Study on the Photocatalytic Properties of Flower-Shaped SnO2

Abstract

:1. Introduction

2. Experimental

2.1. Synthesis of SnO2

2.2. Photocatalytic Testing

3. Results and Discussion

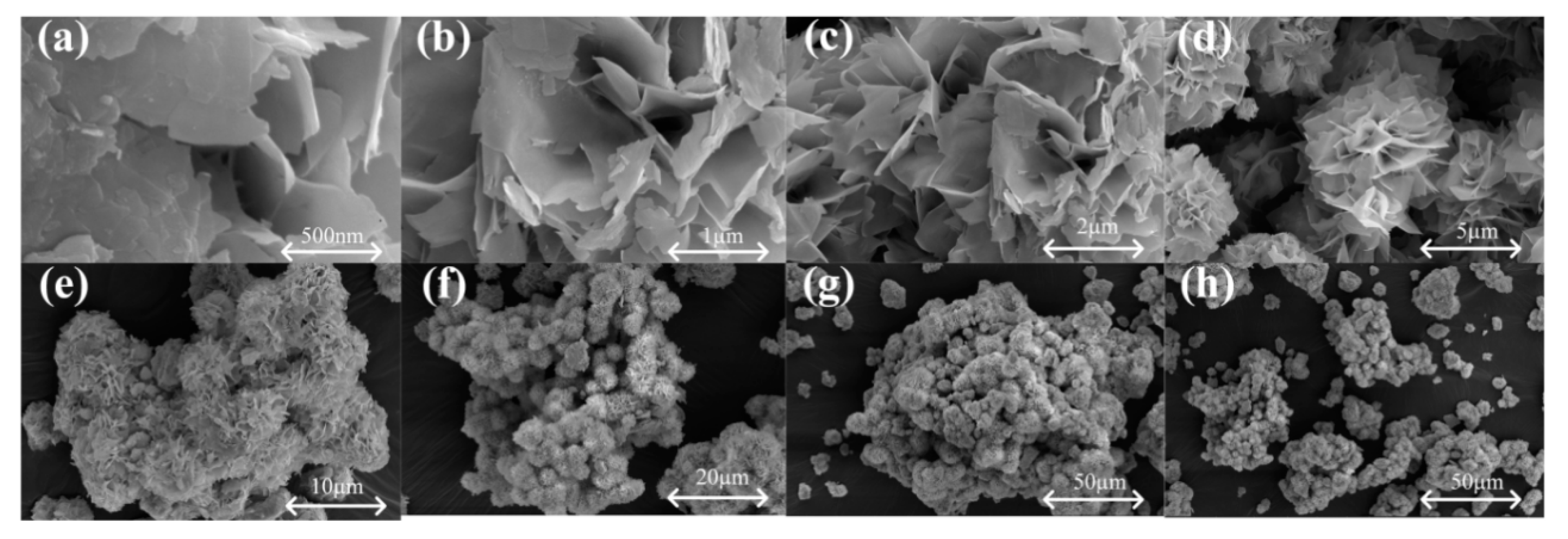

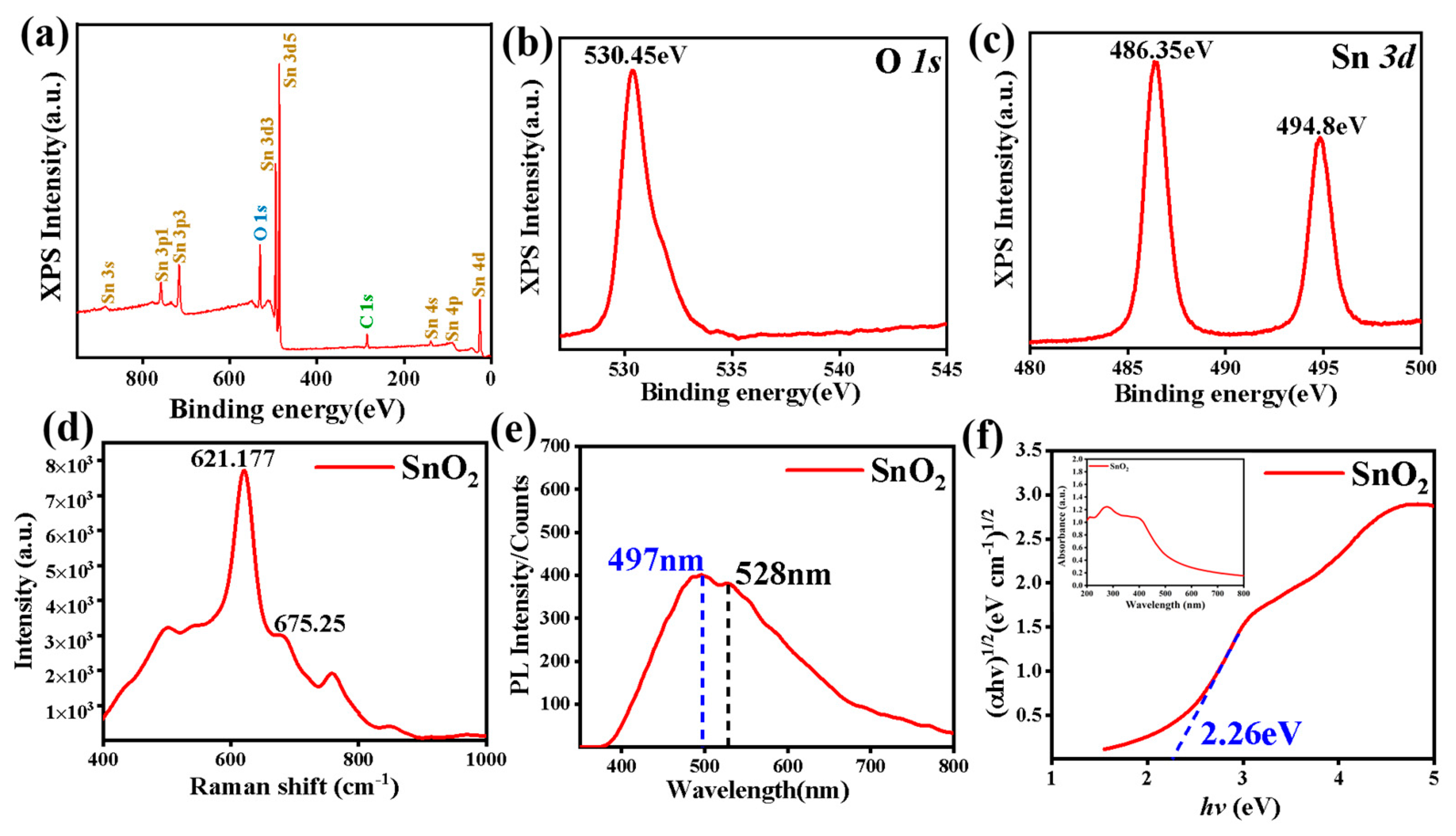

3.1. Materials Characterization

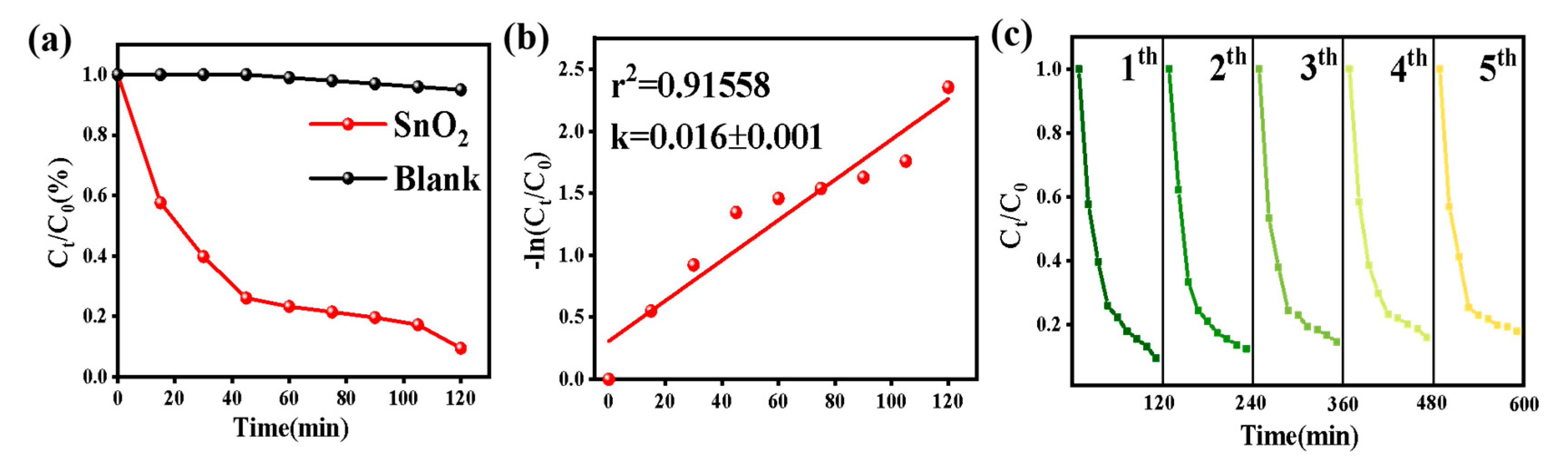

3.2. Photocatalysis Performance

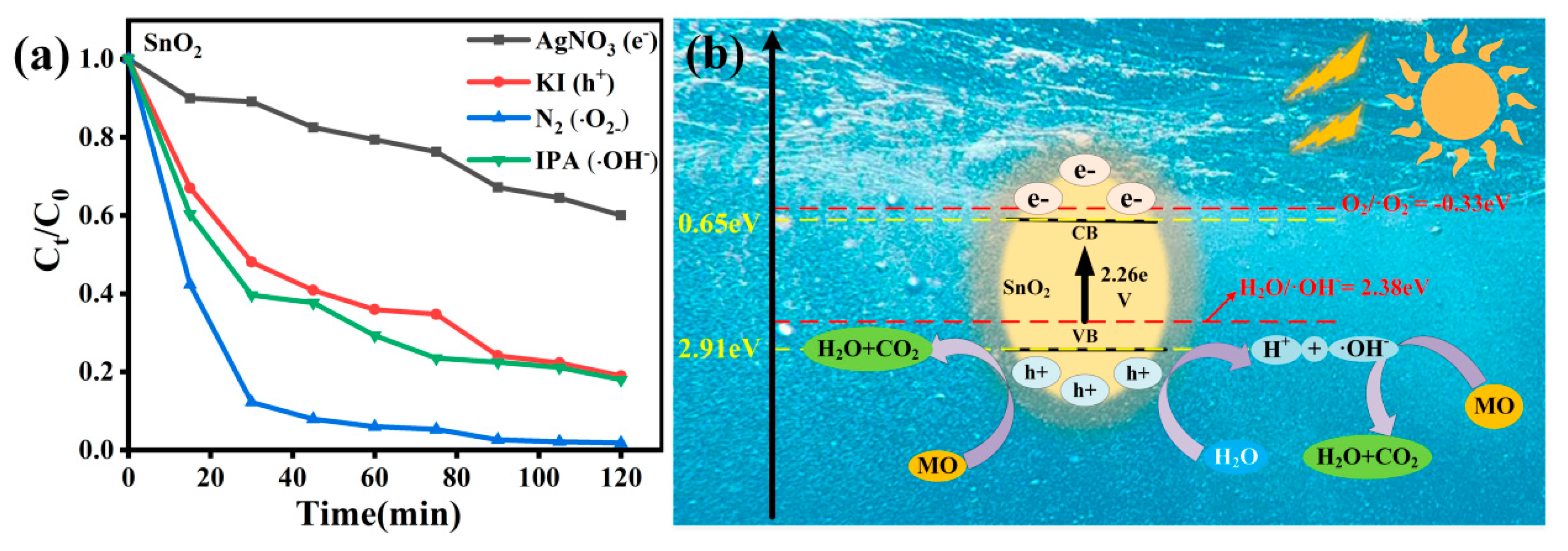

3.3. Reaction Mechanism

3.4. Theoretical Calculation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sheng, H.; Wang, W.; Dai, R.; Ning, J.; Zhang, W.B. New insights into Cd2+/Fe3+ Co-Doped BiOBr for enhancing the photocatalysis efficiency of dye decomposition under visible-light. Nanomaterials 2021, 11, 423. [Google Scholar] [CrossRef]

