Dispersion of Multi-Walled Carbon Nanotubes into White Cement Mortars: The Effect of Concentration and Surfactants

Abstract

:1. Introduction

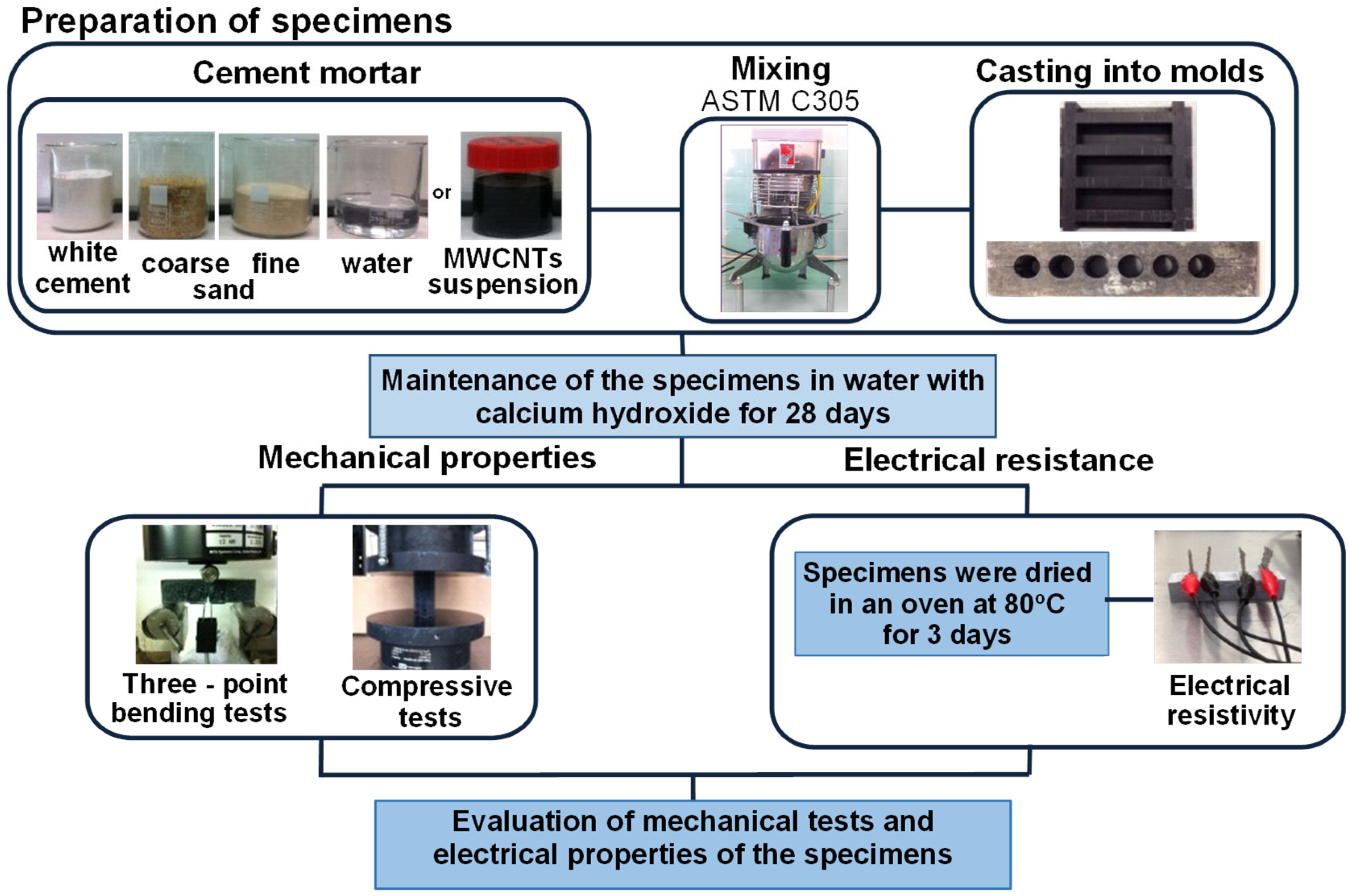

2. Materials and Methods

2.1. Materials

2.2. Preparation of Aqueous MWCNT Dispersions

2.3. Preparation of Cement Mortar Specimens

2.4. Electrical Resistance Measurements and Mechanical Testing

