Review of Metasurfaces and Metadevices: Advantages of Different Materials and Fabrications

Abstract

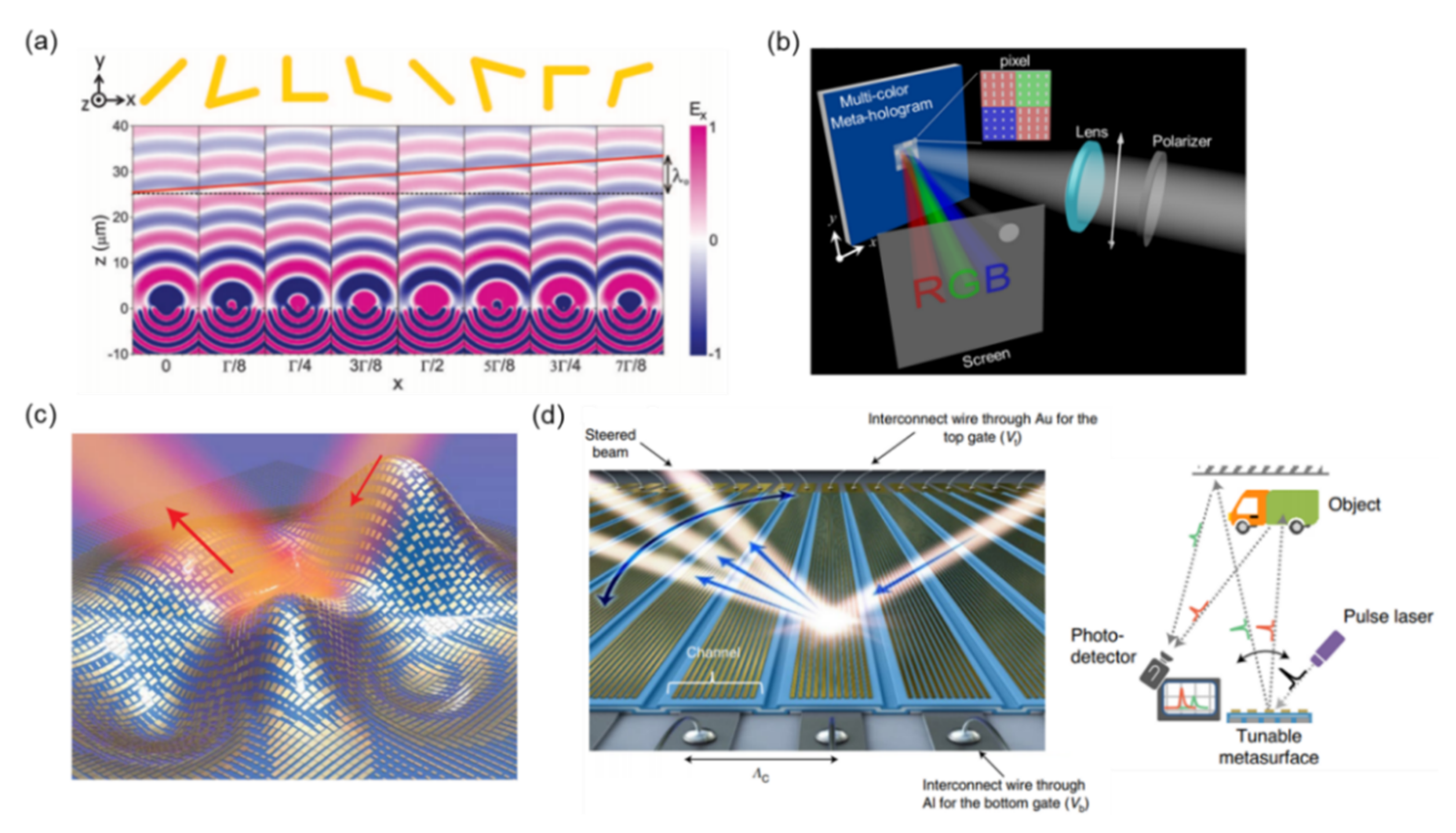

:1. Introduction

2. Metasurfaces Based on Different Materials

2.1. Metal-Based Metasurfaces

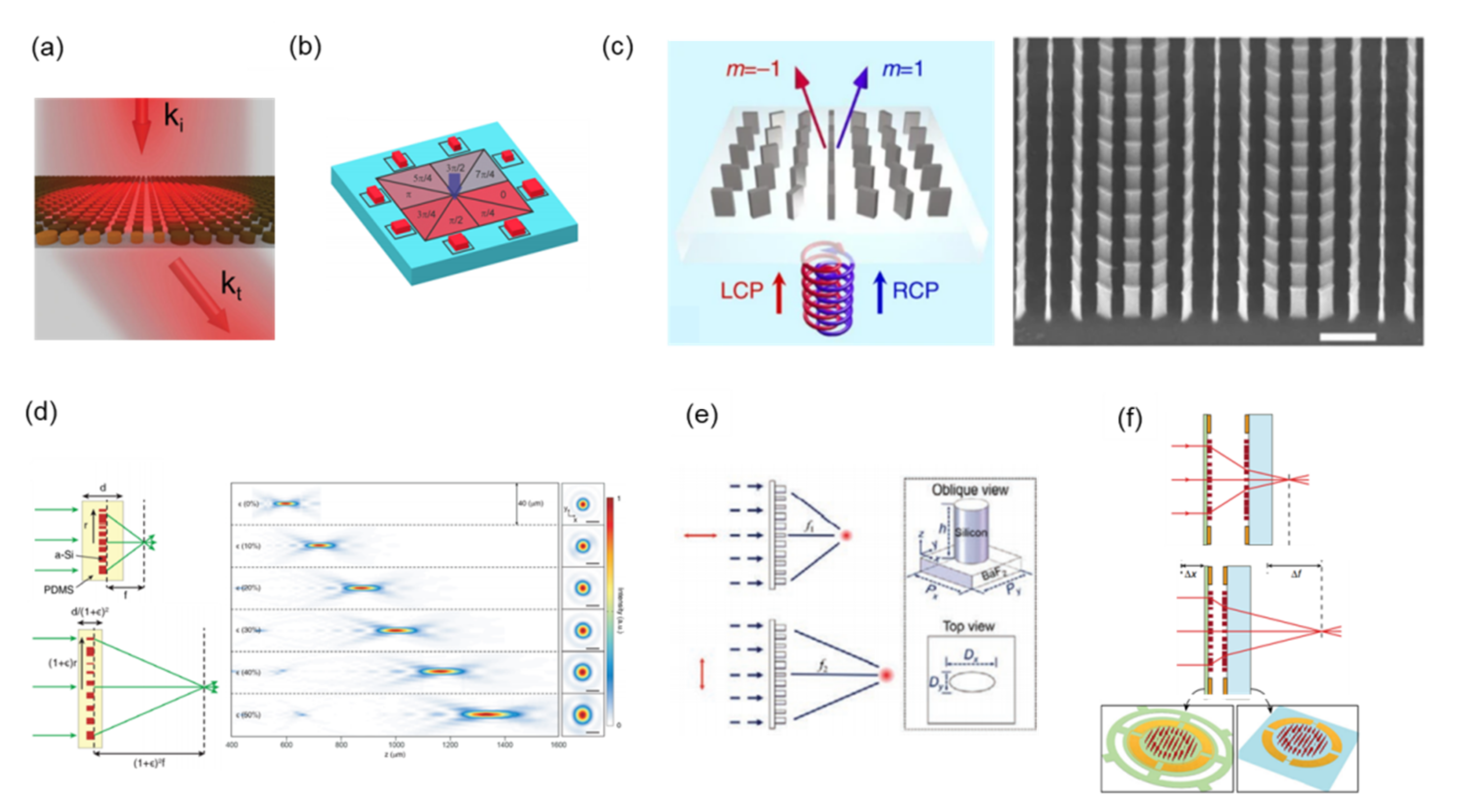

2.2. Si-Based Metasurfaces

2.3. TiO2-Based Metasurfaces

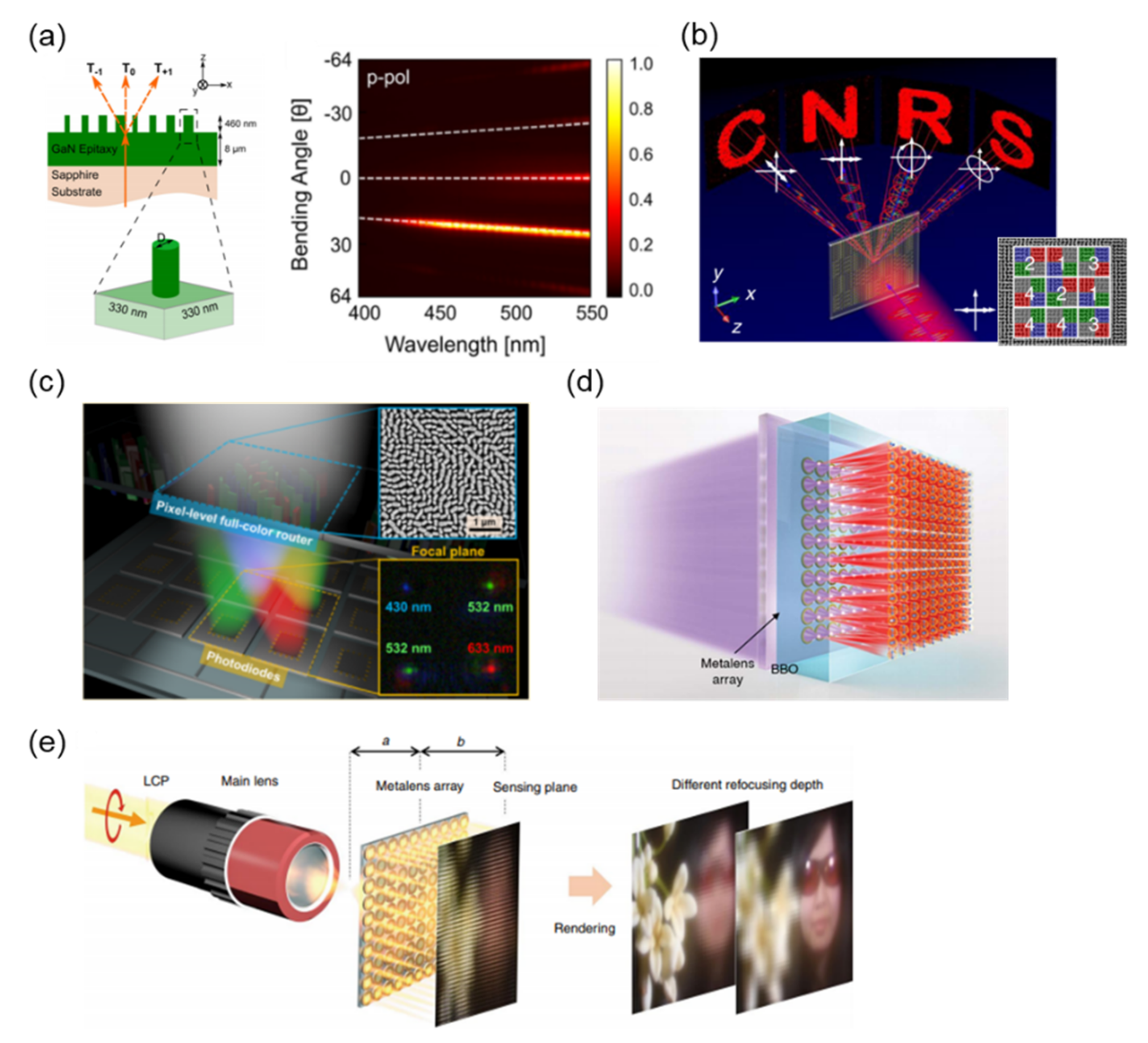

2.4. GaN-Based Metasurfaces

2.5. SiN-Based Metasurfaces

3. Fabrication Methods

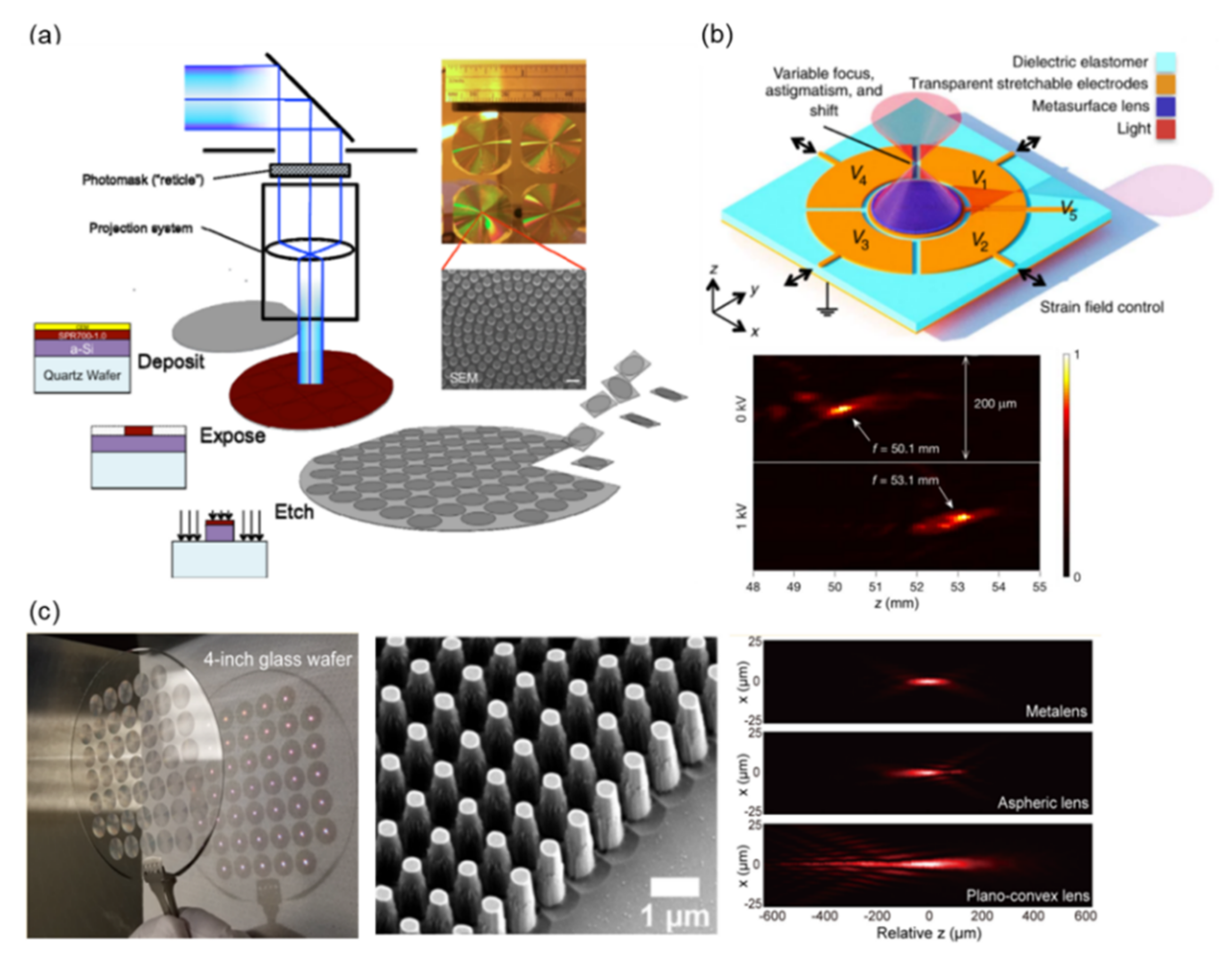

3.1. UV Lithography

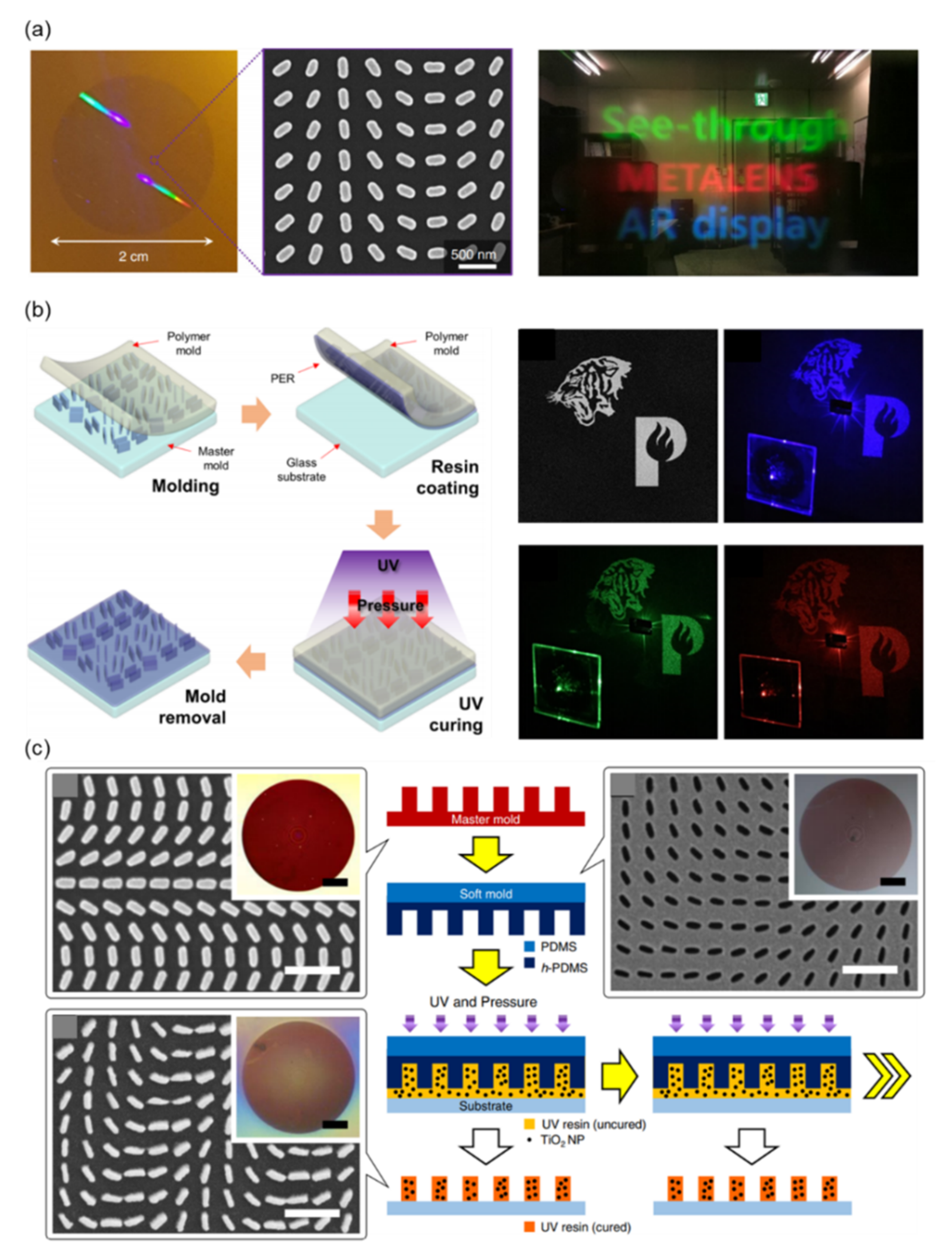

