Adsorption of Different Pollutants by Using Microplastic with Different Influencing Factors and Mechanisms in Wastewater: A Review

Abstract

:1. Introduction

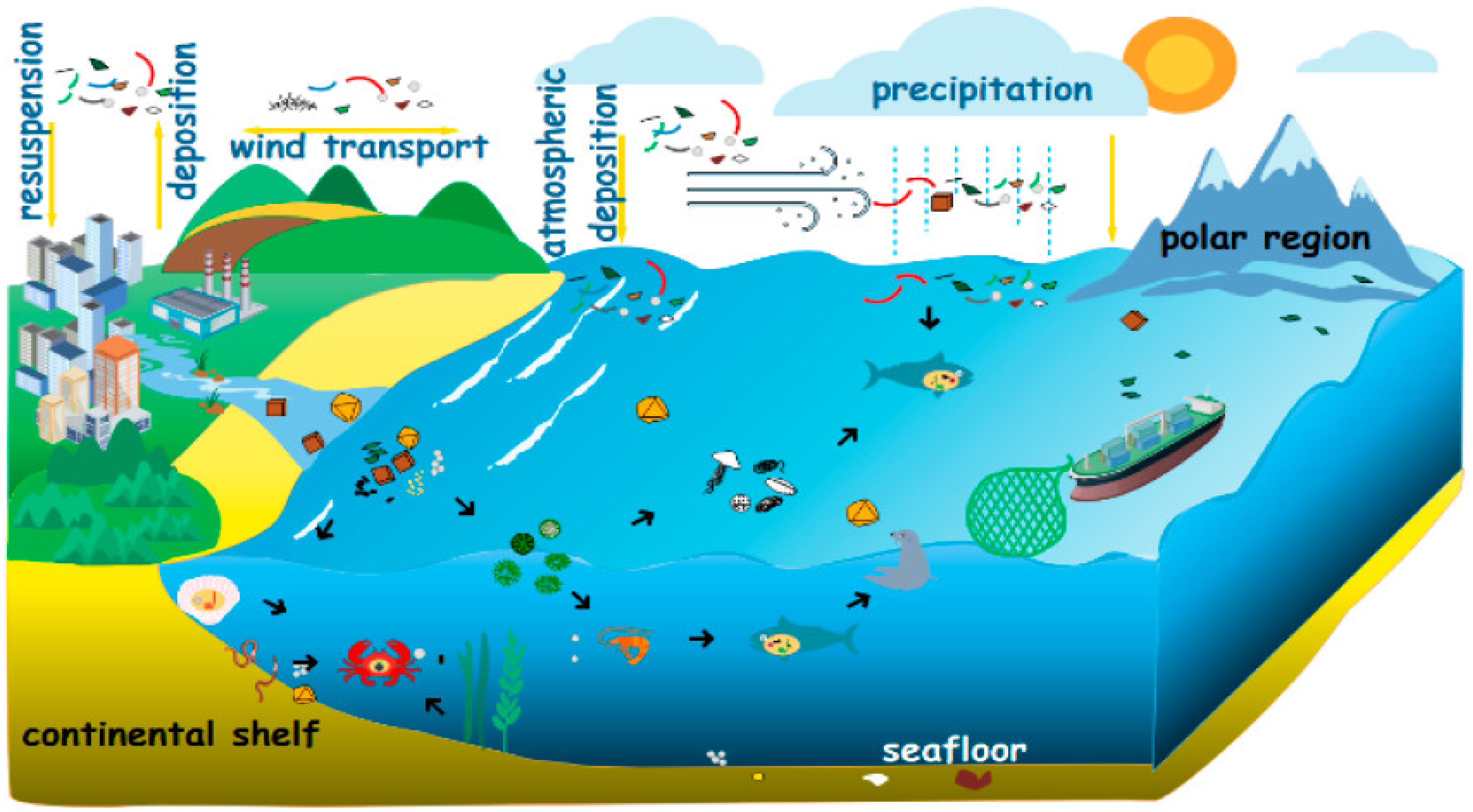

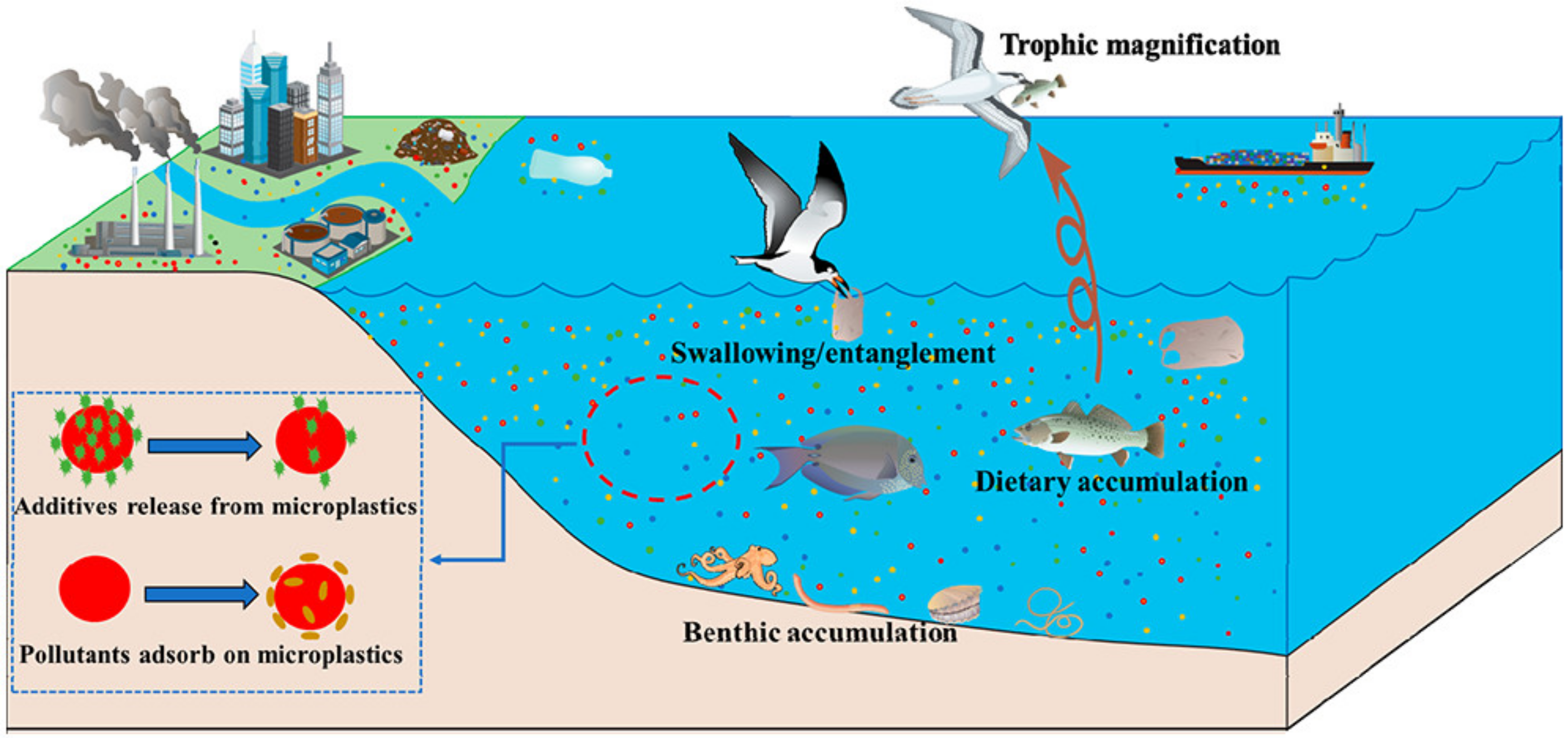

2. Activity of Microplastics in the Environment

2.1. Activities of Microplastics in Soil

2.2. Activities of Microplastics in Water

3. Classification of Microplastics

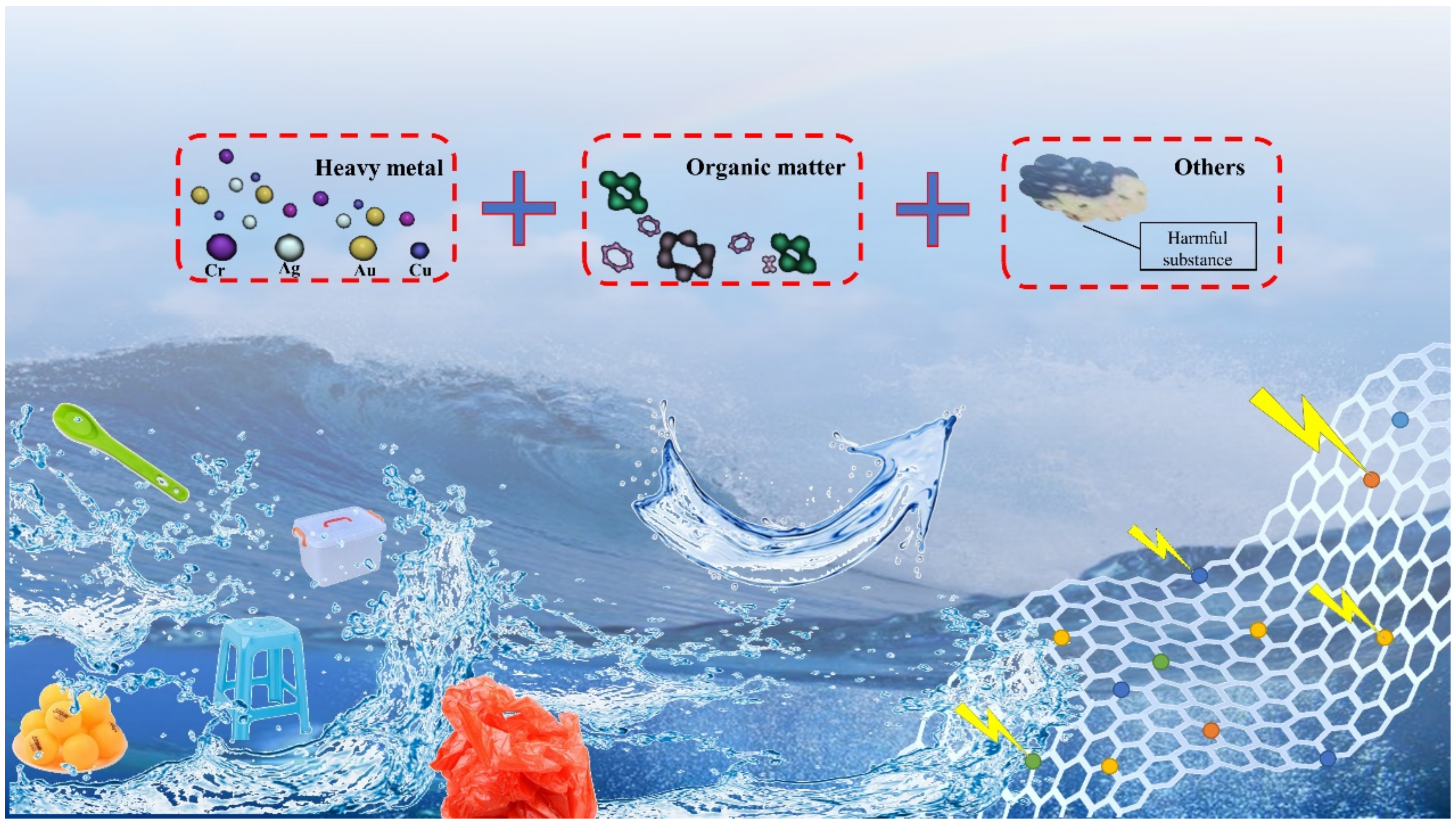

4. Classification of Pollutants

5. Factors Affecting the Adsorption of Microplastics

5.1. Effect of pH

5.2. Effects of Particle Size

5.3. Effects of Temperature

5.4. Effects of Salinity

5.5. Effects of Functional Groups

5.6. Effects of Ionic Strength

5.7. Effects of Surfactants

5.8. Effects of Solubility, Concentration and Dosage

5.9. Effects of Adsorption Selectivity

| Adsorbent | Size Range | Pollutants | Influencing Factors | Reference |

|---|---|---|---|---|

| plastic cellulose acetate | --- | 2,4-diallyl (sorbic acid) | pH | [51] |

| PE, PS, PVC | --- | PFOS, FOSA | pH | [52] |

| polymer resin | --- | phenol | pH | [53] |

| polylipoic acid ester-base coagulant | 0.40–0.56 and 0.15–0.30 mm | organic pollutants (pops) | temperature, pH | [55] |

| HDPE, PS, LDPE, PVC, SSA | --- | the Philippines, Nitrobenzene and naphthalene | particle size, crystallinity, | [67] |

| anion exchange resin | --- | phenol | amino | [76] |

| glass fiber reinforced plastic | --- | polyacrylic acid | tert-butyl ester groups | [77] |

| porous polycarboxarene | --- | organic micropollutants | π | [79] |

| the original rusty water microplastic | 0.2 mm | ions, organic pollutants | the surfactant | [84] |

