Manufacturing of Zinc Oxide Nanoparticle (ZnO NP)-Loaded Polyvinyl Alcohol (PVA) Nanostructured Mats Using Ginger Extract for Tissue Engineering Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

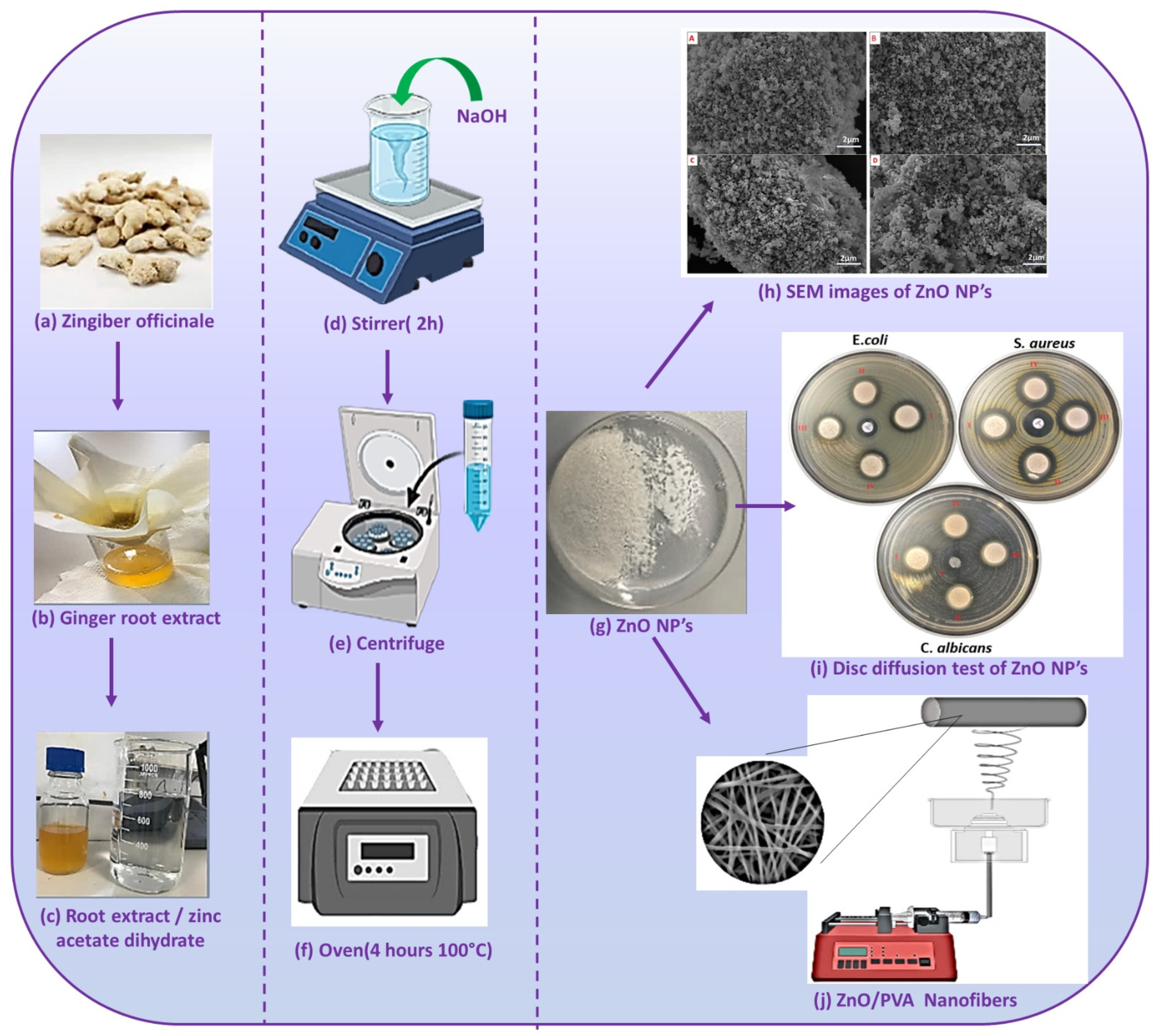

2.2. Methods

2.2.1. Preparation of the Zingiber Officinale Root Extract

2.2.2. Preparation of Zinc Oxide Nanoparticles

2.2.3. Production of the PVA/ZnO NPs Composite Gels

