Nanocellulose-Based Nanocomposites for Sustainable Applications: A Review

Abstract

1. Introduction

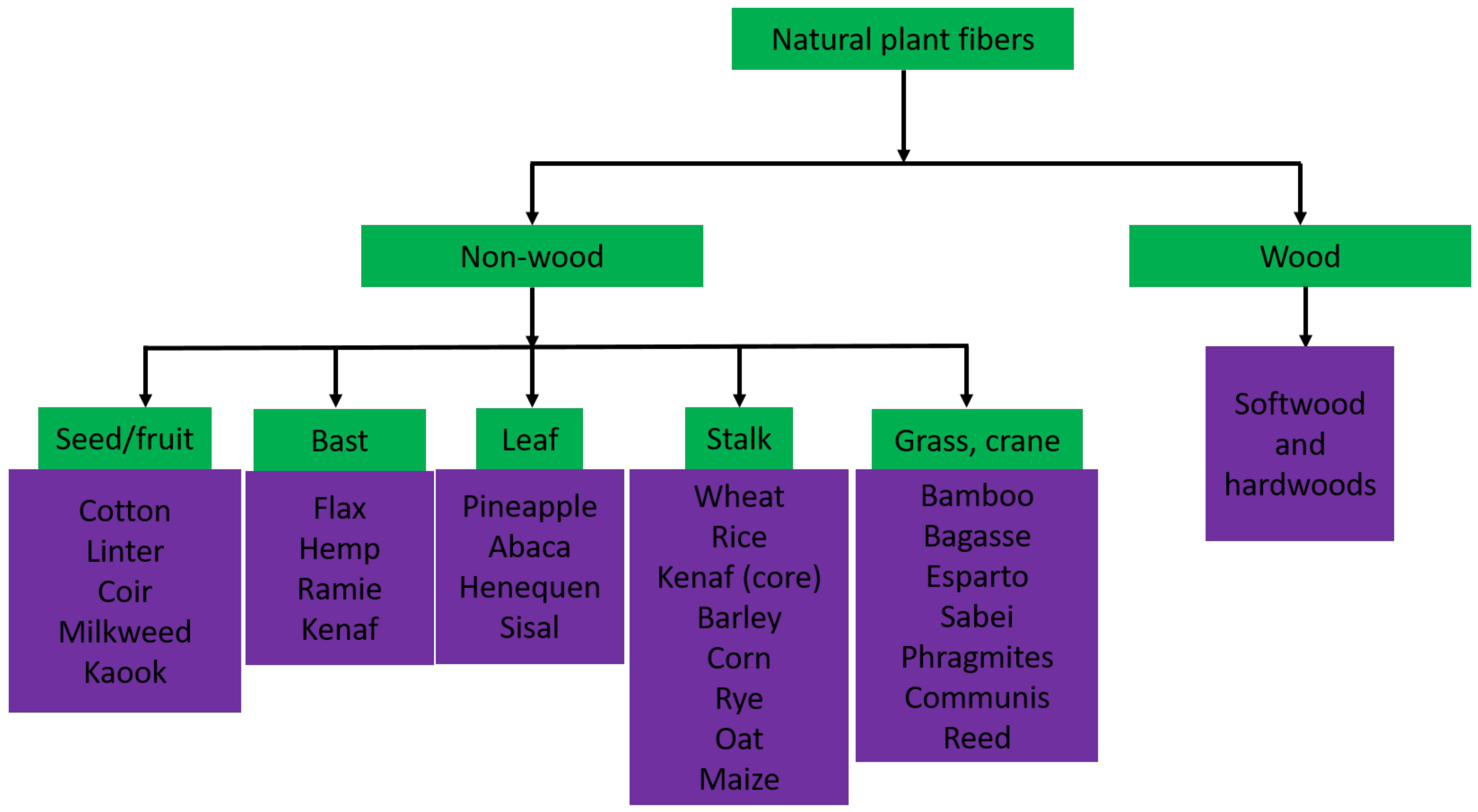

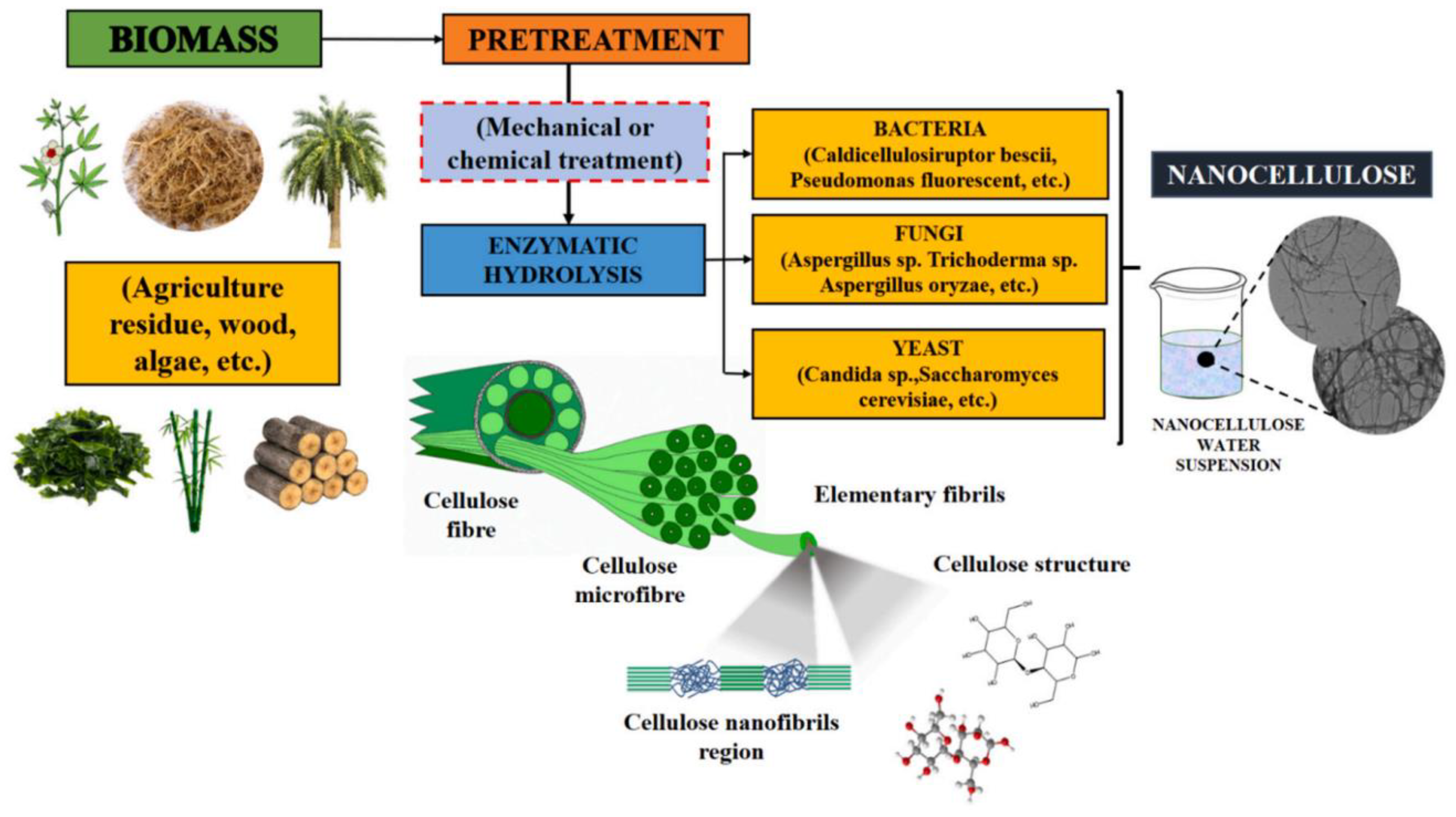

2. Nanocellulose from Plant Fiber

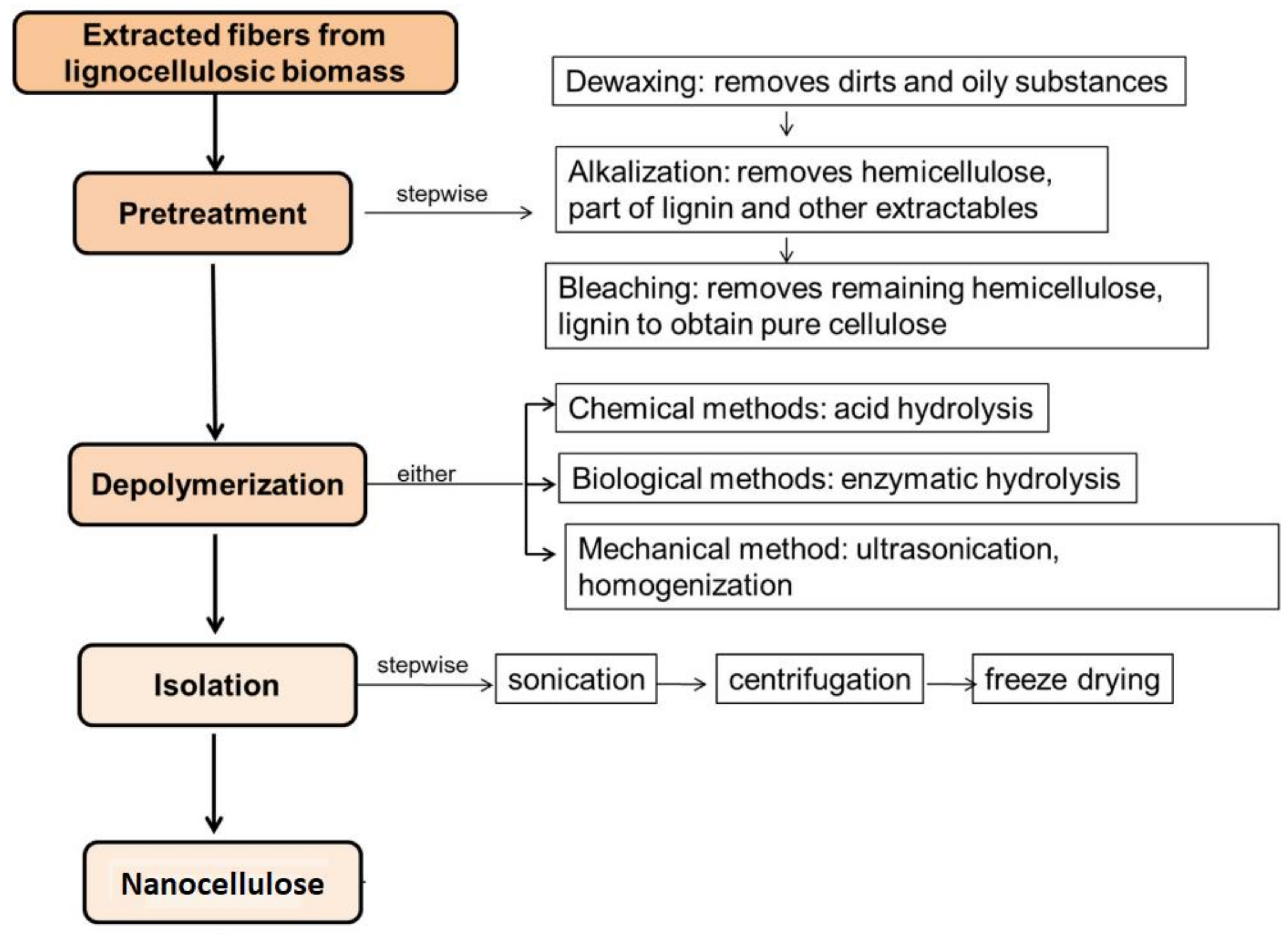

3. Isolation of Nanocellulose from Plant Fiber

- I.

- Dewaxing of the fiber;

- II.

- Mercerization or alkalization;

- III.

- Bleaching;

- IV.

- Depolymerization (chemical, mechanical or biological methods);

- V.

- Isolation.

