Highly Sensitive RNA-Based Electrochemical Aptasensor for the Determination of C-Reactive Protein Using Carbon Nanofiber-Chitosan Modified Screen-Printed Electrode

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents and Chemicals

2.2. Apparatus

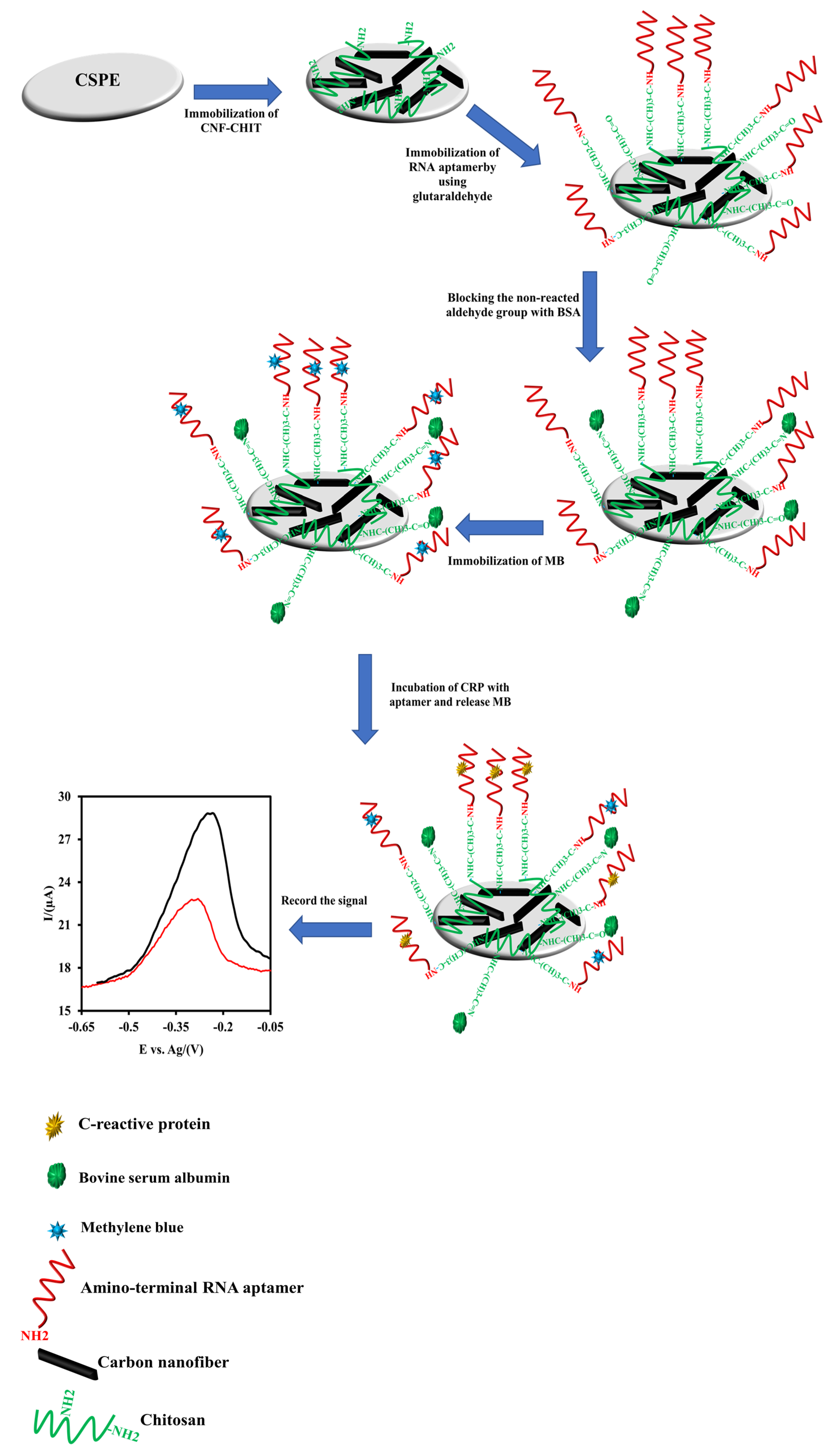

