Interface Adhesion Property and Laser Ablation Performance of GAP-PET Double-Layer Tape with Plasma Treatment

Abstract

:1. Introduction

2. Measurement Methods and Experimental Equipment

2.1. Propulsion Parameters

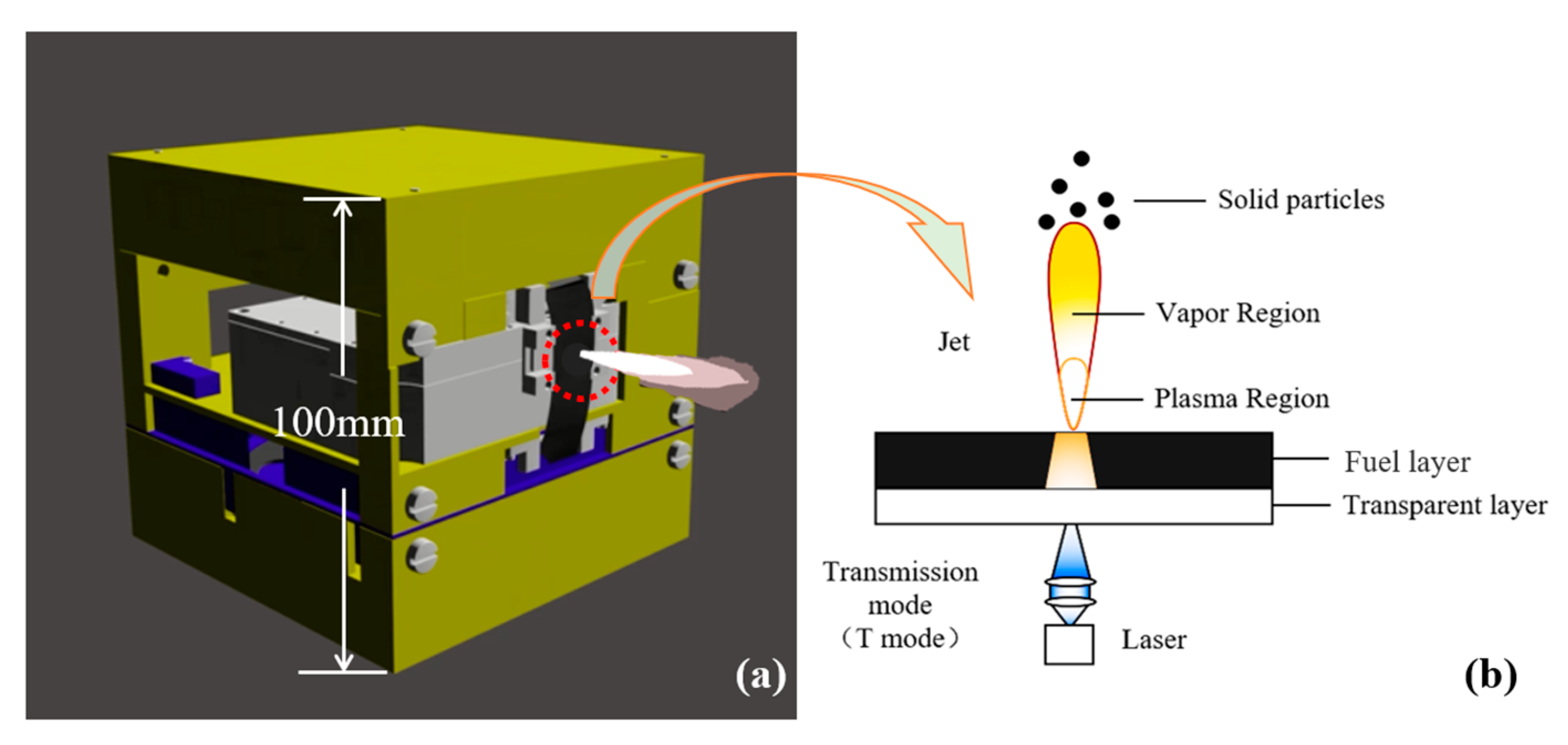

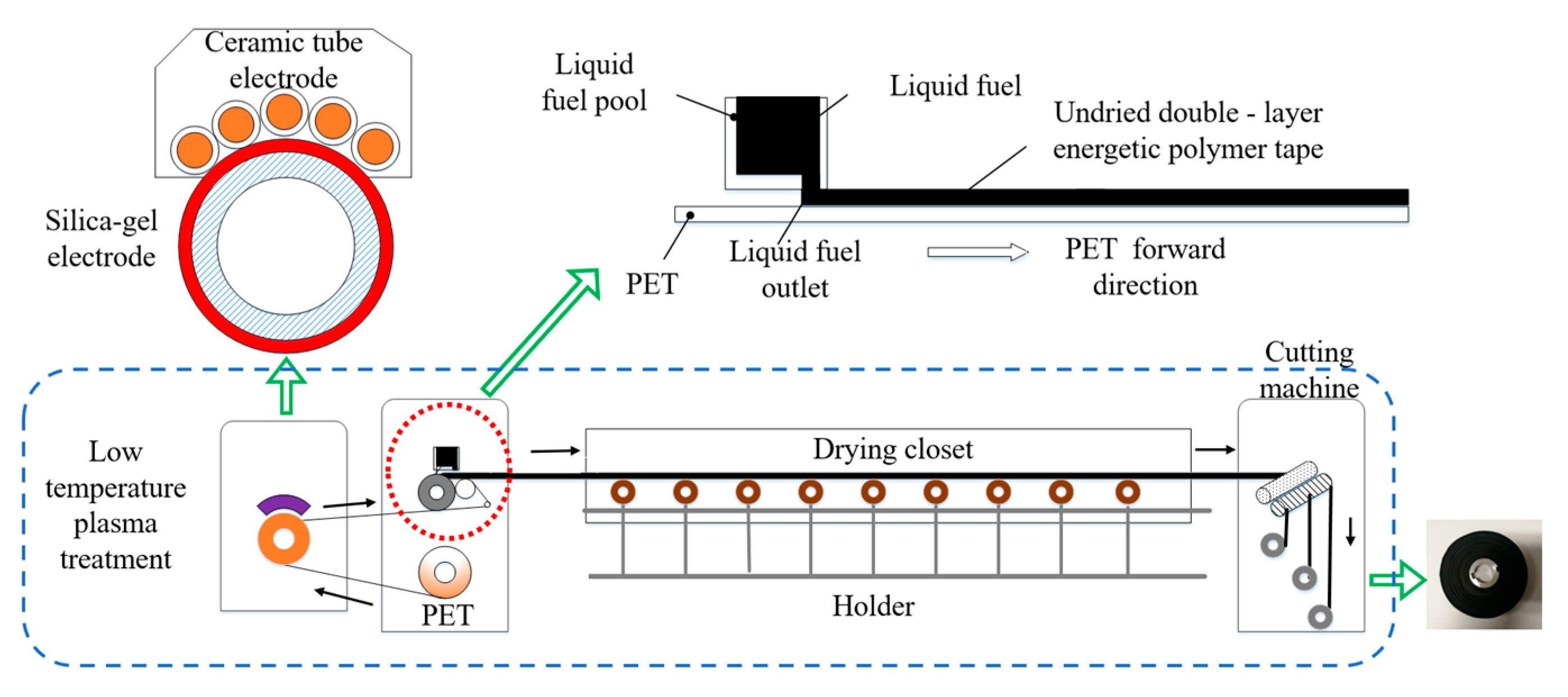

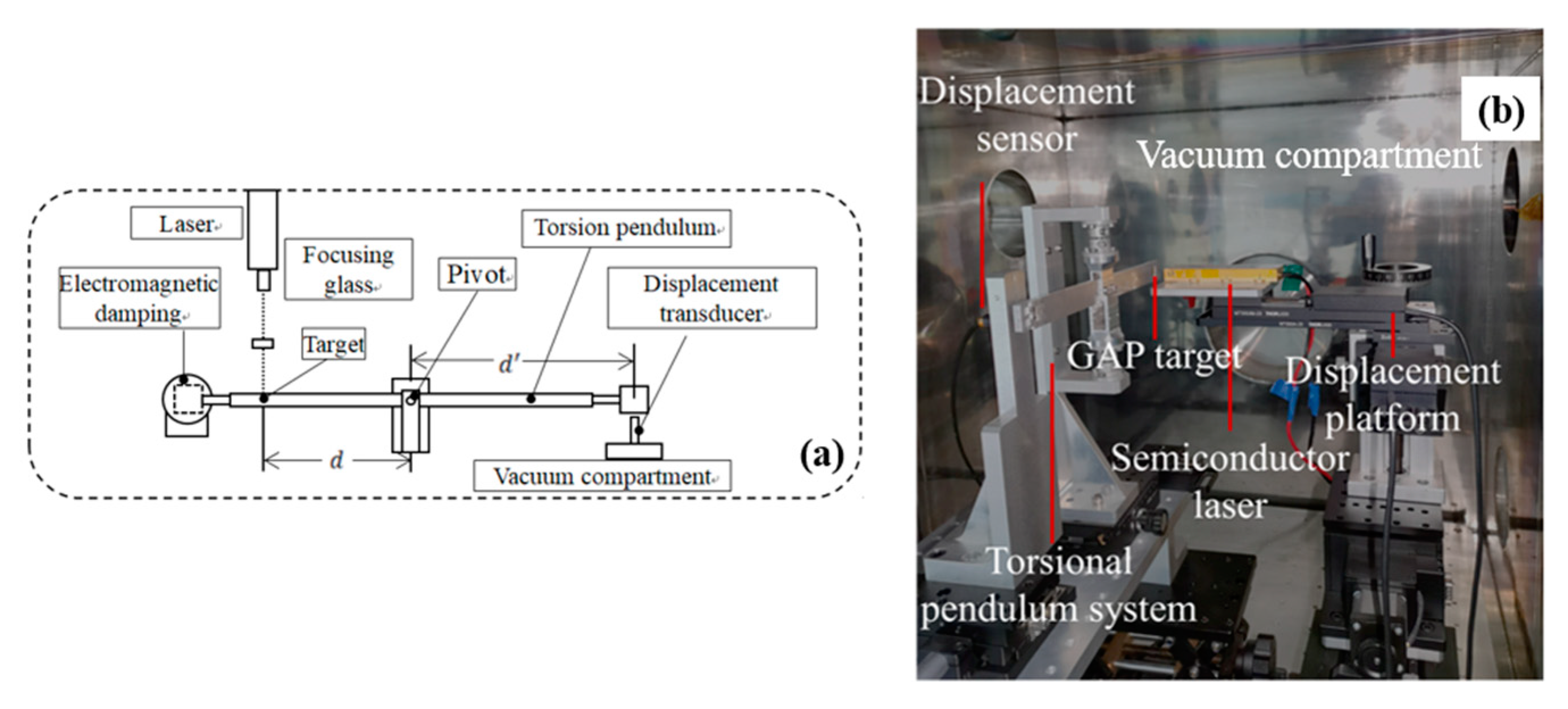

2.2. Experimental System and Measurement Method

2.3. Characterization of Double-Layer Tape

3. Result and Discussion