- Ning, J.; Zhang, J.; Dai, R.; Wu, Q.; Zhang, L.; Zhang, W.B.; Yan, J.F.; Zhang, F.C. Experiment and DFT study on the photocatalytic properties of La-doped Bi2WO6 nanoplate-like materials. Appl. Surf. Sci. 2021, 579, 152219. [Google Scholar] [CrossRef]

- Shao, T.T.; Zhang, F.C.; Dai, R.; Ding, H.H.; Zhou, Q.; Wang, X.Y.; Wang, W.; Zhang, S.L. Hydrothermal Synthesis and Properties of SnO2 Nanopowder. Integr. Ferroelectr. 2021, 219, 76–83. [Google Scholar] [CrossRef]

- Periyasamy, M.; Kar, A. Modulating the properties of SnO2 nanocrystals: Morphological effects on structural, photoluminescence, photocatalytic, electrochemical and gas sensing properties. J. Mater. Chem. C 2020, 60, 4604–4635. [Google Scholar] [CrossRef]

- Bhuvaneswari, K.; Nguyen, B.S.; Nguyen, V.H.; Nguyen, V.Q.; Nguyen, Q.H.; Palanisamy, G.; Sivashanmugan, K.; Pazhanivel, T. Enhanced photocatalytic activity of ethylenediamine-assisted tin oxide (SnO2) nanorods for methylene blue dye degradation. Mater. Lett. 2020, 276, 128173. [Google Scholar] [CrossRef]

- Gao, N.B.; Li, H.Y.; Zhang, W.H.; Zhang, Y.Z.; Zeng, Y.; Hu, Z.X.; Liu, J.Y.; Jiang, J.J.; Miao, L.; Yi, F.; et al. QCM-based humidity sensor and sensing properties employing colloidal SnO2 nanowires. Sens. Actuators B Chem. 2019, 293, 129–135. [Google Scholar] [CrossRef]

- He, Z.K.; Kamali, A.R.; Wang, Z.R.; Sun, Q.; Shi, Z.N.; Wang, D.X. Rapid preparation and characterization of oxygen-deficient SnO2 nanobelts with enhanced Li diffusion kinetics. J. Electroanal. Chem. 2020, 871, 114276. [Google Scholar] [CrossRef]

- Sun, Y.P.; Zhao, Y.F.; Sun, H.; Jia, F.C.; Parveen, K.; Liu, B. Synthesis and room-temperature H2S sensing of Pt nanoparticle-functionalized SnO2 mesoporous nanoflowers. J. Alloys Compd. 2020, 842, 155813. [Google Scholar] [CrossRef]

- Li, W.N.; Kan, K.; He, L.; Ma, L.F.; Zhang, X.F.; Si, J.Q.; Ikram, M.; Ullah, M.; Khan, M.; Shi, K. Biomorphic synthesis of 3D mesoporous SnO2 with substantially increased gas-sensing performance at room temperature using a simple one-pot hydrothermal method. Appl. Surf. Sci. 2020, 512, 145657. [Google Scholar] [CrossRef]

- Acharyulu, N.P.S.; Srinivasu, C.; Fakruddin, B.S.K. Synthesis of carbon nano spherical structures and nano composite oxide [TiO2/SnO2(2:1)] hollow spheres by hydrothermal method and study of characterization with photo catalytic activity. Mater. Today Proc. 2020, 27, 1282–1288. [Google Scholar] [CrossRef]

