A Novel Two-Stage Heat Treatment with Medium-Temperature Aging Influence on Microstructure, Al3(Sc, Zr) Nanoprecipitation, and Application Properties, Enhancing Selective Laser Melting of Al–Mg–Sc–Zr Alloy

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

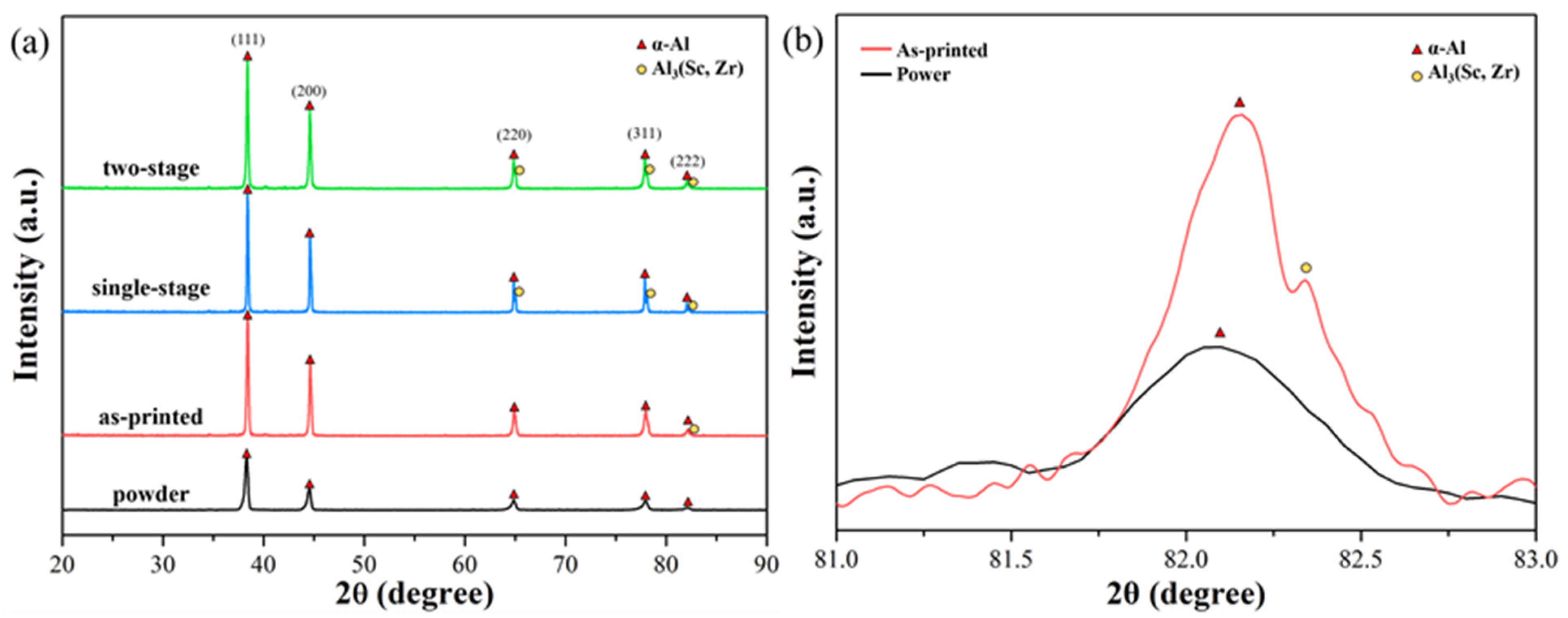

3.1. Microstructure and Phase Analysis

3.2. Mechanical Properties at Room Temperature

3.3. High-Temperature Mechanical Properties

3.4. Rotation Fatigue Characteristics

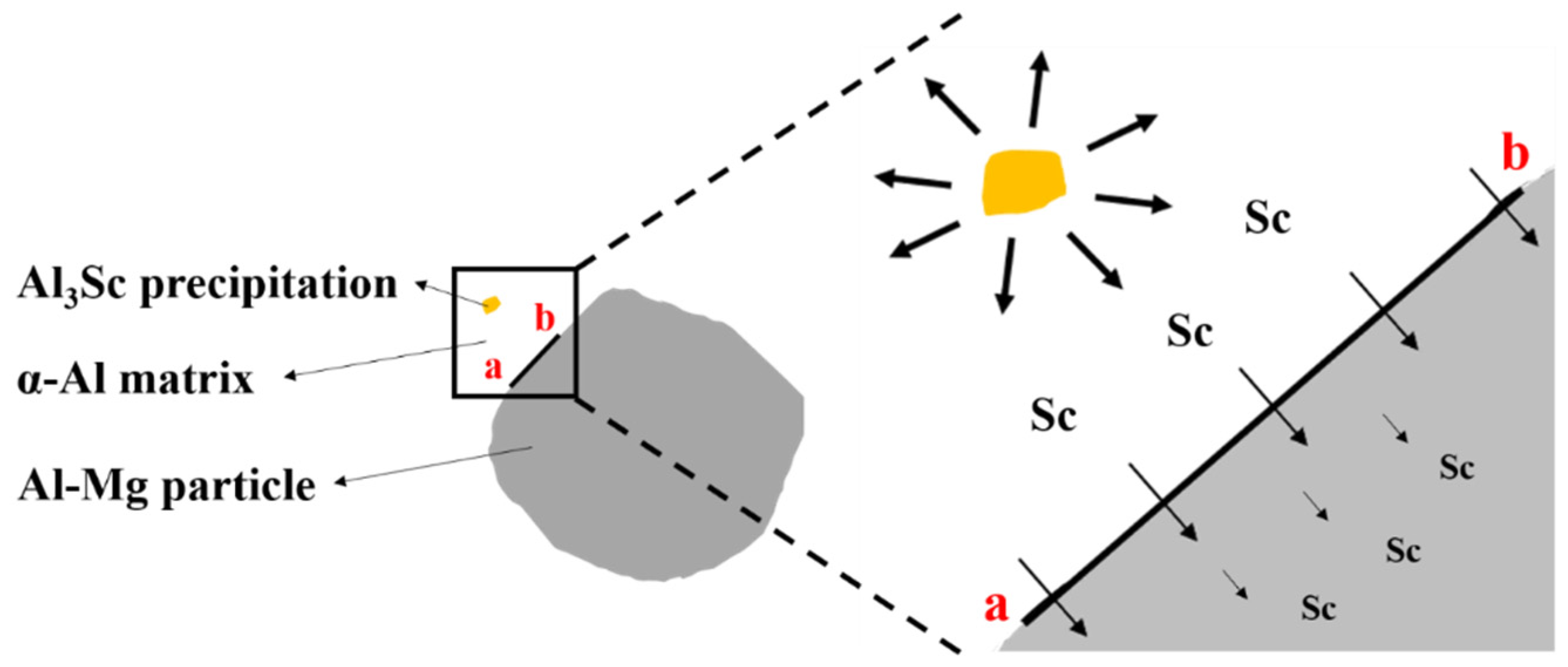

3.5. Thermal Diffusion and Strengthening Effect during Two-Stage Heat Treatment

4. Conclusions

- After single-stage heat treatment, Al3(Sc, Zr) precipitated at the boundaries with a residual melting pool texture effect increasing its strength but decreasing its ductility. The combination of single-stage heat treatment and solid solution treatment (two-stage heat treatment) decomposes the melting pool structure and induces a homogeneous precipitation, thereby apparently increasing the fatigue resistance.

- As the tensile temperature increased, the DSA effect of each specimen decreased. At 100 °C, where the DSA effect decreased, SLM Al–Mg–Sc–Zr alloy exhibited the highest high-temperature strength, and the upper limit for high-temperature applications was approximately 200 °C.

- After the two-stage heat treatment process, the melting pool boundaries of SLM Al–Mg–Sc–Zr alloys decomposed and precipitated homogeneously. The Sc strengthening mechanism was composed of Al3Sc precipitation and Sc solid solution after thermal diffusion under heat treatment, increasing matrix strength and inhibiting fatigue crack propagation to provide high fatigue resistance.

