Anisotropic Thermal Conductivity of Inkjet-Printed 2D Crystal Films: Role of the Microstructure and Interfaces

Abstract

1. Introduction

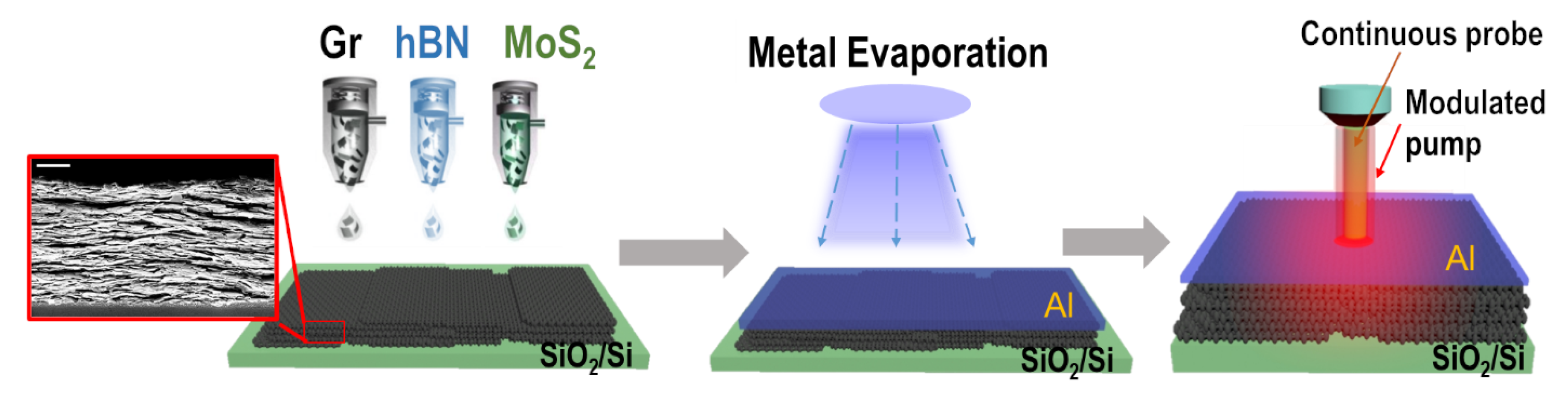

2. 2D Crystal Film Preparation and Characterization

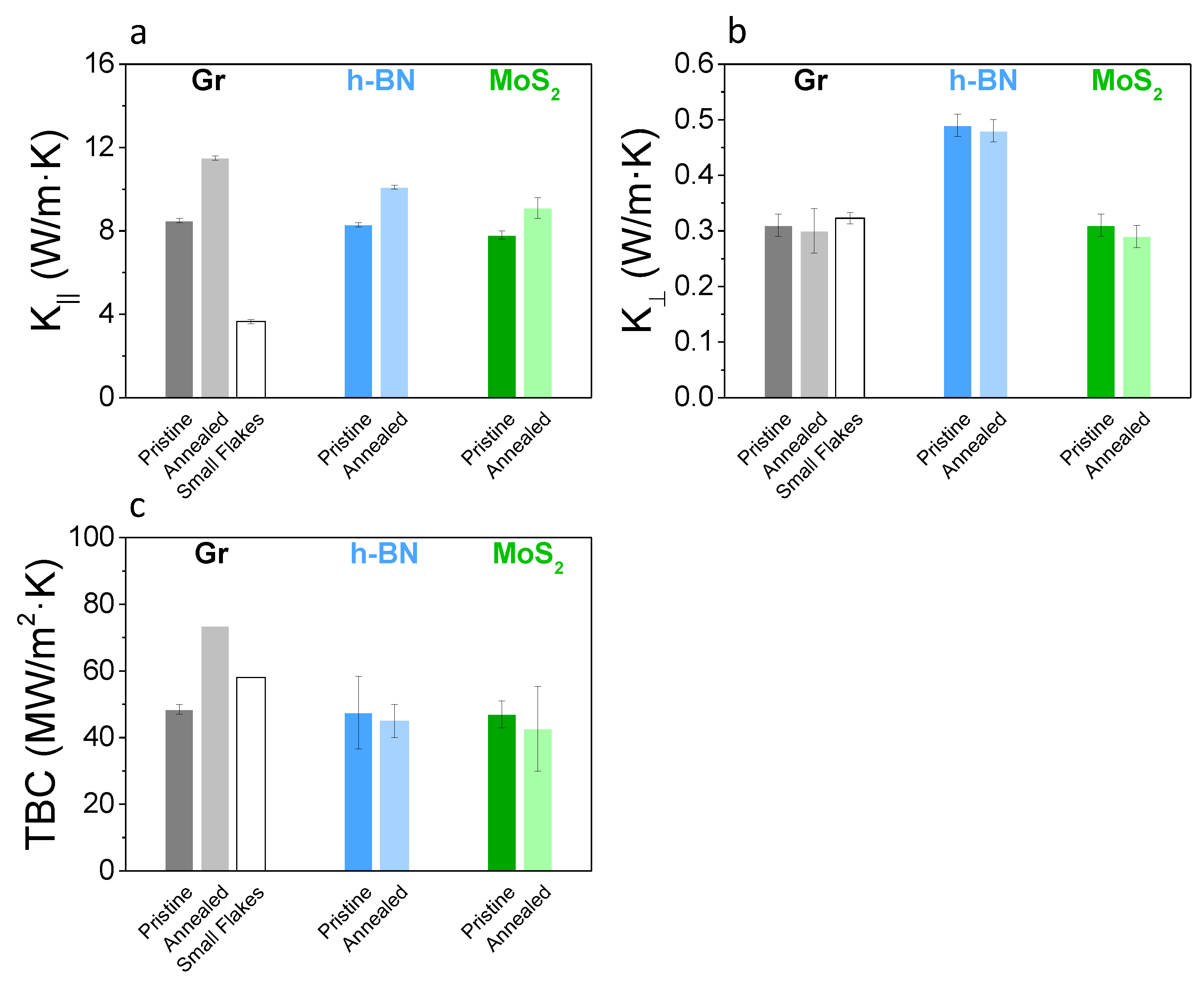

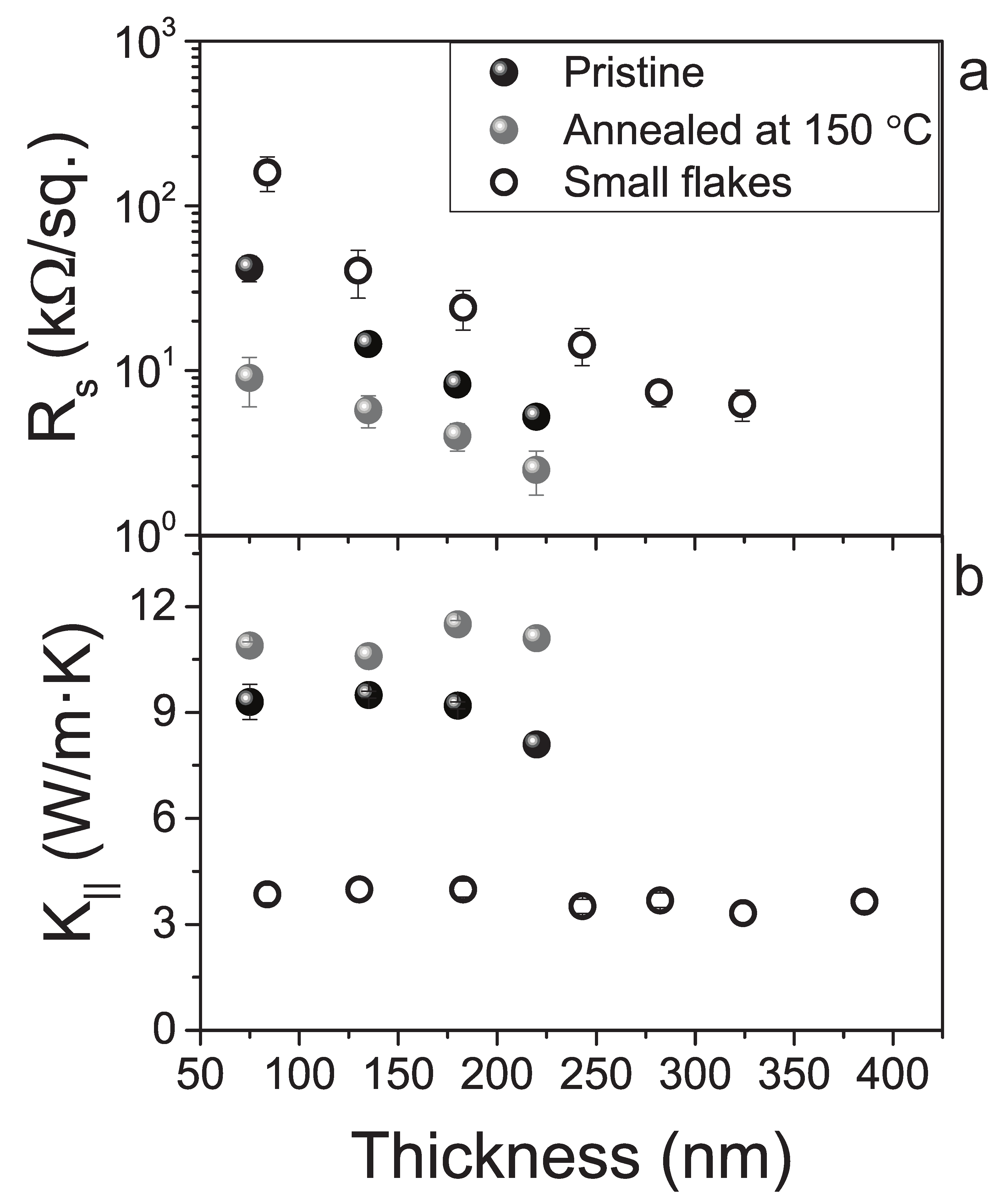

3. Results

| Materials | Flake Thickness (nm) | Lateral Size (m) | Thickness (m) | (WmK) | (WmK) | Method | Reference | |

|---|---|---|---|---|---|---|---|---|

| rGO | 1.1 | — | 4.3–12 | 1100 | — | — | 2000 C annealed | [49] |

| rGO | ∼1 | Avg. area 23 m2 | 7.5 | 1390 ± 65 | — | — | VF, HI acid reduced | [50] |

| rGO | ∼1 | Avg. area 1 m2 | — | 900 ± 45 | — | — | VF, HI acid reduced | [50] |

