Bilayer Designed Paper-Based Solar Evaporator for Efficient Seawater Desalination

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

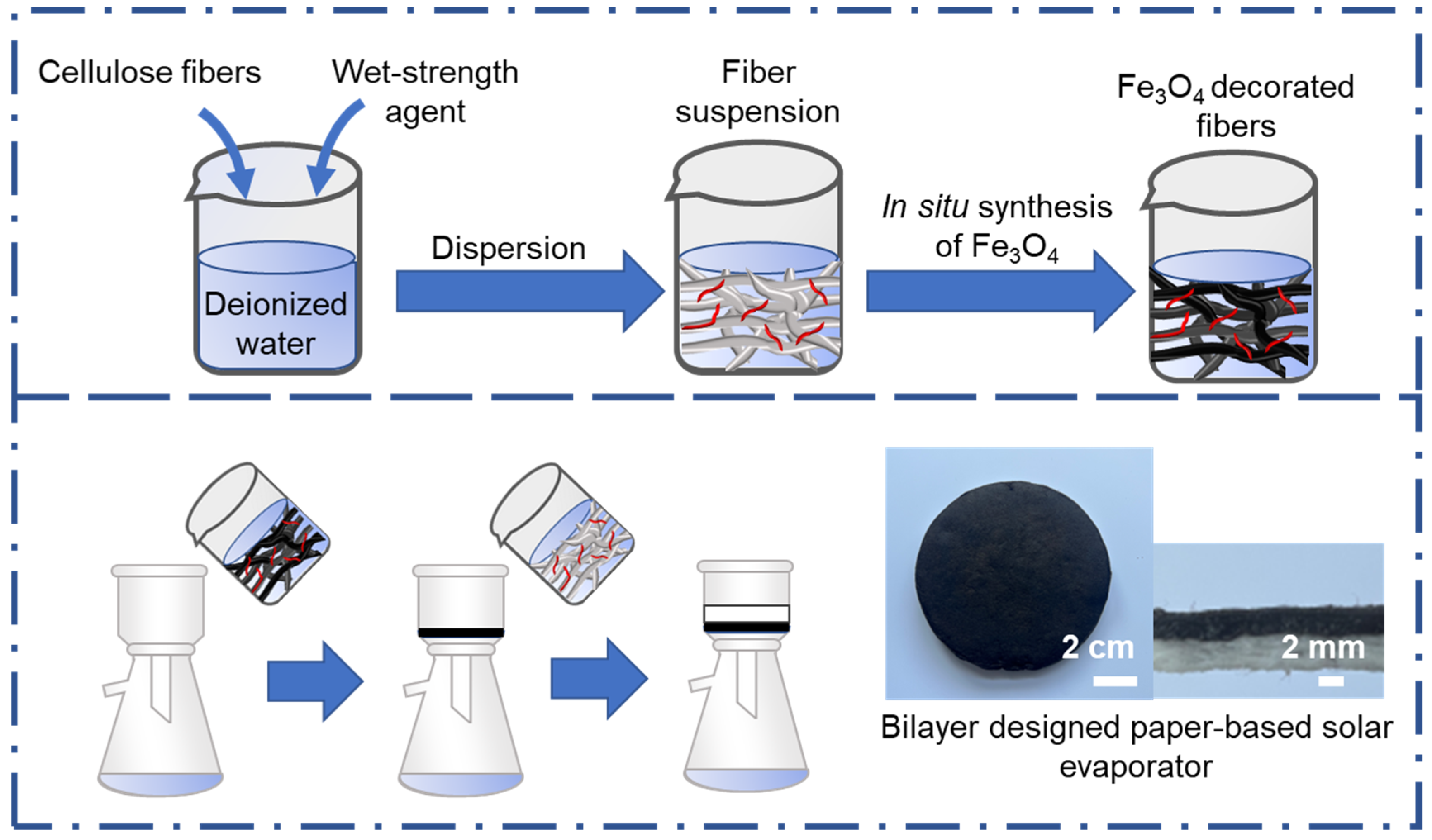

2.2. Preparation of Fe3O4-Decorated Fibers

2.3. Preparation of Bilayered Paper-Based Evaporator

2.4. Solar Steam Generation Test and Desalination Test

2.5. Characterization of Paper-Based Evaporator

3. Results and Discussion

3.1. Preparation of Bilayered Paper-Based Evaporator

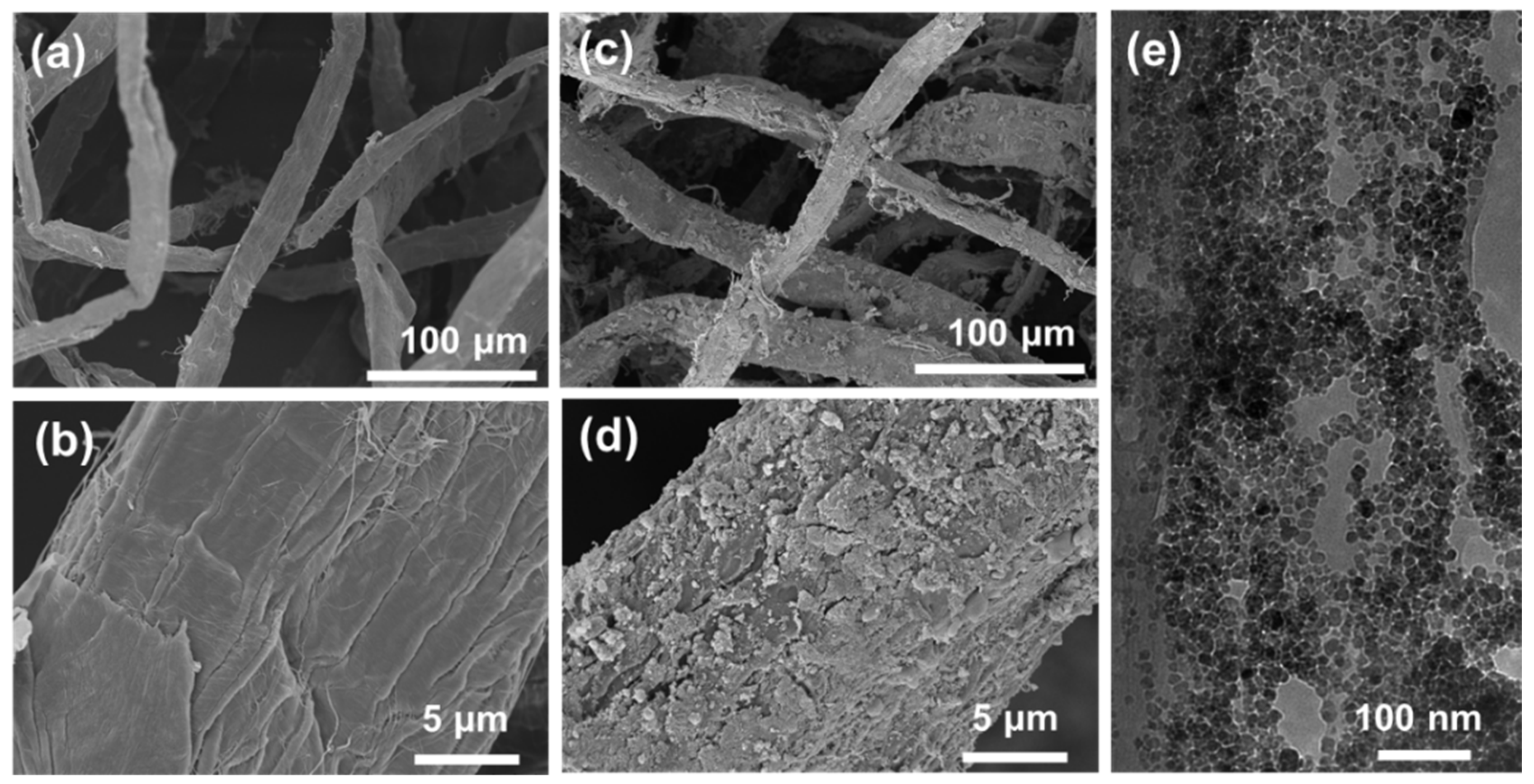