- Overall, the two-stage-heat-treated SLM Al–Mg–Sc–Zr alloy shows better mechanical tensile properties and fatigue resistance, providing wide applicability as an additive manufacturing Al alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Avtokratova, E.; Sitdikov, O.; Markushev, M.; Mulyukov, R. Extraordinary high-strain rate superplasticity of severely deformed Al–Mg–Sc–Zr alloy. Mater. Sci. Eng. A 2012, 538, 386–390. [Google Scholar] [CrossRef]

- Filatov, Y.A.; Yelagin, V.I.; Zakharov, V.V. New Al–Mg–Sc alloys. Mater. Sci. Eng. A 2000, 280, 97–101. [Google Scholar] [CrossRef]

- Fang, H.; Liu, H.; Yan, Y.; Luo, X.; Xu, X.; Chu, X.; Lu, Y.; Yu, K.; Wang, D. Evolution of Texture, Microstructure, Tensile Strength and Corrosion Properties of Annealed Al-Mg-Sc-Zr Alloys. Mater. Sci. Eng. A 2020, 804, 140682. [Google Scholar] [CrossRef]

- Barnes, A.J.; Raman, H.; Lowerson, A.; Edwards, D. Recent application of superformed 5083 aluminum alloy in the aerospace industry. Mater. Sci. Forum 2013, 735, 361–371. [Google Scholar] [CrossRef]

- Joy, D.; Aravindakshan, R.; Varrma, N.S. Effect of Zirconium additions on microstructure and mechanical properties of hot rolled Al-Mg alloys. Mater. Today Proceedings 2021, 47, 5098–5103. [Google Scholar]

- Churyumov, A.Y.; Pozdniakov, A.V.; Prosviryakov, A.S.; Loginova, I.S.; Daubarayte, D.K.; Ryabov, D.K.; Korolev, V.A.; Solonin, A.N.; Pavlov, M.D.; Valchuk, S.V. Microstructure and mechanical properties of a novel selective laser melted Al–Mg alloy with low Sc content. Mater. Res. Express. 2019, 6, 126595. [Google Scholar] [CrossRef]

- Vinogradov, A.; Washikita, A.; Kitagawa, K.; Kopylov, V.I. Fatigue life of fine-grain Al–Mg–Sc alloys produced by equal-channel angular pressing. Mater. Sci. Eng. A 2003, 349, 318–326. [Google Scholar] [CrossRef]

- Sawtell, R.R.; Jensen, C.L. Mechanical properties and microstructures of Al-Mg-Sc alloys. Metall. Trans. A 1990, 21, 421–430. [Google Scholar] [CrossRef]

- Ma, R.; Peng, C.; Cai, Z.; Wang, R.; Zhou, Z.; Li, X.; Cao, X. Effect of bimodal microstructure on the tensile properties of selective laser melt Al-Mg-Sc-Zr alloy. J. Alloys Compd. 2020, 815, 152422. [Google Scholar] [CrossRef]

- Gu, D.; Zhang, H.; Dai, D.; Ma, C.; Zhang, H.; Li, Y.; Li, S. Anisotropic corrosion behavior of Sc and Zr modified Al-Mg alloy produced by selective laser melting. Corros. Sci. 2020, 170, 108657. [Google Scholar] [CrossRef]

- Kendig, K.L.; Miracle, D.B. Strengthening mechanisms of an Al-Mg-Sc-Zr alloy. Acta Mater. 2002, 50, 4165–4175. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, X.; Kang, N.; Hu, Y.; Chen, J.; Huang, W. Strength-ductility synergy of selective laser melted Al-Mg-Sc-Zr alloy with a heterogeneous grain structure. Addit. Manuf. 2020, 34, 101260. [Google Scholar] [CrossRef]

- Ren, L.; Gu, H.; Wang, W.; Wang, S.; Li, C.; Wang, Z.; Zhai, Y.; Ma, P. Effect of Mg content on microstructure and properties of Al–Mg alloy produced by the wire arc additive manufacturing method. Materials 2019, 12, 4160. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Spierings, A.B.; Dawson, K.; Dumitraschkewitz, P.; Pogatscher, S.; Wegener, K. Microstructure characterization of SLM-processed Al-Mg-Sc-Zr alloy in the heat treated and HIPed condition. Addit. Manuf. 2018, 20, 173–181. [Google Scholar] [CrossRef]

- Sun, S.; Liu, P.; Hu, J.; Hong, C.; Qiao, X.; Liu, S.; Zhang, R.; Wu, C. Effect of solid solution plus double aging on microstructural characterization of 7075 Al alloys fabricated by selective laser melting (SLM). Opt. Laser Technol. 2019, 114, 158–163. [Google Scholar] [CrossRef]

- Chen, K.J.; Hung, F.Y.; Lui, T.S.; Tsai, C.L. Improving the applicability of wear-resistant Al-10Si-0.5Mg alloy obtained through selective laser melting with T6 treatment in high-temperature, and high-wear environments. J. Mater. Res. Technol. 2020, 9, 9242–9252. [Google Scholar] [CrossRef]