3. Results and Discussion

3.1. Effect of the Surfactant Type

3.2. Effect of the Superplasticizer Concentration

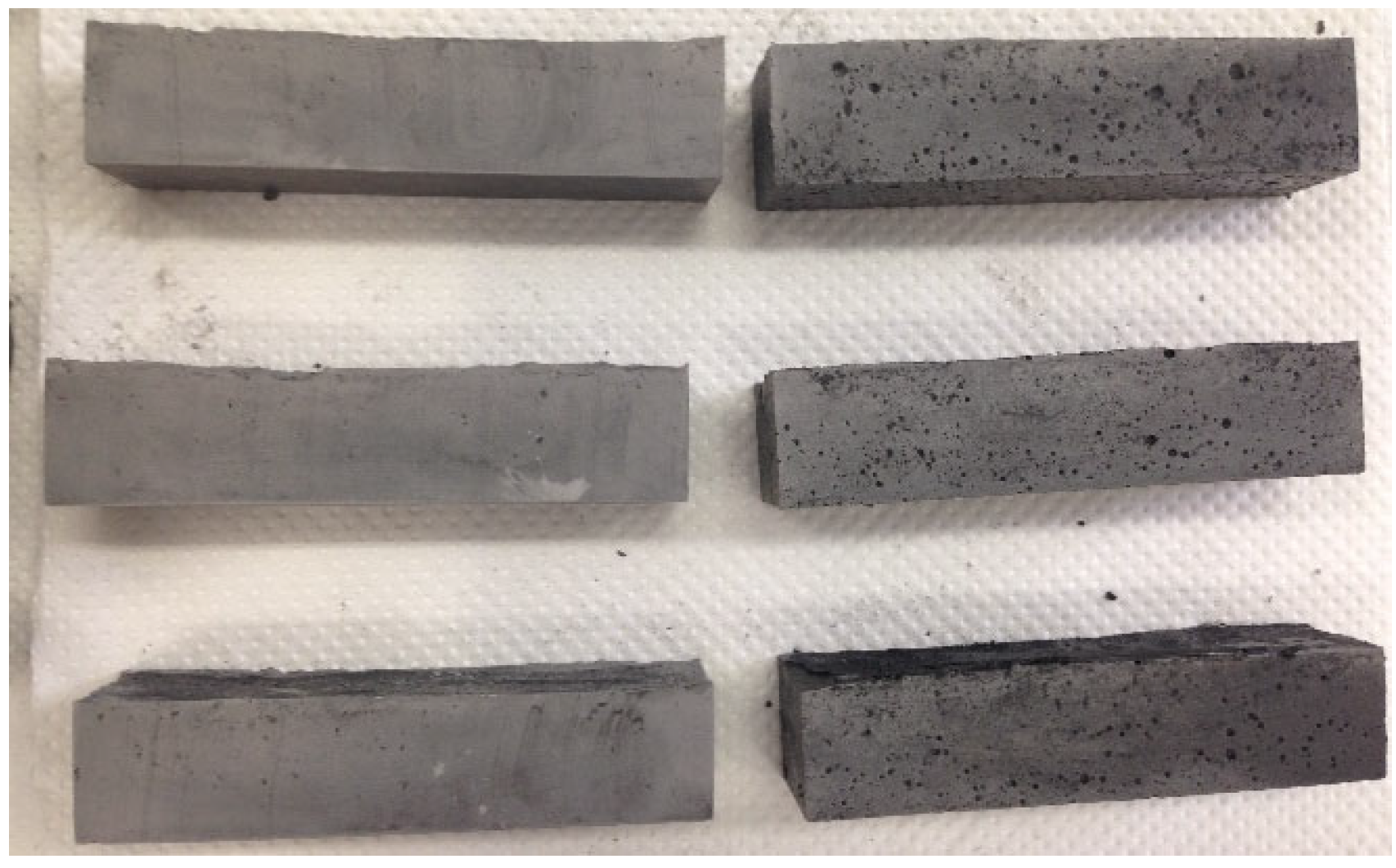

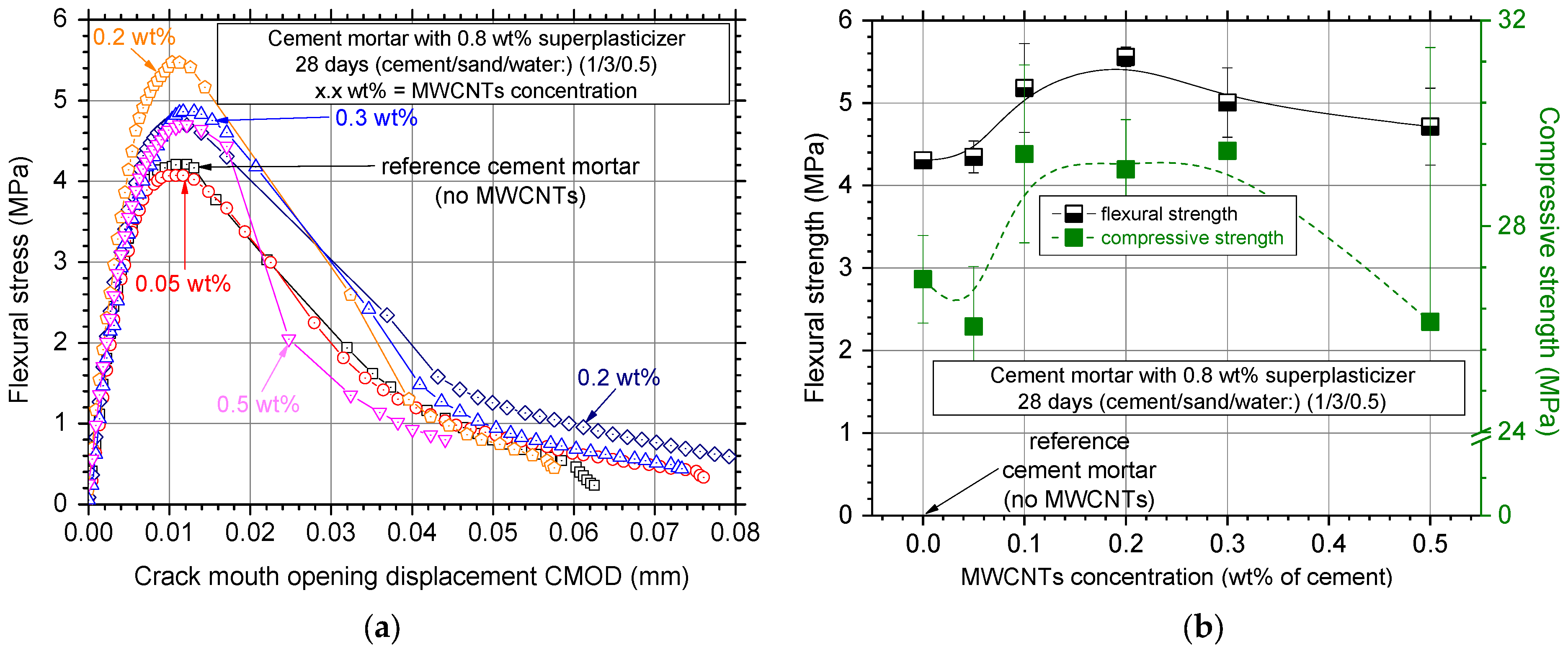

3.3. Effect of MWCNT Concentration

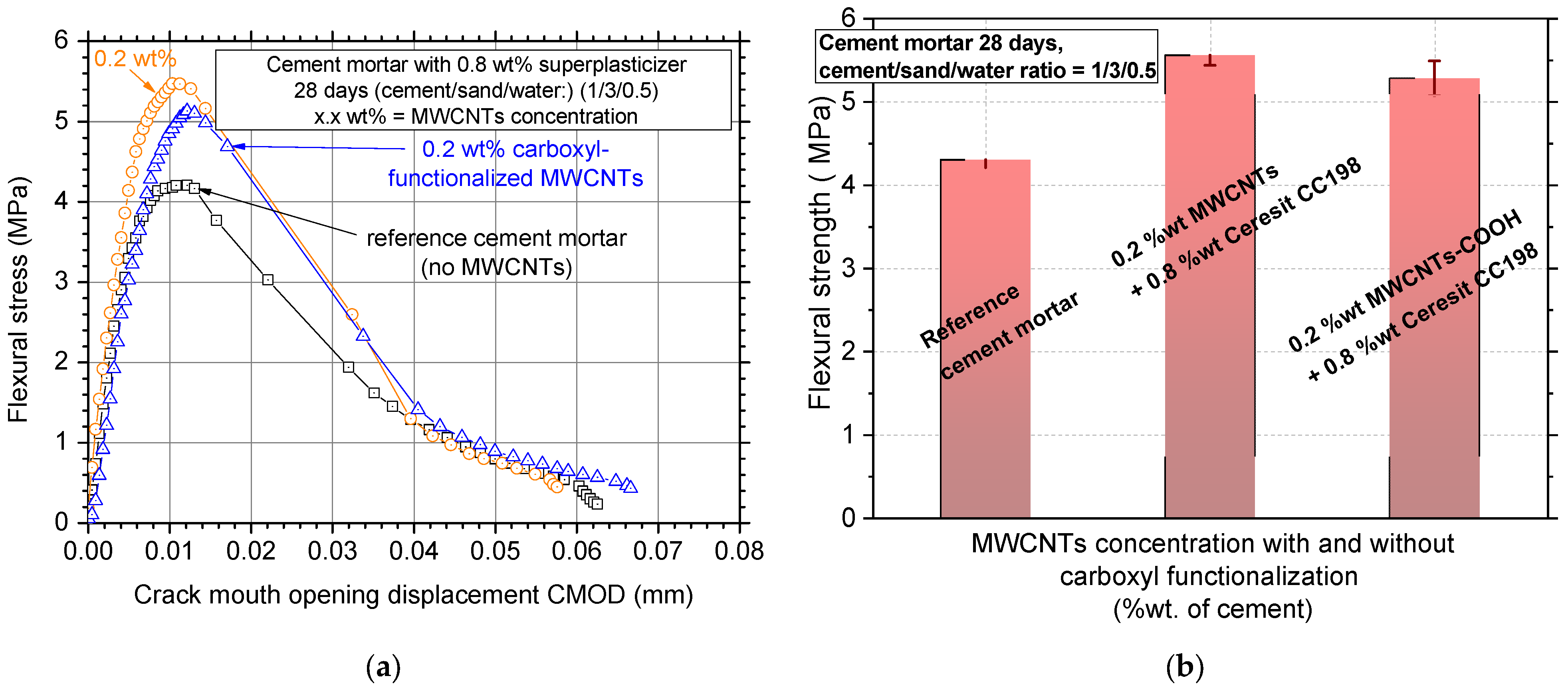

3.4. Effect of Carboxyl Functionalization

4. Conclusions

- The surfactants sodium dodecylbenzene sulfonate (SDBS) and Triton X-100 proved incompatible with cement-based composites. The surfactants caused a slight decrease in the electrical conductivity (by an average of −10%) of the matrix; however, the mechanical properties were essentially decreased by an average of 60%.

- The superplasticizer Ceresit CC 198 was found to be appropriate for the satisfactory dispersion of MWCNTs in the white mortar cementitious matrix.

- The optimal superplasticizer concentration was determined to be around 0.8 wt% of cement as it led to the electrical resistivity decrease and increase in both the flexural and compressive strength of the white cement mortar.