2.3. Fabrication of the CSPE/CNF-CHIT/RNA Aptamer-MB

2.4. Measurement Process of the CRP Concentration

3. Results and Discussion

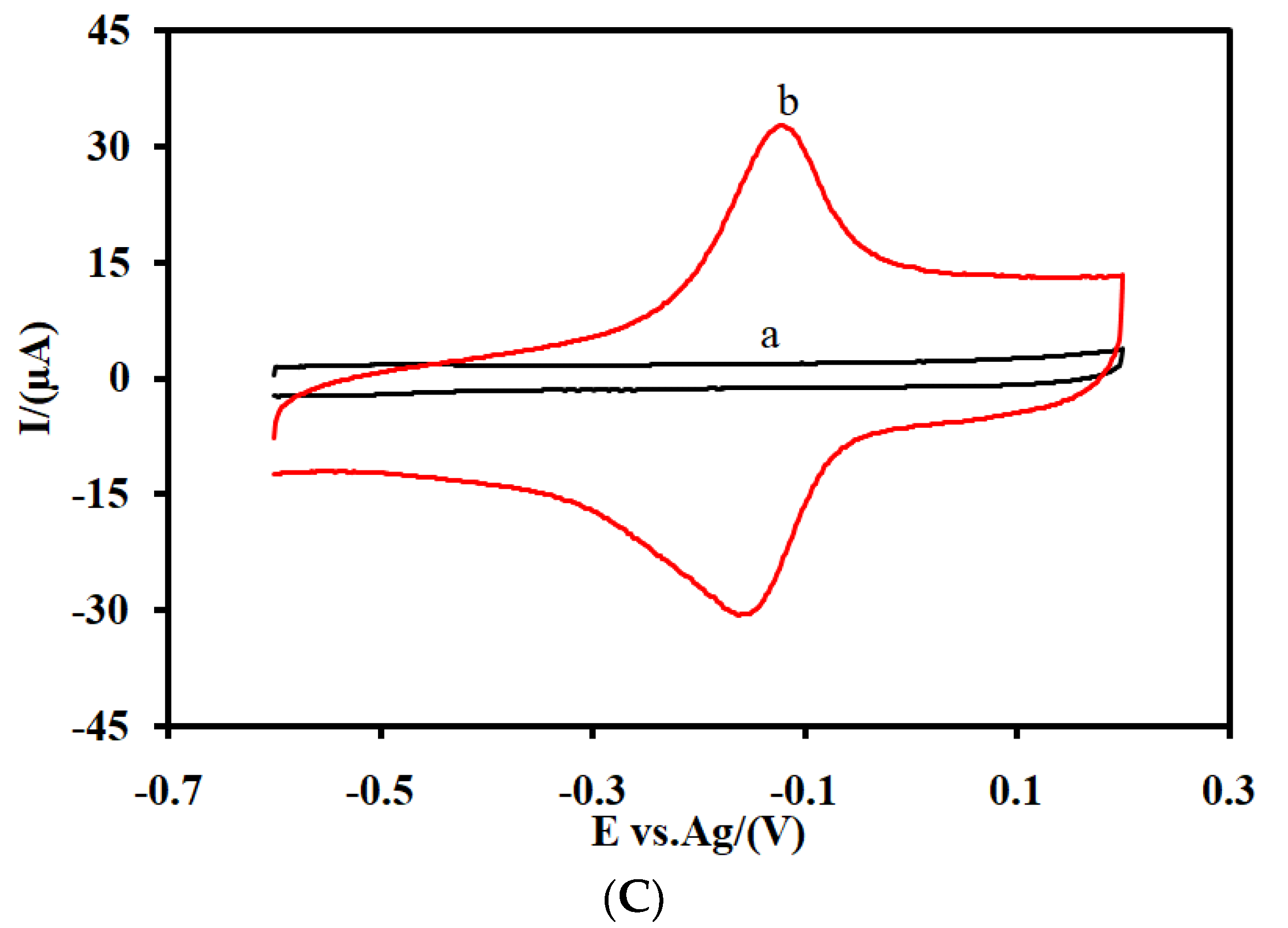

3.1. Electrochemical Activity of the Modified Electrode

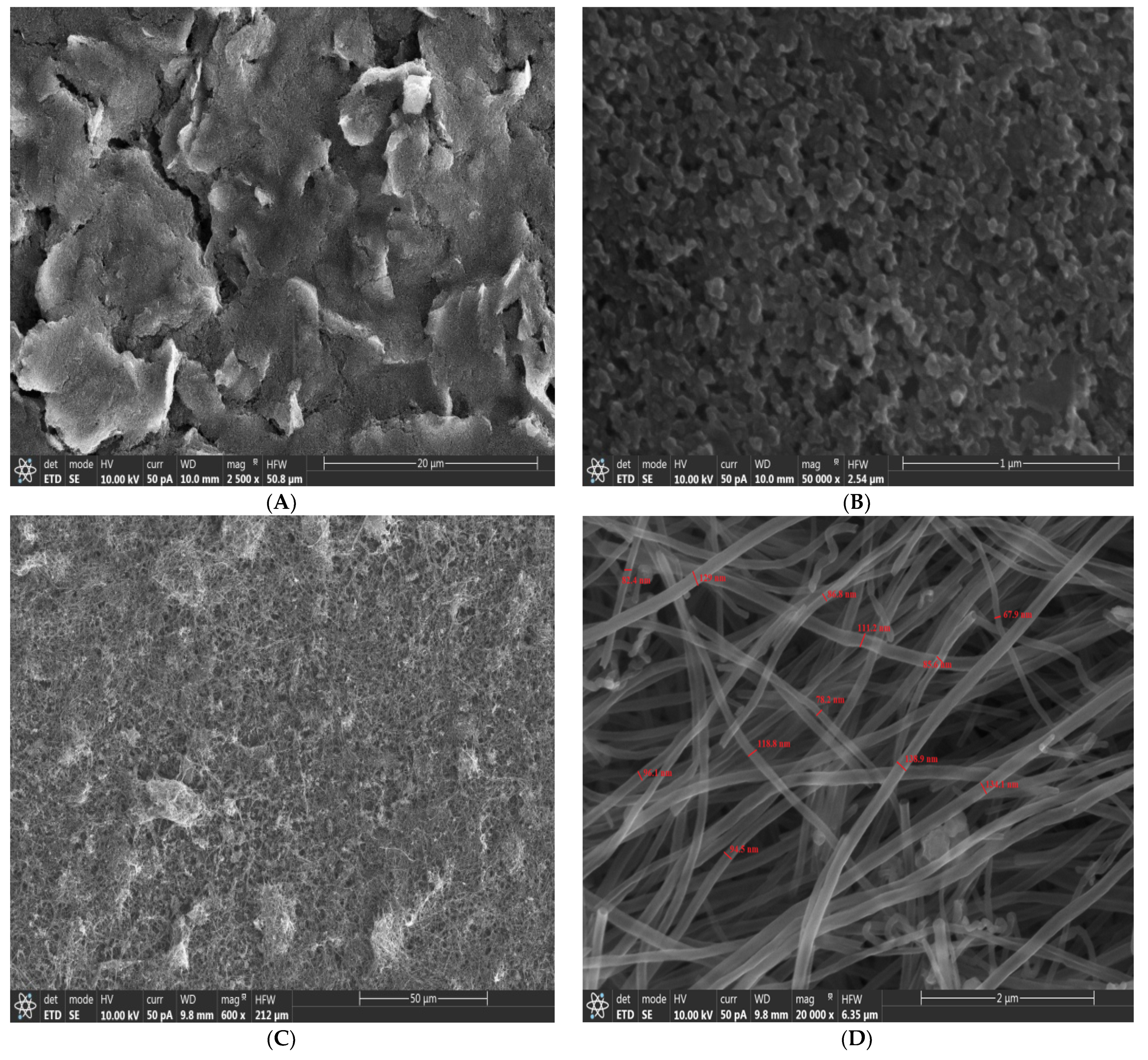

3.2. Surface Characterization of the Modified Electrode