| polyethylene, neoprene, polyvinyl chloride and polyurethane foam | 12 mm | chlorinated methane | chlorinated methane solubility, concentration | [85] |

| functionalized polystyrene nano ball | --- | 2,4,6-trinitrotoluene (TNT) | the dosage of KH-570 | [87] |

| acrylate polymer YWB-7 resin | 0.4–0.6 mm | 5–2 sulfo sodium isophthalic acid | methanol content | [88] |

| micro polyvinyl chloride (PVC) plastic | 80–210 μm | Fe and single hydroxyl derivatives | adsorbent dosage | [90] |

| PA, PVC, PET | --- | sulfanilamide | UV-irradiation, temperature | [93] |

| polyethylene and polyvinyl chloride (PVC) plastic | 1–5, 0.425–1, 0.125–0.425 and 0.045–0.125 mm | san zhang butyl ester phosphate and phosphate (2-ethyl chloride) | particle size | [94] |

| polystyrene | 80.4 ± 7.9 nm | organic pollutants (pops) | the concentration of | [95] |

| biological membrane reinforced plastic microfiber | 2–3 mm | perfluorinated octane sulfonic acid (PFOS) | aging | [96] |

| PE, PS, PA, and PVC | 152.53 ± 57.92, 168.55 ± 57.50, 109.44 ± 44.53, and 57.64 ± 26.50 μm | nonpolar organic compounds | adsorbent performance | [97] |

| PS and PP | 3.5 mm in length +2.2 mm wide and 3–5 mm | fuel aromatics and ether | aging | [98] |

| polystyrene | 29 μm | nonionic organic compounds | functional groups | [99] |

| Adsorbent | Surface Area | Pollutants | Influencing Factors | Reference |

|---|---|---|---|---|

| polystyrene (MPS) | --- | nanometer oxide (CeNPs) | heavy metals (HM) | [46] |

| iminodiacetic acid chelating resin | 0.40–0.56 and 0.15–0.30 mm | Sc(III), Y(III), La(III), Fe(III), Al(III), Ga(III), In(III) | pH | [55] |

| modification of polyethyleneimine | 0.15 and 0.075 mm | Cr(III), Fe(III) | pH, adsorbent dosage, temperature | [56] |