| rGO | — | 25 | — | 1434 | — | — | Electrospray deposition, 2850 C annealed | [51] |

| rGO | 1–7 | 108 | 10 | 1940 ± 113 | — | — | Scraping deposition, compressed and 3000 C annealed | [36] |

| rGO | <1 | >6 | 0.8 | 3200 | — | — | 2850 C annealed, compressed | [52] |

| rGO | — | — | 170 | 62 | 0.09 | 675 | 1000 C annealed | [23] |

| rGO + Carbon nanorings | — | — | — | 890 | 5.8 | 15 | VF, in situ growth of CNR (800 C) | [53] |

| LPE graphene | <10 layers | — | 30 | 110 | 0.25 | 440 | VF | [24] |

| LPE graphene | — | 0.96–1.24 | 9–44 | 40–90 | — | — | VF, compressed | [21] |

| ECE graphene | 4 | 3–4 | — | 1023 | — | — | VF, 2500 C annealed | [43] |

| ECE graphene | ≤8 layers | — | 33 | 674 | — | — | VF | [54] 1 |

| ECE graphene | ∼2.2 | >10 | 5–10 | 3390 | 5.5 | 616 | VF | [46] |

| Fluorinated graphene | 0.8–2.3 | 0.8 | 10–100 | 88–242 | 0.4–22 | 220–11 | Ball milling, VF | [26] |

| Functionalized FLG | 7.35 | — | 1050 | 112–123 | 1.62–1.81 | 69–68 | VF | [27] |

| GNP | ≤10 | 15 | — | 178 ± 12 | 1.28 ± 0.12 | 139 | Microwave exfoliation, VF, 340 C annealed | [28] |

| GNP | 4–5 layers | 0.648 | 30–70 | 1529 | — | — | Ball milling, 2850 C annealed | [44] |

| IJP graphene | ∼2 | ∼0.2 | 0.08–0.4 | ∼12 | 0.3 | ∼27–40 | LPE, IJP, 150 C annealed | This work |

| hBN laminate | 10 | 1 | 10–100 | 20 | — | — | LPE, VF | [22] |

| BN NSs | 2.9 ± 0.3 | 1.8 ± 0.1 | 10–30 | 58 | 3.3 | 18 | Molten alkali-assisted exfoliation, VF, 450 C annealed | [29] |

| IJP hBN | ∼2 | ∼0.2 | 0.2–1 | ∼11 | 0.5 | ∼22 | LPE, IJP, 150 C annealed | This work |

| MXene (TiCTx) | — | — | 3000 | 55 | — | — | Chemical etching, VF | [55] |

| IJP MoS | ∼4 | ∼0.05 | 0.06–0.25 | ∼9.5 | 0.3 | ∼32 | LPE, IJP, 150 C annealed | This work |