3.1. Dewaxing

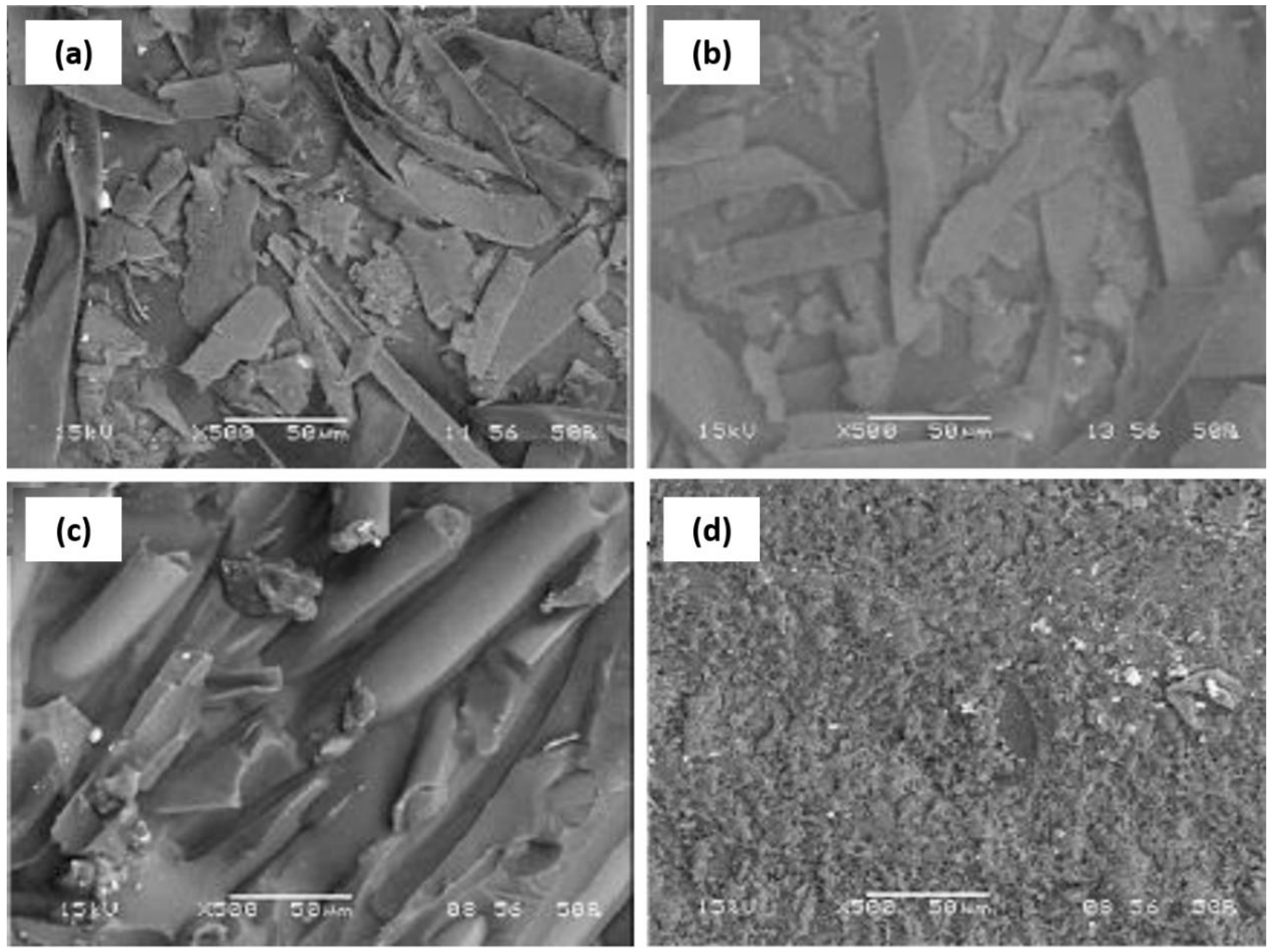

3.2. Alkalization or Mercerization

3.3. Bleaching

3.4. Depolymerization

3.4.1. Chemical Techniques

3.4.2. Mechanical Technique

3.4.3. Enzymatic Technique

3.5. Isolation

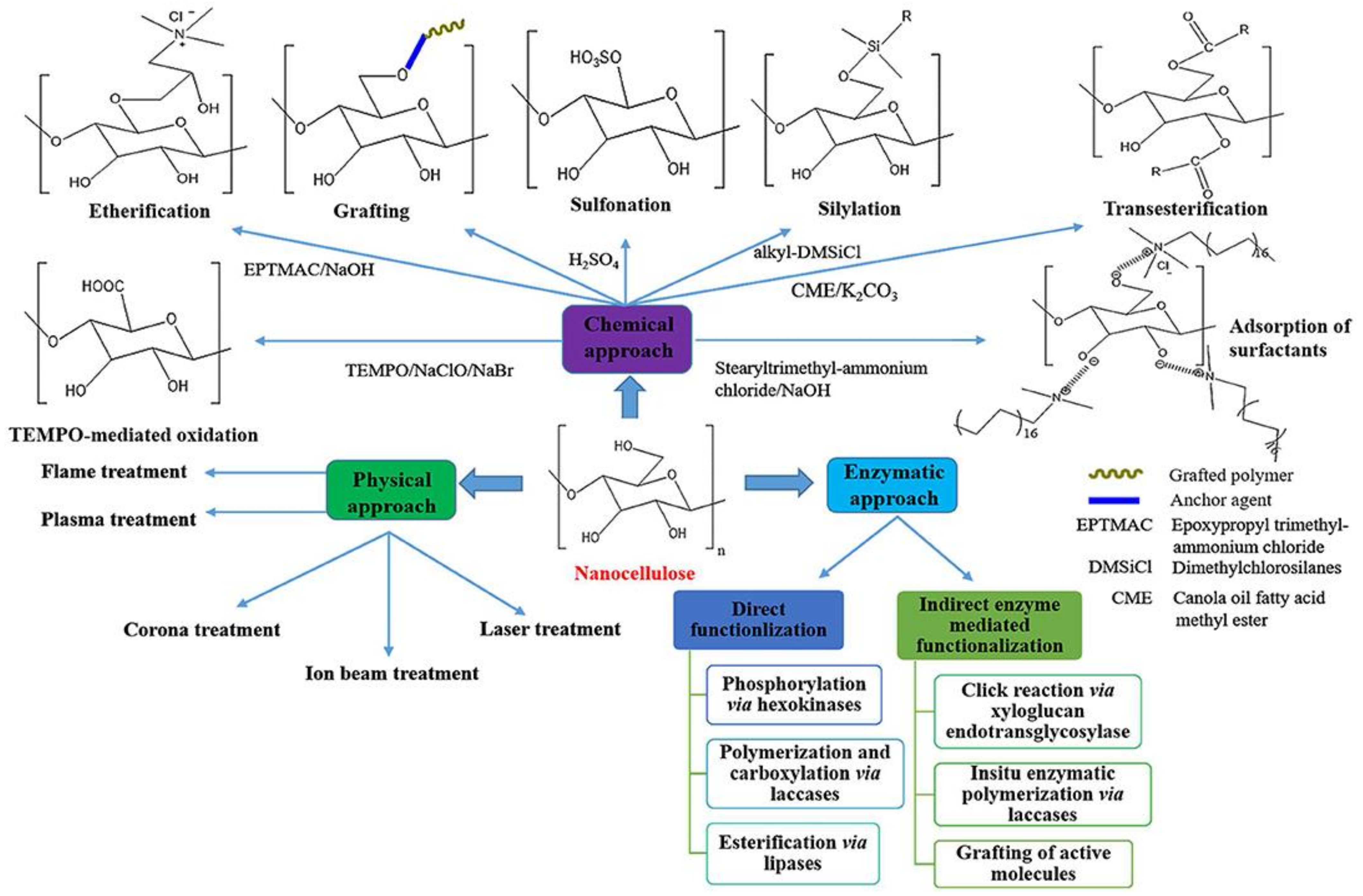

4. Modification of Properties, Processability and Functionalization of Nanocellulose

4.1. Physical Approach of Functionalization of Nanocellulose

4.2. Chemical Approach of Functionalization of Nanocellulose

4.3. Enzymatic Approach of Functionalization of Nanocellulose

5. Nanocellulose-Based Nanocomposites Processing

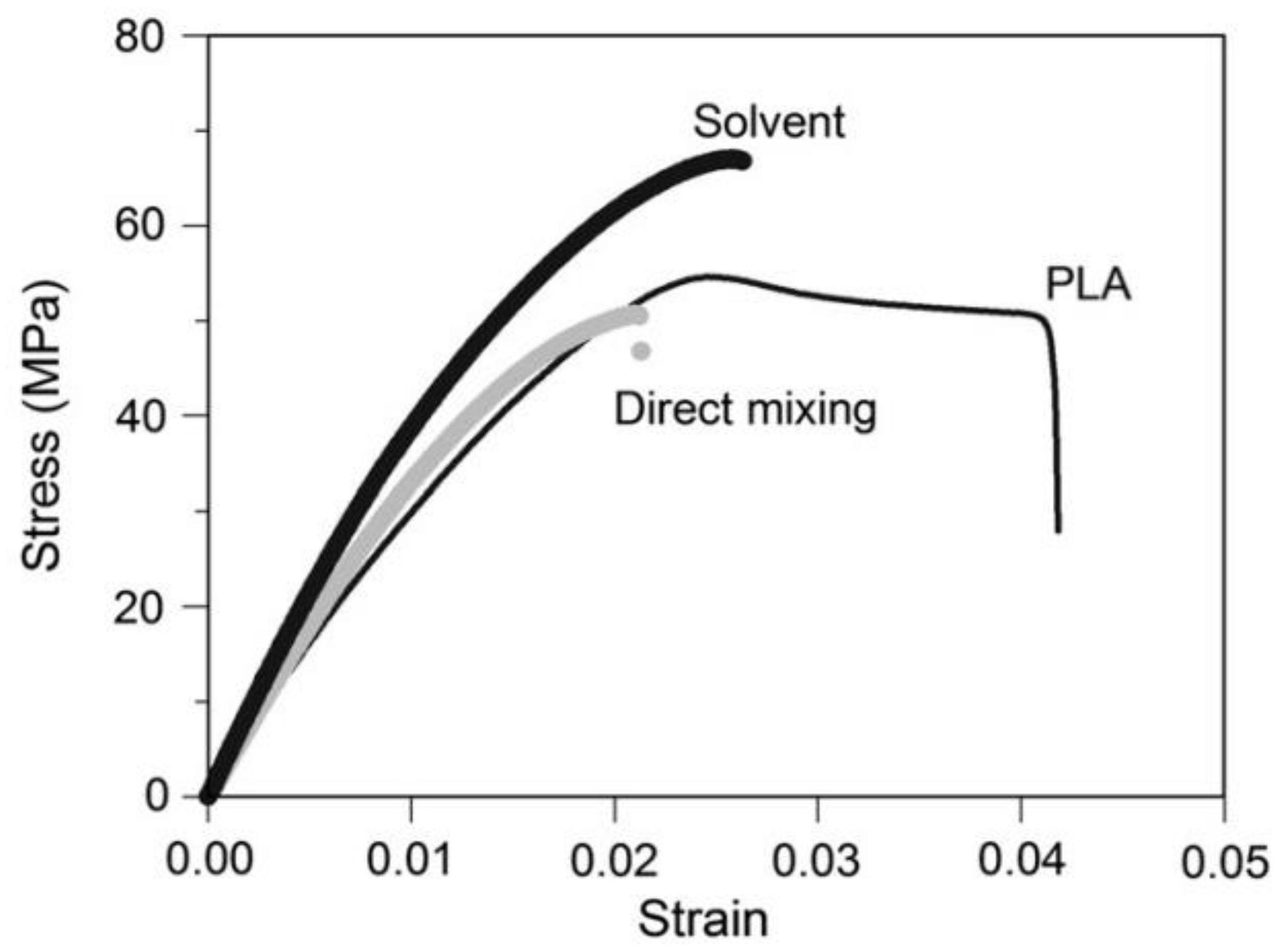

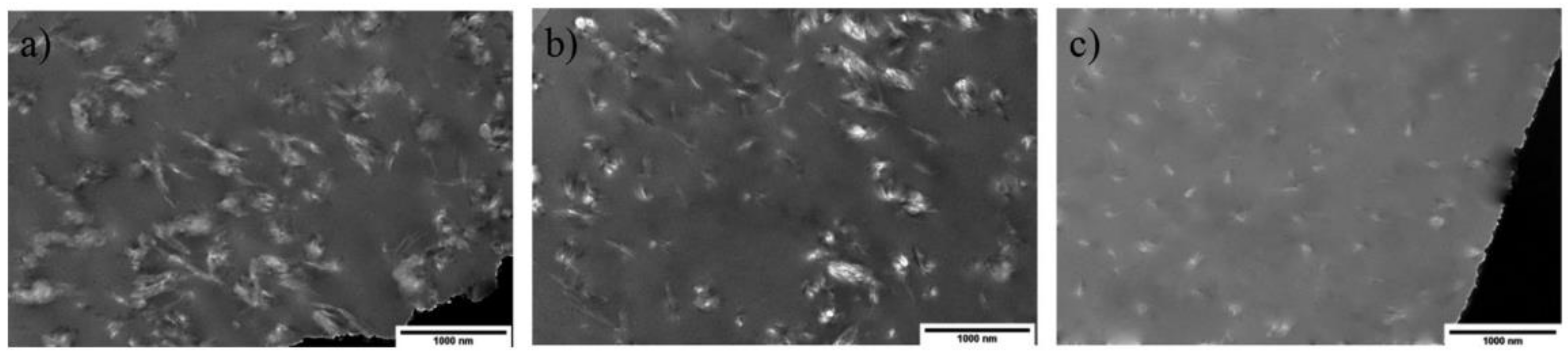

5.1. Solution Casting

5.2. Melt Intercalation

5.3. Impregnation

5.4. In-Situ Polymerization

5.5. Coating

6. Nanocellulose Based Nanocomposites for Sustainable Applications

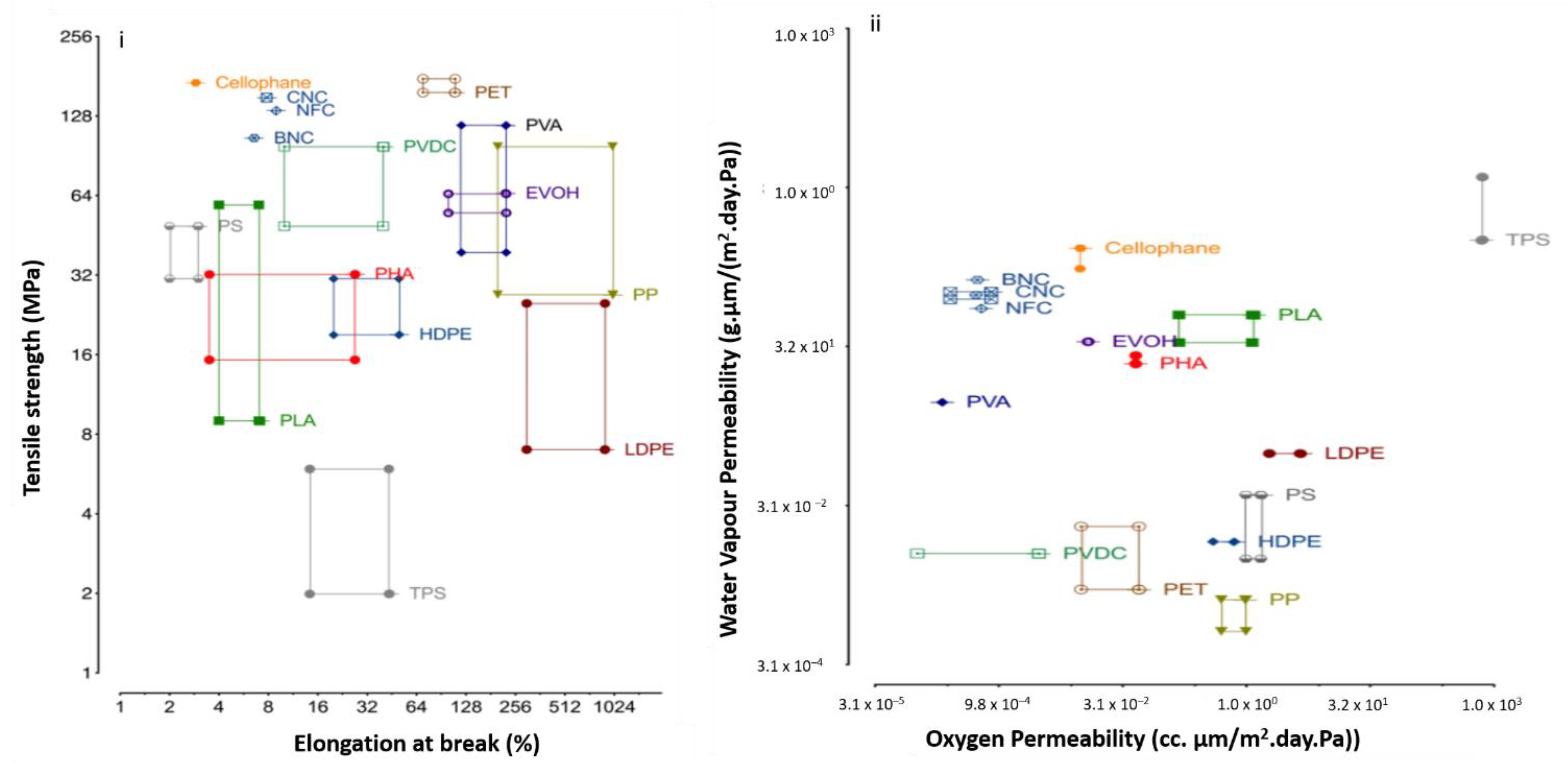

6.1. Food Packaging

6.2. Biomedical

6.3. Automotive and Aerospace

6.4. Sensor

6.5. Water Purification Treatment

6.6. Electronic and Optical

7. Future Prospects and Challenges

8. Economic Assessment of the Nanocellulose Extraction Process

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abral, H.; Basri, A.; Muhammad, F.; Fernando, Y.; Hafizulhaq, F.; Mahardika, M.; Sugiarti, E.; Sapuan, S.M.; Ilyas, R.A.; Stephane, I. A simple method for improving the properties of the sago starch films prepared by using ultrasonication treatment. Food Hydrocoll. 2019, 93, 276–283. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Norizan, M.N.; Fadil, F.; Osman, S.; Ahmad, S. Water absorption and thickness swelling characteristic of the bionanocomposites. In Polymer Based Bio-Nanocomposites: Properties, Durability and Applications; Muthukumar, C., Thiagamani, S.M.K., Krishnasamy, S., Nagarajan, R., Siengchin, S., Eds.; Springer: Singapore, 2022; pp. 159–180. [Google Scholar] [CrossRef]

- Brown, T.D.; Dalton, P.D.; Hutmacher, D.W. Melt electrospinning today: An opportune time for an emerging polymer process. Prog. Polym. Sci. 2016, 56, 116–166. [Google Scholar] [CrossRef]

- He, K.; Huo, H.; Zhang, Q.; He, D.; An, F.; Wang, M.; Walsh, M.P. Oil consumption and CO2 emissions in China’s road transport: Current status, future trends, and policy implications. Energy Policy 2005, 33, 1499–1507. [Google Scholar] [CrossRef]

- He, M.; Xie, H.; Peng, S.; Jiang, Y.-D. Study on rock mechanics in deep mining engineering. Yanshilixue Yu Gongcheng Xuebao/Chin. J. Rock Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S.; Atikah, M.S.N. Characterization of sugar palm nanocellulose and its potential for reinforcement with a starch-based composite. In Sugar Palm Biofibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2018; pp. 189–220. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers 2021, 13, 2170. [Google Scholar] [CrossRef] [PubMed]

- Kamarudin, S.; Luqman Chuah, A.; Aung, M.M.; Ratnam, C. Thermal and Structural Analysis of Epoxidized Jatropha Oil and Alkaline Treated Kenaf Fiber Reinforced Poly(Lactic Acid) Biocomposites. Polymers 2020, 12, 2604. [Google Scholar] [CrossRef]

