Silicon Thermo-Optic Switches with Graphene Heaters Operating at Mid-Infrared Waveband

Abstract

:1. Introduction

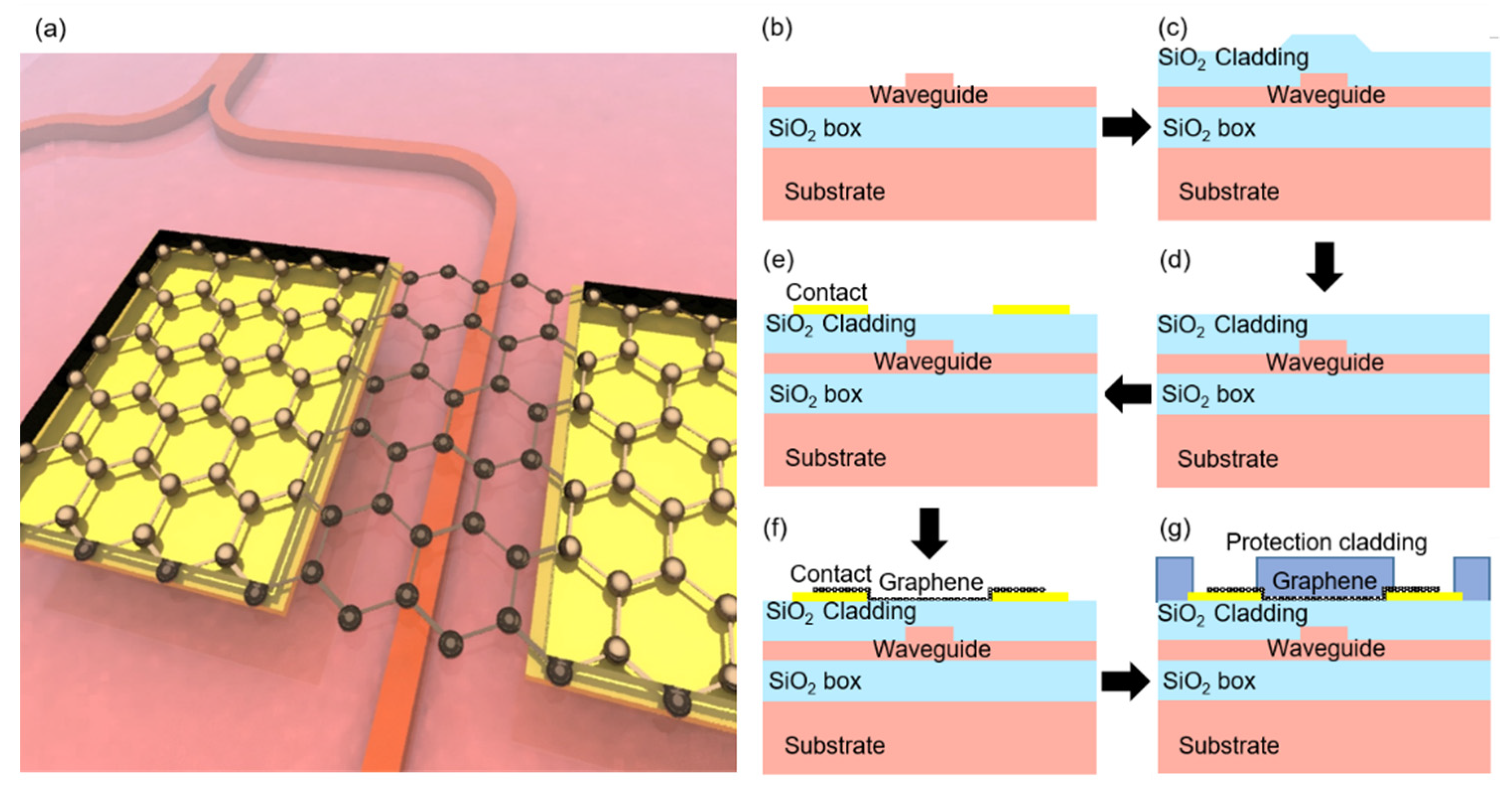