2.2.4. Electrospinning Procedure of Nanofibers

2.2.5. Crosslinking Process of Nanofibers

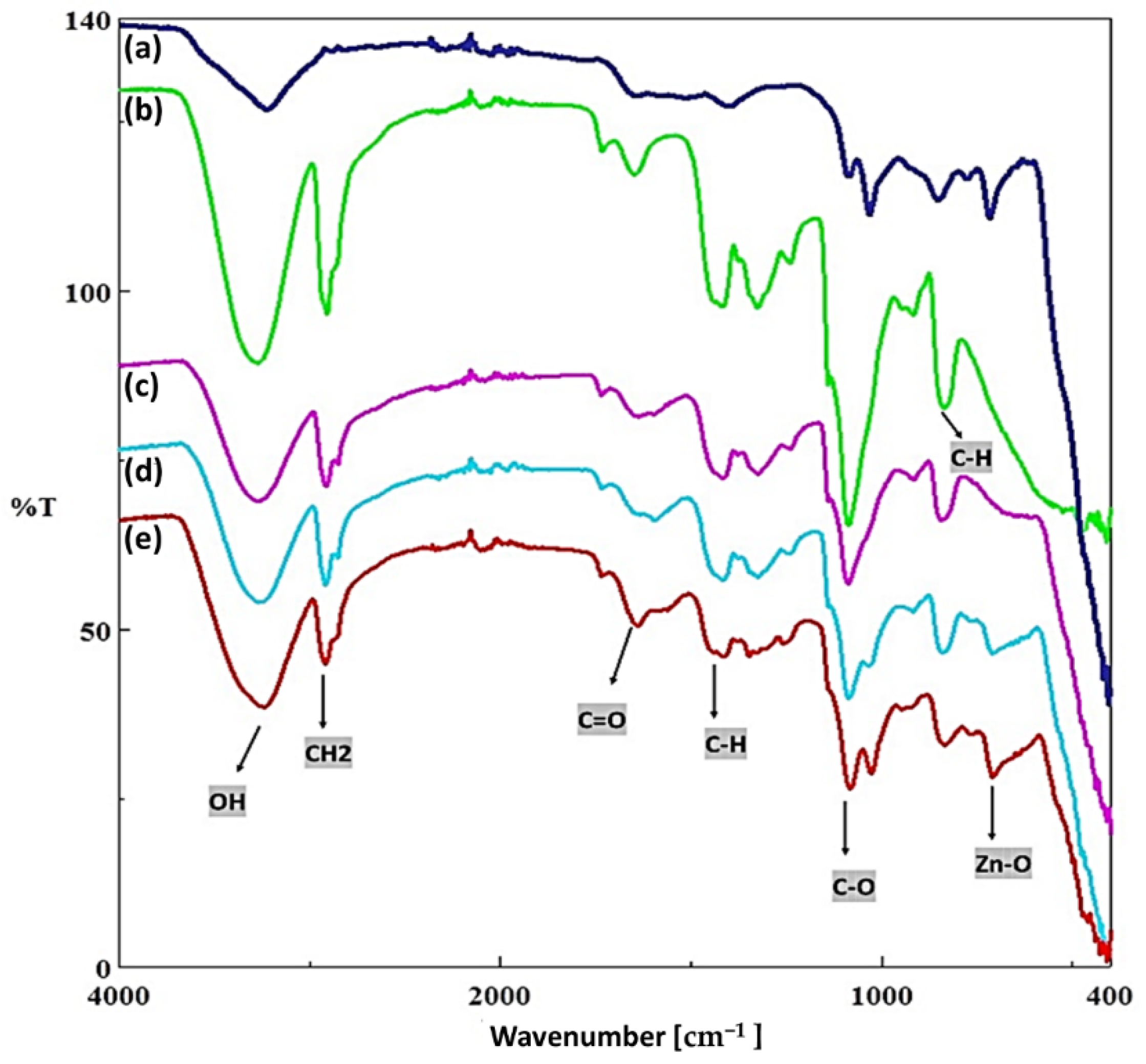

2.2.6. Fourier Transform Infrared Spectroscopy (FT-IR)

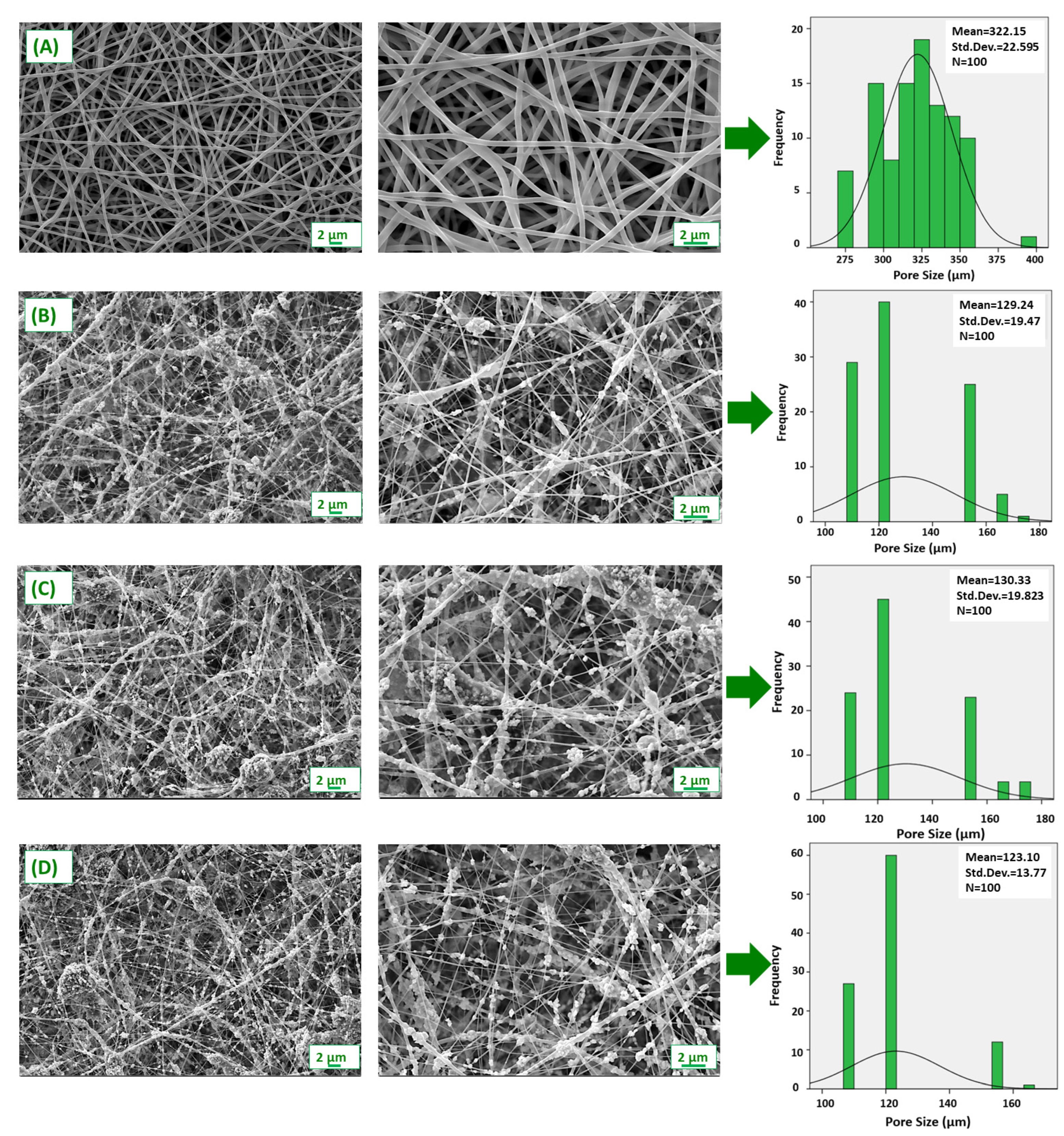

2.2.7. Scanning Electron Microscope (SEM)

2.2.8. Mechanical Properties of Fibers

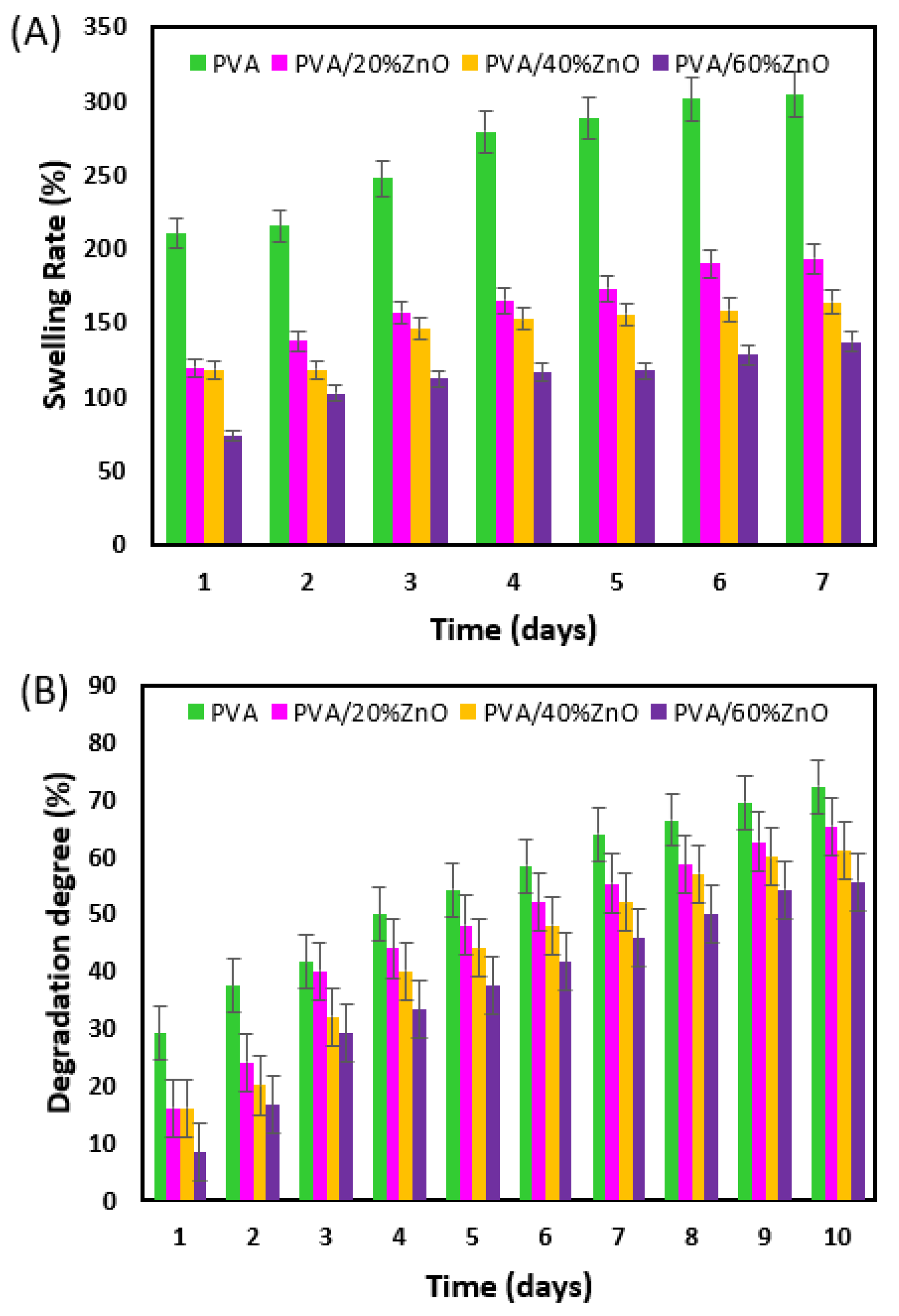