| polyethylimine | --- | Pb and Hg | the aperture | [57] |

| polystyrene nanofibers | --- | Cd, Ni | pH, adsorbent dosage | [58] |

| polyacrylonitrile-2-amino thiazole resin | 25.9 nm | Hg, Cd, Pb, Cu, Zn, and Ni | pH | [59] |

| acrylic acid grafted polytetrafluoroethylene fibers | --- | Er(III) | pH, temperature, initial metal ion concentration | [60] |

| IRN77 cation exchange resin | <0.300 mm, >1.180 mm | Co(II), Cr(III), Ni(II) | dosage, pH, stirring time, and initial concentration | [61] |

| polyacrylonitrile-2-amino-2-thiazole moiety resin | --- | precious metal ions | temperature, pH | [62] |

| amines and sulfur chelating resin | --- | Zn (II), Cd (II), Hg (II) | pH | [63] |

| polyacrylonitrile-amino thiourea resin | 25.1 nm | Rh(III), Ru(IV), Pd(II), Ir(IV) | pH, functional groups | [64] |

| methyl glycidyl ester of acrylic resin | 0.07, 0.15 and 0.06 μm | Cu(II), Pb(II) | pH | [65] |

| cationic polystyrene balls | --- | paper anion pollutants in water | temperature, distributed control system | [68] |

| crosslinked polystyrene diethanolamine load DiDai type of dendritic polymers | --- | metal ions | temperature, content of functional groups | [69] |

| grafted polytetrafluoroethylene fibers | --- | Cu(II) | temperature | [70] |

| coal and polyvinyl chloride (PVC) scrap | 150–200 μm | Hg | temperature | [78] |

| porous cellulose modified polyethylene imine carrier | --- | Hg | the adsorption selectivity | [80] |

| IRN-77 cation exchange resin | <0.300 mm, >1.180 mm | Co(II), Ni(II), Cr(III) | adsorbent dosage | [89] |

| 3-aminopyridine hydrophilic spacer chelating resin | --- | Hg(II), Ag(I), Fe(III), Pb(II), Co(II), Cu(II), Ni(II), Cd(II) | the adsorption capacity | [91] |

| IRC748 and NDC702 | 36.85 and 34.53 nm | Cu(II), Pb(II), Cd(II) | pH | [100] |

| new IDA-chelating resin | --- | Cu(II), Pb(II), Cd(II) | pH | [101] |

| D152 resin | 10.3 nm | Cd(II) | pH, temperature | [102] |

| polyacrylic acid-PVC composite adsorbent | --- | cadmium pollution of wastewater | pH | [103] |

| PS | --- | Cr(VI) | aging | [104] |

| doped polyaniline | --- | anionic dye | doping | [105] |

| “X” shape of the cavity 2 d coordination polymer | --- | oxygen anion pollutants | the adsorption selectivity | [106] |

| phytic acid doped polyaniline nanofibers | 80–100 nm | water-borne Cu(II) | pH | [107] |

| new type of sulfur-containing polyamine chelating resin | --- | precious metal | The solvent, temperature, and time | [108] |

| electrospinning fiber membrane | --- | heavy metal | porosity, specific surface area | [109] |

| amination polyacrylonitrile fiber | --- | Pb, Cu | pH | [110] |

| Adsorbent | Surface Area | Pollutants | Influencing Factors | Reference |

|---|---|---|---|---|

| porous super hydrophobic foam plastic | --- | oily wastewater | a small amount of span 80 and silica particles | [83] |

| carbonized polypropylene | --- | oil | NiO catalyst diameter | [111] |

| weak base anion exchange resin | --- | benzene sulfonate | pH | [112] |

| polystyrene matrix | --- | protein fiber connection | the concentration of | [113] |

| polystyrene | --- | thrombin | cone methyl sulfonate and sulfanilamide essence | [114] |

| La(OH)3@SA/PAM | --- | methylene blue, crystal violet, and malachite green | ultraviolet light | [115] |

| metal ions impregnated polystyrene resin | --- | antibiotics in water pollutants | pH | [116] |

| grafted polyethylene imine melamine formaldehyde | --- | CO2 | temperature | [117] |

| polyvinyl chloride (PVC)/polystyrene fiber electrostatic spinning | 70–300 μm | oil pollution | porosity | [118] |

| polyvinyl chloride (PVC) mesoporous membrane | 45 nm | methylene blue | porosity | [119] |

| 2-amino modified Chloromethylated polystyrene and GQ-08 resin | 9.93 and 8.99 nm | glyphosate | pH | [120] |

| PTFE membrane | 0.1 μm | crude oil | crude oil initial concentration, contact time, pH, ionic strength, temperature | [121] |

| polymer nanocomposites | --- | harmful pollutants in the water or wastewater | pH | [122] |

| low poly beta cyclodextrin coupling polystyrene | --- | puerarin | solubility | [123] |

6. Adsorption Mechanism

6.1. Adsorption Affinity

6.2. Chemical Bonds

6.3. Ion Exchange

6.4. Hydrophobic Interaction

6.5. Role of the Environment

6.6. Electrostatic Interaction

6.7. Other Adsorption Mechanisms

7. Conclusions

7.1. Summary

7.2. Prospect

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, S.; Huang, J.; Zhang, W.; Shi, L.; Yi, K.; Yu, H.; Zhang, C.; Li, S.; Li, J. Microplastics as a vehicle of heavy metals in aquatic environments: A review of adsorption factors, mechanisms, and biological effects. J. Environ. Manag. 2022, 302, 113995. [Google Scholar] [CrossRef] [PubMed]

- Costigan, E.; Collins, A.; Hatinoglu, M.D.; Bhagat, K.; Macrae, J.; Perreault, F.; Apul, O. Adsorption of Organic Pollutants by Microplastics: Overview of A Dissonant Literature. J. Hazard. Mater. Adv. 2022, 6, 100091. [Google Scholar] [CrossRef]

- Cole, M.; Lindeque, P.; Halsband, C.; Galloway, T.S. Microplastics as contaminants in the marine environment: A review. Mar. Pollut. Bull. 2011, 62, 2588–2597. [Google Scholar] [CrossRef]

- Kilavuz, S.; Kor, D.; Bulut, F.; Serbes, M.; Karagoz, D.; Altıntaş, D.; Bişgin, A.; Şeydaoğlu, G.; Mungan, H.Ö. Real-world patient data on immunity and COVID-19 status of patients with MPS, Gaucher, and Pompe diseases from Turkey. Arch. Pediatr. 2022; In press. [Google Scholar] [CrossRef]

- Frias, J.; Sobral, P.; Ferreira, A.M. Organic pollutants in microplastics from two beaches of the Portuguese coast. Mar. Pollut. Bull. 2010, 60, 1988–1992. [Google Scholar] [CrossRef] [PubMed]

- Prata, J.C. Microplastics in wastewater: State of the knowledge on sources, fate and solutions. Mar. Pollut. Bull. 2018, 129, 262–265. [Google Scholar] [CrossRef]

- Migwi, F.K.; Ogunah, J.A.; Kiratu, J.M. Occurrence and spatial distribution of microplastics in the surface waters of Lake Naivasha, Kenya. Environ. Toxicol. Chem. 2020, 39, 765–774. [Google Scholar] [CrossRef]

- Ma, J.; Chen, F.; Zhu, Y.; Li, X.; Yu, H.; Sun, Y. Joint effects of microplastics and ciprofloxacin on their toxicity and fates in wheat: A hydroponic study. Chemosphere 2022, 135023. [Google Scholar] [CrossRef]

- Yang, H.; He, Y.; Yan, Y.; Junaid, M.; Wang, J. Characteristics, Toxic Effects, and Analytical Methods of Microplastics in the Atmosphere. Nanomaterials 2021, 11, 2747. [Google Scholar] [CrossRef]

- Lai, H.; Liu, X.; Qu, M. Nanoplastics and Human Health: Hazard Identification and Biointerface. Nanomaterials 2022, 12, 1298. [Google Scholar] [CrossRef]

