Microwave Synthesis of Molybdenum Disulfide Nanoparticles Using Response Surface Methodology for Tribological Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of MoS2 Nanoparticles Using Microwave

2.3. Experimental Design and Statistical Analysis

2.4. Formulation of the Nanolubricant

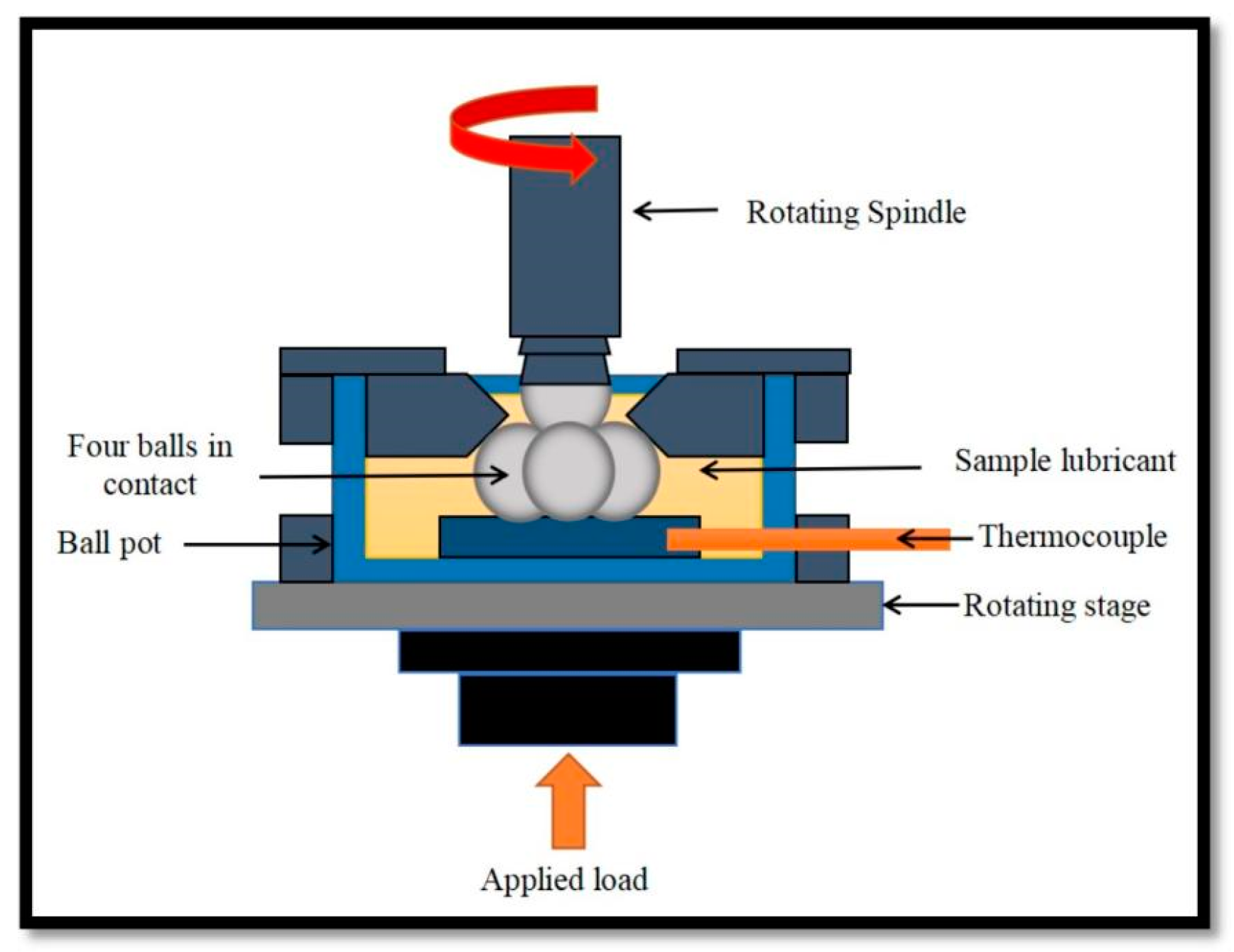

2.5. Tribological Study

2.6. Characterization of Nanoparticles

3. Result and Discussion

