1. Introduction

Nanostructures made of temperature-dependent functionally graded materials (FGMs) have played a key role in the advancement of nanotechnologies for the design of devices such as nanoswitches, nanosensors, nanoactuators, and nanogenerators, as well as nanoelectromechanical systems (NEMS), for use even under extreme temperature and humidity conditions [

1,

2,

3,

4,

5,

6,

7,

8]. Recent studies have also shown that, by managing some fabrication parameters during the manufacture of FGMs, different kinds of porosity distributions can be obtained within their structure to further improve the physical and mechanical characteristics of the material [

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19].

Therefore, it is necessary to research theoretical models that can capture the small effects in the overall mechanical response of the porous FG structure and the hygrothermal ones that cause damage due to the expansion of the material and the initial stresses induced by the hygrothermal conditions. It is well-known that the size-dependent behavior of nanostructures, observed in experimental nanoscale tests and atomistic simulations [

20], cannot be captured by the classical constitutive law that does not include size effects. In order to overcome the complexity of the experimental tests at nanoscale and the high computational cost of the atomistic simulations, several higher-order continuum mechanics theories have been developed in the last years. The two milestones on this topic are Eringen’s strain-driven nonlocal integral model (Eringen’s StrainDM) [

21,

22] and Lim’s nonlocal strain gradient theory (Lim’s NStrainGT) [

23], which have been widely used in a large number of investigations, respectively, in [

24,

25,

26,

27,

28,

29] and [

30,

31,

32,

33,

34,

35], due to their simply differential formulation.

As widely argued in [

36] for Eringen’s StrainDM and in [

37] for Lim’s NStrainGT, both theories have been declared ill-posed since the constitutive boundary conditions are in conflict with equilibrium requirements. Their inapplicability was bypassed by using other theories such as the local-nonlocal mixture constitutive model [

38], the coupled theories [

39], or resorting the stress-driven nonlocal integral model (StressDM) [

40]. More recently, based on a variational approach, the local/nonlocal strain-driven gradient (L/NStrainG) and local/nonlocal stress-driven gradient (L/NStressG) theories were used by Romano and Sciarra in [

41,

42] to examine the size-dependent structural problems of nano-beams via a mathematically and mechanically consistent approach.

Although several studies were used to assess small effects both in the static and dynamic behavior, as well as in the buckling response of a nanobeam in hygrothermal environments, to the best of the authors’ knowledge the research on the mechanical behavior of nanobeams in extreme conditions is not sufficient. In order to help fill some knowledge gaps on this topic, based on the nonlocal elasticity theory, the hygrothermal static behavior [

43] and the vibration and buckling response of an FG sandwich nanobeam were analyzed in [

44].

Recent studies were developed using innovative L/NStrainG and/or the L/NstressG theories. In detail, the bending response and the free linear vibration of porous FG nanobeams under hygrothermal environments were analyzed by the same authors of this paper in [

45,

46]. Moreover, the dynamic response of Bernoulli–Euler multilayered polymer functionally graded carbon nanotubes-reinforced composite nano-beams subjected to hygro-thermal environments was investigated in [

47]. In addition, in [

48], the L/NStrainG theory was adopted to study the effect of a hygrothermal environment on the buckling behavior of 2D FG Timoshenko nanobeams.

The main aim of this study is to help fill these gaps by proposing an application of the higher-order Hamilton approach [

49,

50,

51,

52,

53,

54,

55,

56,

57] to the nonlinear free vibrations analysis of porous FG nano-beams in a hygro-thermal environment based on the L/NStressG model.

In particular, the nonlinear transverse free vibrations of a Bernoulli–Euler nano-beam made of a metal–ceramic functionally graded porous material in a hygrothermal environment, with von Kármán type nonlinearity were studied employing the local/nonlocal stress-driven integral model. By using the Galerkin method, the governing equations were reduced to a nonlinear ordinary differential equation. The closed form analytical solution of the nonlinear natural flexural frequency was then established using the higher-order Hamiltonian approach to nonlinear oscillators.

Finally, a numerical investigation was developed to analyze the influence of different parameters both on the thermo-elastic material properties and the structural response, such as material gradient index, porosity volume fraction, nonlocal parameter, gradient length parameter, mixture parameter, and the amplitude of nonlinear oscillator on the nonlinear flexural vibrations of metal–ceramic FG porous Bernoulli–Euler nano-beams.

2. Functionally Graded Materials

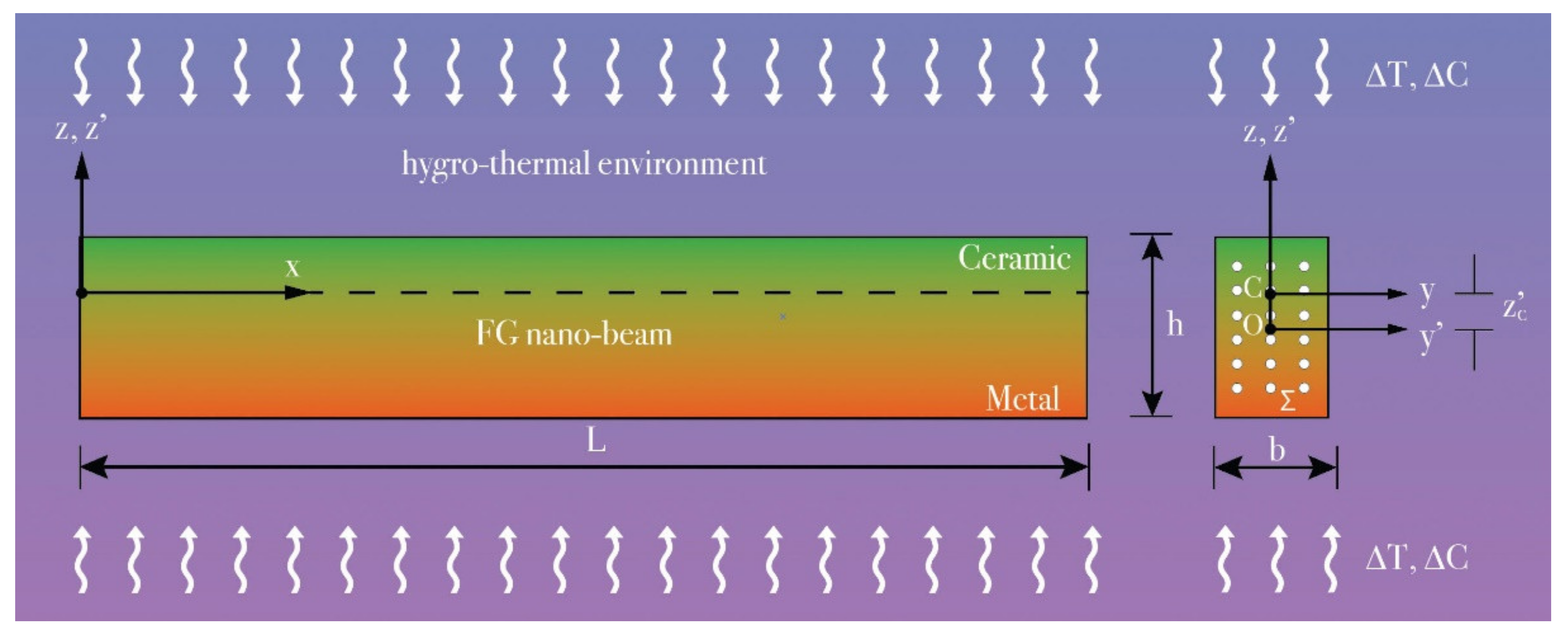

Considering a porous functionally graded (FG) nano-beam with length “L” made of a ceramic (Si

3N

4)/metal (SuS

3O

4) material and subjected to hygrothermal loadings as shown in

Figure 1, in which

y’ and

z’ are the principal axes of the geometric inertia originating at the geometric center O of its rectangular cross-section, Σ(

x), having thickness “h” and width “b”.