- Oh, S.; Hur, H.; Kim, Y.; Shin, S.; Woo, H.; Choi, J.; Lee, H.H. Peptide Specific Nanoplastic Detection Based on Sandwich Typed Localized Surface Plasmon Resonance. Nanomaterials 2021, 11, 2887. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Peng, Y.; Deng, Y.; Ye, F.; Zhang, C.; Hu, X.; Liu, Y.; Zhang, D. Recycling and Reutilizing Polymer Waste via Electrospun Micro/Nanofibers: A Review. Nanomaterials 2022, 12, 1663. [Google Scholar] [CrossRef] [PubMed]

- Lionetto, F.; Lionetto, M.G.; Mele, C.; Corcione, C.E.; Bagheri, S.; Udayan, G.; Maffezzoli, A. Autofluorescence of Model Polyethylene Terephthalate Nanoplastics for Cell Interaction Studies. Nanomaterials 2022, 12, 1560. [Google Scholar] [CrossRef]

- Abramova, A.V.; Abramov, V.O.; Fedulov, I.S.; Baranchikov, A.E.; Kozlov, D.A.; Veselova, V.O.; Kameneva, S.V.; Ivanov, V.K.; Cravotto, G. Strong Antibacterial Properties of Cotton Fabrics Coated with Ceria Nanoparticles under High-Power Ultrasound. Nanomaterials 2021, 11, 2704. [Google Scholar] [CrossRef] [PubMed]

- Camacho, M.; Herrera, A.; Gómez, M.; Acosta-Dacal, A.; Martínez, I.; Henríquez-Hernández, L.A.; Luzardo, O.P. Organic pollutants in marine plastic debris from Canary Islands beaches. Sci. Total Environ. 2019, 662, 22–31. [Google Scholar] [CrossRef] [PubMed]

- Lionetto, F.; Esposito Corcione, C. An overview of the sorption studies of contaminants on poly (Ethylene Terephthalate) microplastics in the marine environment. J. Mar. Sci. Eng. 2021, 9, 445. [Google Scholar] [CrossRef]

- Sun, J.; Dai, X.; Wang, Q.; van Loosdrecht, M.C.; Ni, B.-J. Microplastics in wastewater treatment plants: Detection, occurrence and removal. Water Res. 2019, 152, 21–37. [Google Scholar] [CrossRef]

- Rodrigues, J.P.; Duarte, A.C.; Santos-Echeandía, J.; Rocha-Santos, T. Significance of interactions between microplastics and POPs in the marine environment: A critical overview. TrAC Trends Anal. Chem. 2019, 111, 252–260. [Google Scholar] [CrossRef]

- Fred-Ahmadu, O.H.; Bhagwat, G.; Oluyoye, I.; Benson, N.U.; Ayejuyo, O.O.; Palanisami, T. Interaction of chemical contaminants with microplastics: Principles and perspectives. Sci. Total Environ. 2020, 706, 135978. [Google Scholar] [CrossRef]

- Vockenberg, T.; Wichard, T.; Ueberschaar, N.; Franke, M.; Stelter, M.; Braeutigam, P. The sorption behaviour of amine micropollutants on polyethylene microplastics–impact of aging and interactions with green seaweed. Environ. Sci. Proc. Impacts 2020, 22, 1678–1687. [Google Scholar] [CrossRef]

- Guo, X.; Pang, J.; Chen, S.; Jia, H. Sorption properties of tylosin on four different microplastics. Chemosphere 2018, 209, 240–245. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Huang, G.; Li, M.; An, C. Will the chemical contaminants in agricultural soil affect the ecotoxicity of microplastics? ACS Agr. Sci. Tech. 2021, 1, 3–4. [Google Scholar] [CrossRef]

- Azeem, I.; Adeel, M.; Ahmad, M.A.; Shakoor, N.; Jiangcuo, G.D.; Azeem, K.; Ishfaq, M.; Shakoor, A.; Ayaz, M.; Xu, M.; et al. Uptake and Accumulation of Nano/Microplastics in Plants: A Critical Review. Nanomaterials 2021, 11, 2935. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Wang, X.; Wang, X.; Cheng, T.; Fu, K.; Qin, Z.; Feng, K. Biofilm Structural and Functional Features on Microplastic Surfaces in Greenhouse Agricultural Soil. Sustainability 2022, 14, 7024. [Google Scholar] [CrossRef]

- Liu, K.; Wu, T.; Wang, X.; Song, Z.; Zong, C.; Wei, N.; Li, D. Consistent transport of terrestrial microplastics to the ocean through atmosphere. Environ. Sci. Technol. 2019, 53, 10612–10619. [Google Scholar] [CrossRef]

- Mai, L.; Sun, X.-F.; Xia, L.-L.; Bao, L.-J.; Liu, L.-Y.; Zeng, E.Y. Global riverine plastic outflows. Environ. Sci. Technol. 2020, 54, 10049–10056. [Google Scholar] [CrossRef]

- Hamidian, A.H.; Ozumchelouei, E.J.; Feizi, F.; Wu, C.; Zhang, Y.; Yang, M. A review on the characteristics of microplastics in wastewater treatment plants: A source for toxic chemicals. J. Clean. Prod. 2021, 295, 126480. [Google Scholar] [CrossRef]

- Murphy, F.; Ewins, C.; Carbonnier, F.; Quinn, B. Wastewater treatment works (WwTW) as a source of microplastics in the aquatic environment. Environ. Sci. Technol. 2016, 50, 5800–5808. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Wang, B.; Duan, L.; Zhang, Y.; Zhou, Y.; Sui, Q.; Xu, D.; Qu, H.; Yu, G. Occurrence and distribution of microplastics in domestic, industrial, agricultural and aquacultural wastewater sources: A case study in Changzhou, China. Water Res. 2020, 182, 115956. [Google Scholar] [CrossRef]

- Chen, C.; Chen, L.; Yao, Y.; Artigas, F.; Huang, Q.; Zhang, W. Organotin release from polyvinyl chloride microplastics and concurrent photodegradation in water: Impacts from salinity, dissolved organic matter, and light exposure. Environ. Sci. Technol. 2019, 53, 10741–10752. [Google Scholar] [CrossRef]

- Du, S.; Zhu, R.; Cai, Y.; Xu, N.; Yap, P.-S.; Zhang, Y.; He, Y.; Zhang, Y. Environmental fate and impacts of microplastics in aquatic ecosystems: A review. RSC Adv. 2021, 11, 15762–15784. [Google Scholar] [CrossRef] [PubMed]

- Qiu, X.; Saovany, S.; Takai, Y.; Akasaka, A.; Inoue, Y.; Yakata, N.; Liu, Y.; Waseda, M.; Shimasaki, Y.; Oshima, Y. Quantifying the vector effects of polyethylene microplastics on the accumulation of anthracene to Japanese medaka (Oryzias latipes). Aquat. Toxicol. 2020, 228, 105643. [Google Scholar] [CrossRef] [PubMed]

- Brennecke, D.; Duarte, B.; Paiva, F.; Caçador, I.; Canning-Clode, J. Microplastics as vector for heavy metal contamination from the marine environment. Estuar. Coast. Shelf Sci. 2016, 178, 189–195. [Google Scholar] [CrossRef]

- Bakir, A.; Rowland, S.J.; Thompson, R.C. Competitive sorption of persistent organic pollutants onto microplastics in the marine environment. Mar. Pollut. Bull. 2012, 64, 2782–2789. [Google Scholar] [CrossRef] [PubMed]

- Qu, H.; Ma, R.; Wang, B.; Zhang, Y.; Yin, L.; Yu, G.; Deng, S.; Huang, J.; Wang, Y. Effects of microplastics on the uptake, distribution and biotransformation of chiral antidepressant venlafaxine in aquatic ecosystem. J. Hazard. Mater. 2018, 359, 104–112. [Google Scholar] [CrossRef]