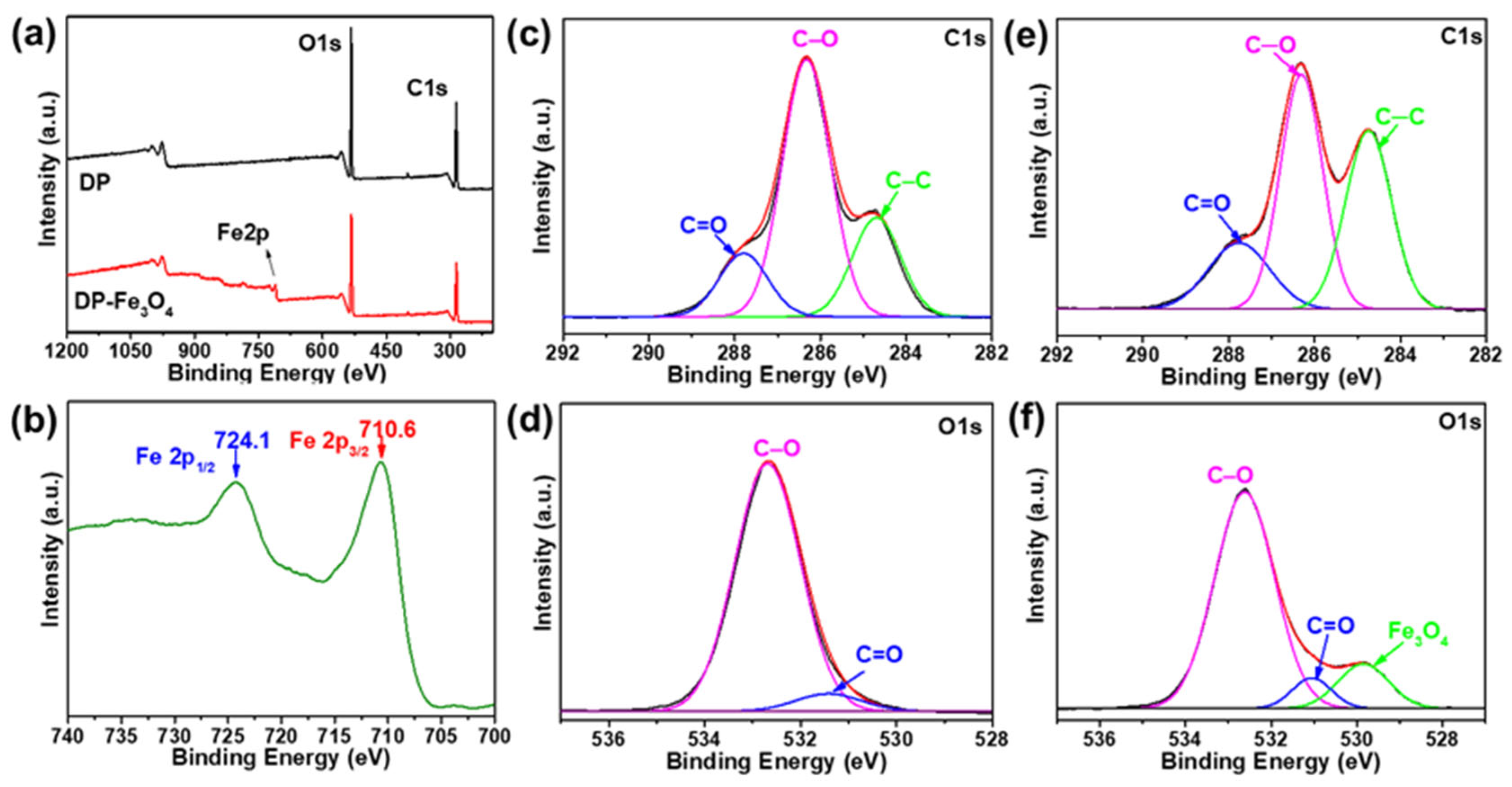

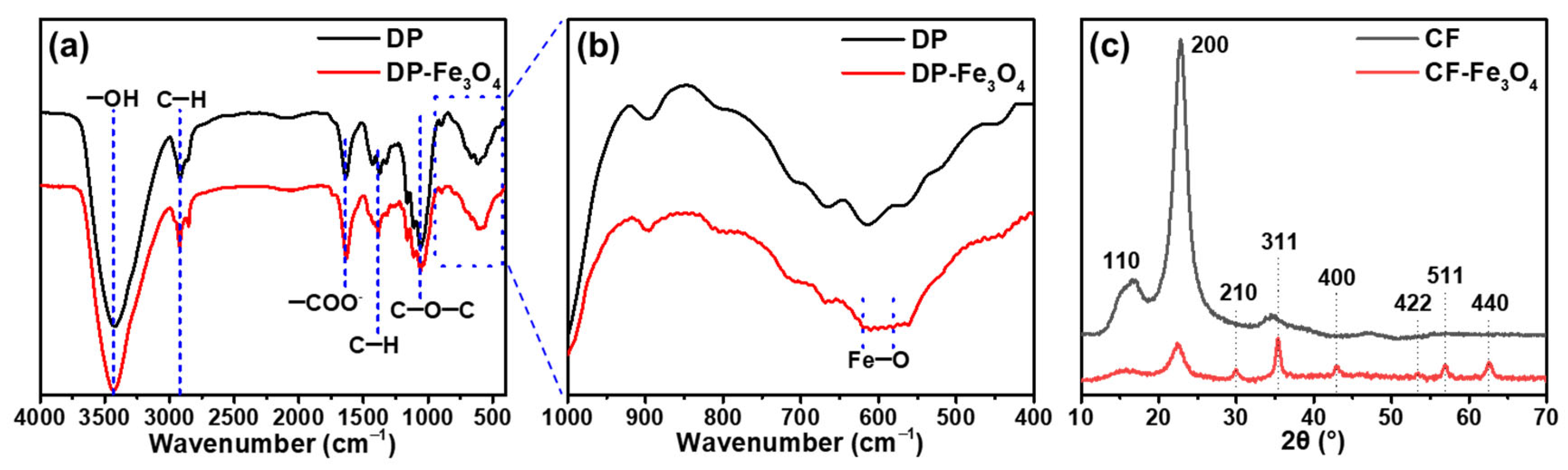

3.2. Characterization of Bilayered Paper-Based Evaporator

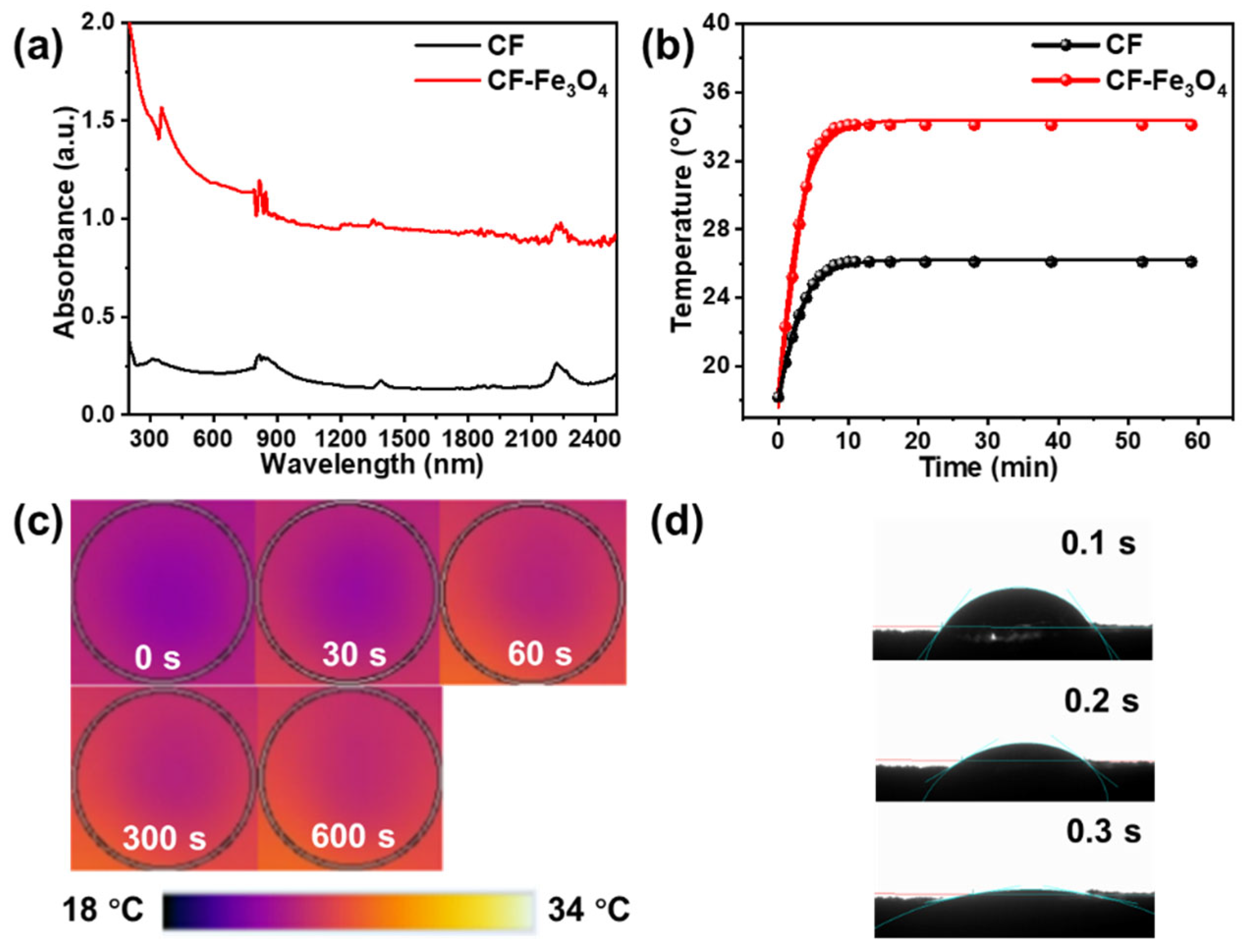

3.3. Photothermal Conversion of Bilayered Paper-Based Evaporator

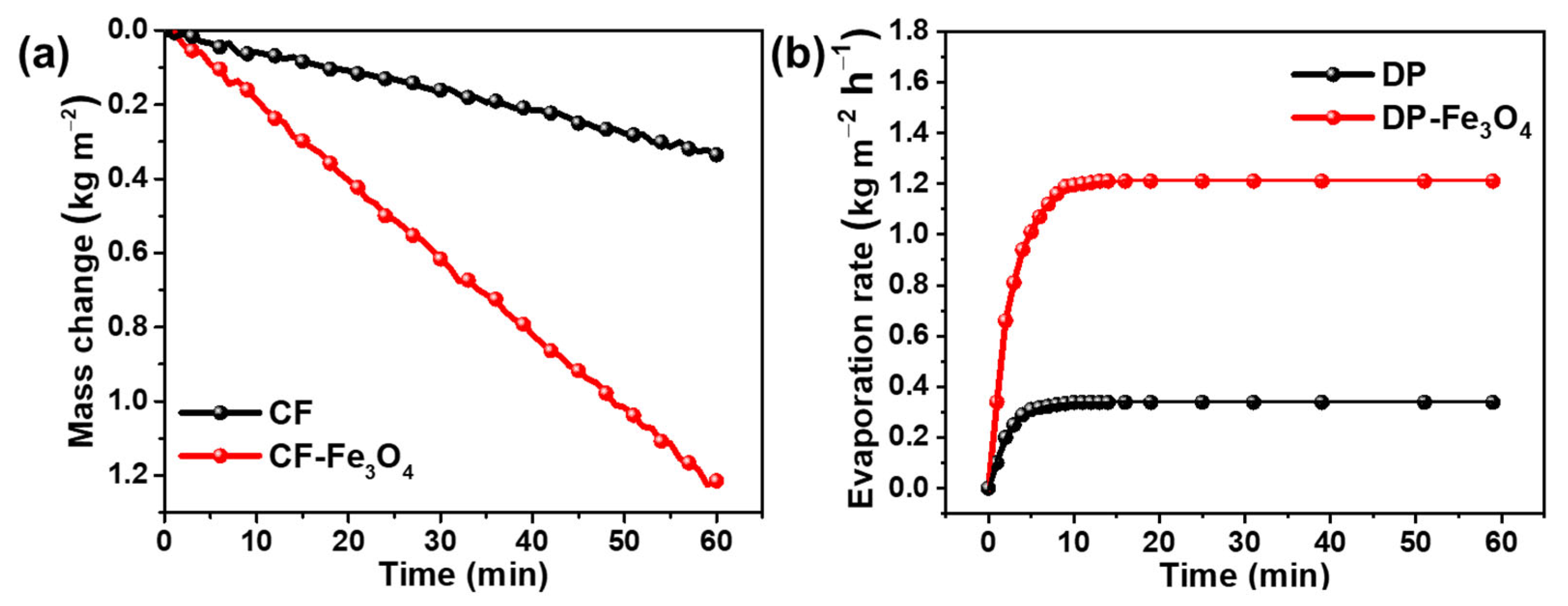

3.4. Solar Desalination Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, W.; Xing, Y.; Liu, J.; Wu, H.; Cui, Y.; Li, D.; Guo, D.; Li, C.; Liu, A.; Bai, H. Efficient water transport and solar steam generation via radially, hierarchically structured aerogels. ACS Nano 2019, 13, 7930–7938. [Google Scholar] [CrossRef] [PubMed]