- Barbash, V.A.; Yashchenko, O.V.; Vasylieva, O.A. Preparation, properties and application of miscanthus nanocellulose as coating Layer. In Microstructure and Properties of Micro- and Nanoscale Materials, Films, and Coatings (NAP 2019); Pogrebnjak, A.D., Bondar, O., Eds.; Springer: Singapore, 2020; pp. 211–218. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M. The preparation methods and processing of natural fibre bio-polymer composites. Curr. Org. Synth. 2020, 16, 1068–1070. [Google Scholar] [CrossRef]

- Barbash, V.A.; Yashchenko, O.V.; Vasylieva, O.A. Preparation and application of nanocellulose from Miscanthus × giganteus to improve the quality of paper for bags. SN Appl. Sci. 2020, 2, 727. [Google Scholar] [CrossRef]

- Hakimi, M.I.; Najmuddin, S.U.F.S.; Yusuff, S.M.; Norrrahim, M.N.F.; Janudin, N.; Yusoff, M.Z.M.; Ilyas, R.A. 18—Nanocellulose as a bioadsorbent for water and wastewater purification. In Industrial Applications of Nanocellulose and Its Nanocomposites; Sapuan, S.M., Norrrahim, M.N.F., Ilyas, R.A., Soutis, C., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 409–437. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Farid, M.A.A.; Jenol, M.A.; Nurazzi, N.M.; Hakimi, M.I.; Shazleen, S.S.; Ilyas, R.A. 2—Economic insights into the production of cellulose nanofibrils from oil palm biomass. In Industrial Applications of Nanocellulose and Its Nanocomposites; Sapuan, S.M., Norrrahim, M.N.F., Ilyas, R.A., Soutis, C., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 39–48. [Google Scholar] [CrossRef]

- Rashid, S.; Dutta, H. Characterization of nanocellulose extracted from short, medium and long grain rice husks. Ind. Crops Prod. 2020, 154, 112627. [Google Scholar] [CrossRef]

- Thompson, L.; Azadmanjiri, J.; Nikzad, M.; Sbarski, I.; Wang, J.; Yu, A. Cellulose nanocrystals: Production, functionalization and advanced applications. Rev. Adv. Mater. Sci. 2019, 58, 1–16. [Google Scholar] [CrossRef]

- Kalia, S.; Dufresne, A.; Cherian, B.M.; Kaith, B.S.; Avérous, L.; Njuguna, J.; Nassiopoulos, E. Cellulose-Based Bio- and Nanocomposites: A Review. Int. J. Polym. Sci. 2011, 2011, 1–35. [Google Scholar] [CrossRef]

- Curvello, R.; Raghuwanshi, V.S.; Garnier, G. Engineering nanocellulose hydrogels for biomedical applications. Adv. Colloid Interface Sci. 2019, 267, 47–61. [Google Scholar] [CrossRef] [PubMed]

- Abe, K.; Iwamoto, S.; Yano, H. Obtaining Cellulose Nanofibers with a Uniform Width of 15 nm from Wood. Biomacromolecules 2007, 8, 3276–3278. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Syamsir, A.; Zahari, N.M.; Supian, A.B.M.; Ishak, M.R.; Sapuan, S.M.; Sharma, S.; Rashedi, A.; Razman, M.R.; Zakaria, S.Z.S.; et al. Product Development of Natural Fibre-Composites for Various Applications: Design for Sustainability. Polymers 2022, 14, 920. [Google Scholar] [CrossRef] [PubMed]

- Soriano, M.L.; Dueñas-Mas, M.J. Promising sensing platforms based on nanocellulose. In Carbon-Based Nanosensor Technology; Kranz, C., Ed.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 273–301. [Google Scholar] [CrossRef]

- Jorfi, M.; Foster, E.J. Recent advances in nanocellulose for biomedical applications. J. Appl. Polym. Sci. 2015, 132, 1–19. [Google Scholar] [CrossRef]

- Kim, J.H.; Shim, B.S.; Kim, H.S.; Lee, Y.J.; Min, S.K.; Jang, D.; Abas, Z.; Kim, J. Review of nanocellulose for sustainable future materials. Int. J. Precis. Eng. Manuf. Green Technol. 2015, 2, 197–213. [Google Scholar] [CrossRef]

- Lin, N.; Dufresne, A. Nanocellulose in biomedicine: Current status and future prospect. Eur. Polym. J. 2014, 59, 302–325. [Google Scholar] [CrossRef]

- Siró, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Wei, H.; Rodriguez, K.; Renneckar, S.; Vikesland, P.J. Environmental science and engineering applications of nanocellulose-based nanocomposites. Environ. Sci. Nano 2014, 1, 302–316. [Google Scholar] [CrossRef]

- Thiruganasambanthan, T.; Ilyas, R.A.; Norrrahim, M.N.F.; Kumar, T.S.M.; Siengchin, S.; Misenan, M.S.M.; Farid, M.A.A.; Nurazzi, N.M.; Asyraf, M.R.M.; Zakaria, S.Z.S.; et al. Emerging Developments on Nanocellulose as Liquid Crystals: A Biomimetic Approach. Polymers 2022, 14, 1546. [Google Scholar] [CrossRef]

- Sharip, N.S.; Yasim-Anuar, T.A.T.; Norrrahim, M.N.F.; Shazleen, S.S.; Nurazzi, N.M.; Sapuan, S.M.; Ilyas, R.A. A review on nanocellulose composites in biomedical application. In Composites in Biomedical Applications; CRC Press: Boca Raton, FL, USA, 2020; pp. 161–190. [Google Scholar]

- Ma, T.; Hu, X.; Lu, S.; Liao, X.; Song, Y.; Hu, X. Nanocellulose: A promising green treasure from food wastes to available food materials. Crit. Rev. Food Sci. Nutr. 2022, 62, 989–1002. [Google Scholar] [CrossRef] [PubMed]

- Berthet, M.-A.; Angellier-Coussy, H.; Guillard, V.; Gontard, N. Vegetal fiber-based biocomposites: Which stakes for food packaging applications? J. Appl. Polym. Sci. 2016, 133, 42528. [Google Scholar] [CrossRef]

- Dhar, P.; Bhardwaj, U.; Kumar, A.; Katiyar, V. Poly (3-hydroxybutyrate)/cellulose nanocrystal films for food packaging applications: Barrier and migration studies. Polym. Eng. Sci. 2015, 55, 2388–2395. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Nurazzi, N.M.; Shazleen, S.S.; Najmuddin, S.U.F.S.; Yasim-Anuar, T.A.T.; Naveen, J.; Ilyas, R.A. Biocompatibility, Biodegradability, and Environmental Safety of PLA/Cellulose Composites; CRC Press: Boca Raton, FL, USA, 2022; pp. 251–264. [Google Scholar] [CrossRef]

- Ariffin, H.; Norrrahim, M.N.F.; Yasim-Anuar, T.A.T.; Nishida, H.; Hassan, M.A.; Ibrahim, N.A.; Yunus, W.M.Z.W. Oil palm biomass cellulose-fabricated Polylactic Acid composites for packaging applications. In Bionanocomposites for Packaging Applications; Springer: Berlin/Heidelberg, Germany, 2018; pp. 95–105. [Google Scholar]

- Ilyas, R.A.; Nurazzi, N.M.; Norrrahim, M.N.F. Fiber-Reinforced Polymer Nanocomposites. Nanomaterials 2022, 12, 3045. [Google Scholar] [CrossRef]

- Mahfoudhi, N.; Boufi, S. Nanocellulose as a novel nanostructured adsorbent for environmental remediation: A review. Cellulose 2017, 24, 1171–1197. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Misenan, M.S.M.; Janudin, N.; Shah, N.A.A.; Kasim, N.; Yusoff, W.Y.W.; Noor, S.A.M.; Jamal, S.H.; et al. Nanocellulose: A bioadsorbent for chemical contaminant remediation. RSC Adv. 2021, 11, 7347–7368. [Google Scholar] [CrossRef]

- Ferrer, A.; Pal, L.; Hubbe, M. Nanocellulose in packaging: Advances in barrier layer technologies. Ind. Crops Prod. 2017, 95, 574–582. [Google Scholar] [CrossRef]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef]

- de Amorim, J.D.P.; de Souza, K.C.; Duarte, C.R.; da Silva Duarte, I.; de Assis Sales Ribeiro, F.; Silva, G.S.; de Farias, P.M.A.; Stingl, A.; Costa, A.F.S.; Vinhas, G.M.; et al. Plant and bacterial nanocellulose: Production, properties and applications in medicine, food, cosmetics, electronics and engineering. A review. Environ. Chem. Lett. 2020, 18, 851–869. [Google Scholar] [CrossRef]

- Zinge, C.; Kandasubramanian, B. Nanocellulose based biodegradable polymers. Eur. Polym. J. 2020, 133, 109758. [Google Scholar] [CrossRef]

- Razali, N.A.M.; Mohd Sohaimi, R.; Othman, R.N.I.R.; Abdullah, N.; Demon, S.Z.N.; Jasmani, L.; Yunus, W.M.Z.W.; Ya’acob, W.M.H.W.; Salleh, E.M.; Norizan, M.N.; et al. Comparative Study on Extraction of Cellulose Fiber from Rice Straw Waste from Chemo-Mechanical and Pulping Method. Polymers 2022, 14, 387. [Google Scholar] [CrossRef] [PubMed]

- Djafari Petroudy, S.R. Physical and mechanical properties of natural fibers. In Advanced High Strength Natural Fibre Composites in Construction; Elsevier: Amsterdam, The Netherlands, 2017; pp. 59–83. [Google Scholar] [CrossRef]

- Trache, D.; Thakur, V.K. Nanocellulose and nanocarbons based hybrid materials: Synthesis, characterization and applications. Nanomaterials 2020, 10, 1800. [Google Scholar] [CrossRef]

- Pennells, J.; Godwin, I.D.; Amiralian, N.; Martin, D.J. Trends in the production of cellulose nanofibers from non-wood sources. Cellulose 2020, 27, 575–593. [Google Scholar] [CrossRef]

- Isogai, A. Cellulose Nanofibers: Recent Progress and Future Prospects. J. Fiber Sci. Technol. 2020, 76, 310–326. [Google Scholar] [CrossRef]

- Rusdi, R.A.A.; Halim, N.A.; Nurazzi, N.M.; Abidin, Z.H.Z.; Abdullah, N.; Ros, F.C.; Ahmad, N.; Azmi, A.F.M. The effect of layering structures on mechanical and thermal properties of hybrid bacterial cellulose/Kevlar reinforced epoxy composites. Heliyon 2022, 09442. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindström, T.; Nietzsche, S.; et al. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mater. Today 2018, 21, 720–748. [Google Scholar] [CrossRef]

- Poddar, P.; Gupta, A.; Sharma, S. Isolation of Nano Cellulose from Rubber Wood Fibre and Fibrillation Effects on Nano Cellulose Reinforced Poly (Ethylene Oxide); The National Conference for Postgraduate Research 2016; Universiti Malaysia Pahang: Kuantan, Malaysia, 2016. [Google Scholar]

- Sabaruddin, F.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Lee, S.H.; Abdan, K.; Mazlan, N.; Roseley, A.S.M.; Abdul Khalil, H.P.S. The effects of unbleached and bleached nanocellulose on the thermal and flammability of polypropylene-reinforced kenaf core hybrid polymer bionanocomposites. Polymers 2021, 13, 116. [Google Scholar] [CrossRef]

- Song, Y.; Jiang, W.; Zhang, Y.; Wang, H.; Zou, F.; Yu, K.; Han, G. A novel process of nanocellulose extraction from kenaf bast. Mater. Res. Express 2018, 5, 085032. [Google Scholar] [CrossRef]

- Kian, L.K.; Jawaid, M.; Ariffin, H.; Karim, Z. Isolation and characterization of nanocrystalline cellulose from roselle-derived microcrystalline cellulose. Int. J. Biol. Macromol. 2018, 114, 54–63. [Google Scholar] [CrossRef]

- Owonubi, S.J.; Agwuncha, S.C.; Malima, N.M.; Shombe, G.B.; Makhatha, E.M.; Revaprasadu, N. Non-woody Biomass as Sources of Nanocellulose Particles: A Review of Extraction Procedures. Front. Energy Res. 2021, 9, 608825. [Google Scholar] [CrossRef]

- Wulandari, W.T.; Rochliadi, A.; Arcana, I.M. Nanocellulose prepared by acid hydrolysis of isolated cellulose from sugarcane bagasse. IOP Conf. Ser. Mater. Sci. Eng. 2016, 107, 012045. [Google Scholar] [CrossRef]

- Supian, M.A.F.; Amin, K.N.M.; Jamari, S.S.; Mohamad, S. Production of cellulose nanofiber (CNF) from empty fruit bunch (EFB) via mechanical method. J. Environ. Chem. Eng. 2020, 8, 103024. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Ariffin, H.; Yasim-Anuar, T.A.T.; Hassan, M.A.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Nishida, H. Performance Evaluation of Cellulose Nanofiber with Residual Hemicellulose as a Nanofiller in Polypropylene-Based Nanocomposite. Polymers 2021, 13, 1064. [Google Scholar] [CrossRef] [PubMed]

- Wahlström, N.; Edlund, U.; Pavia, H.; Toth, G.; Jaworski, A.; Pell, A.J.; Choong, F.X.; Shirani, H.; Nilsson, K.P.R.; Richter-Dahlfors, A. Cellulose from the green macroalgae Ulva lactuca: Isolation, characterization, optotracing, and production of cellulose nanofibrils. Cellulose 2020, 27, 3707–3725. [Google Scholar] [CrossRef]

- Prakash Menon, M.; Selvakumar, R.; Suresh Kumar, P.; Ramakrishna, S. Extraction and modification of cellulose nanofibers derived from biomass for environmental application. RSC Adv. 2017, 7, 42750–42773. [Google Scholar] [CrossRef]

- Zaki, M.; HPS, A.K.; Sabaruddin, F.A.; Bairwan, R.D.; Oyekanmi, A.A.; Alfatah, T.; Danish, M.; Mistar, E.M.; Abdullah, C.K. Microbial treatment for nanocellulose extraction from marine algae and its applications as sustainable functional material. Bioresour. Technol. Rep. 2021, 16, 100811. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Atikah, M.S.N. Production of nanocellulose from sustainable algae marine biomass. In Seminar on Advanced Bio- and Mineral based Natural Fibre Composites (SBMC2021); Institute of Tropical Forestry and Forest Product (INTROP), Universiti Putra Malaysia: Serdang, Malaysia, 2021. [Google Scholar]

- Ahmad Farid, M.A.; Hassan, M.A.; Roslan, A.M.; Ariffin, H.; Norrrahim, M.N.F.; Othman, M.R.; Yoshihito, S. Improving the decolorization of glycerol by adsorption using activated carbon derived from oil palm biomass. Environ. Sci. Pollut. Res. 2021, 28, 27976–27987. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Nurazzi, N.M.; Jenol, M.A.; Farid, M.A.A.; Janudin, N.; Ujang, F.A.; Yasim-Anuar, T.A.T.; Najmuddin, S.U.F.S.; Ilyas, R.A. Emerging Development on Nanocellulose as Antimicrobial Material: An Overview. Mater. Adv. 2021, 2, 3538–3551. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Farid, M.A.A.; Lawal, A.A.; Yasim-Anuar, T.A.T.; Samsudin, M.H.; Zulkifli, A.A. Emerging technologies for value-added use of oil palm biomass. Environ. Sci. Adv. 2022, 1, 259–275. [Google Scholar] [CrossRef]

- Dhali, K.; Ghasemlou, M.; Daver, F.; Cass, P.; Adhikari, B. A review of nanocellulose as a new material towards environmental sustainability. Sci. Total Environ. 2021, 775, 145871. [Google Scholar] [CrossRef]