As already shown in [

46], the effective value of the FG material generic property,

can be obtained as a combination of the corresponding thermo-elastic and physical properties of ceramic,

, and metal,

, by using the following rule of mixture equation

where

k (

k ≥ 0) and

ζ (

ζ << 1) are the gradient index and the porosity volume fraction of the FG material, respectively.

The characteristic values

of the thermo-elastic properties of the two constituent materials, in terms of the Young’s modulus,

Ec and

Em, mass density,

ρc and

ρm, thermal expansion coefficient,

αc and

αm, and moisture expansion coefficient,

βc and

βm, are summarized in the following

Table 1.

It is well-known that the temperature dependence of the generic elastic property,

is taken into account with the following nonlinear expression:

being

and

the coefficients of the material phases for ceramic and metal (

Table 2).

Moreover, by evaluating the thermo-elastic material properties with respect to the elastic Cartesian coordinate system (

Figure 1), originating at the elastic center

C, whose position,

is expressed as

the bending–extension coupling, due to the variation of the functionally graded material, is eliminated.

3. Governing Equations

Under the assumption of Bernoulli–Euler beam theory, the only nonzero Cartesian components of the displacement field can be expressed by

being

,

the displacement components along

x and

z directions, and

u(), w() the axial and transverse displacements of the elastic centre

C, at time

t, respectively.

According to conventional Von-Kármán geometrical nonlinearity, which includes small strains but moderately large rotation, the elastic axial strain is given as

where the “Von-Kármán” strain,

, and the geometrical curvature, χ, have the following expressions

In the case of free vibrations, the nonlinear equations of motion are derived by using the Hamilton’s principle

with the corresponding boundary conditions at the nano-beam ends:

where

,

, and

denote the local axial force, the bending moment resultant and the equivalent shear force, respectively. In Equations (9) and (10),

and

are, respectively, the temperature-dependent rotary inertia and the effective cross-sectional mass of the porous FG nano-beam, expressed as follows

and

and

denote the hygro-thermal axial force resultants, respectively, defined as

in which

and

are the increments of the temperature and moisture concentration, respectively. In the following, we will also denote

4. Local/Nonlocal Stress Gradient (NStressG) Model of Elasticity

As shown in [

46], by using the local/nonlocal stress gradient integral formulation, the elastic axial strain,

, can be expressed by the following constitutive mixture equation

being:

and

the position vectors of the points of the domain at time

; and

the axial stress component and its gradient, respectively;

the mixture parameter;

the scalar averaging kernel

and

the length-scale and the gradient length parameters, respectively.

By choosing the bi-exponential function for the kernel

as

the integro-differential relation of Equation (18) admits the following solution

with

∈ [0, L], if and only if the following two pairs of constitutive boundary conditions (CBCs) are satisfied at the nano-beam ends

5. Nonlinear Transverse Free Vibrations (NStressG)

Following the mathematical derivations summarized in

Appendix A, we obtain the nonlinear transverse free vibrations equation based on a local/nonlocal stress gradient model of elasticity

By introducing the following dimensionless quantities

in which

and

are the axial and bending stiffnesses of an FG nano-beam, respectively, defined as

Equation (22) can be rewritten as

Finally, by imposing the dimensionless term

equal to zero, on which the nonlinear nature of the equations depends, from the previous equation, we obtain the linear transverse free oscillations equation

6. Higher-Order Hamiltonian Approach to Nonlinear Free Vibrations: Solution Procedure

Natural frequencies and mode shapes of flexural vibrations can be evaluated by employing the classical separation of the spatial and time variables

being ω the natural frequency of flexural vibrations. Enforcing the separation of the variables Equation (28) to the differential condition of dynamic equilibrium, the governing equation of the linear flexural spatial mode shape for the NStressG model,

, is obtained as

The analytical solution of the governing equation of the flexural spatial mode shape Equation (29) can be expressed by

wherein

are the roots of the characteristic equation, and

are six unknown constants to be determined by imposing the standard boundary conditions and the constitutive boundary conditions associated with NStressG.

Equation (26) describes the nonlinear free vibrations in the NStressG model of elasticity and in a hygrothermal environment. On the basis of the Galerkin method, the transverse displacement function

in Equation (26) can be defined by

where

is the i-

th test function which depends on the assigned boundary conditions (Equation (30)) and

is the unknown i-

th time-dependent coefficient.

In this study, we assume the test function form to be equal to the NStressG linear modal shape (

i = 1)

6.1. First-Order Hamiltonian Approach

Based on the First-order Hamiltonian approach introduced by [

49], the time base function,

is given by the following approximate cosine solution

being

the first nonlinear vibration frequency,

the amplitude of the nonlinear oscillator; moreover

is assumed to be equal to the linear spatial mode based on the NStressG model of elasticity

Now, substituting Equation (32) into Equation (27) and multiplying the resulting equation with the fundamental vibration mode

, then integrating across the length of the nanobeam, leads to the following equation

where

are four coefficients obtained by splitting up the terms.

Finally, in agreement with Hamiltonian approach to nonlinear oscillators [

49], it is easy to establish a variational principle for Equation (35) [

50]

where

is the period of the nonlinear oscillator.

The frequency–amplitude relationship can be obtained from the following equation

which gives the approximate nonlinear fundamental vibration frequency of a porous FG nano-beam

Note that the linear vibration frequency of a porous FG nano-beam can be determined from the previous Equation (38) by setting .

6.2. Second-Order Hamiltonian Approach

In order to find the Second-order approximate solution and frequency, we assume that a Second-order trial solution can be expressed by

with the following initial condition

Applying the mathematical resolution method previously introduced for the First-order Hamiltonian approach [

51], we obtain the following system of equations

Solving Equations (40) and (41) simultaneously, and assuming Equation (39), one can obtain the Second-order solution and the approximate frequency according to the Hamiltonian approach.

6.3. Third-Order Hamiltonian Approach

The accuracy of the results will be further improved by consider the following equation as the response of the system

where the initial condition is

By using the same procedure explained above (§ 6.2), the following system of equations follows

Similarly, by solving Equation (44) simultaneously with Equation (43), the amplitude-frequency relation up to the Third-order approximation is obtained.

7. Convergence and Comparison Study

In order to validate the accuracy and reliability of the proposed approach, three numerical examples are presented in this paragraph.

To this purpose, both a uniform temperature rise,

and a moisture concentration,

between the bottom (

z’ = −h/2) and the top surface (z’ = +h/2) of the nano-beam cross-section, are considered (

Figure 1),

and

being the reference values of the temperature and moisture concentration at the bottom surface, respectively, and

their increments.

In the first two comparison examples, the normalized frequency ratio between the dimensionless nonlocal fundamental frequency,

, and the dimensionless local natural frequency,

, of a clamped–clamped (C–C) porous FG nano-beam in a hygrothermal environment, were compared (

Table 3 and

Table 4), with the results obtained by Penna et al. in [

46] for

λc = 0.2 and assuming:

λl = 0.0 or 0.10; ξ

1 = 0.0 or 0.5; Δ

T = 0, 50, and 100 [K].

In the third example (

Table 5), the present approach is compared with the model proposed by Barretta et al. in [

42] for a C–C porous FG nano-beam in absence of hygrothermal loads for

λl = 0.1, varying

λc, in the set {0.0

+, 0.2, 0.4, 0.6, 0.8, 1.0} and assuming ξ

1 = 0.0 or 0.5, and the gyration radius,

, equal to 1/20.

From these comparison examples, the accuracy of the higher order Hamiltonian approach to the nonlinear oscillators here employed is validated.

8. Results and Discussion

The effects of the hygrothermal loads on the nonlinear dynamic behavior of a C–C Bernoulli–Euler porous FG nano-beam is discussed here, varying the nonlocal parameter, λc, the gradient length parameter, λl, the mixture parameter, ξ1, and the nonlinear oscillator amplitude, .