3.3. Electrochemical Characterization of the Assembled Interface of the Surface of the RNA Aptasensor

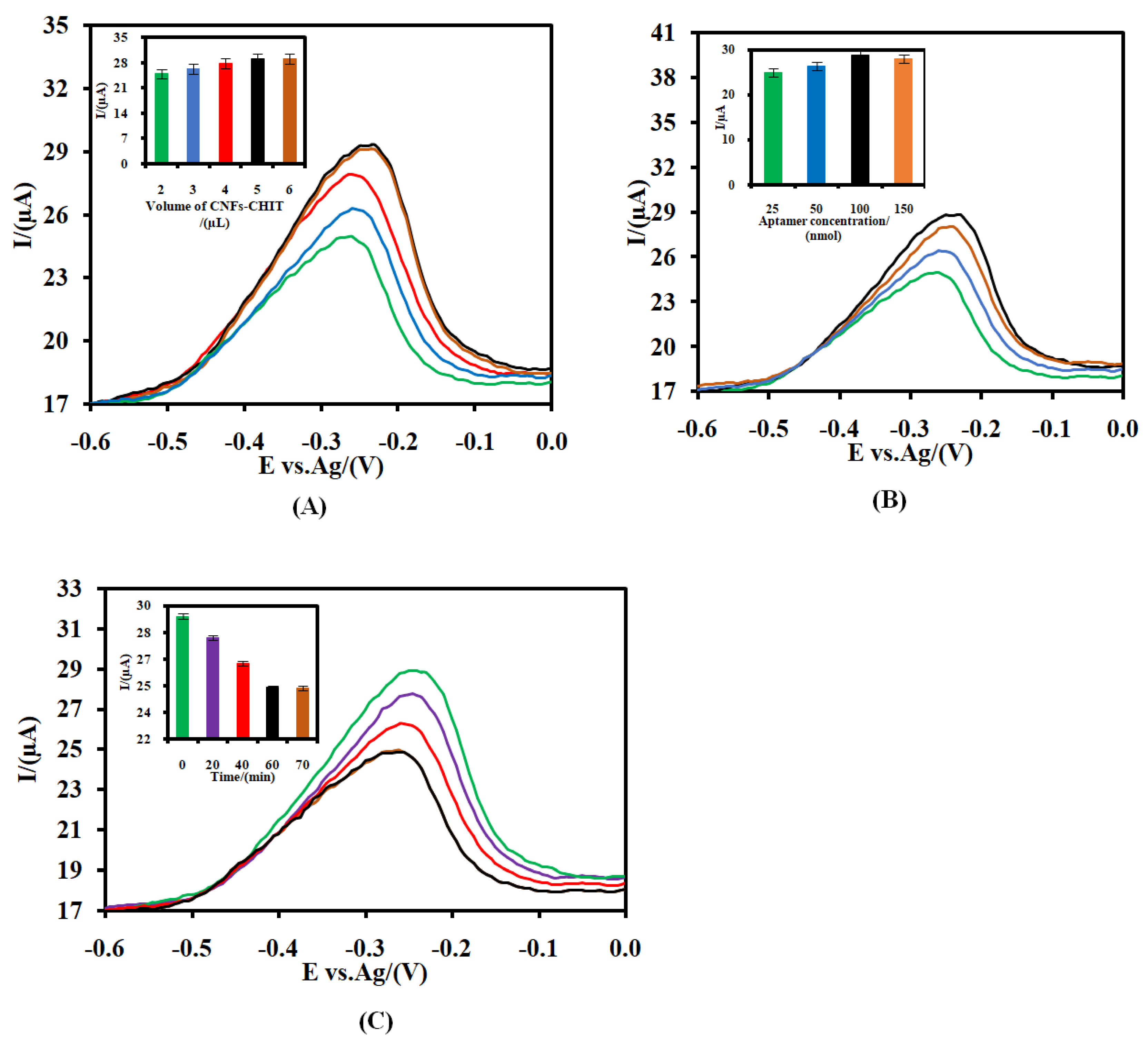

3.4. Optimization of the Response Time and the RNA Aptamer Probe Concentration on the Response of the CSPE/CNFs-CHIT-GLU-RNA Aptamer-MB

