Flexible Piezoresistive Pressure Sensor Based on Electrospun Rough Polyurethane Nanofibers Film for Human Motion Monitoring

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Electrospun PU Film and PU/Ag Film

2.3. Preparation of PDMS Substrate

2.4. Assembly of the Piezoresistive Pressure Sensor

2.5. Characterization

3. Results and Discussions

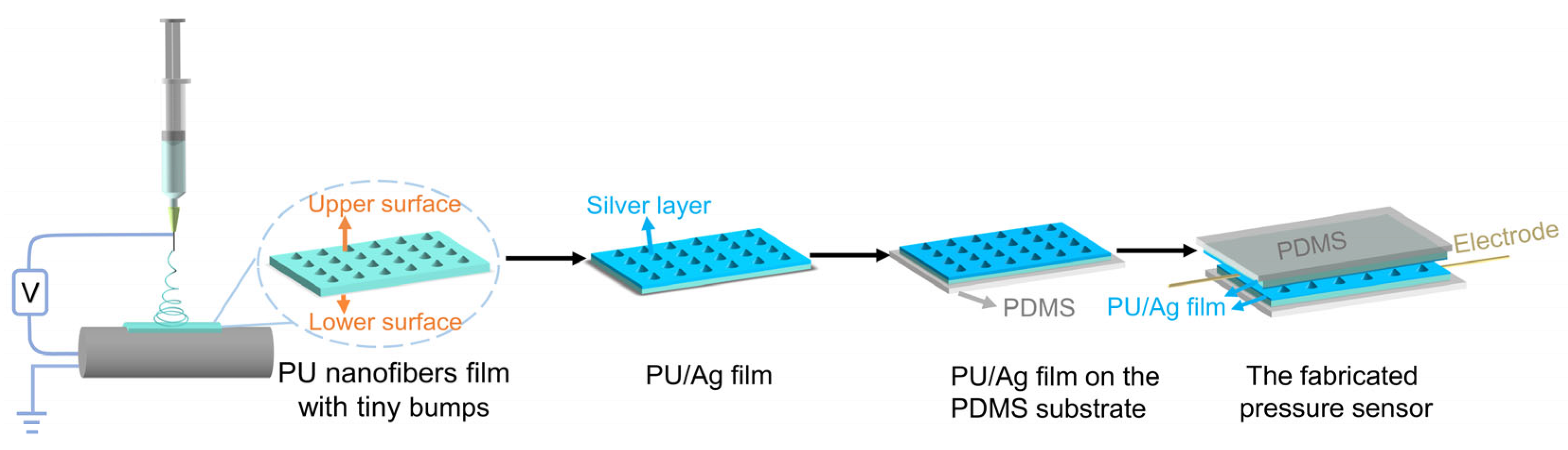

3.1. Fabrication Process of the Piezoresistive Pressure Sensor

