Deformation of Copper Nanowire under Coupled Tension–Torsion Loading

Abstract

1. Introduction

2. Methods

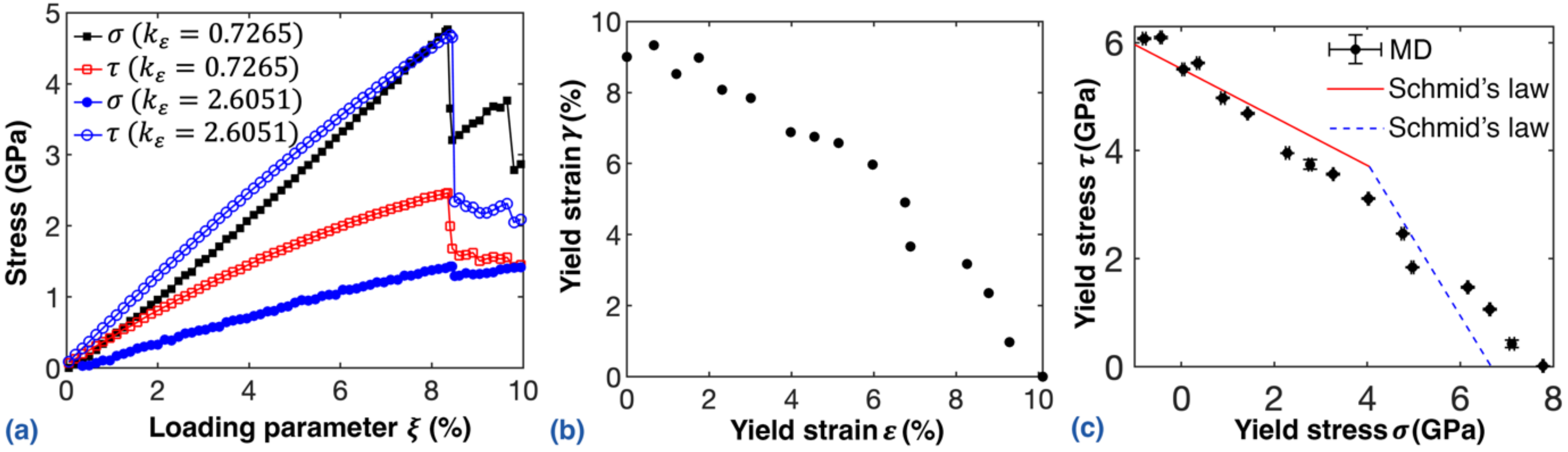

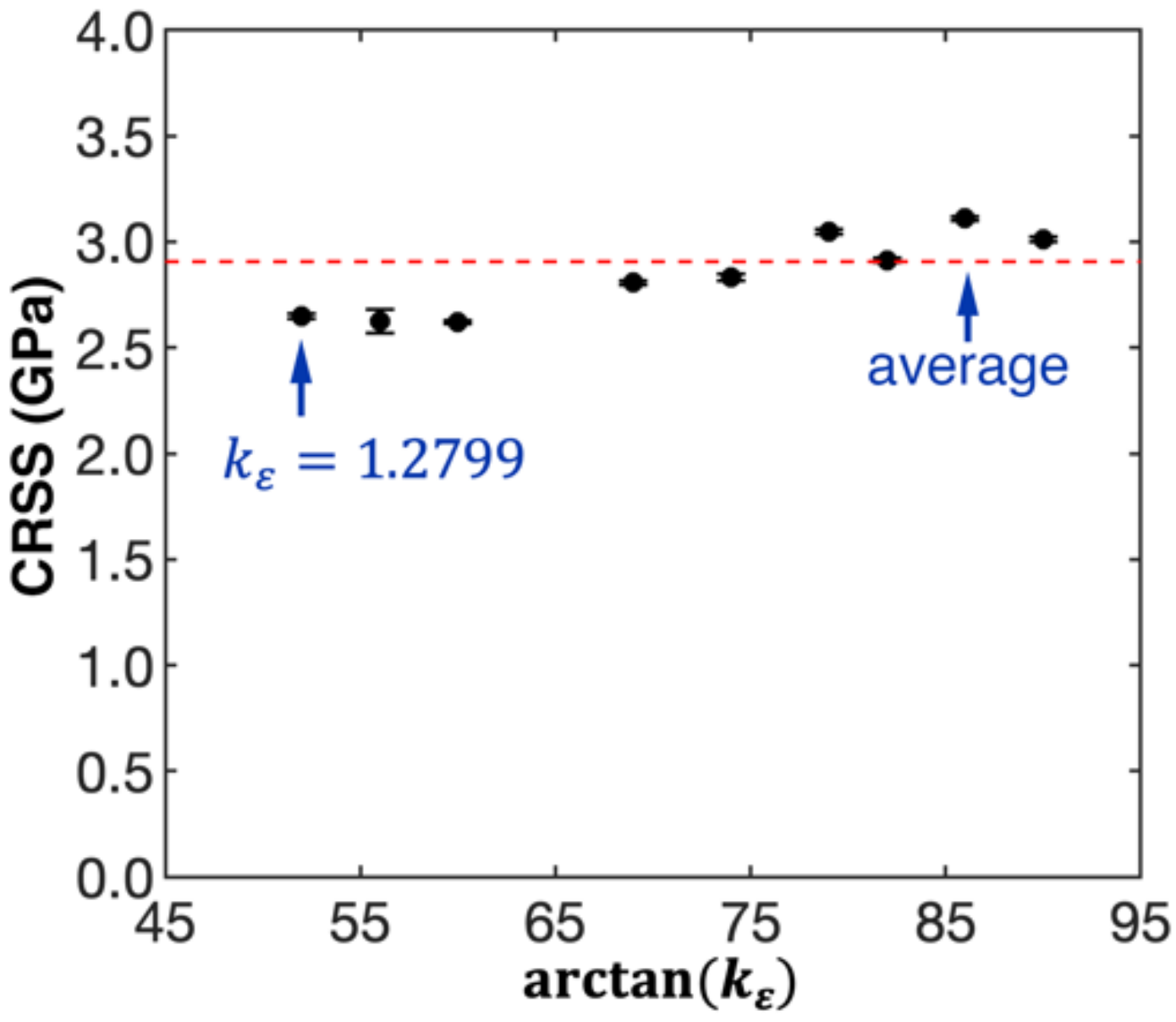

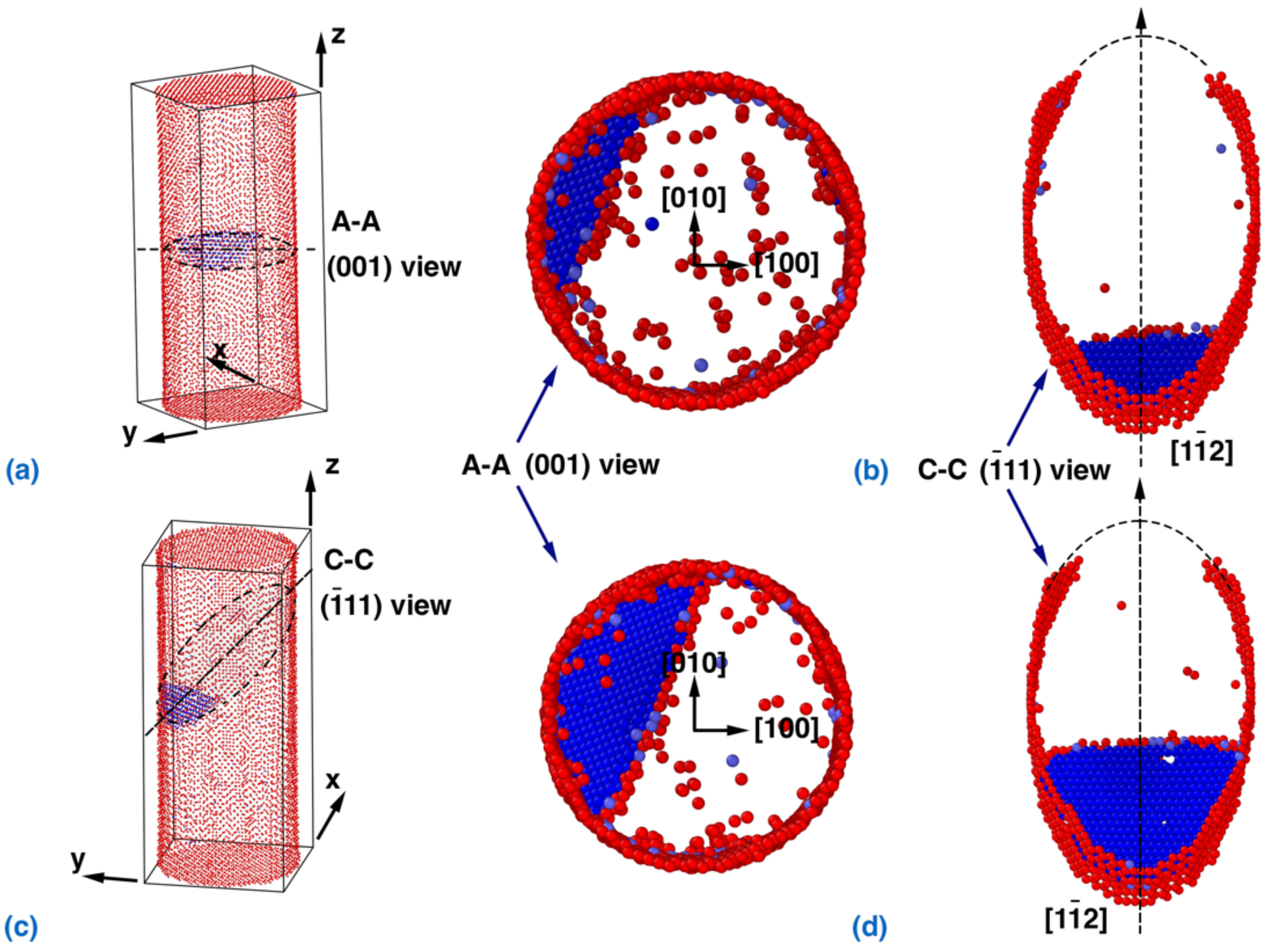

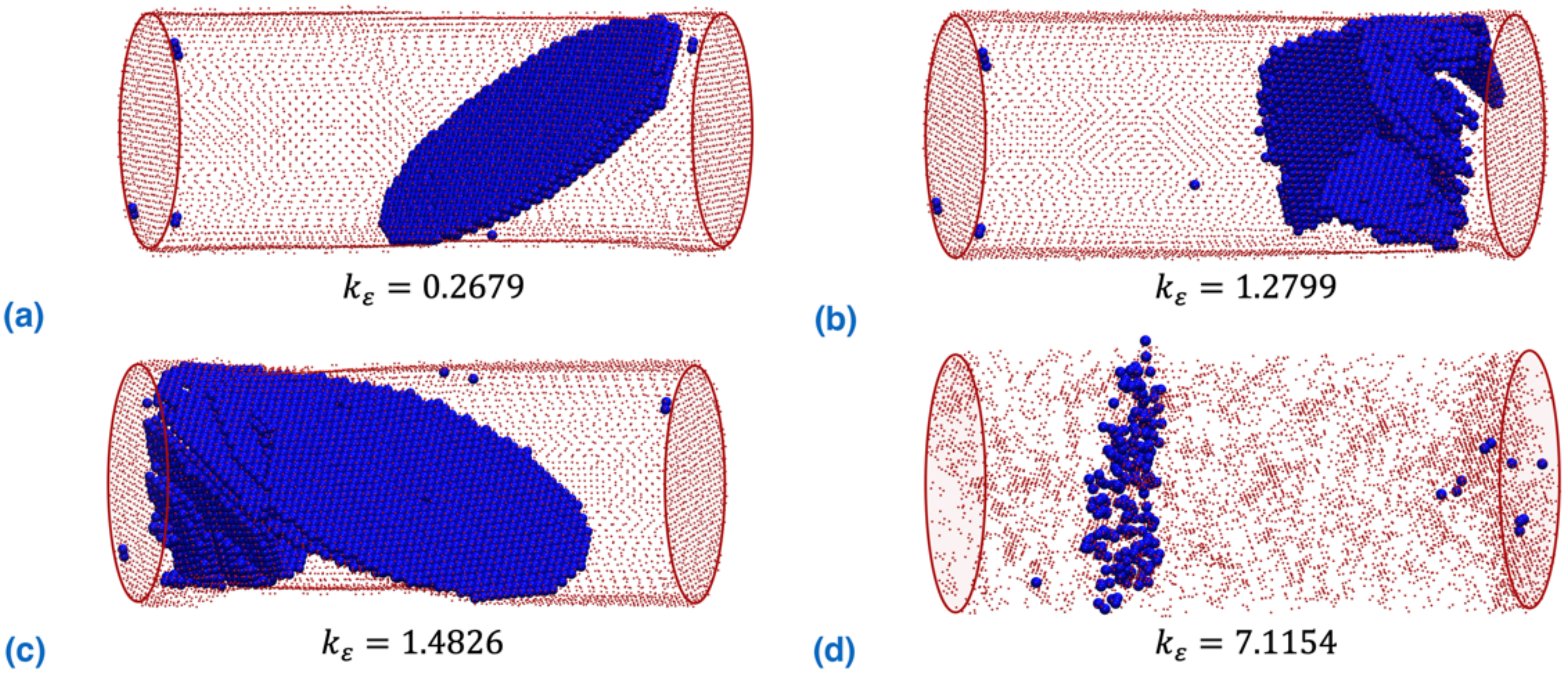

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, K.; Yap, L.W.; Gong, S.; Wang, R.; Wang, S.J.; Cheng, W. Nanowire-Based Soft Wearable Human–Machine Interfaces for Future Virtual and Augmented Reality Applications. Adv. Funct. Mater. 2021, 31, 2008347. [Google Scholar] [CrossRef]