3.2. Nanoimprint Lithography

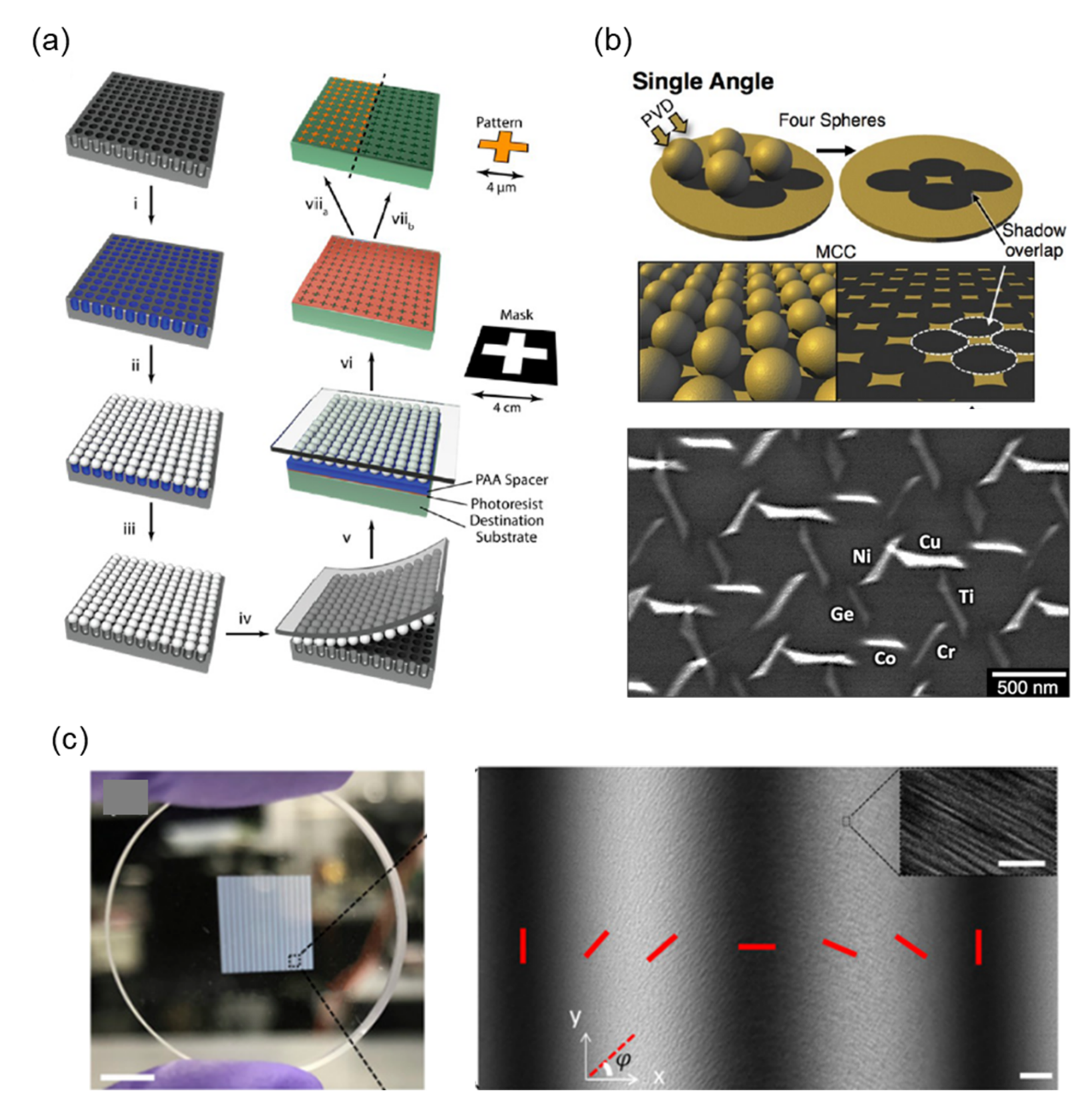

3.3. Other Processes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smith, D.R.; Pendry, J.B.; Wiltshire, M.C.K. Metamaterials and Negative Refractive Index. Science 2004, 305, 788–792. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Valentine, J.; Zhang, S.; Zentgraf, T.; Ulin-Avila, E.; Genov, D.A.; Bartal, G.; Zhang, X. Three-dimensional optical metamaterial with a negative refractive index. Nature 2008, 455, 376–379. [Google Scholar] [CrossRef] [PubMed]