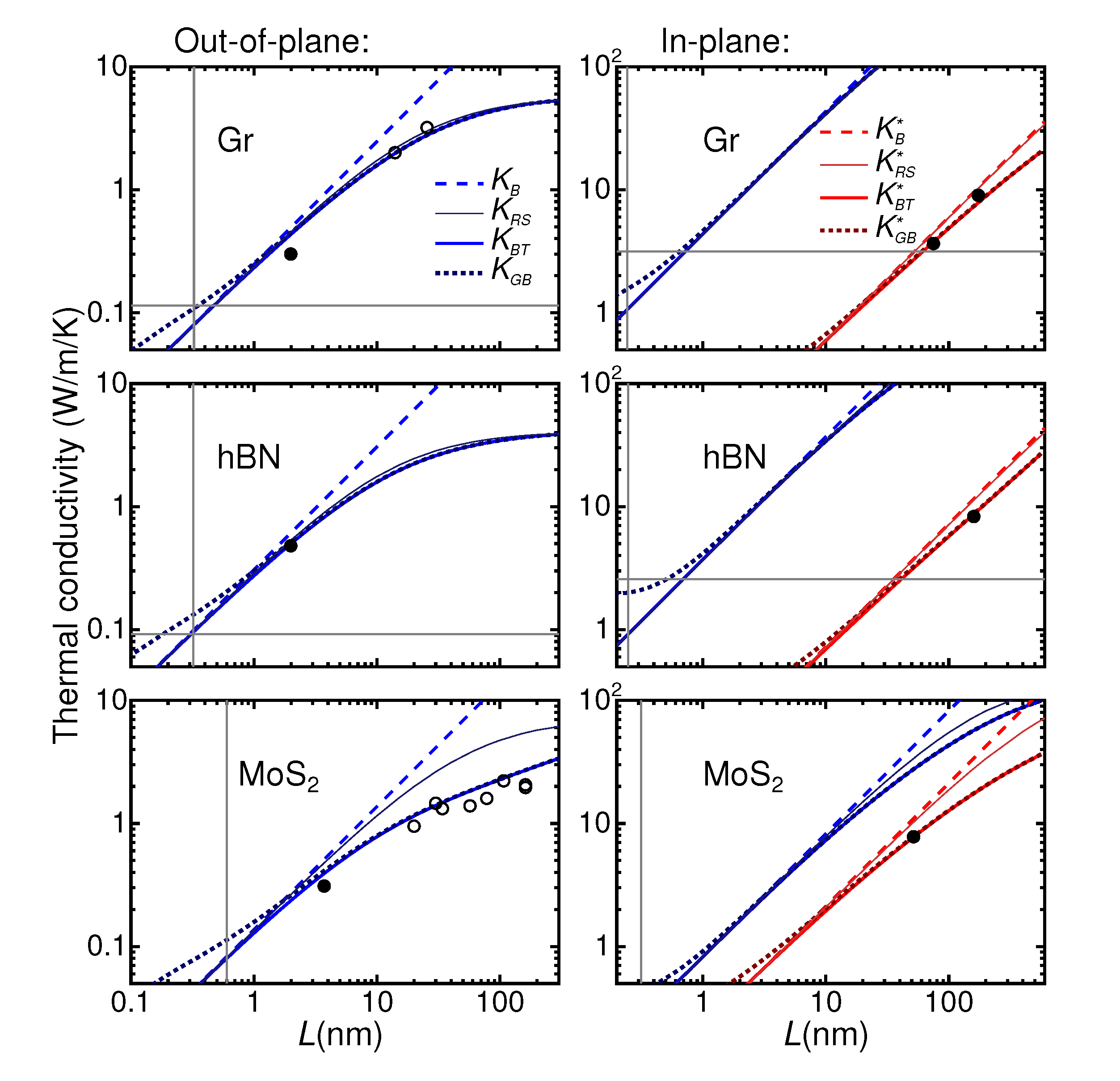

4. Ab-Initio Modeling

4.1. Ballistic Model and Ideal Interface

4.2. Ballistic vs. Diffusive Transport

4.3. Disorder Limit for the BTE

4.4. Hard Limits of the Phonon Models

4.5. Ideal vs. Dirty Interfaces

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, W.; Wang, R.; Majumdar, A. Nanostructuring expands thermal limits. Nano Today 2007, 2, 40–47. [Google Scholar] [CrossRef]

- Pop, E. Energy dissipation and transport in nanoscale devices. Nano Res. 2010, 3, 147–169. [Google Scholar] [CrossRef]

- Stan, M. Discovery and design of nuclear fuels. Mater. Today 2009, 12, 20–28. [Google Scholar] [CrossRef]

- Zhao, L.D.; Lo, S.H.; Zhang, Y.; Sun, H.; Tan, G.; Uher, C.; Wolverton, C.; Dravid, V.P.; Kanatzidis, M.G. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 2014, 508, 373–377. [Google Scholar] [CrossRef]

- Wu, S.; Yan, T.; Kuai, Z.; Pan, W. Thermal conductivity enhancement on phase change materials for thermal energy storage: A review. Energy Storage Mater. 2020, 25, 251–295. [Google Scholar] [CrossRef]

- Baur, J.; Silverman, E. Challenges and Opportunities in Multifunctional Nanocomposite Structures for Aerospace Applications. MRS Bull. 2007, 32, 328–334. [Google Scholar] [CrossRef]

- Shi, X.; Kong, H.; Li, C.P.; Uher, C.; Yang, J.; Salvador, J.R.; Wang, H.; Chen, L.; Zhang, W. Low thermal conductivity and high thermoelectric figure of merit in n-type BaxYbyCo4Sb12 double-filled skutterudites. Appl. Phys. Lett. 2008, 92, 182101. [Google Scholar] [CrossRef]

- Tian, X.; Itkis, M.E.; Bekyarova, E.B.; Haddon, R.C. Anisotropic Thermal and Electrical Properties of Thin Thermal Interface Layers of Graphite Nanoplatelet-Based Composites. Sci. Rep. 2013, 3, 1710. [Google Scholar] [CrossRef]

- Bain, J.A.; Malen, J.A.; Jeong, M.; Ganapathy, T. Nanoscale thermal transport aspects of heat-assisted magnetic recording devices and materials. MRS Bull. 2018, 43, 112–118. [Google Scholar] [CrossRef]

- Slack, G.A. Nonmetallic crystals with high thermal conductivity. J. Phys. Chem. Solids 1973, 34, 321–335. [Google Scholar] [CrossRef]

- Cahill, D.G.; Pohl, R.O. Lattice Vibrations and Heat Transport in Crystals and Glasses. Annu. Rev. Phys. Chem. 1988, 39, 93–121. [Google Scholar] [CrossRef]

- Chiritescu, C.; Cahill, D.G.; Nguyen, N.; Johnson, D.; Bodapati, A.; Keblinski, P.; Zschack, P. Ultralow Thermal Conductivity in Disordered, Layered WS2 Crystals. Science 2007, 315, 351. [Google Scholar] [CrossRef] [PubMed]

- Lindroth, D.O.; Erhart, P. Thermal transport in van der Waals solids from first-principles calculations. Phys. Rev. B 2016, 94, 115205. [Google Scholar] [CrossRef]

- Hadland, E.; Jang, H.; Falmbigl, M.; Fischer, R.; Medlin, D.L.; Cahill, D.G.; Johnson, D.C. Synthesis, Characterization, and Ultralow Thermal Conductivity of a Lattice-Mismatched SnSe2(MoSe2)1.32 Heterostructure. Chem. Mater. 2019, 31, 5699–5705. [Google Scholar] [CrossRef]

- Qian, X.; Gu, X.; Dresselhaus, M.S.; Yang, R. Anisotropic Tuning of Graphite Thermal Conductivity by Lithium Intercalation. J. Phys. Chem. Lett. 2016, 7, 4744–4750. [Google Scholar] [CrossRef]