In particular, the dimensionless nonlocal fundamental frequency has been evaluated assuming k = 0.3 and ζ = 0.15 with a temperature increment ranging in the set {0, 50, 100 [K]} and considering C = 2 [wt.%H2O]. Moreover, we have also investigated the effects of the porosity volume fraction, ζ, the gradient index, k, and temperature rise on the dimensionless bending stiffness, , the dimensionless axial stiffness, , the dimensionless effective cross sectional mass, , and the dimensionless rotary inertia, . Note that and represent the bending and axial stiffness of a non-porous purely ceramic nano-beam, respectively, while , are the effective cross-sectional mass and rotary inertia of a non-porous purely ceramic nano-beam, respectively.

8.1. Influence of Porosity Volume Fraction and Gradient Index

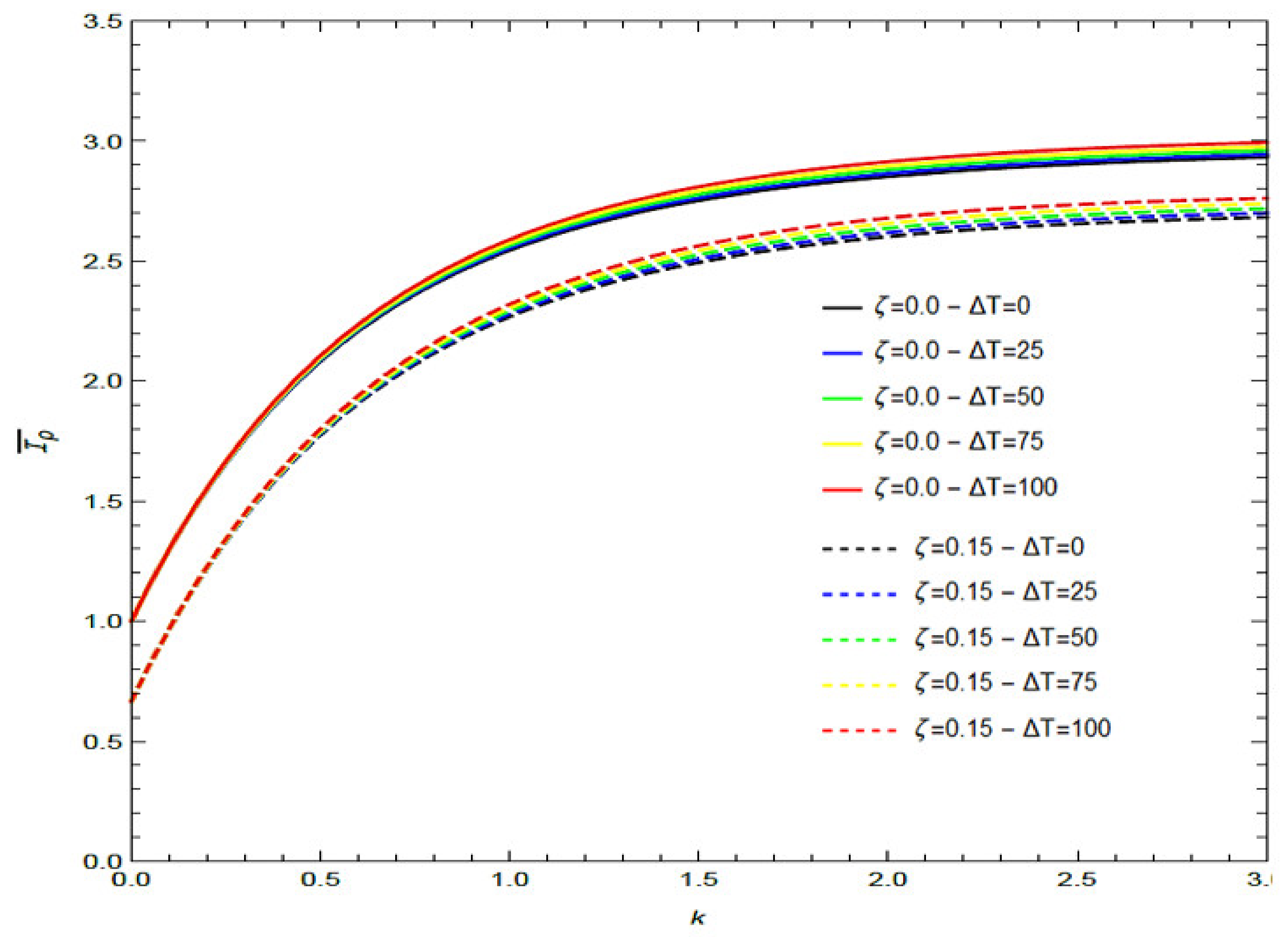

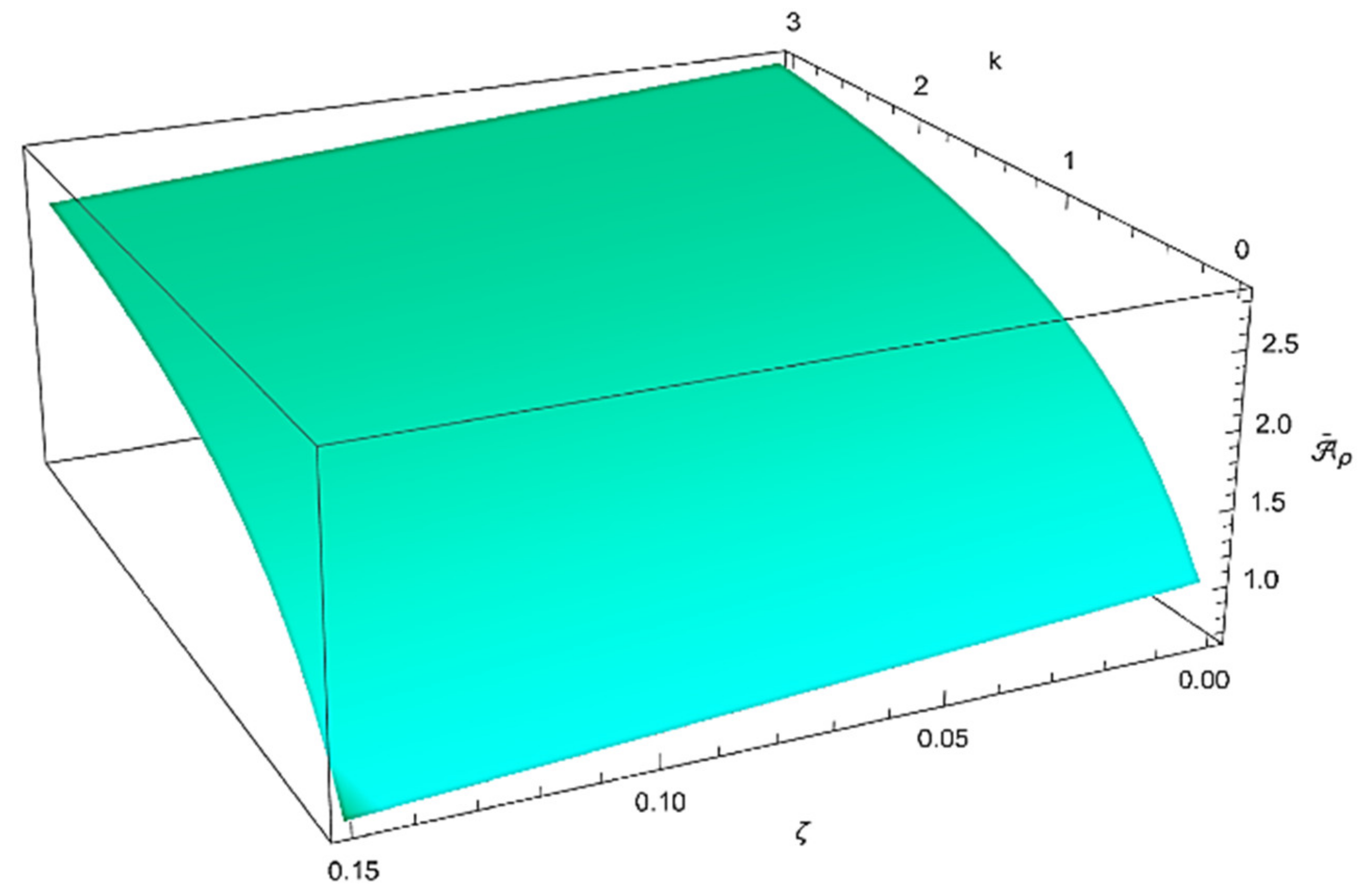

The combined effects of both the gradient index,

, and the porosity volume fraction,

, on the thermo-mechanical properties of the porous FG nanobeam under investigation are presented in