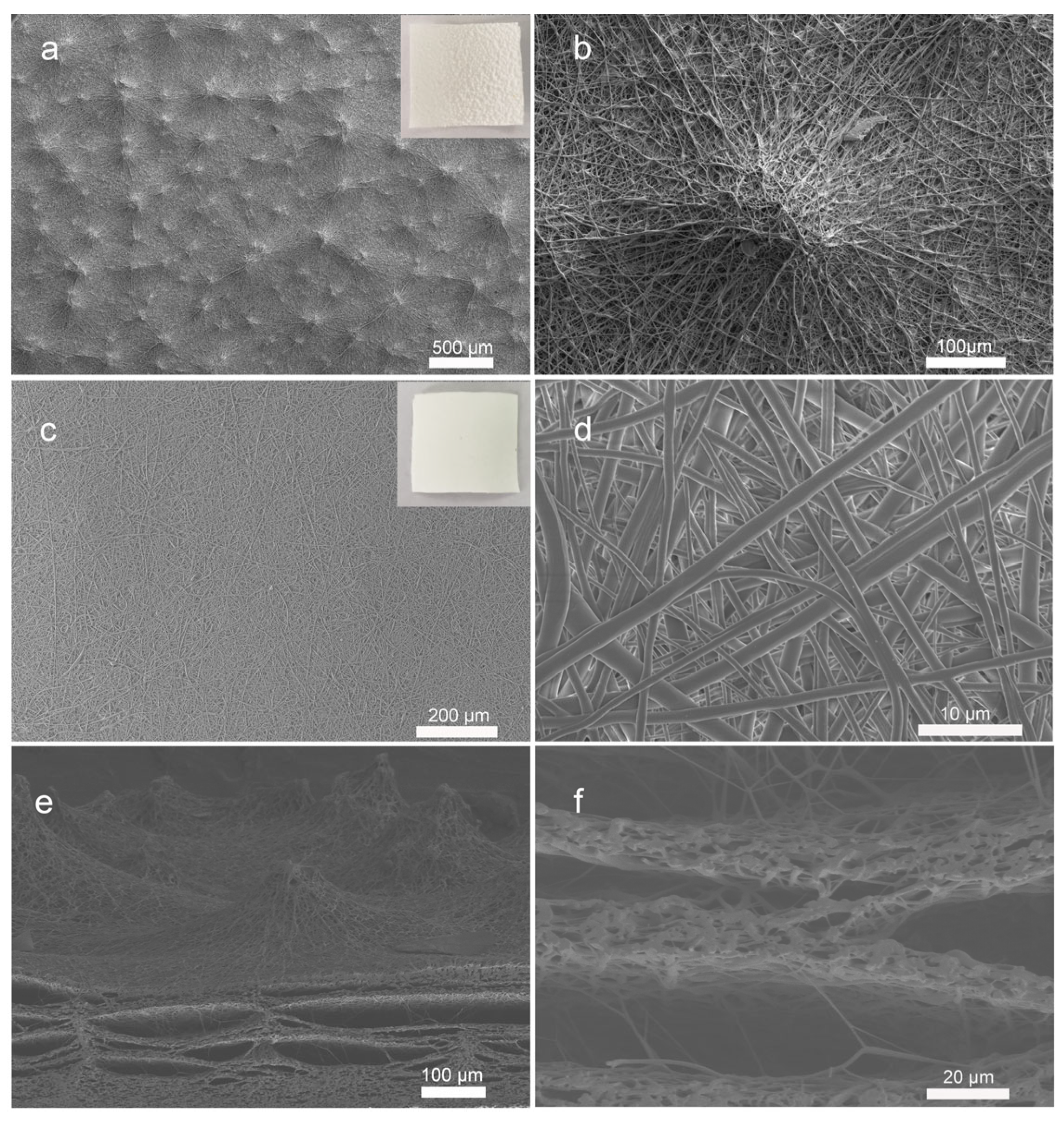

3.2. Morphologies of the Electrospun PU and PU/Ag Film

3.3. Sensitivity and Working Mechanism

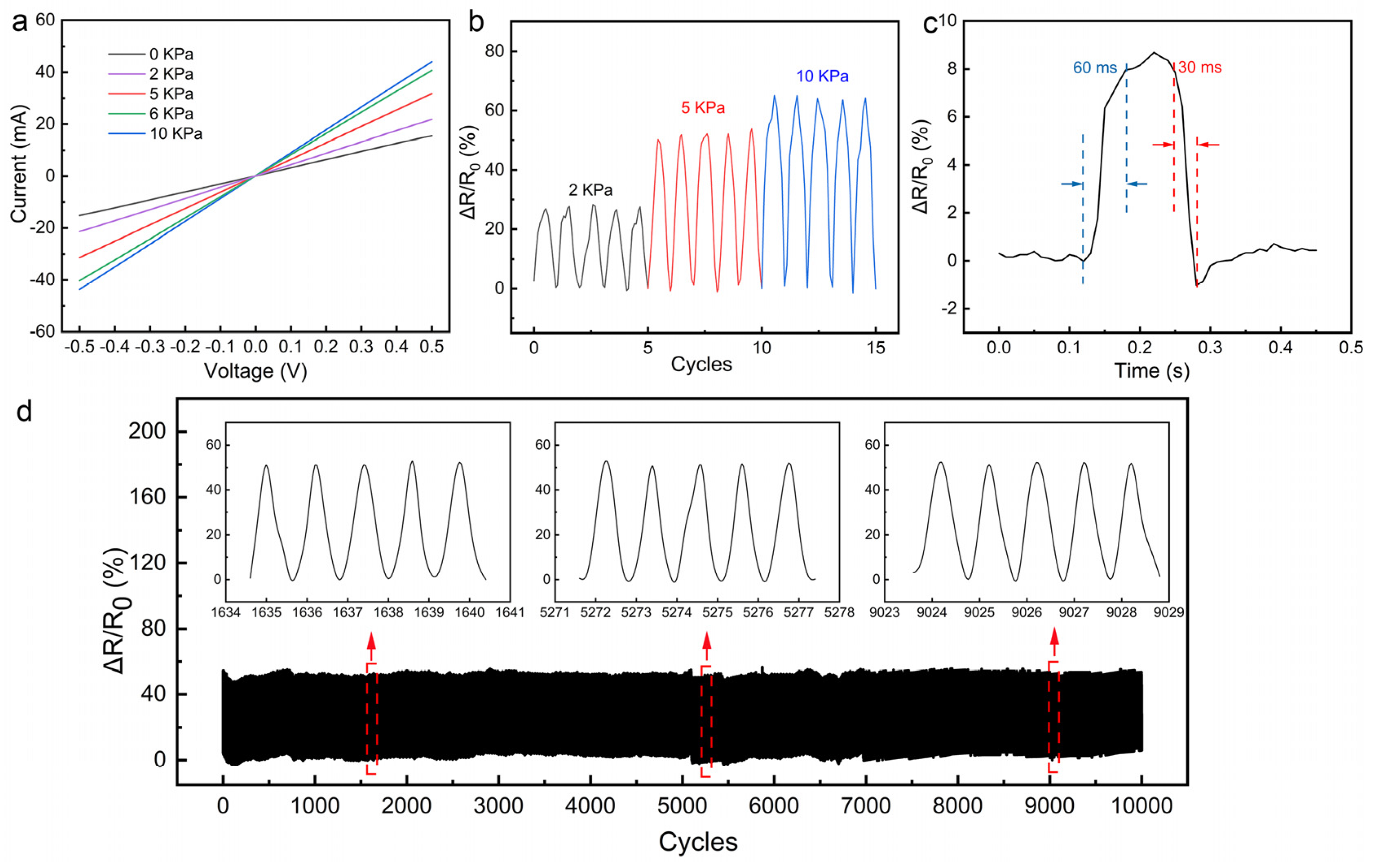

3.4. Pressure Sensing Performance

3.5. Applications of the Fabricated Sensor

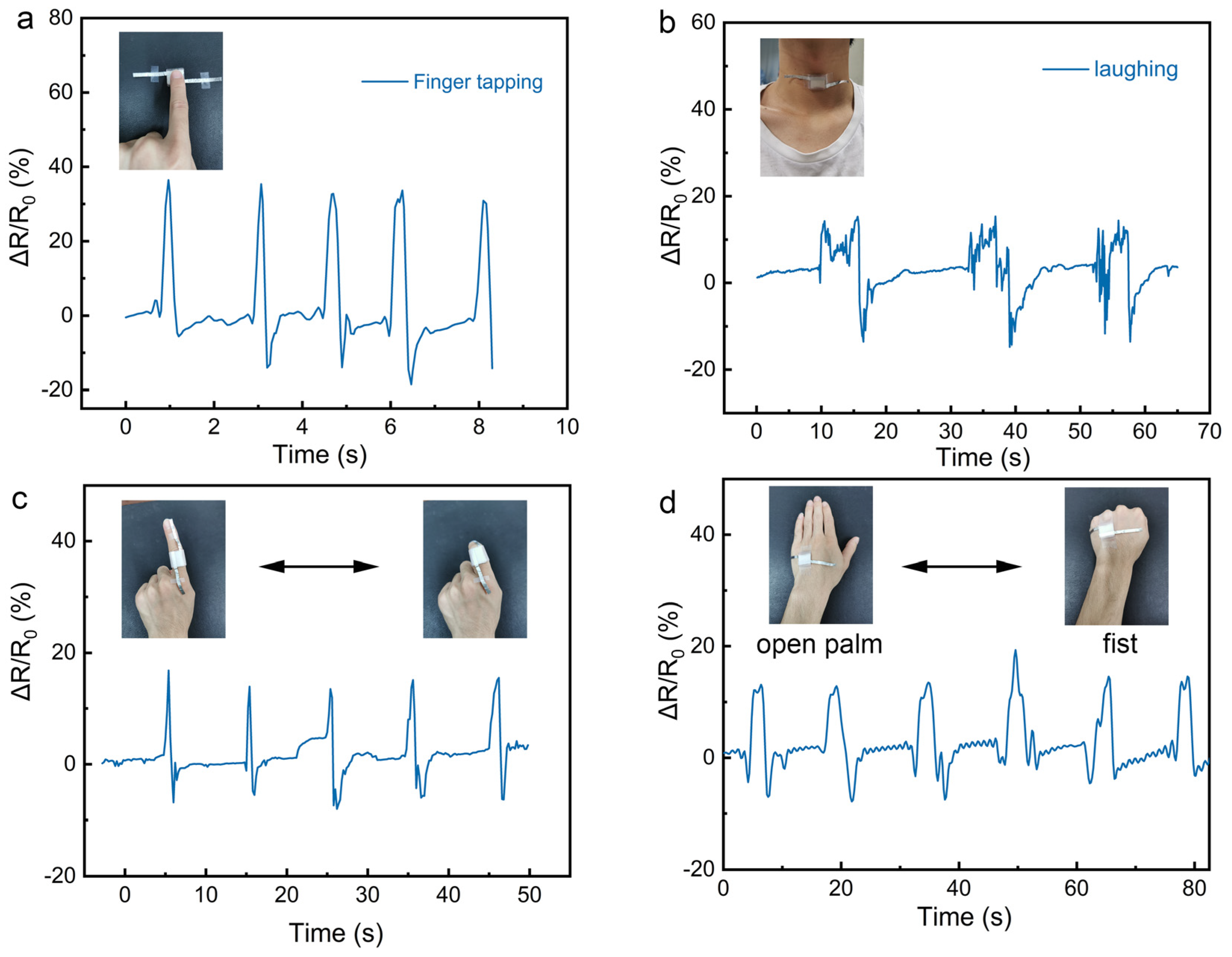

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bu, T.; Xiao, T.; Yang, Z.; Liu, G.; Fu, X.; Nie, J.; Guo, T.; Pang, Y.; Zhao, J.; Xi, F.; et al. Stretchable Triboelectric-Photonic Smart Skin for Tactile and Gesture Sensing. Adv. Mater. 2018, 30, e1800066. [Google Scholar] [CrossRef]

- Pu, J.H.; Zha, X.J.; Tang, L.S.; Bai, L.; Bao, R.Y.; Liu, Z.Y.; Yang, M.B.; Yang, W. Human Skin-Inspired Electronic Sensor Skin with Electromagnetic Interference Shielding for the Sensation and Protection of Wearable Electronics. ACS Appl. Mater. Interfaces 2018, 10, 40880–40889. [Google Scholar] [CrossRef]

- Li, B.Z.; Zhang, F.F.; Guan, S.; Zheng, J.M.; Xu, C.Y. Wearable piezoelectric device assembled by one-step continuous electrospinning. J. Mater. Chem. C 2016, 4, 6988–6995. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, S.H.; Lin, Q.H.; Wang, M.J.; Yang, Z.; Zhang, Y.L.; Wang, F.X.; Sun, L.N. Highly sensitive and wide-detection range pressure sensor constructed on a hierarchical-structured conductive fabric as a human-machine interface. Nanoscale 2020, 12, 21271–21279. [Google Scholar] [CrossRef]