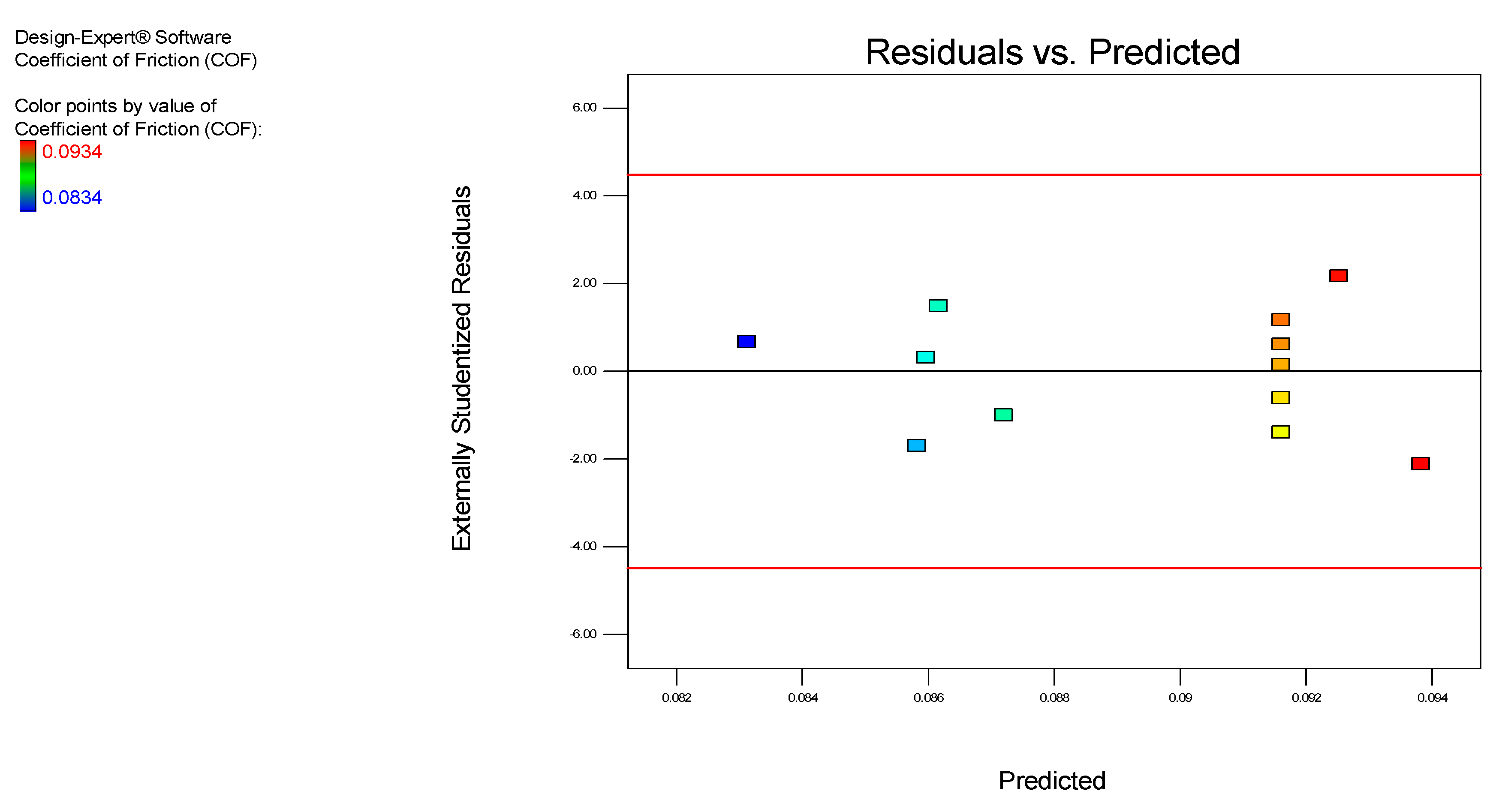

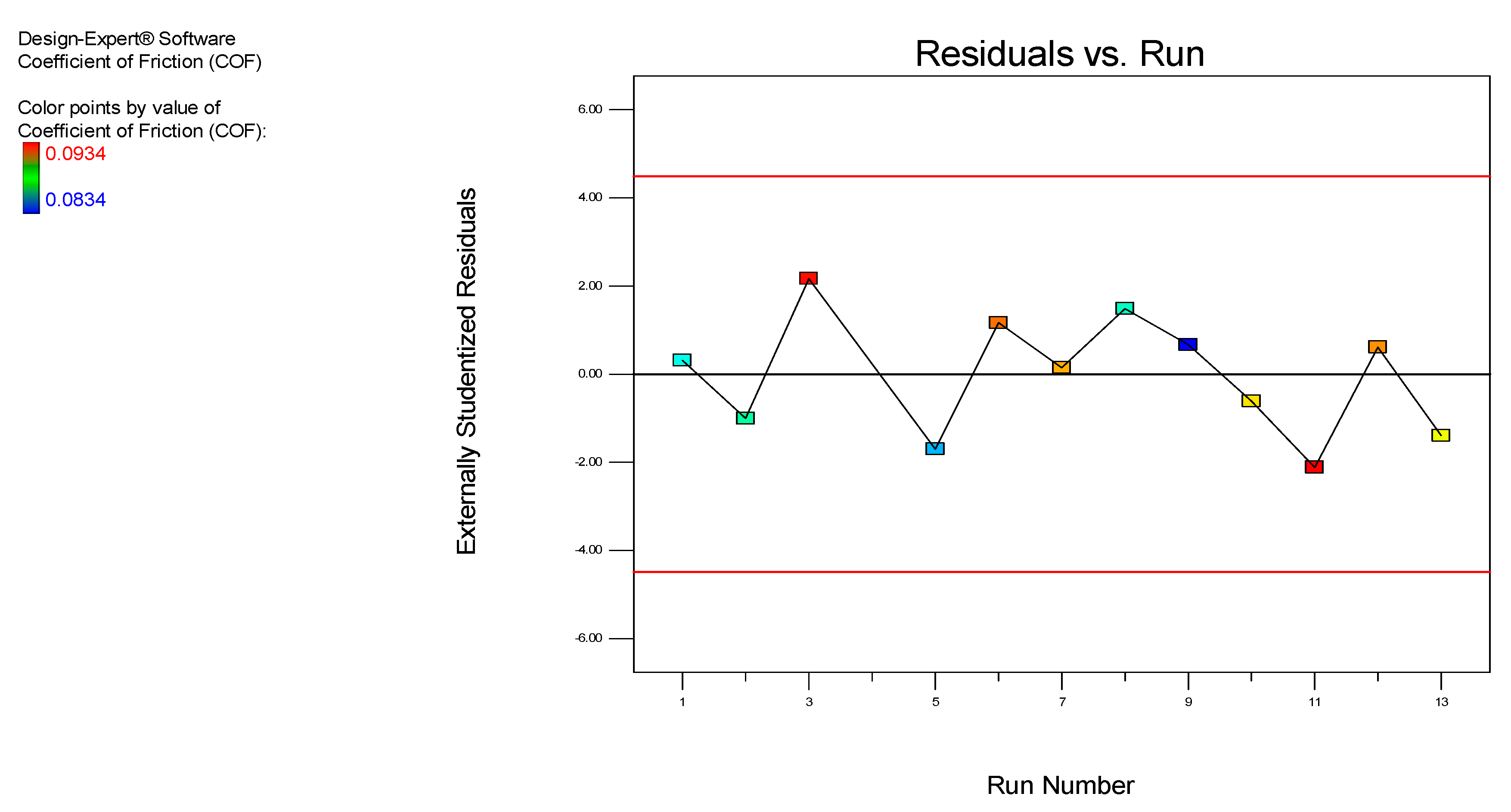

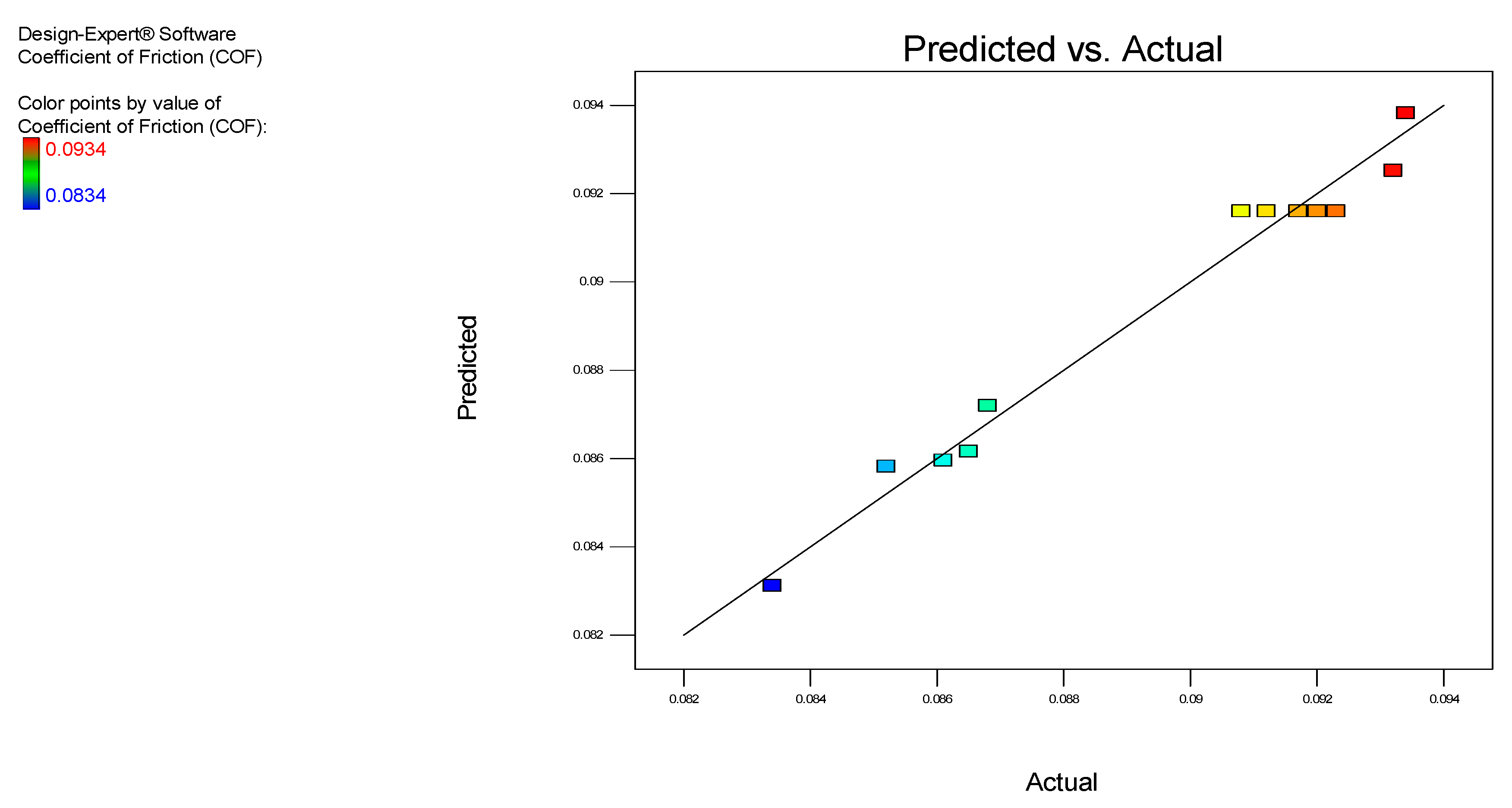

3.1. Design of Experiments and Analysis of Variance (ANOVA)