2.2.9. Swelling and Degradation Behaviours of Fibers

2.2.10. Antimicrobial Activity of ZnO NPs and Fibers

2.2.11. Cell-Culture Studies

3. Results and Discussion

3.1. Characterization Process of Nanoparticles

3.2. Fourier Transform-Infrared Spectroscopy (FT-IR)

3.3. Scanning Electron Microscope (SEM)

3.4. Mechanical Properties of Fibrous Patches

3.5. Swelling and Degradation Behaviours of Fibers

3.6. Antimicrobial Activity of ZnO NPs and Fibers

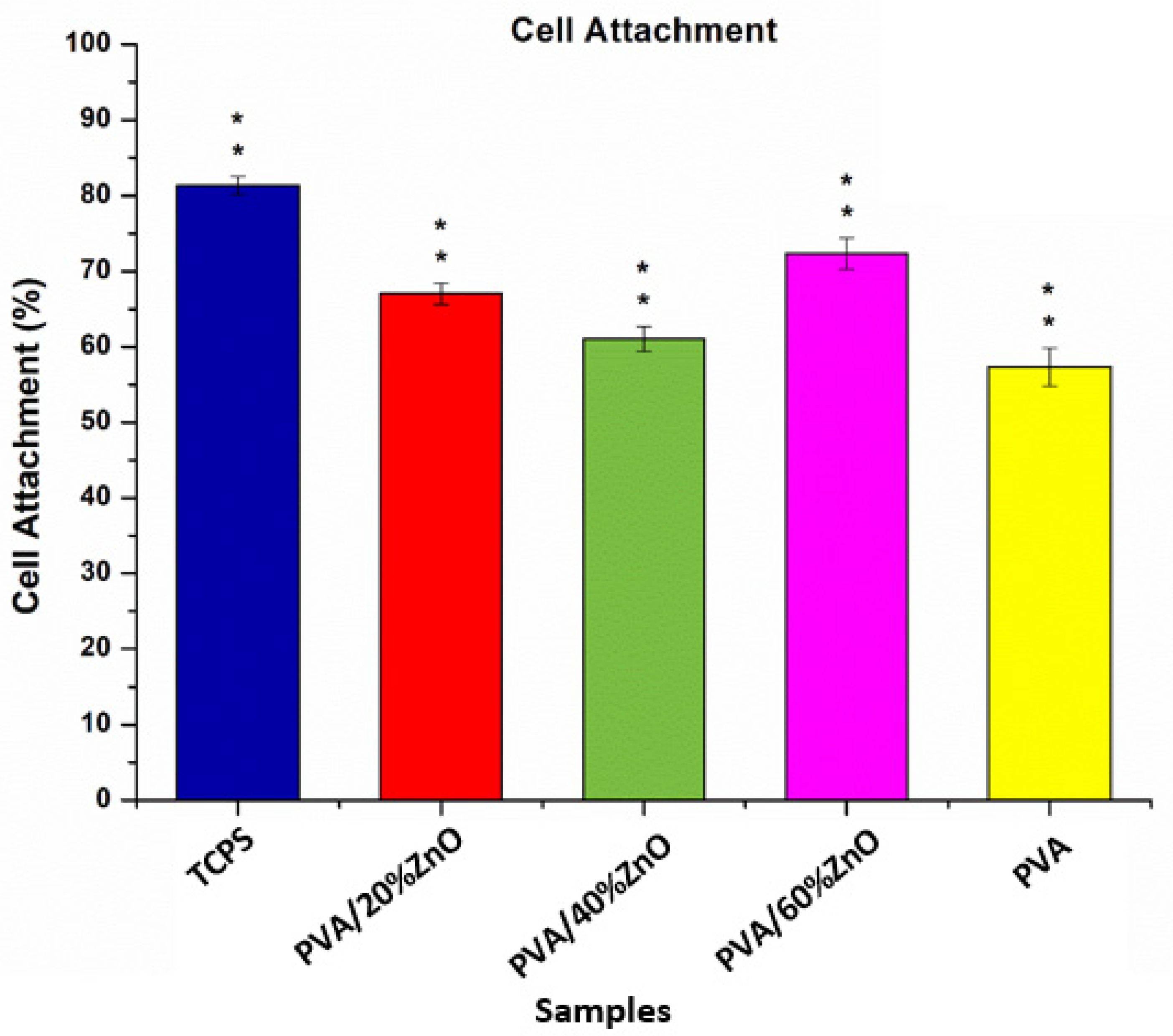

3.7. Cell-Culture Studies

3.7.1. Cell Attachment

3.7.2. Cell Viability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Danie Kingsley, J.; Ranjan, S.; Dasgupta, N.; Saha, P. Nanotechnology for tissue engineering: Need, techniques and applications. J. Pharm. Res. 2013, 7, 200–204. [Google Scholar] [CrossRef]