- Liu, R.; Wang, H.; Lu, W.; Cui, L.; Wang, S.; Wang, Y.; Chen, Q.; Guan, Y.; Zhang, Y. Highly tough, stretchable and resilient hydrogels strengthened with molecular springs and their application as a wearable, flexible sensor. Chem. Eng. J. 2021, 415, 128839. [Google Scholar] [CrossRef]

- Zhong, M.J.; Zhang, L.J.; Liu, X.; Zhou, Y.N.; Zhang, M.Y.; Wang, Y.J.; Yang, L.; Wei, D. Wide linear range and highly sensitive flexible pressure sensor based on multistage sensing process for health monitoring and human-machine interfaces. Chem. Eng. J. 2021, 412, 128649. [Google Scholar] [CrossRef]

- Sun, H.L.; Zhao, Y.; Wang, C.F.; Zhou, K.K.; Yan, C.; Zheng, G.Q.; Huang, J.J.; Dai, K.; Liu, C.T.; Shen, C.Y. Ultra-Stretchable, durable and conductive hydrogel with hybrid double network as high performance strain sensor and stretchable triboelectric nanogenerator. Nano Energy 2020, 76, 105035. [Google Scholar] [CrossRef]

- Cao, Z.R.; Yang, Y.N.; Zheng, Y.H.; Wu, W.; Xu, F.F.; Wang, R.R.; Sun, J. Highly flexible and sensitive temperature sensors based on Ti3C2Tx (MXene) for electronic skin. J. Mater. Chem. A 2019, 7, 25314–25323. [Google Scholar] [CrossRef]

- Zhu, P.; Ou, H.; Kuang, Y.; Hao, L.; Diao, J.; Chen, G. Cellulose Nanofiber/Carbon Nanotube Dual Network-Enabled Humidity Sensor with High Sensitivity and Durability. ACS Appl. Mater. Interfaces 2020, 12, 33229–33238. [Google Scholar] [CrossRef]

- Ervasti, H.; Jarvinen, T.; Pitkanen, O.; Bozo, E.; Hiitola-Keinanen, J.; Huttunen, O.H.; Hiltunen, J.; Kordas, K. Inkjet-Deposited Single-Wall Carbon Nanotube Micropatterns on Stretchable PDMS-Ag Substrate-Electrode Structures for Piezoresistive Strain Sensing. ACS Appl. Mater. Interfaces 2021, 13, 27284–27294. [Google Scholar] [CrossRef]

- Guan, X.Y.; Xu, B.G.; Gong, J.L. Hierarchically architected polydopamine modified BaTiO3@P(VDF-TrFE) nanocomposite fiber mats for flexible piezoelectric nanogenerators and self-powered sensors. Nano Energy 2020, 70, 104516. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, X.X.; Song, W.Z.; Qiu, H.J.; Zhang, J.; Fan, Z.; Yu, M.; Long, Y.Z. Wireless Single-Electrode Self-Powered Piezoelectric Sensor for Monitoring. ACS Appl. Mater. Interfaces 2020, 12, 8288–8295. [Google Scholar] [CrossRef]

- Wen, Z.; Yang, Y.Q.; Sun, N.; Li, G.F.; Liu, Y.N.; Chen, C.; Shi, J.H.; Xie, L.J.; Jiang, H.X.; Bao, D.Q.; et al. A Wrinkled PEDOT:PSS Film Based Stretchable and Transparent Triboelectric Nanogenerator for Wearable Energy Harvesters and Active Motion Sensors. Adv. Funct. Mater. 2018, 28, 1803684. [Google Scholar] [CrossRef]