- Khuje, S.; Sheng, A.; Yu, J.; Ren, S. Flexible Copper Nanowire Electronics for Wireless Dynamic Pressure Sensing. ACS Appl. Electron. Mater. 2021, 3, 5468–5474. [Google Scholar] [CrossRef]

- Patil, J.J.; Chae, W.H.; Trebach, A.; Carter, K.J.; Lee, E.; Sannicolo, T.; Grossman, J.C. Failing forward: Stability of transparent electrodes based on metal nanowire networks. Adv. Mater. 2021, 33, 2004356. [Google Scholar] [CrossRef] [PubMed]

- Zhang, A.; Lee, J.-H.; Lieber, C.M. Nanowire-enabled bioelectronics. Nano Today 2021, 38, 101135. [Google Scholar] [CrossRef]

- Huang, S.; Liu, Y.; Jafari, M.; Siaj, M.; Wang, H.; Xiao, S.; Ma, D. Highly Stable Ag–Au Core–Shell Nanowire Network for ITO-Free Flexible Organic Electrochromic Device. Adv. Funct. Mater. 2021, 31, 2010022. [Google Scholar] [CrossRef]

- Chen, Z.; Boyajian, N.; Lin, Z.; Yin, R.T.; Obaid, S.N.; Tian, J.; Brennan, J.A.; Chen, S.W.; Miniovich, A.N.; Lin, L. Flexible and transparent metal nanowire microelectrode arrays and interconnects for electrophysiology, optogenetics, and optical mapping. Adv. Mater. Technol. 2021, 6, 2100225. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, Y.; Zheng, Z. Metal-Based Flexible Transparent Electrodes: Challenges and Recent Advances. Adv. Electron. Mater. 2021, 7, 2001121. [Google Scholar] [CrossRef]

- Park, H.S.; Zimmerman, J.A. Modeling inelasticity and failure in gold nanowires. Phys. Rev. B 2005, 72, 54106. [Google Scholar] [CrossRef]

- Park, N.-Y.; Nam, H.-S.; Cha, P.-R.; Lee, S.-C. Size-dependent transition of the deformation behavior of Au nanowires. Nano Res. 2015, 8, 941–947. [Google Scholar] [CrossRef]

- Yu, Y.; Cui, F.; Sun, J.; Yang, P. Atomic Structure of Ultrathin Gold Nanowires. Nano Lett. 2016, 16, 3078–3084. [Google Scholar] [CrossRef]

- Zheng, Y.G.; Zhang, H.W.; Chen, Z.; Lu, C.; Mai, Y.W. Roles of grain boundary and dislocations at different deformation stages of nanocrystalline copper under tension. Phys. Lett. A 2009, 373, 570–574. [Google Scholar] [CrossRef]