- Hsu, L.; Ndao, A.; Kanté, B. Broadband and linear polarization metasurface carpet cloak in the visible. Opt. Lett. 2019, 44, 2978–2981. [Google Scholar] [CrossRef] [PubMed]

- Qian, C.; Zheng, B.; Shen, Y.C.; Jing, L.; Li, E.P.; Shen, L.; Chen, H.S. Deep-learning-enabled self-adaptive microwave cloak without human intervention. Nat. Photonics 2020, 14, 383–390. [Google Scholar] [CrossRef]

- Cheng, B.H.; Lan, Y.-C.; Tsai, D.P. Breaking optical diffraction limitation using optical Hybrid-Super-Hyperlens with radially polarized light. Opt. Express 2013, 21, 14898–14906. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Z. Superlenses to overcome the diffraction limit. Nat. Mater. 2008, 7, 435–441. [Google Scholar] [CrossRef]

- Cheng, B.H.; Ho, Y.Z.; Lan, Y.-C.; Tsai, D.P. Optical Hybrid-Superlens Hyperlens for Superresolution Imaging. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 4601305. [Google Scholar] [CrossRef]

- Murray, W.A.; Barnes, W.L. Plasmonic materials. Adv. Mater. 2007, 19, 3771–3782. [Google Scholar] [CrossRef]

- Larouche, S.; Tsai, Y.-J.; Tyler, T.; Jokerst, N.M.; Smith, D.R. Infrared metamaterial phase holograms. Nat. Mater. 2012, 11, 450–454. [Google Scholar] [CrossRef]

- Güney, D.O.; Koschny, T.; Soukoulis, C.M. Reducing ohmic losses in metamaterials by geometric tailoring. Phys. Rev. B 2009, 80, 125129. [Google Scholar] [CrossRef] [Green Version]

- Liu, N.; Guo, H.C.; Fu, L.W.; Kaiser, S.; Schweizer, H.; Giessen, H. Three-dimensional photonic metamaterials at optical frequencies. Nat. Mater. 2008, 7, 31–37. [Google Scholar] [CrossRef] [PubMed]

- Wu, P.C.; Liao, C.Y.; Chen, J.-W.; Tsai, D.P. Isotropic Absorption and Sensor of Vertical Split-Ring Resonator. Adv. Opt. Mater. 2017, 5, 1600581. [Google Scholar] [CrossRef]

- Tanaka, T.; Ishikawa, A. Towards three-dimensional optical metamaterials. Nano Converg. 2017, 4, 34. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tseng, M.L.; Wu, P.C.; Sun, S.; Chang, C.M.; Chen, W.T.; Chu, C.H.; Chen, P.L.; Zhou, L.; Huang, D.W.; Yen, T.J.; et al. Fabrication of multilayer metamaterials by femtosecond laser-induced forward-transfer technique. Laser Photonics Rev. 2012, 6, 702–707. [Google Scholar] [CrossRef]

- Sun, S.L.; Yang, K.-Y.; Wang, C.-M.; Juan, T.-K.; Chen, W.T.; Liao, C.Y.; He, Q.; Xiao, S.Y.; Kung, W.-T.; Guo, G.-Y.; et al. High-Efficiency Broadband Anomalous Reflection by Gradient Meta-Surfaces. Nano Lett. 2012, 12, 6223–6229. [Google Scholar] [CrossRef] [PubMed]

- Wu, P.C.; Chen, W.T.; Yang, K.-Y.; Hsiao, C.T.; Sun, G.; Liu, A.Q.; Zheludev, N.I.; Tsai, D.P. Magnetic plasmon induced transparency in three-dimensional metamolecules. Nanophotonics 2012, 1, 131–138. [Google Scholar] [CrossRef]

- Wu, P.C.; Sun, G.; Chen, W.T.; Yang, K.Y.; Huang, Y.W.; Chen, Y.H.; Huang, H.L.; Hsu, W.L.; Chiang, H.P.; Tsai, D.P. Vertical split-ring resonator based nanoplasmonic sensor. Appl. Phys. Lett. 2014, 105, 033105. [Google Scholar] [CrossRef]

- Deng, Z.-L.; Deng, J.; Zhuang, X.; Wang, S.; Shi, T.; Wang, G.P.; Wang, Y.; Xu, J.; Cao, Y.Y.; Wang, X.L.; et al. Facile metagrating holograms with broadband and extreme angle tolerance. Light. Sci. Appl. 2018, 7, 78. [Google Scholar] [CrossRef] [Green Version]

- Jang, M.; Horie, Y.; Shibukawa, A.; Brake, J.; Liu, Y.; Kamali, S.M.; Arbabi, A.; Ruan, H.W.; Faraon, A.; Yang, C.H. Wavefront shaping with disorder-engineered metasurfaces. Nat. Photonics 2018, 12, 84–90. [Google Scholar] [CrossRef]

- Yang, Y.M.; Wang, W.Y.; Moitra, P.; Kravchenko, I.I.; Briggs, D.P.; Valentine, J. Dielectric Meta-Reflectarray for Broadband Linear Polarization Conversion and Optical Vortex Generation. Nano Lett. 2014, 14, 1394–1399. [Google Scholar] [CrossRef]

- Liu, W.W.; Chen, S.Q.; Li, Z.C.; Cheng, H.; Yu, P.; Li, J.X.; Tian, J.G. Realization of broadband cross-polarization conversion in transmission mode in the terahertz region using a single-layer metasurface. Opt. Lett. 2015, 40, 3185–3188. [Google Scholar] [CrossRef]

- Ni, X.J.; Kildishev, A.V.; Shalaev, V.M. Metasurface holograms for visible light. Nat. Commun. 2013, 4, 2807. [Google Scholar] [CrossRef]

- Zheng, G.X.; Mühlenbernd, H.; Kenney, M.; Li, G.X.; Zentgraf, T.; Zhang, S. Metasurface holograms reaching 80% efficiency. Nat. Nanotechnol. 2015, 10, 308–312. [Google Scholar] [CrossRef] [PubMed]

- Hsu, W.-L.; Wu, P.C.; Chen, J.-W.; Chen, T.-Y.; Cheng, B.H.; Chen, W.T.; Huang, Y.-W.; Liao, C.Y.; Sun, G.; Tsai, D.P. Vertical split-ring resonator based anomalous beam steering with high extinction ratio. Sci. Rep. 2015, 5, 11226. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, D.; Fan, P.; Hasman, E.; Brongersma, M.L. Dielectric gradient metasurface optical elements. Science 2014, 345, 298–302. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.M.; Kravchenko, I.I.; Briggs, D.P.; Valentine, J. All-dielectric metasurface analogue of electromagnetically induced transparency. Nat. Commun. 2014, 5, 5753. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Monti, A.; Alu, A.; Toscano, A.; Bilotti, F. Surface Impedance Modeling of All-Dielectric Metasurfaces. IEEE Trans. Antennas Propag. 2019, 68, 1799–1811. [Google Scholar] [CrossRef]

- Jahani, S.; Jacob, Z. All-dielectric metamaterials. Nat. Nanotechnol. 2016, 11, 23–36. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Liu, W.W.; Li, Z.C.; Cheng, H.; Zhang, Y.B.; Jia, G.Z.; Chen, S.Q.; Tian, J.G. Ultrathin polarization-insensitive wide-angle broadband near-perfect absorber in the visible regime based on few-layer MoS2 films. Appl. Phys. Lett. 2017, 111, 111109. [Google Scholar] [CrossRef] [Green Version]

- Huygens, C. Traiteé de la Lumieère; Pieter van der Aa: Leyden, France, 1690. [Google Scholar]

- Wu, L.W.; Ma, H.F.; Gou, Y.; Wu, R.Y.; Wang, Z.X.; Wang, M.; Gao, X.X.; Cui, T.J. High-Transmission Ultrathin Huygens’ Metasurface with 360 degrees Phase Control by Using Double-Layer Transmitarray Elements. Phys. Rev. Appl. 2019, 12, 024012. [Google Scholar] [CrossRef]

- Pfeiffer, C.; Grbic, A. Metamaterial Huygens’ Surfaces: Tailoring Wave Fronts with Reflectionless Sheets. Phys. Rev. Lett. 2013, 110, 197401. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Abdo-Sánchez, E.; Epstein, A.; Eleftheriades, G.V. Theory, design, and experimental verification of a reflectionless bianisotropic Huygens’ metasurface for wide-angle refraction. Phys. Rev. B 2018, 97, 125433. [Google Scholar] [CrossRef] [Green Version]

- Pfeiffer, C.; Emani, N.K.; Shaltout, A.M.; Boltasseva, A.; Shalaev, V.M.; Grbic, A. Efficient Light Bending with Isotropic Metamaterial Huygens’ Surfaces. Nano Lett. 2014, 14, 2491–2497. [Google Scholar] [CrossRef]

- Zhao, W.Y.; Jiang, H.; Liu, B.Y.; Song, J.; Jiang, Y.Y.; Tang, C.C.; Li, J.J. Dielectric Huygens’ Metasurface for High-Efficiency Hologram Operating in Transmission Mode. Sci. Rep. 2016, 6, 30613. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Decker, M.; Staude, I.; Falkner, M.; Dominguez, J.; Neshev, D.N.; Brener, I.; Pertsch, T.; Kivshar, Y.S. High-Efficiency Dielectric Huygens’ Surfaces. Adv. Opt. Mater. 2015, 3, 813–820. [Google Scholar] [CrossRef] [Green Version]

- Mie, G. Beiträge zur Optik Trüber Medien, Speziell Kolloidaler Metallösungen. Ann. Phys. 1908, 330, 377–445. [Google Scholar] [CrossRef]