- Yang, D.; Guo, H.Y.; Chen, X.Y.; Wang, L.F.; Jiang, P.; Zhang, W.Q.; Zhang, L.Q.; Wang, Z.L. A flexible and wide pressure range triboelectric sensor array for real-time pressure detection and distribution mapping. J. Mater. Chem. A 2020, 8, 23827–23833. [Google Scholar] [CrossRef]

- Tabi, G.D.; Kim, J.S.; Nketia-Yawson, B.; Kim, H.; Noh, Y.Y. High-capacitance polyurethane ionogels for low-voltage operated organic transistors and pressure sensors. J. Mater. Chem. C 2020, 8, 17107–17113. [Google Scholar] [CrossRef]

- Hwang, J.; Kim, Y.; Yang, H.; Oh, J.H. Fabrication of hierarchically porous structured PDMS composites and their application as a flexible capacitive pressure sensor. Compos. Part B 2021, 211, 108607. [Google Scholar] [CrossRef]

- Cheng, H.N.; Wang, B.; Yang, K.; Wang, C.X. A low-cost piezoresistive pressure sensor with a wide strain range-featuring polyurethane sponge@poly(vinyl alcohol)/sulfuric gel electrolyte. J. Mater. Chem. C 2021, 9, 1014–1024. [Google Scholar] [CrossRef]

- Wu, J.J.; Li, H.Q.; Lai, X.J.; Chen, Z.H.; Zeng, X.R. Conductive and superhydrophobic F-rGO@CNTs/chitosan aerogel for piezoresistive pressure sensor. Chem. Eng. J. 2020, 386, 123998. [Google Scholar] [CrossRef]

- Huang, L.; Chen, J.; Xu, Y.; Hu, D.; Cui, X.; Shi, D.; Zhu, Y. Three-dimensional light-weight piezoresistive sensors based on conductive polyurethane sponges coated with hybrid CNT/CB nanoparticles. Appl. Surf. Sci. 2021, 548, 149268. [Google Scholar] [CrossRef]

- Qiu, Y.; Tian, Y.; Sun, S.S.; Hu, J.H.; Wang, Y.Y.; Zhang, Z.; Liu, A.P.; Cheng, H.Y.; Gao, W.Z.; Zhang, W.N.; et al. Bioinspired, multifunctional dual -mode pressure sensors as electronic skin for decoding complex loading processes and human motions. Nano Energy 2020, 78, 105337. [Google Scholar] [CrossRef]

- Zhang, W.; Xiao, Y.; Duan, Y.; Li, N.; Wu, L.; Lou, Y.; Wang, H.; Peng, Z. A High-Performance Flexible Pressure Sensor Realized by Overhanging Cobweb-like Structure on a Micropost Array. ACS Appl. Mater. Interfaces 2020, 12, 48938–48947. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Yu, G.H.; Tan, J.P.; Xuan, F.Z. Sandpaper-molded wearable pressure sensor for electronic skins. Sens. Actuators A 2018, 280, 205–209. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Hong, J.; Ha, M.; Jung, Y.D.; Lim, H.; Kim, S.Y.; Ko, H. Giant tunneling piezoresistance of composite elastomers with interlocked microdome arrays for ultrasensitive and multimodal electronic skins. ACS Nano 2014, 8, 4689–4697. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.J.; Zhuang, J.; Venkatesh, S.; Zhou, Y.; Han, S.T.; Wu, W.; Kong, K.W.; Li, W.J.; Chen, X.; Li, R.K.Y.; et al. Highly Sensitive and Ultrastable Skin Sensors for Biopressure and Bioforce Measurements Based on Hierarchical Microstructures. ACS Appl. Mater. Interfaces 2018, 10, 4086–4094. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.B.; Qiu, Z.G.; Hong, Y.; Wang, Y.; Zhang, J.M.; Liu, Q.X.; Wu, Z.G.; Guo, C.F. A Highly Sensitive Flexible Capacitive Tactile Sensor with Sparse and High-Aspect-Ratio Microstructures. Adv. Electron. Mater. 2018, 4, 1700586. [Google Scholar] [CrossRef]