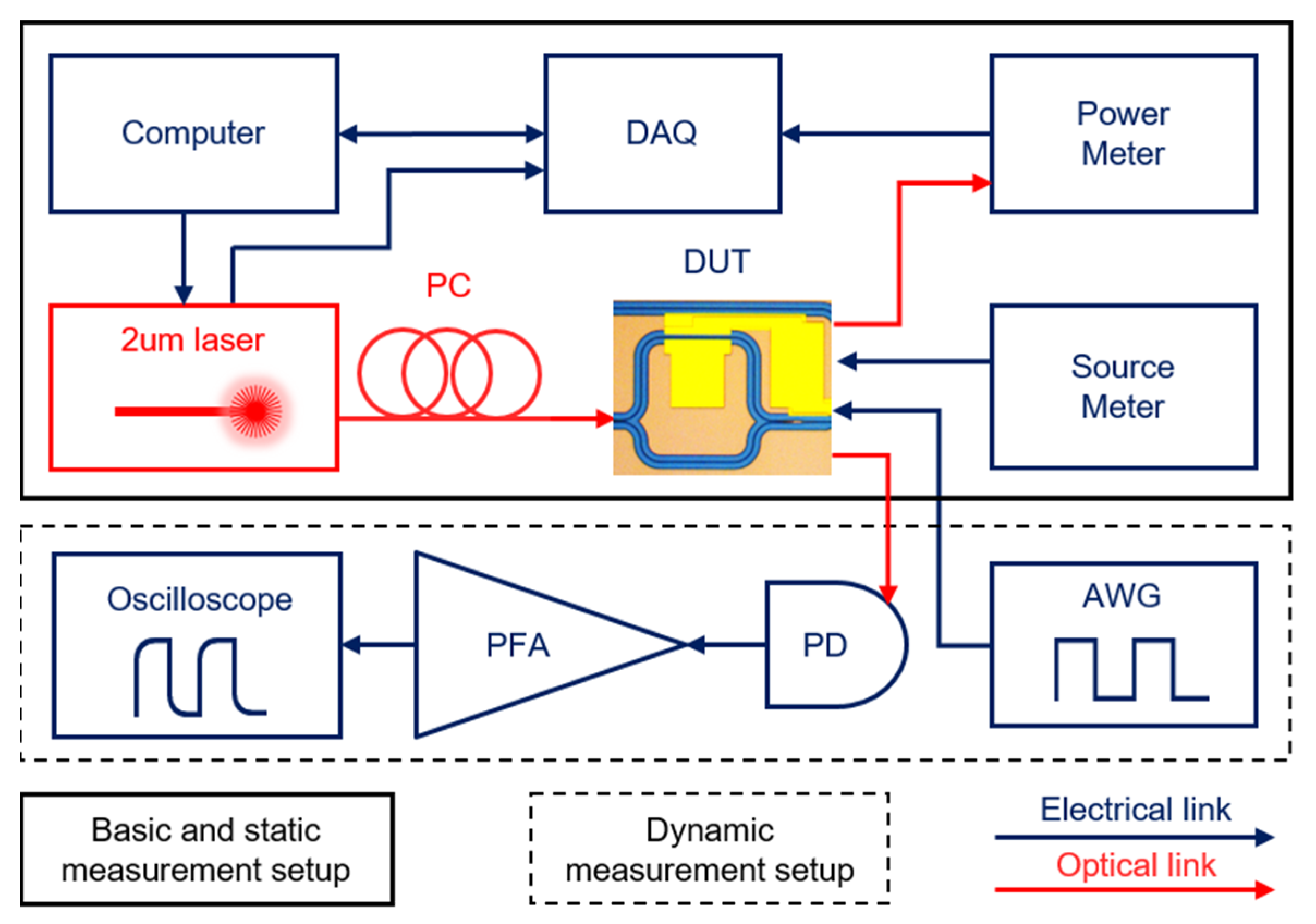

2. Device Fabrication and Characterization Method

3. Results and Discussion

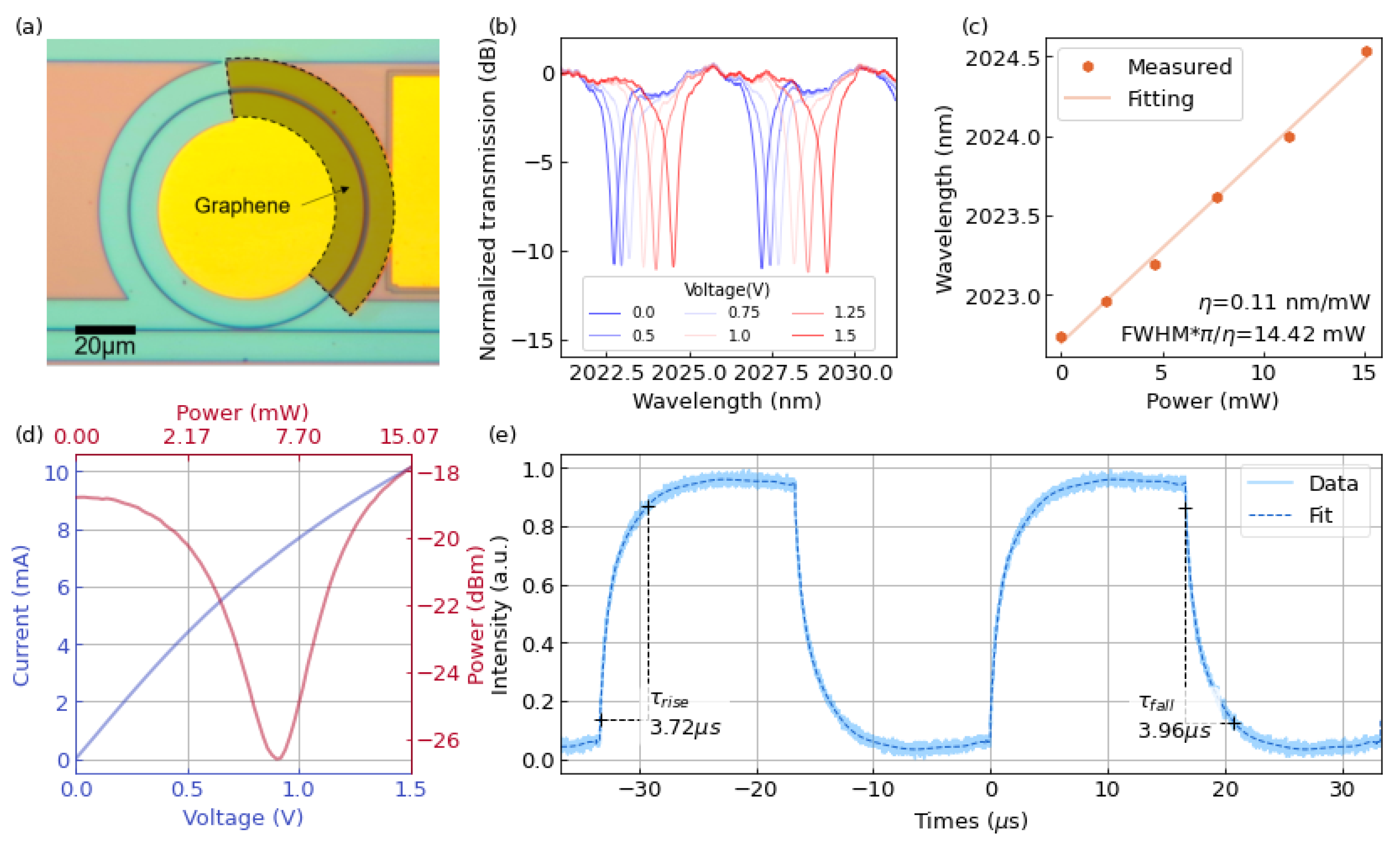

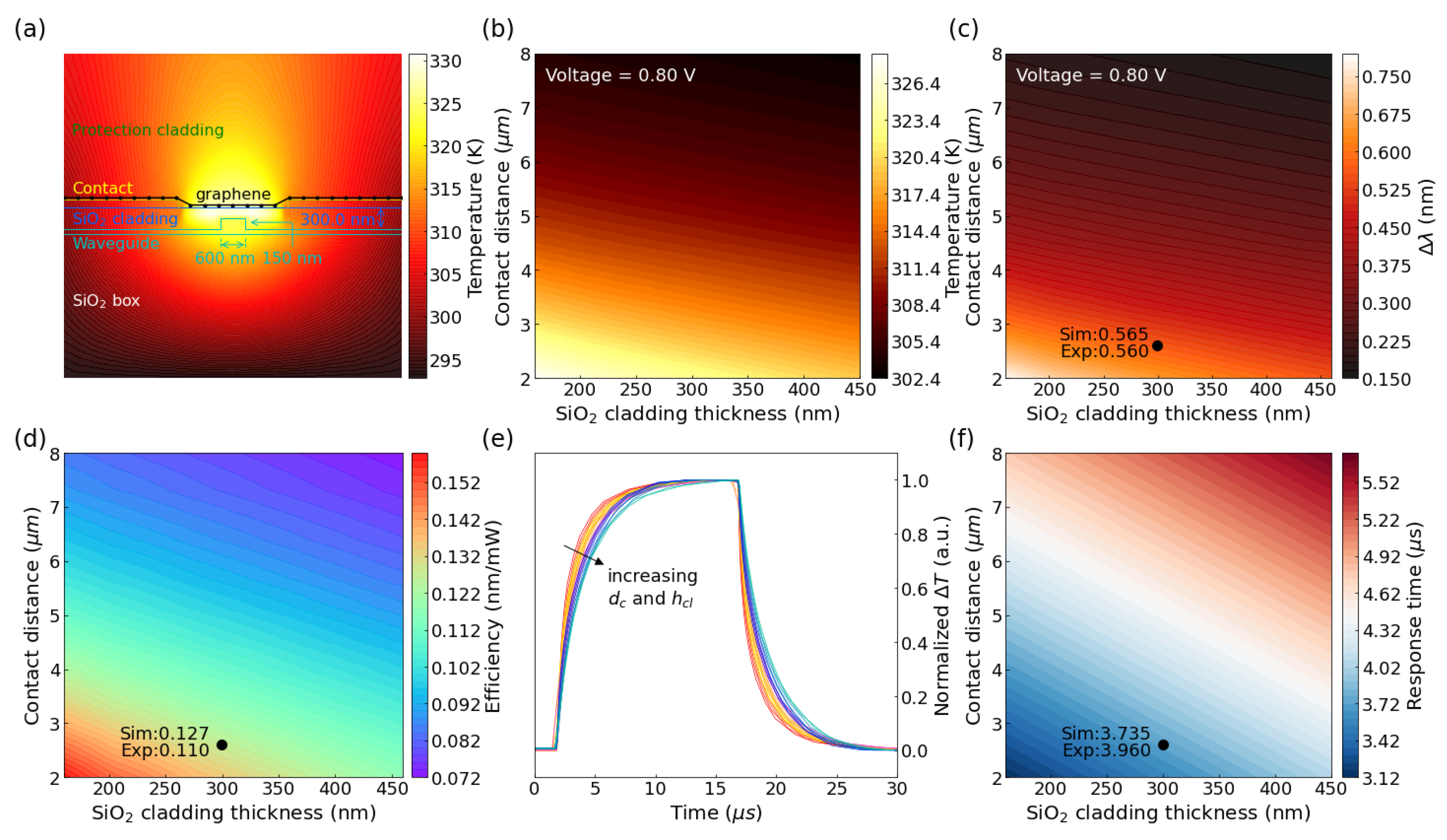