- Ding, F.; Yang, Y.Q.; Bozhevolnyi, S.I. Dynamic Metasurfaces Using Phase-Change Chalcogenides. Adv. Opt. Mater. 2019, 7, 1801709. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.D.; Song, J.L.; Zhao, W.X.; Ren, X.C.; Cheng, Q.; Luo, X.B.; Fang, N.X.L.; Hu, R. Dynamic thermal camouflage via a liquid-crystal-based radiative metasurface. Nanophotonics 2020, 9, 855–863. [Google Scholar] [CrossRef] [Green Version]

- Li, L.L.; Cui, T.J.; Ji, W.; Liu, S.; Ding, J.; Wan, X.; Li, Y.B.; Jiang, M.; Qiu, C.-W.; Zhang, S. Electromagnetic reprogrammable coding-metasurface holograms. Nat. Commun. 2017, 8, 197. [Google Scholar] [CrossRef] [Green Version]

- Li, L.L.; Ruan, H.X.; Liu, C.; Li, Y.; Shuang, Y.; Alù, A.; Qiu, C.-W.; Cui, T.J. Machine-learning reprogrammable metasurface imager. Nat. Commun. 2019, 10, 1082. [Google Scholar] [CrossRef]

- Ma, Q.; Bai, G.D.; Jing, H.B.; Yang, C.; Li, L.; Cui, T.J. Smart metasurface with self-adaptively reprogrammable functions. Light. Sci. Appl. 2019, 8, 98. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pancharatnam, S. Generalized theory of interference, and its applications. Proc. Indian Acad. Sci. A 1956, 44, 247–262. [Google Scholar] [CrossRef]

- Berry, M.V. The Adiabatic Phase and Pancharatnam’s Phase for Polarized Light. J. Mod. Opt. 1987, 34, 1401–1407. [Google Scholar] [CrossRef]

- Niv, A.; Biener, G.; Kleiner, V.; Hasman, E. Propagation-invariant vectorial Bessel beams obtained by use of quantized Pancharatnam-Berry phase optical elements. Opt. Lett. 2004, 29, 238–240. [Google Scholar] [CrossRef]

- Biener, G.; Niv, A.; Kleiner, V.; Hasman, E. Formation of helical beams by use of Pancharatnam–Berry phase optical elements. Opt. Lett. 2002, 27, 1875–1877. [Google Scholar] [CrossRef]

- Bomzon, Z.; Biener, G.; Kleiner, V.; Hasman, E. Space-variant Pancharatnam-Berry phase optical elements with computer-generated subwavelength gratings. Opt. Lett. 2002, 27, 1141–1143. [Google Scholar] [CrossRef]

- Xu, H.-X.; Wang, G.-M.; Cai, T.; Xiao, J.; Zhuang, Y.-Q. Tunable Pancharatnam–Berry metasurface for dynamical and high-efficiency anomalous reflection. Opt. Express 2016, 24, 27836–27848. [Google Scholar] [CrossRef]

- Yin, X.B.; Ye, Z.L.; Rho, J.; Wang, Y.; Zhang, X. Photonic Spin Hall Effect at Metasurfaces. Science 2013, 339, 1405–1407. [Google Scholar] [CrossRef] [Green Version]

- Bomzon, Z.; Kleiner, V.; Hasman, E. Pancharatnam–Berry phase in space-variant polarization-state manipulations with subwavelength gratings. Opt. Lett. 2001, 26, 1424–1426. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.M.; Monticone, F.; Zhang, K.; Zhang, L.; Gao, D.L.; Burokur, S.N.; de Lustrac, A.; Wu, Q.; Qiu, C.-W.; Alù, A. Ultrathin Pancharatnam-Berry Metasurface with Maximal Cross-Polarization Efficiency. Adv. Mater. 2015, 27, 1195–1200. [Google Scholar] [CrossRef]

- Chen, X.Z.; Huang, L.L.; Muhlenbernd, H.; Li, G.X.; Bai, B.F.; Tan, Q.F.; Jin, G.F.; Qiu, C.W.; Zhang, S.; Zentgraf, T. Dual-polarity plasmonic metalens for visible light. Nat. Commun. 2012, 3, 1198. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Zhou, Z.Y.; Qi, Y.L.; Zhang, X.F.; Wei, Q.H. Pancharatnam-Berry optical lenses. J. Opt. Soc. Am. B 2019, 36, D107–D111. [Google Scholar] [CrossRef]

- Song, Q.H.; Baroni, A.; Sawant, R.; Ni, P.; Brandli, V.; Chenot, S.; Vézian, S.; Damilano, B.; de Mierry, P.; Khadir, S.; et al. Ptychography retrieval of fully polarized holograms from geometric-phase metasurfaces. Nat. Commun. 2020, 11, 2651. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Chen, L.W.; Li, Y.; Zhang, X.H.; Pu, M.B.; Zhao, Z.Y.; Ma, X.L.; Wang, Y.Q.; Hong, M.H.; Luo, X.G. Multicolor 3D meta-holography by broadband plasmonic modulation. Sci. Adv. 2016, 2, e1601102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, G.-Y.; Hsu, W.-L.; Pan, J.-W.; Wang, C.-M. Refractive and Meta-Optics Hybrid System. J. Light. Technol. 2021, 39, 6880–6885. [Google Scholar] [CrossRef]

- Zuo, R.Z.; Liu, W.W.; Cheng, H.; Chen, S.Q.; Tian, J.G. Breaking the Diffraction Limit with Radially Polarized Light Based on Dielectric Metalenses. Adv. Opt. Mater. 2018, 6, 1800795. [Google Scholar] [CrossRef]

- Chen, M.K.; Wu, Y.F.; Feng, L.; Fan, Q.B.; Lu, M.H.; Xu, T.; Tsai, D.P. Principles, Functions, and Applications of Optical Meta-Lens. Adv. Opt. Mater. 2021, 9, 2001414. [Google Scholar] [CrossRef]

- Lalanne, P.; Astilean, S.; Chavel, P.; Cambril, E.; Launois, H. Blazed binary subwavelength gratings with efficiencies larger than those of conventional échelette gratings. Opt. Lett. 1998, 23, 1081–1083. [Google Scholar] [CrossRef]

- Lalanne, P.; Astilean, S.; Chavel, P.; Cambril, E.; Launois, H. Design and fabrication of blazed binary diffractive elements with sampling periods smaller than the structural cutoff. J. Opt. Soc. Am. A 1999, 16, 1143–1156. [Google Scholar] [CrossRef]

- Khorasaninejad, M.; Shi, Z.; Zhu, A.Y.; Chen, W.T.; Sanjeev, V.; Zaidi, A.; Capasso, F. Achromatic Metalens over 60 nm Bandwidth in the Visible and Metalens with Reverse Chromatic Dispersion. Nano Lett. 2017, 17, 1819–1824. [Google Scholar] [CrossRef]

- Cheng, J.R.; Jafar-Zanjani, S.; Mosallaei, H. All-dielectric ultrathin conformal metasurfaces: Lensing and cloaking applications at 532 nm wavelength. Sci. Rep. 2016, 6, 38440. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, R.J.; Su, V.-C.; Wang, S.M.; Chen, M.K.; Chung, T.L.; Chen, Y.H.; Kuo, H.Y.; Chen, J.-W.; Chen, J.; Huang, Y.-T.; et al. Achromatic metalens array for full-colour light-field imaging. Nat. Nanotechnol. 2019, 14, 227–231. [Google Scholar] [CrossRef] [PubMed]

- Engelberg, J.; Zhou, C.; Mazurski, N.; Bar-David, J.; Kristensen, A.; Levy, U. Near-IR wide-field-of-view Huygens metalens for outdoor imaging applications. Nanophotonics 2020, 9, 361–370. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Xu, Q.; Zhang, X.Q.; Tian, C.X.; Xu, Y.H.; Gu, J.Q.; Tian, Z.; Ouyang, C.M.; Zhang, X.X.; Han, J.G.; et al. All-Dielectric Meta-Holograms with Holographic Images Transforming Longitudinally. ACS Photonics 2018, 5, 599–606. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Zhang, X.Q.; Xu, Y.H.; Gu, J.Q.; Li, Y.F.; Tian, Z.; Singh, R.; Zhang, S.; Han, J.G.; Zhang, W.L. Broadband metasurface holograms: Toward complete phase and amplitude engineering. Sci. Rep. 2016, 6, 32867. [Google Scholar] [CrossRef]

- Fu, R.; Shan, X.; Deng, L.G.; Dai, Q.; Guan, Z.Q.; Li, Z.L.; Zheng, G.X. Multiplexing meta-hologram with separate control of amplitude and phase. Opt. Express 2021, 29, 27696–27707. [Google Scholar] [CrossRef]

- Deng, J.; Yang, Y.; Tao, J.; Deng, L.G.; Liu, D.Q.; Guan, Z.Q.; Li, G.F.; Li, Z.L.; Yu, S.H.; Zheng, G.X.; et al. Spatial Frequency Multiplexed Meta-Holography and Meta-Nanoprinting. ACS Nano 2019, 13, 9237–9246. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, S.M.; Wang, Y.H.; Gao, Y.S.; Fan, Y.B.; Huang, C.; Zhang, N.; Yang, W.H.; Song, Q.H. Lead Halide Perov-skite-Based Dynamic Metasurfaces. Laser Photonics Rev. 2019, 13, 1900079. [Google Scholar] [CrossRef] [Green Version]

- Tiguntseva, E.Y.; Baranov, D.G.; Pushkarev, A.P.; Munkhbat, B.; Komissarenko, F.; Franckevicius, M.; Zakhidov, A.A.; Shegai, T.; Kivshar, Y.S.; Makarov, S.V. Tunable Hybrid Fano Resonances in Halide Perovskite Nanoparticles. Nano Lett. 2018, 18, 5522–5529. [Google Scholar] [CrossRef]

- Long, G.K.; Adamo, G.; Tian, J.Y.; Klein, M.; Krishnamoorthy, H.N.S.; Feltri, E.; Wang, H.; Soci, C. Perovskite metasurfaces with large superstructural chirality. Nat. Commun. 2022, 13, 1551. [Google Scholar] [CrossRef]

- Makarov, S.; Furasova, A.; Tiguntseva, E.; Hemmetter, A.; Berestennikov, A.; Pushkarev, A.; Zakhidov, A.; Kivshar, Y. Halide-Perovskite Resonant Nanophotonics. Adv. Opt. Mater. 2019, 7, 1800784. [Google Scholar] [CrossRef]

- Chen, B.H.; Wu, P.C.; Su, V.-C.; Lai, Y.-C.; Chu, C.H.; Lee, I.C.; Chen, J.-W.; Chen, Y.H.; Lan, Y.-C.; Kuan, C.-H.; et al. GaN Metalens for Pixel-Level Full-Color Routing at Visible Light. Nano Lett. 2017, 17, 6345–6352. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Liu, Z.X.; Ren, X.F.; Wang, S.M.; Su, V.-C.; Chen, M.-K.; Chu, C.H.; Kuo, H.Y.; Liu, B.H.; Zang, W.B.; et al. Metalens-array–based high-dimensional and multiphoton quantum source. Science 2020, 368, 1487–1490. [Google Scholar] [CrossRef] [PubMed]

- Zhan, A.; Colburn, S.; Trivedi, R.; Fryett, T.K.; Dodson, C.M.; Majumdar, A. Low-Contrast Dielectric Metasurface Optics. ACS Photonics 2016, 3, 209–214. [Google Scholar] [CrossRef] [Green Version]