- Wang, X.; Gu, Y.; Xiong, Z.; Cui, Z.; Zhang, T. Silk-molded flexible, ultrasensitive, and highly stable electronic skin for monitoring human physiological signals. Adv. Mater. 2014, 26, 1336–1342. [Google Scholar] [CrossRef]

- Jian, M.Q.; Xia, K.L.; Wang, Q.; Yin, Z.; Wang, H.M.; Wang, C.Y.; Xie, H.H.; Zhang, M.C.; Zhang, Y.Y. Flexible and Highly Sensitive Pressure Sensors Based on Bionic Hierarchical Structures. Adv. Funct. Mater. 2017, 27, 1606066. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, W.; Chen, S.M.; Yao, D.W.; Zhang, X.; Chen, H.D.; Xu, H.L. Piezoresistive Electronic-Skin Sensors Produced With Self-Channeling Laser Microstructured Silicon Molds. IEEE Trans. Electron Devices 2021, 68, 786–792. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Guan, X.; Huang, H.Y.; Wang, H.F.; Lin, W.E.; Peng, Z.C. Full 3D Printing of Stretchable Piezoresistive Sensor with Hierarchical Porosity and Multimodulus Architecture. Adv. Funct. Mater. 2019, 29, 1807569. [Google Scholar] [CrossRef]

- Liu, C.X.; Zhu, W.J.; Li, M.D.; Sun, X.H.; Guo, X.H.; Liu, J.; Liu, P.; Zhang, Y.Y.; Huang, Y. Highly stable pressure sensor based on carbonized melamine sponge using fully wrapped conductive path for flexible electronic skin. Org. Electron. 2020, 76, 8. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Zhang, J.R.; Han, D.D.; Zhang, Y.L.; Sun, H.B. Versatile Electronic Skins with Biomimetic Micronanostructures Fabricated Using Natural Reed Leaves as Templates. ACS Appl. Mater. Interfaces 2019, 11, 38084–38091. [Google Scholar] [CrossRef] [PubMed]

- Qi, K.; He, J.; Wang, H.; Zhou, Y.; You, X.; Nan, N.; Shao, W.; Wang, L.; Ding, B.; Cui, S. A Highly Stretchable Nanofiber-Based Electronic Skin with Pressure-, Strain-, and Flexion-Sensitive Properties for Health and Motion Monitoring. ACS Appl. Mater. Interfaces 2017, 9, 42951–42960. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Y.; Zhang, P.; Li, Y.; Zhang, K.; Su, J.; Huang, L. Flexible capacitive pressure sensor based on multi-walled carbon nanotubes microstructure electrodes. J. Phys. D Appl. Phys. 2021, 54, 155101. [Google Scholar] [CrossRef]

- Ma, L.; Yu, X.; Yang, Y.; Hu, Y.; Zhang, X.; Li, H.; Ouyang, X.; Zhu, P.; Sun, R.; Wong, C.-P. Highly sensitive flexible capacitive pressure sensor with a broad linear response range and finite element analysis of micro-array electrode. J. Mater. 2020, 6, 321–329. [Google Scholar] [CrossRef]

- Yang, J.C.; Kim, J.O.; Oh, J.; Kwon, S.Y.; Sim, J.Y.; Kim, D.W.; Choi, H.B.; Park, S. Microstructured Porous Pyramid-Based Ultrahigh Sensitive Pressure Sensor Insensitive to Strain and Temperature. ACS Appl. Mater. Interfaces 2019, 11, 19472–19480. [Google Scholar] [CrossRef]

- Bijender; Kumar, A. Flexible and wearable capacitive pressure sensor for blood pressure monitoring. Sens. Bio-Sens. Res. 2021, 33, 100434. [Google Scholar]

- Zhang, Z.; Gui, X.; Hu, Q.; Yang, L.; Yang, R.; Huang, B.; Yang, B.R.; Tang, Z. Highly Sensitive Capacitive Pressure Sensor Based on a Micropyramid Array for Health and Motion Monitoring. Adv. Electron. Mater. 2021, 7, 2100174. [Google Scholar] [CrossRef]