3.1. Optimization of Double-Layer Tape

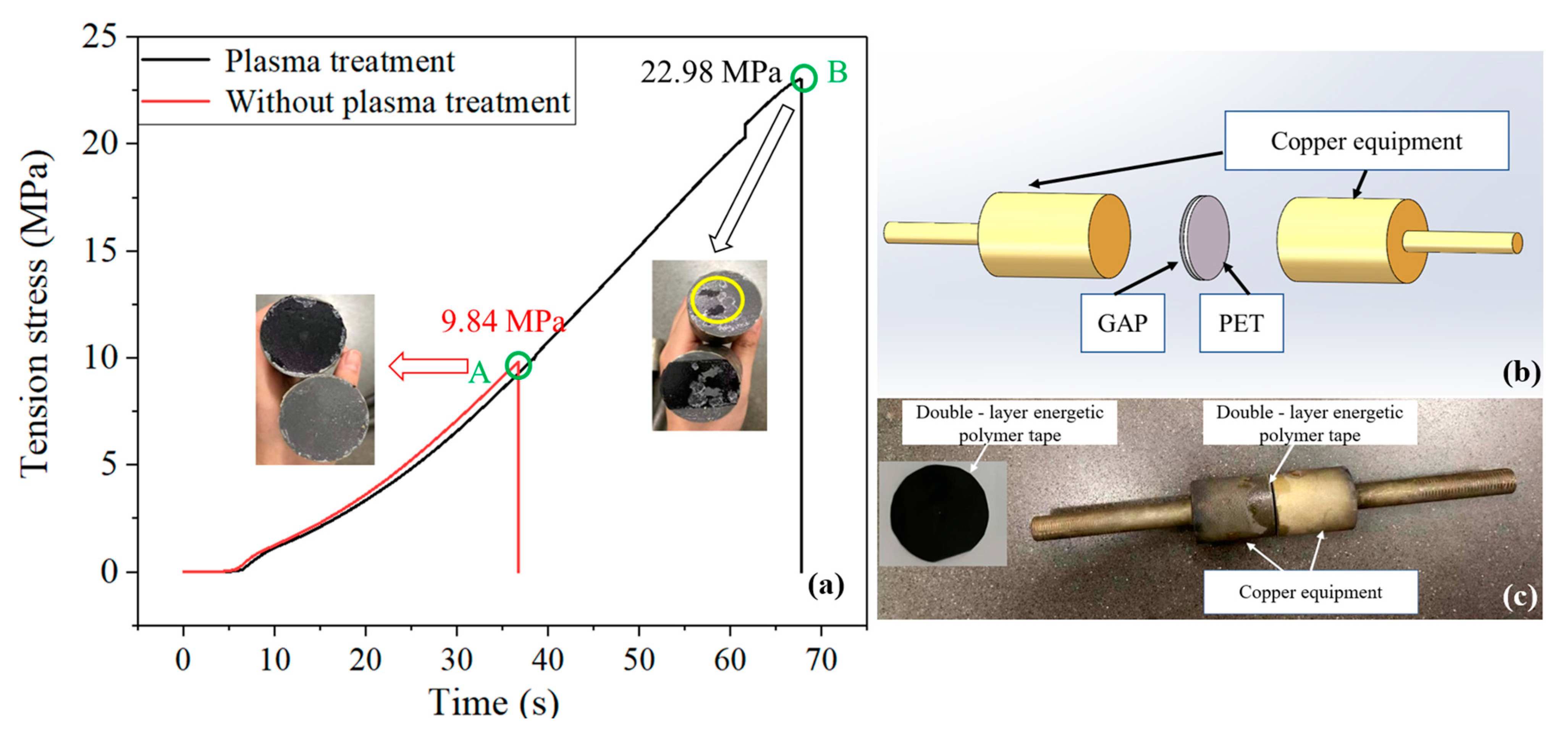

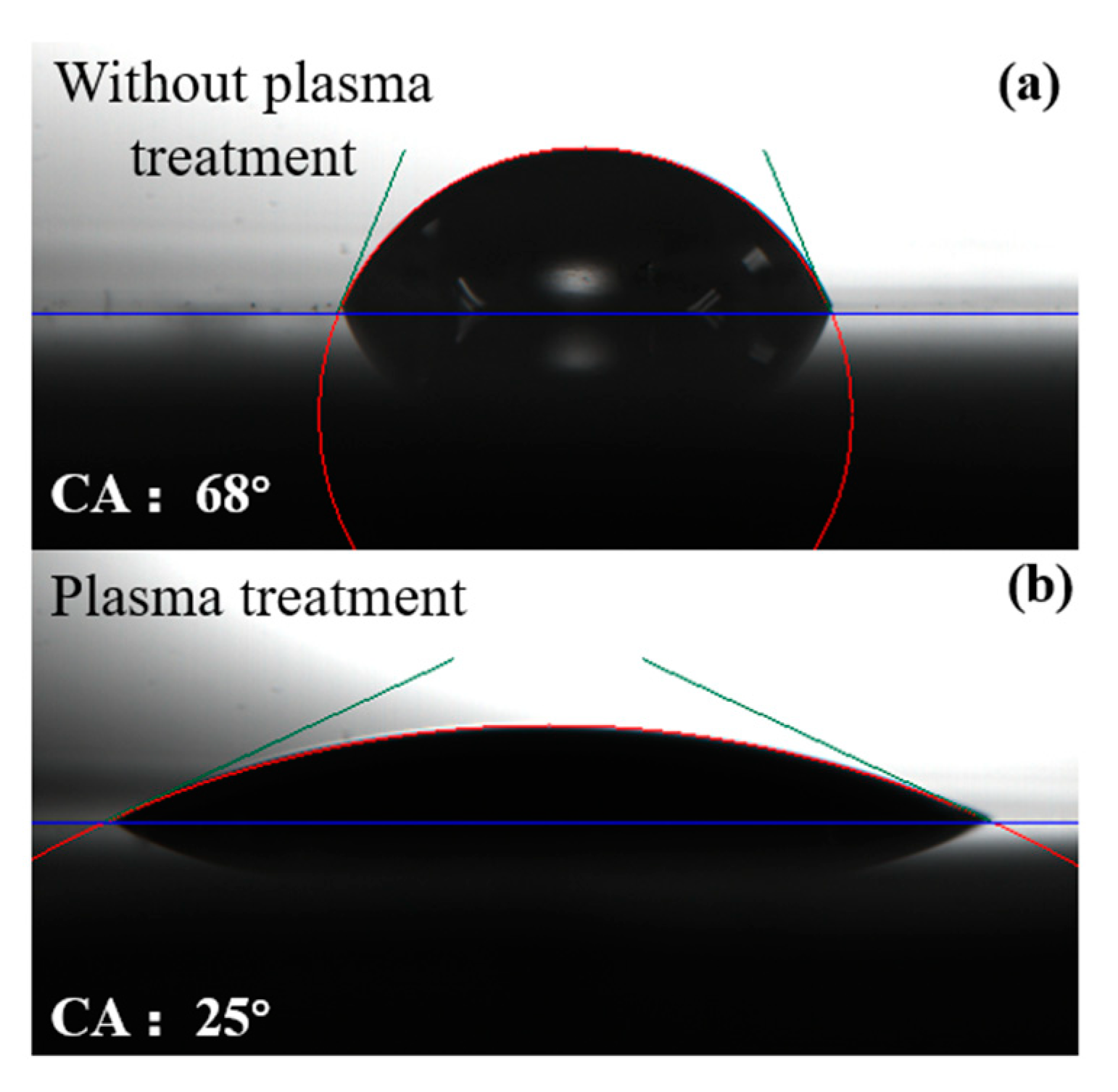

3.1.1. Adhesion Test and Contact Angle Measurement

3.1.2. Chemical Composition Analysis: XPS Results