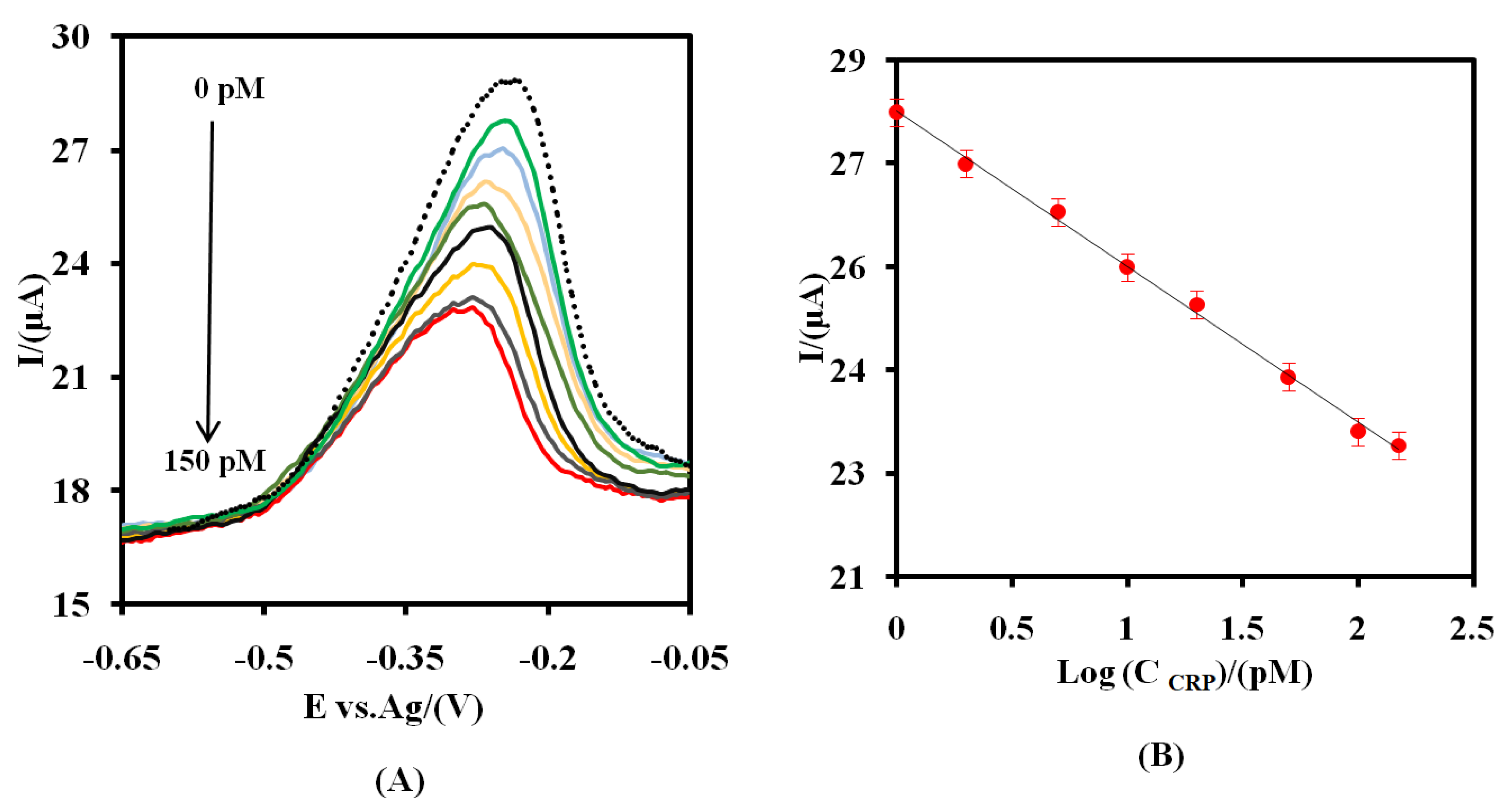

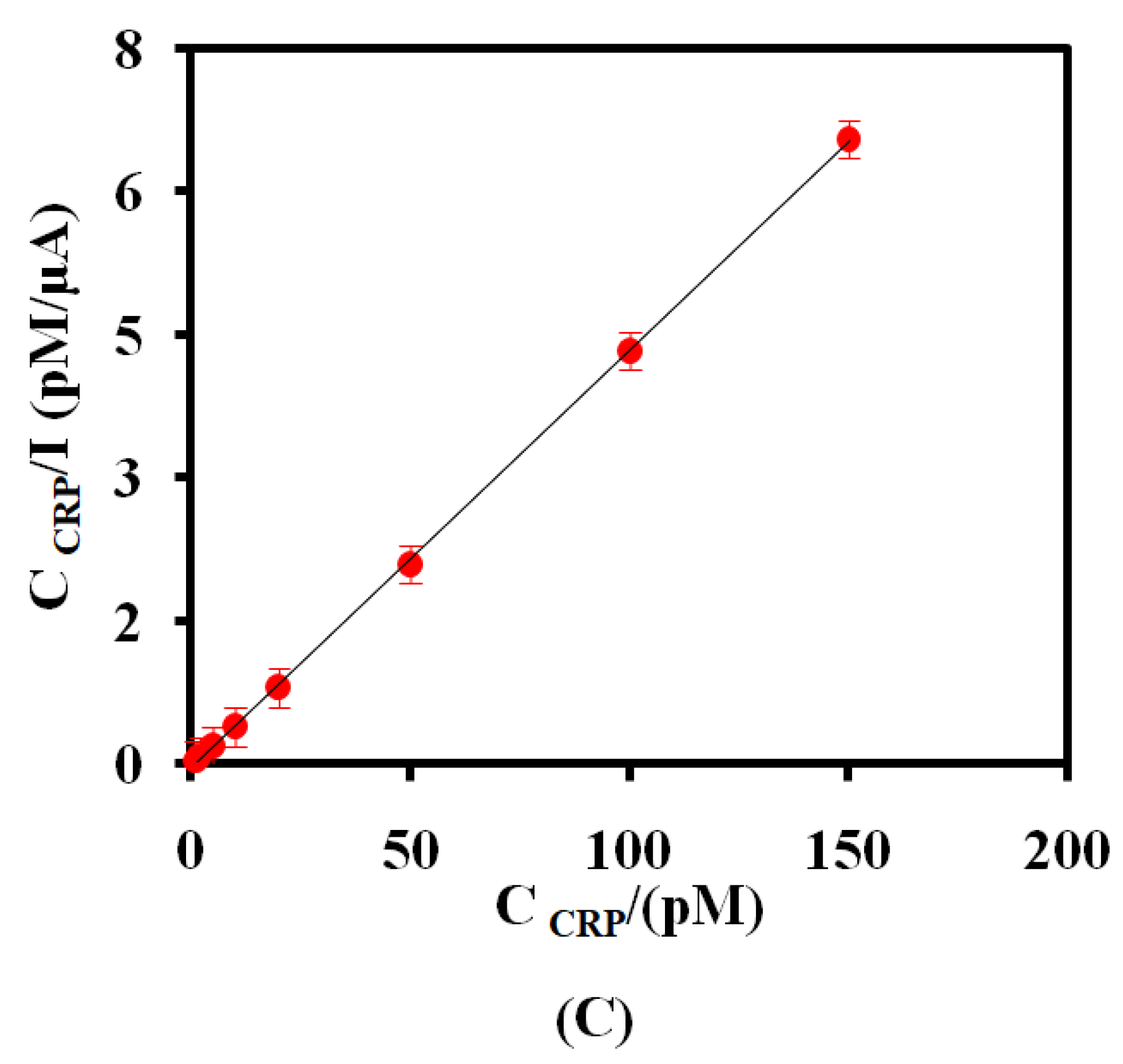

3.5. Voltammetric Detection of CRP

3.6. Stability, Reproducibility, and Selectivity of the CSPE/CNFs-CHIT-GLU-RNA Aptamer-MB

3.7. Analytical Application of the Modified Electrode

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ponti, G.; Maccaferri, M.; Ruini, C.; Tomasi, A.; Ozben, T. Biomarkers associated with COVID-19 disease progression. Crit. Rev. Clin. Lab. Sci. 2020, 57, 389–399. [Google Scholar] [CrossRef] [PubMed]