- The optimum concentration of MWCNTs was determined to be around 0.2 wt% of cement and therefore the ratio of 1 to 4 in MWCNTs to superplasticizer is appropriate.

- The nanocomposite reinforced with MWCNTs without carboxyl-functionalization showed better results than the MWCNTs with chemical modification, possibly due to surface defects on the MWCNTs during functionalization.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Silvestro, L.; Gleize, P.J.P. Effect of carbon nanotubes on compressive, flexural and tensile strengths of Portland cement-based materials: A systematic literature review. Constr. Build. Mater. 2020, 264, 120237. [Google Scholar] [CrossRef]

- Yu, X.; Kwon, E. A carbon nanotube/cement composite with piezoresistive properties. Smart Mater. Struct. 2009, 30, 055010. [Google Scholar] [CrossRef]

- Shi, T.; Li, Z.; Guo, J.; Gong, H.; Gu, C. Research progress on CNTs/CNFs-modified cement-based composites—A review. Constr. Build. Mater. 2019, 202, 290–307. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Kwon, E.; Ou, J. Effects of CNT concentration level and water/cement ratio on the piezoresistivity of CNT/cement composites. J. Compos. Mater. 2012, 46, 19–25. [Google Scholar] [CrossRef]

- Hilding, J.; Grulke, E.A.; Zhang, Z.G.; Lockwood, F. Dispersion of carbon nanotubes in liquids. J. Dispers. Sci. Technol. 2003, 24, 1–41. [Google Scholar] [CrossRef]

- Ramezani, M.; Kim, Y.H.; Sun, Z. Modeling the mechanical properties of cementitious materials containing CNTs. Cem. Concr. Compos. 2019, 104, 103347. [Google Scholar] [CrossRef]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Rana, S.; Alagirusamy, R.; Joshi, M. Effect of carbon nanofiber dispersion on the ten-sile properties of epoxy nanocomposites. J. Comp. Mater. 2011, 45, 2247–2256. [Google Scholar] [CrossRef]

- Hielscher, T. Ultrasonic production of nano-size dispersions and emulsions. In Proceedings of the 1st Workshop on NanoTechnology Transfer in Europe, Paris, France, 14–16 December 2005; TIMA Editions: Grenoble, France, 2006; pp. 138–143. [Google Scholar]

- Luo, Z.P.; Koo, J.H. Quantitative study of the dispersion degree in carbon nano-fiber/polymer and carbon nanotube/polymer nanocomposites. Mater. Lett. 2008, 62, 3493–3496. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.W. Processing-structure-multi-functional property relation-ship in carbon nanotube/epoxy composites. Carbon 2006, 44, 3022–3029. [Google Scholar] [CrossRef]

- Tibbetts, G.G.; Lake, M.L.; Strong, K.L.; Rice, B.P. A review of the fabrication and properties of vapor-grown carbon nanofiber/polymer composites. Compos. Sci. Technol. 2007, 67, 1709–1718. [Google Scholar] [CrossRef]

- Vaisman, L.; Wagner, H.D.; Marom, G. The role of surfactants in dispersion of carbon nanotubes. Adv. Colloid Interface Sci. 2006, 128, 37–46. [Google Scholar] [CrossRef]

- Bose, S.; Khare, R.A.; Moldenaers, P. Assessing the strengths and weaknesses of various types of pre-treatments of carbon nanotubes on the properties of polymer/carbon nanotubes composites: A critical review. Polymer 2010, 51, 975–993. [Google Scholar] [CrossRef] [Green Version]

- Hill, D.E.; Lin, Y.; Rao, A.M.; Allard, L.F.; Sun, Y.P. Functionalization of carbon nanotubes with polystyrene. Macromolecules 2002, 35, 9466–9471. [Google Scholar] [CrossRef]

- Clark, M.D.; Subramanian, S.; Krishnamoorti, R. Understanding surfactant aided aqueous dispersion of multi-walled carbon nanotubes. J. Colloid Interf. Sci. 2011, 354, 144–151. [Google Scholar] [CrossRef]