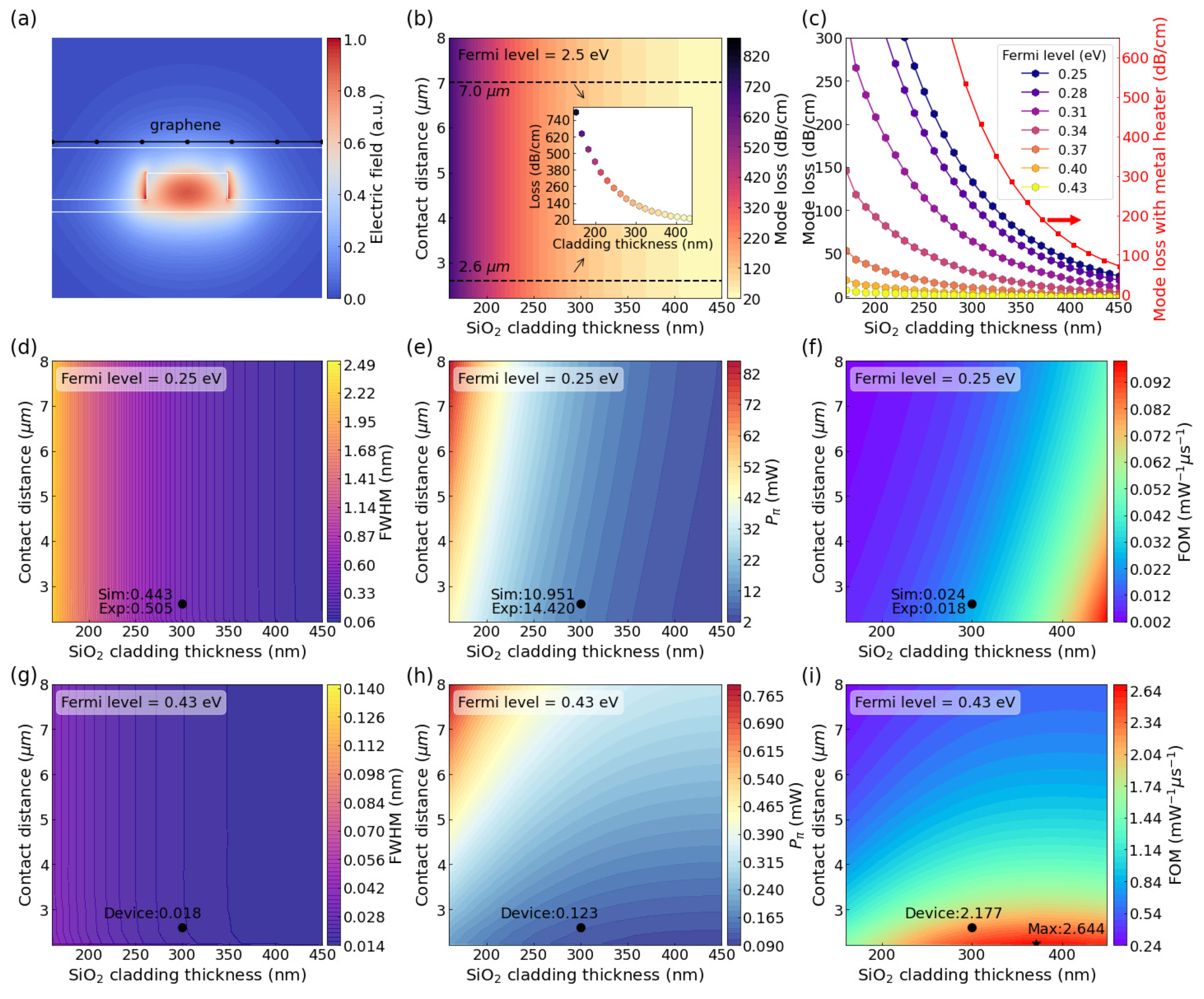

3.1. MRR-Based Switches

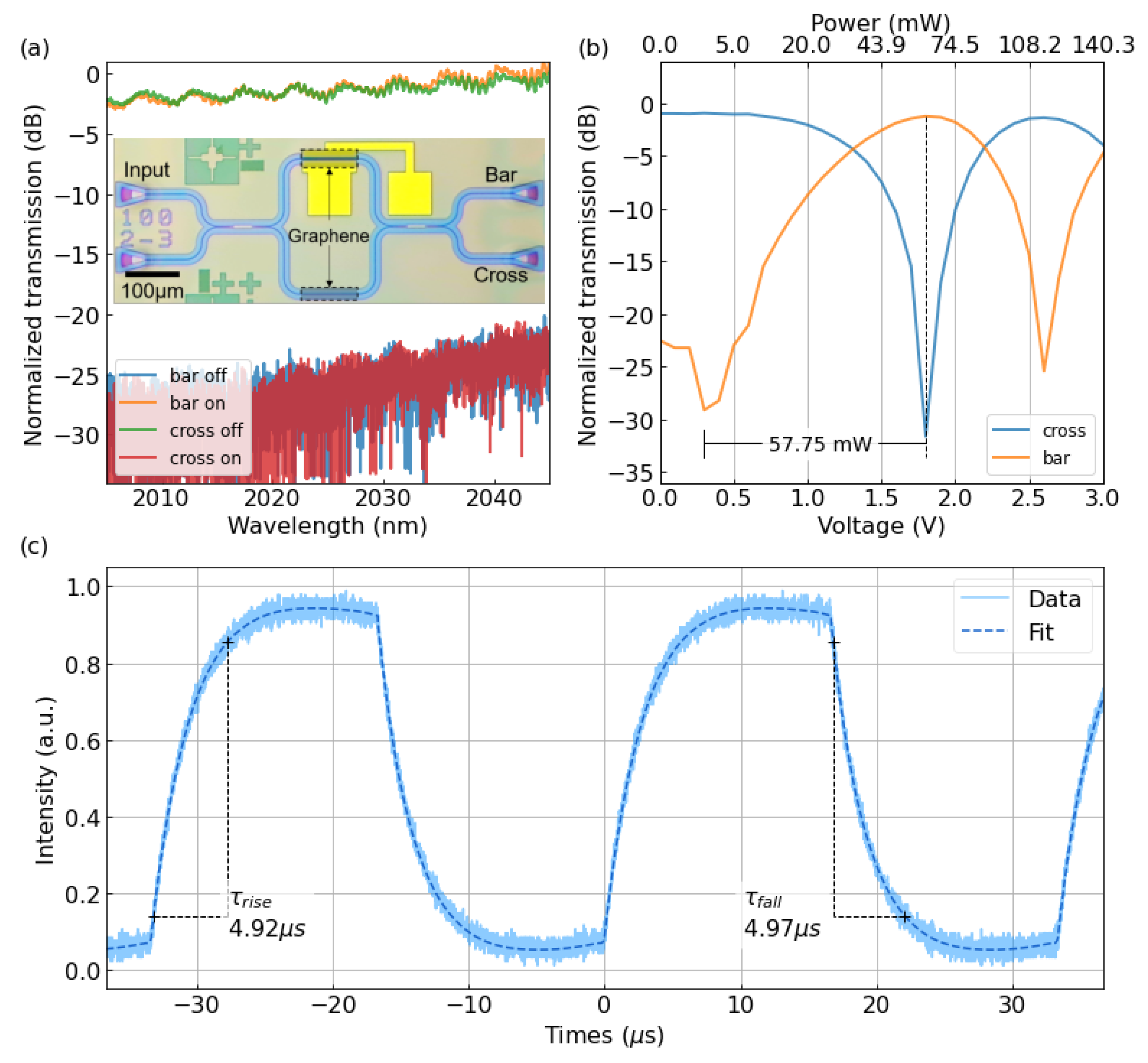

3.2. 2 × 2 MZI Switches

4. Numerical Analysis and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Soref, R. Mid-infrared photonics in silicon and germanium. Nat. Photonics 2010, 4, 495–497. [Google Scholar] [CrossRef]