- Riese, H.; Vrijkotte, T.G.M.; Meijer, P.; Kluft, C.; de Geus, E.J.C. Diagnostic strategies for c-reactive protein. BMC Cardiovasc. Disord. 2002, 2, 9. [Google Scholar] [CrossRef] [PubMed]

- Tabrizi, M.A. The electrochemical aptasensors for the determination of tumor markers. In Graphene Bioelectronics; Tiwari, A., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; Chapter 9; pp. 193–218. [Google Scholar]

- Vance, S.A.; Sandros, M.G. Zeptomole detection of c-reactive protein in serum by a nanoparticle amplified surface plasmon resonance imaging aptasensor. Sci. Rep. 2014, 4, 5129. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Zhao, J.; Jin, T.; Sun, S.; Liu, W.; Tan, Y. An aptasensor based on the microscopic enumeration of encoding gold nanoparticles for the detection of c-reactive protein. RSC Adv. 2019, 9, 34293–34298. [Google Scholar] [CrossRef]

- Centi, S.; BonelSanmartin, L.; Tombelli, S.; Palchetti, I.; Mascini, M. Detection of c reactive protein (crp) in serum by an electrochemical aptamer-based sandwich assay. Electroanalysis 2009, 21, 1309–1315. [Google Scholar] [CrossRef]

- Jayasena, S.D. Aptamers: An emerging class of molecules that rival antibodies in diagnostics. Clin. Chem. 1999, 45, 1628–1650. [Google Scholar] [CrossRef]

- Jarczewska, M.; Ziółkowski, R.; Górski, Ł.; Malinowska, E. Application of rna aptamers as recognition layers for the electrochemical analysis of c-reactive protein. Electroanalysis 2018, 30, 658–664. [Google Scholar] [CrossRef]

- Xue, S.; Yi, H.; Yuan, Y.; Jing, P.; Xu, W. A label-free and sensitive electrochemical aptasensor for thrombin based on the direct electron transfer of hemin and hemin@rgo nanosheets as the signal probe. Anal. Methods 2015, 7, 8771–8777. [Google Scholar] [CrossRef]

- Voyvodic, P.L.; Pandi, A.; Koch, M.; Conejero, I.; Valjent, E.; Courtet, P.; Renard, E.; Faulon, J.-L.; Bonnet, J. Plug-and-play metabolic transducers expand the chemical detection space of cell-free biosensors. Nat. Commun. 2019, 10, 1697. [Google Scholar] [CrossRef]

- Arroyo-Currás, N.; Somerson, J.; Vieira, P.A.; Ploense, K.L.; Kippin, T.E.; Plaxco, K.W. Real-time measurement of small molecules directly in awake, ambulatory animals. PNAS 2017, 114, 645. [Google Scholar] [CrossRef]

- Arris, F.A.; Benoudjit, A.M.; Sanober, F.; Wan Salim, W.W.A. Characterization of electrochemical transducers for biosensor applications. In Multifaceted Protocol in Biotechnology; Springer: Berlin/Heidelberg, Germany, 2018; pp. 119–137. [Google Scholar]

- Meirinho, S.G.; Dias, L.G.; Peres, A.M.; Rodrigues, L.R. Voltammetric aptasensors for protein disease biomarkers detection: A review. Biotechnol. Adv. 2016, 34, 941–953. [Google Scholar] [CrossRef] [PubMed]

- Bini, A.; Centi, S.; Tombelli, S.; Minunni, M.; Mascini, M. Development of an optical rna-based aptasensor for c-reactive protein. Anal. Bioanal. Chem. 2008, 390, 1077–1086. [Google Scholar] [CrossRef] [PubMed]

- Díaz-Fernández, A.; Lorenzo-Gómez, R.; Miranda-Castro, R.; de-los-Santos-Álvarez, N.; Lobo-Castañón, M.J. Electrochemical aptasensors for cancer diagnosis in biological fluids—A review. Anal. Chim. Acta 2020, 1124, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Suresh, R.R.; Lakshmanakumar, M.; Arockia Jayalatha, J.B.B.; Rajan, K.S.; Sethuraman, S.; Krishnan, U.M.; Rayappan, J.B.B. Fabrication of screen-printed electrodes: Opportunities and challenges. J. Mater. Sci. 2021, 56, 8951–9006. [Google Scholar] [CrossRef]