- Li, R.; Wang, M.; Li, Z.; Cao, P.; Yuan, T.; Zhu, H. Developing a high-strength Al-Mg-Si-Sc-Zr alloy for selective laser melting: Crack-inhibiting and multiple strengthening mechanisms. Acta Mater. 2020, 193, 83–98. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Kern, K.; Palm, F.; Wegener, K. SLM-processed Sc-and Zr-modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment. Mater. Sci. Eng. A 2017, 701, 264–273. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Musin, F.; Lesuer, D.R.; Nieh, T.G. Superplastic behavior of an Al–Mg alloy at elevated temperatures. Mater. Sci. Eng. A 2003, 342, 169–177. [Google Scholar] [CrossRef]

- Musin, F.; Kaibyshev, R.; Motohashi, Y.; Itoh, G. High strain rate superplasticity in a commercial Al–Mg–Sc alloy. Scr. Mater. 2004, 50, 511–516. [Google Scholar] [CrossRef]

- Chang, K.C.; Zhao, J.R.; Hung, F.Y. Microstructure, Mechanical Properties, and Fatigue Fracture Characteristics of High-Fracture-Resistance Selective Laser Melting Al-Ni-Cu Alloys. Metals 2021, 11, 87. [Google Scholar] [CrossRef]

- Besel, M.; Besel, Y.; Mercado, U.A.; Kakiuchi, T.; Uematsu, Y. Fatigue behavior of friction stir welded Al–Mg–Sc alloy. Int. J. Fatigue 2015, 77, 1–11. [Google Scholar] [CrossRef]

- Li, R.; Chen, H.; Chen, C.; Zhu, H.; Wang, M.; Yuan, T.; Song, B. Selective laser melting of gas atomized Al–3.02 Mg–0.2 Sc–0.1 Zr alloy powder: Microstructure and mechanical properties. Adv. Eng. Mater. 2019, 21, 1800650. [Google Scholar] [CrossRef]

- Avtokratova, E.; Sitdikov, O.; Mukhametdinova, O.; Markushev, M.; Murty, S.N.; Prasad, M.J.N.V.; Kashyap, B.P. Microstructural evolution in Al–Mg–Sc–Zr alloy during severe plastic deformation and annealing. J. Alloys Compd. 2016, 673, 182–194. [Google Scholar] [CrossRef]

- Rajasekaran, S.; Udayashankar, N.K.; Nayak, J. T4 and T6 treatment of 6061 Al-15 vol.% SiCP composite. Int. Math. Res. Not. 2012, 2012, 374719. [Google Scholar] [CrossRef] [Green Version]

- Xia, S.L.; Ma, M.; Zhang, J.X.; Wang, W.X.; Liu, W.C. Effect of heating rate on the microstructure, texture and tensile properties of continuous cast AA 5083 aluminum alloy. Mater. Sci. Eng. A 2014, 609, 168–176. [Google Scholar] [CrossRef]

- Zhang, H.; Gu, D.; Dai, D.; Ma, C.; Li, Y.; Cao, M.; Li, S. Influence of heat treatment on corrosion behavior of rare earth element Sc modified Al-Mg alloy processed by selective laser melting. Appl. Surf. Sci. 2020, 509, 145330. [Google Scholar] [CrossRef]

- Cottrell, H.; Jaswon, M.A. Distribution of Solute Atoms Round a Slow Dislocation, P. Roy. Soc. Lond. A Mat. 1949, 199, 104–114. [Google Scholar]

- Cottrell, A.H. A note on the Portevin-Le Chatelier Effect. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1953, 44, 829–832. [Google Scholar] [CrossRef]

- Shin, J.H.; Rim, G.Y.; Kim, S.D.; Jang, J.H.; Park, S.J.; Lee, J. Effects of aging heat-treatment on dynamic strain aging behavior in high-Mn lightweight steel. Mater. Charact. 2020, 164, 110316. [Google Scholar] [CrossRef]

- Zhou, P.; Song, Y.; Hua, L.; Lu, J.; Zhang, J.; Wang, F. Mechanical behavior and deformation mechanism of 7075 aluminum alloy under solution induced dynamic strain aging. Mater. Sci. Eng. A 2019, 759, 498–505. [Google Scholar] [CrossRef]