- Zhang, H.; Pap, S.; Taggart, M.A.; Boyd, K.G.; James, N.A.; Gibb, S.W. A review of the potential utilisation of plastic waste as adsorbent for removal of hazardous priority contaminants from aqueous environments. Environ. Pollut. 2020, 258, 113698. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Liu, Y.; Chen, Y.; Zhang, W.; Zhao, J.; He, S.; Yang, C.; Zhang, T.; Tang, C.; Zhang, C. A review: Research progress on microplastic pollutants in aquatic environments. Sci. Total Environ. 2021, 766, 142572. [Google Scholar] [CrossRef]

- Hou, L.; Kumar, D.; Yoo, C.G.; Gitsov, I.; Majumder, E.L.-W. Conversion and removal strategies for microplastics in wastewater treatment plants and landfills. Chem. Eng. J. 2021, 406, 126715. [Google Scholar] [CrossRef]

- Yang, Z.; Li, S.; Ma, S.; Liu, P.; Peng, D.; Ouyang, Z.; Guo, X. Characteristics and removal efficiency of microplastics in sewage treatment plant of Xi’an City, northwest China. Sci. Total Environ. 2021, 771, 145377. [Google Scholar] [CrossRef]

- Wang, F.; Wong, C.S.; Chen, D.; Lu, X.; Wang, F.; Zeng, E.Y. Interaction of toxic chemicals with microplastics: A critical review. Water Res. 2018, 139, 208–219. [Google Scholar] [CrossRef]

- Burns, E.E.; Boxall, A.B. Microplastics in the aquatic environment: Evidence for or against adverse impacts and major knowledge gaps. Environ. Toxicol. Chem. 2018, 37, 2776–2796. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McCormick, A.R.; Hoellein, T.J.; London, M.G.; Hittie, J.; Scott, J.W.; Kelly, J.J. Microplastic in surface waters of urban rivers: Concentration, sources, and associated bacterial assemblages. Ecosphere 2016, 7, e01556. [Google Scholar] [CrossRef]

- Godoy, V.; Martín-Lara, M.; Calero, M.; Blázquez, G. The relevance of interaction of chemicals/pollutants and microplastic samples as route for transporting contaminants. Process Saf. Environ. Prot. 2020, 138, 312–323. [Google Scholar] [CrossRef]

- Ricardo, I.A.; Alberto, E.A.; Júnior, A.H.S.; Macuvele, D.L.P.; Padoin, N.; Soares, C.; Riella, H.G.; Starling, M.C.V.; Trovo, A.G. A critical review on microplastics, interaction with organic and inorganic pollutants, impacts and effectiveness of advanced oxidation processes applied for their removal from aqueous matrices. Chem. Eng. J. 2021, 424, 130282. [Google Scholar] [CrossRef]

- Gao, X.; Hassan, I.; Peng, Y.; Huo, S.; Ling, L. Behaviors and influencing factors of the heavy metals adsorption onto microplastics: A review. J. Clean. Prod. 2021, 319, 128777. [Google Scholar] [CrossRef]

- Ho, W.-K.; Leung, K.S.-Y. The crucial role of heavy metals on the interaction of engineered nanoparticles with polystyrene microplastics. Water Res. 2021, 201, 117317. [Google Scholar] [CrossRef]

- Binda, G.; Spanu, D.; Monticelli, D.; Pozzi, A.; Bellasi, A.; Bettinetti, R.; Carnati, S.; Nizzetto, L. Unfolding the interaction between microplastics and (trace) elements in water: A critical review. Water Res. 2021, 204, 117637. [Google Scholar] [CrossRef]

- Li, X.; Jiang, X.; Song, Y.; Chang, S.X. Coexistence of polyethylene microplastics and biochar increases ammonium sorption in an aqueous solution. J. Hazard. Mater. 2021, 405, 124260. [Google Scholar] [CrossRef]

- Yu, F.; Yang, C.; Zhu, Z.; Bai, X.; Ma, J. Adsorption behavior of organic pollutants and metals on micro/nanoplastics in the aquatic environment. Sci. Total Environ. 2019, 694, 133643. [Google Scholar] [CrossRef]

- Fang, S.; Yu, W.; Li, C.; Liu, Y.; Qiu, J.; Kong, F. Adsorption behavior of three triazole fungicides on polystyrene microplastics. Sci. Total Environ. 2019, 691, 1119–1126. [Google Scholar] [CrossRef]

- Saski, W. Adsorption of sorbic acid by plastic cellulose acetates. J. Pharm. Sci. 1963, 52, 264–268. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Shih, K.M.; Li, X.Y. The partition behavior of perfluorooctanesulfonate (PFOS) and perfluorooctanesulfonamide (FOSA) on microplastics. Chemosphere 2015, 119, 841–847. [Google Scholar] [CrossRef] [PubMed]

- Caetano, M.; Valderrama, C.; Farran, A.; Cortina, J.L. Phenol removal from aqueous solution by adsorption and ion exchange mechanisms onto polymeric resins. J. Colloid Interface Sci. 2009, 338, 402–409. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Chakraborty, P.; Ghosh, R.; Paul, S.; Mondal, S.; Panja, A.; Nandi, A.K. Folic acid-polyaniline hybrid hydrogel for adsorption/reduction of chromium(VI) and selective adsorption of anionic dye from water. ACS Sustain. Chem. Eng. 2017, 5, 9325–9337. [Google Scholar] [CrossRef]

- Yuchi, A.; Sato, T.; Morimoto, Y.; Mizuno, H.; Wada, H. Adsorption mechanism of trivalent metal ions on chelating resins containing iminodiacetic acid groups with reference to selectivity. Anal. Chem. 1997, 69, 2941–2944. [Google Scholar] [CrossRef]

- He, Z.; Song, H.; Cui, Y.; Zhu, W.; Du, K.; Yao, S. Porous spherical cellulose carrier modified with polyethyleneimine and its adsorption for Cr(III) and Fe(III) from aqueous solutions. Chin. J. Chem. Eng. 2014, 22, 984–990. [Google Scholar] [CrossRef]

- Delacour, M.L.; Gailliez, E.; Bacquet, M.; Morcellet, M. Poly (ethylenimine) coated onto silica gels: Adsorption capacity toward lead and mercury. J. Appl. Polym. Sci. 1999, 73, 899–906. [Google Scholar] [CrossRef]

- Bahramzadeh, A.; Zahedi, P.; Abdouss, M. Acrylamide-plasma treated electrospun polystyrene nanofibrous adsorbents for cadmium and nickel ions removal from aqueous solutions. J. Appl. Polym. Sci. 2016, 133, 42944. [Google Scholar] [CrossRef]

- Xiong, C.; Jia, Q.; Chen, X.; Wang, G.; Yao, C. Optimization of polyacrylonitrile-2-aminothiazole resin synthesis, characterization, and its adsorption performance and mechanism for removal of Hg(II) from aqueous solutions. Ind. Eng. Chem. Res. 2013, 52, 4978–4986. [Google Scholar] [CrossRef]

- Xiong, C.; Yao, C. Preparation and application of acrylic acid grafted polytetrafluoroethylene fiber as a weak acid cation exchanger for adsorption of Er(III). J. Hazard. Mater. 2009, 170, 1125–1132. [Google Scholar] [CrossRef]

- Rengaraj, S.; Yeon, K.-H.; Kang, S.-Y.; Lee, J.-U.; Kim, K.-W.; Moon, S.-H. Studies on adsorptive removal of Co(II), Cr(III) and Ni(II) by IRN77 cation-exchange resin. J. Hazard. Mater. 2002, 92, 185–198. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, Y. Synthesis and characterization of polyacrylonitrile-2-amino-2-thiazoline resin and its sorption behaviors for noble metal ions. React. Funct. Polym. 2003, 55, 89–98. [Google Scholar] [CrossRef]