- Li, R.; Ma, X.; Li, J.; Cao, J.; Gao, H.; Li, T.; Zhang, X.; Wang, L.; Zhang, Q.; Wang, G.; et al. Flexible and high-performance electrochromic devices enabled by self-assembled 2d tio2/mxene heterostructures. Nat. Commun. 2021, 12, 1587. [Google Scholar] [CrossRef]

- Liu, N.; Xiang, X.; Fu, L.; Cao, Q.; Huang, R.; Liu, H.; Han, G.; Wu, L. Regenerative field effect transistor biosensor for in vivo monitoring of dopamine in fish brains. Biosens. Bioelectron. 2021, 188, 113340. [Google Scholar] [CrossRef]

- Tabrizi, M.A.; Ferré-Borrull, J.; Kapruwan, P.; Marsal, L.F. A photoelectrochemical sandwich immunoassay for protein s100β, a biomarker for alzheimer’s disease, using an ito electrode modified with a reduced graphene oxide-gold conjugate and cds-labeled secondary antibody. Microchim. Acta 2019, 186, 117. [Google Scholar] [CrossRef]

- Huang, J.; Liu, Y.; You, T. Carbon nanofiber based electrochemical biosensors: A review. Anal. Chem. 2010, 2, 202–211. [Google Scholar] [CrossRef]

- Hao, C.; Ding, L.; Zhang, X.; Ju, H. Biocompatible conductive architecture of carbon nanofiber-doped chitosan prepared with controllable electrodeposition for cytosensing. Anal. Chem. 2007, 79, 4442–4447. [Google Scholar] [CrossRef]

- Lim, S.A.; Ahmed, M.U. A carbon nanofiber-based label free immunosensor for high sensitive detection of recombinant bovine somatotropin. Biosens. Bioelectron. 2015, 70, 48–53. [Google Scholar] [CrossRef]

- Shi, X.; Chen, M.; Feng, H.; Zhou, Z.; Wu, R.; Li, W.; Liang, J.; Chen, J.; Li, G. Glypican-3 electrochemical aptasensor based on reduced graphene oxide-chitosan-ferrocene deposition of platinum–palladium bimetallic nanoparticles. J. Appl. Electrochem. 2021, 51, 781–794. [Google Scholar] [CrossRef]

- Tani, A.; Thomson, A.J.; Butt, J.N. Methylene blue as an electrochemical discriminator of single- and double-stranded oligonucleotides immobilised on gold substrates. Analyst 2001, 126, 1756–1759. [Google Scholar] [CrossRef] [PubMed]

- Jarczewska, M.; Rębiś, J.; Górskia, Ł.; Malinowska, E. Development of DNA aptamer-based sensor for electrochemical detection of C-reactive protein. Talanta 2018, 189, 45–54. [Google Scholar] [CrossRef] [PubMed]

- Migneault, I.; Dartiguenave, C.; Bertrand, M.J.; Waldron, K.C. Glutaraldehyde: Behavior in aqueous solution, reaction with proteins, and application to enzyme crosslinking. BioTechniques 2004, 37, 790–802. [Google Scholar] [CrossRef]

- García-Miranda Ferrari, A.; Foster, C.W.; Kelly, P.J.; Brownson, D.A.C.; Banks, C.E. Determination of the electrochemical area of screen-printed electrochemical sensing platforms. Biosensors 2018, 8, 53. [Google Scholar] [CrossRef]

- Festinger, N.; Morawska, K.; Ivanovski, V.; Ziąbka, M.; Jedlińska, K.; Ciesielski, W.; Smarzewska, S. Comparative electroanalytical studies of graphite flake and multilayer graphene paste electrodes. Sensors 2020, 20, 1684. [Google Scholar] [CrossRef]

- David, K. Gosser, Cyclic Voltammetry—Simulation and Analysis of Reaction Mechanisms; VCH, Weinheim: New York, NY, USA, 1993; Volume xi, p. 154. [Google Scholar]

- Mata-Miranda, M.M.; Vazquez-Zapien, G.J.; Rojas-Lopez, M.; Sanchez-Monroy, V.; Perez-Ishiwara, D.G.; Delgado-Macuil, R.J. Morphological, molecular and ftir spectroscopic analysis during the differentiation of kidney cells from pluripotent stem cells. Biol. Res. 2017, 50, 14. [Google Scholar] [CrossRef]

- Mello, M.L.; Vidal, B.C. Changes in the infrared microspectroscopic characteristics of DNA caused by cationic elements, different base richness and single-stranded form. PLoS ONE 2012, 7, e43169. [Google Scholar] [CrossRef]