- Gao, X.; Zheng, M.; Yan, X.; Fu, J.; Zhu, M.; Hou, Y. The alignment of BCZT particles in PDMS boosts the sensitivity and cycling reliability of a flexible piezoelectric touch sensor. J. Mater. Chem. C 2019, 7, 961–967. [Google Scholar] [CrossRef]

- Feng, W.; Chen, Y.; Wang, W.; Yu, D. A waterproof and breathable textile pressure sensor with high sensitivity based on PVDF/ZnO hierarchical structure. Colloids Surf. A 2022, 633, 127890. [Google Scholar] [CrossRef]

- Li, X.; Ji, D.; Yu, B.; Ghosh, R.; He, J.; Qin, X.; Ramakrishna, S. Boosting piezoelectric and triboelectric effects of PVDF nanofiber through carbon-coated piezoelectric nanoparticles for highly sensitive wearable sensors. Chem. Eng. J. 2021, 426, 130345. [Google Scholar] [CrossRef]

- Zhao, Q.; Yang, L.; Ma, Y.; Huang, H.; He, H.; Ji, H.; Wang, Z.; Qiu, J. Highly sensitive, reliable and flexible pressure sensor based on piezoelectric PVDF hybrid film using MXene nanosheet reinforcement. J. Alloys Compd. 2021, 886, 161069. [Google Scholar] [CrossRef]

- Su, Y.; Li, W.; Yuan, L.; Chen, C.; Pan, H.; Xie, G.; Conta, G.; Ferrier, S.; Zhao, X.; Chen, G.; et al. Piezoelectric fiber composites with polydopamine interfacial layer for self-powered wearable biomonitoring. Nano Energy 2021, 89, 106321. [Google Scholar] [CrossRef]

| Active Material | Sensing Mechanism | Maximum Sensitivity | Stability | Ref. |

|---|---|---|---|---|

| PVA/H2SO4@PU composite | Piezoresistive | 8.0 kPa−1 | 1325 cycles | [17] |

| F-rGO@CNTs/CS aerogel | Piezoresistive | 4.97 kPa−1 | 1000 cycles | [18] |

| Microstructured PDMS films | Piezoresistive | 0.54 kPa−1 | N/A | [28] |

| TPU/Carbon Black | Piezoresistive | 5.54 kPa−1 | 10,000 cycles | [29] |

| carbonized melamine sponge/silicone rubber | Piezoresistive | 0.635 kPa−1 | ~2000 cycles | [30] |

| Microstructured PU/Ag film | Piezoresistive | 10.53 kPa−1 | 10,000 cycles | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, B.; Xie, H.; Zhao, J.; Zheng, J.; Xu, C. Flexible Piezoresistive Pressure Sensor Based on Electrospun Rough Polyurethane Nanofibers Film for Human Motion Monitoring. Nanomaterials 2022, 12, 723. https://doi.org/10.3390/nano12040723

Xue B, Xie H, Zhao J, Zheng J, Xu C. Flexible Piezoresistive Pressure Sensor Based on Electrospun Rough Polyurethane Nanofibers Film for Human Motion Monitoring. Nanomaterials. 2022; 12(4):723. https://doi.org/10.3390/nano12040723

Chicago/Turabian StyleXue, Bin, Haiyi Xie, Jinxu Zhao, Jianming Zheng, and Chunye Xu. 2022. "Flexible Piezoresistive Pressure Sensor Based on Electrospun Rough Polyurethane Nanofibers Film for Human Motion Monitoring" Nanomaterials 12, no. 4: 723. https://doi.org/10.3390/nano12040723

APA StyleXue, B., Xie, H., Zhao, J., Zheng, J., & Xu, C. (2022). Flexible Piezoresistive Pressure Sensor Based on Electrospun Rough Polyurethane Nanofibers Film for Human Motion Monitoring. Nanomaterials, 12(4), 723. https://doi.org/10.3390/nano12040723