- Fugallo, G.; Cepellotti, A.; Paulatto, L.; Lazzeri, M.; Marzari, N.; Mauri, F. Thermal Conductivity of Graphene and Graphite: Collective Excitations and Mean Free Paths. Nano Lett. 2014, 14, 6109–6114. [Google Scholar] [CrossRef] [PubMed]

- Erhart, P.; Hyldgaard, P.; Lindroth, D.O. Microscopic Origin of Thermal Conductivity Reduction in Disordered van der Waals Solids. Chem. Mater. 2015, 27, 5511–5518. [Google Scholar] [CrossRef]

- Dechaumphai, E.; Lu, D.; Kan, J.J.; Moon, J.; Fullerton, E.E.; Liu, Z.; Chen, R. Ultralow Thermal Conductivity of Multilayers with Highly Dissimilar Debye Temperatures. Nano Lett. 2014, 14, 2448–2455. [Google Scholar] [CrossRef]

- Shahzadeh, M.; Andriyevska, O.; Salikhov, R.; Fallarino, L.; Hellwig, O.; Pisana, S. Nondiffusive Transport and Anisotropic Thermal Conductivity in High-Density Pt/Co Superlattices. ACS Appl. Electron. Mater. 2021, 3, 1931–1936. [Google Scholar] [CrossRef]

- Sood, A.; Xiong, F.; Chen, S.; Cheaito, R.; Lian, F.; Asheghi, M.; Cui, Y.; Donadio, D.; Goodson, K.E.; Pop, E. Quasi-Ballistic Thermal Transport Across MoS2 Thin Films. Nano Lett. 2019, 19, 2434–2442. [Google Scholar] [CrossRef]

- Malekpour, H.; Chang, K.H.; Chen, J.C.; Lu, C.Y.; Nika, D.L.; Novoselov, K.S.; Balandin, A.A. Thermal Conductivity of Graphene Laminate. Nano Lett. 2014, 14, 5155–5161. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.C.; Zhang, L.; Kretinin, A.V.; Morozov, S.V.; Wang, Y.B.; Wang, T.; Li, X.; Ren, F.; Zhang, J.; Lu, C.Y.; et al. High thermal conductivity of hexagonal boron nitride laminates. 2D Mater. 2016, 3, 011004. [Google Scholar] [CrossRef]

- Renteria, J.D.; Ramirez, S.; Malekpour, H.; Alonso, B.; Centeno, A.; Zurutuza, A.; Cocemasov, A.I.; Nika, D.L.; Balandin, A.A. Strongly Anisotropic Thermal Conductivity of Free-Standing Reduced Graphene Oxide Films Annealed at High Temperature. Adv. Funct. Mater. 2015, 25, 4664–4672. [Google Scholar] [CrossRef]

- Zhang, Y.; Edwards, M.; Samani, M.K.; Logothetis, N.; Ye, L.; Fu, Y.; Jeppson, K.; Liu, J. Characterization and simulation of liquid phase exfoliated graphene-based films for heat spreading applications. Carbon 2016, 106, 195–201. [Google Scholar] [CrossRef]

- McManus, D.; Vranic, S.; Withers, F.; Sanchez-Romaguera, V.; Macucci, M.; Yang, H.; Sorrentino, R.; Parvez, K.; Son, S.K.; Iannaccone, G.; et al. Water-based and biocompatible 2D crystal inks for all-inkjet-printed heterostructures. Nat. Nanotechnol. 2017, 12, 343. [Google Scholar] [CrossRef]

- Vu, M.C.; Thi Thieu, N.A.; Lim, J.H.; Choi, W.K.; Chan Won, J.; Islam, M.A.; Kim, S.R. Ultrathin thermally conductive yet electrically insulating exfoliated graphene fluoride film for high performance heat dissipation. Carbon 2020, 157, 741–749. [Google Scholar] [CrossRef]

- Liang, Q.; Yao, X.; Wang, W.; Liu, Y.; Wong, C.P. A Three-Dimensional Vertically Aligned Functionalized Multilayer Graphene Architecture: An Approach for Graphene-Based Thermal Interfacial Materials. ACS Nano 2011, 5, 2392–2401. [Google Scholar] [CrossRef]

- Xiang, J.; Drzal, L.T. Thermal conductivity of exfoliated graphite nanoplatelet paper. Carbon 2011, 49, 773–778. [Google Scholar] [CrossRef]

- Fu, L.; Wang, T.; Yu, J.; Dai, W.; Sun, H.; Liu, Z.; Sun, R.; Jiang, N.; Yu, A.; Lin, C.T. An ultrathin high-performance heat spreader fabricated with hydroxylated boron nitride nanosheets. 2D Mater. 2017, 4, 025047. [Google Scholar] [CrossRef]

- Worsley, R.; Pimpolari, L.; McManus, D.; Ge, N.; Ionescu, R.; Wittkopf, J.A.; Alieva, A.; Basso, G.; Macucci, M.; Iannaccone, G.; et al. All-2D Material Inkjet-Printed Capacitors: Toward Fully Printed Integrated Circuits. ACS Nano 2019, 13, 54–60. [Google Scholar] [CrossRef]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Withers, F.; Gebremedhn, E.; Lewis, E.; Britnell, L.; Felten, A.; Palermo, V.; Haigh, S.; Beljonne, D.; Casiraghi, C. Dielectric nanosheets made by liquid-phase exfoliation in water and their use in graphene-based electronics. 2D Mater. 2014, 1, 011012. [Google Scholar] [CrossRef]