- Rastogi, R.; Kaushal, R.; Tripathi, S.K.; Sharma, A.L.; Kaur, I.; Bharadwaj, L.M. Comparative study of carbon nanotube dispersion using surfactants. J. Colloid Interf. Sci. 2008, 328, 421–428. [Google Scholar] [CrossRef]

- Rausch, J.; Zhuang, R.-C.; Mader, E. Surfactant assisted dispersion of functionalized multi-walled carbon nanotubes in aqueous media. Compos. Part A 2010, 41, 1038–1046. [Google Scholar] [CrossRef]

- Kim, G.; Nam, I.; Yoon, H.N.; Lee, H.K. Effect of superplasticizer type and siliceous materials on the dispersion of carbon nanotube in cementitious composites. Compos. Struct. 2018, 185, 264–272. [Google Scholar] [CrossRef]

- Nam, I.W.; Lee, H.K. Image Analysis and DC Conductivity Measurement for the Evaluation of Carbon Nanotube Distribution in Cement Matrix. Int. J. Concr. Struct. Mater. 2015, 9, 427–438. [Google Scholar] [CrossRef] [Green Version]

- Skoulikidis, T. Corrosion and Conservation of Building Materials for Monuments: The Acropolis Case; University of Crete Publications: Heraklion, Crete, 2000. [Google Scholar]

- Kourkoulis, S.K.; Pasiou, E.D.; Triantis, D.; Stavrakas, I.; Hloupis, G. Innovative experimental techniques in the service of restoration of stone monuments—Part I: The experimental set up. Procedia Eng. 2015, 109, 268–275. [Google Scholar] [CrossRef] [Green Version]

- Freeman, D.D.; Choi, K.; Yu, C. N-Type thermoelectric performance of functionalized carbon nanotube-filled polymer composites. PLoS ONE 2012, 7, e47822. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Duan, Z.; Li, H. The influence of surfactants on the processing of multi-walled carbon nanotubes in reinforcing cement matrix composites. Phys. Status Solidi 2009, 206, 2783–2790. [Google Scholar] [CrossRef]

- Luo, J.; Duan, Z.; Zhao, T.; Li, Q. Effect of multi-wall carbon nanotube on fracture mechanical property of cement-based composite. Adv. Mater. Res. 2011, 146, 581–584. [Google Scholar] [CrossRef]

- Duan, W.H.; Wang, Q.; Collins, F. Dispersion of carbon nanotubes with SDS surfactants: A study from a binding energy perspective. Chem. Sci. 2011, 2, 1407–1413. [Google Scholar] [CrossRef]

- Sobolkina, A.; Mechterine, V.; Khavrus, V.; Maier, D.; Mende, M.; Ritschel, M.; Leonhardt, A. Dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix. Cem. Concr. Compos. 2012, 34, 1104–1113. [Google Scholar] [CrossRef]

- Borode, A.O.; Ahmed, N.A.; Olubambi, P.A. Surfactant-aided dispersion of carbon nanomaterials in aqueous solution. Phys. Fluids 2019, 31, 071301. [Google Scholar] [CrossRef]

- Fatemi, S.M.; Foroutan, M. Study of dispersion of carbon nanotubes by Triton X-100 surfactant using molecular dynamics simulation. J. Iran Chem. Soc. 2015, 12, 1905–1913. [Google Scholar] [CrossRef]

- de Almeida Carísio, P.; dos Santos Mendonça, Y.G.; Soares, C.F.T.; Reales, O.A.M.; de Moraes Rego Fairbairn, E.; Dias Toledo, R.F. Dispersion of carbon nanotubes with different types of superplasticizer as a dispersing agent for self-sensing cementitious materials. Appl. Sci. 2021, 11, 8452. [Google Scholar] [CrossRef]