- Zhan, H.F.; Gu, Y.T. Theoretical and numerical investigation of bending properties of Cu nanowires. Comput. Mater. Sci. 2012, 55, 73–80. [Google Scholar] [CrossRef][Green Version]

- Gall, K.; Diao, J.; Dunn, M.L.; Haftel, M.; Bernstein, N.; Mehl, M.J. Tetragonal Phase Transformation in Gold Nanowires. J. Eng. Mater. Technol. 2005, 127, 417. [Google Scholar] [CrossRef]

- Konuk, M.; Durukanoğlu, S. Strain-induced structural transformation of a silver nanowire. Nanotechnology 2012, 23, 245707. [Google Scholar] [CrossRef] [PubMed]

- Ji, C.; Park, H. Geometric effects on the inelastic deformation of metal nanowires. Appl. Phys. Lett. 2006, 89, 181916. [Google Scholar] [CrossRef]

- Liang, W.; Zhou, M. Atomistic simulations reveal shape memory of fcc metal nanowires. Phys. Rev. B 2006, 73, 115409. [Google Scholar] [CrossRef]

- Park, H.S.; Ji, C. On the thermomechanical deformation of silver shape memory nanowires. Acta Mater. 2006, 54, 2645–2654. [Google Scholar] [CrossRef]

- Yue, Y.; Chen, N.; Li, X.; Zhang, S.; Zhang, Z.; Chen, M.; Han, X. Crystalline Liquid and Rubber-Like Behavior in Cu Nanowires. Nano Lett. 2013, 13, 3812–3816. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, Y.W.; Jhon, M.H.; Gao, H.; Srolovitz, D. Nanowire Failure: Long = brittle, short = ductile. Nano Lett. 2012, 12, 910–914. [Google Scholar] [CrossRef]

- An, B.H.; Jeon, I.T.; Seo, J.-H.; Ahn, J.-P.; Kraft, O.; Choi, I.-S.; Kim, Y.K. Ultrahigh Tensile Strength Nanowires with a Ni/Ni–Au Multilayer Nanocrystalline Structure. Nano Lett. 2016, 16, 3500–3506. [Google Scholar] [CrossRef]

- Wu, Z.X.; Zhang, Y.W.; Jhon, M.H.; Greer, J.R.; Srolovitz, D.J. Nanostructure and surface effects on yield in Cu nanowires. Acta Mater. 2013, 61, 1831–1842. [Google Scholar] [CrossRef]

- Wang, J.; Sansoz, F.; Deng, C.; Xu, G.; Han, G.; Mao, S.X. Strong Hall–Petch Type Behavior in the Elastic Strain Limit of Nanotwinned Gold Nanowires. Nano Lett. 2015, 15, 3865–3870. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, S.; Cheng, G.; Zeng, Z.; Zhu, Y.; Zhu, T. Strain Hardening and Size Effect in Five-fold Twinned Ag Nanowires. Nano Lett. 2015, 15, 4037–4044. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.; Yin, F.; Yu, T.; Lu, G.; Zhang, Y. A new strain-rate-induced deformation mechanism of Cu nanowire: Transition from dislocation nucleation to phase transformation. Acta Mater. 2015, 85, 191–198. [Google Scholar] [CrossRef]

- Jang, D.; Li, X.; Gao, H.; Greer, J.R. Deformation mechanisms in nanotwinned metal nanopillars. Nat. Nanotechnol. 2012, 7, 594–601. [Google Scholar] [CrossRef]

- Wang, J.; Huang, Z.; Duan, H.; Yu, S.; Feng, X.; Wang, G.; Zhang, W.; Wang, T. Surface stress effect in mechanics of nanostructured materials. Acta Mech. Solida Sin. 2011, 24, 52–82. [Google Scholar] [CrossRef]

- Zhan, H.F.; Gu, Y.T. Surface effects on the dual-mode vibration of 110 silver nanowires with different cross-sections. J. Phys. D Appl. Phys. 2012, 45, 465304–465313. [Google Scholar] [CrossRef]

- Zhan, H.F.; Gu, Y.T.; Park, H.S. Beat phenomena in metal nanowires, and their implications for resonance-based elastic property measurements. Nanoscale 2012, 4, 6779–6785. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Zhang, X.; Misra, A. Growth Twins and Deformation Twins in Metals. Annu. Rev. Mater. Res. 2014, 44, 329–363. [Google Scholar] [CrossRef]