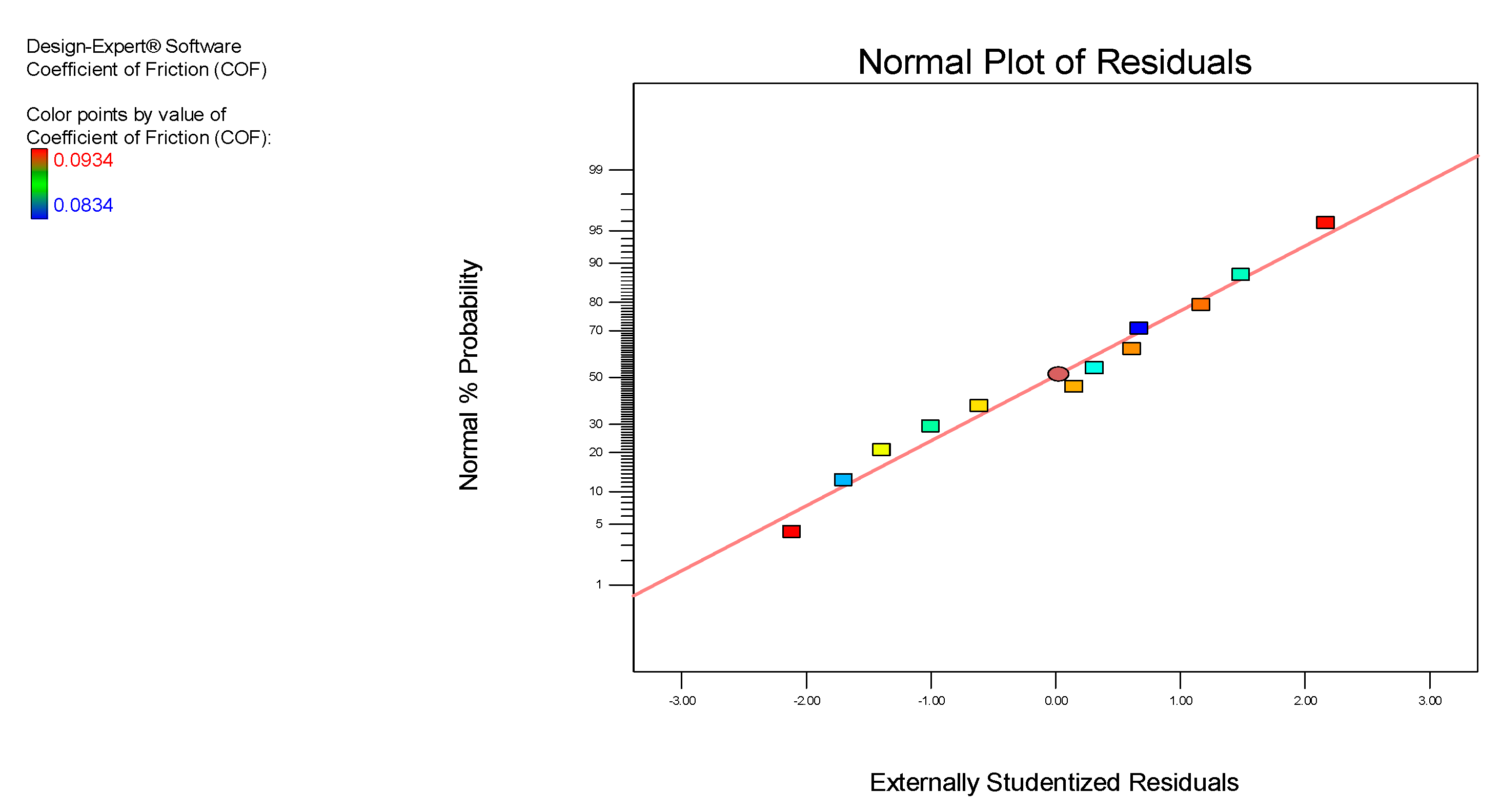

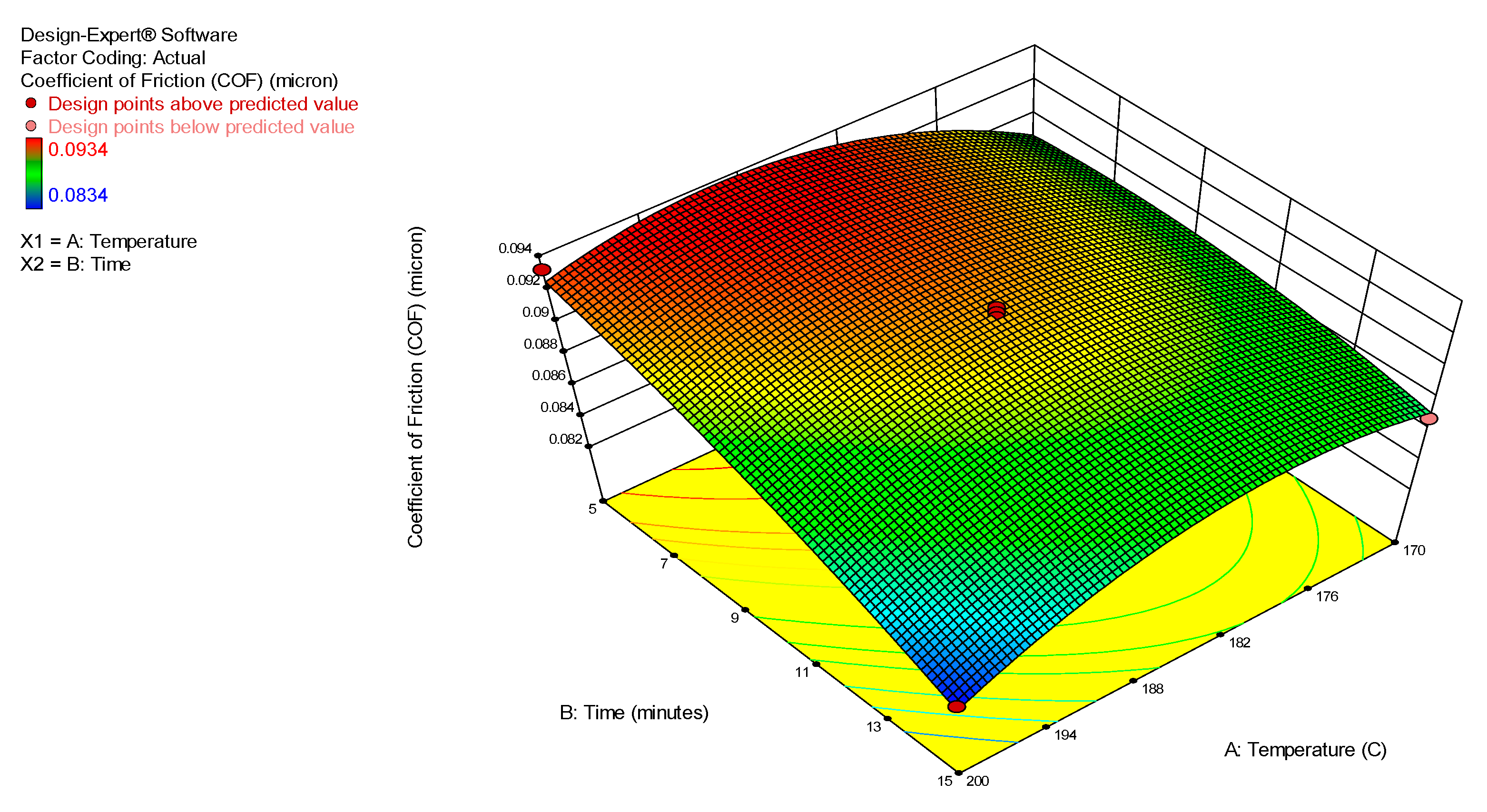

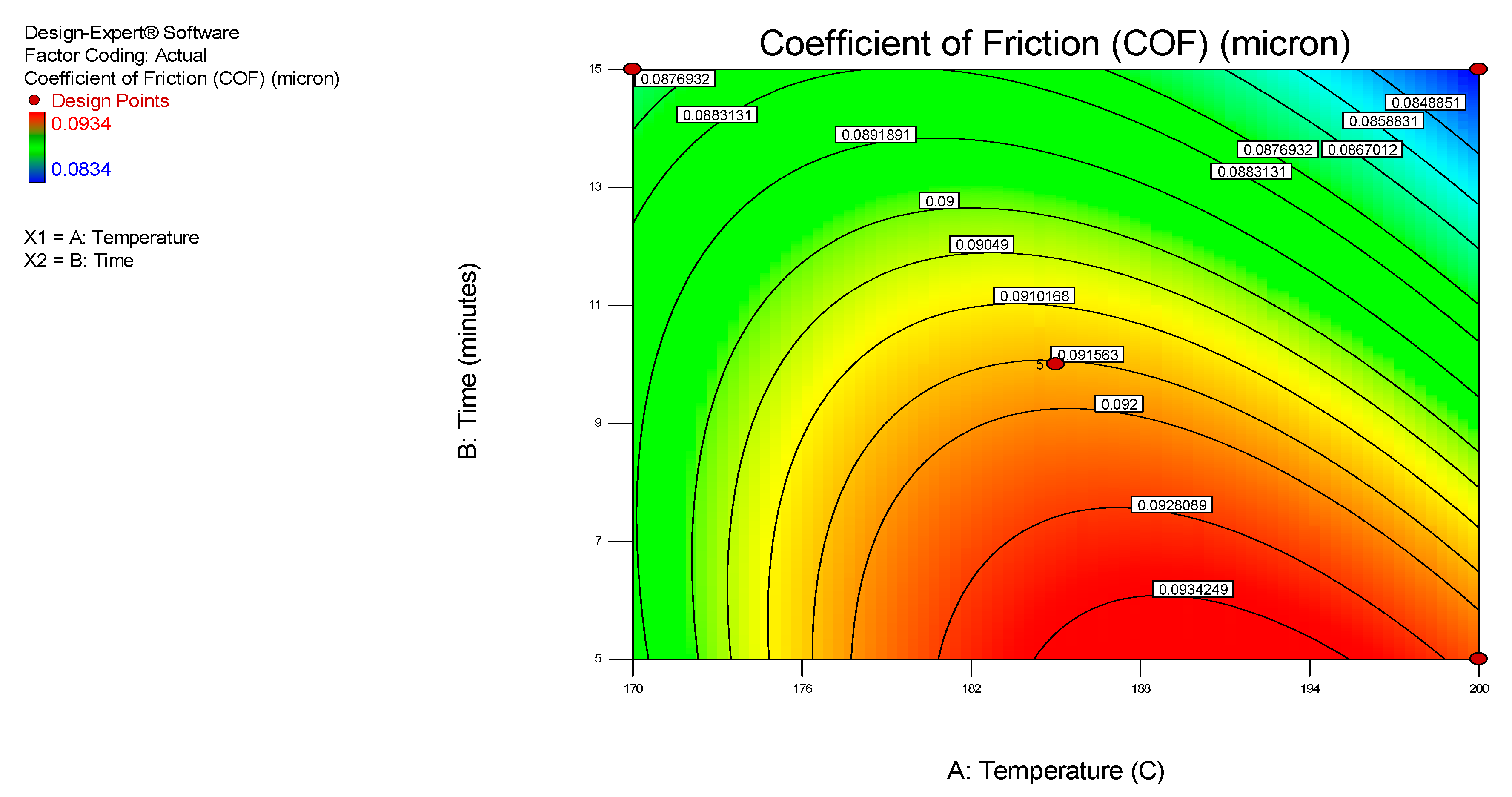

3.1.1. Effect of Microwave Synthesis Temperature and Time on COF

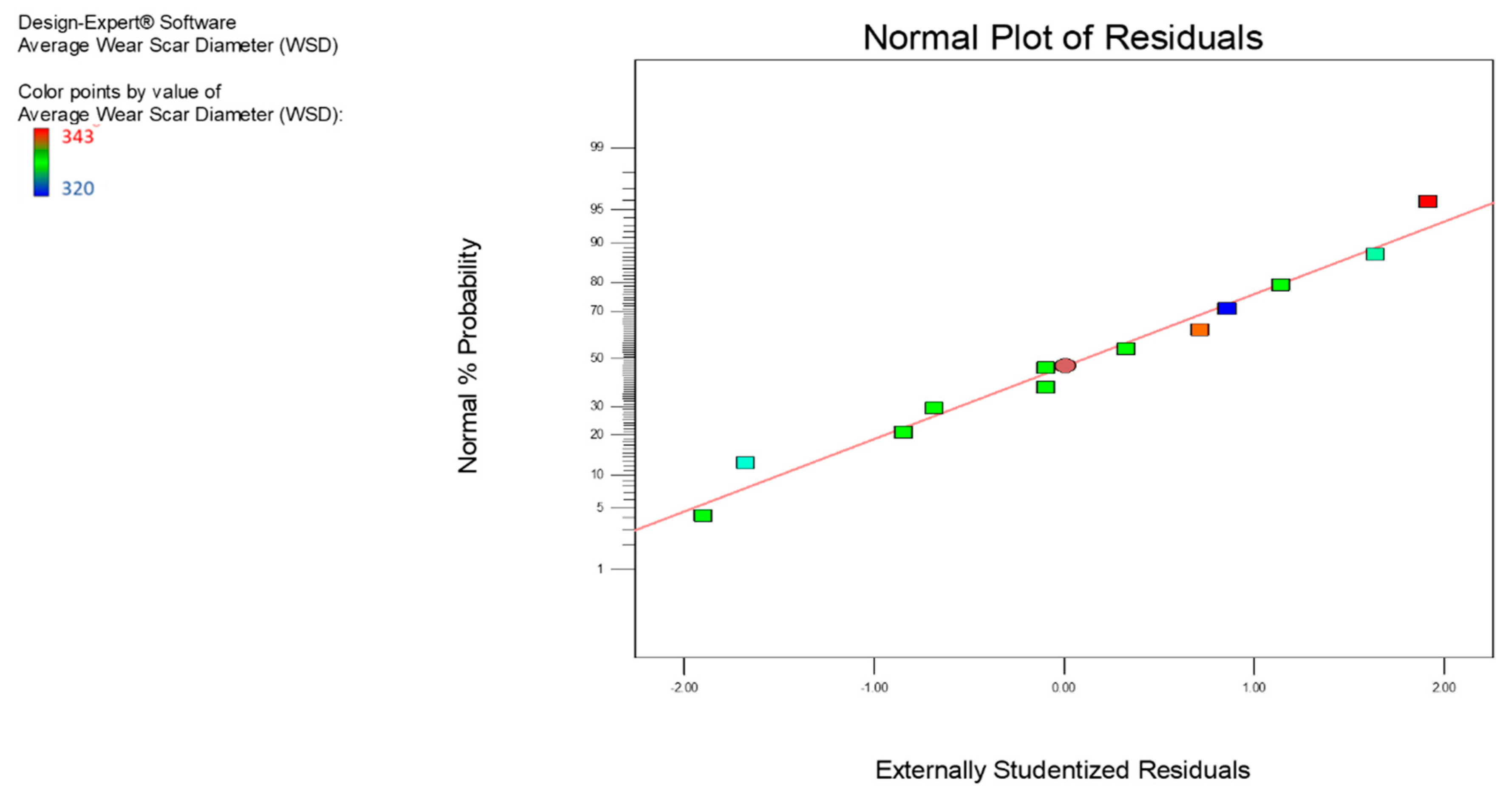