- Atia, A.A.; Donia, A.M.; Yousif, A.M. Synthesis of amine and thio chelating resins and study of their interaction with zinc(II), cadmium(II) and mercury(II) ions in their aqueous solutions. React. Funct. Polym. 2003, 56, 75–82. [Google Scholar] [CrossRef]

- Chen, Y.-Y.; Liang, C.; Chao, Y. Synthesis and characterization of polyacrylonitrile-thiosemicarbazide resin and its sorption behavior for Rh(III) Ru(IV) Pd(II) and Ir(IV) ions. React. Funct. Polym. 1998, 36, 51–58. [Google Scholar] [CrossRef]

- Atia, A.A.; Donia, A.M.; Abou-El-Enein, S.A.; Yousif, A.M. Studies on uptake behaviour of copper(II) and lead(II) by amine chelating resins with different textural properties. Sep. Purif. Technol. 2003, 33, 295–301. [Google Scholar] [CrossRef]

- Singh, N.; Khandelwal, N.; Tiwari, E.; Naskar, N.; Lahiri, S.; Lützenkirchen, J.; Darbha, G.K. Interaction of metal oxide nanoparticles with microplastics: Impact of weathering under riverine conditions. Water Res. 2021, 189, 116622. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Liu, G. Sorption behaviors of phenanthrene, nitrobenzene, and naphthalene on mesoplastics and microplastics. Environ. Sci. Pollut. Res. Int. 2019, 26, 12563–12573. [Google Scholar] [CrossRef]

- Xiao, H.; He, B.; Qian, L.; Li, J. Cationic polystyrene spheres for removal of anionic contaminants in white water of papermaking. J. Appl. Polym. Sci. 2015, 132, 41379. [Google Scholar] [CrossRef]

- Sun, C.; Qu, R.; Ji, C.; Wang, C.; Sun, Y.; Yue, Z.; Cheng, G. Preparation and adsorption properties of crosslinked polystyrene-supported low-generation diethanolamine-typed dendrimer for metal ions. Talanta 2006, 70, 14–19. [Google Scholar] [CrossRef]

- Li, J.-H.; Miao, X.-X.; Chen, X.-Y.; Lu, L.; Yang, Y.; Fu, Y.-Q.; Xiong, C.-H. Application and characterization of grafted polytetrafluoroethylene fiber for enhanced adsorption of Cu(II) in aqueous solutions. J. Cent. South Univ. 2016, 23, 2513–2519. [Google Scholar] [CrossRef]

- Dong, Y.; Gao, M.; Song, Z.; Qiu, W. Adsorption mechanism of As(III) on polytetrafluoroethylene particles of different size. Environ. Pollut. 2019, 254, 112950. [Google Scholar] [CrossRef] [PubMed]

- Uwayid, R.; Guyes, E.N.; Shocron, A.N.; Gilron, J.; Elimelech, M.; Suss, M.E. Perfect divalent cation selectivity with capacitive deionization. Water Res. 2022, 210, 117959. [Google Scholar] [CrossRef] [PubMed]

- Zhong, L.-B.; Liu, Q.; Wu, P.; Niu, Q.; Zhang, H.; Zheng, Y. Facile on-site aqueous pollutant monitoring using a flexible, ultra-light and robust SERS substrate: Interface self-assembly of Au@Ag nanocubes on polyvinyl chloride template. Environ. Sci. Technol. 2018, 52, 5812–5820. Available online: https://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGHY201806002474.htm (accessed on 16 April 2018). [CrossRef] [PubMed]

- Liu, N.; Yu, F.; Wang, Y.; Ma, J. Effects of environmental aging on the adsorption behavior of antibiotics from aqueous solutions in microplastic-graphene coexisting systems. Sci. Total Environ. 2022, 806, 150956. [Google Scholar] [CrossRef] [PubMed]

- Duan, J.; Bolan, N.; Li, Y.; Ding, S.; Atugoda, T.; Vithanage, M.; Sarkar, B.; Tsang, D.C.; Kirkham, M. Weathering of microplastics and interaction with other coexisting constituents in terrestrial and aquatic environments. Water Res. 2021, 196, 117011. [Google Scholar] [CrossRef]

- Pollio, F.X.; Kunin, R. Sorption of phenols by anion-exchange resin. Environ. Sci. Technol. 1967, 1, 160–163. [Google Scholar] [CrossRef]

- Terabayashi, T.; Maruyama, T.; Shimizu, Y.; Komatsu, M.; Takahashi, T. Surface modification with acrylic polyampholytes 1, adsorption of acrylic polyampholytes on fiberglass reinforced plastics, and characterization of the polymer adsorbed surfaces. J. Appl. Polym. Sci. 2006, 101, 4454–4461. [Google Scholar] [CrossRef]

- Xu, Y.; Zeng, X.; Zhang, B.; Zhu, X.; Zhou, M.; Zou, R.; Sun, P.; Luo, G.; Yao, H. Experiment and kinetic study of elemental mercury adsorption over a novel chlorinated sorbent derived from coal and waste polyvinyl chloride. Energy Fuels 2016, 30, 10635–10642. [Google Scholar] [CrossRef]

- Shetty, D.; Jahovic, I.; Raya, J.; Asfari, Z.; Olsen, J.-C.; Trabolsi, A. Porous polycalix [4] arenes for fast and efficient removal of organic micropollutants from water. ACS Appl. Mater. Interfaces 2018, 10, 2976–2981. [Google Scholar] [CrossRef]

- Navarro, R.R.; Sumi, K.; Fujii, N.; Matsumura, M. Mercury removal from wastewater using porous cellulose carrier modified with polyethyleneimine. Water Res. 1996, 30, 2488–2494. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, M.; Zhang, L.; Wang, K.; Yu, X.; Zheng, Z.; Zheng, R. Sorption behaviors of phenanthrene on the microplastics identified in a mariculture farm in Xiangshan Bay, southeastern China. Sci. Total Environ. 2018, 628, 1617–1626. [Google Scholar] [CrossRef] [PubMed]

- Hai, N.; Liu, X.; Li, Y.; Kong, F.; Zhang, Y.; Fang, S. Effects of microplastics on the adsorption and bioavailability of three strobilurin fungicides. ACS Omega 2020, 5, 30679–30686. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.; Lin, W.; Jiang, J.; Jing, Z.; Hong, P.; Li, Y. Preparation of a porous superhydrophobic foam from waste plastic and its application for oil spill cleanup. RSC Adv. 2019, 9, 37759–37767. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; Zhou, J.-J.; Gong, Y.-Y.; Li, Z.-J.; Zeng, E.Y. Strong influence of surfactants on virgin hydrophobic microplastics adsorbing ionic organic pollutants. Environ. Pollut. 2020, 265, 115061. [Google Scholar] [CrossRef]

- Cook, F.C., Jr.; Hartz, K.E. Adsorption of chlorinated methanes from aqueous solution on selected plastic adsorbents. J. Am. Water Works Assoc. 1983, 75, 423–426. [Google Scholar] [CrossRef]

- Boucher, C.; Morin, M.; Bendell, L. The influence of cosmetic microbeads on the sorptive behavior of cadmium and lead within intertidal sediments: A laboratory study. Reg. Stud. Mar. Sci. 2016, 3, 1–7. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Lv, F.; Chu, P.K.; Ye, Z.; Zhou, F.; Zhang, R.; Wei, F. Adsorption behavior and mechanism of 2, 4, 6-trinitrotoluene by functionalized polystyrene nanospheres. J. Appl. Polym. Sci. 2013, 128, 3720–3725. [Google Scholar] [CrossRef]