- Lei, R.; Ni, H.W.; Chen, R.S.; Zhang, B.W.; Zhan, W.T.; Li, Y. Growth of Fe2O3/SnO2 nanobelt arrays on iron foil for efficient photocatalytic degradation of methylene blue. Chem. Phys. Lett. 2017, 673, 1–6. [Google Scholar] [CrossRef]

- Xu, M.Z.; Jia, S.L.; Chen, C.; Zhang, Z.Y.; Yan, J.F.; Guo, Y.X.; Zhang, Y.N.; Zhao, W.; Yun, J.N.; Wang, Y.N. Microwave-assistant hydrothermal synthesis of SnO2@ZnO hierarchical nanostructures enhanced photocatalytic performance under visible light irradiation. Mater. Res. Bull. 2018, 106, 74–80. [Google Scholar] [CrossRef]

- Bezzerrouk, M.A.; Bousmaha, M.; Hassan, M.; Akriche, A.; Kharroubi, B.; Naceur, R.; Guezzoul, M. Enhanced methylene blue removal efficiency of SnO2 thin film using sono-photocatalytic processes. Opt. Mater. 2021, 117, 111116. [Google Scholar] [CrossRef]

- Ali, N.; Babar, A.A.; Zhang, Y.F.; Iqbal, N.; Wang, X.F.; Yu, J.Y.; Ding, B. Porous, flexible, and core-shell structured carbon nanofibers hybridized by tin oxide nanoparticles for efficient carbon dioxide capture. J. Colloid Interface Sci. 2020, 560, 379–387. [Google Scholar] [CrossRef]

- Chaibi, K.; Benhaliliba, M.; Ayeshamariam, A. Computational assessment and experimental study of optical and thermoelectric properties of rutile SnO2 semiconductor. Superlattices Microstruct. 2021, 155, 106923. [Google Scholar] [CrossRef]

- Bhangare, B.; Ramgir, N.S.; Jagtap, S.; Debnath, A.K.; Muthe, K.P.; Terashima, C.; Aswal, D.K.; Gosavi, S.W.; Fujishima, A. XPS and Kelvin probe studies of SnO2/RGO nanohybrids based NO2 sensor. Appl. Surf. Sci. 2019, 487, 918–929. [Google Scholar] [CrossRef]

- Junploy, P.; Phuruangrat, A.; Plubphon, N.; Thongtem, S.; Thongtem, T. Photocatalytic degradation of methylene blue by Zn2SnO4-SnO2 system under UV visible radiation. Mater. Sci. Semicond. Process. 2017, 66, 56–61. [Google Scholar] [CrossRef]

- Liu, X.; Cho, S.M.; Lin, S.; Chen, Z.; Choi, W.; Kim, Y.-M.; Yun, E.; Baek, E.H.; Ryu, D.H.; Lee, H. Constructing two-dimensional holey graphyne with unusual annulative π-extension. Matter 2022, 7, 2306–2318. [Google Scholar] [CrossRef]

- Pearson, R.G. Absolute electronegativity and hardness: Application to inorganic chemistry. Inorg. Chem. 1988, 27, 734–740. [Google Scholar] [CrossRef]

- Aslam, M.; Qamar, M.T.; Ali, S.; Rehman, A.U.; Soomro, M.T.; Ahmed, I.; Ismail, I.M.I.; Hameed, A. Evaluation of SnO2 for sunlight photocatalytic decontamination of water. J. Environ. Manag. 2018, 217, 805–814. [Google Scholar] [CrossRef]

- Smazna, D.; Shree, S.; Polonskyi, O.; Lamaka, S.; Baum, M.; Zheludkevich, M.; Faupel, F.; Adelung, R.; Mishra, Y.K. Mutual Interplay of ZnO Micro-and Nanowires and Methylene Blue during Cyclic Photocatalysis Process. J. Environ. Chem. Eng. 2019, 7, 103016. [Google Scholar] [CrossRef]