- Chakrabarty, A.; Teramoto, Y. Recent advances in nanocellulose composites with polymers: A guide for choosing partners and how to incorporate them. Polymers 2018, 10, 517. [Google Scholar] [CrossRef] [PubMed]

- Sulaiman, H.S.; Chan, C.H.; Chia, C.H.; Zakaria, S.; Jaafar, S.N.S. Isolation and fractionation of cellulose nanocrystals from kenaf core. Sains Malays. 2015, 44, 1635–1642. [Google Scholar]

- Barbash, V.; Yashchenko, O.; Vasylieva, O. Preparation and Properties of Nanocellulose from Miscanthus × giganteus. J. Nanomater. 2019, 2019, 1–8. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Isolation of Nano Fibres from Hemp and Flax and Their Thermoplastic Composites. J. Plast. Polym. Technol. 2013, 2, 9–16. [Google Scholar]

- Correia, C.; Valera, T. Cellulose Nanocrystals and Jute Fiber-reinforced Natural Rubber Composites: Cure Characteristics and Mechanical Properties. Mater. Res. 2019, 22, e20190192. [Google Scholar] [CrossRef]

- Trifol, J.; Sillard, C.; Plackett, D.; Szabo, P.; Bras, J.; Daugaard, A.E. Chemically extracted nanocellulose from sisal fibres by a simple and industrially relevant process. Cellulose 2017, 24, 107–118. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr. Polym. 2018, 202, 186–202. [Google Scholar] [CrossRef]

- Shreedhana, K.; Ilavarasi, R. Fabrication of nanocrystalline cellulose from banana peel obtained from unripe plantain bananas. J. Phys. Conf. Ser. 2020, 1644, 012002. [Google Scholar] [CrossRef]

- Lapuz, A.R.; Tsuchikawa, S.; Inagaki, T.; Ma, T.; Migo, V. Production of Nanocellulose Film from Abaca Fibers. Crystals 2022, 12, 601. [Google Scholar] [CrossRef]

- Han, S.; Yao, Q.; Jin, C.; Fan, B.; Zheng, H.; Sun, Q. Cellulose nanofibers from bamboo and their nanocomposites with polyvinyl alcohol: Preparation and characterization. Polym. Compos. 2018, 39, 2611–2619. [Google Scholar] [CrossRef]

- Asem, M.; Jimat, D.N.; Jafri, N.H.S.; Nawawi, W.M.F.W.; Azmin, N.F.M.; Abd Wahab, M.F. Entangled cellulose nanofibers produced from sugarcane bagasse via alkaline treatment, mild acid hydrolysis assisted with ultrasonication. J. King Saud Univ. Eng. Sci. 2021; in press. [Google Scholar] [CrossRef]

- Ahmad, N.L.; Ahmad, I. Extraction and Characterization of Nano cellulose from Coconut Fiber. Malays. J. Anal. Sci. 2013, 17, 109–118. [Google Scholar]

- Mahardika, M.; Abral, H.; Kasim, A.; Arief, S.; Asrofi, M. Production of nanocellulose from pineapple leaf fibers via high-shear homogenization and ultrasonication. Fibers 2018, 6, 28. [Google Scholar] [CrossRef]

- Rahimi, M.; Behrooz, R. Effect of cellulose characteristic and hydrolyze conditions on morphology and size of nanocrystal cellulose extracted from wheat straw. Int. J. Polym. Mater. Polym. Biomater. 2011, 60, 529–541. [Google Scholar] [CrossRef]

- Kalia, S.; Boufi, S.; Celli, A.; Kango, S. Nanofibrillated cellulose: Surface modification and potential applications. Colloid Polym. Sci. 2014, 292, 5–31. [Google Scholar] [CrossRef]

- de Morais Teixeira, E.; Corrêa, A.C.; Manzoli, A.; de Lima Leite, F.; de Oliveira, C.R.; Mattoso, L.H.C. Cellulose nanofibers from white and naturally colored cotton fibers. Cellulose 2010, 17, 595–606. [Google Scholar] [CrossRef]

- Gamelas, J.A.F.; Pedrosa, J.; Lourenço, A.F.; Ferreira, P.J. Surface properties of distinct nanofibrillated celluloses assessed by inverse gas chromatography. Colloids Surf. A Physicochem. Eng. Asp. 2015, 469, 36–41. [Google Scholar] [CrossRef]

- Flauzino Neto, W.P.; Silvério, H.A.; Dantas, N.O.; Pasquini, D. Extraction and characterization of cellulose nanocrystals from agro-industrial residue—Soy hulls. Ind. Crops Prod. 2013, 42, 480–488. [Google Scholar] [CrossRef]

- de Aguiar, J.; Bondancia, T.J.; Claro, P.I.C.; Mattoso, L.H.C.; Farinas, C.S.; Marconcini, J.M. Enzymatic Deconstruction of Sugarcane Bagasse and Straw to Obtain Cellulose Nanomaterials. ACS Sustain. Chem. Eng. 2020, 8, 2287–2299. [Google Scholar] [CrossRef]

- Espinosa, E.; Rol, F.; Bras, J.; Rodríguez, A. Production of lignocellulose nanofibers from wheat straw by different fibrillation methods. Comparison of its viability in cardboard recycling process. J. Clean. Prod. 2019, 239, 118083. [Google Scholar] [CrossRef]

- Tibolla, H.; Pelissari, F.M.; Rodrigues, M.I.; Menegalli, F.C. Cellulose nanofibers produced from banana peel by enzymatic treatment: Study of process conditions. Ind. Crops Prod. 2017, 95, 664–674. [Google Scholar] [CrossRef]

- Bauli, C.R.; Rocha, D.B.; de Oliveira, S.A.; Rosa, D.S. Cellulose nanostructures from wood waste with low input consumption. J. Clean. Prod. 2019, 211, 408–416. [Google Scholar] [CrossRef]

- García, A.; Gandini, A.; Labidi, J.; Belgacem, N.; Bras, J. Industrial and crop wastes: A new source for nanocellulose biorefinery. Ind. Crops Prod. 2016, 93, 26–38. [Google Scholar] [CrossRef]

- Beltramino, F.; Blanca Roncero, M.; Vidal, T.; Valls, C. A novel enzymatic approach to nanocrystalline cellulose preparation. Carbohydr. Polym. 2018, 189, 39–47. [Google Scholar] [CrossRef] [PubMed]

- Phanthong, P.; Reubroycharoen, P.; Hao, X.; Xu, G.; Abudula, A.; Guan, G. Nanocellulose: Extraction and application. Carbon Resour. Convers. 2018, 1, 32–43. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Atikah, M.S.N.; Ibrahim, R.; Hazrol, M.D.; Sherwani, S.F.K.; Harussani, M.M.; Jamal, T.; Nazrin, A.; Syafiq, R. Natural fibre: A promising source for the production of nanocellulose. In Proceedings of the 7th Postgraduate Seminar on Natural Fibre Reinforced Polymer Composites; Universiti Putra Malaysia; Seri Kembangan, Malaysia, 2020; pp. 14–21. [Google Scholar]

- Bharimalla, A.K.; Patil, P.G.; Mukherjee, S.; Yadav, V.; Prasad, V. Nanocellulose-polymer composites: Novel materials for food packaging applications. In Polymers for Agri-Food Applications; Springer Nature: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Varshney, S.; Mishra, N.; Gupta, M.K. Progress in nanocellulose and its polymer based composites: A review on processing, characterization, and applications. Polym. Compos. 2021, 42, 3660–3686. [Google Scholar] [CrossRef]

- Reshmy, R.; Thomas, D.; Philip, E.; Paul, S.A.; Madhavan, A.; Sindhu, R.; Binod, P.; Pugazhendhi, A.; Sirohi, R.; Tarafdar, A.; et al. Potential of nanocellulose for wastewater treatment. Chemosphere 2021, 281, 130738. [Google Scholar]

- Norrrahim, M.N.F.; Ariffin, H.; Hassan, M.A.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Nishida, H. Utilisation of superheated steam in oil palm biomass pretreatment process for reduced chemical use and enhanced cellulose nanofibre production. Int. J. Nanotechnol. 2019, 16, 668–679. [Google Scholar] [CrossRef]

- Iglesias, M.C.; Gomez-Maldonado, D.; Via, B.K.; Jiang, Z.; Peresin, M.S. Pulping processes and their effects on cellulose fibers and nanofibrillated cellulose properties: A review. For. Prod. J. 2020, 70, 10–21. [Google Scholar] [CrossRef]

- Morán, J.I.; Alvarez, V.A.; Cyras, V.P.; Vázquez, A. Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 2008, 15, 149–159. [Google Scholar] [CrossRef]

- Almendárez-Camarillo, A.; Flores-Hernandez, C.G.; Balcázar-Enríquez, V.; Aguirre-García, M.S.; Martínez-Hernandez, A.L.; Velasco-Santos, C. Nanocellulose Extraction of Pineapple Leaves for Chitosan-starch Nanocomposites. J. Nat. Fibers 2020, 19, 1–14. [Google Scholar] [CrossRef]

- Pai, A.R.; Jagtap, R.N. Surface morphology & mechanical properties of some unique natural fiber reinforced polymer composites-a review. J. Mater. Environ. Sci. 2015, 6, 902–917. [Google Scholar]

- Mani, G.K.; Rayappan, J.B.B.; Bisoyi, D.K. Synthesis and Characterization of Kapok Fibers and its Composites. J. Appl. Sci. 2012, 12, 1661–1665. [Google Scholar] [CrossRef][Green Version]

- Jonoobi, M.; Oladi, R.; Davoudpour, Y.; Oksman, K.; Dufresne, A.; Hamzeh, Y.; Davoodi, R. Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: A review. Cellulose 2015, 22, 935–969. [Google Scholar]

- Verma, D.; Goh, K.L. Effect of mercerization/alkali surface treatment of natural fibres and their utilization in polymer composites: Mechanical and morphological studies. J. Compos. Sci. 2021, 5, 175. [Google Scholar] [CrossRef]

- Ferro, M.; Mannu, A.; Panzeri, W.; Theeuwen, C.H.J.; Mele, A. An integrated approach to optimizing cellulose mercerization. Polymers 2020, 12, 1559. [Google Scholar] [CrossRef]

- Mat Nayan, N.H.; Wan Abdul Rahman, W.A.; Abdul Majid, R. The effect of mercerization process on the structural and morphological properties of pineapple leaf fiber (PALF) pulp. Malays. J. Fundam. Appl. Sci. 2014, 10, 12–16. [Google Scholar] [CrossRef]

- Laftah, W.A.; Wan Abdul Rahman, W.A. Pulping Process and the Potential of Using Non-Wood Pineapple Leaves Fiber for Pulp and Paper Production: A Review. J. Nat. Fibers 2016, 13, 85–102. [Google Scholar] [CrossRef]

- Kamel, R.; El-Wakil, N.A.; Dufresne, A.; Elkasabgy, N.A. Nanocellulose: From an agricultural waste to a valuable pharmaceutical ingredient. Int. J. Biol. Macromol. 2020, 163, 1579–1590. [Google Scholar] [CrossRef]

- Abraham, E.; Deepa, B.; Pothan, L.A.; Jacob, M.; Thomas, S.; Cvelbar, U.; Anandjiwala, R. Extraction of nanocellulose fibrils from lignocellulosic fibres: A novel approach. Carbohydr. Polym. 2011, 86, 1468–1475. [Google Scholar] [CrossRef]

- Thakur, V.; Guleria, A.; Kumar, S.; Sharma, S.; Singh, K. Recent advances in nanocellulose processing, functionalization and applications: A review. Mater. Adv. 2021, 2, 1872–1895. [Google Scholar] [CrossRef]

- Kumar, V.; Pathak, P.; Bhardwaj, N.K. Waste paper: An underutilized but promising source for nanocellulose mining. Waste Manag. 2020, 102, 281–303. [Google Scholar] [CrossRef] [PubMed]

- Johar, N.; Ahmad, I.; Dufresne, A. Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind. Crops Prod. 2012, 37, 93–99. [Google Scholar] [CrossRef]

- Sabaruddin, F.A.; Tahir, P.M.; Hua, L.S.; Li, L.C. The Sulphate Removal via Post Alkaline Treatment on Nanocrystalline Cellulose with Different Lignin Content Extracted from Kenaf Core. J. Adv. Res. Fluid Mech. Therm. Sci. 2021, 84, 11–19. [Google Scholar] [CrossRef]

- Panagiotou, G.; Olsson, L. Effect of compounds released during pretreatment of wheat straw on microbial growth and enzymatic hydrolysis rates. Biotechnol. Bioeng. 2007, 96, 250–258. [Google Scholar] [CrossRef]

- Bule, M.V.; Gao, A.H.; Hiscox, B.; Chen, S. Structural modification of lignin and characterization of pretreated wheat straw by ozonation. J. Agric. Food Chem. 2013, 61, 3916–3925. [Google Scholar] [CrossRef]

- Li, C.; Wang, L.; Chen, Z.; Li, Y.; Wang, R.; Luo, X.; Cai, G.; Li, Y.; Yu, Q.; Lu, J. Ozonolysis pretreatment of maize stover: The interactive effect of sample particle size and moisture on ozonolysis process. Bioresour. Technol. 2015, 183, 240–247. [Google Scholar] [CrossRef]

- Lindström, T. Aspects on nanofibrillated cellulose (NFC) processing, rheology and NFC-film properties. Curr. Opin. Colloid Interface Sci. 2017, 29, 68–75. [Google Scholar] [CrossRef]

- Saito, T.; Kimura, S.; Nishiyama, Y.; Isogai, A. Cellulose Nanofibers Prepared by TEMPO-Mediated Oxidation of Native Cellulose. Biomacromolecules 2007, 8, 2485–2491. [Google Scholar] [CrossRef]

- Saito, T.; Kuramae, R.; Wohlert, J.; Berglund, L.A.; Isogai, A. An Ultrastrong Nanofibrillar Biomaterial: The Strength of Single Cellulose Nanofibrils Revealed via Sonication-Induced Fragmentation. Biomacromolecules 2013, 14, 248–253. [Google Scholar] [CrossRef]

- Iwamoto, S.; Kai, W.; Isogai, A.; Iwata, T. Elastic Modulus of Single Cellulose Microfibrils from Tunicate Measured by Atomic Force Microscopy. Biomacromolecules 2009, 10, 2571–2576. [Google Scholar] [CrossRef] [PubMed]

- Akhtar, N.; Gupta, K.; Goyal, D.; Goyal, A. Recent advances in pretreatment technologies for efficient hydrolysis of lignocellulosic biomass. Environ. Prog. Sustain. Energy 2016, 35, 489–511. [Google Scholar] [CrossRef]

- Thakur, V.; Sharma, E.; Guleria, A.; Sangar, S.; Singh, K. Modification and management of lignocellulosic waste as an ecofriendly biosorbent for the application of heavy metal ions sorption. Mater. Today Proc. 2020, 32, 608–619. [Google Scholar] [CrossRef]

- Mehanny, S.; Magd, E.E.A.E.; Sorbara, S.; Navarro, J.; Gil-San-Millan, R. Spanish poplar biomass as a precursor for nanocellulose extraction. Appl. Sci. 2021, 11, 6863. [Google Scholar] [CrossRef]

- Zimmermann, T.; Bordeanu, N.; Strub, E. Properties of nanofibrillated cellulose from different raw materials and its reinforcement potential. Carbohydr. Polym. 2010, 79, 1086–1093. [Google Scholar] [CrossRef]

- Rusdi, R.A.A.; Halim, N.A.; Norizan, M.N.; Abidin, Z.H.Z.; Abdullah, N.; Ros, F.C.; Ahmad, N.; Azmi, A.F.M. Pre-treatment effect on the structure of bacterial cellulose from Nata de Coco (Acetobacter xylinum). Polimery 2022, 67, 110–118. [Google Scholar] [CrossRef]

- Babicka, M.; Woźniak, M.; Szentner, K.; Bartkowiak, M.; Peplińska, B.; Dwiecki, K.; Borysiak, S.; Ratajczak, I. Nanocellulose production using ionic liquids with enzymatic pretreatment. Materials 2021, 14, 3264. [Google Scholar] [CrossRef]