- Yang, W.; Li, A.; Zhang, Q.; Fei, Z.; Liu, F. Adsorption of 5-sodiosulfoisophthalic acids from aqueous solutions onto acrylic ester polymer YWB-7 resin. Sep. Purif. Technol. 2005, 46, 161–167. [Google Scholar] [CrossRef]

- Kang, S.-Y.; Lee, J.-U.; Moon, S.-H.; Kim, K.-W. Competitive adsorption characteristics of Co2+, Ni2+, and Cr3+ by IRN-77 cation exchange resin in synthesized wastewater. Chemosphere 2004, 56, 141–147. [Google Scholar] [CrossRef]

- Bao, Z.-Z.; Chen, Z.-F.; Zhong, Y.; Wang, G.; Qi, Z.; Cai, Z. Adsorption of phenanthrene and its monohydroxy derivatives on polyvinyl chloride microplastics in aqueous solution: Model fitting and mechanism analysis. Sci. Total Environ. 2021, 764, 142889. [Google Scholar] [CrossRef]

- Ji, C.; Song, S.; Wang, C.; Sun, C.; Qu, R.; Wang, C.; Chen, H. Preparation and adsorption properties of chelating resins containing 3-aminopyridine and hydrophilic spacer arm for Hg(II). Chem. Eng. J. 2010, 165, 573–580. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, K.; Wang, L.; Yao, Y.; Sun, H. Strong but reversible sorption on polar microplastics enhanced earthworm bioaccumulation of associated organic compounds. J. Hazard. Mater. 2022, 423, 127079. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Li, Y.; Peng, L.; Gao, W.; Wang, G. Distinct Chemical Adsorption Behaviors of Sulfanilamide as a Model Antibiotic onto Weathered Microplastics in Complex Systems. Colloids Surf. A 2022, 129337. [Google Scholar] [CrossRef]

- Chen, S.; Tan, Z.; Qi, Y.; Ouyang, C. Sorption of tri-n-butyl phosphate and tris (2-chloroethyl) phosphate on polyethylene and polyvinyl chloride microplastics in seawater. Mar. Pollut. Bull. 2019, 149, 110490. [Google Scholar] [CrossRef]

- Liu, J.; Ma, Y.; Zhu, D.; Xia, T.; Qi, Y.; Yao, Y.; Guo, X.; Ji, R.; Chen, W. Polystyrene nanoplastics-enhanced contaminant transport: Role of irreversible adsorption in glassy polymeric domain. Environ. Sci. Technol. 2018, 52, 2677–2685. [Google Scholar] [CrossRef]

- Bhagwat, G.; Tran, T.K.A.; Lamb, D.; Senathirajah, K.; Grainge, I.; O’Connor, W.; Juhasz, A.; Palanisami, T. Biofilms Enhance the Adsorption of Toxic Contaminants on Plastic Microfibers under Environmentally Relevant Conditions. Environ. Sci. Technol. 2021, 55, 8877–8887. [Google Scholar] [CrossRef]

- Hüffer, T.; Hofmann, T. Sorption of non-polar organic compounds by micro-sized plastic particles in aqueous solution. Environ. Pollut. 2016, 214, 194–201. [Google Scholar] [CrossRef] [PubMed]

- Müller, A.; Becker, R.; Dorgerloh, U.; Simon, F.-G.; Braun, U. The effect of polymer aging on the uptake of fuel aromatics and ethers by microplastics. Environ. Pollut. 2018, 240, 639–646. [Google Scholar] [CrossRef]

- Uber, T.H.; Hüffer, T.; Planitz, S.; Schmidt, T.C. Sorption of non-ionic organic compounds by polystyrene in water. Sci. Total Environ. 2019, 682, 348–355. [Google Scholar] [CrossRef]

- Ling, P.; Liu, F.; Li, L.; Jing, X.; Yin, B.; Chen, K.; Li, A. Adsorption of divalent heavy metal ions onto IDA-chelating resins: Simulation of physicochemical structures and elucidation of interaction mechanisms. Talanta 2010, 81, 424–432. [Google Scholar] [CrossRef]

- Li, L.; Liu, F.; Jing, X.; Ling, P.; Li, A. Displacement mechanism of binary competitive adsorption for aqueous divalent metal ions onto a novel IDA-chelating resin: Isotherm and kinetic modeling. Water Res. 2011, 45, 1177–1188. [Google Scholar] [CrossRef] [PubMed]

- Xiong, C.; Yao, C. Study on the adsorption of cadmium(II) from aqueous solution by D152 resin. J. Hazard. Mater. 2009, 166, 815–820. [Google Scholar] [CrossRef] [PubMed]

- Park, S.W.; Bediako, J.K.; Song, M.-H.; Choi, J.-W.; Lee, H.-C.; Yun, Y.-S. Facile fabrication of polyacrylic acid-polyvinyl chloride composite adsorbents for the treatment of cadmium-contaminated wastewater. J. Environ. Eng. 2018, 6, 2401–2408. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Su, F.; Wang, Y.; Peng, L.; Liu, D. Adsorption behaviour of microplastics on the heavy metal Cr (VI) before and after ageing. Chemosphere 2022, 302, 134865. [Google Scholar] [CrossRef] [PubMed]

- Mahanta, D.; Madras, G.; Radhakrishnan, S.; Patil, S. Adsorption and Desorption Kinetics of Anionic Dyes on Doped Polyaniline. J. Phys. Chem. B 2009, 113, 2293–2299. [Google Scholar] [CrossRef] [PubMed]

- Nath, K.; Maity, K.; Biradha, K. Two-dimensional coordination polymers with “X”-Shaped cavities as adsorbents of oxoanion pollutants and toxic dyes. Cryst. Growth Des. 2017, 17, 4437–4444. [Google Scholar] [CrossRef]

- Kim, H.J.; Im, S.; Kim, J.C.; Hong, W.G.; Shin, K.; Jeong, H.Y.; Hong, Y.J. Phytic acid doped polyaniline nanofibers for enhanced aqueous copper(II) adsorption capability. ACS Sustain. Chem. Eng. 2017, 5, 6654–6664. [Google Scholar] [CrossRef]

- Qu, R.; Wang, C.; Ji, C.; Sun, C.; Sun, X.; Cheng, G. Preparation, characterization, and metal binding behavior of novel chelating resins containing sulfur and polyamine. J. Appl. Polym. Sci. 2005, 95, 1558–1565. [Google Scholar] [CrossRef]

- Huang, Y.; Miao, Y.E.; Liu, T. Electrospun fibrous membranes for efficient heavy metal removal. J. Appl. Polym. Sci. 2014, 131, 40864. [Google Scholar] [CrossRef]

- Deng, S.; Bai, R.; Chen, J.P. Aminated polyacrylonitrile fibers for lead and copper removal. Langmuir 2003, 19, 5058–5064. [Google Scholar] [CrossRef]

- Gong, J.; Liu, J.; Chen, X.; Jiang, Z.; Wen, X.; Mijowska, E.; Tang, T. Striking influence of NiO catalyst diameter on the carbonization of polypropylene into carbon nanomaterials and their high performance in the adsorption of oils. RSC Adv. 2014, 4, 33806–33814. [Google Scholar] [CrossRef]

- Hinrichs, R.; Snoeyink, V. Sorption of benzenesulfonates by weak base anion exchange resins. Water Res. 1976, 10, 79–87. [Google Scholar] [CrossRef]

- Lhoest, J.B.; Detrait, E.; Van Den Bosch De Aguilar, P.; Bertrand, P. Fibronectin adsorption, conformation, and orientation on polystyrene substrates studied by radiolabeling, XPS, and ToF SIMS. J. Biomed. Mater. Res. 1998, 41, 95–103. [Google Scholar] [CrossRef]