- Favvas, E.P.; Nitodas, S.F.; Stefopoulos, A.A.; Papageorgiou, S.K.; Stefanopoulos, K.L.; Mitropoulos, A.C. High purity multi-walled carbon nanotubes: Preparation, characterization and performance as filler materials in co-polyimide hollow fiber membranes. Sep. Purif. Technol. 2014, 122, 262–269. [Google Scholar] [CrossRef]

- Geng, Y.; Liu, M.Y.; Li, J.; Shi, X.M.; Kim, J.K. Effects of surfactant treatment on mechanical and electrical properties of CNT/epoxy nanocomposites. Compos. A Appl. Sci. Manuf. 2008, 39, 1876–1883. [Google Scholar] [CrossRef]

- Fujigaya, T.; Saegusa, Y.; Momota, S.; Uda, N.; Nakashima, N. Interfacial engineering of epoxy/carbon nanotubes using reactive glue for effective reinforcement of the composite. Polym. J. 2016, 48, 183–188. [Google Scholar] [CrossRef]

- Kang, J.; Al-Sabah, S.; Théo, R. Effect of Single-walled Carbon Nanotubes on Strength Properties of Cement Composites. Materials 2020, 13, 1305. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choi, K.; Kyung Min, Y.; Chung, W.; Lee, S.-E.; Kang, S.W. Effects of dispersants and defoamers on the enhanced electrical performance by carbon nanotube networks embedded in cement-matrix composites. Compos. Struct. 2020, 243, 112193. [Google Scholar] [CrossRef]

- Rodriguez, B.; Correa, E.; Arias, Y.P.; Quintero, J.H.; Calderón, J.A.; Mendoza, O.A. Carbonation study in a cement matrix with carbon nanotubes. J. Phys. Conf. Ser. 2019, 1247, 012024. [Google Scholar] [CrossRef]

- Rodríguez, B.; Quintero-Orozco, J.; Arias, Y.; Mendoza, O.; Ochoa-Botero, J.; Dias Toledo, R.F. Influence of MWCNT/surfactant dispersions on the mechanical properties of Portland cement pastes. J. Phys. Conf. Ser. 2017, 935, 012014. [Google Scholar]

- Ullah, Q.; Khushnood, R.A.; Ahmad, S. Performance Evaluation of MWCNTs Reinforced Cement Mortar Composites using Natural and Commercial Surfactants. J. Wuhan Univ. Technol. Mat. Sci. Edit. 2022, 37, 47–57. [Google Scholar] [CrossRef]

- Atahan, H.N.; Carlos, C.; Chae, S.; Monteiro, P.J.M.; Bastacky, J. The morphology of entrained air voids in hardened cement paste generated with different anionic surfactants. Cem. Concr Compos. 2008, 30, 566–575. [Google Scholar] [CrossRef]

- Papayianni, I.; Tsohos, G.; Oikonomou, N.; Mavria, P. Influence of superplasticizer type and mix design parameters on the performance of them in concrete mixtures. Cem. Concr. Compos. 2005, 27, 217–222. [Google Scholar]

- Mardani-Aghabaglou, A.; Tuyan, M.; Yılmaz, G.; Arıöz, Ö.; Ramyar, K. Effect of different types of superplasticizer on fresh, rheological and strength properties of self-consolidating concrete. Constr. Build. Mater. 2013, 47, 1020–1025. [Google Scholar] [CrossRef]

- Chen, J.; Akono, A.-T. Influence of multi-walled carbon nanotubes on the hydration products of ordinary Portland cement paste. Cem. Concr. Res. 2020, 137, 106197. [Google Scholar] [CrossRef]

- Gao, F.; Tian, W.; Wang, Z.; Wang, F. Effect of diameter of multi-walled carbon nanotubes on mechanical properties and microstructure of the cement-based materials. Constr. Build. Mater. 2020, 260, 120452. [Google Scholar] [CrossRef]