- Ilhan, E.; Ulag, S.; Sahin, A.; Ekren, N.; Kilic, O.; Oktar, F.N.; Gunduz, O. Production of 3D-printed tympanic membrane scaffolds as a tissue engineering application. In Lecture Notes in Computer Science (İncluding Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Cham, Switzerland, 2020. [Google Scholar]

- Tasci, M.E.; Dede, B.; Tabak, E.; Gur, A.; Sulutas, R.B.; Cesur, S.; Ilhan, E.; Lin, C.C.; Paik, P.; Ficai, D.; et al. Production, optimization and characterization of polylactic acid microparticles using electrospray with porous structure. Appl. Sci. 2021, 11, 5090. [Google Scholar] [CrossRef]

- Chung, B.G.; Kang, L.; Khademhosseini, A. Micro- and nanoscale technologies for tissue engineering and drug discovery applications. Expert Opin. Drug Discov. 2007, 2, 1653–1668. [Google Scholar] [CrossRef] [PubMed]

- Geltmeyer, J.; Van der Schueren, L.; Goethals, F.; De Buysser, K.; De Clerck, K. Optimum sol viscosity for stable electrospinning of silica nanofibres. J. Sol-Gel Sci. Technol. 2013, 67, 188–195. [Google Scholar] [CrossRef]

- Kenry; Lim, C.T. Nanofiber technology: Current status and emerging developments. Prog. Polym. Sci. 2017, 70, 1–17. [Google Scholar] [CrossRef]

- Cui, W.; Zhou, Y.; Chang, J. Electrospun nanofibrous materials for tissue engineering and drug delivery. Sci. Technol. Adv. Mater. 2010, 11, 014108. [Google Scholar] [CrossRef]

- Yang, D.; Li, Y.; Nie, J. Preparation of gelatin/PVA nanofibers and their potential application in controlled release of drugs. Carbohydr. Polym. 2007, 69, 538–543. [Google Scholar] [CrossRef]

- Bai, J.; Li, Y.; Yang, S.; Du, J.; Wang, S.; Zheng, J.; Wang, Y.; Yang, Q.; Chen, X.; Jing, X. A simple and effective route for the preparation of poly(vinylalcohol) (PVA) nanofibers containing gold nanoparticles by electrospinning method. Solid State Commun. 2007, 141, 292–295. [Google Scholar] [CrossRef]

- Cesur, S.; Cam, M.E.; Sayın, F.S.; Su, S.; Harker, A.; Edirisinghe, M.; Gunduz, O. Metformin-loaded polymer-based microbubbles/nanoparticles generated for the treatment of type 2 diabetes mellitus. Langmuir 2021, 38, 5040–5051. [Google Scholar] [CrossRef]

- Cesur, S.; Cam, M.E.; Sayin, F.S.; Gunduz, O. Electrically controlled drug release of donepezil and BiFeO3 magnetic nanoparticle-loaded PVA microbubbles/nanoparticles for the treatment of Alzheimer’s disease. J. Drug Deliv. Sci. Technol. 2022, 67, 102977. [Google Scholar] [CrossRef]

- Pulit-Prociak, J.; Staroń, A.; Staroń, P.; Chmielowiec-Korzeniowska, A.; Drabik, A.; Tymczyna, L.; Banach, M. Preparation and of PVA-based compositions with embedded silver, copper and zinc oxide nanoparticles and assessment of their antibacterial properties. J. Nanobiotechnol. 2020, 18, 148. [Google Scholar] [CrossRef] [PubMed]

- Anand Raj, L.F.A.; Jayalakshmy, E. Biosynthesis and characterization of zinc oxide nanoparticles using root extract of Zingiber officinale. Orient. J. Chem. 2015, 31, 51–56. [Google Scholar] [CrossRef]

- Sangeetha, G.; Rajeshwari, S.; Venckatesh, R. Green synthesis of zinc oxide nanoparticles by aloe barbadensis miller leaf extract: Structure and optical properties. Mater. Res. Bull. 2011, 46, 2560–2566. [Google Scholar] [CrossRef]

- Dhandapani, K.V.; Anbumani, D.; Gandhi, A.D.; Annamalai, P.; Muthuvenkatachalam, B.S.; Kavitha, P.; Ranganathan, B. Green route for the synthesis of zinc oxide nanoparticles from Melia azedarach leaf extract and evaluation of their antioxidant and antibacterial activities. Biocatal. Agric. Biotechnol. 2020, 24, 101517. [Google Scholar] [CrossRef]