- Kuang, Y.; Chen, C.; He, S.; Hitz, E.M.; Wang, Y.; Gan, W.; Mi, R.; Hu, L. A high-performance self-regenerating solar evaporator for continuous water desalination. Adv. Mater. 2019, 31, 1900498. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wu, L.; Wang, X.; Yu, J.; Ding, B. Super hygroscopic nanofibrous membrane-based moisture pump for solar-driven indoor dehumidification. Nat. Commun. 2020, 11, 3302. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Sun, L.; Zhang, H.; Aslan, H.; Sun, Y.; Huang, Y.; Rosei, F.; Yu, M. A solution to break the salt barrier for high-rate sustainable solar desalination. Energ. Environ. Sci. 2021, 14, 2451–2459. [Google Scholar] [CrossRef]

- Han, X.; Besteiro, L.V.; Koh, C.S.L.; Lee, H.K.; Phang, I.Y.; Phan-Quang, G.C.; Ng, J.Y.; Sim, H.Y.F.; Lay, C.L.; Govorov, A.; et al. Intensifying heat using MOF-isolated graphene for solar-driven seawater desalination at 98% solar-to-thermal efficiency. Adv. Funct. Mater. 2021, 31, 2008904. [Google Scholar] [CrossRef]

- Mu, X.; Gu, Y.; Wang, P.; Shi, J.; Wei, A.; Tian, Y.; Zhou, J.; Chen, Y.; Zhang, J.; Sun, Z.; et al. Energy matching for boosting water evaporation in direct solar steam generation. Sol. RRL 2020, 4, 2000341. [Google Scholar] [CrossRef]

- Ghaffour, N.; Missimer, T.M.; Amy, G.L. Technical review and evaluation of the economics of water desalination: Current and future challenges for better water supply sustainability. Desalination 2013, 309, 197–207. [Google Scholar] [CrossRef]