- Colburn, S.; Zhan, A.; Majumdar, A. Varifocal zoom imaging with large area focal length adjustable metalenses. Optica 2018, 5, 825–831. [Google Scholar] [CrossRef]

- Mueller, J.P.B.; Rubin, N.A.; Devlin, R.C.; Groever, B.; Capasso, F. Metasurface Polarization Optics: Independent Phase Control of Arbitrary Orthogonal States of Polarization. Phys. Rev. Lett. 2017, 118, 113901. [Google Scholar] [CrossRef] [Green Version]

- Khorasaninejad, M.; Chen, W.T.; Devlin, R.C.; Oh, J.; Zhu, A.Y.; Capasso, F. Metalenses at visible wavelengths: Diffraction-limited focusing and subwavelength resolution imaging. Science 2016, 352, 1190–1194. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.T.; Zhu, A.Y.; Sanjeev, V.; Khorasaninejad, M.; Shi, Z.J.; Lee, E.; Capasso, F. A broadband achromatic metalens for focusing and imaging in the visible. Nat. Nanotechnol. 2018, 13, 220–226. [Google Scholar] [CrossRef] [Green Version]

- Park, J.-S.; Zhang, S.Y.; She, A.; Chen, W.T.; Lin, P.; Yousef, K.M.A.; Cheng, J.-X.; Capasso, F. All-Glass, Large Metalens at Visible Wavelength Using Deep-Ultraviolet Projection Lithography. Nano Lett. 2019, 19, 8673–8682. [Google Scholar] [CrossRef]

- Emani, N.K.; Khaidarov, E.; Paniagua-Dominguez, R.; Fu, Y.H.; Valuckas, V.; Lu, S.P.; Zhang, X.L.; Tan, S.T.; Demir, H.V.; Kuznetsov, A.I. High-efficiency and low-loss gallium nitride dielectric metasurfaces for nanophotonics at visible wavelengths. Appl. Phys. Lett. 2017, 111, 221101. [Google Scholar] [CrossRef]

- Kim, K.; Yoon, G.; Baek, S.; Rho, J.; Lee, H. Facile Nanocasting of Dielectric Metasurfaces with Sub-100 nm Resolution. ACS Appl. Mater. Interfaces 2019, 11, 26109–26115. [Google Scholar] [CrossRef] [PubMed]

- Yoon, G.; Kim, K.; Huh, D.; Lee, H.; Rho, J. Single-step manufacturing of hierarchical dielectric metalens in the visible. Nat. Commun. 2020, 11, 2268. [Google Scholar] [CrossRef] [PubMed]

- Feth, N.; König, M.; Husnik, M.; Stannigel, K.; Niegemann, J.; Busch, K.; Wegener, M.; Linden, S. Electromagnetic interaction of split-ring resonators: The role of separation and relative orientation. Opt. Express 2010, 18, 6545–6554. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, N.; Liu, H.; Zhu, S.N.; Giessen, H. Stereometamaterials. Nat. Photonics 2009, 3, 157–162. [Google Scholar] [CrossRef]

- Zhu, W.M.; Liu, A.Q.; Zhang, X.M.; Tsai, D.P.; Bourouina, T.; Teng, J.H.; Zhang, X.H.; Guo, H.C.; Tanoto, H.; Mei, T.; et al. Switchable Magnetic Metamaterials Using Micromachining Processes. Adv. Mater. 2011, 23, 1792–1796. [Google Scholar] [CrossRef] [PubMed]

- Yen, T.J.; Padilla, W.J.; Fang, N.; Vier, D.C.; Smith, D.R.; Pendry, J.B.; Basov, D.N.; Zhang, X. Terahertz Magnetic Response from Artificial Materials. Science 2004, 303, 1494–1496. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaelberer, T.; Fedotov, V.A.; Papasimakis, N.; Tsai, D.P.; Zheludev, N.I. Toroidal Dipolar Response in a Metamaterial. Science 2010, 330, 1510–1512. [Google Scholar] [CrossRef] [Green Version]

- Liu, N.; Kaiser, S.; Giessen, H. Magnetoinductive and Electroinductive Coupling in Plasmonic Metamaterial Molecules. Adv. Mater. 2008, 20, 4521–4525. [Google Scholar] [CrossRef]

- Chen, W.T.; Chen, C.J.; Wu, P.C.; Sun, S.; Zhou, L.; Guo, G.-Y.; Hsiao, C.T.; Yang, K.-Y.; Zheludev, N.I.; Tsai, D.P. Optical magnetic response in three-dimensional metamaterial of upright plasmonic meta-molecules. Opt. Express 2011, 19, 12837–12842. [Google Scholar] [CrossRef] [Green Version]

- Ameling, R.; Giessen, H. Microcavity plasmonics: Strong coupling of photonic cavities and plasmons. Laser Photonics Rev. 2013, 7, 141–169. [Google Scholar] [CrossRef]

- Ye, J.; Van Dorpe, P. Improvement of Figure of Merit for Gold Nanobar Array Plasmonic Sensors. Plasmonics 2011, 6, 665–671. [Google Scholar] [CrossRef]

- Dmitriev, A.; Hägglund, C.; Chen, S.; Fredriksson, H.; Pakizeh, T.; Käll, M.; Sutherland, D.S. Enhanced Nanoplasmonic Optical Sensors with Reduced Substrate Effect. Nano Lett. 2008, 8, 3893–3898. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.L.; Chen, X.Z.; Mühlenbernd, H.; Li, G.X.; Bai, B.F.; Tan, Q.F.; Jin, G.F.; Zentgraf, T.; Zhang, S. Dispersionless Phase Discontinuities for Controlling Light Propagation. Nano Lett. 2012, 12, 5750–5755. [Google Scholar] [CrossRef]

- Zhang, J.; MacDonald, K.F.; Zheludev, N.I. Optical gecko toe: Optically controlled attractive near-field forces between plasmonic metamaterials and dielectric or metal surfaces. Phys. Rev. B 2012, 85, 205123. [Google Scholar] [CrossRef] [Green Version]

- Zhu, W.M.; Liu, A.Q.; Bourouina, T.; Tsai, D.P.; Teng, J.H.; Zhang, X.H.; Lo, G.Q.; Kwong, D.L.; Zheludev, N.I. Microelec-tromechanical Maltese-cross metamaterial with tunable terahertz anisotropy. Nat. Commun. 2012, 3, 1274. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Tang, M.L.; Hentschel, M.; Giessen, H.; Alivisatos, P. Nanoantenna-enhanced gas sensing in a single tailored nanofocus. Nat. Mater. 2011, 10, 631–636. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Jin, J.; Kim, Y.J.; Park, I.Y.; Kim, Y.; Kim, S.W. Nanostructure-enhanced atomic line emission reply. Nature 2012, 485, E2–E3. [Google Scholar] [CrossRef]

- Palmer, S.J.; Xiao, X.F.; Pazos-Perez, N.; Guerrini, L.; Correa-Duarte, M.A.; Maier, S.A.; Craster, R.V.; Alvarez-Puebla, R.A.; Giannini, V. Extraordinarily transparent compact metallic metamaterials. Nat. Commun. 2019, 10, 2118. [Google Scholar] [CrossRef] [Green Version]

- Kilic, U.; Hilfiker, M.; Ruder, A.; Feder, R.; Schubert, E.; Schubert, M.; Argyropoulos, C. Broadband Enhanced Chirality with Tunable Response in Hybrid Plasmonic Helical Metamaterials. Adv. Funct. Mater. 2021, 31, 2010329. [Google Scholar] [CrossRef]

- Yu, N.F.; Genevet, P.; Kats, M.A.; Aieta, F.; Tetienne, J.P.; Capasso, F.; Gaburro, Z. Light Propagation with Phase Discontinuities: Generalized Laws of Reflection and Refraction. Science 2011, 334, 333–337. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.W.; Chen, W.T.; Tsai, W.Y.; Wu, P.C.; Wang, C.M.; Sun, G.; Tsai, D.P. Aluminum Plasmonic Multicolor Meta-Hologram. Nano Lett. 2015, 15, 3122–3127. [Google Scholar] [CrossRef] [PubMed]

- Ni, X.J.; Wong, Z.J.; Mrejen, M.; Wang, Y.; Zhang, X. An ultrathin invisibility skin cloak for visible light. Science 2015, 349, 1310–1314. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Jung, S.; Chen, P.-Y.; Lu, F.; Demmerle, F.; Boehm, G.; Amann, M.-C.; Alù, A.; Belkin, M.A. Ultrafast Electrically Tunable Polaritonic Metasurfaces. Adv. Opt. Mater. 2014, 2, 1057–1063. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, X.; Rukhlenko, I.D.; Chen, H.-T.; Zhu, W.R. Electrically Tunable Metasurface with Independent Frequency and Amplitude Modulations. ACS Photonics 2020, 7, 265–271. [Google Scholar] [CrossRef]

- Kim, Y.; Wu, P.C.; Sokhoyan, R.; Mauser, K.A.; Glaudell, R.; Shirmanesh, G.K.; Atwater, H.A. Phase Modulation with Electrically Tunable Vanadium Dioxide Phase-Change Metasurfaces. Nano Lett. 2019, 19, 3961–3968. [Google Scholar] [CrossRef] [Green Version]

- Yu, P.; Li, J.X.; Liu, N. Electrically Tunable Optical Metasurfaces for Dynamic Polarization Conversion. Nano Lett. 2021, 21, 6690–6695. [Google Scholar] [CrossRef]

- Kowerdziej, R.; Wróbel, J.; Kula, P. Ultrafast electrical switching of nanostructured metadevice with dual-frequency liquid crystal. Sci. Rep. 2019, 9, 20367. [Google Scholar] [CrossRef] [Green Version]

- Rout, S.; Qi, Z.; Biener, M.M.; Courtwright, D.; Adrien, J.C.; Mills, E.; Shahabuddin, M.; Noginova, N.; Noginov, M.A. Na-noporous gold nanoleaf as tunable metamaterial. Sci. Rep. 2021, 11, 1795. [Google Scholar] [CrossRef]

- Park, J.; Jeong, B.G.; Kim, S.I.; Lee, D.; Kim, J.; Shin, C.; Lee, C.B.; Otsuka, T.; Kyoung, J.; Kim, S.; et al. All-solid-state spatial light modulator with independent phase and amplitude control for three-dimensional LiDAR applications. Nat. Nanotechnol. 2021, 16, 69–76. [Google Scholar] [CrossRef]

- Komar, A.; Aoni, R.A.; Xu, L.; Rahmani, M.; Miroshnichenko, A.E.; Neshev, D.N. Edge Detection with Mie-Resonant Dielectric Metasurfaces. ACS Photonics 2021, 8, 864–871. [Google Scholar] [CrossRef]

- Tripathi, A.; John, J.; Kruk, S.; Zhang, Z.; Nguyen, H.S.; Berguiga, L.; Romeo, P.R.; Orobtchouk, R.; Ramanathan, S.; Kivshar, Y.; et al. Tunable Mie-Resonant Dielectric Metasurfaces Based on VO2 Phase-Transition Materials. ACS Photonics 2021, 8, 1206–1213. [Google Scholar] [CrossRef]