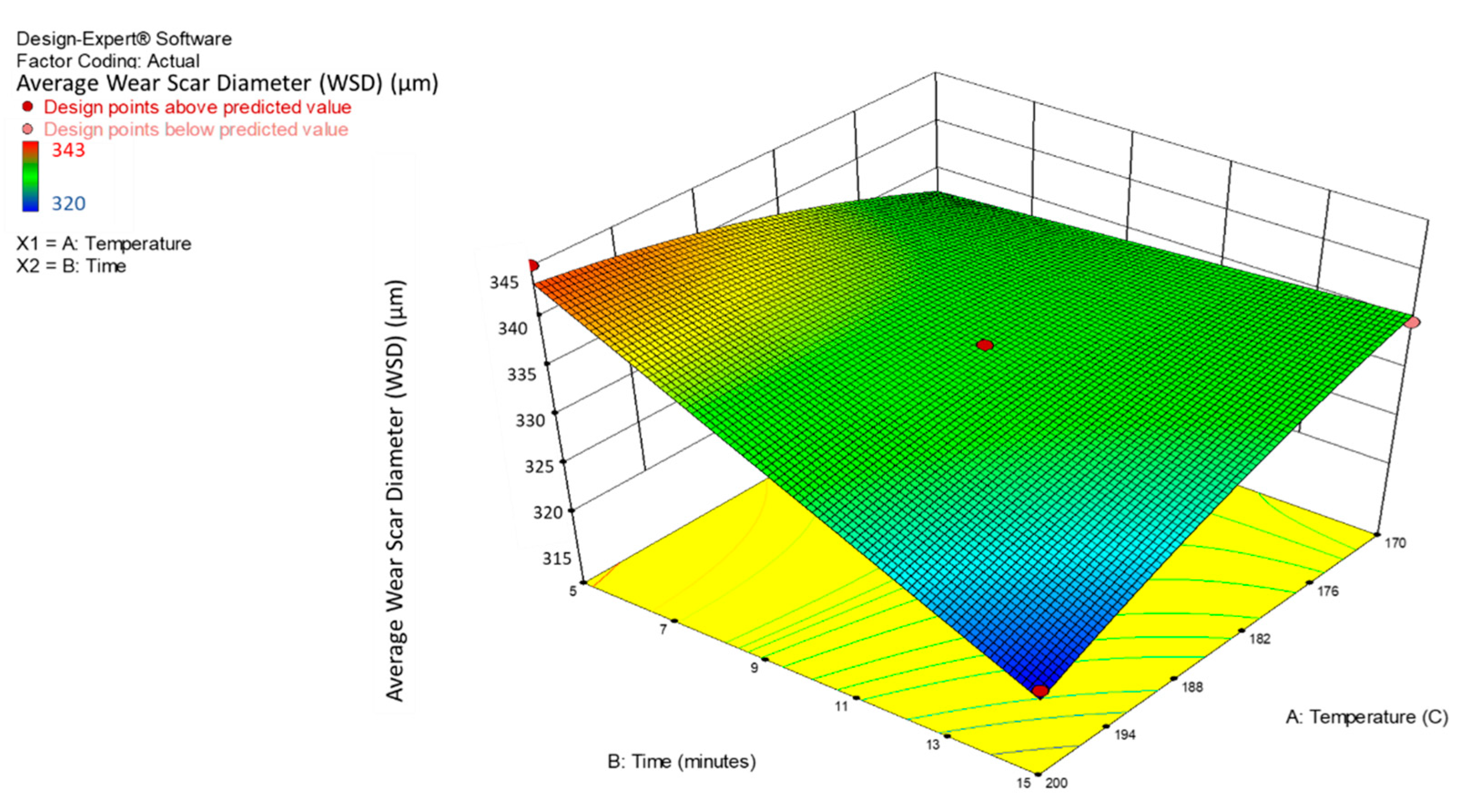

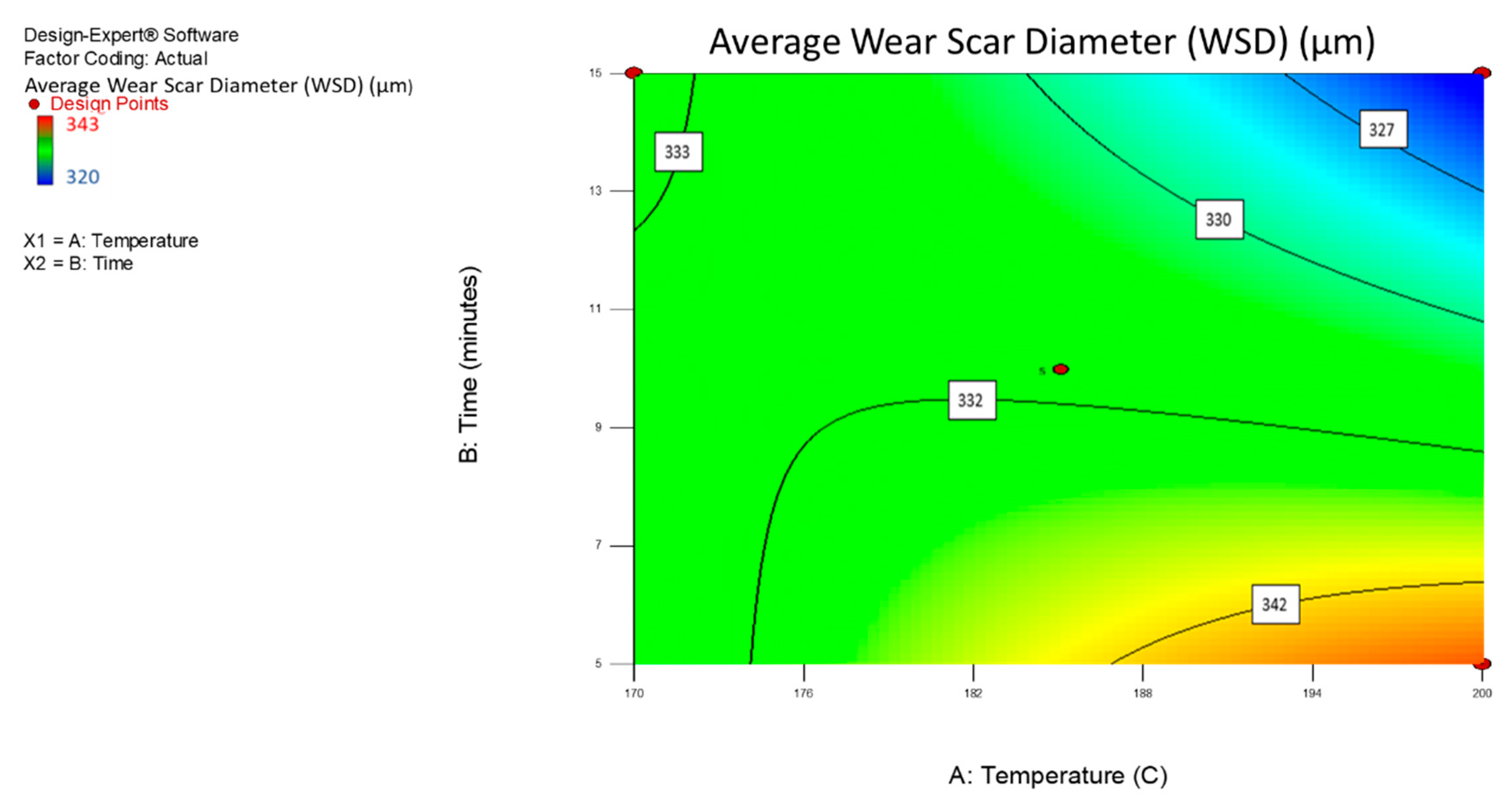

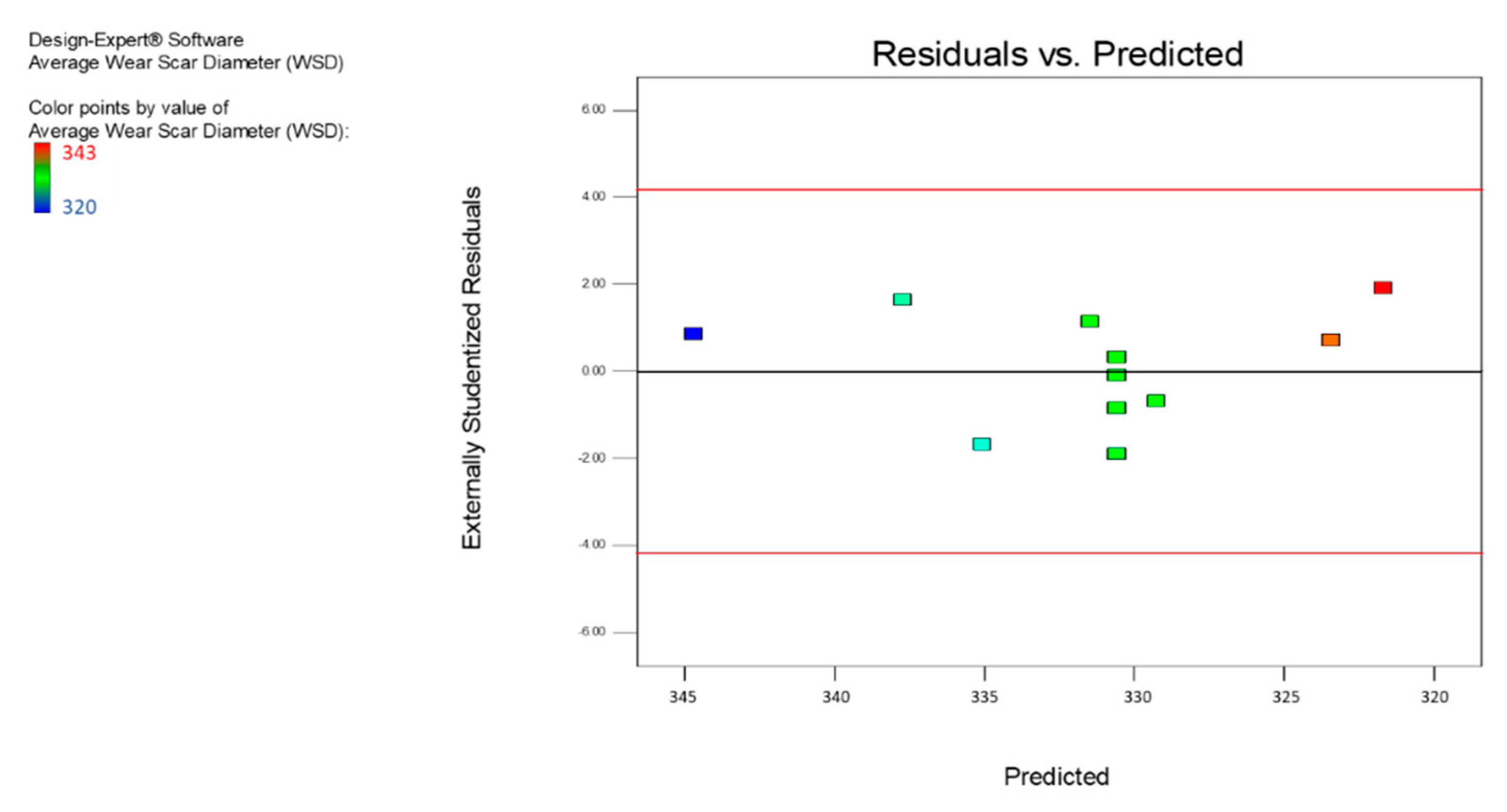

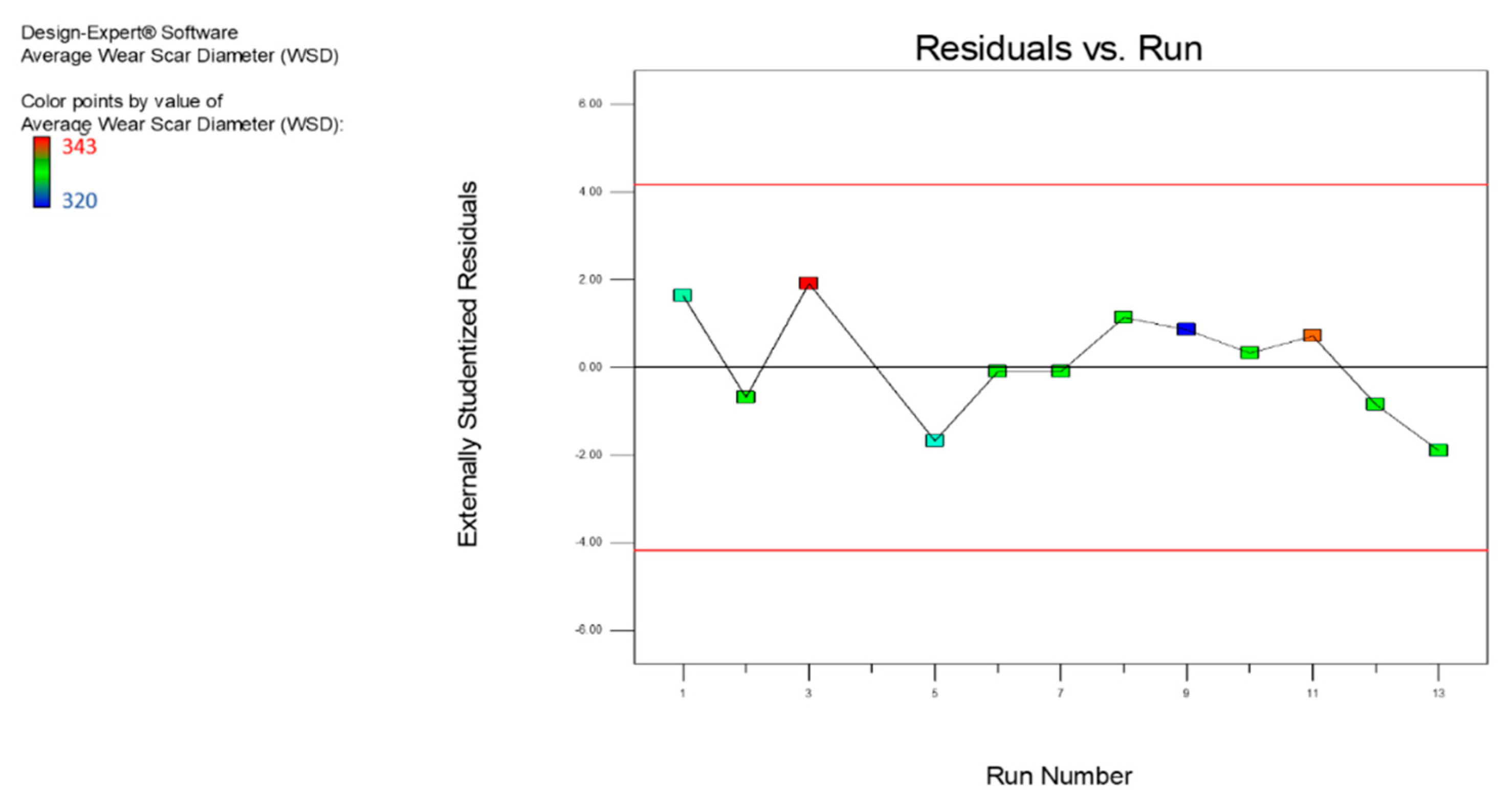

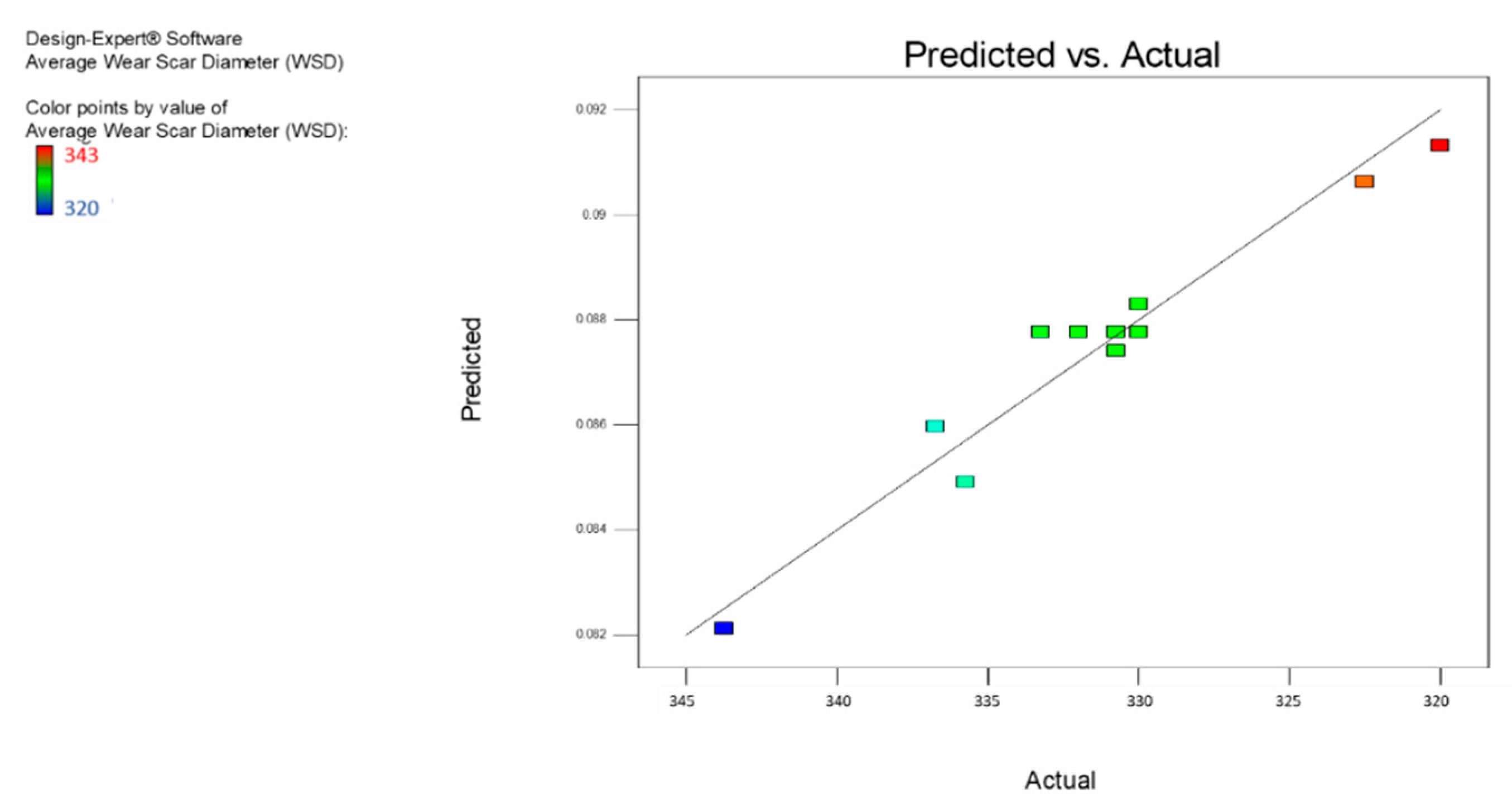

3.1.2. ANOVA Analysis of Average WSD

3.2. Characterization of MoS2

3.2.1. Field Emission Scanning Electron Microscope (FESEM) and Energy Dispersive X-ray Spectroscopy (EDS) of Optimized MoS2 Nanoparticle