- Robinson, J.M.; Shaw, M.P. Microstructural and mechanical influences on dynamic strain aging phenomena. Int. Mater. Rev. 1994, 39, 113–122. [Google Scholar] [CrossRef]

- Rodriguez, P. Serrated plastic flow. Bull. Mater. Sci. 1984, 6, 653–663. [Google Scholar] [CrossRef]

- Guo, H.; Yan, P.F.; Wang, Y.B.; Tan, J.; Zhang, Z.F.; Sui, M.L.; Ma, E. Tensile ductility and necking of metallic glass. Nat. Mater. 2007, 6, 735–739. [Google Scholar] [CrossRef] [PubMed]

- Ling, Y. Uniaxial true stress-strain after necking. AMP J. Technol. 1996, 5, 37–48. [Google Scholar]

- Knysh, P.; Korkolis, Y.P. Identification of the post-necking hardening response of rate-and temperature-dependent metals. Int. J. Solids Struct 2017, 115, 149–160. [Google Scholar] [CrossRef]

- Lin, J. Selection of material models for predicting necking in superplastic forming. Int. J. Plast. 2003, 19, 469–481. [Google Scholar] [CrossRef]

- Bahaideen, F.B.; Saleem, A.M.; Hussain, K.; Ripin, Z.M.; Ahmad, Z.A.; Samad, Z.; Badarulzaman, N.A. Fatigue behaviour of aluminum alloy at elevated temperature. Mod. Appl. Sci. 2009, 3, 52–61. [Google Scholar] [CrossRef]

- Nakamura, Y.; Sakai, T.; Hirano, H.; Chandran, K.R. Effect of alumite surface treatments on long-life fatigue behavior of a cast aluminum in rotating bending. Int. J. Fatigue 2010, 32, 621–626. [Google Scholar] [CrossRef]

- Kuwamura, H. Transition between fatigue and ductile fracture in steel. J. Struct. Eng. 1997, 123, 864–870. [Google Scholar] [CrossRef]

- Farfan, S.; Rubio-Gonzalez, C.; Cervantes-Hernandez, T.; Mesmacque, G. High cycle fatigue, low cycle fatigue and failure modes of a carburized steel. Int. J. Fatigue 2004, 26, 673–678. [Google Scholar] [CrossRef]

- Hiraiwa, C.; Han, D.; Kuramitsu, A.; Kuwabara, A.; Takeuchi, H.; Majima, M.; Uda, T. Chemical expansion and change in lattice constant of Y-doped BaZrO3 by hydration/dehydration reaction and final heat-treating temperature. J. Am. Ceram. Soc. 2013, 96, 879–884. [Google Scholar] [CrossRef]

- Chang, K.C.; Zhao, J.R.; Hung, F.Y. Effects of Hyper-High-Temperature Solid-Solution Treatment on Microstructure Evolution and Nanoprecipitation of the Al-Ni-Cu-Fe-Zr-Sc Alloy Manufactured by Selective Laser Melting. J. Alloys Compd. 2021, 883, 160781. [Google Scholar] [CrossRef]

- Kilian, R.; Heilbronner, R.; Stünitz, H. Quartz grain size reduction in a granitoid rock and the transition from dislocation to diffusion creep. J. Struct. Geol. 2011, 33, 1265–1284. [Google Scholar] [CrossRef]

| Laser Power | Scanning Speed | Beam Size | Hatch Space | Layer Thickness |

|---|---|---|---|---|

| 300 W | 700 mm/s | 35 μm | 100 μm | 30 μm |

| Element | Al | Mg | Sc | Zr | Mn |

| Wt.% | Bal. | 4.50–5.10 | 0.68–0.88 | 0.21–0.52 | 0.30–0.81 |

| Element | Si | Fe | Ti | O | H |

| Wt.% | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.05 | ≤0.01 |

| Specimen ID | Specimen Type | Heat Treatment |

|---|---|---|

| A | as-printed | None |

| B | single-stage heat treatment | 350 °C for 6 h/air cooling |

| C | two-stage heat treatment | 500 °C for 1 h/water quenching + 350 °C for 6 h/air cooling |