- Rosales-Calderon, O.; Pereira, B.; Arantes, V. Economic assessment of the conversion of bleached eucalyptus Kraft pulp into cellulose nanocrystals in a stand-alone facility via acid and enzymatic hydrolysis. Biofuels Bioprod. Biorefining 2021, 15, 1775–1788. [Google Scholar] [CrossRef]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Hamidon, T.S.; Masruchin, N.; Brosse, N.; Hussin, M.H. Nanocellulose: From Fundamentals to Advanced Applications. Front. Chem. 2020, 8, 392. [Google Scholar] [CrossRef]

- Csiszar, E.; Kalic, P.; Kobol, A.; Ferreira, E.D.P. The effect of low frequency ultrasound on the production and properties of nanocrystalline cellulose suspensions and films. Ultrason. Sonochem. 2016, 31, 473–480. [Google Scholar] [CrossRef]

- Peng, Y.; Via, B. The effect of cellulose nanocrystal suspension treatment on suspension viscosity and casted film property. Polymers 2021, 13, 2168. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Gardner, D.J.; Han, Y.; Kiziltas, A.; Cai, Z.; Tshabalala, M.A. Influence of drying method on the material properties of nanocellulose I: Thermostability and crystallinity. Cellulose 2013, 20, 2379–2392. [Google Scholar] [CrossRef]

- Kondo, T.; Kose, R.; Naito, H.; Kasai, W. Aqueous counter collision using paired water jets as a novel means of preparing bio-nanofibers. Carbohydr. Polym. 2014, 112, 284–290. [Google Scholar] [CrossRef] [PubMed]

- Misenan, S.; Shaffie, A.; Zulkipli, N.; Norrrahim, F. Nanocellulose in Sensors; Woodhead Publishing: Cambridge, UK, 2022; pp. 213–240. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Misenan, M.S.M.; Janudin, N.; Shah, N.A.A.; Halim, N.A.; Noor, S.A.M.; Jamal, S.H.; Ong, K.K. 7—Nanocellulose as an adsorbent for heavy metals. In Industrial Applications of Nanocellulose and Its Nanocomposites; Sapuan, S.M., Norrrahim, M.N.F., Ilyas, R.A., Soutis, C., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 197–211. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Jenol, M.A.; Kamarudin, S.H.; Aisyah, H.A.; Hao, L.C.; Yusuff, S.M.; Amira, M.N.; Harussani, M.M.; Norrrahim, M.N.F.; Ilyas, R.A.; et al. 19—Nanocellulose composites in the automotive industry. In Industrial Applications of Nanocellulose and Its Nanocomposites; Sapuan, S.M., Norrrahim, M.N.F., Ilyas, R.A., Soutis, C., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 439–467. [Google Scholar] [CrossRef]

- Capron, I.; Rojas, O.J.; Bordes, R. Behavior of nanocelluloses at interfaces. Curr. Opin. Colloid Interface Sci. 2017, 29, 83–95. [Google Scholar] [CrossRef]

- Rol, F.; Belgacem, M.N.; Gandini, A.; Bras, J. Recent advances in surface-modified cellulose nanofibrils. Prog. Polym. Sci. 2019, 88, 241–264. [Google Scholar] [CrossRef]

- Missoum, K.; Belgacem, M.N.; Bras, J. Nanofibrillated Cellulose Surface Modification: A Review. Materials 2013, 6, 1745–1766. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Ong, K.K.; Noor, S.A.M.; Jamal, S.H.; Shah, N.A.A.; Halim, N.A.; Ilyas, R.A.; Yunus, W.M.Z.W. Cationic Nanocellulose as Promising Candidate for Filtration Material of COVID-19: A Perspective. Appl. Sci. Eng. Prog. 2021, 14, 580–587. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Mohd Kasim, N.A.; Knight, V.F.; Ong, K.K.; Mohd Noor, S.A.; Abdul Halim, N.; Ahmad Shah, N.A.; Jamal, S.H.; Janudin, N.; Misenan, M.S.M.; et al. Emerging Developments Regarding Nanocellulose-Based Membrane Filtration Material against Microbes. Polymers 2021, 13, 3249. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Ujang, F.A.; Janudin, N.; Razak, M.A.I.A.; Shah, N.A.A.; Noor, S.A.M.; Jamal, S.H.; Ong, K.K.; et al. Nanocellulose: The Next Super Versatile Material for the Military. Mater. Adv. 2021, 2, 1485–1506. [Google Scholar] [CrossRef]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef] [PubMed]

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H. Recent advances in nanocellulose-based different biomaterials: Types, properties, and emerging applications. J. Mater. Res. Technol. 2021, 14, 2601–2623. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Gabor, R.A.; Nicolae, C.A.; Parau, A.C.; Vitelaru, C.; Raditoiu, V.; Chipara, M. Block Copolymer Elastomer with Graphite Filler: Effect of Processing Conditions and Silane Coupling Agent on the Composite Properties. Polymers 2018, 10, 46. [Google Scholar] [CrossRef] [PubMed]

- Bhanthumnavin, W.; Wanichapichart, P.; Taweepreeda, W.; Sirijarukula, S.; Paosawatyanyong, B. Surface modification of bacterial cellulose membrane by oxygen plasma treatment. Surf. Coat. Technol. 2016, 306, 272–278. [Google Scholar] [CrossRef]

- Iotti, M. Coating Composition of Nano Cellulose, Its Uses and a Method for Its Manufacture. WO 2,014,044,870 A1, 27 March 2014. [Google Scholar]

- Ragoubi, M.; George, B.; Molina, S.; Bienaimé, D.; Merlin, A.; Hiver, J.M.; Dahoun, A. Effect of corona discharge treatment on mechanical and thermal properties of composites based on miscanthus fibres and polylactic acid or polypropylene matrix. Compos. Part A Appl. Sci. Manuf. 2012, 43, 675–685. [Google Scholar] [CrossRef]

- Pakharenko, V.; Pervaiz, M.; Pande, H.; Sain, M. Chemical and physical techniques for surface modification of nanocellulose reinforcements. In Interface/Interphase in Polymer Nanocomposites; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 283–310. [Google Scholar] [CrossRef]

- Luo, J.; Deng, W.; Yang, F.; Wu, Z.; Huang, M.; Gu, M. Gold nanoparticles decorated graphene oxide/nanocellulose paper for NIR laser-induced photothermal ablation of pathogenic bacteria. Carbohydr. Polym. 2018, 198, 206–214. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Norrrahim, M.N.F.; Hirata, S.; Hassan, M.A. Hydrothermal and wet disk milling pretreatment for high conversion of biosugars from oil palm mesocarp fiber. Bioresour. Technol. 2015, 181, 263–269. [Google Scholar] [CrossRef]

- Peinado, P.; Sangiao, S.; de Teresa, J.M. Focused Electron and Ion Beam Induced Deposition on Flexible and Transparent Polycarbonate Substrates. ACS Nano 2015, 9, 6139–6146. [Google Scholar] [CrossRef]

- Liangdeng, Y.; Intarasiri, S.; Kamwanna, T.; Singkarat, S. Ion Beam Synthesis and Modification of Silicon Carbide. 2008. Available online: http://inis.iaea.org/search/search.aspx?orig_q=RN:40018370 (accessed on 10 September 2022).

- Islam, M.; Alam, M.; Zoccola, M. Review on modification of nanocellulose for application in composites. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 5445. [Google Scholar]

- Xu, Q.; Poggi, G.; Resta, C.; Baglioni, M.; Baglioni, P. Grafted nanocellulose and alkaline nanoparticles for the strengthening and deacidification of cellulosic artworks. J. Colloid Interface Sci. 2020, 576, 147–157. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; Belgacem, M.N.; Dufresne, A. Short natural-fibre reinforced polyethylene and natural rubber composites: Effect of silane coupling agents and fibres loading. Compos. Sci. Technol. 2007, 67, 1627–1639. [Google Scholar] [CrossRef]

- García-Hernández, E.; Licea-Claveríe, A.; Zizumbo, A.; Alvarez-Castillo, A.; Herrera-Franco, P.J. Improvement of the interfacial compatibility between sugar cane bagasse fibers and polystyrene for composites. Polym. Compos. 2004, 25, 134–145. [Google Scholar] [CrossRef]

- Soeta, H.; Fujisawa, S.; Saito, T.; Isogai, A. Controlling Miscibility of the Interphase in Polymer-Grafted Nanocellulose/Cellulose Triacetate Nanocomposites. ACS Omega 2020, 5, 23755–23761. [Google Scholar] [CrossRef] [PubMed]

- Blockx, J.; Verfaillie, A.; Deschaume, O.; Bartic, C.; Muylaert, K.; Thielemans, W. Glycine betaine grafted nanocellulose as an effective and bio-based cationic nanocellulose flocculant for wastewater treatment and microalgal harvesting. Nanoscale Adv. 2021, 3, 4133–4144. [Google Scholar] [CrossRef] [PubMed]

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Halim, N.A.; Shah, N.A.A.; Noor, S.A.M.; Jamal, S.H.; Ong, K.K.; Yunus, W.M.Z.W.; Farid, M.A.A.; et al. Performance Evaluation of Cellulose Nanofiber Reinforced Polymer Composites. Funct. Compos. Struct. 2021, 3, 024001. [Google Scholar] [CrossRef]

- Frank, B.P.; Smith, C.; Caudill, E.R.; Lankone, R.S.; Carlin, K.; Benware, S.; Pedersen, J.A.; Fairbrother, D.H. Biodegradation of Functionalized Nanocellulose. Environ. Sci. Technol. 2021, 55, 10744–10757. [Google Scholar] [CrossRef]

- Thomas, B.; Raj, M.C.; Joy, J.; Moores, A.; Drisko, G.L.; Sanchez, C. Nanocellulose, a Versatile Green Platform: From Biosources to Materials and Their Applications. Chem. Rev. 2018, 118, 11575–11625. [Google Scholar] [CrossRef]

- Xu, H.; Xie, Y.; Zhu, E.; Liu, Y.; Shi, Z.; Xiong, C.; Yang, Q. Supertough and ultrasensitive flexible electronic skin based on nanocellulose/sulfonated carbon nanotube hydrogel films. J. Mater. Chem. A Mater. 2020, 8, 6311–6318. [Google Scholar] [CrossRef]

- Michelin, M.; Gomes, D.G.; Romaní, A.; Polizeli, M.d.L.T.M.; Teixeira, J.A. Nanocellulose production: Exploring the enzymatic route and residues of pulp and paper industry. Molecules 2020, 25, 3411. [Google Scholar] [CrossRef]

- Maqsood, H.S.; Bashir, U.; Wiener, J.; Puchalski, M.; Sztajnowski, S.; Militky, J. Ozone treatment of jute fibers. Cellulose 2017, 24, 1543–1553. [Google Scholar] [CrossRef]

- Meftahi, A.; Samyn, P.; Geravand, S.A.; Khajavi, R.; Alibkhshi, S.; Bechelany, M.; Barhoum, A. Nanocelluloses as skin biocompatible materials for skincare, cosmetics, and healthcare: Formulations, regulations, and emerging applications. Carbohydr. Polym. 2022, 278, 118956. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Mozuch, M.D.; Sabo, R.C.; Kersten, P.; Zhu, J.Y.; Jin, Y. Production of cellulose nanofibrils from bleached eucalyptus fibers by hyperthermostable endoglucanase treatment and subsequent microfluidization. Cellulose 2015, 22, 351–361. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Huzaifah, M.R.M.; Farid, M.A.A.; Shazleen, S.S.; Misenan, M.S.M.; Yasim-Anuar, T.A.T.; Naveen, J.; Nurazzi, N.M.; Rani, M.S.A.; Hakimi, M.I.; et al. Greener Pretreatment Approaches for the Valorisation of Natural Fibre Biomass into Bioproducts. Polymers 2021, 13, 2971. [Google Scholar] [CrossRef] [PubMed]

- Martelli-Tosi, M.; Torricillas, M.d.S.; Martins, M.A.; Assis, O.B.G.; de Tapia-Blácido, D.R. Using Commercial Enzymes to Produce Cellulose Nanofibers from Soybean Straw. J. Nanomater. 2016, 2016, 8106814. [Google Scholar] [CrossRef]

- Bondancia, T.J.; Corrêa, L.J.; Cruz, A.J.; Badino, A.C.; Mattoso, L.H.C.; Marconcini, J.M.; Farinas, C.S. Enzymatic production of cellulose nanofibers and sugars in a stirred-tank reactor: Determination of impeller speed, power consumption, and rheological behavior. Cellulose 2018, 25, 4499–4511. [Google Scholar] [CrossRef]

- Khalil, H.A.; Davoudpour, Y.; Islam, M.N.; Mustapha, A.; Sudesh, K.; Dungani, R.; Jawaid, M. Production and modification of nanofibrillated cellulose using various mechanical processes: A review. Carbohydr. Polym. 2014, 99, 649–665. [Google Scholar] [CrossRef]

- Besbes, I.; Vilar, M.R.; Boufi, S. Nanofibrillated cellulose from Alfa, Eucalyptus and Pine fibres: Preparation, characteristics and reinforcing potential. Carbohydr. Polym. 2011, 86, 1198–1206. [Google Scholar] [CrossRef]

- Toyosaki, H.; Naritomi, T.; Seto, A.; Matsuoka, M.; Tsuchida, T.; Yoshinaga, F. Screening of Bacterial Cellulose-producing Acetobacter Strains Suitable for Agitated Culture. Biosci. Biotechnol. Biochem. 1995, 59, 1498–1502. [Google Scholar] [CrossRef]

- Marimuthu, T.S.; Atmakuru, R. Isolation and characterization of cellulose nanofibers from the aquatic weed water hyacinth: Eichhornia crassipes. Carbohydr. Polym. 2015, 87, 37–46. [Google Scholar]

- Jaffar, S.S.; Saallah, S.; Misson, M.; Siddiquee, S.; Roslan, J.; Saalah, S.; Lenggoro, W. Recent Development and Environmental Applications of Nanocellulose-Based Membranes. Membranes 2022, 12, 287. [Google Scholar] [CrossRef]

- Mokhena, T.C.; Sefadi, J.S.; Sadiku, E.R.; John, M.J.; Mochane, M.J.; Mtibe, A. Thermoplastic Processing of PLA/Cellulose Nanomaterials Composites. Polymers 2018, 10, 1363. [Google Scholar] [CrossRef] [PubMed]

- Siqueira, G.; Bras, J.; Dufresne, A. Cellulosic bionanocomposites: A review of preparation, properties and applications. Polymers 2010, 2, 728–765. [Google Scholar] [CrossRef]

- Souza, S.F.; Ferreira, F.V.; Cherian, B.M.; Silva, V.R.; Manzato, L.; Pinheiro, I.F. Processing of nanocellulose-based composites. In Fiber-Reinforced Nanocomposites: Fundamentals and Applications; Han, B., Sharma, S., Nguyen, T.A., Longbiao, L., Bhat, K.S., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 431–448. [Google Scholar] [CrossRef]

- Rani, M.S.A.; Abdullah, N.A.; Sainorudin, M.H.; Mohammad, M.; Mohammad, M. The development of poly(ethylene oxide)reinforced with a nanocellulose-basednanocomposite polymer electrolytein dye-sensitized solar cells. Mater. Adv. 2021, 2, 5465–5470. [Google Scholar] [CrossRef]

- Sung, S.H.; Chang, Y.; Han, J. Development of polylactic acid nanocomposite films reinforced with cellulose nanocrystals derived from coffee silverskin. Carbohydr. Polym. 2017, 169, 495–503. [Google Scholar] [CrossRef]

- Benini, K.C.C.d.C.; Cioffi, M.O.H.; Voorwald, H.J.C. PHBV/cellulose nanofibrils composites obtained by solution casting and electrospinning process. Rev. Mater. 2017, 22, 1–9. [Google Scholar] [CrossRef]

- Iwatake, A.; Nogi, M.; Yano, H. Cellulose nanofiber-reinforced polylactic acid. Compos. Sci. Technol. 2008, 68, 2103–2106. [Google Scholar] [CrossRef]

- Sapkota, J.; Kumar, S.; Weder, C.; Foster, E.J. Influence of Processing Conditions on Properties of Poly (Vinyl acetate)/Cellulose Nanocrystal Nanocomposites. Macromol. Mater. Eng. 2015, 300, 562–571. [Google Scholar] [CrossRef]

- Vaia, R.A.; Ishii, H.; Giannelis, E.P. Synthesis and properties of two-dimensional nanostructures by direct intercalation of polymer melts in layered silicates. Chem. Mater. 1993, 5, 1694–1696. [Google Scholar] [CrossRef]

- Bharimalla, A.K.; Deshmukh, S.P.; Vigneshwaran, N.; Patil, P.G.; Prasad, V. Nanocellulose-Polymer Composites for Applications in Food Packaging: Current Status, Future Prospects and Challenges. Polym. Plast. Technol. Eng. 2017, 56, 805–823. [Google Scholar] [CrossRef]

- Qasim, U.; Osman, A.I.; Al-Muhtaseb, A.A.H.; Farrell, C.; Al-Abri, M.; Ali, M.; Vo, D.V.N.; Jamil, F.; Rooney, D.W. Renewable cellulosic nanocomposites for food packaging to avoid fossil fuel plastic pollution: A review. Environ. Chem. Lett. 2020, 19, 613–614. [Google Scholar] [CrossRef]

- Das, S.K.; Chakrabortyb, S.; Naskarc, S.; Rajabalayad, R. 3-Techniques and methods used for the fabrication of bionanocomposites. In Bionanocomposites in Tissue Engineering and Regenerative Medicine; Woodhead Publishing Series: Amsterdam, The Netherlands, 2021; p. 17. [Google Scholar]

- Ayadi, A.; Deléglise-Lagardère, M.; Park, C.H.; Krawczak, P. Analysis of Impregnation Mechanism of Weft-Knitted Commingled Yarn Composites by Staged Consolidation and Laboratory X-ray Computed Tomography. Front. Mater. 2019, 6, 255. [Google Scholar] [CrossRef]

- Thomas, G.P. Composite Prepregs—Manufacturing, Benefits and Applications. Azo Materials. 2013. Available online: https://www.azom.com/article.aspx?ArticleID=8353 (accessed on 30 August 2022).