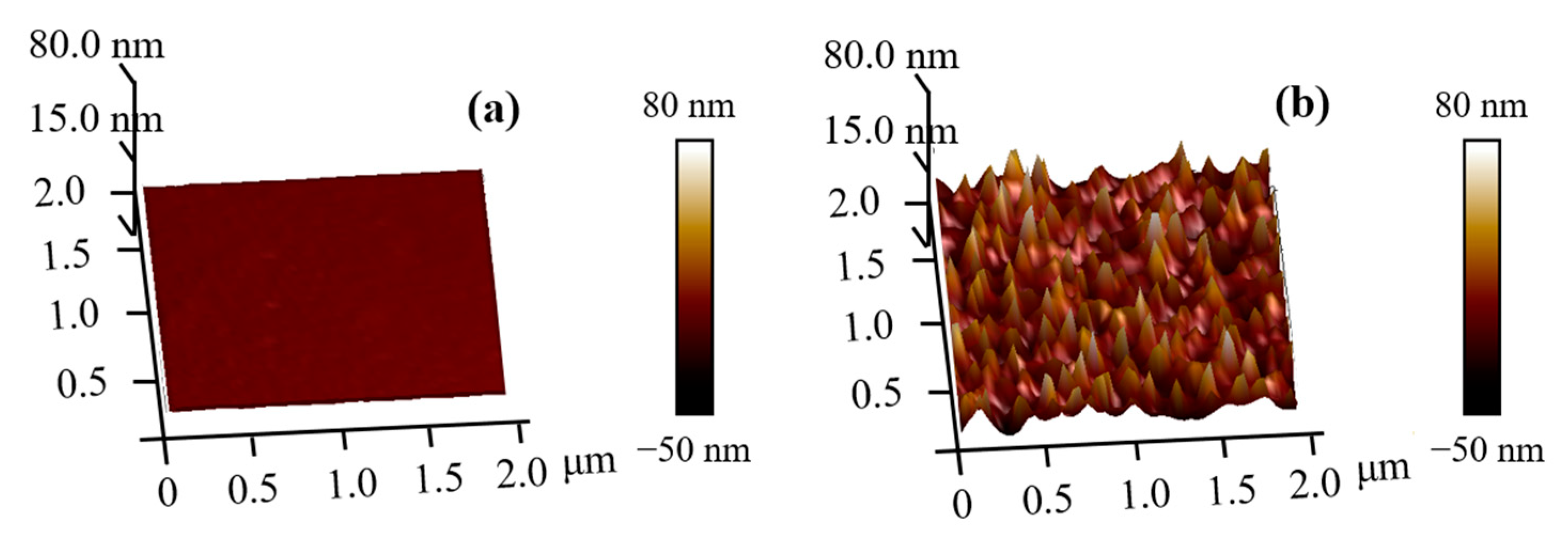

3.1.3. Morphological Analysis: AFM Results

3.2. Optimization and Research of Laser Ablation Performance

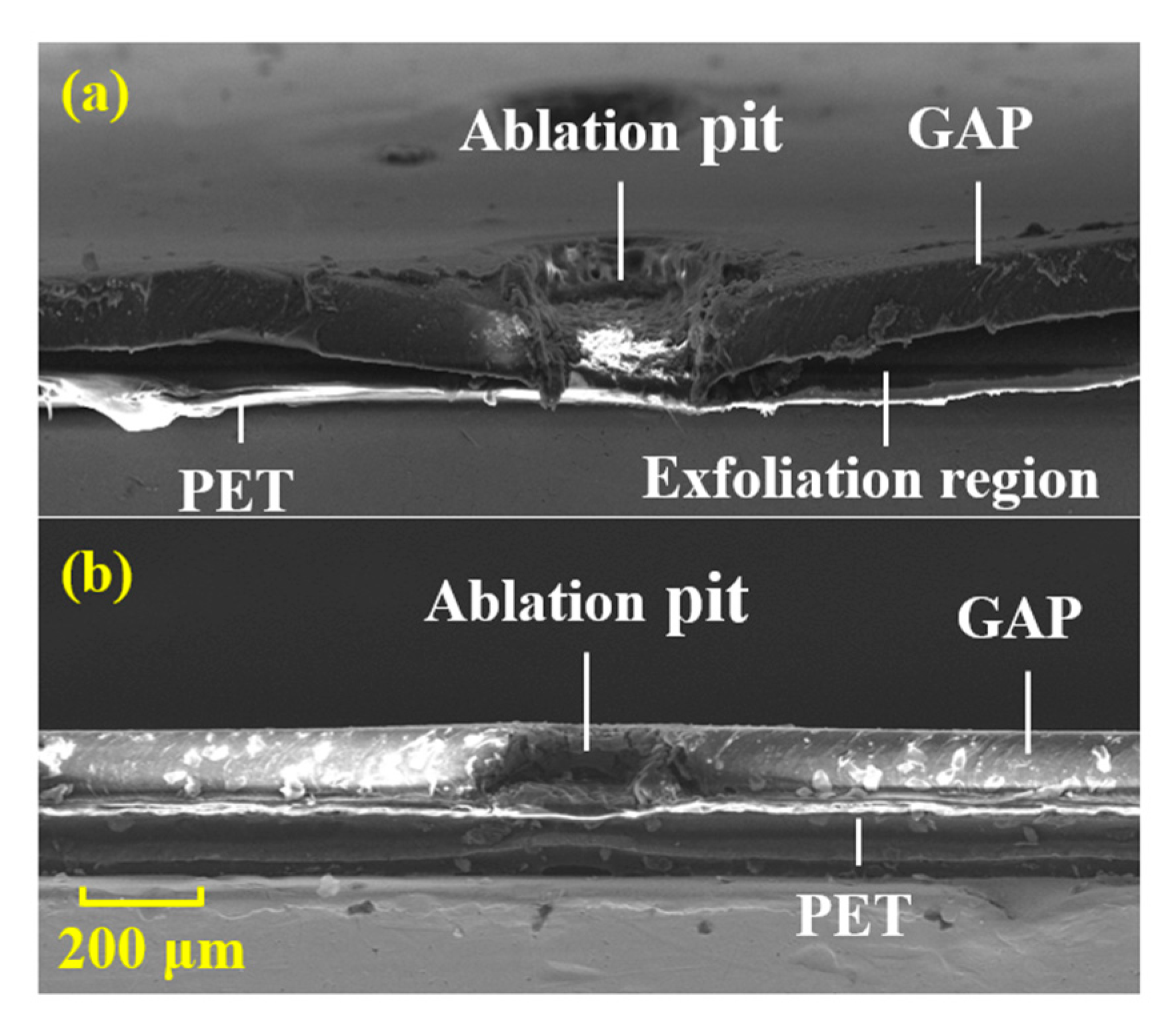

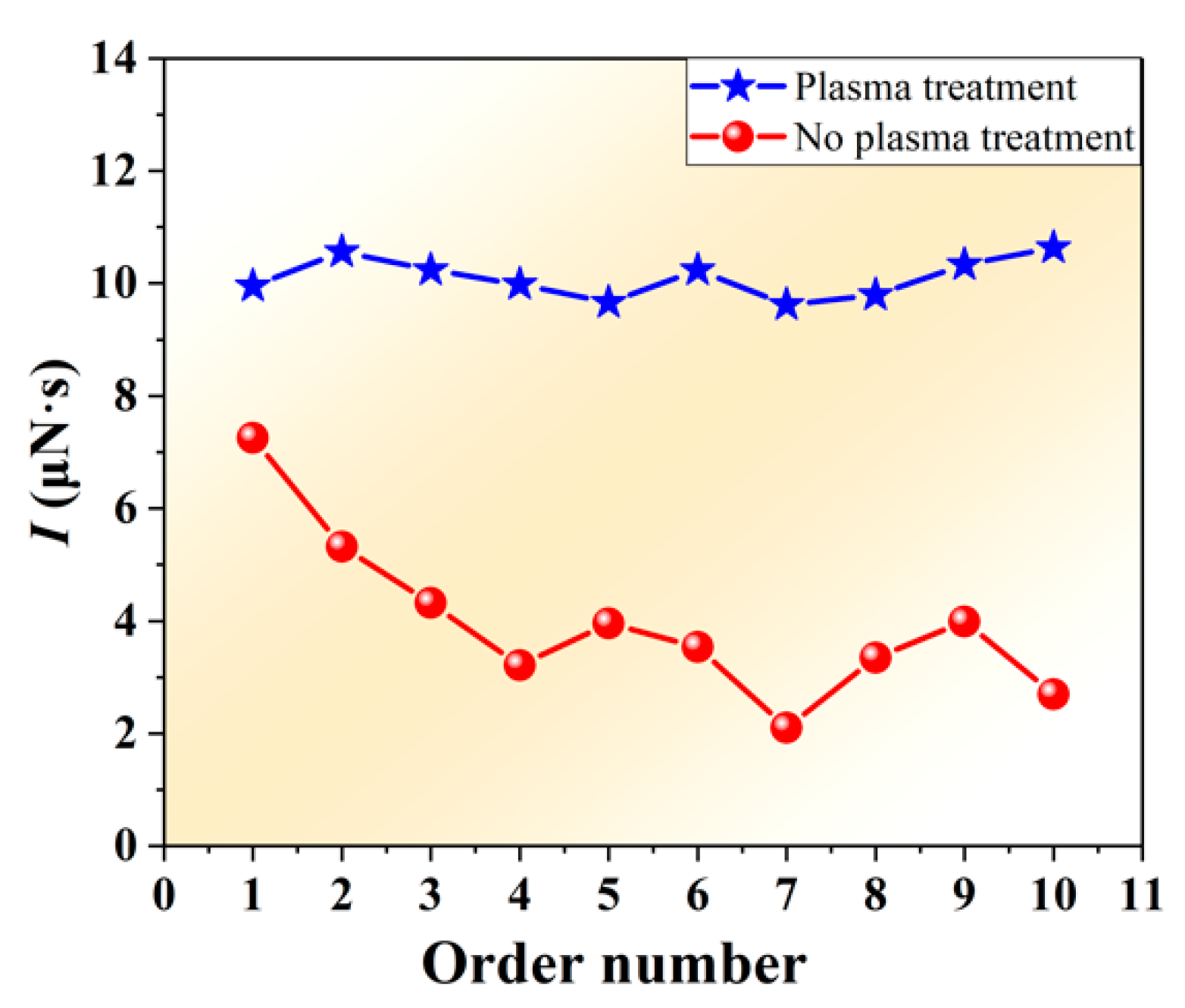