Figure 2,

Figure 3 and

Figure 4. It can be noted how the dimensionless bending and axial stiffnesses, as well as the dimensionless rotary inertia and effective cross-sectional mass, decrease as the porosity volume fraction increases, while they increase as the material gradient index increases.

8.2. Influence of Hygrothermal Loads

In this subsection, the influence of hygrothermal loads on the normalized fundamental flexural frequency is discussed. Firstly, as can be observed from

Table 9,

Table 10,

Table 11,

Table 12,

Table 13,

Table 14,

Table 15,

Table 16 and

Table 17, the values of the normalized linear fundamental flexural frequency (

, based on a local/nonlocal stress-driven gradient theory of elasticity, always decrease as the temperature rise increases. Moreover, in the range of values here considered, an opposite trend is obtained for the normalized nonlinear fundamental flexural frequency as

and

increase.

With reference to the influence of the temperature on the thermo-mechanical properties of the porous FG nanobeam, it can be observed (

Figure 2) that the dimensionless bending stiffness and dimensionless axial stiffness decrease as

increases. In addition, the curves of

Figure 3 show that the dimensionless rotary inertia increases as the temperature increases, although the hygrothermal effect is noticeable when

k > 1.

8.3. Influence of Nonlocal Parameter, Gradient Length Parameter, and Mixture Parameter

From

Table 9,

Table 10,

Table 11,

Table 12,

Table 13,

Table 14,

Table 15,

Table 16 and

Table 17, on one hand, it can be seen that an increase in the values of

results in an increase of the frequency ratio,

/

, but on the other, it can be found that as

increases, the values of the aforementioned frequency ratio decrease. It is also possible to note that the ratio

/

, decreases by increasing the mixture parameter

ξ1.

8.4. Influence of Higher-Order Hamilton Approach

Finally, the nonlinear dimensionless natural frequencies of the porous FG nano-beam under investigation corresponding to the First-, Second-, and Third-order approximate solutions are summarized in

Table 9,

Table 10,

Table 11,

Table 12,

Table 13,

Table 14,

Table 15,

Table 16 and

Table 17, varying the oscillator amplitude in the set {0.0, 0.01, 0.05, 0.10}. From these tables, it can be seen that the aforementioned flexural frequency always increase as the amplitude of the nonlinear oscillator increases, while they decrease as the order of the Hamiltonian approach increases.

The above parametrical analysis assumes relevance in the study of the nonlinear vibrations of porous FG nano-beams because their behavior is influenced by the dimensionless term

, which is proportional to the ratio between the axial and the bending stiffness of the nanobeam cross-section, both depending on the porosity distribution of the structure of the nano-beam material and on the temperature increment and the material gradient index. Moreover, the term

allows us to take into account the nonlinear response due to the mid-plane stretching effect introduced in the following

Appendix A.

9. Conclusions

In this paper, the nonlinear dynamic behavior of a Bernoulli–Euler nano-beam made of a metal–ceramic functionally graded porous material in a hygrothermal environment, with von Kármán type nonlinearity, was studied, employing the local/nonlocal stress-driven integral model.

The governing equations have been reduced to a nonlinear ordinary differential equation by using the Galerkin method. Then, the higher-order Hamiltonian approach to nonlinear oscillators was employed.

In view of the numerical results obtained in the present study, the following main conclusions may be formulated:

- (1)

the flexural frequency always increases with the increase of the nonlocal parameter;

- (2)

the flexural frequency decreases always by increasing the gradient length parameter;

- (3)

an increase in the values of the mixture parameter always leads to a decrease in the flexural frequency;

- (4)

the flexural frequency always increases as the amplitude of the nonlinear oscillator increases, while they decrease as the order of the Hamiltonian approach increases.

In conclusion, the results obtained in this study show that the proposed approach is capable of capturing the nonlinear dynamic behavior of porous Bernoulli–Euler functionally graded nano-beams in a hygrothermal environment and represent a valuable reference point for engineers and researchers to validate different numerical methods, as well as for the practical design of nano-scaled beam-like components of nano electromechanical systems (NEMS).

Author Contributions

Conceptualization: L.F., R.P. and F.F.; methodology: L.F., R.P. and F.F.; software: R.P. and G.L.; validation: L.F., R.P. and F.F.; formal analysis: R.P. and G.L.; investigation: L.F., R.P. and G.L.; resources: L.F., R.P. and F.F.; data curation: L.F. and R.P.; writing—original draft preparation: L.F. and R.P.; writing—review and editing: L.F. and R.P.; visualization: L.F. and R.P.; supervision: L.F., R.P. and F.F; project administration: L.F.; funding acquisition: L.F. and F.F. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge the financial support of the Italian Ministry of University and Research (MUR), Research Grant PRIN 2020 No. 2020EBLPLS on “Opportunities and challenges of nanotechnology in advanced and green construction materials”.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

In this appendix, we report the mathematical steps taken to arrive at the equation that governs the problem of nonlinear transverse free vibrations of the nano-beam studied.

By manipulating Equation (6) and substituting into Equations (19)–(21), then multiplying by (1, z), the integration over the nano-beam cross section provides the following NStressG equations in terms of axial and transverse displacement

with the following constitutive boundary conditions (CBC)

By manipulating the nonlinear equations of motion (Equations (9) and (10)), as well as Equations (A1) and (A2), we obtain the expression of nonlocal axial force and moment resultant in the NStressG model of elasticity

Moreover, by substituting Equations (A7) and (A8) into Equations (9) and (10), the following stress gradient equations of motion can be derived

Employing the axial and flexural kinematic compatibility, the differential condition of dynamic equilibrium governing the vibrations of NStressG nano-beams is given by

with the following natural boundary conditions at the nano-beam ends

being

,

and

the assigned generalized forces acting at the nano-beam ends together and with the constitutive boundary conditions at the nano-beam ends given by Equations (A3)–(A6) which can be rewritten as a function of the displacement components

Furthermore, if in Equation (A7) we neglect the axial inertia term,

, we obtain

wherein

is a constant.

Note that, for a nano-beam with immovable ends (

=

= 0 and

=

= 0), by integrating both sides of Equation (A20) over the domain [0, L] yields to the following expression

which coincides with the “mid-plane stretching effect” introduced in [

45].

Based on this assumption, from Equation (A12), it follows

Now, by substituting Equation (A21) into Equation (A22), we obtain

which describes the nonlinear transverse free vibrations of nano-beams in a hygrothermal environment.