- Baché, E.; Dupleix-Couderc, C.; Arquis, E.; Berdoyes, I. Impregnation of Composite Materials: A Numerical Study. Appl. Compos. Mater. 2018, 25, 1287–1305. [Google Scholar] [CrossRef]

- Risicato, J.V.; Kelly, F.; Soulat, D.; Legrand, X.; Trümper, W.; Cochrane, C.; Koncar, V. A Complex Shaped Reinforced Thermoplastic Composite Part Made of Commingled Yarns With Integrated Sensor. Appl. Compos. Mater. 2015, 22, 81–98. [Google Scholar] [CrossRef]

- Alagirusamy, R.; Ogale, V. Commingled and air jet-textured hybrid yarns for thermoplastic composites. J. Ind. Text. 2004, 33, 223–243. [Google Scholar] [CrossRef]

- Kim, S.H.; Park, C.H. Direct impregnation of thermoplastic melt into flax textile reinforcement for semi-structural composite parts. Ind. Crops Prod. 2017, 95, 651–663. [Google Scholar] [CrossRef]

- Studer, J.; Dransfeld, C.; Cano, J.J.; Keller, A.; Wink, M.; Masania, K.; Fiedler, B. Effect of fabric architecture, compaction and permeability on through thickness thermoplastic melt impregnation. Compos. Part A Appl. Sci. Manuf. 2019, 122, 45–53. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef]

- Dufresne, A. Processing of nanocellulose-based materials. In Nanocellulose: From Nature to High Performance Tailored Materials; De Gruyter: Boston, MA, USA, 2017; pp. 351–418. [Google Scholar] [CrossRef]

- Grothe, J.; Kaskel, S.; Leuteritz, A. Nanocomposites and hybrid materialS. In Polymer Science: A Comprehensive Reference; Matyjaszewski, K., Möller, M., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2012; pp. 177–209. [Google Scholar]

- Motaung, T.E.; Mochane, M.J.; Linganiso, Z.L.; Mashigo, A.P. In-situ Polymerization of Nylon-Cellulose Nano composite. Polym. Sci. 2017, 3, 1–8. [Google Scholar] [CrossRef]

- Cao, X.; Habibi, Y.; Lucia, L.A. One-pot polymerization, surface grafting, and processing of waterborne polyurethane–cellulose nanocrystal nanocomposites. J. Mater. Chem. 2009, 19, 7137–7145. [Google Scholar] [CrossRef]

- Park, S.; Ruoff, R.S. Chemical methods for the production of graphenes. Nat. Nanotechnol. 2009, 4, 217–224. [Google Scholar] [CrossRef]

- Ray, D.; Sain, S. In situ processing of cellulose nanocomposites. Compos. Part A 2016, 83, 19–37. [Google Scholar] [CrossRef]

- Tang, L.C.; Zhao, L.; Qiang, F.; Wu, Q.; Gong, L.X.; Peng, J.P. Mechanical properties of rubber nanocomposites containing carbon nanofillers. In Carbon-Based Nanofillers and Their Rubber Nanocomposites: Fundamentals and Applications; Yaragalla, S., Mishra, R.K., Thomas, S., Kalarikkal, N., Maria, H.J., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 367–423. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Ferrer, A.; Tyagi, P.; Yin, Y.; Salas, C.; Pal, L.; Rojas, O.J. Nanocellulose in Thin Films, Coatings, and Plies for Packaging Applications: A Review. Bioresources 2017, 12, 2143–2233. [Google Scholar] [CrossRef]

- Amara, C.; El Mahdi, A.; Medimagh, R.; Khwaldia, K. Nanocellulose-based composites for packaging applications. Curr. Opin. Green Sustain. 2021, 31, 100512. [Google Scholar] [CrossRef]

- Ansari, F.; Ding, Y.; Berglund, L.A.; Dauskardt, R.H. Toward Sustainable Multifunctional Coatings Containing Nanocellulose in a Hybrid Glass Matrix. ACS Nano 2018, 12, 5495–5503. [Google Scholar] [CrossRef] [PubMed]

- Koppolu, R.; Lahti, J.; Abitbol, T.; Swerin, A.; Kuusipalo, J.; Toivakka, M. Continuous Processing of Nanocellulose and Polylactic Acid into Multilayer Barrier Coatings. ACS Appl. Mater. Interfaces 2019, 11, 11920–11927. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; López, D.; Kenny, J.M.; Peponi, L. Biodegradable electrospun bionanocomposite fibers based on plasticized PLA–PHB blends reinforced with cellulose nanocrystals. Ind. Crops Prod. 2016, 93, 290–301. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Yasim-Anuar, T.A.T.; Jenol, M.A.; Nurazzi, N.M.; Sapuan, S.M.; Ilyas, R.A. Performance evaluation of cellulose nanofiber reinforced polypropylene biocomposites for Automotive applications. In Biocomposite and Synthetic Composites for Automotive Applications; Woodhead Publishing Series: Amsterdam, The Netherlands, 2020; pp. 119–215. [Google Scholar]

- Fareez, I.M.; Jasni, A.H.; Norrrahim, M.N.F. Nanofibrillated cellulose based bio-phenolic composites. In Phenolic Polymers Based Composite Materials; Springer: Singapore, 2020; pp. 139–151. [Google Scholar]

- Norrrahim, M.N.F. Superheated Steam Pretreatment of Oil Palm Biomass for Improving Nanofibrillation of Cellulose and Performance of Polypropylene/Cellulose Nanofiber Composites; Universiti Putra Malaysia: Seri Kembangan, Malaysia, 2018. [Google Scholar]

- Norrrahim, M.N.F.; Tengku Yasim-Anuar, T.A.; Sapuan, S.M.; Ilyas, R.A.; Hakimi, M.I.; Syed Najmuddin, S.U.F.; Jenol, M.A. Nanocellulose reinforced polypropylene and polyethylene composite for packaging application. In Bio-Based Packaging: Material, Environmental and Economic Aspects; Wiley Online Library: Hoboken, NJ, USA, 2021. [Google Scholar] [CrossRef]

- Lee, C.H.; Lee, S.H.; Padzil, F.N.M.; Ainun, Z.M.A.; Norrrahim, M.N.F.; Chin, K.L. Biocomposites and Nanocomposites. In Composite Materials; CRC Press: Boca Raton, FL, USA, 2021; pp. 29–60. [Google Scholar]

- Charreau, H.; Cavallo, E.; Foresti, M.L. Patents involving nanocellulose: Analysis of their evolution since 2010. Carbohydr. Polym. 2020, 237, 116039. [Google Scholar] [CrossRef]

- De France, K.; Zeng, Z.; Wu, T.; Nyström, G. Functional materials from nanocellulose: Utilizing structure–property relationships in bottom-up fabrication. Adv. Mater. 2021, 33, 2000657. [Google Scholar] [CrossRef]

- Jenol, M.A.; Norrrahim, M.N.F.; Nurazzi, N.M. 17—Nanocellulose nanocomposites in textiles. In Industrial Applications of Nanocellulose and Its Nanocomposites; Sapuan, S.M., Norrrahim, M.N.F., Ilyas, R.A., Soutis, C., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 397–408. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Asyraf, M.R.M.; Aisyah, H.A.; Sapuan, S.M.; Norrrahim, M.N.F.; Ibrahim, R.; Atikah, M.S.N.; Atiqah, A.; Zainudin, E.S.; Ishak, M.R.; et al. 1-Introduction to nanocellulose production from biological waste. In Industrial Applications of Nanocellulose and Its Nanocomposites; Sapuan, S.M., Norrrahim, M.N.F., Ilyas, R.A., Soutis, C., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 1–37. [Google Scholar] [CrossRef]

- Adachi, K.; Daicho, K.; Furuta, M.; Shiga, T.; Saito, T.; Kodama, T. Thermal conduction through individual cellulose nanofibers. Appl. Phys. Lett. 2021, 118, 053701. [Google Scholar] [CrossRef]

- Uetani, K.; Kasuya, K.; Wang, J.; Huang, Y.; Watanabe, R.; Tsuneyasu, S.; Satoh, T.; Koga, H.; Nogi, M. Kirigami-processed cellulose nanofiber films for smart heat dissipation by convection. NPG Asia Mater. 2021, 13, 62. [Google Scholar] [CrossRef]

- Reshmy, R.; Philip, E.; Paul, S.A.; Madhavan, A.; Sindhu, R.; Binod, P.; Pandey, A.; Sirohi, R. Nanocellulose-based products for sustainable applicationsrecent trends and possibilities. Rev. Environ. Sci. Biotechnol. 2020, 19, 779–806. [Google Scholar] [CrossRef]

- Shahsavari, S. 2021. Application of Nanocellulose in Food Packaging: A review. Int. J. Bio-Inorg. Hybr. Nanomater. 2021, 10, 5–10. [Google Scholar]

- Silva, F.A.G.S.; Dourado, F.; Gama, M.; Poças, F. Nanocellulose bio-based composites for food packaging. Nanomaterials 2020, 10, 2041. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, K.R.; Dixit, S.; Pal, D.B.; Mishra, P.K.; Srivastava, P.; Srivastava, N.; Hashem, A.; Alqarawi, A.A.; Abd_Allah, E.F. Effect of nanocellulose on mechanical and barrier properties of PVA–banana pseudostem fiber composite films. Environ. Technol. Innov. 2021, 21, 101312. [Google Scholar] [CrossRef]

- Asad, M.; Saba, N.; Asiri, A.M.; Jawaid, M.; Indarti, E.; Wanrosli, W.D. 2-Preparation and characterization of nanocomposite films from oil palm pulp nanocellulose/poly (Vinyl alcohol) by casting method. Carbohydr. Polym. 2018, 191, 103–111. [Google Scholar] [CrossRef]

- Patel, B.H.; Joshi, P.V. Banana Nanocellulose Fiber/PVOH Composite Film as Soluble Packaging Material: Preparation and Characterization. J. Packag. Technol. Res. 2020, 4, 95–101. [Google Scholar] [CrossRef]

- Tsai, Y.-H.; Yang, Y.-N.; Ho, Y.-C.; Tsai, M.-L.; Mi, F.-L. Drug release and antioxidant/antibacterial activities of silymarin-zein nanoparticle/bacterial cellulose nanofiber composite films. Carbohydr. Polym. 2018, 15, 286–296. [Google Scholar] [CrossRef]

- Moreirinha, C.; Vilela, C.; Silva, N.H.; Pinto, R.J.; Almeida, A.; Rocha, M.A.M.; Coelho, E.; Coimbra, M.A.; Silvestre, A.J.; Freire, C.S. Antioxidant and antimicrobial films based on brewers spent grain arabinoxylans, nanocellulose and feruloylated compounds for active packaging. Food Hydrocoll. 2020, 108, 105836. [Google Scholar] [CrossRef]

- Fuertes, G.; Soto, I.; Carrasco, R.; Vargas, M.; Sabattin, J.; Lagos, C. Intelligent Packaging Systems: Sensors and Nanosensors to Monitor Food Quality and Safety. J. Sens. 2016, 2016, 1–8. [Google Scholar] [CrossRef]

- Kuswandi, B.; Jayus, O.R.; Abdullah, A.; Heng, L.Y. Novel On-Package Sticker Sensor Based on Methyl Red forReal-Time Monitoring of Broiler Chicken Cut Freshness. Packag. Technol. Sci. 2014, 27, 69–81. [Google Scholar] [CrossRef]

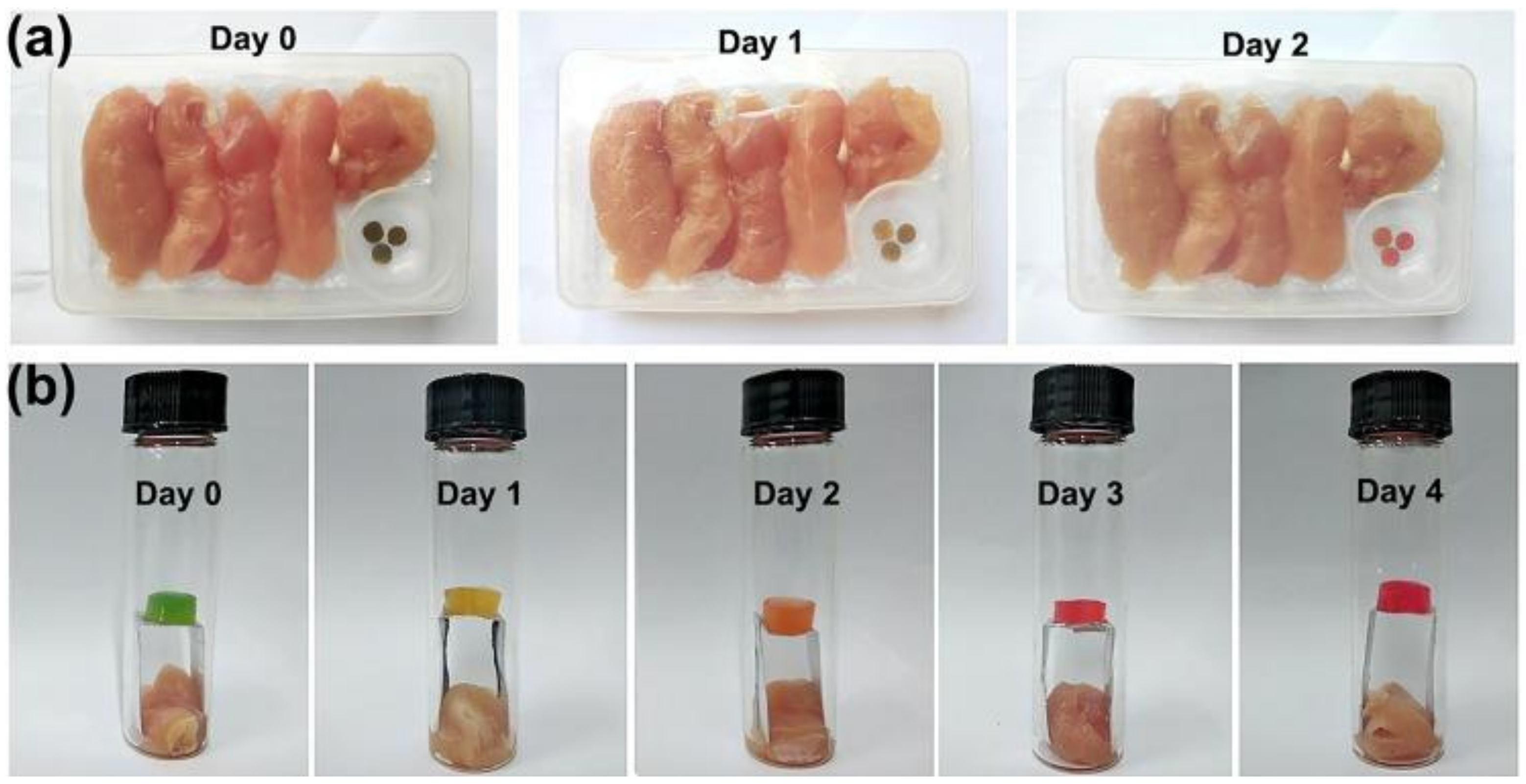

- Lu, P.; Yang, Y.; Liu, R.; Liu, X.; Ma, J.; Wu, M.; Wang, S. Preparation of sugarcane bagasse nanocellulose hydrogel as a colourimetric freshness indicator for intelligent food packaging. Carbohydr. Polym. 2020, 249, 116831. [Google Scholar] [CrossRef] [PubMed]