- Lin, H.T.; Luo, Z.Q.; Gu, T.; Kimerling, L.C.; Wada, K.; Agarwal, A.; Hu, J.J. Mid-infrared integrated photonics on silicon: A perspective. Nanophotonics 2018, 7, 393–420. [Google Scholar] [CrossRef]

- Petersen, C.R.; Moller, U.; Kubat, I.; Zhou, B.; Dupont, S.; Ramsay, J.; Benson, T.; Sujecki, S.; Abdel-Moneim, N.; Tang, Z.; et al. Mid-infrared supercontinuum covering the 1.4–13.3 mu m molecular fingerprint region using ultra-high NA chalcogenide step-index fibre. Nat. Photonics 2014, 8, 830–834. [Google Scholar] [CrossRef]

- Lochbaum, A.; Fedoryshyn, Y.; Dorodnyy, A.; Koch, U.; Hafner, C.; Leuthold, J. On-Chip Narrowband Thermal Emitter for Mid-IR Optical Gas Sensing. ACS Photonics 2017, 4, 1371–1380. [Google Scholar] [CrossRef] [Green Version]

- Rodrigo, D.; Limaj, O.; Janner, D.; Etezadi, D.; Garcia de Abajo, F.J.; Pruneri, V.; Altug, H. Mid-infrared plasmonic biosensing with graphene. Science 2015, 349, 165–168. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, L.; Ding, J.; Zheng, H.; An, S.; Lin, H.; Zheng, B.; Du, Q.; Yin, G.; Michon, J.; Zhang, Y.; et al. Ultra-thin high-efficiency mid-infrared transmissive Huygens meta-optics. Nat. Commun. 2018, 9, 1481. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Titterton, D.H. Development of Infrared Countermeasure Technology and Systems. In Mid-Infrared Semiconductor Optoelectronics; Springer: London, UK, 2006; pp. 635–671. [Google Scholar]

- Fedeli, J.-M.; Nicoletti, S. Mid-Infrared (Mid-IR) Silicon-Based Photonics. Proc. IEEE 2018, 106, 2302–2312. [Google Scholar] [CrossRef]

- Marksteiner, U.; Lemmerz, C.; Lux, O.; Rahm, S.; Reitebuch, O.J.R.S. Calibrations and Wind Observations of an Airborne Direct-Detection Wind LiDAR Supporting ESA’s Aeolus Mission. Remote Sens. 2018, 10, 2056. [Google Scholar] [CrossRef] [Green Version]

- Scholle, K.; Lamrini, S.; Koopmann, P.; Fuhrberg, P. 2 µm Laser Sources and Their Possible Applications. In Frontiers in Guided Wave Optics and Optoelectronics; IntechOpen: London, UK, 2010. [Google Scholar]

- Li, C.; Zhang, M.; Xu, H.; Tan, Y.; Shi, Y.; Dai, D. Subwavelength silicon photonics for on-chip mode-manipulation. PhotoniX 2021, 2, 11. [Google Scholar] [CrossRef]

- Moscoso-Martir, A.; Tabatabaei-Mashayekh, A.; Muller, J.; Nojic, J.; Setter, R.; Nielsen, M.; Sandomirsky, A.; Rockman, S.; Mentovich, E.; Merget, F.; et al. 8-channel WDM silicon photonics transceiver with SOA and semiconductor mode-locked laser. Opt. Express 2018, 26, 25446–25459. [Google Scholar] [CrossRef]

- Wang, R.; Sprengel, S.; Boehm, G.; Baets, R.; Amann, M.-C.; Roelkens, G. Broad wavelength coverage 2.3 μm III-V-on-silicon DFB laser array. Optica 2017, 4, 972–975. [Google Scholar] [CrossRef] [Green Version]

- Volet, N.; Spott, A.; Stanton, E.J.; Davenport, M.L.; Chang, L.; Peters, J.D.; Briles, T.C.; Vurgaftman, I.; Meyer, J.R.; Bowers, J.E. Semiconductor optical amplifiers at 2.0-µm wavelength on silicon. Laser Photonics Rev. 2017, 11, 1600165. [Google Scholar] [CrossRef]

- Miller, S.A.; Yu, M.; Ji, X.; Griffith, A.G.; Cardenas, J.; Gaeta, A.L.; Lipson, M. Low-loss silicon platform for broadband mid-infrared photonics. Optica 2017, 4, 707–712. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.; Li, D.; Yao, Y.; Du, J.; He, Z.; Xu, K. Thermo-optic tunable silicon arrayed waveguide grating at 2-μm wavelength band. IEEE Photonics J. 2020, 12, 1–8. [Google Scholar] [CrossRef]

- Zheng, S.; Huang, M.; Cao, X.; Wang, L.; Ruan, Z.; Shen, L.; Wang, J. Silicon-based four-mode division multiplexing for chip-scale optical data transmission in the 2 μm waveband. Photonics Res. 2019, 7, 1030–1035. [Google Scholar] [CrossRef]

- Xie, H.; Liu, Y.; Sun, W.; Wang, Y.; Xu, K.; Du, J.; He, Z.; Song, Q. Inversely designed 1 × 4 power splitter with arbitrary ratios at 2-μm spectral band. IEEE Photonics J. 2018, 10, 1–6. [Google Scholar] [CrossRef]

- Nedeljkovic, M.; Stankovic, S.; Mitchell, C.J.; Khokhar, A.Z.; Reynolds, S.A.; Thomson, D.J.; Gardes, F.Y.; Littlejohns, C.G.; Reed, G.T.; Mashanovich, G.Z. Mid-Infrared Thermo-Optic Modulators in SoI. IEEE Photonics Technol. Lett. 2014, 26, 1352–1355. [Google Scholar] [CrossRef] [Green Version]