- Tonkaev, P.; Kivshar, Y. High-Q Dielectric Mie-resonant Nanostructures (Mini-review). JETP Lett. 2020, 112, 615–622. [Google Scholar] [CrossRef]

- Choi, S.; Son, H.; Lee, B. Chirality-selective all-dielectric metasurface structural color display. Opt. Express 2021, 29, 41258–41267. [Google Scholar] [CrossRef]

- Arbabi, A.; Horie, Y.; Ball, A.J.; Bagheri, M.; Faraon, A. Subwavelength-thick lenses with high numerical apertures and large efficiency based on high-contrast transmitarrays. Nat. Commun. 2015, 6, 7069. [Google Scholar] [CrossRef]

- Qin, F.F.; Liu, Z.Z.; Zhang, Z.; Zhang, Q.; Xiao, J.J. Broadband full-color multichannel hologram with geometric metasurface. Opt. Express 2018, 26, 11577–11586. [Google Scholar] [CrossRef]

- Su, P.; Shalaginov, M.; Gu, T.; An, S.S.; Li, D.H.; Li, L.; Jiang, H.; Joo, S.; Kimerling, L.; Zhang, H.; et al. Large-area optical metasurface fabrication using nanostencil lithography. Opt. Lett. 2021, 46, 2324–2327. [Google Scholar] [CrossRef]

- Hu, T.; Zhong, Q.Z.; Li, N.X.; Dong, Y.; Xu, Z.J.; Fu, Y.H.; Li, D.D.; Bliznetsov, V.; Zhou, Y.; Lai, K.H.; et al. CMOS-compatible a-Si metalenses on a 12-inch glass wafer for fingerprint imaging. Nanophotonics 2020, 9, 823–830. [Google Scholar] [CrossRef] [Green Version]

- Li, N.X.; Xu, Z.J.; Dong, Y.; Hu, T.; Zhong, Q.Z.; Fu, Y.H.; Zhu, S.Y.; Singh, N. Large-area metasurface on CMOS-compatible fabrication platform: Driving flat optics from lab to fab. Nanophotonics 2020, 9, 3071–3087. [Google Scholar] [CrossRef]

- Xu, Z.J.; Dong, Y.; Tseng, C.-K.; Hu, T.; Tong, J.C.; Zhong, Q.Z.; Li, N.X.; Sim, L.; Lai, K.H.; Lin, Y.; et al. CMOS-compatible all-Si metasurface polarizing bandpass filters on 12-inch wafers. Opt. Express 2019, 27, 26060–26069. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kim, Y.; Han, S.; Kim, J.; Yoon, J.W.; Lee, K.Y.; Song, S.H.; Yang, K.; Lee, C.S. CMOS-compatible Si metasurface at visible wavelengths prepared by low-temperature green laser annealing. Nanotechnology 2019, 30, 045301. [Google Scholar] [CrossRef]

- Yu, Y.F.; Zhu, A.Y.; Paniagua-Dominguez, R.; Fu, Y.H.; Luk’Yanchuk, B.; Kuznetsov, A.I. High-transmission dielectric metasurface with 2 phase control at visible wavelengths. Laser Photonics Rev. 2015, 9, 412–418. [Google Scholar] [CrossRef]

- Sroor, H.; Huang, Y.-W.; Sephton, B.; Naidoo, D.; Vallés, A.; Ginis, V.; Qiu, C.-W.; Ambrosio, A.; Capasso, F.; Forbes, A. High-purity orbital angular momentum states from a visible metasurface laser. Nat. Photonics 2020, 14, 498–503. [Google Scholar] [CrossRef]

- Huang, Y.-W.; Rubin, N.A.; Ambrosio, A.; Shi, Z.; Devlin, R.C.; Qiu, C.-W.; Capasso, F. Versatile total angular momentum generation using cascaded J-plates. Opt. Express 2019, 27, 7469–7484. [Google Scholar] [CrossRef] [PubMed]

- Shalaev, M.I.; Sun, J.B.; Tsukernik, A.; Pandey, A.; Nikolskiy, K.; Litchinitser, N.M. High-Efficiency All-Dielectric Metasurfaces for Ultracompact Beam Manipulation in Transmission Mode. Nano Lett. 2015, 15, 6261–6266. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khorasaninejad, M.; Crozier, K. Silicon nanofin grating as a miniature chirality-distinguishing beam-splitter. Nat. Commun. 2014, 5, 5386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barbero, S. The Alvarez and Lohmann refractive lenses revisited. Opt. Express 2009, 17, 9376–9390. [Google Scholar] [CrossRef]

- Bernet, S.; Ritsch-Marte, M. Adjustable refractive power from diffractive Moiré elements. Appl. Opt. 2008, 47, 3722–3730. [Google Scholar] [CrossRef]

- Ojeda-Castaneda, J.; Ledesma, S.; Gomez-Sarabia, C.M. Tunable apodizers and tunable focalizers using helical pairs. Photonics Lett. Pol. 2013, 5, 20–22. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.; Cheng, Y.Z.; Luo, H. A Broadband Tunable Terahertz Metamaterial Absorber Based on Single-Layer Complementary Gammadion-Shaped Graphene. Materials 2020, 13, 860. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.; Lee, D.; Eom, S.; Lim, S. Stretchable Metamaterial Absorber Using Liquid Metal-Filled Polydimethylsiloxane (PDMS). Sensors 2016, 16, 521. [Google Scholar] [CrossRef] [Green Version]

- Sun, K.; Dong, J.N.; Wang, Z.X.; Wang, Z.Y.; Fan, G.H.; Hou, Q.; An, L.Q.; Dong, M.Y.; Fan, R.H.; Guo, Z.H. Tunable Negative Permittivity in Flexible Graphene/PDMS Metacomposites. J. Phys. Chem. C 2019, 123, 23635–23642. [Google Scholar] [CrossRef]

- Ling, K.; Kim, K.; Lim, S. Flexible liquid metal-filled metamaterial absorber on polydimethylsiloxane (PDMS). Opt. Express 2015, 23, 21375–21383. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.Q.; Liu, X.J.; Tian, Y.P.; Zheng, Y. Mechanically stretchable metamaterial with tunable mid-infrared optical properties. Opt. Express 2021, 29, 37368–37375. [Google Scholar] [CrossRef]

- Lee, S.; Kim, S.; Kim, T.-T.; Kim, Y.; Choi, M.; Lee, S.H.; Kim, J.-Y.; Min, B. Reversibly Stretchable and Tunable Terahertz Metamaterials with Wrinkled Layouts. Adv. Mater. 2012, 24, 3491–3497. [Google Scholar] [CrossRef] [PubMed]

- Kamali, S.M.; Arbabi, E.; Arbabi, A.; Horie, Y.; Faraon, A. Highly tunable elastic dielectric metasurface lenses. Laser Photonics Rev. 2016, 10, 1002–1008. [Google Scholar] [CrossRef] [Green Version]

- Fan, Q.B.; Wang, Y.L.; Liu, M.Z.; Xu, T. High-efficiency, linear-polarization-multiplexing metalens for long-wavelength infrared light. Opt. Lett. 2018, 43, 6005–6008. [Google Scholar] [CrossRef]

- Arbabi, E.; Arbabi, A.; Kamali, S.M.; Horie, Y.; Faraji-Dana, M.; Faraon, A. MEMS-tunable dielectric metasurface lens. Nat. Commun. 2018, 9, 812. [Google Scholar] [CrossRef] [Green Version]

- Han, Z.Y.; Colburn, S.; Majumdar, A.; Böhringer, K.F. MEMS-actuated metasurface Alvarez lens. Microsyst. Nanoeng. 2020, 6, 79. [Google Scholar] [CrossRef]

- Shimura, T.; Kinoshita, T.; Koto, Y.; Umeda, N.; Iwami, K. Birefringent reconfigurable metasurface at visible wavelengths by MEMS nanograting. Appl. Phys. Lett. 2018, 113, 171905. [Google Scholar] [CrossRef]

- Roy, T.; Zhang, S.; Jung, I.W.; Troccoli, M.; Capasso, F.; Lopez, D. Dynamic metasurface lens based on MEMS technology. APL Photonics 2018, 3, 021302. [Google Scholar] [CrossRef]

- Bosch, M.; Shcherbakov, M.R.; Won, K.; Lee, H.S.; Kim, Y.; Shvets, G. Electrically Actuated Varifocal Lens Based on Liquid-Crystal-Embedded Dielectric Metasurfaces. Nano Lett. 2021, 21, 3849–3856. [Google Scholar] [CrossRef]

- Li, S.-Q.; Xu, X.W.; Veetil, R.M.; Valuckas, V.; Paniagua-Domínguez, R.; Kuznetsov, A.I. Phase-only transmissive spatial light modulator based on tunable dielectric metasurface. Science 2019, 364, 1087–1090. [Google Scholar] [CrossRef] [Green Version]

- Lininger, A.; Zhu, A.Y.; Park, J.S.; Palermo, G.; Chatterjee, S.; Boyd, J.; Capasso, F.; Strangi, G. Optical properties of metasurfaces infiltrated with liquid crystals. Proc. Natl. Acad. Sci. USA 2020, 117, 20390–20396. [Google Scholar] [CrossRef]

- Gorkunov, M.V.; Kasyanova, I.V.; Artemov, V.V.; Ezhov, A.A.; Mamonova, A.V.; Simdyankin, I.V.; Palto, S.P. Superperiodic Liquid-Crystal Metasurfaces for Electrically Controlled Anomalous Refraction. ACS Photonics 2020, 7, 3096–3105. [Google Scholar] [CrossRef]

- Khorasaninejad, M.; Zhuit, A.Y.; Roques-Carmes, C.; Chen, W.T.; Oh, J.; Mishra, I.; Devlin, R.C.; Capasso, F. Polarization-Insensitive Metalenses at Visible Wavelengths. Nano Lett. 2016, 16, 7229–7234. [Google Scholar] [CrossRef]

- Chen, T.-A.; Chou, Y.-C.; Huang, T.-Y.; Lu, Y.-J.; Kuang, Y.-P.; Yen, T.-J. TiO2 Nanodisk Arrays as All-Dielectric Huygens’ Metasurfaces for Engineering the Wavefront of Near-UV Light. ACS Appl. Nano Mater. 2021, 5, 925–930. [Google Scholar] [CrossRef]

- Lin, Y.-T.; Hassanfiroozi, A.; Jiang, W.-R.; Liao, M.-Y.; Lee, W.-J.; Wu, P.C. Photoluminescence enhancement with all-dielectric coherent metasurfaces. Nanophotonics 2022, 11, 2701–2709. [Google Scholar] [CrossRef]

- Alquliah, A.; Elkabbash, M.; Cheng, J.L.; Verma, G.; Saraj, C.S.; Li, W.; Guo, C.L. Reconfigurable metasurface-based 1 × 2 waveguide switch. Photonics Res. 2021, 9, 2104–2115. [Google Scholar] [CrossRef]

- Deng, Z.L.; Tu, Q.A.; Wang, Y.J.; Wang, Z.Q.; Shi, T.; Feng, Z.W.; Qiao, X.C.; Wang, G.P.; Xiao, S.M.; Li, X.P. Vectorial Compound Metapixels for Arbitrary Nonorthogonal Polarization Steganography. Adv. Mater. 2021, 33, 2103472. [Google Scholar] [CrossRef]