3.2.1. Comparison of Ablation Performance Pre- and Post-Plasma Treatment

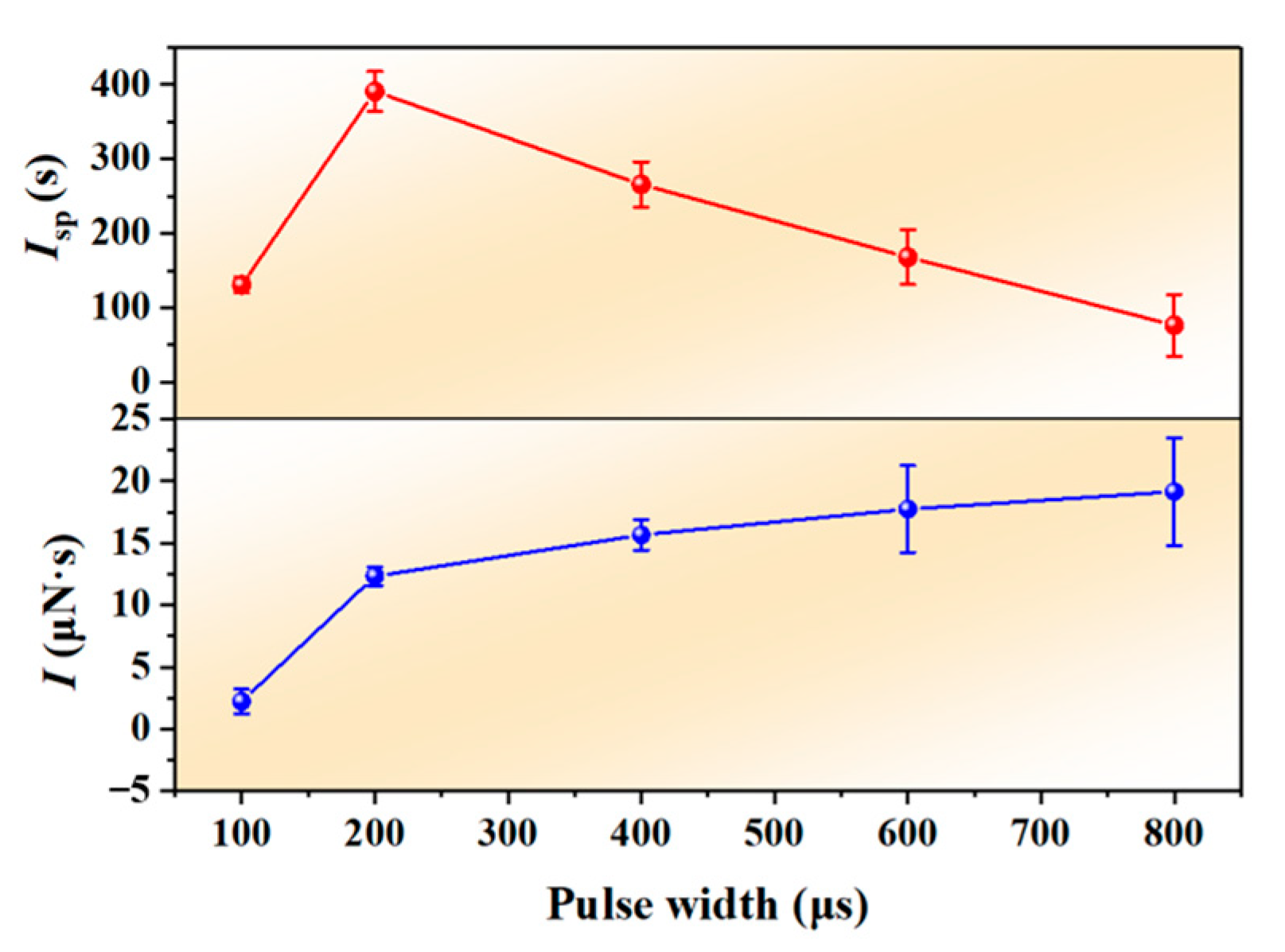

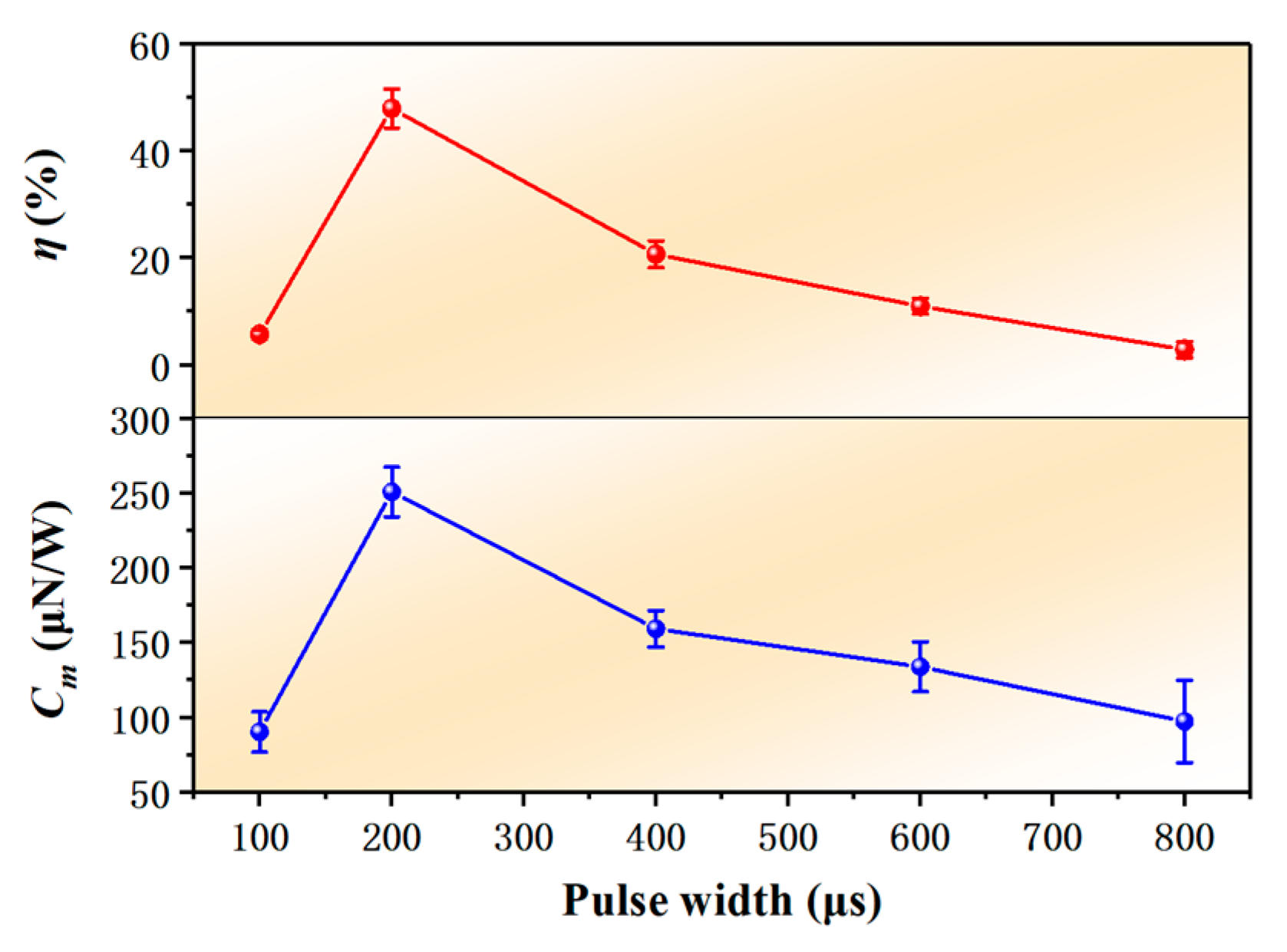

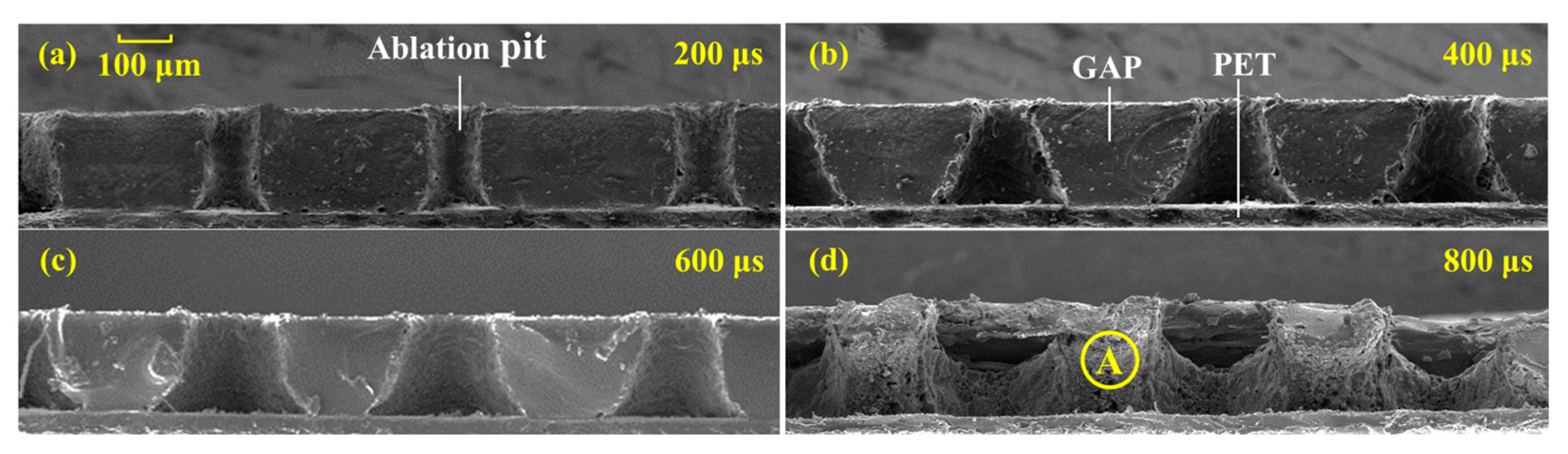

3.2.2. Optimization of Ablation Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krejci, D.; Lozano, P. Space Propulsion Technology for Small Spacecraft. Proc. IEEE 2018, 106, 362–378. [Google Scholar] [CrossRef] [Green Version]