- Malik, A.; Dwivedi, S.; Van Landschoot, L.; Muneeb, M.; Shimura, Y.; Lepage, G.; Van Campenhout, J.; Vanherle, W.; Van Opstal, T.; Loo, R.; et al. Ge-on-Si and Ge-on-SOI thermo-optic phase shifters for the mid-infrared. Opt. Express 2014, 22, 28479–28488. [Google Scholar] [CrossRef]

- Montesinos-Ballester, M.; Vakarin, V.; Ramirez, J.M.; Liu, Q.; Alonso-Ramos, C.; Le Roux, X.; Frigerio, J.; Ballabio, A.; Barzaghi, A.; Deniel, L.; et al. Optical modulation in Ge-rich SiGe waveguides in the mid-infrared wavelength range up to 11 µm. Commun. Mater. 2020, 1, 6. [Google Scholar] [CrossRef]

- Ackert, J.J.; Thomson, D.J.; Shen, L.; Peacock, A.C.; Jessop, P.E.; Reed, G.T.; Mashanovich, G.Z.; Knights, A.P. High-speed detection at two micrometres with monolithic silicon photodiodes. Nat. Photonics 2015, 9, 393–396. [Google Scholar] [CrossRef]

- Rahim, A.; Hermans, A.; Wohlfeil, B.; Petousi, D.; Kuyken, B.; Van Thourhout, D.; Baets, R. Taking silicon photonics modulators to a higher performance level: State-of-the-art and a review of new technologies. Adv. Photonics 2021, 3, 024003. [Google Scholar] [CrossRef]

- Poulton, C.V.; Yaacobi, A.; Cole, D.B.; Byrd, M.J.; Raval, M.; Vermeulen, D.; Watts, M.R. Coherent solid-state LIDAR with silicon photonic optical phased arrays. Opt. Lett. 2017, 42, 4091–4094. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liang, L.; Chen, Y.; Jia, P.; Qin, L.; Liu, Y.; Ning, Y.; Wang, L. Improved performance of optical phased arrays assisted by transparent graphene nanoheaters and air trenches. RSC Adv. 2018, 8, 8442–8449. [Google Scholar] [CrossRef] [Green Version]

- Lavchiev, V.M.; Jakoby, B. Photonics in the Mid-Infrared: Challenges in Single-Chip Integration and Absorption Sensing. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 452–463. [Google Scholar] [CrossRef]

- Shen, Y.; Harris, N.C.; Skirlo, S.; Prabhu, M.; Baehr-Jones, T.; Hochberg, M.; Sun, X.; Zhao, S.; Larochelle, H.; Englund, D.; et al. Deep learning with coherent nanophotonic circuits. Nat. Photonics 2017, 11, 441–446. [Google Scholar] [CrossRef]

- Biberman, A.; Lee, B.G.; Sherwood-Droz, N.; Lipson, M.; Bergman, K. Broadband Operation of Nanophotonic Router for Silicon Photonic Networks-on-Chip. IEEE Photonics Technol. Lett. 2010, 22, 926–928. [Google Scholar] [CrossRef]

- Cao, W.; Hagan, D.; Thomson, D.J.; Nedeljkovic, M.; Littlejohns, C.G.; Knights, A.; Alam, S.-U.; Wang, J.; Gardes, F.; Zhang, W.; et al. High-speed silicon modulators for the 2 μm wavelength band. Optica 2018, 5, 1055–1062. [Google Scholar] [CrossRef]

- Coppola, G. Advance in thermo-optical switches: Principles, materials, design, and device structure. Opt. Eng. 2011, 50, 071112. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Meng, Y.; Xu, K.; Du, J.; Wang, F.; He, Z.; Song, Q. 2-μm Wavelength Grating Coupler, Bent Waveguide, and Tunable Microring on Silicon Photonic MPW. IEEE Photonics Technol. Lett. 2018, 30, 471–474. [Google Scholar] [CrossRef]

- Shen, L.; Huang, M.; Zheng, S.; Yang, L.; Peng, X.; Cao, X.; Li, S.; Wang, J. High-Performance Silicon 2 × 2 Thermo-Optic Switch for the 2-um Wavelength Band. IEEE Photonics J. 2019, 11, 1–6. [Google Scholar]

- Shen, W.; Du, J.; Xu, K.; He, Z. On-Chip Selective Dual-Mode Switch for 2-μm Wavelength High-Speed Optical Interconnection. IEEE Photonics Technol. Lett. 2021, 33, 483–486. [Google Scholar] [CrossRef]

- Dong, P.; Qian, W.; Liang, H.; Shafiiha, R.; Feng, D.; Li, G.; Cunningham, J.E.; Krishnamoorthy, A.V.; Asghari, M. Thermally tunable silicon racetrack resonators with ultralow tuning power. Opt. Express 2010, 18, 20298–20304. [Google Scholar] [CrossRef] [PubMed]

- Englund, D.; Ellis, B.; Edwards, E.; Sarmiento, T.; Harris, J.S.; Miller, D.A.; Vuckovic, J. Electrically controlled modulation in a photonic crystal nanocavity. Opt. Express 2009, 17, 15409–15419. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhong, C.; Ma, H.; Sun, C.; Wei, M.; Ye, Y.; Tang, B.; Zhang, P.; Liu, R.; Li, J.; Li, L.; et al. Fast thermo-optical modulators with doped-silicon heaters operating at 2 μm. Opt. Express 2021, 29, 23508–23516. [Google Scholar] [CrossRef] [PubMed]

- Sturm, J.C.; Reaves, C.M. Fundamental Mechanisms and Doping Effects in Silicon Infrared Absorption for Temperature Measurement by Infrared Transmission. Rapid Therm. Relat. Process. Tech. 1990, 1393, 309–315. [Google Scholar]

- Isenberg, J.; Warta, W. Free carrier absorption in heavily doped silicon layers. Appl. Phys. Lett. 2004, 84, 2265–2267. [Google Scholar] [CrossRef]

- Schmid, P.E. Optical absorption in heavily doped silicon. Phys. Rev. B 1981, 23, 5531–5536. [Google Scholar] [CrossRef]