References

- Hui, Y.; Gomez-Diaz, J.S.; Qian, Z.; Alù, A.; Rinaldi, M. Plasmonic piezoelectric nanomechanical resonator for spectrally selective infrared sensing. Nat. Commun. 2016, 7, 11249. [Google Scholar] [CrossRef] [PubMed]

- Akhavan, H.; Ghadiri, M.; Zajkani, A. A new model for the cantilever MEMS actuator in magnetorheological elastomer cored sandwich form considering the fringing field and Casimir effects. Mech. Syst. Signal Process. 2019, 121, 551–561. [Google Scholar] [CrossRef]

- Basutkar, R. Analytical modelling of a nanoscale series-connected bimorph piezoelectric energy harvester incorporating the flexoelectric effect. Int. J. Eng. Sci. 2019, 139, 42–61. [Google Scholar] [CrossRef]

- SoltanRezaee, M.; Afrashi, M. Modeling the nonlinear pull-in behavior of tunable nano-switches. Int. J. Eng. Sci. 2016, 109, 73–87. [Google Scholar] [CrossRef]

- Qiu, L.; Zhu, N.; Feng, Y.; Michaelides, E.E.; Żyła, G.; Jing, D.; Zhang, X.; Norris, P.M.; Markides, C.N.; Mahian, O. A review of recent advances in thermophysical properties at the nanoscale: From solid state to colloids. Phys. Rep. 2020, 843, 1–81. [Google Scholar] [CrossRef]

- Imani, A.; Rabczuk, A.; Friswell, T.; Ian, M. A finite element model for the thermo-elastic analysis of functionally graded porous nanobeams. Eur. J. Mech. A Solids 2019, 77, 103767. [Google Scholar]

- Barretta, R.; Feo, L.; Luciano, R. Some closed-form solutions of functionally graded beams undergoing nonuniform torsion. Compos. Struct. 2015, 123, 132–136. [Google Scholar] [CrossRef]

- Huang, K.; Yao, J. Beam Theory of Thermal–Electro-Mechanical Coupling for Single-Wall Carbon Nanotubes. Nanomaterials 2021, 11, 923. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Jafari, A. A Higher-Order Thermomechanical Vibration Analysis of Temperature-Dependent FGM Beams with Porosities. J. Eng. 2016, 2016, 9561504. [Google Scholar] [CrossRef] [Green Version]

- Kresge, C.T.; Leonowicz, M.E.; Roth, W.J.; Vartuli, J.C.; Beck, J.S. Ordered mesoporous molecular sieves synthesized by a liquid-crystal template mechanism. Nature 1992, 359, 710–712. [Google Scholar] [CrossRef]

- Beck, J.S.; Vartuli, J.C.; Roth, W.J.; Leonowicz, M.E.; Kresge, C.T.; Schmitt, K.D.; Chu, C.T.W.; Olson, D.H.; Sheppard, E.W.; McCullen, S.B.; et al. A new family of mesoporous molecular sieves prepared with liquid crystal templates. J. Am. Chem. Soc. 1992, 114, 10834–10843. [Google Scholar] [CrossRef]

- Velev, O.; Jede, T.A.; Lobo, R.F.; Lenhoff, A. Porous silica via colloidal crystallization. Nature 1997, 389, 447–448. [Google Scholar] [CrossRef]

- Alizada, A.N.; Sofiyev, A.H. Modified Young’s moduli of nano-materials taking into account the scale effects and vacancies. Meccanica 2010, 46, 915–920. [Google Scholar] [CrossRef]

- Wang, Y.Q. Electro-mechanical vibration analysis of functionally graded piezoelectric porous plates in the translation state. Acta Astronaut. 2018, 143, 263–271. [Google Scholar] [CrossRef]

- Chai, Q.; Wang, Y.Q. Traveling wave vibration of graphene platelet reinforced porous joined conical-cylindrical shells in a spinning motion. Eng. Struct. 2021, 252, 113718. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Zu, J.W. Vibration behaviors of functionally graded rectangular plates with porosities and moving in thermal environment. Aerosp. Sci. Technol. 2017, 69, 550–562. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Ye, C.; Zu, J.W. Nonlinear vibration of metal foam cylindrical shells reinforced with graphene platelets. Aerosp. Sci. Technol. 2018, 85, 359–370. [Google Scholar] [CrossRef]

- Alibakhshi, A.; Dastjerdi, S.; Malikan, M.; Eremeyev, V.A. Nonlinear Free and Forced Vibrations of a Hyperelastic Micro/Nanobeam Considering Strain Stiffening Effect. Nanomaterials 2021, 11, 3066. [Google Scholar] [CrossRef]

- Ye, C.; Wang, Y.Q. Nonlinear forced vibration of functionally graded graphene platelet-reinforced metal foam cylindrical shells: Internal resonances. Nonlinear Dyn. 2021, 104, 2051–2069. [Google Scholar] [CrossRef]

- Pelliciari, M.; Tarantino, A.M. A nonlinear molecular mechanics model for graphene subjected to large in-plane deformations. Int. J. Eng. Sci. 2021, 167, 103527. [Google Scholar] [CrossRef]

- Eringen, A. Linear theory of nonlocal elasticity and dispersion of plane waves. Int. J. Eng. Sci. 1972, 10, 425–435. [Google Scholar] [CrossRef]

- Eringen, A.C. On differential equations of nonlocal elasticity and solutions of screw dislocation and surface waves. J. Appl. Phys. 1983, 54, 4703–4710. [Google Scholar] [CrossRef]

- Lim, C.; Zhang, G.; Reddy, J. A higher-order nonlocal elasticity and strain gradient theory and its applications in wave propagation. J. Mech. Phys. Solids 2015, 78, 298–313. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Barati, M.R. A unified formulation for dynamic analysis of nonlocal heterogeneous nanobeams in hygro-thermal environment. Appl. Phys. A 2016, 122, 792. [Google Scholar] [CrossRef]

- Ebrahimi-Nejad, S.; Shaghaghi, G.R.; Miraskari, F.; Kheybari, M. Size-dependent vibration in two-directional functionally graded porous nanobeams under hygro-thermo-mechanical loading. Eur. Phys. J. Plus 2019, 134, 465. [Google Scholar] [CrossRef]

- Dastjerdi, S.; Malikan, M.; Dimitri, R.; Tornabene, F. Nonlocal elasticity analysis of moderately thick porous functionally graded plates in a hygro-thermal environment. Compos. Struct. 2020, 255, 112925. [Google Scholar] [CrossRef]

- Ashoori, A.; Salari, E.; Vanini, S.S. Size-dependent thermal stability analysis of embedded functionally graded annular nanoplates based on the nonlocal elasticity theory. Int. J. Mech. Sci. 2016, 119, 396–411. [Google Scholar] [CrossRef]

- Samani, M.S.E.; Beni, Y.T. Size dependent thermo-mechanical buckling of the flexoelectric nanobeam. Mater. Res. Express 2018, 5, 085018. [Google Scholar] [CrossRef]

- Salari, E.; Vanini, S.S. Investigation of thermal preloading and porosity effects on the nonlocal nonlinear instability of FG nanobeams with geometrical imperfection. Eur. J. Mech. A/Solids 2020, 86, 104183. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Barati, M.R. Hygrothermal effects on vibration characteristics of viscoelastic FG nanobeams based on nonlocal strain gradient theory. Compos. Struct. 2017, 159, 433–444. [Google Scholar] [CrossRef]

- Chu, L.; Dui, G.; Zheng, Y. Thermally induced nonlinear dynamic analysis of temperature-dependent functionally graded flexoelectric nanobeams based on nonlocal simplified strain gradient elasticity theory. Eur. J. Mech. A/Solids 2020, 82, 103999. [Google Scholar] [CrossRef]

- Karami, B.; Janghorban, M.; Rabczuk, T. Dynamics of two-dimensional functionally graded tapered Timoshenko nanobeam in thermal environment using nonlocal strain gradient theory. Compos. Part B Eng. 2019, 182, 107622. [Google Scholar] [CrossRef]

- Cornacchia, F.; Fabbrocino, F.; Fantuzzi, N.; Luciano, R.; Penna, R. Analytical solution of cross- and angle-ply nano plates with strain gradient theory for linear vibrations and buckling. Mech. Adv. Mater. Struct. 2021, 28, 1201–1215. [Google Scholar] [CrossRef]