- Jiang, S.; Zhang, H.; Zheng, Y.; Chen, Z. Loading path effect on the mechanical behaviour and fivefold twinning of copper nanowires. J. Phys. D Appl. Phys. 2010, 43, 335402. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, H. Do Twin Boundaries Always Strengthen Metal Nanowires? Nanoscale Res. Lett. 2009, 4, 34–38. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Zhan, H.F.; Gu, Y.T.; Yan, C.; Feng, X.Q.; Yarlagadda, P. Numerical exploration of plastic deformation mechanisms of copper nanowires with surface defects. Comput. Mater. Sci. 2011, 50, 3425–3430. [Google Scholar] [CrossRef]

- Diao, J.; Gall, K.; Dunn, M.; Zimmerman, J. Atomistic simulations of the yielding of gold nanowires. Acta Mater. 2006, 54, 643–653. [Google Scholar] [CrossRef]

- Park, H.S.; Zimmerman, J.A. Stable nanobridge formation in 1 1 0 gold nanowires under tensile deformation. Scr. Mater. 2006, 54, 1127–1132. [Google Scholar] [CrossRef]

- Tschopp, M.; Spearot, D.; McDowell, D. Atomistic simulations of homogeneous dislocation nucleation in single crystal copper. Modell. Simul. Mater. Sci. Eng. 2007, 15, 693. [Google Scholar] [CrossRef]

- Dupont, V.; Germann, T.C. Strain rate and orientation dependencies of the strength of single crystalline copper under compression. Phys. Rev. B 2012, 86, 134111. [Google Scholar] [CrossRef]

- Olsson, P.A.T.; Park, H.S. Atomistic study of the buckling of gold nanowires. Acta Mater. 2011, 59, 3883–3894. [Google Scholar] [CrossRef]

- Lee, S.; Lee, B.; Cho, M. Compressive pseudoelastic behavior in copper nanowires. Phys. Rev. B 2010, 81, 224103. [Google Scholar] [CrossRef]

- Jiang, S.; Zhang, H.; Zheng, Y.; Chen, Z. Atomistic study of the mechanical response of copper nanowires under torsion. J. Phys. D Appl. Phys. 2009, 42, 135408. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, F.; Zhu, T.; Zhao, J. Investigation on the mechanical behaviors of copper nanowires under torsion. Comput. Mater. Sci. 2010, 49, 826. [Google Scholar] [CrossRef]

- Weinberger, C.R.; Cai, W. Plasticity of metal wires in torsion: Molecular dynamics and dislocation dynamics simulations. J. Mech. Phys. Solids 2010, 58, 1011–1025. [Google Scholar] [CrossRef]

- Wang, J.S.; Feng, X.Q.; Wang, G.F.; Yu, S.W. Twisting of nanowires induced by anisotropic surface stresses. Appl. Phys. Lett. 2008, 92, 191901. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, J.; Fan, J. Orientation dependence of the torsional behavior of copper nanowires: An atomistic simulation study. In Proceedings of the Third International Conference on Heterogeneous Material Mechanics, Shanghai, China, 22–26 May 2011; p. 124. [Google Scholar]

- Yun, G.; Park, H. Surface stress effects on the bending properties of fcc metal nanowires. Phys. Rev. B 2009, 79, 195421. [Google Scholar] [CrossRef]

- Wu, B.; Heidelberg, A.; Boland, J.J. Mechanical properties of ultrahigh-strength gold nanowires. Nat. Mater. 2005, 4, 525–529. [Google Scholar] [CrossRef]

- Zhan, H.F.; Gu, Y.T.; Yan, C.; Yarlagadda, P.K.D.V. Bending properties of Ag nanowires with pre-existing surface defects. Comput. Mater. Sci. 2014, 81, 45–51. [Google Scholar] [CrossRef]

- Park, H.S.; Klein, P.A. Surface stress effects on the resonant properties of metal nanowires: The importance of finite deformation kinematics and the impact of the residual surface stress. J. Mech. Phys. Solids 2008, 56, 3144–3166. [Google Scholar] [CrossRef]

- Zhan, H.F.; Gu, Y.T. A fundamental numerical and theoretical study for the vibrational properties of nanowires. J. Appl. Phys. 2012, 111, 124303–124309. [Google Scholar] [CrossRef]