- Al Obaidi, A.; Karaca, I.M.; Ayhan, Z.; Haskaraca, G.; Gultekin, E. Fabrication and validation of CO2-sensitive indicator to monitor the freshness of poultry meat. Food Packag. Shelf Life 2022, 34, 100930. [Google Scholar] [CrossRef]

- Guise, C.; Fangueiro, R. Biomedical applications of nanocellulose. In Natural Fibres: Advances in Science and Technology towards Industrial Applications; Fangueiro, R., Rana, S., Eds.; Springer: Dordrecht, The Netherlands, 2016; pp. 155–169. [Google Scholar] [CrossRef]

- Nehra, P.; Chauhan, R.P. Eco-friendly Nanocellulose and its Biomedical Applications: Current Status and Future Prospect. J. Biomater. Sci. Polym. Ed. 2020, 32, 112–149. [Google Scholar] [CrossRef] [PubMed]

- Siqueira, P.; Siqueira, É.; De Lima, A.E.; Siqueira, G.; Pinzón-Garcia, A.D.; Lopes, A.P.; Segura, M.E.C.; Isaac, A.; Pereira, F.V.; Botaro, V.R. Three-Dimensional Stable Alginate-NanocelluloseGels for Biomedical Applications: Towards TunableMechanical Properties and Cell Growing. Nanomaterials 2019, 9, 78. [Google Scholar] [CrossRef]

- Ludwicka, K.; Kolodziejczyk, M.; Gendaszewska-Darmach, E.; Chrzanowski, M.; Jedrzejczak-Krzepkowska, M.; Rytczak, P.; Bielecki, S. Stable composite of bacterial nanocellulose and perforated polypropylene mesh for biomedical applications. J. Biomed. Mater. Res. B Appl. Biomater. 2018, 107, 978–987. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Shi, Y.; Cheng, L.; Sun, J.; Yu, S.; Lu, X.; Biranje, S.; Xu, W.; Zhang, X.; Song, J.; et al. Growth factor functionalized biodegradable nanocellulose scaffolds for potential wound healing application. Cellulose 2021, 28, 5643–5656. [Google Scholar] [CrossRef]

- Sanoj, P.; Balasubramanian, K. High performance structural nano cellulose composites for motor vehicle spring suspension system. J. Plast. Technol. 2014, 18, 383–389. [Google Scholar] [CrossRef]

- Duzik, A.; Ko, H.U.; Kim, H.J.; Kim, J.; Kim, J.H.; Choi, S.H.; Bryant, R.G. Fabrication Method, Characteristics and Applications of Cellulose Nano Fiber (CNF) Film; NASA/TM-2019-220268; NASA Langley Research Center: Hampton, VA, USA, 2019. [Google Scholar]

- Bheekhun, N.; Talib, A.R.A.; Hassan, M.R. Aerogels in Aerospace: An Overview. Adv. Mater. Sci. Eng. 2013, 2013, 406065. [Google Scholar] [CrossRef]

- Nguyen, L.H.; Naficy, S.; Chandrawati, R.; Dehghani, F. Nanocellulose for Sensing Applications. Adv. Mater. Interfaces 2019, 6, 1900424. [Google Scholar] [CrossRef]

- Jaiswal, A.K.; Hokkanen, A.; Kumar, V.; Makela, T.; Harlin, A.; Orelma, H. Thermoresponsive Nanocellulose Films as an Optical Modulation Device: Proof-of-Concept. ACS Appl. Mater. Interfaces 2021, 13, 25346–25356. [Google Scholar] [CrossRef]

- Wang, D.C.; Yu, H.Y.; Qi, D.; Ramasamy, M.; Yao, J.; Tang, F.; Tam, K.M.C.; Ni, Q. Supramolecular Self-Assembly of 3D Conductive Cellulose Nanofiber Aerogels for Flexible Supercapacitors and Ultrasensitive Sensors. ACS Appl. Mater. Interfaces 2019, 11, 24435–24446. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Yu, H.; Zhang, Y.; Dong, F.; Li, Z. Colloids and Surfaces B: Biointerfaces Cellulose acetate nanofibers coated layer-by-layer with polyethylenimine and graphene oxide on a quartz crystal microbalance for use as a highly sensitive ammonia sensor. Colloids Surf. B Biointerfaces 2016, 148, 263–269. [Google Scholar] [CrossRef] [PubMed]

- Pang, Z.; Yang, Z.; Chen, Y.; Zhang, J.; Wang, Q.; Huang, F.; Wei, Q. A room temperature ammonia gas sensor based on cellulose/TiO2/PANI composite nanofibers. Colloids Surf. A Physicochem. Eng. Asp. 2016, 494, 248–255. [Google Scholar] [CrossRef]

- Sadasivuni, K.K.; Ponnamma, D.; Ko, H.U.; Kim, H.C.; Zhai, L.; Kim, J. Flexible NO2 sensors from renewable cellulose nanocrystals/iron oxide composites. Sens. Actuators B Chem. 2016, 233, 633–638. [Google Scholar] [CrossRef]

- Hu, W.; Chen, S.; Liu, L.; Ding, B.; Wang, H. Formaldehyde sensors based on nanofibrous polyethyleneimine/bacterial cellulose membranes coated quartz crystal microbalance. Sens. Actuators B Chem. 2011, 157, 554–559. [Google Scholar] [CrossRef]

- Wu, X.; Lu, C.; Han, Y.; Zhou, Z.; Yuan, G.; Zhang, X. Cellulose nanowhisker modulated 3D hierarchical conductive structure of carbon black/natural rubber nanocomposites for liquid and strain sensing application. Compos. Sci. Technol. 2016, 124, 44–51. [Google Scholar] [CrossRef]

- Cao, J.; Zhang, X.; Wu, X.; Wang, S.; Lu, C. Cellulose nanocrystals mediated assembly of graphene in rubber composites for chemical sensing applications. Carbohydr. Polym. 2016, 140, 88–95. [Google Scholar] [CrossRef]

- Edwards, J.V.; Prevost, N.; Sethumadhavan, K.; Ullah, A.; Condon, B. Peptide conjugated cellulose nanocrystals with sensitive human neutrophil elastase sensor activity. Cellulose 2013, 20, 1223–1235. [Google Scholar] [CrossRef]

- Guyomard-Lack, A.; Cerclier, C.; Beury, N.; Jean, B.; Cousin, F.; Moreau, C.; Cathala, B. Nano-structured cellulose nanocrystals-xyloglucan multilayered films for the detection of cellulase activity. Eur. Phys. J. Spec. Top 2012, 213, 291–294. [Google Scholar] [CrossRef]

- Schyrr, B.; Pasche, S.; Voirin, G.; Weder, C.; Simon, Y.C.; Foster, E.J. Biosensors based on porous cellulose nanocrystal–poly (vinyl alcohol) scaffolds. ACS Appl. Mater. Interfaces 2014, 6, 12674–12683. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Q.; Zhou, J.; Zhang, L. Synthesis and Photophysical Behavior of Pyrene-Bearing Cellulose Nanocrystals for Fe3+ Sensing. Macromol. Chem. Phys. 2012, 213, 1612–1617. [Google Scholar] [CrossRef]

- Kacmaz, S.; Ertekin, K.; Gocmenturk, M.; Suslu, A.; Ergun, Y.; Celik, E. Selective sensing of Fe3+ at pico-molar level with ethyl cellulose based electrospun nanofibers. React. Funct. Polym. 2013, 73, 674–682. [Google Scholar] [CrossRef]

- Weishaupt, R.; Siqueira, G.; Schubert, M.; Kämpf, M.M.; Zimmermann, T.; Maniura-Weber, K.; Faccio, G. A Protein-Nanocellulose Paper for Sensing Copper Ions at the Nano- to Micromolar Level. Adv. Funct. Mater. 2017, 27, 1604291. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, X.; Ren, S.; Lei, T.; Sun, X.; Qi, Y.; Wu, Q. Poly(diallyldimethylammonium chloride)–cellulose nanocrystals supported Au nanoparticles for nonenzymatic glucose sensing. RSC Adv. 2016, 6, 6436–6442. [Google Scholar] [CrossRef]

- Wang, S.; Sun, J.; Jia, Y.; Yang, L.; Wang, N.; Xianyu, Y.; Chen, W.; Li, X.; Cha, R.; Jiang, X. Nanocrystalline Cellulose-Assisted Generation of Silver Nanoparticles for Nonenzymatic Glucose Detection and Antibacterial Agent. Biomacromolecules 2016, 17, 2472–2478. [Google Scholar] [CrossRef]

- Yu, X.; Tong, S.; Ge, M.; Wu, L.; Zuo, J.; Cao, C.; Song, W. Adsorption of heavy metal ions from aqueous solution by carboxylated cellulose nanocrystals. J. Environ. Sci. 2013, 25, 933–943. [Google Scholar] [CrossRef]

- Goswami, R.; Mishra, A.; Bhatt, N.; Mishra, A.; Naithani, P. Potential of chitosan/nanocellulose based composite membrane for the removal of heavy metal (chromium ion). Mater. Today Proc. 2021, 46, 10954–10959. [Google Scholar] [CrossRef]

- Rodrigues, F.H.A.; Magalhães, C.E.d.C.; Medina, A.L.; Fajardo, A.R. Hydrogel composites containing nanocellulose as adsorbents for aqueous removal of heavy metals: Design, optimization, and application. Cellulose 2019, 26, 9119–9133. [Google Scholar] [CrossRef]

- Sorriaux, M.; Sorieul, M.; Chen, Y. Bio-Based and Robust Polydopamine Coated Nanocellulose/Amyloid Composite Aerogel for Fast and Wide-Spectrum Water Purification. Polymers 2021, 13, 3442. [Google Scholar] [CrossRef]

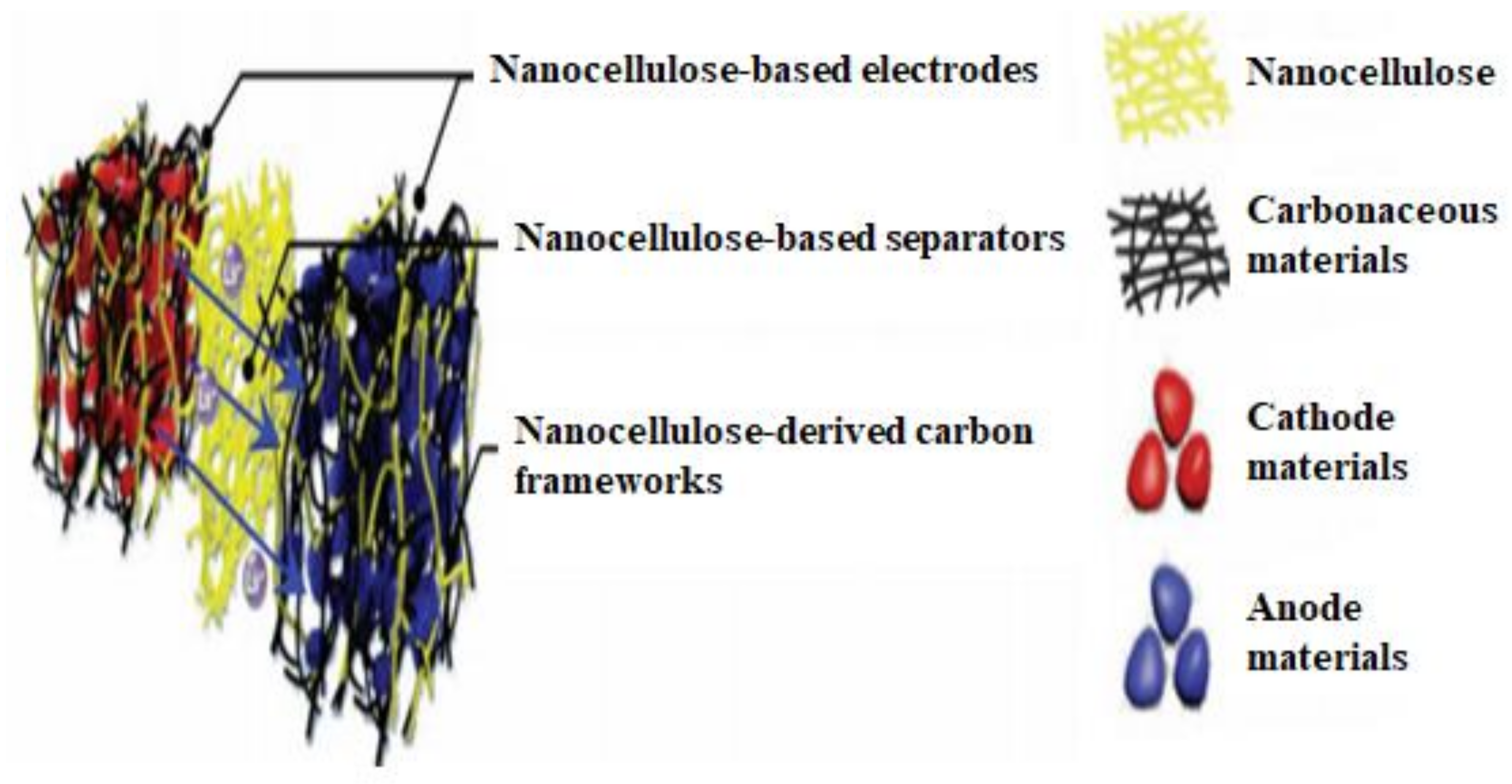

- Du, X.; Zhang, Z.; Liu, W.; Deng, Y. Nanocellulose-based conductive materials and their emerging applications in energy devices—A review. Nano Energy 2017, 35, 299–320. [Google Scholar] [CrossRef]

- QuanLing, Y.; JunWei, Y.; ZhuQun, S.; ShuJie, X.; ChuanXi, X. Recent progress of nanocellulose-based electroconductive materials and their applications as electronic devices. J. For. Eng. 2018, 3, 1–11. [Google Scholar]

- Kim, J.-H.; Yun, S.; Ko, H.-U.; Kim, J. A flexible paper transistor made with aligned single-walled carbon nanotube bonded cellulose composite. Curr. Appl. Phys. 2013, 13, 897–901. [Google Scholar] [CrossRef]

- Kim, J. Disposable and Flexible Chemical Sensors and Biosensors Made with Renewable Materials; World Scientific: Singapore, 2017. [Google Scholar] [CrossRef]