- Nedeljkovic, M.; Soref, R.; Mashanovich, G.Z. Free-Carrier Electrorefraction and Electroabsorption Modulation Predictions for Silicon Over the 1-14-mu m Infrared Wavelength Range. IEEE Photonics J. 2011, 3, 1171–1180. [Google Scholar] [CrossRef]

- Wu, J.; Ma, H.; Yin, P.; Ge, Y.; Zhang, Y.; Li, L.; Zhang, H.; Lin, H. Two-Dimensional Materials for Integrated Photonics: Recent Advances and Future Challenges. Small Sci. 2021, 1, 2000053. [Google Scholar] [CrossRef]

- Wu, J.; Wei, M.; Mu, J.; Ma, H.; Zhong, C.; Ye, Y.; Sun, C.; Tang, B.; Wang, L.; Li, J.; et al. High-Performance Waveguide-Integrated Bi2O2Se Photodetector for Si Photonic Integrated Circuits. ACS Nano 2021, 15, 15982–15991. [Google Scholar] [CrossRef]

- Fang, Y.; Ge, Y.; Wang, C.; Zhang, H. Mid-Infrared Photonics Using 2D Materials: Status and Challenges. Laser Photonics Rev. 2019, 14, 1900098. [Google Scholar] [CrossRef]

- Zhong, C.; Li, J.; Lin, H. Graphene-based all-optical modulators. Front. Optoelectron. 2020, 13, 114–128. [Google Scholar] [CrossRef]

- Flory, N.; Ma, P.; Salamin, Y.; Emboras, A.; Taniguchi, T.; Watanabe, K.; Leuthold, J.; Novotny, L. Waveguide-integrated van der Waals heterostructure photodetector at telecom wavelengths with high speed and high responsivity. Nat. Nanotechnol. 2020, 15, 118–124. [Google Scholar] [CrossRef] [PubMed]

- Yao, B.; Huang, S.W.; Liu, Y.; Vinod, A.K.; Choi, C.; Hoff, M.; Li, Y.; Yu, M.; Feng, Z.; Kwong, D.L.; et al. Gate-tunable frequency combs in graphene-nitride microresonators. Nature 2018, 558, 410–414. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xia, F.; Wang, H.; Xiao, D.; Dubey, M.; Ramasubramaniam, A. Two-dimensional material nanophotonics. Nat. Photonics 2014, 8, 899–907. [Google Scholar] [CrossRef]

- Yu, L.; Yin, Y.; Shi, Y.; Dai, D.; He, S. Thermally tunable silicon photonic microdisk resonator with transparent graphene nanoheaters. Optica 2016, 3, 159–166. [Google Scholar] [CrossRef]

- Liu, M.; Yin, X.; Ulin Avila, E.; Geng, B.; Zentgraf, T.; Ju, L.; Wang, F.; Zhang, X. A graphene-based broadband optical modulator. Nature 2011, 474, 64–67. [Google Scholar] [CrossRef]

- Song, Q.Q.; Chen, K.X.; Hu, Z.F. Low-Power Broadband Thermo-Optic Switch With Weak Polarization Dependence Using a Segmented Graphene Heater. IEEE J. Lightwave Technol. 2020, 38, 1358–1364. [Google Scholar] [CrossRef]

- Sun, Y.; Cao, Y.; Yi, Y.; Tian, L.; Zheng, Y.; Zheng, J.; Wang, F.; Zhang, D. A low-power consumption MZI thermal optical switch with a graphene-assisted heating layer and air trench. RSC Adv. 2017, 7, 39922–39927. [Google Scholar] [CrossRef] [Green Version]

- Lin, H.; Song, Y.; Huang, Y.; Kita, D.; Deckoff-Jones, S.; Wang, K.; Li, L.; Li, J.; Zheng, H.; Luo, Z.; et al. Chalcogenide glass-on-graphene photonics. Nat. Photonics 2017, 11, 798–805. [Google Scholar] [CrossRef] [Green Version]

- Gan, S.; Cheng, C.; Zhan, Y.; Huang, B.; Gan, X.; Li, S.; Lin, S.; Li, X.; Zhao, J.; Chen, H.; et al. A highly efficient thermo-optic microring modulator assisted by graphene. Nanoscale 2015, 7, 20249–20255. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.H.; He, Y.; Zhang, Y.; An, S.H.; Zhu, Q.M.; Li, X.F.; Su, Y.K. Ultracompact and low-power-consumption silicon thermo-optic switch for high-speed data. Nanophotonics 2021, 10, 937–945. [Google Scholar] [CrossRef]

- Yan, S.; Zhu, X.; Frandsen, L.H.; Xiao, S.; Mortensen, N.A.; Dong, J.; Ding, Y. Slow-light-enhanced energy efficiency for graphene microheaters on silicon photonic crystal waveguides. Nat. Commun. 2017, 8, 14411. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Huang, Y.; Song, Y.; Li, L.; Zheng, H.; Wang, H.; Gu, T.; Richardson, K.; Kong, J.; Hu, J.; et al. High-performance graphene-integrated thermo-optic switch: Design and experimental validation [Invited]. Opt. Mater. Express 2020, 10, 387–396. [Google Scholar] [CrossRef]

- Schall, D.; Mohsin, M.; Sagade, A.A.; Otto, M.; Chmielak, B.; Suckow, S.; Giesecke, A.L.; Neumaier, D.; Kurz, H. Infrared transparent graphene heater for silicon photonic integrated circuits. Opt. Express 2016, 24, 7871–7878. [Google Scholar] [CrossRef] [PubMed]

- Ríos, C.; Zhang, Y.; Shalaginov, M.Y.; Deckoff-Jones, S.; Wang, H.; An, S.; Zhang, H.; Kang, M.; Richardson, K.A.; Roberts, C.; et al. Multi-Level Electro-Thermal Switching of Optical Phase-Change Materials Using Graphene. Adv. Photonics Res. 2020, 2, 2000034. [Google Scholar] [CrossRef]