- Janaki, A.C.; Sailatha, E.; Gunasekaran, S. Synthesis, characteristics and antimicrobial activity of ZnO nanoparticles. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2015, 144, 17–22. [Google Scholar] [CrossRef] [PubMed]

- Ferrone, E.; Araneo, R.; Notargiacomo, A.; Pea, M.; Rinaldi, A. ZnO nanostructures and electrospun ZnO–polymeric hybrid nanomaterials in biomedical, health, and sustainability applications. Nanomaterials 2019, 9, 1449. [Google Scholar] [CrossRef]

- Santhoshkumar, J.; Kumar, S.V.; Rajeshkumar, S. Synthesis of zinc oxide nanoparticles using plant leaf extract against urinary tract infection pathogen. Resour. Technol. 2017, 3, 459–465. [Google Scholar] [CrossRef]

- Ilhan, E.; Cesur, S.; Sulutas, R.B.; Pilavci, E.; Dalbayrak, B.; Kaya, E.; Arisan, E.D.; Tinaz, G.B.; Sengor, M.; Kijeńska-Gawrońska, E.; et al. The role of multilayer electrospun poly(vinyl alcohol)/gelatin nanofibers loaded with fluconazole and cinnamaldehyde in the potential treatment of fungal keratitis. Eur. Polym. J. 2022, 176, 111390. [Google Scholar] [CrossRef]

- Ilhan, E.; Karahaliloglu, Z.; Kilicay, E.; Hazer, B.; Denkbas, E.B. Potent bioactive bone cements impregnated with polystyrene-g-soybean oil-AgNPs for advanced bone tissue applications. Mater. Technol. 2020, 35, 179–194. [Google Scholar] [CrossRef]

- Saylam, E.; Akkaya, Y.; Ilhan, E.; Cesur, S.; Guler, E.; Sahin, A.; Cam, E.; Ekren, N.; Nuzhet Oktar, F.; Gunduz, O.; et al. Levodopa-loaded 3D-printed poly (lactic) acid/chitosan neural tissue scaffold as a promising drug delivery system for the treatment of Parkinson’s disease. Appl. Sci. 2021, 11, 10727. [Google Scholar] [CrossRef]

- European Committee on Antimicrobial Susceptibility Testing. Reading Guide EUCAST Disk Diffusion Method for Antimicrobial Susceptibility Testing. Version 8.0; EUCAST: Växjö, Sweden, 2021; pp. 1–30. [Google Scholar]

- Procop, G.W.; Alexander, B.D.; Dufresne, P.J.; Fuller, J.; Ghannoum, M.A.; Hanson, K.E.; Holliday, D.; Holliday, N.M.; Ostrosky-Zeichner, L.; Schuetz, A.N.; et al. Method for Antifungal Disk; Clinical and Laboratory Standards Institute: Wayne, PA, USA, 2018. [Google Scholar]

- Ulag, S.; Ilhan, E.; Aksu, B.; Sengor, M.; Ekren, N.; Kilic, O.; Gunduz, O. Patch-based technology for corneal microbial keratitis. In Lecture Notes in Computer Science (İncluding Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Cham, Switzerland, 2020. [Google Scholar]

- Jamnongkan, T.; Shirota, R.; Sukumaran, S.K.; Sugimoto, M.; Koyama, K. Effect of ZnO nanoparticles on the electrospinning of poly(vinyl alcohol) from aqueous solution: Influence of particle size. Polym. Eng. Sci. 2014, 54, 1969–1975. [Google Scholar] [CrossRef]

- Kayış, A.; Kavgacı, M.; Yaykaşlı, H.; Kerli, S.; Eskalen, H. Investigation of structural, morphological, mechanical, thermal and optical properties of PVA-ZnO nanocomposites. Glas. Phys. Chem. 2021, 47, 451–461. [Google Scholar] [CrossRef]

- Imaan, D.U.; Mir, F.Q.; Ahmad, B. Synthesis and characterization of a novel poly(vinyl alcohol)-based zinc oxide (PVA-ZnO) composite proton exchange membrane for DMFC. Int. J. Hydrogen Energy 2020, 46, 12230–12241. [Google Scholar] [CrossRef]

- Kandulna, R.; Choudhary, R.B. Concentration-dependent behaviors of ZnO-reinforced PVA–ZnO nanocomposites as electron transport materials for OLED application. Polym. Bull. 2018, 75, 3089–3107. [Google Scholar] [CrossRef]

- Ulag, S.; Ilhan, E.; Demirhan, R.; Sahin, A.; Yilmaz, B.K.; Aksu, B.; Sengor, M.; Ficai, D.; Titu, A.M.; Ficai, A.; et al. Propolis-based nanofiber patches to repair corneal microbial keratitis. Molecules 2021, 26, 2577. [Google Scholar] [CrossRef]

- Zhao, M.; Wang, X.; Ning, L.; He, H.; Jia, J.; Zhang, L.; Li, X. Synthesis and optical properties of Mg-doped ZnO nanofibers prepared by electrospinning. J. Alloys Compd. 2010, 507, 97–100. [Google Scholar] [CrossRef]