- Akgöz, B.; Civalek, Ö. Longitudinal vibration analysis for microbars based on strain gradient elasticity theory. J. Vib. Control 2012, 20, 606–616. [Google Scholar] [CrossRef]

- Akgöz, B.; Civalek, Ö. A microstructure-dependent sinusoidal plate model based on the strain gradient elasticity theory. Acta Mech. 2015, 226, 2277–2294. [Google Scholar] [CrossRef]

- Romano, G.; Barretta, R.; Diaco, M.; Marotti de Sciarra, F. Constitutive boundary conditions and paradoxes in nonlocal elastic nano-beams. Int. J. Mech. Sci. 2017, 121, 151–156. [Google Scholar] [CrossRef]

- Zaera, R.; Serrano, Ó.; Fernández-Sáez, J. On the consistency of the nonlocal strain gradient elasticity. Int. J. Eng. Sci. 2019, 138, 65–81. [Google Scholar] [CrossRef]

- Eringen, A.C. Theory of Nonlocal Elasticity and Some Applications. Princet. Univ. Nj Dept. Civ. Eng. 1984, Technical Report No. 62, 1–65. [Google Scholar] [CrossRef]

- Gurtin, M.E.; Murdoch, A.I. A continuum theory of elastic material surfaces. Arch. Ration. Mech. Anal. 1975, 57, 291–323. [Google Scholar] [CrossRef]

- Romano, G.; Barretta, R. Nonlocal elasticity in nanobeams: The stress-driven integral model. Int. J. Eng. Sci. 2017, 115, 14–27. [Google Scholar] [CrossRef]

- Barretta, R.; Marotti de Sciarra, F. Variational nonlocal gradient elasticity for nano-beams. Int. J. Eng. Sci. 2019, 143, 73–91. [Google Scholar] [CrossRef]

- Pinnola, F.; Faghidian, S.A.; Barretta, R.; de Sciarra, F.M. Variationally consistent dynamics of nonlocal gradient elastic beams. Int. J. Eng. Sci. 2020, 149, 103220. [Google Scholar] [CrossRef]

- Jouneghani, F.Z.; Dimitri, R.; Tornabene, F. Structural response of porous FG nanobeams under hygro-thermo-mechanical loadings. Compos. Part B Eng. 2018, 152, 71–78. [Google Scholar] [CrossRef]

- Aria, A.; Friswell, M. Computational hygro-thermal vibration and buckling analysis of functionally graded sandwich microbeams. Compos. Part B Eng. 2019, 165, 785–797. [Google Scholar] [CrossRef] [Green Version]

- Penna, R.; Feo, L.; Lovisi, G. Hygro-thermal bending behavior of porous FG nano-beams via local/nonlocal strain and stress gradient theories of elasticity. Compos. Struct. 2021, 263, 113627. [Google Scholar] [CrossRef]

- Penna, R.; Feo, L.; Lovisi, G.; Fabbrocino, F. Hygro-thermal vibrations of porous FG nano-beams based on local/nonlocal stress gradient theory of elasticity. Nanomaterials 2021, 11, 910. [Google Scholar] [CrossRef]

- Penna, R.; Lovisi, G.; Feo, L. Dynamic Response of Multilayered Polymer Functionally Graded Carbon Nanotube Reinforced Composite (FG-CNTRC) Nano-Beams in Hygro-Thermal Environment. Polymers 2021, 13, 2340. [Google Scholar] [CrossRef]

- Wang, S.; Kang, W.; Yang, W.; Zhang, Z.; Li, Q.; Liu, M.; Wang, X. Hygrothermal effects on buckling behaviors of porous bi-directional functionally graded micro-/nanobeams using two-phase local/nonlocal strain gradient theory. Eur. J. Mech. A Solids 2022, 94, 104554. [Google Scholar] [CrossRef]

- He, J.-H. Hamiltonian approach to nonlinear oscillators. Phys. Lett. A 2010, 374, 2312–2314. [Google Scholar] [CrossRef]

- He, J.-H. Variational approach for nonlinear oscillators. Chaos Solitons Fractals 2007, 34, 1430–1439. [Google Scholar] [CrossRef] [Green Version]

- Ismail, G.; Cveticanin, L. Higher order Hamiltonian approach for solving doubly clamped beam type N/MEMS subjected to the van der Waals attraction. Chin. J. Phys. 2021, 72, 69–77. [Google Scholar] [CrossRef]

- Akbarzade, M.; Kargar, A. Application of the Hamiltonian approach to nonlinear vibrating equations. Math. Comput. Model. 2011, 54, 2504–2514. [Google Scholar] [CrossRef]

- Nawaz, Y.; Arif, M.S.; Bibi, M.; Naz, M.; Fayyaz, R. An effective modification of He’s variational approach to a nonlinear oscillator. J. Low Freq. Noise Vib. Act. Control 2019, 38, 1013–1022. [Google Scholar] [CrossRef]

- Askari, H.; Nia, Z.S.; Yildirim, A.; Yazdi, M.K.; Khan, Y. Application of higher order Hamiltonian approach to nonlinear vibrating systems. J. Theor. Appl. Mech. 2013, 51, 287–296. [Google Scholar]

- Sadeghzadeh, S.; Kabiri, A. Application of Higher Order Hamiltonian Approach to the Nonlinear Vibration of Micro Electro Mechanical Systems. Lat. Am. J. Solids Struct. 2016, 13, 478–497. [Google Scholar] [CrossRef] [Green Version]

- Penna, R.; Feo, L.; Fortunato, A.; Luciano, R. Nonlinear free vibrations analysis of geometrically imperfect FG nano-beams based on stress-driven nonlocal elasticity with initial pretension force. Compos. Struct. 2020, 255, 112856. [Google Scholar] [CrossRef]

- Penna, R.; Feo, L. Nonlinear Dynamic Behavior of Porous and Imperfect Bernoulli-Euler Functionally Graded Nanobeams Resting on Winkler Elastic Foundation. Technologies 2020, 8, 56. [Google Scholar] [CrossRef]

Figure 1.

Coordinate system and configuration of a porous FG Bernoulli–Euler nano-beam.

Figure 1.

Coordinate system and configuration of a porous FG Bernoulli–Euler nano-beam.

Figure 2.

Combined effects of the gradient index (k) and the porosity volume fraction () on the dimensionless bending stiffness (a) and axial stiffness (b) under uniform temperature rises (ΔT = 0, 25, 50, 75, 100 [K]).

Figure 2.

Combined effects of the gradient index (k) and the porosity volume fraction () on the dimensionless bending stiffness (a) and axial stiffness (b) under uniform temperature rises (ΔT = 0, 25, 50, 75, 100 [K]).

Figure 3.

Combined effects of the gradient index (k) and the porosity volume fraction () on the dimensionless rotary inertia under uniform temperature rises (ΔT = 0, 25, 50, 75, 100 [K]).

Figure 3.

Combined effects of the gradient index (k) and the porosity volume fraction () on the dimensionless rotary inertia under uniform temperature rises (ΔT = 0, 25, 50, 75, 100 [K]).

Figure 4.

Combined effect of the gradient index (k) and the porosity volume fraction () on the dimensionless effective cross-sectional mass .

Figure 4.

Combined effect of the gradient index (k) and the porosity volume fraction () on the dimensionless effective cross-sectional mass .

Table 1.

Characteristic values of thermo-elastic properties (

) of ceramic (Si

3N

4) and metal (SuS

3O

4) [

46].

Table 1.