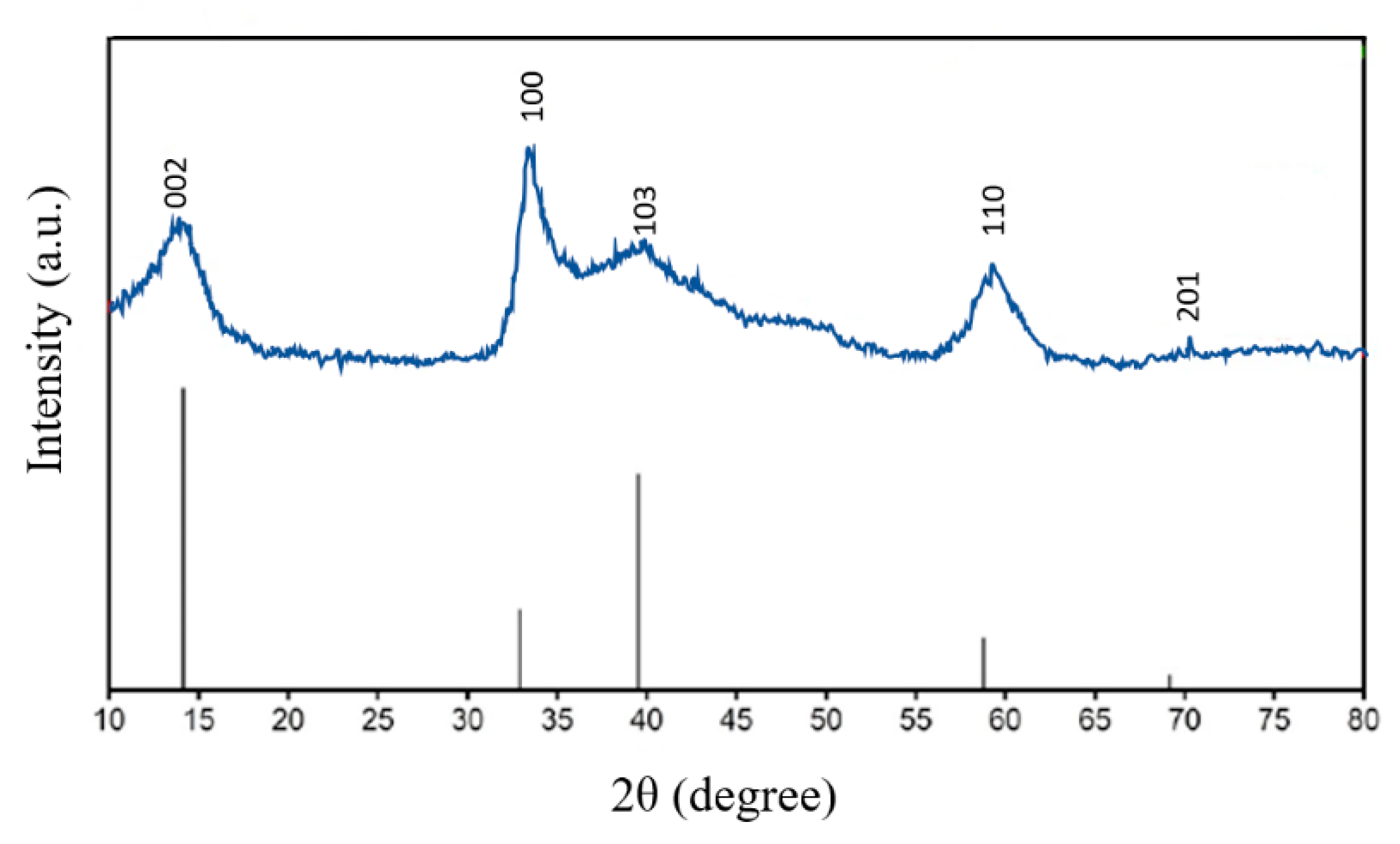

3.2.2. X-ray Diffraction of Optimized MoS2 Nanoparticle

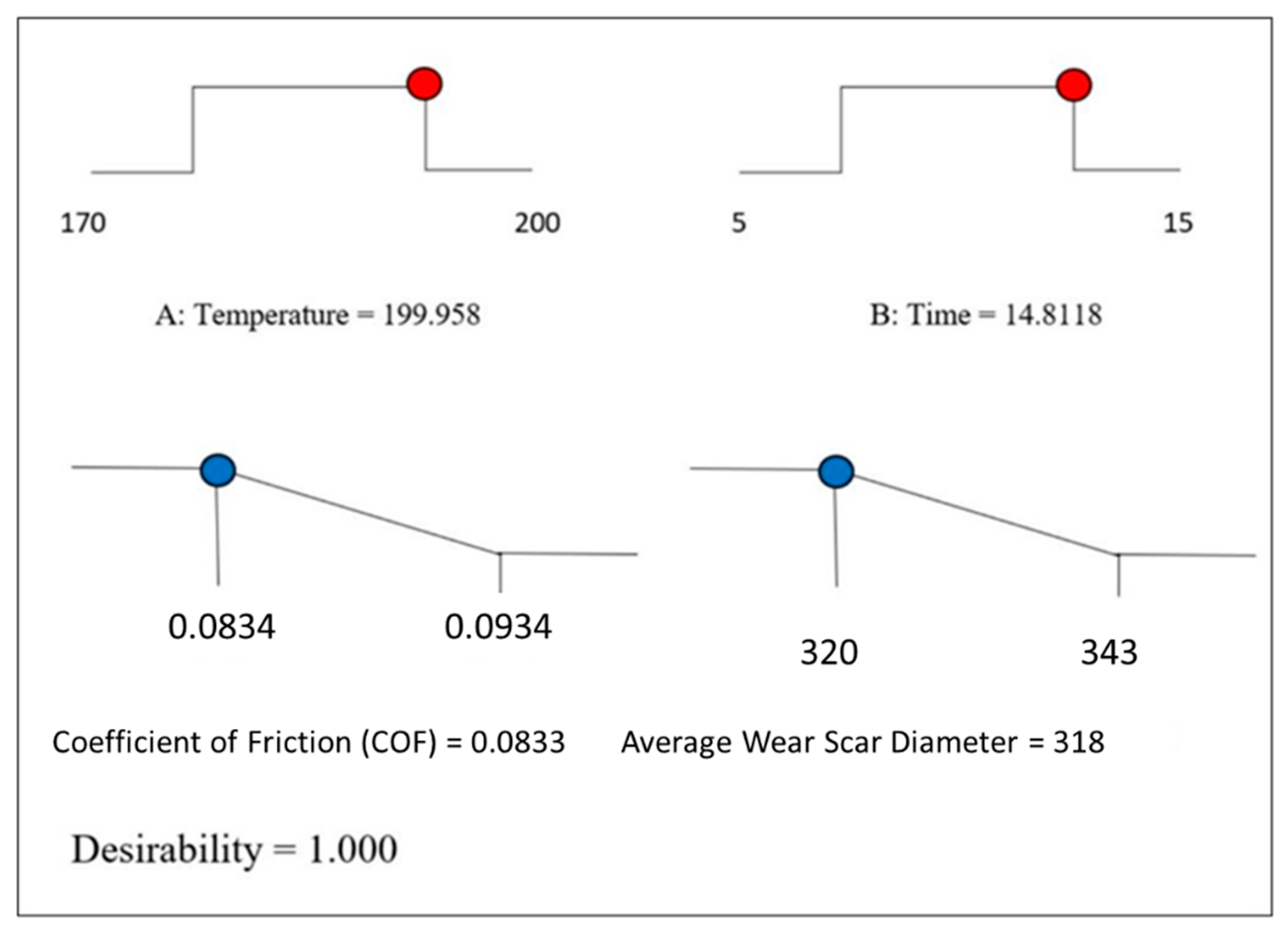

3.3. Optimization of Time and Temperature for MoS2 Microwave Synthesis for Tribological Application

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Srivyas, P.; Charoo, M. A Review on Tribological Characterization of Lubricants with Nano Additives for Automotive Applications. Tribol. Ind. 2018, 40, 594–623. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Xu, X.; Sun, S.; Wang, P.; Lei, A.; Peng, G. Study on tribology performance of diesel engine oil using SRV4 tribometer. Tribol. Online 2015, 10, 172–176. [Google Scholar] [CrossRef]

- Martini, A.; Ramasamy, U.S.; Len, M. Review of viscosity modifier lubricant additives. Tribol. Lett. 2018, 66, 58. [Google Scholar] [CrossRef]

- Agarwal, R.K. Recent Progress in Some Aircraft Technologies; IntechOpen: London, UK, 2016. [Google Scholar]

- Mandlik, S.; Mande, A.; Nimbalkar, S. Experimental analysis of tribological properties of lubricating oil using nanoparticle additives. Int. J. Adv. Res. Innov. Ideas Educ. 2016, 2, 1. [Google Scholar]

- Ali, Z.A.A.A.; Takhakh, A.M.; Al-Waily, M. A review of use of nanoparticle additives in lubricants to improve its tribological properties. Mater. Today Proc. 2021, 52, 1442–1450. [Google Scholar] [CrossRef]

- Song, W.; Yan, J.; Ji, H. Fabrication of GNS/MoS2 composite with different morphology and its tribological performance as a lubricant additive. Appl. Surf. Sci. 2019, 469, 226–235. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of nanoparticles in lubricating oil: A critical review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef]

- Peng, S.; Guo, Y.; Xie, G.; Luo, J. Tribological behavior of polytetrafluoroethylene coating reinforced with black phosphorus nanoparticles. Appl. Surf. Sci. 2018, 441, 670–677. [Google Scholar] [CrossRef]

- Sankaran Nair, S.; Prabhakaran Nair, K.; Rajendrakumar, P.K. Micro and nanoparticles blended sesame oil bio-lubricant: Study of its tribological and rheological properties. Micro Nano Lett. 2018, 13, 1743–1746. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid lubrication with MoS2: A review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Vattikuti, S.; Byon, C. Synthesis and characterization of molybdenum disulfide nanoflowers and nanosheets: Nanotribology. J. Nanomater. 2015, 2015, 9. [Google Scholar] [CrossRef]

- Moazami-Goudarzi, M.; Nemati, A. Tribological behavior of self lubricating Cu/MoS2 composites fabricated by powder metallurgy. Trans. Nonferrous Met. Soc. China 2018, 28, 946–956. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Chowdhury, S.; Roy, A.; Chison Liu, C.; Alam, H.; Ghosh, R.; Chou, H.; Akinwande, D.; Banerjee, S.K. Two-Step Growth of Uniform Monolayer MoS2 Nanosheets by Metal–Organic Chemical Vapor Deposition. ACS Omega 2021, 6, 10343–10351. [Google Scholar] [CrossRef]

- Sun, J.; Chen, Y.; Hu, C.; Liu, H.; Qu, J. Modulation of cation trans-membrane transport in GO-MoS2 membranes through simultaneous control of interlayer spacing and ion-nanochannel interactions. Chemosphere 2019, 222, 156–164. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, G.; Wang, J. Hydrothermal synthesis of two-dimensional MoS2 and its applications. Tungsten 2019, 1, 59–79. [Google Scholar] [CrossRef]

- Mathankumar, M.; Karthick, K.; Nanda Kumar, A.K.; Kundu, S.; Balasubramanian, S. Aiding Time-Dependent Laser Ablation to Direct 1T-MoS2 for an Improved Hydrogen Evolution Reaction. ACS Sustain. Chem. Eng. 2021, 9, 14744–14755. [Google Scholar] [CrossRef]

- Tian, Y.; Yang, X.; Nautiyal, A.; Zheng, Y.; Guo, Q.; Luo, J.; Zhang, X. One-step microwave synthesis of MoS2/MoO3@ graphite nanocomposite as an excellent electrode material for supercapacitors. Adv. Compos. Hybrid Mater. 2019, 2, 151–161. [Google Scholar] [CrossRef]

- Lin, H.; Chen, X.; Li, H.; Yang, M.; Qi, Y. Hydrothermal synthesis and characterization of MoS2 nanorods. Mater. Lett. 2010, 64, 1748–1750. [Google Scholar] [CrossRef]

- Peng, Y.; Meng, Z.; Zhong, C.; Lu, J.; Yu, W.; Yang, Z.; Qian, Y. Hydrothermal synthesis of MoS2 and its pressure-related crystallization. J. Solid State Chem. 2001, 159, 170–173. [Google Scholar] [CrossRef]

- Muralikrishna, S.; Manjunath, K.; Samrat, D.; Reddy, V.; Ramakrishnappa, T.; Nagaraju, D.H. Hydrothermal synthesis of 2D MoS 2 nanosheets for electrocatalytic hydrogen evolution reaction. RSC Adv. 2015, 5, 89389–89396. [Google Scholar] [CrossRef]