- Gharoy Ahangar, E.; Abbaspour-Fard, M.H.; Shahtahmassebi, N.; Khojastehpour, M.; Maddahi, P. Preparation and characterization of PVA/ZnO nanocomposite. J. Food Process. Preserv. 2015, 39, 1442–1451. [Google Scholar] [CrossRef]

- Tan, L.Y. Functionalization of Cotton Fabric with ZnO/PVA for Antibacterial Textile Application. Master’s Dissertation, Universiti Tunku Abdul Rahman, Kampar, Malaysia, 2018. [Google Scholar]

- Yeniay, E.; Öcal, L.; Altun, E.; Giray, B.; Nuzhet Oktar, F.; Talat Inan, A.; Ekren, N.; Kilic, O.; Gunduz, O. Nanofibrous wound dressing material by electrospinning method. Int. J. Polym. Mater. Polym. Biomater. 2019, 68, 11–18. [Google Scholar] [CrossRef]

- Ilhan, E.; Cesur, S.; Guler, E.; Topal, F.; Albayrak, D.; Guncu, M.M.; Cam, M.E.; Taskin, T.; Sasmazel, H.T.; Aksu, B.; et al. Development of Satureja cuneifolia-loaded sodium alginate/polyethylene glycol scaffolds produced by 3D-printing technology as a diabetic wound dressing material. Int. J. Biol. Macromol. 2020, 161, 1040–1054. [Google Scholar] [CrossRef]

- Peter, M.; Binulal, N.S.; Soumya, S.; Nair, S.V.; Furuike, T.; Tamura, H.; Jayakumar, R. Nanocomposite scaffolds of bioactive glass ceramic nanoparticles disseminated chitosan matrix for tissue engineering applications. Carbohydr. Polym. 2010, 79, 284–289. [Google Scholar] [CrossRef]

- Aramwit, P.; Muangman, P.; Namviriyachote, N.; Srichana, T. In vitro evaluation of the antimicrobial effectiveness and moisture binding properties of wound dressings. Int. J. Mol. Sci. 2010, 11, 2864–2874. [Google Scholar] [CrossRef] [PubMed]

- Valencia, J.; Piérola, I.F. Swelling kinetics of poly(N-vinylimidazole-co-sodium styrenesulfonate) hydrogels. J. Appl. Polym. Sci. 2002, 83, 191–200. [Google Scholar] [CrossRef]

- Khalilipour, A.; Paydayesh, A. Characterization of polyvinyl alcohol/ZnO nanocomposite hydrogels for wound dressings. J. Macromol. Sci. Part B Phys. 2019, 58, 371–384. [Google Scholar] [CrossRef]

- Tantiwatcharothai, S.; Prachayawarakorn, J. Characterization of an antibacterial wound dressing from basil seed (Ocimum basilicum L.) mucilage-ZnO nanocomposite. Int. J. Biol. Macromol. 2019, 135, 133–140. [Google Scholar] [CrossRef]

- Marvizadeh, M.M.; Oladzadabbasabadi, N.; Mohammadi Nafchi, A.; Jokar, M. Preparation and characterization of bionanocomposite film based on tapioca starch/bovine gelatin/nanorod zinc oxide. Int. J. Biol. Macromol. 2017, 99, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Grover, C.N.; Cameron, R.E.; Best, S.M. Investigating the morphological, mechanical and degradation properties of scaffolds comprising collagen, gelatin and elastin for use in soft tissue engineering. J. Mech. Behav. Biomed. Mater. 2012, 10, 62–74. [Google Scholar] [CrossRef]

- Oliveira, R.N.; McGuinness, G.B.; Ramos, M.E.T.; Kajiyama, C.E.; Thiré, R.M.S.M. Properties of PVA hydrogel wound-care dressings containing UK propolis. Macromol. Symp. 2016, 368, 122–127. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Seligra, P.G.; Jaramillo, C.M.; Famá, L.; Goyanes, S. Effect of filler properties on the antioxidant response of thermoplastic starch composites. Handb. Compos. Renew. Mater. 2017, 1–8, 337–369. [Google Scholar] [CrossRef]

- Jatoi, A.W.; Jo, Y.K.; Lee, H.; Oh, S.-G.; Hwang, D.S.; Khatri, Z.; Cha, H.J.; Kim, I.S. Antibacterial efficacy of poly(vinyl alcohol) composite nanofibers embedded with silver-anchored silica nanoparticles. J. Biomed. Mater. Res. B Appl. Biomater. 2018, 106, 1121–1128. [Google Scholar] [CrossRef]

- Homaeigohar, S.; Boccaccini, A.R. Antibacterial biohybrid nanofibers for wound dressings. Acta Biomater. 2020, 107, 25–49. [Google Scholar] [CrossRef]

- Dejen, K.D.; Zereffa, E.A.; Murthy, H.C.A.; Merga, A. Synthesis of ZnO and ZnO/PVA nanocomposite using aqueous Moringa Oleifeira leaf extract template: Antibacterial and electrochemical activities. Rev. Adv. Mater. Sci. 2020, 59, 464–476. [Google Scholar] [CrossRef]