- Rahman, M.; Shahzadeh, M.; Braeuninger-Weimer, P.; Hofmann, S.; Hellwig, O.; Pisana, S. Measuring the thermal properties of anisotropic materials using beam-offset frequency domain thermoreflectance. J. Appl. Phys. 2018, 123, 245110. [Google Scholar] [CrossRef]

- Rahman, M.; Shahzadeh, M.; Pisana, S. Simultaneous measurement of anisotropic thermal conductivity and thermal boundary conductance of 2-dimensional materials. J. Appl. Phys. 2019, 126, 205103. [Google Scholar] [CrossRef]

- Schmidt, A.J.; Collins, K.C.; Minnich, A.J.; Chen, G. Thermal conductance and phonon transmissivity of metal-graphite interfaces. J. Appl. Phys. 2010, 107, 104907. [Google Scholar] [CrossRef]

- Jiang, P.; Qian, X.; Gu, X.; Yang, R. Probing Anisotropic Thermal Conductivity of Transition Metal Dichalcogenides MX2 (M = Mo, W and X = S, Se) using Time-Domain Thermoreflectance. Adv. Mater. 2017, 29, 1701068. [Google Scholar] [CrossRef]

- Wei, Z.; Chen, Y.; Dames, C. Negative correlation between in-plane bonding strength and cross-plane thermal conductivity in a model layered material. Appl. Phys. Lett. 2013, 102, 011901. [Google Scholar] [CrossRef]

- Klein, C.A.; Holland, M.G. Thermal Conductivity of Pyrolytic Graphite at Low Temperatures. I. Turbostratic Structures. Phys. Rev. 1964, 136, A575–A590. [Google Scholar] [CrossRef]

- Slack, G.A. Anisotropic Thermal Conductivity of Pyrolytic Graphite. Phys. Rev. 1962, 127, 694–701. [Google Scholar] [CrossRef]

- Schmidt, A.J.; Chen, X.; Chen, G. Pulse accumulation, radial heat conduction, and anisotropic thermal conductivity in pump-probe transient thermoreflectance. Rev. Sci. Instrum. 2008, 79, 114902. [Google Scholar] [CrossRef]

- Lindsay, L.; Broido, D.A. Enhanced thermal conductivity and isotope effect in single-layer hexagonal boron nitride. Phys. Rev. B 2011, 84, 155421. [Google Scholar] [CrossRef]

- Liu, J.; Choi, G.M.; Cahill, D.G. Measurement of the anisotropic thermal conductivity of molybdenum disulfide by the time-resolved magneto-optic Kerr effect. J. Appl. Phys. 2014, 116, 233107. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Kwon, Y.; Park, H.S.; Lee, J.U. Mass-Produced Electrochemically Exfoliated Graphene for Ultrahigh Thermally Conductive Paper Using a Multimetal Electrode System. Adv. Mater. Interfaces 2021, 6, 1900095. [Google Scholar] [CrossRef]

- Teng, C.; Xie, D.; Wang, J.; Yang, Z.; Ren, G.; Zhu, Y. Ultrahigh Conductive Graphene Paper Based on Ball-Milling Exfoliated Graphene. Adv. Funct. Mater. 2021, 27, 1700240. [Google Scholar] [CrossRef]

- Ong, W.L.; Rupich, S.M.; Talapin, D.V.; McGaughey, A.J.H.; Malen, J.A. Surface chemistry mediates thermal transport in three-dimensional nanocrystal arrays. Nat. Mater. 2013, 12, 410–415. [Google Scholar] [CrossRef]

- Gee, C.M.; Tseng, C.C.; Wu, F.Y.; Lin, C.T.; Chang, H.P.; Li, L.J.; Chen, J.C.; Hu, L.H. Few layer graphene paper from electrochemical process for heat conduction. Mater. Res. Innov. 2014, 18, 208–213. [Google Scholar] [CrossRef]

- Costescu, R.M.; Cahill, D.G.; Fabreguette, F.H.; Sechrist, Z.A.; George, S.M. Ultra-Low Thermal Conductivity in W/Al2O3 Nanolaminates. Science 2004, 303, 989–990. [Google Scholar] [CrossRef]

- Muratore, C.; Varshney, V.; Gengler, J.J.; Hu, J.J.; Bultman, J.E.; Smith, T.M.; Shamberger, P.J.; Qiu, B.; Ruan, X.; Roy, A.K.; et al. Cross-plane thermal properties of transition metal dichalcogenides. Appl. Phys. Lett. 2013, 102, 081604. [Google Scholar] [CrossRef]

- Shen, B.; Zhai, W; Zheng, W. Ultrathin flexible graphene film: An excellent thermal conducting material with efficient EMI shielding. Adv. Funct. Mater. 2014, 24, 4542–4548. [Google Scholar] [CrossRef]

- Kumar, P.; Shahzad, F.; Yu, S.; Hong, S.M.; Kim, Y.-H.; Koo, C.M. Large-area reduced graphene oxide thin film with excellent thermal conductivity and electromagnetic interference shielding effectiveness. Carbon 2015, 94, 494–500. [Google Scholar] [CrossRef]