- Dai, R.; Zhang, L.; Ning, J.; Wang, W.; Wu, Q.; Yang, J.; Zhang, F.C.; Wang, J.A. New insights into tuning BiOBr photocatalysis efficiency under visible-light for degradation of broad-spectrum antibiotics: Synergistic calcination and doping. J. Alloys Compd. 2021, 887, 161481. [Google Scholar] [CrossRef]

- Hu, W.Q.; Yuan, X.G.; Liu, X.L.; Guan, Y.; Wu, X. Hierarchical SnO2 nanostructures as high efficient photocatalysts for the degradation of organic dyes. J. Sol-Gel Sci. Technol. 2017, 84, 316–322. [Google Scholar] [CrossRef]

- Aljawfi, R.N.; Abu-Samak, M.; Kumar, S.; Swillam, M.A. Experimental and DFT investigation of electronic structure and ferromagnetic stable state in pristine and Mn: SnO2 NPs. Vacuum 2020, 179, 109536. [Google Scholar] [CrossRef]

- Tong, H.; Ouyang, S.X.; Bi, Y.P.; Umezawa, N.; Oshikiri, M.; Ye, J.H. Nano-photocatalytic Materials: Possibilities and Challenges. Adv. Mater. 2012, 24, 229–251. [Google Scholar] [CrossRef]

- Wazir, M.B.; Daud, M.; Ali, F.; Al-Harthi, M.A. Dendrimer assisted dye-removal: A critical review of adsorption and catalytic degradation for wastewater treatment. J. Mol. Liq. 2020, 315, 113775. [Google Scholar] [CrossRef]

- Crini, G.; Lichtfouse, E. Advantages and disadvantages of techniques used for wastewater treatment. Environ. Chem. Lett. 2019, 17, 145–155. [Google Scholar] [CrossRef]

- Korotta-Gamage, S.M.; Sathasivan, A. A review: Potential and challenges of biologically activated carbon to remove natural organic matter in drinking water purification process. Chemosphere 2017, 167, 120–138. [Google Scholar] [CrossRef]

- Wacławek, S.; Silvestri, D.; Hrabák, P.; Padil, V.V.T.; Torres-Mendieta, R.; Wacławek, M.; Černík, M.; Dionysiou, D.D. Chemical oxidation and reduction of hexachlorocyclohexanes: A review. Water Res. 2019, 162, 302–319. [Google Scholar] [CrossRef]

- Talaiekhozani, A.; Talaei, M.R.; Rezania, S. An overview on production and application of ferrate (VI) for chemical oxidation, coagulation and disinfection of water and wastewater. J. Environ. Chem. Eng. 2017, 5, 1828–1842. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, T.; Cao, X.; Dong, J.; Ning, J.; Zhang, F.; Wang, X.; Cheng, Y.; Kou, H.; Zhang, W. Study on the Photocatalytic Properties of Flower-Shaped SnO2. Nanomaterials 2022, 12, 3419. https://doi.org/10.3390/nano12193419

Shao T, Cao X, Dong J, Ning J, Zhang F, Wang X, Cheng Y, Kou H, Zhang W. Study on the Photocatalytic Properties of Flower-Shaped SnO2. Nanomaterials. 2022; 12(19):3419. https://doi.org/10.3390/nano12193419

Chicago/Turabian StyleShao, Tingting, Xinrui Cao, Juntang Dong, Jing Ning, Fuchun Zhang, Xiaoyang Wang, Yuyang Cheng, Huirong Kou, and Weibin Zhang. 2022. "Study on the Photocatalytic Properties of Flower-Shaped SnO2" Nanomaterials 12, no. 19: 3419. https://doi.org/10.3390/nano12193419

APA StyleShao, T., Cao, X., Dong, J., Ning, J., Zhang, F., Wang, X., Cheng, Y., Kou, H., & Zhang, W. (2022). Study on the Photocatalytic Properties of Flower-Shaped SnO2. Nanomaterials, 12(19), 3419. https://doi.org/10.3390/nano12193419