- Lipovsky, A.; Nitzan, Y.; Gedanken, A.; Lubart, R. Antifungal activity of ZnO nanoparticles—The role of ROS mediated cell injury. Nanotechnology 2011, 22, 105101. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, S.M.; Alves, N.M.; Mano, J.F. Cell interactions with superhydrophilic and superhydrophobic surfaces. J. Adhes. Sci. Technol. 2014, 28, 843–863. [Google Scholar] [CrossRef]

- Lawrence, B.J.; Madihally, S.V. Cell colonization in degradable 3D porous matrices. Cell Adh. Migr. 2008, 2, 9–16. [Google Scholar] [CrossRef]

- Resmi, R.; Yoonus, J.; Beena, B. A novel greener synthesis of ZnO nanoparticles from Nilgiriantusciliantus leaf extract and evaluation of its biomedical applications. Mater. Today Proc. 2020, 46, 3062–3068. [Google Scholar] [CrossRef]

- Patrón-Romero, L.; Luque, P.A.; Soto-Robles, C.A.; Nava, O.; Vilchis-Nestor, A.R.; Barajas-Carrillo, V.W.; Martínez-Ramírez, C.E.; Chávez Méndez, J.R.; Alvelais Palacios, J.A.; Leal Ávila, M.; et al. Synthesis, characterization and cytotoxicity of zinc oxide nanoparticles by green synthesis method. J. Drug Deliv. Sci. Technol. 2020, 60, 101925. [Google Scholar] [CrossRef]

| ZnO NPs Content (wt%) | PVA Content (wt%) | |

|---|---|---|

| PVA | 0 | 10 |

| PVA/20%ZnO | 20 | 10 |

| PVA/40%ZnO | 40 | 10 |

| PVA/60%ZnO | 60 | 10 |

| Sample Number | Sample Name | S. aureus ATCC 29213 (Diameter-mm) | E. coli ATCC 25922 (Diameter-mm) | C. albicans ATCC 5314 (Diameter-mm) |

|---|---|---|---|---|

| I | 2% | 22 mm | 20 mm | 14 mm |

| II | 2.5% | 22 mm | 19 mm | 14 mm |

| III | 3% | 22 mm | 19 mm | 14 mm |

| IV | 4% | 22 mm | 19 mm | 14 mm |

| V | %70 Ethanol | - | - | 15 mm |

| AMP 2 | Ampicillin 2 µg | 18 mm | - | - |

| AMP 10 | Ampicillin 10 µg | - | 12 mm | - |

| E.coli ATCC 25922 (mm) | S. aureus ATCC 29213 (mm) | C. albicans ATCC 90028 (mm) | |

|---|---|---|---|

| ZnO NPs | 22 mm | 20 mm | 15 mm |

| I-PVA | 0 | 0 | 0 |

| II-PVA/20%ZnO | 0 | 12 mm | 0 |

| III-PVA/40%ZnO | 0 | 12 mm | 0 |

| IV-PVA/60%ZnO | 7 mm | 12 mm | 0 |

| (AM)-Ampicillin | 12 mm (10 µg) | 30 mm (2 µg) | 14 mm (%70 ethanol) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Izgis, H.; Ilhan, E.; Kalkandelen, C.; Celen, E.; Guncu, M.M.; Turkoglu Sasmazel, H.; Gunduz, O.; Ficai, D.; Ficai, A.; Constantinescu, G. Manufacturing of Zinc Oxide Nanoparticle (ZnO NP)-Loaded Polyvinyl Alcohol (PVA) Nanostructured Mats Using Ginger Extract for Tissue Engineering Applications. Nanomaterials 2022, 12, 3040. https://doi.org/10.3390/nano12173040

Izgis H, Ilhan E, Kalkandelen C, Celen E, Guncu MM, Turkoglu Sasmazel H, Gunduz O, Ficai D, Ficai A, Constantinescu G. Manufacturing of Zinc Oxide Nanoparticle (ZnO NP)-Loaded Polyvinyl Alcohol (PVA) Nanostructured Mats Using Ginger Extract for Tissue Engineering Applications. Nanomaterials. 2022; 12(17):3040. https://doi.org/10.3390/nano12173040

Chicago/Turabian StyleIzgis, Hursima, Elif Ilhan, Cevriye Kalkandelen, Emrah Celen, Mehmet Mucahit Guncu, Hilal Turkoglu Sasmazel, Oguzhan Gunduz, Denisa Ficai, Anton Ficai, and Gabriel Constantinescu. 2022. "Manufacturing of Zinc Oxide Nanoparticle (ZnO NP)-Loaded Polyvinyl Alcohol (PVA) Nanostructured Mats Using Ginger Extract for Tissue Engineering Applications" Nanomaterials 12, no. 17: 3040. https://doi.org/10.3390/nano12173040

APA StyleIzgis, H., Ilhan, E., Kalkandelen, C., Celen, E., Guncu, M. M., Turkoglu Sasmazel, H., Gunduz, O., Ficai, D., Ficai, A., & Constantinescu, G. (2022). Manufacturing of Zinc Oxide Nanoparticle (ZnO NP)-Loaded Polyvinyl Alcohol (PVA) Nanostructured Mats Using Ginger Extract for Tissue Engineering Applications. Nanomaterials, 12(17), 3040. https://doi.org/10.3390/nano12173040