- Boisson, C.; Jozefonvicz, J.; Brash, J.L. Adsorption of thrombin from buffer and modified plasma to polystyrene resins containing sulphonate and sulphamide arginyl methyl ester groups. Biomaterials 1988, 9, 47–52. [Google Scholar] [CrossRef]

- Qian, D.; Bai, L.; Wang, Y.-S.; Song, F.; Wang, X.-L.; Wang, Y.-Z. A bifunctional alginate-based composite hydrogel with synergistic pollutant adsorption and photocatalytic degradation performance. Ind. Eng. Chem. Res. 2019, 58, 13133–13144. [Google Scholar] [CrossRef]

- Chao, Y.; Zhu, W.; Ye, Z.; Wu, P.; Wei, N.; Wu, X.; Li, H. Preparation of metal ions impregnated polystyrene resins for adsorption of antibiotics contaminants in aquatic environment. J. Appl. Polym. Sci. 2015, 132, 41803. [Google Scholar] [CrossRef]

- Yin, F.; Peng, P.; Mo, W.; Chen, S.; Xu, T. The preparation of a porous melamine–formaldehyde adsorbent grafted with polyethyleneimine and its CO2 adsorption behavior. New J. Chem. 2017, 41, 5297–5304. [Google Scholar] [CrossRef]

- Zhu, H.; Qiu, S.; Jiang, W.; Wu, D.; Zhang, C. Evaluation of electrospun polyvinyl chloride/polystyrene fibers as sorbent materials for oil spill cleanup. Environ. Sci. Technol. 2011, 45, 4527–4531. [Google Scholar] [CrossRef]

- Guo, N.N.; Zhang, Q.G.; Li, H.M.; Wu, X.M.; Liu, Q.L.; Zhu, A.M. Facile fabrication, structure, and applications of polyvinyl chloride mesoporous membranes. Ind. Eng. Chem. Res. 2014, 53, 20068–20073. [Google Scholar] [CrossRef]

- Xiao, G.; Wen, R. Comparative adsorption of glyphosate from aqueous solution by 2-aminopyridine modified polystyrene resin, D301 resin and 330 resin: Influencing factors, salinity resistance and mechanism. Fluid Phase Equilib. 2016, 411, 1–6. [Google Scholar] [CrossRef]

- Zhang, B.; Yu, S.; Zhu, Y.; Shen, Y.; Gao, X.; Shi, W.; Tay, J.H. Adsorption mechanisms of crude oil onto polytetrafluoroethylene membrane: Kinetics and isotherm, and strategies for adsorption fouling control. Sep. Purif. Technol. 2020, 235, 116212. [Google Scholar] [CrossRef]

- Soetaredjo, F.E.; Ismadji, S.; Foe, K.; Woworuntu, G.L. Removal of hazardous contaminants from water or wastewater using polymer nanocomposites materials. Nanotechnol. Sustain. Water Resour. 2018, 2, 103–139. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, H.; Tan, T.; Rahman, A.U. Thermodynamic and NMR investigations on the adsorption mechanism of puerarin with oligo-β-cyclodextrin-coupled polystyrene-based matrix. J. Chem. Technol. Biotechnol. 2009, 84, 611–617. [Google Scholar] [CrossRef]

- Torres, F.G.; Dioses-Salinas, D.C.; Pizarro-Ortega, C.I.; De-la-Torre, G.E. Sorption of chemical contaminants on degradable and non-degradable microplastics: Recent progress and research trends. Sci. Total Environ. 2021, 757, 143875. [Google Scholar] [CrossRef]

- Alimi, O.S.; Farner Budarz, J.; Hernandez, L.M.; Tufenkji, N. Microplastics and nanoplastics in aquatic environments: Aggregation, deposition, and enhanced contaminant transport. Environ. Sci. Technol. 2018, 52, 1704–1724. [Google Scholar] [CrossRef]

- Zhang, Y.; Goss, G.G. Potentiation of polycyclic aromatic hydrocarbon uptake in zebrafish embryos by nanoplastics. Environ. Sci. Nano 2020, 7, 1730–1741. [Google Scholar] [CrossRef]

- Lang, M.; Yu, X.; Liu, J.; Xia, T.; Wang, T.; Jia, H.; Guo, X. Fenton aging significantly affects the heavy metal adsorption capacity of polystyrene microplastics. Sci. Total Environ. 2020, 722, 137762. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, Z.; Li, W.; Chang, X.; Yang, J.; Yang, F. Microplastics in the sediment of lake Ulansuhai of Yellow river basin, China. Water Environ. Res. 2020, 92, 829–839. [Google Scholar] [CrossRef]

- Godoy, V.; Blázquez, G.; Calero, M.; Quesada, L.; Martín-Lara, M. The potential of microplastics as carriers of metals. Environ. Pollut. 2019, 255, 113363. [Google Scholar] [CrossRef]

- Abdurahman, A.; Cui, K.; Wu, J.; Li, S.; Gao, R.; Dai, J.; Liang, W.; Zeng, F. Adsorption of dissolved organic matter (DOM) on polystyrene microplastics in aquatic environments: Kinetic, isotherm and site energy distribution analysis. Ecotoxicol. Environ. Saf. 2020, 198, 110658. [Google Scholar] [CrossRef]

- Yu, H.; Yang, B.; Waigi, M.G.; Peng, F.; Hu, X. The effects of functional groups on the sorption of naphthalene on microplastics. Chemosphere 2020, 261, 127592. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Xiong, J.; Xiao, T.; Long, J.; Wang, Q.; Li, K.; Liu, X.; Zhang, G.; Zhang, H. Biochar derived from watermelon rinds as regenerable adsorbent for efficient removal of thallium(I) from wastewater. Process Saf. Environ. Prot. 2019, 127, 257–266. [Google Scholar] [CrossRef]

- Dong, Y.; Gao, M.; Qiu, W.; Song, Z. Adsorption of arsenite to polystyrene microplastics in the presence of humus. Environ. Sci. Proc. Impacts 2020, 22, 2388–2397. [Google Scholar] [CrossRef]

- Liu, P.; Lu, K.; Li, J.; Wu, X.; Qian, L.; Wang, M.; Gao, S. Effect of aging on adsorption behavior of polystyrene microplastics for pharmaceuticals: Adsorption mechanism and role of aging intermediates. J. Hazard. Mater. 2020, 384, 121193. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, M.; Huang, L.; Arulmani, S.R.B.; Yan, J.; Wu, L.; Wu, T.; Zhang, H.; Xiao, T. Adsorption of Different Pollutants by Using Microplastic with Different Influencing Factors and Mechanisms in Wastewater: A Review. Nanomaterials 2022, 12, 2256. https://doi.org/10.3390/nano12132256

Zhao M, Huang L, Arulmani SRB, Yan J, Wu L, Wu T, Zhang H, Xiao T. Adsorption of Different Pollutants by Using Microplastic with Different Influencing Factors and Mechanisms in Wastewater: A Review. Nanomaterials. 2022; 12(13):2256. https://doi.org/10.3390/nano12132256

Chicago/Turabian StyleZhao, Meng, Lei Huang, Samuel Raj Babu Arulmani, Jia Yan, Lirong Wu, Tao Wu, Hongguo Zhang, and Tangfu Xiao. 2022. "Adsorption of Different Pollutants by Using Microplastic with Different Influencing Factors and Mechanisms in Wastewater: A Review" Nanomaterials 12, no. 13: 2256. https://doi.org/10.3390/nano12132256

APA StyleZhao, M., Huang, L., Arulmani, S. R. B., Yan, J., Wu, L., Wu, T., Zhang, H., & Xiao, T. (2022). Adsorption of Different Pollutants by Using Microplastic with Different Influencing Factors and Mechanisms in Wastewater: A Review. Nanomaterials, 12(13), 2256. https://doi.org/10.3390/nano12132256