| YS (MPa) | UTS (MPa) | UE (%) | TE (%) | HRF | |

|---|---|---|---|---|---|

| A | 244 | 315 | 21.1 | 22.7 | 95 |

| B | 356 | 384 | 9.6 | 11.7 | 107 |

| C | 255 | 334 | 15.6 | 17.1 | 93 |

| Temperature | YS (MPa) | UTS (MPa) | UE (%) | TE (%) | |

|---|---|---|---|---|---|

| A | Room temperature | 244 | 315 | 21.1 | 22.7 |

| 100 °C | 269 | 332 | 16.1 | 18.1 | |

| 150 °C | 244 | 285 | 16.9 | 21.1 | |

| 200 °C | 230 | 237 | 1.1 | 20.7 | |

| 250 °C | 208 | 219 | 2.2 | 13.0 | |

| 300 °C | 142 | 169 | 2.7 | 17.0 | |

| 350 °C | 70 | 75 | 0.9 | 15.1 | |

| B | Room temperature | 356 | 384 | 9.6 | 11.8 |

| 100 °C | 385 | 414 | 11.8 | 13.7 | |

| 150 °C | 331 | 351 | 1.1 | 15.5 | |

| 200 °C | 318 | 324 | 0.6 | 13.8 | |

| 250 °C | 156 | 167 | 1.3 | 11.7 | |

| 300 °C | 151 | 164 | 1.7 | 15.8 | |

| 350 °C | 65 | 72 | 1.5 | 30.8 | |

| C | Room temperature | 255 | 334 | 15.6 | 17.1 |

| 100 °C | 268 | 352 | 16.1 | 18.1 | |

| 150 °C | 185 | 266 | 17.1 | 19.5 | |

| 200 °C | 160 | 183 | 9.6 | 21.5 | |

| 250 °C | 130 | 137 | 4.1 | 22.0 | |

| 300 °C | 73 | 83 | 2.1 | 23.4 | |

| 350 °C | 16 | 19 | 1.2 | 15.2 |

| Load (kg) | Stress (kg/mm2) | N (Average Number of Cycles to Failure) |

|---|---|---|

| A (as-printed) | ||

| 7 | 33.0 | 24,714 |

| 12 | 56.6 | 17,571 |

| 17 | 80.2 | 10,373 |

| 22 | 103.7 | 8005 |

| B (single-stage) | ||

| 7 | 33.0 | 31,272 |

| 12 | 56.6 | 20,241 |

| 17 | 80.2 | 15,696 |

| 22 | 103.7 | 11,288 |

| C (two-stage) | ||

| 7 | 33.0 | 42,455 |

| 12 | 56.6 | 30,353 |

| 17 | 80.2 | 26,785 |

| 22 | 103.7 | 21,303 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.-R.; Lee, L.-Y.; Chang, K.-C.; Hung, F.-Y. A Novel Two-Stage Heat Treatment with Medium-Temperature Aging Influence on Microstructure, Al3(Sc, Zr) Nanoprecipitation, and Application Properties, Enhancing Selective Laser Melting of Al–Mg–Sc–Zr Alloy. Nanomaterials 2022, 12, 2078. https://doi.org/10.3390/nano12122078

Zhao J-R, Lee L-Y, Chang K-C, Hung F-Y. A Novel Two-Stage Heat Treatment with Medium-Temperature Aging Influence on Microstructure, Al3(Sc, Zr) Nanoprecipitation, and Application Properties, Enhancing Selective Laser Melting of Al–Mg–Sc–Zr Alloy. Nanomaterials. 2022; 12(12):2078. https://doi.org/10.3390/nano12122078

Chicago/Turabian StyleZhao, Jun-Ren, Liang-Yan Lee, Kai-Chieh Chang, and Fei-Yi Hung. 2022. "A Novel Two-Stage Heat Treatment with Medium-Temperature Aging Influence on Microstructure, Al3(Sc, Zr) Nanoprecipitation, and Application Properties, Enhancing Selective Laser Melting of Al–Mg–Sc–Zr Alloy" Nanomaterials 12, no. 12: 2078. https://doi.org/10.3390/nano12122078

APA StyleZhao, J.-R., Lee, L.-Y., Chang, K.-C., & Hung, F.-Y. (2022). A Novel Two-Stage Heat Treatment with Medium-Temperature Aging Influence on Microstructure, Al3(Sc, Zr) Nanoprecipitation, and Application Properties, Enhancing Selective Laser Melting of Al–Mg–Sc–Zr Alloy. Nanomaterials, 12(12), 2078. https://doi.org/10.3390/nano12122078