Characteristic values of thermo-elastic properties (

) of ceramic (Si

3N

4) and metal (SuS

3O

4) [

46].

| Material | | Unit | |

|---|

| Ceramic (Si3N4) | Ec | [GPa] | 348.40 |

| ρc | [kg/m3] | 2325 |

| αc | [K−1] | 5.87 × 10−6 |

| βc | [wt.% H2O]−1 | 0 |

| Metal (SuS3O4) | Em | [GPa] | 201.04 |

| ρm | [kg/m3] | 8011 |

| αm | [K−1] | 1.233 × 10−5 |

| βm | [wt.% H2O]−1 | 5 × 10−4 |

Table 2.

Coefficients of material phases (, ) for ceramic (Si3N4) and metal (SuS3O4).

Table 2.

Coefficients of material phases (, ) for ceramic (Si3N4) and metal (SuS3O4).

| | | Ceramic (Si3N4) | Metal (SuS3O4) |

|---|

| Coefficients | Unit | Ec | ρc | αc | βc | Em | ρm | αm | βm |

|---|

| X−1 | [K] | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| X1 | [K−1] | −3.07 × 10−4 | 0 | 9.095 × 10−4 | 0 | 3.079 × 10−4 | 0 | 8.086 × 10−4 | 0 |

| X2 | [K−2] | 2.160 × 10−7 | 0 | 0 | 0 | −6.534 × 10−7 | 0 | 0 | 0 |

| X3 | [K−3] | −8.946 × 10−11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Table 3.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam ( ).

Table 3.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam ( ).

| ξ1 = 0.0 |

|---|

| Present Approach | Ref. [46] | Present Approach | Ref. [46] | Present Approach | Ref. [46] |

|---|

| | |

|---|

| 0.00 | 1.83226 | 1.83226 | 1.82706 | 1.82706 | 1.82313 | 1.82313 |

| 0.10 | 1.57333 | 1.57333 | 1.56718 | 1.56718 | 1.56254 | 1.56254 |

Table 4.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam ( ).

Table 4.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam ( ).

| ξ1 = 0.5 |

|---|

Present

Approach | Ref. [46] | Present

Approach | Ref. [46] | Present

Approach | Ref. [46] |

|---|

| | |

|---|

| 0.00 | 1.23148 | 1.23148 | 1.22424 | 1.22424 | 1.21876 | 1.21876 |

| 0.10 | 1.13883 | 1.13883 | 1.13089 | 1.13089 | 1.12487 | 1.12487 |

Table 5.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam ( ).

Table 5.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam ( ).

| λc | ξ1 = 0.0 | ξ1 = 0.5 |

|---|

Present

Approach | Ref. [42] | Present

Approach | Ref. [42] |

|---|

| 0.0+ | 0.89165 | 0.89165 | 0.88416 | 0.88416 |

| 0.20 | 1.58127 | 1.58127 | 1.14531 | 1.14531 |

| 0.40 | 2.57577 | 2.57577 | 1.28946 | 1.28946 |

| 0.60 | 3.61940 | 3.61940 | 1.34633 | 1.34633 |

| 0.80 | 4.67784 | 4.67784 | 1.37237 | 1.37237 |

| 1.00 | 5.74258 | 5.74258 | 1.38608 | 1.38608 |

Table 6.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.0.

Table 6.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.0.

| ξ1 = 0.0 |

|---|

| λc | | | |

|---|

| | | | | |

|---|

| 0.10 | 1.33333 | 1.15406 | 1.32613 | 1.14551 | 1.32070 | 1.13904 |

| 0.20 | 1.84414 | 1.58369 | 1.83894 | 1.57754 | 1.83504 | 1.57291 |

Table 7.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.5.

Table 7.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.5.

| ξ1 = 0.5 |

|---|

| λc | | | |

|---|

| | | | | |

|---|

| 0.10 | 1.12891 | 1.01093 | 1.12085 | 1.00166 | 1.11477 | 0.99464 |

| 0.20 | 1.23896 | 1.14585 | 1.23170 | 1.13789 | 1.22623 | 1.13187 |

Table 8.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 1.0.

Table 8.

Linear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 1.0.

| ξ1 = 1.0 |

|---|

| λc | | | |

|---|

| | | | | |

|---|

| 0.10 | 0.99999 | 0.91331 | 0.99115 | 0.90336 | 0.98444 | 0.89581 |

| 0.20 | 1.11740 | 0.94718 | 1.13331 | 0.93774 | 1.14511 | 0.93058 |

Table 9.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.0 in the case of First-Order Hamiltonian Approach.

Table 9.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.0 in the case of First-Order Hamiltonian Approach.

| ξ1 = 0.0 | | | | |

|---|

| | | | | |

|---|

| λc = 0.1 | 0.00 | 1.33333 | 1.15406 | 1.32613 | 1.14551 | 1.32070 | 1.13904 |

| 0.01 | 1.33469 | 1.15575 | 1.32761 | 1.14769 | 1.32236 | 1.14117 |

| 0.05 | 1.36706 | 1.19553 | 1.36270 | 1.19886 | 1.36164 | 1.19121 |

| 0.10 | 1.46359 | 1.31211 | 1.46697 | 1.34630 | 1.47766 | 1.33554 |

| λc = 0.2 | 0.00 | 1.84414 | 1.58369 | 1.83894 | 1.57754 | 1.83504 | 1.57291 |

| 0.01 | 1.84464 | 1.58430 | 1.83950 | 1.57821 | 1.83564 | 1.57364 |

| 0.05 | 1.85680 | 1.59886 | 1.85269 | 1.59406 | 1.85004 | 1.59117 |

| 0.10 | 1.89429 | 1.64355 | 1.89333 | 1.64262 | 1.89435 | 1.64471 |

Table 10.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.5 in the case of First-Order Hamiltonian Approach.

Table 10.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.5 in the case of First-Order Hamiltonian Approach.

| ξ1 = 0.5 | | | | |

|---|

| | | | | |

|---|

| λc = 0.1 | 0.00 | 1.12891 | 1.01093 | 1.12085 | 1.00166 | 1.11477 | 0.99464 |

| 0.01 | 1.13040 | 1.01267 | 1.12250 | 1.00362 | 1.11666 | 0.99695 |

| 0.05 | 1.16559 | 1.05373 | 1.16131 | 1.04952 | 1.16128 | 1.05087 |

| 0.10 | 1.26930 | 1.17279 | 1.27499 | 1.18153 | 1.29082 | 1.20390 |

| λc = 0.2 | 0.00 | 1.23896 | 1.14585 | 1.23170 | 1.13789 | 1.22623 | 1.13187 |

| 0.01 | 1.23965 | 1.14660 | 1.23247 | 1.13872 | 1.22711 | 1.13284 |

| 0.05 | 1.25622 | 1.16447 | 1.25082 | 1.15865 | 1.24806 | 1.15590 |

| 0.10 | 1.30663 | 1.21862 | 1.30650 | 1.21884 | 1.31137 | 1.22516 |

Table 11.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 1.0 in the case of First-Order Hamiltonian Approach.

Table 11.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 1.0 in the case of First-Order Hamiltonian Approach.

| ξ1 = 1.0 | | | | |

|---|

| | | | | |

|---|

| λc = 0.1 | 0.00 | 0.99999 | 0.91331 | 0.99115 | 0.90336 | 0.98444 | 0.89581 |

| 0.01 | 1.00161 | 0.91514 | 0.99296 | 0.90544 | 0.98658 | 0.89832 |

| 0.05 | 1.03951 | 0.95786 | 1.03544 | 0.95401 | 1.03662 | 0.95670 |

| 0.10 | 1.14994 | 1.08052 | 1.15820 | 1.09195 | 1.17937 | 1.11968 |

| λc = 0.2 | 0.00 | 1.11740 | 0.94718 | 1.13331 | 0.93774 | 1.14511 | 0.93058 |

| 0.01 | 1.11837 | 0.94804 | 1.13444 | 0.93872 | 1.14645 | 0.93176 |

| 0.05 | 1.14139 | 0.96837 | 1.16110 | 0.96200 | 1.17811 | 0.95983 |

| 0.10 | 1.21050 | 1.02932 | 1.24073 | 1.03137 | 1.27198 | 1.04266 |

Table 12.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.0 in the case of Second-Order Hamiltonian Approach.