- Hu, Y.; Hua, S.; Li, F.; Jiang, Y.; Bai, X.; Li, D.; Niu, L. Green-synthesized gold nanoparticles decorated graphene sheets for label-free electrochemical impedance DNA hybridization biosensing. Biosens. Bioelectron. 2011, 26, 4355–4361. [Google Scholar] [CrossRef]

- Ju, H.; Zhou, J.; Cai, C.; Chen, H. The electrochemical behavior of methylene blue at a microcylinder carbon fiber electrode. Electroanalysis 1995, 7, 1165–1170. [Google Scholar] [CrossRef]

- Steel, A.B.; Herne, T.M.; Tarlov, M.J. Electrochemical quantitation of DNA immobilized on gold. Anal. Chem. 1998, 70, 4670–4677. [Google Scholar] [CrossRef] [PubMed]

- Laviron, E. General expression of the linear potential sweep voltammogram in the case of diffusionless electrochemical systems. J. Electroanal. Chem. Interf. Electrochem. 1979, 101, 19–28. [Google Scholar] [CrossRef]

- He, B.-S.; Yan, S.-S. Electrochemical aptasensor based on aptamer-complimentary strand conjugate and thionine for sensitive detection of tetracycline with multi-walled carbon nanotubes and gold nanoparticles amplification. Anal. Methods 2018, 10, 783–790. [Google Scholar] [CrossRef]

- Schwartz, M.P.; Alvarez, S.D.; Sailor, M.J. Porous sio2 interferometric biosensor for quantitative determination of protein interactions: Binding of protein a to immunoglobulins derived from different species. Anal. Chem. 2007, 79, 327–334. [Google Scholar] [CrossRef] [PubMed]

- Borea, P.A.; Varani, K.; Gessi, S.; Gilli, P.; Dalpiaz, A. Receptor binding thermodynamics as a tool for linking drug efficacy and affinity1presented at the first italian–swiss meeting on medicinal chemistry, turin, italy, september 1997.1. Farmaco 1998, 53, 249–254. [Google Scholar] [CrossRef]

- Wang, J.; Guo, J.; Zhang, J.; Zhang, W.; Zhang, Y. Rna aptamer-based electrochemical aptasensor for c-reactive protein detection using functionalized silica microspheres as immunoprobes. Biosens. Bioelectron. 2017, 95, 100–105. [Google Scholar] [CrossRef]

| Aptasensor | Detection Technique | Linear Response Range | LOD | Kd | Гaptamer | Ref. |

|---|---|---|---|---|---|---|

| MBs-Aptamer-AuNP | Dark-field microscopy | 6.1–49 nM | 2.71 nM | - | - | [5] |

| Gold elecrode/RNA aptamer-MB | SWV | 1–100 pM | 1 pM | 25.9 pM | 4.98 pmol cm−2 | [8] |

| Gold elecrode/DNA aptamer-MB | SWV | 1–100 pM | 1 pM | 6 pM | 8.3 pmol cm−2 | [25] |

| Gold-streptavidin-Biotinated aptamer | SPR | 0.005–0.5 ppm | 0.005 ppm | 125 nM | - | [14] |

| GCE/AuNP/Aptamer-and SiO2-APTES-AuNP-Antibody/BSA-Zn2+ ion | SWV | 5.0–125.0 pg mL−1 | 7.0 pg mL−1 | - | - | [39] |

| CSPE/CNFs-CHIT-RNA aptamer-MB | SWV | 1–150 pM | 0.37 pM | 0.93 pM | 53.8 pmol cm−2 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amouzadeh Tabrizi, M.; Acedo, P. Highly Sensitive RNA-Based Electrochemical Aptasensor for the Determination of C-Reactive Protein Using Carbon Nanofiber-Chitosan Modified Screen-Printed Electrode. Nanomaterials 2022, 12, 415. https://doi.org/10.3390/nano12030415

Amouzadeh Tabrizi M, Acedo P. Highly Sensitive RNA-Based Electrochemical Aptasensor for the Determination of C-Reactive Protein Using Carbon Nanofiber-Chitosan Modified Screen-Printed Electrode. Nanomaterials. 2022; 12(3):415. https://doi.org/10.3390/nano12030415

Chicago/Turabian StyleAmouzadeh Tabrizi, Mahmoud, and Pablo Acedo. 2022. "Highly Sensitive RNA-Based Electrochemical Aptasensor for the Determination of C-Reactive Protein Using Carbon Nanofiber-Chitosan Modified Screen-Printed Electrode" Nanomaterials 12, no. 3: 415. https://doi.org/10.3390/nano12030415

APA StyleAmouzadeh Tabrizi, M., & Acedo, P. (2022). Highly Sensitive RNA-Based Electrochemical Aptasensor for the Determination of C-Reactive Protein Using Carbon Nanofiber-Chitosan Modified Screen-Printed Electrode. Nanomaterials, 12(3), 415. https://doi.org/10.3390/nano12030415