- Metaxa, Z.S.; Konsta-Gdoutos, M.S.; Shah, S.P. Carbon nanofiber cementitious composites: Effect of debulking procedure on dispersion and reinforcing efficiency. Cem Concr Compos. 2013, 36, 25–32. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Zoi, S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Reales, O.A.M.; Dias Toledo, R.F. A review on the chemical, mechanical and microstructural characterization of carbon nanotubes-cement based composites. Constr. Build. Mater. 2017, 154, 697–710. [Google Scholar] [CrossRef]

- Špitalský, Ζ.; Krontiras, C.A.; Georga, S.N.; Galiotis, C. Effect of oxidation treatment of multiwalled carbon nanotubes on the mechanical and electrical properties of their epoxy composites. Compos. Part A Appl. Sci. 2009, 40, 778–783. [Google Scholar] [CrossRef]

| C3S | C2S | C3A | C4AF |

|---|---|---|---|

| 77 (wt%) | 16 (wt%) | 5 (wt%) | 1 (wt%) |

| Density (kg/m3) | 3130 |

| Phenomenological density (kg/m3) | 1100 |

| Curing time of cement according ΕΝ 196-3 | 120 min |

| Variance in the Surfactant/Nano-Reinforcement | MWCNTs (g) | SDBS (g) | TRITON (g) | CERESIT (g) | WATER (g) |

|---|---|---|---|---|---|

| SDBS-1 | 0.5 | 0.5 | - | - | 500 |

| SDBS-2 | 2.5 | 2.5 | - | - | 500 |

| SDBS-3 | 5 | 5 | - | - | 500 |

| SDBS-4 | 5 | 10 | - | - | 500 |

| Triton-X | 2 | - | 12 | - | 500 |

| Ceresit-1 | 2 | - | - | 4 | 500 |

| Ceresit-2 | 2 | - | - | 6 | 500 |

| Ceresit-3 | 2 | - | - | 8 | 500 |

| Ceresit-4 | 2 | - | - | 12 | 500 |

| Ceresit-5 | 2 | - | - | 16 | 500 |

| MWCNTs-1 | 0.5 | - | - | 8 | 500 |

| MWCNTs-2 | 1 | - | - | 8 | 500 |

| MWCNTs-3 | 2 | - | - | 8 | 500 |

| MWCNTs-4 | 3 | - | - | 8 | 500 |

| MWCNTs-5 | 5 | - | - | 8 | 500 |

| MWCNTs-6 | 2 * | - | - | 8 | 500 |

| Cement (g) | Quartz Sand | w/c | ||

|---|---|---|---|---|

| Coarse (g) | Fine (g) | |||

| Mortar | 260 | 520 | 260 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Metaxa, Z.S.; Boutsioukou, S.; Amenta, M.; Favvas, E.P.; Kourkoulis, S.K.; Alexopoulos, N.D. Dispersion of Multi-Walled Carbon Nanotubes into White Cement Mortars: The Effect of Concentration and Surfactants. Nanomaterials 2022, 12, 1031. https://doi.org/10.3390/nano12061031

Metaxa ZS, Boutsioukou S, Amenta M, Favvas EP, Kourkoulis SK, Alexopoulos ND. Dispersion of Multi-Walled Carbon Nanotubes into White Cement Mortars: The Effect of Concentration and Surfactants. Nanomaterials. 2022; 12(6):1031. https://doi.org/10.3390/nano12061031

Chicago/Turabian StyleMetaxa, Zoi S., Spyridoula Boutsioukou, Maria Amenta, Evangelos P. Favvas, Stavros K. Kourkoulis, and Nikolaos D. Alexopoulos. 2022. "Dispersion of Multi-Walled Carbon Nanotubes into White Cement Mortars: The Effect of Concentration and Surfactants" Nanomaterials 12, no. 6: 1031. https://doi.org/10.3390/nano12061031

APA StyleMetaxa, Z. S., Boutsioukou, S., Amenta, M., Favvas, E. P., Kourkoulis, S. K., & Alexopoulos, N. D. (2022). Dispersion of Multi-Walled Carbon Nanotubes into White Cement Mortars: The Effect of Concentration and Surfactants. Nanomaterials, 12(6), 1031. https://doi.org/10.3390/nano12061031