- Zhou, H.; Li, X.; Wang, Y.; Liu, Z.; Yang, W.; Gao, H. Torsional detwinning domino in nanotwinned one-dimensional nanostructures. Nano Lett. 2015, 15, 6082–6087. [Google Scholar] [CrossRef]

- Weinberger, C.; Cai, W. Orientation-Dependent Plasticity in Metal Nanowires under Torsion: Twist Boundary Formation and Eshelby Twist. Nano Lett. 2010, 10, 139–142. [Google Scholar] [CrossRef]

- Mishin, Y.; Mehl, M.; Papaconstantopoulos, D.; Voter, A.; Kress, J. Structural stability and lattice defects in copper: Ab initio, tight-binding, and embedded-atom calculations. Phys. Rev. B 2001, 63, 224106. [Google Scholar] [CrossRef]

- Hoover, W.G. Canonical dynamics: Equilibrium phase-space distributions. Phys. Rev. A 1985, 31, 1695–1697. [Google Scholar] [CrossRef] [PubMed]

- Nosé, S. A unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 1984, 81, 511. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Zhan, H.; Zhang, G.; Bell, J.M.; Tan, V.B.C.; Gu, Y. High density mechanical energy storage with carbon nanothread bundle. Nat. Commun. 2020, 11, 1905. [Google Scholar] [CrossRef] [PubMed]

- Ackland, G.J.; Jones, A.P. Applications of local crystal structure measures in experiment and simulation. Phys. Rev. B 2006, 73, 054104. [Google Scholar] [CrossRef]

- Cai, W.; Fong, W.; Elsen, E.; Weinberger, C.R. Torsion and bending periodic boundary conditions for modeling the intrinsic strength of nanowires. J. Mech. Phys. Solids 2008, 56, 3242–3258. [Google Scholar] [CrossRef]

| Test | () | (°) | ||

|---|---|---|---|---|

| 1 | 0 | 0 | 0.01 | 0 |

| 2 | 0.1051 | 6 | 0.0099 | 0.0060 |

| 3 | 0.2679 | 15 | 0.0097 | 0.0148 |

| 4 | 0.3839 | 21 | 0.0094 | 0.0205 |

| 5 | 0.5317 | 28 | 0.0088 | 0.0269 |

| 6 | 0.7265 | 36 | 0.0081 | 0.0337 |

| 7 | 1.0000 | 45 | 0.0071 | 0.0405 |

| 8 | 1.2799 | 52 | 0.0062 | 0.0451 |

| 9 | 1.4826 | 56 | 0.0056 | 0.0475 |

| 10 | 1.7321 | 60 | 0.0050 | 0.0496 |

| 11 | 2.6051 | 69 | 0.0036 | 0.0535 |

| 12 | 3.4874 | 74 | 0.0028 | 0.0551 |

| 13 | 5.1446 | 79 | 0.0019 | 0.0562 |

| 14 | 7.1154 | 82 | 0.0014 | 0.0567 |

| 15 | 14.3007 | 86 | 0.0007 | 0.0572 |

| 16 | 90 | 0 | 0.0573 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, H.; Dong, B.; Zhang, J.; Lü, C.; Zhan, H. Deformation of Copper Nanowire under Coupled Tension–Torsion Loading. Nanomaterials 2022, 12, 2203. https://doi.org/10.3390/nano12132203

Lu H, Dong B, Zhang J, Lü C, Zhan H. Deformation of Copper Nanowire under Coupled Tension–Torsion Loading. Nanomaterials. 2022; 12(13):2203. https://doi.org/10.3390/nano12132203

Chicago/Turabian StyleLu, Hongquan, Bin Dong, Junqian Zhang, Chaofeng Lü, and Haifei Zhan. 2022. "Deformation of Copper Nanowire under Coupled Tension–Torsion Loading" Nanomaterials 12, no. 13: 2203. https://doi.org/10.3390/nano12132203

APA StyleLu, H., Dong, B., Zhang, J., Lü, C., & Zhan, H. (2022). Deformation of Copper Nanowire under Coupled Tension–Torsion Loading. Nanomaterials, 12(13), 2203. https://doi.org/10.3390/nano12132203