- Amy, G.; Ghaffour, N.; Li, Z.Y.; Francis, L.; Linares, R.V.; Missimer, T.; Lattemann, S. Membrane-based seawater desalination: Present and future prospects. Desalination 2017, 401, 16–21. [Google Scholar] [CrossRef]

- Liu, H.; Chen, X.; Zheng, Y.; Zhang, D.; Zhao, Y.; Wang, C.; Pan, C.; Liu, C.; Shen, C. Lightweight, superelastic, and hydrophobic polyimide nanofiber/MXene composite aerogel for wearable piezoresistive sensor and oil/water separation applications. Adv. Funct. Mater. 2021, 31, 2008006. [Google Scholar] [CrossRef]

- Lotfy, H.R.; Stas, J.; Roubik, H. Renewable energy powered membrane desalination-review of recent development. Environ. Sci. Pollut. R. 2022, 29, 46552–46568. [Google Scholar] [CrossRef]

- Al-Karaghouli, A.; Kazmerski, L.L. Energy consumption and water production cost of conventional and renewable-energy-powered desalination processes. Renew. Sust. Energ. Rev. 2013, 24, 343–356. [Google Scholar] [CrossRef]

- Ali, A.; Tufa, R.A.; Macedonio, F.; Curcio, E.; Drioli, E. Membrane technology in renewable-energy-driven desalination. Renew. Sust. Energ. Rev. 2018, 81, 1–21. [Google Scholar] [CrossRef]

- Jiang, Q.; Singamaneni, S. Water from wood: Pouring through pores. Joule 2017, 1, 429–430. [Google Scholar] [CrossRef]

- Jia, C.; Li, Y.; Yang, Z.; Chen, G.; Yao, Y.; Jiang, F.; Kuang, Y.; Pastel, G.; Xie, H.; Yang, B.; et al. mesostructures derived from natural woods for solar steam generation. Joule 2017, 1, 588–599. [Google Scholar] [CrossRef]

- Ibrahim, Y.; Banat, F.; Yousef, A.F.; Bahamon, D.; Vega, L.F.; Hasan, S.W. Surface modification of anti-fouling novel cellulose/graphene oxide (GO) nanosheets (NS) microfiltration membranes for seawater desalination applications. J. Chem. Technol. Biot. 2020, 95, 1915–1925. [Google Scholar] [CrossRef]

- Cao, S.; Jiang, J.; Tian, Q.; Guo, C.; Wang, X.; Dai, K.; Xu, Q. Building of multifunctional and hierarchical HxMoO3/PNIPAM hydrogel for high-efficiency solar vapor generation. Green Energy Environ. 2020, 5, 1006–1013. [Google Scholar] [CrossRef]

- Dong, X.; Cao, L.; Si, Y.; Ding, B.; Deng, H. Cellular structured CNTs@SiO2 nanofibrous aerogels with vertically aligned vessels for salt-resistant solar desalination. Adv. Mater. 2020, 32, 1908269. [Google Scholar] [CrossRef]

- Li, B.; Xu, C.; Liu, L.; Yu, J.; Fan, Y. Facile and sustainable etherification of ethyl cellulose towards excellent UV blocking and fluorescence properties. Green Chem. 2021, 23, 479–489. [Google Scholar] [CrossRef]

- Zhang, Z.; Mu, P.; Han, J.; He, J.; Zhu, Z.; Sun, H.; Liang, W.; Li, A. Superwetting and mechanically robust MnO2 nanowire–reduced graphene oxide monolithic aerogels for efficient solar vapor generation. J. Mater. Chem. A 2019, 7, 18092–18099. [Google Scholar] [CrossRef]

- Zhang, W.H.; Yin, M.J.; Zhao, Q.; Jin, C.G.; Wang, N.; Ji, S.; Ritt, C.L.; Elimelech, M.; An, Q.F. Graphene oxide membranes with stable porous structure for ultrafast water transport. Nat. Nanotechnol. 2021, 16, 337–343. [Google Scholar] [CrossRef]

- Storer, D.P.; Phelps, J.L.; Wu, X.; Owens, G.; Khan, N.I.; Xu, H. Graphene and rice-straw-fiber-based 3D photothermal aerogels for highly efficient solar evaporation. ACS Appl. Mater. Inter. 2020, 12, 15279–15287. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Qiao, L.; He, J.; Wang, S.; Yu, L.; Murto, P.; Li, X.; Xu, X. Solar-driven interfacial evaporation and self-powered water wave detection based on an all-cellulose monolithic design. Adv. Funct. Mater. 2020, 31, 2008681. [Google Scholar] [CrossRef]