- Alashwal, B.Y.; Bala, M.S.; Gupta, A.; Soubam, T. Strategies using of Design of Experiments (DOE) techniques: In view of a Review. Maejo Int. J. Energy Environ. Commun. 2021, 3, 1–5. [Google Scholar] [CrossRef]

- Nehme, G.N. Tribological behavior and wear prediction of molybdenum disulfide grease lubricated rolling bearings under variable loads and speeds via experimental and statistical approach. Wear 2017, 376, 876–884. [Google Scholar] [CrossRef]

- Danish, M.; Yahya, S.M.; Saha, B.B. Modelling and optimization of thermophysical properties of aqueous titania nanofluid using response surface methodology. J. Therm. Anal. Calorim. 2020, 139, 3051–3063. [Google Scholar] [CrossRef]

- Draper, N.R.; Smith, H. Applied Regression Analysis; John Wiley & Sons: Hoboken, NJ, USA, 1998; Volume 326. [Google Scholar]

- Al-Saffar, A.; Ali, H.T.M. Using Power Transformations in Response Surface Methodology. In Proceedings of the 2022 International Conference on Computer Science and Software Engineering (CSASE), Duhok, Iraq, 15–17 March 2022. [Google Scholar]

- Solomon, G.; Mazzaro, R.; You, S.; Natile, M.M.; Morandi, V.; Concina, I.; Vomiero, A. Ag2S/MoS2 nanocomposites anchored on reduced graphene oxide: Fast interfacial charge transfer for hydrogen evolution reaction. ACS Appl. Mater. Interfaces 2019, 11, 22380–22389. [Google Scholar] [CrossRef]

- Park, S.K.; Yu, S.H.; Woo, S.; Quan, B.; Lee, D.C.; Kim, M.K.; Sung, Y.-E.; Piao, Y. A simple l-cysteine-assisted method for the growth of MoS 2 nanosheets on carbon nanotubes for high-performance lithium ion batteries. Dalton Trans. 2013, 42, 2399–2405. [Google Scholar] [CrossRef]

- Xu, D.; Wang, C.; Espejo, C.; Wang, J.; Neville, A.; Morina, A. Understanding the friction reduction mechanism based on molybdenum disulfide tribofilm formation and removal. Langmuir 2018, 34, 13523–13533. [Google Scholar] [CrossRef]

- Yi, M.; Qiu, J.; Xu, W. Tribological performance of ultrathin MoS2 nanosheets in formulated engine oil and possible friction mechanism at elevated temperatures. Tribol. Int. 2022, 167, 107426. [Google Scholar] [CrossRef]

- Vaitkunaite, G.; Espejo, C.; Wang, C.; Thiebaut, B.; Charrin, C.; Neville, A.; Morina, A. MoS2 tribofilm distribution from low viscosity lubricants and its effect on friction. Tribol. Int. 2020, 151, 106531. [Google Scholar] [CrossRef]

| Coded Name | Variable Name | Type | Parameter Range | Parameter Unit |

|---|---|---|---|---|

| A | Temperature | Continuous | Level 1/low 170 Level 2/high 200 | °C |

| B | Time | Continuous | Level 1/low 5 Level 2/high 15 | Minutes |

| Properties | Ball Bearing |

|---|---|

| Material | Carbon-chromium steel |

| Hardness (H), HRC | 1 |

| Density (ρ), gm/cm3 | 7.79 |

| Surface roughness (Ra), μm | 0.022 |

| Factor 1 | Factor 2 | Response 1 | Response 2 | |

|---|---|---|---|---|

| Run | Synthesis Temperature (°C) | Synthesis Time (Minutes) | Coefficient of Friction (COF) | Average Wear Scar Diameter (WSD) (µm) |

| 1 | 185 | 17.0711 | 0.0861 | 331 |

| 2 | 170 | 15 | 0.0868 | 333 |

| 3 | 200 | 5 | 0.0932 | 343 |

| 4 | 206 | 10 | 0.0852 | 327 |

| 5 | 185 | 10 | 0.0923 | 334 |

| 6 | 185 | 10 | 0.0917 | 333 |

| 7 | 164 | 10 | 0.0865 | 334 |

| 8 | 200 | 15 | 0.0834 | 320 |

| 9 | 185 | 10 | 0.0912 | 333 |

| 10 | 185 | 3 | 0.0934 | 342 |

| 11 | 185 | 10 | 0.092 | 334 |

| 12 | 185 | 10 | 0.0908 | 333 |

| Source | Sum of Squares | Degrees of Freedom (df) | Mean Square | F-Value | p-Value Prob > F | Significance |

|---|---|---|---|---|---|---|

| Model | 1.329 × 10−4 | 5 | 2.659 × 10−5 | 55.80 | <0.0001 | Significant |

| A-Temperature | 8.626 × 10−8 | 1 | 8.626 × 10−8 | 0.18 | 0.6853 | - |

| B-Time | 4.639 × 10−5 | 1 | 4.639 × 10−5 | 97.35 | <0.0001 | - |

| AB | 8.846 × 10−6 | 1 | 8.846 × 10−6 | 18.56 | 0.0050 | - |

| A2 | 5.103 × 10−5 | 1 | 5.103 × 10−5 | 107.10 | <0.0001 | - |

| B2 | 4.741 × 10−6 | 1 | 4.741 × 10−6 | 9.95 | 0.0197 | - |

| Residual | 2.859 × 10−6 | 6 | 4.765 × 10−7 | - | - | - |

| Lack of Fit | 1.399 × 10−6 | 2 | 6.995 × 10−7 | 1.92 | 0.2608 | Not significant |

| Pure Error | 1.460 × 10−6 | 4 | 3.650 × 10−7 | - | - | - |

| Cor Total | 1.358 × 10−4 | 11 | - | - | - | - |

| R-Squared | Adjusted R-Squared | Predicted R-Squared | Adequate Precision |

|---|---|---|---|

| 0.9789 | 0.9614 | 0.7907 | 21.926 |

| Source | Sum of Squares | Degrees of Freedom (df) | Mean Square | F-Value | p-Value Prob > F | Significance |

|---|---|---|---|---|---|---|

| Model | 6.339 × 10−5 | 4 | 1.585 × 10−5 | 31.53 | 0.0001 | Significant |

| A-Temperature | 1.584 × 10−6 | 1 | 1.584 × 10−6 | 3.15 | 0.1191 | - |

| B-Time | 2.496 × 10−5 | 1 | 2.496 × 10−5 | 49.66 | 0.0002 | - |

| AB | 1.641 × 10−5 | 1 | 1.641 × 10−5 | 32.66 | 0.0007 | - |

| A2 | 1.955 × 10−6 | 1 | 1.955 × 10−6 | 3.89 | 0.0892 | - |

| Residual | 3.518 × 10−6 | 7 | 5.026 × 10−7 | - | - | - |

| Lack of Fit | 2.466 × 10−6 | 3 | 8.220 × 10−7 | 3.13 | 0.1499 | Not significant |

| Pure Error | 1.052 × 10−6 | 4 | 2.630 × 10−7 | - | - | - |

| Cor Total | 6.691 × 10−5 | 11 | - | - | - | - |

| R-Squared | Adjusted R-Squared | Predicted R-Squared | Adequate Precision |

|---|---|---|---|

| 0.9474 | 0.9174 | 0.7367 | 20.112 |

| Response | Predicted | Experimental | % Error |

|---|---|---|---|

| COF | 0.0833 | 0.0849 | 1.88 |

| Average WSD (μm) | 318 | 320 | 0.625 |

| Response | Base Oil + MoS2 Nanoparticle | Base Oil | % Reduction |

|---|---|---|---|

| COF | 0.0849 | 0.0946 | 10.25 |

| Average WSD (μm) | 320 | 345 | 10.60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagarajan, T.; Khalid, M.; Sridewi, N.; Jagadish, P.; Walvekar, R. Microwave Synthesis of Molybdenum Disulfide Nanoparticles Using Response Surface Methodology for Tribological Application. Nanomaterials 2022, 12, 3369. https://doi.org/10.3390/nano12193369

Nagarajan T, Khalid M, Sridewi N, Jagadish P, Walvekar R. Microwave Synthesis of Molybdenum Disulfide Nanoparticles Using Response Surface Methodology for Tribological Application. Nanomaterials. 2022; 12(19):3369. https://doi.org/10.3390/nano12193369

Chicago/Turabian StyleNagarajan, Thachnatharen, Mohammad Khalid, Nanthini Sridewi, Priyanka Jagadish, and Rashmi Walvekar. 2022. "Microwave Synthesis of Molybdenum Disulfide Nanoparticles Using Response Surface Methodology for Tribological Application" Nanomaterials 12, no. 19: 3369. https://doi.org/10.3390/nano12193369

APA StyleNagarajan, T., Khalid, M., Sridewi, N., Jagadish, P., & Walvekar, R. (2022). Microwave Synthesis of Molybdenum Disulfide Nanoparticles Using Response Surface Methodology for Tribological Application. Nanomaterials, 12(19), 3369. https://doi.org/10.3390/nano12193369