- Gao, Y.; Choi, S. Stepping Toward Self-Powered Papertronics: Integrating Biobatteries into a Single Sheet of Paper. Adv. Mater. Technol. 2016, 2, 1600194. [Google Scholar] [CrossRef]

- Han, J.; Lu, K.; Yue, Y.; Mei, C.; Huang, C.; Wu, Q.; Xu, X. Nanocellulose-templated assembly of polyaniline in natural rubber-based hybrid elastomers toward flexible electronic conductors. Ind. Crops Prod. 2019, 128, 94–107. [Google Scholar] [CrossRef]

- Inui, T.; Koga, H.; Nogi, M.; Komoda, N.; Suganuma, K. A Miniaturized Flexible Antenna Printed on a High Dielectric Constant Nanopaper Composite. Adv. Mater. 2015, 27, 1112–1116. [Google Scholar] [CrossRef]

- He, W.; Tian, J.; Li, J.; Jin, H.; Li, Y. Characterization and properties of cellulose nanofiber/polyaniline film composites synthesized through in situ polymerization. Bioresources 2016, 11, 8535–8547. [Google Scholar] [CrossRef]

- Zhang, J.; Fu, J.; Song, X.; Jiang, G.; Zarrin, H.; Xu, P.; Li, K.; Yu, A.; Chen, Z. Laminated Cross-Linked Nanocellulose/Graphene Oxide Electrolyte for Flexible Rechargeable Zinc–Air Batteries. Adv. Energy Mater. 2016, 6, 1600476. [Google Scholar] [CrossRef]

- Mishra, S.; Unnikrishnan, L.; Nayak, S.K.; Mohanty, S. Advances in piezoelectric polymer composites for energy harvesting applications: A systematic review. Macromol. Mater. Eng. 2019, 34, 1800463. [Google Scholar] [CrossRef]

- Han, L.; Cui, S.; Yu, H.Y.; Song, M.; Zhang, H.; Grishkewich, N.; Huang, C.; Kim, D.; Tam, K.M.C. Self-Healable Conductive Nanocellulose Nanocomposites for Biocompatible Electronic Skin Sensor Systems. ACS Appl. Mater. Interfaces 2019, 11, 44642–44651. [Google Scholar] [CrossRef]

- Liu, D.; Gao, Y.; Song, Y.; Zhu, H.; Zhang, L.; Xie, Y.; Shi, H.; Shi, Z.; Yang, Q.; Xiong, C. Highly Sensitive Multifunctional Electronic Skin Based on Nanocellulose/MXene Composite Films with Good Electromagnetic Shielding Biocompatible Antibacterial Properties. Biomacromolecules 2022, 23, 182–195. [Google Scholar] [CrossRef]

- Hanif, Z.; Choi, D.; Tariq, M.Z.; La, M.; Park, S.J. Water-Stable Flexible Nanocellulose Chiral Nematic Films through Acid Vapor Cross-Linked Glutaraldehyde for Chiral Nematic Templating. ACS Macro Lett. 2020, 9, 146–151. [Google Scholar] [CrossRef] [PubMed]

- Qu, D.; Chu, G.; Martin, P.; Vasilyev, G.; Vilensky, R.; Zussman, E. Modulating the Structural Orientation of Nanocellulose Composites through Mechano-Stimuli. ACS Appl. Mater. Interfaces 2019, 11, 40443–40450. [Google Scholar] [CrossRef] [PubMed]

- Hou, L.; Xing, B.; Zeng, H.; Kang, W.; Guo, H.; Cheng, S.; Huang, G.; Cao, Y.; Chen, Z.; Zhang, C. Aluminothermic reduction synthesis of Si/C composite nanosheets from waste vermiculite as high-performance anode materials for lithium-ion batteries. J. Alloys Compd. 2022, 922, 166134. [Google Scholar] [CrossRef]

- Lasrado, D.; Ahankari, S. Nanocellulose-based polymer composites for energy applications—A review. J. Appl. Polym. Sci. 2020, 137, 1–14. [Google Scholar] [CrossRef]

- Nair, J.R.; Bella, F.; Angulakshmi, N.; Manuel, A.; Gerbaldi, C. Nanocellulose-laden composite polymer electrolytes for high performing lithium—Sulphur batteries. Energy Storage Mater. 2016, 3, 69–76. [Google Scholar] [CrossRef]

- Gou, J.; Liu, W.; Tang, A. A renewable and biodegradable nanocellulose-based gel polymer electrolyte for lithium-ion battery. J. Mater. Sci. 2020, 55, 10699–10711. [Google Scholar] [CrossRef]

- MARKETSANDMARKETS. Nanocellulose Market. 2022. Available online: https://www.marketsandmarkets.com/Market-Reports/nano-cellulose-market-56392090 (accessed on 12 August 2022).

- Mao, J.; Abushammala, H.; Brown, N.; Laborie, M.-P. Comparative Assessment of Methods for Producing Cellulose I Nanocrystals from Cellulosic Sources. In ACS Symposium Series; ACS Publications: Washington, DC, USA, 2017; pp. 19–53. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, J.Y.; Baez, C.; Kitin, P.; Elder, T. Highly thermal-stable and functional cellulose nanocrystals and nanofibrils produced using fully recyclable organic acids. Green Chem. 2016, 18, 3835–3843. [Google Scholar] [CrossRef]

- Camarero Espinosa, S.; Kuhnt, T.; Foster, E.J.; Weder, C. Isolation of Thermally Stable Cellulose Nanocrystals by Phosphoric Acid Hydrolysis. Biomacromolecules 2013, 14, 1223–1230. [Google Scholar] [CrossRef]

- de Assis, C.A.; Houtman, C.; Phillips, R.; Bilek, E.M.; Rojas, O.J.; Pal, L.; Peresin, M.S.; Jameel, H.; Gonzalez, R. Conversion Economics of Forest Biomaterials: Risk and Financial Analysis of CNC Manufacturing. Biofuels Bioprod. Biorefining 2017, 11, 682–700. [Google Scholar] [CrossRef]

- Bondancia, T.J.; Batista, G.; de Aguiar, J.; Lorevice, M.V.; Cruz, A.J.; Marconcini, J.M.; Mattoso, L.H.; Farinas, C.S. Cellulose Nanocrystals from Sugar Cane Bagasse Using Organic and/or Inorganic Acids: Techno-Economic Analysis and Life Cycle Assessment. ACS Sustain. Chem. Eng. 2022, 10, 4660–4676. [Google Scholar] [CrossRef]

- Bondancia, T.J.; de Aguiar, J.; Batista, G.; Cruz, A.J.; Marconcini, J.M.; Mattoso, L.H.C.; Farinas, C.S. Production of Nanocellulose Using Citric Acid in a Biorefinery Concept: Effect of the Hydrolysis Reaction Time and Techno-Economic Analysis. Ind. Eng. Chem. Res. 2020, 59, 11505–11516. [Google Scholar] [CrossRef]

- Arantes, V.; Dias, I.K.; Berto, G.L.; Pereira, B.; Marotti, B.S.; Nogueira, C.F. The current status of the enzyme-mediated isolation and functionalization of nanocelluloses: Production, properties, techno-economics, and opportunities. Cellulose 2020, 27, 10571–10630. [Google Scholar] [CrossRef]

- Squinca, P.; Bilatto, S.; Badino, A.C.; Farinas, C.S. Nanocellulose Production in Future Biorefineries: An Integrated Approach Using Tailor-Made Enzymes. ACS Sustain. Chem. Eng. 2020, 8, 2277–2286. [Google Scholar] [CrossRef]

- Clauser, N.; Felissia, F.; Area, M.; Vallejos, M. Technological and economic barriers of industrial-scale production of nanocellulose. In Green Nanomaterials for Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 21–39. [Google Scholar] [CrossRef]

- Jiang, J.; Zhu, Y.; Jiang, F. Sustainable isolation of nanocellulose from cellulose and lignocellulosic feedstocks: Recent progress and perspectives. Carbohydr. Polym. 2021, 267, 118188. [Google Scholar] [CrossRef] [PubMed]

- Sharma, N.; Munagala, M.; Rajkhowa, R.; Aallardyce, B.; Shastri, Y.; Agrawal, R. Nanocellulose: Resources, Physio-Chemical Properties, Current Uses and Future Applications. Front. Nanotechnol. 2021, 3, 82. [Google Scholar]

| Nanocellulose Type | Degree of Polymerization | Crystallinity/Crystal Structure |

|---|---|---|

| Bacterial nanocellulose (BNC) | 4000–10,000 | Iα (shell) and Iβ (core)—the highest degree of crystallinity |

| Cellulose nanofiber (CNF) | ≥500 | Primarily Iβ—lowest degree of crystallinity |

| Cellulose nanocrystals (CNC) | 500–15,000 | Primarily Iβ, sometimes Iα—medium degree of crystallinity |

| Source | Type of Nanocellulose | Diameter (nm) | Ref. |

|---|---|---|---|

| Kenaf | CNC | 45–55 | [64] |

| Miscanthus × giganteus | CNF | 10–20 | [65] |

| Flax | CNC | 20–100 | [66] |

| Hemp | CNC | 20–100 | [66] |

| Jute | CNC | 16 | [67] |

| Sisal | CNF | 27 | [68] |

| Sugar palm fiber | CNC | 8.5 | [69] |

| Banana | CNC | 14.02 | [70] |

| Abaca | CNF | 3.12 | [71] |

| Bamboo | BCNF | 15.02 | [72] |

| Sugarcane bagasse | CNF | 20–30 | [73] |

| Coconut fiber | CNC | 13.7 | [74] |

| Pineapple leaf fiber | CNC | 68 | [75] |

| Wheat straw fiber | CNC | 10–80 | [76] |

| Kenaf bast | CNC | 10–60 | [49] |

| Kenaf bast | CNF | 2–6 | [77] |

| Wood | CNF | 15 | [78] |

| Bagasse | CNF | 5–15 | [79] |

| Soy hulls | CNF | 20–120 | [80] |

| Rice straw | CNF | 4–13 | |

| Soybean stock | CNF | 50–100 | [79] |

| Cotton | CNF | 10–25 | |

| Oil palm empty fruit bunch | CNF | 18 | [53] |

| Source | Type of Nanocellulose | Yield (kg) | Ref. |

|---|---|---|---|

| Sugarcane bagasse (SB) | CNC | 11.3 | [81] |

| Sugarcane straw (SS) | CNC | 12 | [81] |

| Wheat straw | CNF | 42.3 | [82] |

| Banana peel | CNF | 27–71 | [83] |

| Wood flour | CNC | 11.43 | [84] |

| Grapevine stems | CNF | 15–20 | [85] |

| Grapevine pomace | CNC | 10–15 | [85] |

| Cotton linters | CNC | 80 | [86] |

| Treatment Type | Definition and Requirement | Benefits | Significant Findings | Ref. |

|---|---|---|---|---|

| Plasma |

|

|

| [139,140] |

| Flame |

|

|

| [141] |

| Corona |

|

|

| [142] |

| Laser |

|

|

| [143] |

| Hydrothermal |

|

|

| [144,145] |

| Ion Beam |

|

|

| [146,147] |

| Treatment Type | Definition and Requirement | Benefits | Significant Findings | Ref. |

|---|---|---|---|---|

| Alkalization/Mercerization |

|

|

| [149] |

| Silylation |

|

|

| [150,151] |

| Grafting |

|

|

| [152,153,154] |

| Etherification |

|

|

| [155] |

| Sulfonation |

|

|

| [156,157] |

| Fabrication Method | Advantages | Disadvantages |

|---|---|---|

| Solution casting |

|

|

| Melt intercalation |

|

|

| Impregnation |

|

|

| In-situ polymerization |

|

|

| Coating |

|

|

| Application Area | Properties | Key Application |

|---|---|---|

| Food packaging | Flexible, rigid, improved barrier | Packaging films |

| Biomedical | Nontoxic, excellent biocompatibility and biodegradability | Scaffolds, water absorbent pads, antimicrobial films and tampons, sanitary napkins or wound dressing |

| Cosmetics | Durability, compatibility, good elasticity | Composite coating agent for nails, hair, or eyelashes |

| Electronics | High dielectric, excellent mechanical and biocompatible | Sensor, electronic displays and windows |

| Optical materials | Crystalline, flexibility, biocompatible | Electronic transistor, sensors |

| Automobile | Good electrical, thermal, magnetic, physico-chemical properties | Lightweight and high strength components such as bumpers, side panels and dashboards |

| Constructions | Increase fracture toughness, cheaper, low density, high strength | Blocks, sensors to monitor stress levels in bridge |

| Aerospace | High strength, light weight | Windows, sensors |

| Textiles | Easy care, low impurity, good mechanical strength, biocompatible | Antimicrobial medical field, paste printing |

| Paper industry | Easy availability, eco-friendly, renewability | Grease-proof paper |

| Water purification | Biosorable, low cost, nontoxic | Filtration |

| Sensor Type | Target | Composite Description | Detection Limit | Ref. |

|---|---|---|---|---|

| Gas sensor | Ammonia | QCM/CA/PEI/ GO | 1 ppm | [236] |

| Cellulose/TiO2/PANI | 2 ppm | [237] | ||

| Nitrogen dioxide (NO2) | CNC/Fe2O3 | 2 ppm | [238] | |

| Chemical sensor | Formaldehyde | PEI/BC/QCM | 1 ppm | [239] |

| Catechol | CB/CNC/NR | - | [240] | |

| Toluene | rGO/CNC/NR | - | [241] | |

| Enzyme sensor | HNE | Peptide/CNC | 50 mU mL−1 | [242] |

| Cellulase | XG/CNC | - | [243] | |

| Xylanase | CX/CNC | - | [243] | |

| Trypsin | Peptide/PVA/CNC | 20 µg mL−1 | [244] | |

| Ion sensor | Fe3+ | Py/CNC | 10−3 × 10−3 M | [245] |

| Pb2+ | CNINH/CNC | 7 × 10−11 × 10−3 M | [246] | |

| Cu2+ | CPC/CNF | 0.2 × 10−6 M | [247] | |

| Glucose sensor | Glucose | GO/CNF | 250 mg L−1 | [248] |

| Ag/CNC | 0.116 × 10−6 M | [249] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Norizan, M.N.; Shazleen, S.S.; Alias, A.H.; Sabaruddin, F.A.; Asyraf, M.R.M.; Zainudin, E.S.; Abdullah, N.; Samsudin, M.S.; Kamarudin, S.H.; Norrrahim, M.N.F. Nanocellulose-Based Nanocomposites for Sustainable Applications: A Review. Nanomaterials 2022, 12, 3483. https://doi.org/10.3390/nano12193483

Norizan MN, Shazleen SS, Alias AH, Sabaruddin FA, Asyraf MRM, Zainudin ES, Abdullah N, Samsudin MS, Kamarudin SH, Norrrahim MNF. Nanocellulose-Based Nanocomposites for Sustainable Applications: A Review. Nanomaterials. 2022; 12(19):3483. https://doi.org/10.3390/nano12193483

Chicago/Turabian StyleNorizan, Mohd Nurazzi, Siti Shazra Shazleen, Aisyah Humaira Alias, Fatimah Atiyah Sabaruddin, Muhammad Rizal Muhammad Asyraf, Edi Syams Zainudin, Norli Abdullah, Mohd Saiful Samsudin, Siti Hasnah Kamarudin, and Mohd Nor Faiz Norrrahim. 2022. "Nanocellulose-Based Nanocomposites for Sustainable Applications: A Review" Nanomaterials 12, no. 19: 3483. https://doi.org/10.3390/nano12193483

APA StyleNorizan, M. N., Shazleen, S. S., Alias, A. H., Sabaruddin, F. A., Asyraf, M. R. M., Zainudin, E. S., Abdullah, N., Samsudin, M. S., Kamarudin, S. H., & Norrrahim, M. N. F. (2022). Nanocellulose-Based Nanocomposites for Sustainable Applications: A Review. Nanomaterials, 12(19), 3483. https://doi.org/10.3390/nano12193483