrystalline silicon. Precis. Eng. 2020, 66, 315–323. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Cao, P.H.; Deng, B.H.; Huang, L.P.; Shi, Y.F. Strain rate-dependent tensile response of glassy silicon nanowires studied by accelerated atomistic simulations. J. Appl. Phys. 2021, 130, 085105. [Google Scholar] [CrossRef]

- Xu, W.T.; Kim, W.K. Molecular dynamics simulation of the uniaxial tensile test of silicon nanowires using the MEAM potential. Mech. Mater. 2019, 137, 103140. [Google Scholar] [CrossRef]

- Chen, T.; Xu, R.; Li, Q.B. Effect of strain rate on tensile strength of defective silicon nanorods. Acta Mech. Solida Sin. 2015, 28, 133–144. [Google Scholar] [CrossRef]

- Jeng, Y.R.; Tsai, P.C.; Fang, T.H. Effects of temperature, strain rate, and vacancies on tensile and fatigue behaviors of silicon-based nanotubes. Phys. Rev. B 2005, 71, 085411. [Google Scholar] [CrossRef]

- Jing, Y.H.; Meng, Q.Y.; Zhao, W. Molecular dynamics simulations of the tensile and melting behaviours of silicon nanowires. Physica E 2009, 41, 685–689. [Google Scholar] [CrossRef]

- Kang, K.W.; Cai, W. Size and temperature effects on the fracture mechanisms of silicon nanowires: Molecular dynamics simulations. Int. J. Plasticity 2010, 26, 1387–1401. [Google Scholar] [CrossRef]

- Voter, A.F.; Montalenti, F.; Germann, T.C. Extending the time scale in atomistic simulation of materials. Annu. Rev. Mater. Res. 2012, 32, 321–346. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.; Cao, P.; Tao, W.; Sharma, P.; Park, H.S. Atomistic modeling at experimental strain rates and timescales. J. Phys. Appl. Phys. 2016, 49, 493002. [Google Scholar] [CrossRef] [Green Version]

- Kerrache, A.; Mousseau, N.; Lewis, L.J. Crystallization of amorphous silicon induced by mechanical shear deformations. Phys. Rev. B 2011, 84, 014110. [Google Scholar] [CrossRef] [Green Version]

- Li, P.H.; Guo, X.G.; Yuan, S.; Li, M.; Kang, R.K.; Guo, D.M. Effects of grinding speeds on the subsurface damage of single crystal silicon based on molecular dynamics simulations. Appl. Surf. Sci. 2021, 554, 149668. [Google Scholar] [CrossRef]

- Berendsen, H.J.C.; Postma, J.P.M.; VanGunsteren, W.F.; DiNola, A.; Haak, J.R. Molecular dynamics with coupling to an external bath. J. Chem. Phys. 1984, 81, 3684. [Google Scholar] [CrossRef] [Green Version]

- Tersoff, J. Empirical interatomic potential for silicon with improved elastic properties. Phys. Rev. B 1988, 38, 9902. [Google Scholar] [CrossRef]

- Guillonneau, G.; Mieszala, M.; Wehrs, J.; Schwiedrzik, J.; Grop, S.; Frey, D.; Philippe, L.; Breguet, J.M.; Michler, J.; Wheeler, J.M. Nanomechanical testing at high strain rates: New instrumentation for nanoindentation and microcompression. Mater. Design 2018, 148, 39–48. [Google Scholar] [CrossRef]

- Cowper, G.R.; Symonds, P.S. Strain-hardening and strain-rate effects in the impact loading of cantilever beams. Small Bus. Econ. 1957, 31, 235–263. [Google Scholar]

- Song, Y.Q.; Cheng, Y.C.; Wang, X.W. Mechanical meaning of strain-rate sensitivity index and criterion of it’s measurement under tension condition. Chin. J. Mech. Eng. 2000, 36, 6. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with ovito–the open visualization tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Wan, W.; Tang, C.X.; Qiu, A.; Xiang, Y.K. The size effects of point defect on the mechanical properties of monocrystalline silicon: A molecular dynamics study. Materials 2021, 14, 3011. [Google Scholar] [CrossRef] [PubMed]