- Mashanovich, G.; Cao, W.; Qu, Z.; Li, K.; Thomson, D.; Nedeljkovic, M.; Hagan, D.; Knights, A. Mid-Infrared Silicon Photonics for Communications. IJEEC—Int. J. Electr. Eng. Comput. 2019, 3, 32–36. [Google Scholar] [CrossRef]

- Gunning, F.; Corbett, B. Time to Open the 2-μm Window? Opt. Photonics News 2019, 30, 42–47. [Google Scholar] [CrossRef]

- Chralyvy, A. Plenary paper: The coming capacity crunch. In Proceedings of the 2009 35th European Conference on Optical Communication, Vienna, Austria, 20–24 September 2009; p. 1. [Google Scholar]

- Wu, M.; Zhang, Z.; Xu, X.; Zhang, Z.; Duan, Y.; Dong, J.; Qiao, R.; You, S.; Wang, L.; Qi, J.; et al. Seeded growth of large single-crystal copper foils with high-index facets. Nature 2020, 581, 406–410. [Google Scholar] [CrossRef]

- Ullah, S.; Yang, X.; Ta, H.Q.; Hasan, M.; Bachmatiuk, A.; Tokarska, K.; Trzebicka, B.; Fu, L.; Rummeli, M.H. Graphene transfer methods: A review. Nano Res. 2021, 14, 3756–3772. [Google Scholar] [CrossRef]

- Jayatilleka, H.; Shoman, H.; Chrostowski, L.; Shekhar, S. Photoconductive heaters enable control of large-scale silicon photonic ring resonator circuits. Optica 2019, 6, 84–91. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.; Yang, H.; Tang, B.; Wei, M.; Li, J.; Wu, J.; Zhang, P.; Sun, C.; Li, L.; Lin, H. Passive devices at 2 µm wavelength on 200 mm CMOS-compatible silicon photonics platform [Invited]. Chin. Opt. Lett. 2021, 19, 071301. [Google Scholar] [CrossRef]

- Hu, J. Planar Chalcogenide Glass Materials and Devices. Doctoral Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2009. [Google Scholar]

- Lin, H.; Yi, Z.; Hu, J. Double resonance 1-D photonic crystal cavities for single-molecule mid-infrared photothermal spectroscopy: Theory and design. Opt. Lett. 2012, 37, 1304–1306. [Google Scholar] [CrossRef] [PubMed]

- Atad-Ettedgui, E.; Frey, B.J.; Antebi, J.; Leviton, D.B.; Madison, T.J.; Lemke, D. Temperature-dependent refractive index of silicon and germanium. Optomech. Technol. Astron. 2006, 6273, 62732J. [Google Scholar]

- Tan, C.Z.; Arndt, J. Temperature dependence of refractive index of glassy SiO2 in the infrared wavelength range. J. Phys. Chem. Solids 2000, 61, 1315–1320. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Y.; Zhu, D. Chemical doping of graphene. J. Mater. Chem. 2011, 21, 3335–3345. [Google Scholar] [CrossRef]

- Wang, L.; Meric, I.; Huang, P.Y.; Gao, Q.; Gao, Y.; Tran, H.; Taniguchi, T.; Watanabe, K.; Campos, L.M.; Muller, D.A.; et al. One-Dimensional Electrical Contact to a Two-Dimensional Material. Science 2013, 342, 614–617. [Google Scholar] [CrossRef] [Green Version]

| Device | Heater | η (nm/mW) | τ (μs) Rise/Fall | Pπ (mW) | FOM (mW−1μs−1) | Year [Ref.] |

|---|---|---|---|---|---|---|

| MZI | TiN | N/A | 15/15 | 32.3 | 0.002 | 2019 [32] |

| MZI | TiN | N/A | 9.2/13.2 | 19.2 | 0.004 | 2021 [33] |

| MZI | Doped silicon | 0.17 | 3.49/3.46 | 25.21 | 0.011 | 2021 [36] |

| MRR | Doped silicon | 0.1 | 3.65/3.70 | 6.66 | 0.0405 | 2021 [36] |

| MRR | graphene | 0.11 | 3.72/3.96 | 14.42 | 0.0175 | this work |

| MZI | graphene | N/A | 4.92/4.97 | 57.75 | 0.003 | this work |

| MRR | graphene | 0.127 | 3.735/- | 0.123 | 2.644 | Prediction |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, C.; Zhang, Z.; Ma, H.; Wei, M.; Ye, Y.; Wu, J.; Tang, B.; Zhang, P.; Liu, R.; Li, J.; et al. Silicon Thermo-Optic Switches with Graphene Heaters Operating at Mid-Infrared Waveband. Nanomaterials 2022, 12, 1083. https://doi.org/10.3390/nano12071083

Zhong C, Zhang Z, Ma H, Wei M, Ye Y, Wu J, Tang B, Zhang P, Liu R, Li J, et al. Silicon Thermo-Optic Switches with Graphene Heaters Operating at Mid-Infrared Waveband. Nanomaterials. 2022; 12(7):1083. https://doi.org/10.3390/nano12071083

Chicago/Turabian StyleZhong, Chuyu, Zhibin Zhang, Hui Ma, Maoliang Wei, Yuting Ye, Jianghong Wu, Bo Tang, Peng Zhang, Ruonan Liu, Junying Li, and et al. 2022. "Silicon Thermo-Optic Switches with Graphene Heaters Operating at Mid-Infrared Waveband" Nanomaterials 12, no. 7: 1083. https://doi.org/10.3390/nano12071083

APA StyleZhong, C., Zhang, Z., Ma, H., Wei, M., Ye, Y., Wu, J., Tang, B., Zhang, P., Liu, R., Li, J., Li, L., Hu, X., Liu, K., & Lin, H. (2022). Silicon Thermo-Optic Switches with Graphene Heaters Operating at Mid-Infrared Waveband. Nanomaterials, 12(7), 1083. https://doi.org/10.3390/nano12071083