- Xin, G.; Sun, H.; Hu, T.; Fard, H.R.; Sun, X.; Koratkar, N.; Borca-Tasciuc, T.; Lian, J. Large-area freestanding graphene paper for superior thermal management. Adv. Mater. 2014, 26, 4521–4526. [Google Scholar] [CrossRef]

- Wang, N.; Samani, M.K.; Li, H.; Dong, L.; Zhang, Z.; Su, P.; Chen, S.; Chen, J.; Huang, S.; Yuan, G.; et al. Tailoring the thermal and mechanical properties of graphene film by structural engineering. Small 2018, 29, 1801346. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, G.; Jiang, C.; Ju, S.; Jiang, D. 3D bridged carbon nanoring/graphene hybrid paper as a high-performance lateral heat spreader. Small 2015, 11, 6197–6204. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Zhang, K.; Yuen, M.M.F.; Fu, X.-Z.; Sun, R.; Wong, C.P. Electrochemically exfoliated graphene nanosheets for thermal and electrical conductions. In Proceedings of the 2015 16th International Conference on Electronic Packaging Technology (ICEPT), Changsha, China, 11–14 August 2015; 2015; pp. 253–255. [Google Scholar]

- Liu, R.; Li, W. High-thermal-stability and high-thermal-conductivity Ti3C2Tx MXene/poly(vinyl alcohol) (PVA) composites. ACS Omega 2018, 3, 2609–2617. [Google Scholar] [CrossRef] [PubMed]

- Jiang, P.; Qian, X.; Yang, R.; Lindsay, L. Anisotropic thermal transport in bulk hexagonal boron nitride. Phys. Rev. Mater. 2018, 2, 064005. [Google Scholar] [CrossRef]

- Fugallo, G.; Lazzeri, M.; Paulatto, L.; Mauri, F. Ab initio variational approach for evaluating lattice thermal conductivity. Phys. Rev. B 2013, 88, 045430. [Google Scholar] [CrossRef]

- Giannozzi, P.; Baroni, S.; Bonini, N.; Calandra, M.; Car, R.; Cavazzoni, C.; Ceresoli, D.; Chiarotti, G.L.; Cococcioni, M.; Dabo, I.; et al. QUANTUM ESPRESSO: A modular and open-source software project for quantum simulations of materials. J. Phys. Condens. Matter 2009, 21, 395502. [Google Scholar] [CrossRef]

- Baroni, S.; de Gironcoli, S.; Dal Corso, A.; Giannozzi, P. Phonons and related crystal properties from density-functional perturbation theory. Rev. Mod. Phys. 2001, 73, 515–562. [Google Scholar] [CrossRef]

- Paulatto, L.; Mauri, F.; Lazzeri, M. Anharmonic properties from a generalized third-order ab initio approach: Theory and applications to graphite and graphene. Phys. Rev. B 2013, 87, 214303. [Google Scholar] [CrossRef]

- Swartz, E.T.; Pohl, R.O. Thermal boundary resistance. Rev. Mod. Phys. 1989, 61, 605–668. [Google Scholar] [CrossRef]

- Datta, S. Electronic Transport in Mesoscopic Systems; Cambridge University Press: Cambridge, UK, 1995. [Google Scholar]

- Chen, G. Thermal conductivity and ballistic-phonon transport in the cross-plane direction of superlattices. Phys. Rev. B 1998, 57, 14958–14973. [Google Scholar] [CrossRef]

- Hua, C.; Minnich, A.J. Semi-analytical solution to the frequency-dependent Boltzmann transport equation for cross-plane heat conduction in thin films. J. Appl. Phys. 2015, 117, 175306. [Google Scholar] [CrossRef]

- Maassen, J.; Lundstrom, M. Steady-state heat transport: Ballistic-to-diffusive with Fourier’s law. J. Appl. Phys. 2015, 117, 035104. [Google Scholar] [CrossRef]

- Minnich, A.J. Determining Phonon Mean Free Paths from Observations of Quasiballistic Thermal Transport. Phys. Rev. Lett. 2012, 109, 205901. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, X.; Jho, Y.D.; Minnich, A.J. Temperature-Dependent Mean Free Path Spectra of Thermal Phonons Along the c-Axis of Graphite. Nano Lett. 2016, 16, 1643–1649. [Google Scholar] [CrossRef]

- Ziman, J. Electrons and Phonons; Clarendon Press: Oxford, UK, 1960. [Google Scholar]

- Simoncelli, M.; Marzari, N.; Mauri, F. Unified theory of thermal transport in crystals and glasses. Nat. Phys. 2019, 15, 809–813. [Google Scholar] [CrossRef]

- Isaeva, L.; Barbalinardo, G.; Donadio, D.; Baroni, S. Modeling heat transport in crystals and glasses from a unified lattice-dynamical approach. Nat. Commun. 2019, 10, 3853. [Google Scholar] [CrossRef]

- Allen, P.B.; Feldman, J.L. Thermal conductivity of disordered harmonic solids. Phys. Rev. B 1993, 48, 12581–12588. [Google Scholar] [CrossRef]

- Chen, Z.; Dames, C. An anisotropic model for the minimum thermal conductivity. Appl. Phys. Lett. 2015, 107, 193104. [Google Scholar] [CrossRef]

- Cahill, D.G.; Watson, S.K.; Pohl, R.O. Lower limit to the thermal conductivity of disordered crystals. Phys. Rev. B 1992, 46, 6131–6140. [Google Scholar] [CrossRef] [PubMed]