Table 12.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.0 in the case of Second-Order Hamiltonian Approach.

| ξ1 = 0.0 | | | | |

|---|

| | | | | |

|---|

| λc = 0.1 | 0.00 | 1.33333 | 1.15406 | 1.32613 | 1.14551 | 1.32070 | 1.13904 |

| 0.01 | 1.33469 | 1.15575 | 1.32761 | 1.14769 | 1.32236 | 1.41117 |

| 0.05 | 1.36699 | 1.19542 | 1.36263 | 1.19868 | 1.36154 | 1.19103 |

| 0.10 | 1.46272 | 1.31073 | 1.46596 | 1.34421 | 1.47644 | 1.33352 |

| λc = 0.2 | 0.00 | 1.84414 | 1.58369 | 1.83894 | 1.57754 | 1.83504 | 1.57291 |

| 0.01 | 1.84464 | 1.58430 | 1.83950 | 1.57821 | 1.83564 | 1.57364 |

| 0.05 | 1.85679 | 1.59885 | 1.85268 | 1.59405 | 1.85003 | 1.59115 |

| 0.10 | 1.89418 | 1.64338 | 1.89320 | 1.64241 | 1.89421 | 1.64447 |

Table 13.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.5 in the case of Second-Order Hamiltonian Approach.

Table 13.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.5 in the case of Second-Order Hamiltonian Approach.

| ξ1 = 0.5 | | | | |

|---|

| | | | | |

|---|

| λc = 0.1 | 0.00 | 1.12891 | 1.01093 | 1.12085 | 1.00166 | 1.11477 | 0.99464 |

| 0.01 | 1.13040 | 1.01267 | 1.12250 | 1.00362 | 1.11666 | 0.99695 |

| 0.05 | 1.16550 | 1.05359 | 1.16199 | 1.04935 | 1.16133 | 1.05064 |

| 0.10 | 1.26817 | 1.17121 | 1.27364 | 1.17962 | 1.28911 | 1.20143 |

| λc = 0.2 | 0.00 | 1.23896 | 1.14585 | 1.23170 | 1.13789 | 1.22623 | 1.13187 |

| 0.01 | 1.23965 | 1.14660 | 1.23247 | 1.13872 | 1.22711 | 1.13284 |

| 0.05 | 1.25620 | 1.16445 | 1.25080 | 1.15862 | 1.24802 | 1.15585 |

| 0.10 | 1.30635 | 1.21828 | 1.30616 | 1.21842 | 1.31904 | 1.22461 |

Table 14.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 1.0 in the case of Second-Order Hamiltonian Approach.

Table 14.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 1.0 in the case of Second-Order Hamiltonian Approach.

| ξ1 = 1.0 | | | | |

|---|

| | | | | |

|---|

| λc = 0.1 | 0.00 | 0.99999 | 0.91331 | 0.99115 | 0.90336 | 0.98444 | 0.89581 |

| 0.01 | 1.00161 | 0.91514 | 0.99296 | 0.90544 | 0.98658 | 0.89832 |

| 0.05 | 1.03939 | 0.95769 | 1.03529 | 0.95380 | 1.03641 | 0.95640 |

| 0.10 | 1.14854 | 1.07872 | 1.15650 | 1.08974 | 1.17716 | 1.11674 |

| λc = 0.2 | 0.00 | 1.11740 | 0.94718 | 1.13331 | 0.93774 | 1.14511 | 0.93058 |

| 0.01 | 1.11837 | 0.94804 | 1.13444 | 0.93872 | 1.14645 | 0.93176 |

| 0.05 | 1.14135 | 0.96833 | 1.16105 | 0.96195 | 1.17804 | 0.95975 |

| 0.10 | 1.20955 | 1.02882 | 1.24003 | 1.03073 | 1.27104 | 1.04178 |

Table 15.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.0 in the case of Third-Order Hamiltonian Approach.

Table 15.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.0 in the case of Third-Order Hamiltonian Approach.

| ξ1 = 0.0 | | | | |

|---|

| | | | | |

|---|

| λc = 0.1 | 0.00 | 1.33333 | 1.15406 | 1.32613 | 1.14551 | 1.32070 | 1.13904 |

| 0.01 | 1.33469 | 1.15575 | 1.32761 | 1.14769 | 1.32236 | 1.14117 |

| 0.05 | 1.36699 | 1.19542 | 1.36262 | 1.19867 | 1.36154 | 1.19102 |

| 0.10 | 1.46271 | 1.31070 | 1.46595 | 1.34416 | 1.47642 | 1.33347 |

| λc = 0.2 | 0.00 | 1.84414 | 1.58369 | 1.83894 | 1.57754 | 1.83504 | 1.57291 |

| 0.01 | 1.84464 | 1.58430 | 1.83850 | 1.57821 | 1.83564 | 1.57364 |

| 0.05 | 1.85679 | 1.59885 | 1.85268 | 1.59405 | 1.85003 | 1.59115 |

| 0.10 | 1.89417 | 1.64337 | 1.89319 | 1.64241 | 1.89420 | 1.64446 |

Table 16.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.5 in the case of Third-Order Hamiltonian Approach.

Table 16.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 0.5 in the case of Third-Order Hamiltonian Approach.

| ξ1 = 0.5 | | | | |

|---|

| | | | | |

|---|

| λc = 0.1 | 0.00 | 1.12891 | 1.01093 | 1.12085 | 1.00166 | 1.11477 | 0.99464 |

| 0.01 | 1.13040 | 1.01267 | 1.12250 | 1.00362 | 1.11666 | 0.99695 |

| 0.05 | 1.16550 | 1.05359 | 1.16199 | 1.04935 | 1.16113 | 1.05087 |

| 0.10 | 1.26815 | 1.17117 | 1.27362 | 1.17958 | 1.28907 | 1.20390 |

| λc = 0.2 | 0.00 | 1.23896 | 1.14585 | 1.23170 | 1.13789 | 1.22623 | 1.13187 |

| 0.01 | 1.23965 | 1.14660 | 1.23247 | 1.13872 | 1.22711 | 1.13284 |

| 0.05 | 1.25620 | 1.16445 | 1.25080 | 1.15862 | 1.24802 | 1.15585 |

| 0.10 | 1.30634 | 1.21827 | 1.30615 | 1.21841 | 1.31093 | 1.22460 |

Table 17.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 1.0 in the case of Third-Order Hamiltonian Approach.

Table 17.

Nonlinear dimensionless natural frequencies of porous FG clamped–clamped (C–C) nano-beam for ξ1 = 1.0 in the case of Third-Order Hamiltonian Approach.

| ξ1 = 1.0 | | | | |

|---|

| | | | | |

|---|

| λc = 0.1 | 0.00 | 0.99999 | 0.91331 | 0.99115 | 0.90336 | 0.98444 | 0.89581 |

| 0.01 | 1.00161 | 0.91514 | 0.99296 | 0.90544 | 0.98658 | 0.89832 |

| 0.05 | 1.03939 | 0.95769 | 1.03529 | 0.95380 | 1.03641 | 0.95640 |

| 0.10 | 1.14851 | 1.07868 | 1.15646 | 1.08968 | 1.17711 | 1.11665 |

| λc = 0.2 | 0.00 | 1.11740 | 0.94718 | 1.13331 | 0.93774 | 1.14511 | 0.93058 |

| 0.01 | 1.11837 | 0.94804 | 1.13444 | 0.93872 | 1.14645 | 0.97176 |

| 0.05 | 1.14135 | 0.96833 | 1.16105 | 0.96195 | 1.17804 | 0.95975 |

| 0.10 | 1.20954 | 1.02881 | 1.24002 | 1.03072 | 1.27103 | 1.04176 |

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).