- Tian, Y.; Deng, P.; Wu, Y.; Li, J.; Liu, J.; Li, G.; He, Q. MnO2 nanowires-decorated reduced graphene oxide modified glassy carbon electrode for sensitive determination of bisphenol A. J. Electrochem. Soc. 2020, 167, 046514. [Google Scholar] [CrossRef]

- Wang, F.; Dai, J.; Huang, L.; Si, Y.; Yu, J.; Ding, B. Biomimetic and superelastic silica nanofibrous aerogels with rechargeable bactericidal function for antifouling water disinfection. ACS Nano 2020, 14, 8975–8984. [Google Scholar] [CrossRef]

- Guo, Y.; Lu, H.; Zhao, F.; Zhou, X.; Shi, W.; Yu, G. Biomass-derived hybrid hydrogel evaporators for cost-effective solar water purification. Adv. Mater. 2020, 32, 1907061. [Google Scholar] [CrossRef]

- Zhu, M.; Li, Y.; Chen, G.; Jiang, F.; Yang, Z.; Luo, X.; Wang, Y.; Lacey, S.D.; Dai, J.; Wang, C.; et al. Tree-inspired design for high-efficiency water extraction. Adv. Mater. 2017, 29, 1704107. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Li, Y.; Chen, F.; Zhu, X.; Dai, J.; Li, Y.; Yang, Z.; Yan, X.; Song, J.; Wang, Y.; et al. Plasmonic wood for high-efficiency solar steam generation. Adv. Energy Mater. 2018, 8, 1701028. [Google Scholar] [CrossRef]

- He, F.; Han, M.; Zhang, J.; Wang, Z.; Wu, X.; Zhou, Y.; Jiang, L.; Peng, S.; Li, Y. A simple, mild and versatile method for preparation of photothermal woods toward highly efficient solar steam generation. Nano Energy 2020, 71, 104650. [Google Scholar] [CrossRef]

- Hobisch, M.A.; Zabler, S.; Bardet, S.M.; Zankel, A.; Nypelo, T.; Eckhart, R.; Bauer, W.; Spirk, S. How cellulose nanofibrils and cellulose microparticles impact paper strength—A visualization approach. Carbohyd. Polym. 2021, 254, 117406. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Mo, J.L.; Fu, Q.; Liu, Y.H.; Wang, S.F.; Nie, S.X. Wood-cellulose-fiber-based functional materials for triboelectric nanogenerators. Nano Energy 2021, 81, 105637. [Google Scholar] [CrossRef]

- Ghasemi, H.; Ni, G.; Marconnet, A.M.; Loomis, J.; Yerci, S.; Miljkovic, N.; Chen, G. Solar steam generation by heat localization. Nat. Commun. 2014, 5, 4449. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Zhu, K.H.; Gan, Q.M.; Yu, Y.Q.; Zhang, T.Q.; Liu, X.W.; Ye, M.M.; Yin, Y.D. Interfacial solar heating by self-assembled Fe3O4@C film for steam generation. Mater. Chem. Front. 2017, 1, 2620–2626. [Google Scholar] [CrossRef]

- Wang, Q.M.; Qin, Y.; Jia, F.F.; Song, S.X.; Li, Y.M. Recyclable Fe3O4@Polydopamine (PDA) nanofluids for highly efficient solar evaporation. Green Energy Environ. 2022, 7, 35–42. [Google Scholar] [CrossRef]

- Kokol, V. Influence of hydroxyethyl and carboxymethyl celluloses on the rheology, water retention and surface tension of water-suspended microfibrillated cellulose. Cellulose 2022, 29, 7063–7081. [Google Scholar] [CrossRef]

- Li, M.X.; Liu, H.B.; Chen, T.H.; Dong, C.; Sun, Y.B. Synthesis of magnetic biochar composites for enhanced uranium (VI) adsorption. Sci. Total Environ. 2019, 651, 1020–1028. [Google Scholar] [CrossRef]

- Song, Y.B.; Sun, Y.X.; Zhang, X.Z.; Zhou, J.P.; Zhang, L.N. Homogeneous quaternization of cellulose in NaOH/urea aqueous solutions as gene carriers. Biomacromolecules 2008, 9, 2259–2264. [Google Scholar] [CrossRef]

- Yang, W.; Tian, H.F.; Liao, J.; Wang, Y.; Liu, L.J.; Zhang, L.N.; Lu, A. Flexible and strong Fe3O4/cellulose composite film as magnetic and UV sensor. Appl. Surf. Sci. 2020, 507, 145092. [Google Scholar] [CrossRef]

- Zhu, R.Y.; Xia, J.; Zhang, H.J.; Kong, F.G.; Hu, X.; Shen, Y.A.; Zhang, W.H. Synthesis of magnetic activated carbons from black liquor lignin and Fenton sludge in a one-step pyrolysis for methylene blue adsorption. J. Environ. Chem. Eng. 2021, 9, 106538. [Google Scholar] [CrossRef]