- Wan, W.; Tang, C.X.; Zhang, J.J.; Zhou, L. General molecular dynamics approach to understand the mechanical anisotropy of monocrystalline silicon under the nanoscale effects of point defect. Nanomaterials 2021, 11, 1965. [Google Scholar] [CrossRef] [PubMed]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 85007. [Google Scholar] [CrossRef]

- Schiøtz, J.; Vegge, T.; Tolla, F.D.D.; Jacobsen, K.W. Atomic-scale simulations of the mechanical deformation of nanocrystalline metals. Phys. Rev. B 1999, 60, 11971–11983. [Google Scholar] [CrossRef] [Green Version]

- Thompson, A.P.; Plimpton, S.J.; Mattson, W. General formulation of pressure and stress tensor for arbitrary many-body interaction potentials under periodic boundary conditions. J. Chem. Phys. 2009, 131, 154107. [Google Scholar] [CrossRef] [Green Version]

- Heyes, D.M. Pressure tensor of partial-charge and point-dipole lattices with bulk and surface geometries. Phys. Rev. B 1994, 49, 755. [Google Scholar] [CrossRef]

- Goel, S.; Luo, X.C.; Agrawal, A.; Reuben, R.L. Diamond machining of silicon: A review of advances in molecular dynamics simulation. Int. J. Mach. Tool. Manu. 2015, 88, 131–164. [Google Scholar] [CrossRef] [Green Version]

- Erhart, P.; Albe, K. Analytical potential for atomistic simulations of silicon, carbon, and silicon carbide. Phys. Rev. B 2005, 71, 035211. [Google Scholar] [CrossRef] [Green Version]

- Balamane, H.; Halicioglu, T.; Tiller, W.A. Comparative study of silicon empirical interatomic potentials. Phys. Rev. B 1992, 46, 2250. [Google Scholar] [CrossRef]

- Nielsen, O.H.; Martin, R.M. Stresses in semiconductors: Ab initio calculations on Si, Ge, and GaAs. Phys. Rev. B 1985, 32, 3792. [Google Scholar] [CrossRef]

- Lenosky, T.J.; Kress, J.D.; Kwon, I.; Voter, A.F.; Edwards, B.; Yang, D.F.; Yang, S.; Adams, J.B. Highly optimized tight-binding model of silicon. Phys. Rev. B 1997, 55, 1528. [Google Scholar] [CrossRef]

- Tersoff, J. Modeling solid-state chemistry: Interatomic potentials for multicomponent systems. Phys. Rev. B 1989, 39, 5566. [Google Scholar] [CrossRef] [PubMed]

- Stillinger, F.H.; Weber, T.A. Computer simulation of local order in condensed phases of silicon. Phys. Rev. B 1985, 31, 5262. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Justo, J.F.; Bazant, M.Z.; Kaxiras, E.; Bulatov, V.V.; Yip, S. Interatomic potential for silicon defects and disordered phases. Phys. Rev. B 1998, 58, 2539. [Google Scholar] [CrossRef] [Green Version]

- Dyson, A.J.; Smith, P.V. Extension of the Brenner Empirical Interatomic Potential to C–Si–H Systems. Surf. Sci. 1996, 355, 140–150. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Wan, W.; Li, Q.; Xiong, Z.; Tang, C.; Zhou, L. Revisiting the Rate-Dependent Mechanical Response of Typical Silicon Structures via Molecular Dynamics. Nanomaterials 2022, 12, 1203. https://doi.org/10.3390/nano12071203

Liu Y, Wan W, Li Q, Xiong Z, Tang C, Zhou L. Revisiting the Rate-Dependent Mechanical Response of Typical Silicon Structures via Molecular Dynamics. Nanomaterials. 2022; 12(7):1203. https://doi.org/10.3390/nano12071203

Chicago/Turabian StyleLiu, Yi, Wei Wan, Quan Li, Zhenkang Xiong, Changxin Tang, and Lang Zhou. 2022. "Revisiting the Rate-Dependent Mechanical Response of Typical Silicon Structures via Molecular Dynamics" Nanomaterials 12, no. 7: 1203. https://doi.org/10.3390/nano12071203

APA StyleLiu, Y., Wan, W., Li, Q., Xiong, Z., Tang, C., & Zhou, L. (2022). Revisiting the Rate-Dependent Mechanical Response of Typical Silicon Structures via Molecular Dynamics. Nanomaterials, 12(7), 1203. https://doi.org/10.3390/nano12071203