- Hernandez, Y.; Nicolosi, V.; Lotya, M.; Blighe, F.M.; Sun, Z.; De, S.; McGovern, I.T.; Holland, B.; Byrne, M.; Gun’Ko, Y.K.; et al. High-yield production of graphene by liquid-phase exfoliation of graphite. Nat. Nanotechnol. 2008, 3, 563. [Google Scholar] [CrossRef] [PubMed]

- Coleman, J.N.; Lotya, M.; O’Neill, A.; Bergin, S.D.; King, P.J.; Khan, U.; Young, K.; Gaucher, A.; De, S.; Smith, R.J.; et al. Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 2011, 331, 568. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, Y.; Azumi, T.; Sekine, Y. Heat capacity of aluminum from 80 to 800 K. Themochimica Acta 1989, 139, 133. [Google Scholar] [CrossRef]

- Butland, A.T.D.; Maddison, R.J. The specific heat of graphite: An evaluation of measurements. J. Nucl. Mater. 1973, 49, 45. [Google Scholar] [CrossRef]

- Dworkin, A.S.; Sasmor, D.J.; van Artsdalen, E.R. The thermodynamics of boron nitride: Low-temperature heat capacity and entropy; heats of combustion and formation. J. Chem. Phys. 1954, 22, 837. [Google Scholar] [CrossRef]

- Volovik, L.S.; Fesenko, V.V.; Bolgar, A.S.; Drozdova, S.V.; Klochkov, L.A.; Primachenko, V.F. Enthalpy and heat capacity of molybdenum disulfide. Sov. Powder Metall. Met. Ceram. 1978, 17, 697. [Google Scholar] [CrossRef]

- Foss, C.J.; Aksamija, Z. Quantifying thermal boundary conductance of 2D-3D interfaces. 2D Mater. 2019, 6, 025019. [Google Scholar] [CrossRef]

- Gabourie, A.J.; Koroglu, C.; Pop, E. Substrate-dependence of monolayer MoS2 thermal conductivity and thermal boundary conductance. arXiv 2022, arXiv:2204:11381. [Google Scholar] [CrossRef]

- Lide, D.R. CRC Handbook of Chemistry and Physics; Taylor & Francis: Abingdon, UK, 2007. [Google Scholar]

- Perdew, J.P.; Zunger, A. Self-interaction correction to density-functional approximations for many-electron systems. Phys. Rev. B 1981, 23, 5048. [Google Scholar] [CrossRef]

- Chen, S.; Sood, A.; Pop, E.; Goodson, K.E.; Donadio, D. Strongly tunable anisotropic thermal transport in MoS2 by strain and lithium intercalations: First-principles calculations. 2D Mater. 2019, 6, 025033. [Google Scholar] [CrossRef]

- Serrano, J.; Bosak, A.; Arenal, R.; Krisch, M.; Watanabe, K.; Taniguchi, T.; Kanda, H.; Rubio, A.; Wirtz, L. Vibrational properties of hexagonal boron nitride: Inelastic x-ray scattering and ab initio calculations. Phys. Rev. Lett. 2007, 98, 095503. [Google Scholar] [CrossRef] [PubMed]

- Nemanich, R.J.; Solin, S.A.; Martin, R.M. Light scattering study of boron nitride microcrystals. Phys. Rev. B 1981, 23, 6348. [Google Scholar] [CrossRef]

- Wakabayashi, N.; Smith, H.G.; Nicklow, R.M. Lattice dynamics of hexagonal MoS2 studied by neutron scattering. Phys. Rev. B 1975, 12, 659. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.; Parvez, K.; Fugallo, G.; Dun, C.; Read, O.; Alieva, A.; Urban, J.J.; Lazzeri, M.; Casiraghi, C.; Pisana, S. Anisotropic Thermal Conductivity of Inkjet-Printed 2D Crystal Films: Role of the Microstructure and Interfaces. Nanomaterials 2022, 12, 3861. https://doi.org/10.3390/nano12213861

Rahman M, Parvez K, Fugallo G, Dun C, Read O, Alieva A, Urban JJ, Lazzeri M, Casiraghi C, Pisana S. Anisotropic Thermal Conductivity of Inkjet-Printed 2D Crystal Films: Role of the Microstructure and Interfaces. Nanomaterials. 2022; 12(21):3861. https://doi.org/10.3390/nano12213861

Chicago/Turabian StyleRahman, Mizanur, Khaled Parvez, Giorgia Fugallo, Chaochao Dun, Oliver Read, Adriana Alieva, Jeffrey J. Urban, Michele Lazzeri, Cinzia Casiraghi, and Simone Pisana. 2022. "Anisotropic Thermal Conductivity of Inkjet-Printed 2D Crystal Films: Role of the Microstructure and Interfaces" Nanomaterials 12, no. 21: 3861. https://doi.org/10.3390/nano12213861

APA StyleRahman, M., Parvez, K., Fugallo, G., Dun, C., Read, O., Alieva, A., Urban, J. J., Lazzeri, M., Casiraghi, C., & Pisana, S. (2022). Anisotropic Thermal Conductivity of Inkjet-Printed 2D Crystal Films: Role of the Microstructure and Interfaces. Nanomaterials, 12(21), 3861. https://doi.org/10.3390/nano12213861