- Chang, C.Y.; Zhang, L.Z.; Zhou, J.P.; Zhang, L.N.; Kennedy, J.F. Structure and properties of hydrogels prepared from cellulose in NaOH/urea aqueous solutions. Carbohyd. Polym. 2010, 82, 122–127. [Google Scholar] [CrossRef]

- Mu, J.B.; Chen, B.; Guo, Z.C.; Zhang, M.Y.; Zhang, Z.Y.; Zhang, P.; Shao, C.L.; Liu, Y.C. Highly dispersed Fe3O4 nanosheets on one-dimensional carbon nanofibers: Synthesis, formation mechanism, and electrochemical performance as supercapacitor electrode materials. Nanoscale 2011, 3, 5034–5040. [Google Scholar] [CrossRef]

- Xiao, L.; Li, J.; Brougham, D.F.; Fox, E.K.; Feliu, N.; Bushmelev, A.; Schmidt, A.; Mertens, N.; Kiessling, F.; Valldor, M.; et al. Water-soluble superparamagnetic magnetite nanoparticles with biocompatible coating for enhanced magnetic resonance imaging. ACS Nano 2011, 5, 6315–6324. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Chen, G.Y.; Zhang, W.; Liu, X.K.; Xu, H.L. A plant-transpiration-process-inspired strategy for highly efficient solar evaporation. Adv. Sustain. Syst. 2017, 1, 1700046. [Google Scholar] [CrossRef]

- Asuha, S.; Wan, H.L.; Zhao, S.; Deligeer, W.; Wu, H.Y.; Song, L.; Tegus, O. Water-soluble, mesoporous Fe3O4: Synthesis, characterization, and properties. Ceram. Int. 2012, 38, 6579–6584. [Google Scholar] [CrossRef]

- Hong, S.H.; Shi, Y.; Li, R.Y.; Zhang, C.L.; Jin, Y.; Wang, P. Nature-Inspired, 3D Origami Solar Steam Generator toward Near Full Utilization of Solar Energy. ACS Appl. Mater. Inter. 2018, 10, 28517–28524. [Google Scholar] [CrossRef] [PubMed]

- Ni, G.; Zandavi, S.H.; Javid, S.M.; Boriskina, S.V.; Cooper, T.A.; Chen, G. A salt-rejecting floating solar still for low-cost desalination. Energ. Environ. Sci. 2018, 11, 1510–1519. [Google Scholar] [CrossRef]

- Li, X.Q.; Xu, W.C.; Tang, M.Y.; Zhou, L.; Zhu, B.; Zhu, S.N.; Zhu, J. Graphene oxide-based efficient and scalable solar desalination under one sun with a confined 2D water path. Proc. Natl. Acad. Sci. USA 2016, 113, 13953–13958. [Google Scholar] [CrossRef]

- Jiang, F.; Liu, H.; Li, Y.; Kuang, Y.D.; Xu, X.; Chen, C.J.; Huang, H.; Jia, C.; Zhao, X.P.; Hitz, E.; et al. Lightweight, mesoporous, and highly absorptive all-nanofiber aerogel for efficient solar steam generation. ACS Appl. Mater. Inter. 2018, 10, 1104–1112. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Y.; Li, Y.; Wu, R.; Wang, X.; Qin, J.; Fu, Y.; Qin, M.; Wang, Z.; Zhang, Y.; Zhang, F. Bilayer Designed Paper-Based Solar Evaporator for Efficient Seawater Desalination. Nanomaterials 2022, 12, 3487. https://doi.org/10.3390/nano12193487

Qin Y, Li Y, Wu R, Wang X, Qin J, Fu Y, Qin M, Wang Z, Zhang Y, Zhang F. Bilayer Designed Paper-Based Solar Evaporator for Efficient Seawater Desalination. Nanomaterials. 2022; 12(19):3487. https://doi.org/10.3390/nano12193487

Chicago/Turabian StyleQin, Ying, Yongzheng Li, Ruijie Wu, Xiaodi Wang, Jinli Qin, Yingjuan Fu, Menghua Qin, Zhiwei Wang, Yongchao Zhang, and Fengshan Zhang. 2022. "Bilayer Designed Paper-Based Solar Evaporator for Efficient Seawater Desalination" Nanomaterials 12, no. 19: 3487. https://doi.org/10.3390/nano12193487

APA StyleQin, Y., Li, Y., Wu, R., Wang, X., Qin, J., Fu, Y., Qin, M., Wang, Z., Zhang, Y., & Zhang, F. (2022). Bilayer Designed Paper-Based Solar Evaporator for Efficient Seawater Desalination. Nanomaterials, 12(19), 3487. https://doi.org/10.3390/nano12193487