- Yu, D.; Li, J.; Li, H.; Li, Y.; Jiang, B. Experimental Study on the Effects of Magnetic Field Configuration near the Channel Exit on the Plume Divergence of Hall Thrusters. Plasma Sci. Technol. 2009, 11, 714–720. [Google Scholar] [CrossRef]

- Akshay, R.T.; Atri, D. An Overview of Cube-Satellite Propulsion Technologies and Trends. Aerospace 2017, 4, 58. [Google Scholar] [CrossRef] [Green Version]

- Phipps, C.R.; Luke, J.R.; Helgeson, W. Laser Space Propulsion Overview. In Proceedings of the XVI International Symposium on Gas Flow, Chemical Lasers, and High-Power Lasers, Gmunden, Austria, 26 April 2007; SPIE-The International Society for Optical Engineering: Bellingham, WA, USA, 2007; Volume 6606, pp. 15–26. [Google Scholar] [CrossRef]

- Phipps, C.R.; Luke, J.R.; Thomas, L.; Marc, H.; Alexander, W. Micropropulsion using laser ablation. Appl. Phys. A 2004, 79, 1385–1389. [Google Scholar] [CrossRef]

- Zhang, Z.; Hang, G.; Qi, J.; Zhang, Z.; Zhang, Z.; Liu, J.; Yang, W.; Tang, H. Design and fabrication of a full elastic sub-micron-Newton scale thrust measurement system for plasma micro thrusters. Plasma Sci. Technol. 2021, 23, 104004. [Google Scholar] [CrossRef]

- Yu, H.; Li, H.; Wang, Y.; Cui, L.; Liu, S.; Yang, J. Brief review on pulse laser propulsion. Opt. Laser Technol. 2018, 100, 57–74. [Google Scholar] [CrossRef]

- Phipps, C.R. Micro Laser Plasma Thrusters for Small Satellites. STTR 1999-F49620-98-C-0038. In Proceedings of the SPIE: High-Power Laser Ablation III, Santa Fe, NM, USA, 24–28 April 2000; Volume 4065. [Google Scholar]

- Phipps, C.R.; Luke, J.R.; McDuff, G.G.; Thomas, L. Laser-driven micro-rocket. Appl. Phys. A 2003, 77, 193–201. [Google Scholar] [CrossRef]

- Lorbeer, R.A.; Weixler, S.; Bauer, T.; Scharring, S.; Eckel, H.A. Single Printed Circuit Board Laser Ablative Thruster. In Proceedings of the 10th Pico and Nano Satellite Workshop, Würzburg, Germany, 13–14 September 2017. [Google Scholar]

- Reif, J. Processing with Ultrashort Laser Pulses. In Laser Processing of Materials; Schaaf, P., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; p. 139. [Google Scholar] [CrossRef]

- Gurin, A.V.; Kuvaev, K.Y.; Loktionov, E.Y.; Protasov, Y.S.; Sirenko, K.N.; Zakharov, V.I. First attempt of a laser thruster space flight test: Lost at launch. Opt. Laser Technol. 2019, 120, 105656. [Google Scholar] [CrossRef]

- Jiao, L.; Cai, J.; Ma, H.; Li, L.; Shen, Z.; Tang, Z. Research on applications of rectangular beam in micro laser propulsion. Appl. Surf. Sci. 2014, 301, 481–487. [Google Scholar] [CrossRef]

- Phipps, C.R.; Zhigilei, L.; Polynkin, P.; Baumert, T.; Sarnet, T.; Bulgakova, N.; Bohn, W.; Reif, J. Laser interaction with material: Introduction. Appl. Opt. 2014, 53, LIM1–LIM3. [Google Scholar] [CrossRef]

- Reif, J.; Costache, F.; Eckert, S.; Henyk, M. Mechanisms of ultra-short laser pulse ablation from ionic crystals. Appl. Phys. A 2004, 79, 1229–1231. [Google Scholar] [CrossRef]

- Zhang, H.; Duan, B.; Wu, L.; Hua, Z.; BAO, Z.; Guo, N.; Ye, Y.; Galfetti, L.; DeLuca, L.T.; Ruiqi, S. Actualization of an efficient throttleable laser propulsion mode. Energy 2021, 221, 119870. [Google Scholar] [CrossRef]

- Fang, J.; Hong, Y.; Li, Q. Numerical Analysis of Interaction Between Single-Pulse Laser-Induced Plasma and Bow Shock in a Supersonic Flow. Plasma Sci. Technol. 2012, 14, 741–746. [Google Scholar] [CrossRef]

- Phipps, C.R.; Luke, J.R.; Thomas, L.; Marc, H.; Alexander, W. Micropropulsion Using a Laser Ablation Jet. J. Propuls. Technol. 2005, 20, 1000–1011. [Google Scholar] [CrossRef]

- Wang, S.; Du, B.; Du, B.; Zheng, Y.; Hong, Y.; Ye, J.; Xing, B.; Li, C.; Zhang, Y. Impacts of laser pulse width and target thickness on laser micro-propulsion performance. Plasma Sci. Technol. 2022; in press. [Google Scholar] [CrossRef]

- Phipps, C.R.; Luke, J.R.; Helgeson, W.; Naud, D.; Hiskey, M.; Urech, L.; Thomas, L.; Alexander, W. Giant Momentum Coupling Coefficients form Nanoscale laser-Initiated Exothermic Compounds. In Proceedings of the 41st AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Tucson, AZ, USA, 10–13 July 2005. [Google Scholar]

- Thomas, L.; Christian, D.; Marc, H.; Phipps, C.R.; Alexander, W. Tailor-Made Polymers for Laser Ablation. Laser Orig. 2001, 29, 734–738. [Google Scholar]

- Urech, L.; Thomas, L.; Phipps, C.R.; Alexander, W. Polymer ablation: From fundamentals of polymer design to laser plasma thruster. Appl. Surf. Sci. 2007, 253, 6409–6415. [Google Scholar] [CrossRef]

- Phipps, C.R.; Luke, J.R.; Helgeson, W. Liquid-fueled, Laser-powered, N-class thrust Space Engine with Variable Specific Impulse. AIP Conf. Proc. 2008, 997, 222–231. [Google Scholar] [CrossRef]