- Murai, S.; Agata, K.; Tanaka, K. Photoluminescence from an emitter layer sandwiched between the stack of metasurfaces. J. Appl. Phys. 2021, 129, 183101. [Google Scholar] [CrossRef]

- Naveed, M.A.; Ansari, M.A.; Kim, I.; Badloe, T.; Kim, J.; Oh, D.K.; Riaz, K.; Tauqeer, T.; Younis, U.; Saleem, M.; et al. Optical spin-symmetry breaking for high-efficiency directional helicity-multiplexed metaholograms. Microsyst. Nanoeng. 2021, 7, 5. [Google Scholar] [CrossRef]

- Zhu, W.; Yang, R.S.; Geng, G.Z.; Fan, Y.C.; Guo, X.Y.; Li, P.; Fu, Q.H.; Zhang, F.L.; Gu, C.Z.; Li, J.J. Titanium dioxide metasurface manipulating high-efficiency and broadband photonic spin Hall effect in visible regime. Nanophotonics 2020, 9, 4327–4335. [Google Scholar] [CrossRef]

- Park, Y.; Kim, H.; Lee, J.-Y.; Ko, W.; Bae, K.; Cho, K.-S. Direction control of colloidal quantum dot emission using dielectric metasurfaces. Nanophotonics 2020, 9, 1023–1030. [Google Scholar] [CrossRef]

- Gortari, A.N.; Bouchoule, S.; Cambril, E.; Cattoni, A.; Hauke, L.; Enderlein, J.; Rehfeldt, F.; Giacomotti, A. Metasurface-based total internal reflection microscopy. Biomed. Opt. Express 2020, 11, 1967–1976. [Google Scholar] [CrossRef]

- Zhang, C.; Jing, J.X.; Wu, Y.K.; Fan, Y.B.; Yang, W.H.; Wang, S.; Song, Q.H.; Xiao, S.M. Stretchable All-Dielectric Metasurfaces with Polarization-Insensitive and Full-Spectrum Response. ACS Nano 2020, 14, 1418–1426. [Google Scholar] [CrossRef]

- Wu, Y.K.; Yang, W.H.; Fan, Y.B.; Song, Q.H.; Xiao, S.M. TiO2 metasurfaces: From visible planar photonics to photochemistry. Sci. Adv. 2019, 5, eaax0939. [Google Scholar] [CrossRef] [Green Version]

- Wen, D.D.; Cadusch, J.J.; Meng, J.; Crozier, K.B. Multifunctional Dielectric Metasurfaces Consisting of Color Holograms Encoded into Color Printed Images. Adv. Funct. Mater. 2020, 30, 1906415. [Google Scholar] [CrossRef]

- Aiello, M.D.; Backer, A.S.; Sapon, A.J.; Smits, J.; Perreault, J.D.; Llull, P.; Acosta, V.M. Achromatic Varifocal Metalens for the Visible Spectrum. ACS Photonics 2019, 6, 2432–2440. [Google Scholar] [CrossRef] [Green Version]

- Koirala, I.; Lee, S.-S.; Choi, D.-Y. Highly transmissive subtractive color filters based on an all-dielectric metasurface incorporating TiO2 nanopillars. Opt. Express 2018, 26, 18320–18330. [Google Scholar] [CrossRef]

- Sun, S.; Yang, W.H.; Zhang, C.; Jing, J.X.; Gao, Y.S.; Yu, X.Y.; Song, Q.H.; Xiao, S.M. Real-Time Tunable Colors from Microfluidic Reconfigurable All-Dielectric Metasurfaces. ACS Nano 2018, 12, 2151–2159. [Google Scholar] [CrossRef]

- Khaidarov, E.; Hao, H.F.; Paniagua-Domínguez, R.; Yu, Y.F.; Fu, Y.H.; Valuckas, V.; Yap, S.L.K.; Toh, Y.T.; Ng, J.S.K.; Kuznetsov, A.I. Asymmetric Nanoantennas for Ultrahigh Angle Broadband Visible Light Bending. Nano Lett. 2017, 17, 6267–6272. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Zhou, Z.X.; Zhang, C.; Gao, Y.S.; Duan, Z.H.; Xiao, S.M.; Song, Q.H. All-Dielectric Full-Color Printing with TiO2 Metasurfaces. ACS Nano 2017, 11, 4445–4452. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.T.; Zhu, A.Y.; Sisler, J.; Huang, Y.-W.; Yousef, K.M.A.; Lee, E.; Qiu, C.-W.; Capasso, F. Broadband Achromatic Metasurface-Refractive Optics. Nano Lett. 2018, 18, 7801–7808. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.T.; Zhu, A.Y.; Sisler, J.; Bharwani, Z.; Capasso, F. A broadband achromatic polarization-insensitive metalens consisting of anisotropic nanostructures. Nat. Commun. 2019, 10, 355. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.Y.; Lin, P.; Huang, Y.-W.; Park, J.-S.; Chen, W.T.; Shi, Z.J.; Qiu, C.-W.; Cheng, J.-X.; Capasso, F. Meta-optics achieves RGB-achromatic focusing for virtual reality. Sci. Adv. 2021, 7, eabe4458. [Google Scholar] [CrossRef]

- Hu, Y.Q.; Li, L.; Wang, Y.J.; Meng, M.; Jin, L.; Luo, X.H.; Chen, Y.Q.; Li, X.; Xiao, S.M.; Wang, H.B.; et al. Trichromatic and Tripolarization-Channel Holography with Noninterleaved Dielectric Metasurface. Nano Lett. 2020, 20, 994–1002. [Google Scholar] [CrossRef]

- Chen, M.H.; Yen, C.W.; Guo, C.C.; Su, V.C.; Kuan, C.H.; Lin, H.Y. Polarization-insensitive GaN metalenses at visible wave-lengths. Sci. Rep. 2021, 11, 14541. [Google Scholar] [CrossRef]

- Wang, M.; Lin, Y.; Yi, J.-M.; Li, D.-Y.; Liu, J.-P.; Cao, B.; Wang, C.-H.; Wang, J.-F.; Xu, K. High-efficiency circularly polarized green light emission from GaN-based laser diodes integrated with GaN metasurface quarterwave plate. Appl. Phys. Lett. 2021, 119, 241103. [Google Scholar] [CrossRef]

- Guo, K.; Xu, H.S.; Peng, Z.Y.; Liu, X.; Guo, Z.Y. High-Efficiency Full-Vector Polarization Analyzer Based on GaN Metasurface. IEEE Sens. J. 2019, 19, 3654–3659. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Xu, H.S.; Guo, K.; Shen, F.; Zhou, H.P.; Zhou, Q.F.; Gao, J.; Yin, Z.P. High-Efficiency Visible Transmitting Polarizations Devices Based on the GaN Metasurface. Nanomaterials 2018, 8, 333. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Xu, F.Y.; Lin, Y.; Cao, B.; Chen, L.H.; Wang, C.H.; Wang, J.F.; Xu, K. Metasurface integrated high energy efficient and high linearly polarized InGaN/GaN light emitting diode. Nanoscale 2017, 9, 9104–9111. [Google Scholar] [CrossRef] [PubMed]

- Hao, M.; Ishikawa, H.; Egawa, T. Formation chemistry of high-density nanocraters on the surface of sapphire substrates with an in situ etching and growth mechanism of device-quality GaN films on the etched substrates. Appl. Phys. Lett. 2004, 84, 4041–4043. [Google Scholar] [CrossRef]

- Hu, N.; Dinh, D.V.; Pristovsek, M.; Honda, Y.; Amano, H. How to obtain metal-polar untwinned high-quality (10−13) GaN on m-plane sapphire. J. Cryst. Growth 2019, 507, 205–208. [Google Scholar] [CrossRef]

- Hu, H.X.; Zhang, B.G.; Wu, Y.Z.; Shao, Y.L.; Liu, L.; Hao, X.P. High-Quality GaN Crystal Grown on Laser Decomposed GaNSapphire Substrate and Its Application in Photodetector. Phys. Status Solidi A 2020, 217, 2000380. [Google Scholar] [CrossRef]

- Poti, B.; Tagliente, M.A.; Passaseo, A. High quality MOCVD GaN film grown on sapphire substrates using HT-AlN buffer layer. J. Non-Cryst. Solids 2006, 352, 2332–2334. [Google Scholar] [CrossRef]

- Sakai, M.; Ishikawa, H.; Egawa, T.; Jimbo, T.; Umeno, M.; Shibata, T.; Asai, K.; Sumiya, S.; Kuraoka, Y.; Tanaka, M.; et al. Growth of high-quality GaN films on epitaxial AlN/sapphire templates by MOVPE. J. Cryst. Growth 2002, 244, 6–11. [Google Scholar] [CrossRef]

- Sakai, M.; Ishikawa, H.; Egawa, T.; Jimbo, T.; Umeno, M.; Shibata, T.; Asai, K.; Sumiya, S.; Kuraoka, Y.; Tanaka, M.; et al. High-quality GaN growth on AlN/sapphire templates by MOVPE. Inst. Phys. Conf. Ser. 2002, 783–788. [Google Scholar]

- Maegami, Y.; Okano, M.; Cong, G.W.; Ohno, M.; Yamada, K. Completely CMOS compatible SiN-waveguide-based fiber coupling structure for Si wire waveguides. Opt. Express 2016, 24, 16856–16865. [Google Scholar] [CrossRef]

- Hooten, S.; van Vaerenbergh, T.; Sun, P.; Mathai, S.; Huang, Z.H.; Beausoleil, R.G. Adjoint Optimization of Efficient CMOS-Compatible Si-SiN Vertical Grating Couplers for DWDM Applications. J. Light. Technol. 2020, 38, 3422–3430. [Google Scholar] [CrossRef]

- Fan, Z.-B.; Shao, Z.-K.; Xie, M.-Y.; Pang, X.-N.; Ruan, W.-S.; Zhao, F.-L.; Chen, Y.-J.; Yu, S.-Y.; Dong, J.-W. Silicon Nitride Metalenses for Close-to-One Numerical Aperture and Wide-Angle Visible Imaging. Phys. Rev. Appl. 2018, 10, 014005. [Google Scholar] [CrossRef] [Green Version]

- Zhan, A.; Colburn, S.; Dodson, C.M.; Majumdar, A. Metasurface Freeform Nanophotonics. Sci. Rep. 2017, 7, 1673. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- She, A.; Zhang, S.Y.; Shian, S.; Clarke, D.R.; Capasso, F. Adaptive metalenses with simultaneous electrical control of focal length, astigmatism, and shift. Sci. Adv. 2018, 4, eaap9957. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, S.Y.; Kim, M.-H.; Aieta, F.; She, A.; Mansuripur, T.; Gabay, I.; Khorasaninejad, M.; Rousso, D.; Wang, X.J.; Troccoli, M.; et al. High efficiency near diffraction-limited mid-infrared flat lenses based on metasurface reflectarrays. Opt. Express 2016, 24, 18024–18034. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- She, A.; Zhang, S.Y.; Shian, S.; Clarke, D.R.; Capasso, F. Large area metalenses: Design, characterization, and mass manufacturing. Opt. Express 2018, 26, 1573–1585. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, Y.; Xu, Z.J.; Li, N.X.; Tong, J.C.; Fu, Y.H.; Zhou, Y.Y.; Hu, T.; Zhong, Q.Z.; Bliznetsov, V.; Zhu, S.Y.; et al. Si metasurface half-wave plates demonstrated on a 12-inch CMOS platform. Nanophotonics 2020, 9, 149–157. [Google Scholar] [CrossRef]