- Wiacek, A.E.; Jurak, M.; Gozdecka, A.; Worzakowska, M. Interfacial properties of PET and PET/starch polymers developed by air plasma processing. Colloids Surf. A 2017, 532, 323–331. [Google Scholar] [CrossRef]

- Mick, D.; Vladimir, M.; Denis, P.D. Activation of PET Using an RF Atmospheric Plasma System. Plasma Chem. Plasma Process. 2013, 33, 941–957. [Google Scholar] [CrossRef]

- Mehmood, T.; Kaynak, A.; Dai, X.J.; Kouzani, A.; Magniez, K.; Rubin, D.C.D.; Hurren, C.J.; Du Plessis, J. Study of oxygen plasma pre-treatment of polyester fabric for improved polypyrrole adhesion. Mater. Chem. Phys. 2014, 143, 668–675. [Google Scholar] [CrossRef]

- Vesel, A.; Mozetic, M.; Zalar, A. XPS study of oxygen plasma activated PET. Vacuum 2009, 82, 248–251. [Google Scholar] [CrossRef]

- Vesel, A.; Zaplotnik, R.; Primc, G.; Mozetič, M. Evolution of the Surface Wettability of PET Polymer upon Treatment with an Atmospheric-Pressure Plasma Jet. Polymers 2020, 12, 87. [Google Scholar] [CrossRef] [Green Version]

- Phipps, C.R.; Luke, J.R.; McDuff, G.G.; Lippert, T. Laser-Ablation-Powered Mini-Thruster. In Proceedings of the 33rd Plasmadynamics and Lasers Conference, Maui, HI, USA, 20–23 May 2002. [Google Scholar]

- Amanatides, E.; Mataras, D.; Katsikogianni, M. Plasma surface treatment of polyethylene terephthalate films for bacterial repellence. Surf. Coat. Technol. 2006, 200, 6331–6335. [Google Scholar] [CrossRef]

- Hong, Y.; Li, D.; Feng, X.; Jin, X.; Wang, S. Measurement and Evaluation Methods of Satellite Microthruster Propulsion Performance; Science Press: Shang Hai, China, 2021. [Google Scholar]

- Yang, W.; Ji, Y.; Ye, M.; Tang, H. A micro-force measurement system based on high-temperature superconducting magnetic levitation. Meas. Sci. Technol. 2019, 30, 125020. [Google Scholar] [CrossRef]

- Noeske, M.; Degenhardt, J.; Strudthoff, S.; Lommatzsch, U. Plasma Jet Treatment of five Polymers at Atmospheric Pressure: Surface Modifications and the Relevance for Adhesion. Int. J. Adhes. Adhes. 2004, 24, 171–177. [Google Scholar] [CrossRef]

- Kostov, K.G.; Nishime, T.M.C.; Castro, A.H.R.; Toth, A.; Hein, L.R.O. Surface Modification of Polymeric Materials by Cold Atmospheric Plasma Jet. Appl. Surf. Sci. 2014, 314, 367–375. [Google Scholar] [CrossRef] [Green Version]

- Cheng, C.; Zhang, L.Y.; Zhan, R. Surface modification of polymer fibre by the new atmospheric pressure cold plasma jet. Surf. Coat. Technol. 2007, 200, 6659–6665. [Google Scholar] [CrossRef]

- Sun, J.; Yao, L.; Gao, Z.; Peng, S.; Wang, C.; Qiu, Y. Surface Modification of PET films by Atmospheric Pressure Plasma-induced Acrylic Acid Inverse Emulsion Graft Polymerization. Surf. Coat. Technol. 2010, 204, 4101–4106. [Google Scholar] [CrossRef]

- Pandiyaraj, K.N.; Selvarajan, V.; Deshmukh, R.R.; Gao, C. Adhesive properties of polypropylene (PP) and polyethylene terephthalate (PET) film surfaces treated by DC glow discharge plasma. Vacuum 2008, 83, 332–339. [Google Scholar] [CrossRef]

- Luke, J.R.; Phipps, C.R.; McDuff, G.G. Laser plasma thruster continuous thrust experiment. In Proceedings of the SPIE, High-Power Laser Ablation IV, Taos, NM, USA, 13 September 2002; Volume 4760, pp. 843–851. [Google Scholar] [CrossRef]

| Film Surface | PET | |||

|---|---|---|---|---|

| C 1s at% | O 1s at% | N 1s at% | Si 1s at% | |

| Untreated sample | 68.21 | 28.03 | - | 2.77 |

| Treated sample | 65.47 | 32.49 | 1.16 | 0.88 |

| Binding Energy (eV) | Untreated Sample at% | Treated Sample at% | Possible Functional Groups |

|---|---|---|---|

| 289.00 | 19.09 | 16.25 | O=C–O |

| 286.70 | - | 14.69 | C–OH/COOH |

| 286.12 | 17.15 | 7.45 | C–O |

| 288.44 | - | 4.77 | CON |

| 284.80 | 63.76 | 56.84 | C–C/C–H |

| Properties | Ra nm | Rq nm |

|---|---|---|

| Untreated sample | 1.45 (± 0.22) | 1.74 (± 0.39) |

| Treated sample | 14.30 (± 5.86) | 19.10 (± 6.34) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Du, B.; Xing, B.; Hong, Y.; Wang, Y.; Du, B.; Zheng, Y.; Ye, J.; Li, C. Interface Adhesion Property and Laser Ablation Performance of GAP-PET Double-Layer Tape with Plasma Treatment. Nanomaterials 2022, 12, 1827. https://doi.org/10.3390/nano12111827

Wang S, Du B, Xing B, Hong Y, Wang Y, Du B, Zheng Y, Ye J, Li C. Interface Adhesion Property and Laser Ablation Performance of GAP-PET Double-Layer Tape with Plasma Treatment. Nanomaterials. 2022; 12(11):1827. https://doi.org/10.3390/nano12111827

Chicago/Turabian StyleWang, Sibo, Bangdeng Du, Baoyu Xing, Yanji Hong, Ying Wang, Baosheng Du, Yongzan Zheng, Jifei Ye, and Chenglin Li. 2022. "Interface Adhesion Property and Laser Ablation Performance of GAP-PET Double-Layer Tape with Plasma Treatment" Nanomaterials 12, no. 11: 1827. https://doi.org/10.3390/nano12111827

APA StyleWang, S., Du, B., Xing, B., Hong, Y., Wang, Y., Du, B., Zheng, Y., Ye, J., & Li, C. (2022). Interface Adhesion Property and Laser Ablation Performance of GAP-PET Double-Layer Tape with Plasma Treatment. Nanomaterials, 12(11), 1827. https://doi.org/10.3390/nano12111827