- Li, N.X.; Fu, Y.H.; Dong, Y.; Hu, T.; Xu, Z.J.; Zhong, Q.Z.; Li, D.D.; Lai, K.H.; Zhu, S.Y.; Lin, Q.Y.; et al. Large-area pixelated metasurface beam deflector on a 12-inch glass wafer for random point generation. Nanophotonics 2019, 8, 1855–1861. [Google Scholar] [CrossRef] [Green Version]

- Scheerlinck, S.; Dubruel, P.; Bienstman, P.; Schacht, E.; van Thourhout, D.; Baets, R. Metal Grating Patterning on Fiber Facets by UV-Based Nano Imprint and Transfer Lithography Using Optical Alignment. J. Light. Technol. 2009, 27, 1417–1422. [Google Scholar] [CrossRef]

- Guo, L.J. Nanoimprint Lithography: Methods and Material Requirements. Adv. Mater. 2007, 19, 495–513. [Google Scholar] [CrossRef] [Green Version]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint of sub-25 Nm Vias and trenches in polymers. Appl. Phys. Lett. 1995, 67, 3114–3116. [Google Scholar] [CrossRef] [Green Version]

- Gates, B.D.; Xu, Q.B.; Stewart, M.; Ryan, D.; Willson, C.G.; Whitesides, G.M. New Approaches to Nanofabrication: Molding, Printing, and Other Techniques. Chem. Rev. 2005, 105, 1171–1196. [Google Scholar] [CrossRef]

- Zhang, G.M.; Zhang, J.; Xie, G.Y.; Liu, Z.F.; Shao, H.B. Cicada Wings: A Stamp from Nature for Nanoimprint Lithography. Small 2006, 2, 1440–1443. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.J. Recent progress in nanoimprint technology and its applications. J. Phys. D Appl. Phys. 2004, 37, R123–R141. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint Lithography with 25-Nanometer Resolution. Science 1996, 272, 85–87. [Google Scholar] [CrossRef]

- Lee, G.-Y.; Hong, J.-Y.; Hwang, S.; Moon, S.; Kang, H.; Jeon, S.; Kim, H.; Jeong, J.-H.; Lee, B. Metasurface eyepiece for augmented reality. Nat. Commun. 2018, 9, 4562. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gonidec, M.; Hamedi, M.M.; Nemiroski, A.; Rubio, L.M.; Torres-Luna, C.; Whitesides, G.M. Fabrication of Nonperiodic Metasurfaces by Microlens Projection Lithography. Nano Lett. 2016, 16, 4125–4132. [Google Scholar] [CrossRef]

- Nemiroski, A.; Gonidec, M.; Fox, J.M.; Jean-Remy, P.; Turnage, E.; Whitesides, G.M. Engineering Shadows to Fabricate Optical Metasurfaces. ACS Nano 2014, 8, 11061–11070. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.X.; Qian, H.L.; Chen, C.-F.; Zhao, J.X.; Li, G.R.; Wu, Q.Y.; Luo, H.L.; Wen, S.C.; Liu, Z.W. Optical edge detection based on high-efficiency dielectric metasurface. Proc. Natl. Acad. Sci. USA 2019, 116, 11137–11140. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arbabi, A.; Horie, Y.; Bagheri, M.; Faraon, A. Dielectric metasurfaces for complete control of phase and polarization with subwavelength spatial resolution and high transmission. Nat. Nanotechnol. 2015, 10, 937–943. [Google Scholar] [CrossRef] [Green Version]

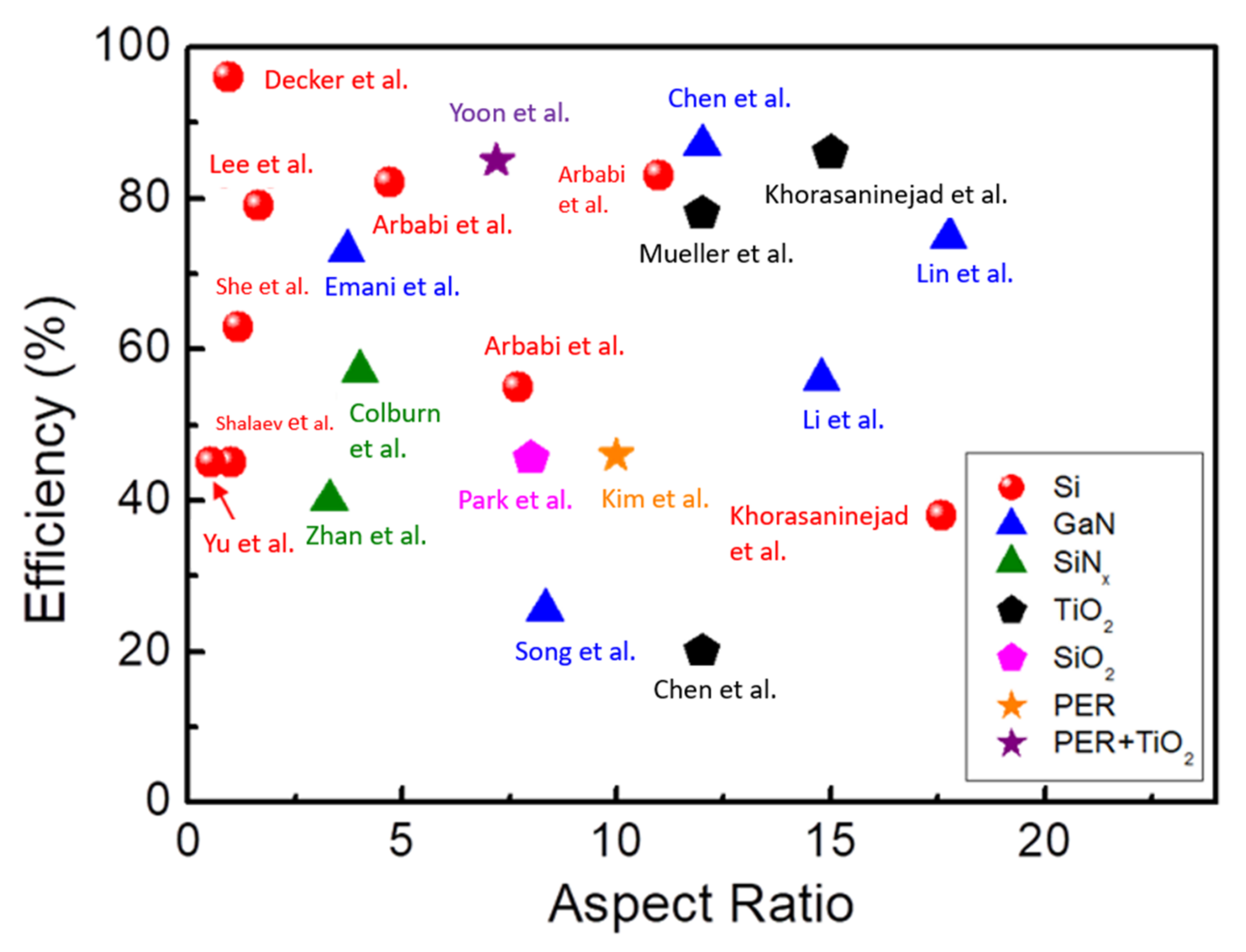

| Material | Wavelength (nm) | Aspect Ratio | Eff. (%) | Process | Application | Ref. |

|---|---|---|---|---|---|---|

| a-Si | 1358 | 0.93 | 96% | EBL | Wavefront engineering | [36] |

| a-Si | 1550 | 4.7 | 82% | EBL | Metalenses | [115] |

| a-Si | 705 | 0.54 | 45% | EBL | Beam steering | [122] |

| a-Si | 974 | 17.6 | 38% (m = 1) | EBL | Beam steering | [126] |

| a-Si | 915 | 7.7 | 55% | EBL | Metalenses | [138] |

| a-Si | 1550 | 1.17 | 63% | SL | Metalenses | [183] |

| a-Si | 915 | 11 | 83% | EBL | Metalenses | [199] |

| poly-Si | 1550 | 1 | 45% | EBL | Vortex converter | [125] |

| poly-Si | 473–660 | 1.66 | 79% | NIL | Metalenses | [195] |

| GaN | 600 | 8.33 | 25.40% | EBL | Metahologram | [54] |

| GaN | 404 | 14.8 | 56% | EBL | Quantum source | [74] |

| GaN | 430–470 | 3.7 | 73.00% | EBL | Beam splitting | [81] |

| GaN | 430–633 | 12 | 87% @430 nm | EBL | Metalenses | [73] |

| GaN | 400–660 | 17.77 | 74.8% @420 nm | EBL | Metalenses | [63] |

| SiNx | 633 | 3.29 | 40% | EBL | Metalenses | [75] |

| SiNx | 1550 | 4 | 57% | SL | Metalenses | [76] |

| TiO2 | 532 | 12 | 78% | EBL | Metahologram | [77] |

| TiO2 | 405–660 | 15 | 86% @405 nm | EBL | Metalenses | [78] |

| TiO2 | 470–670 | 12 | 20% @500 nm | EBL | Metalenses | [79] |

| SiO2 | 488–660 | 8 | 45.6% @633 nm | SL | Metalenses | [80] |

| PER | 450–635 | 10 | 46% @532 nm | NIL | Metahologram | [82] |

| PER + TiO2 particle | 450–635 | 7.2 | 85% @532 nm | NIL | Metalenses | [83] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, W.-L.; Chen, Y.-C.; Yeh, S.P.; Zeng, Q.-C.; Huang, Y.-W.; Wang, C.-M. Review of Metasurfaces and Metadevices: Advantages of Different Materials and Fabrications. Nanomaterials 2022, 12, 1973. https://doi.org/10.3390/nano12121973

Hsu W-L, Chen Y-C, Yeh SP, Zeng Q-C, Huang Y-W, Wang C-M. Review of Metasurfaces and Metadevices: Advantages of Different Materials and Fabrications. Nanomaterials. 2022; 12(12):1973. https://doi.org/10.3390/nano12121973

Chicago/Turabian StyleHsu, Wei-Lun, Yen-Chun Chen, Shang Ping Yeh, Qiu-Chun Zeng, Yao-Wei Huang, and Chih-Ming Wang. 2022. "Review of Metasurfaces and Metadevices: Advantages of Different Materials and Fabrications" Nanomaterials 12, no. 12: 1973. https://doi.org/10.3390/nano12121973

APA StyleHsu, W.-L., Chen, Y.-C., Yeh, S. P., Zeng, Q.-C., Huang, Y.-W., & Wang, C.-M. (2022). Review of Metasurfaces and Metadevices: Advantages of Different Materials and Fabrications. Nanomaterials, 12(12), 1973. https://doi.org/10.3390/nano12121973