Improved Sensitivity of Surface-Enhanced Raman Scattering with Gold Nanoparticles-Insulator-Metal Sandwich Layers on Flat Sapphire Substrate

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Materials

2.2. Characterization Methods

2.3. Calculation Based on Electromagnetics Theory

3. Results and Discussion

3.1. Surface Morphology of AuNP/Si and AuNP/SiO2/Au/Sapphire Substrates

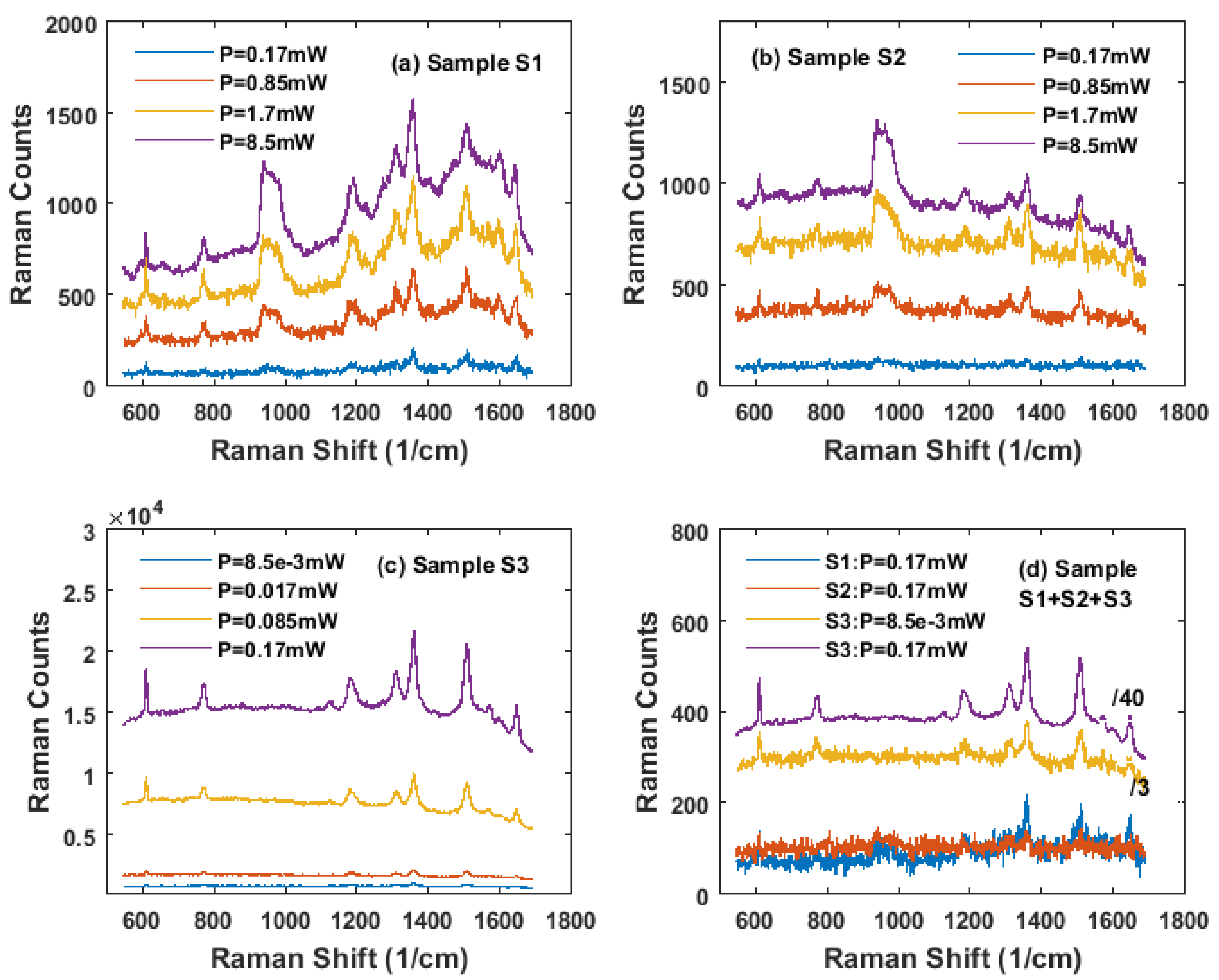

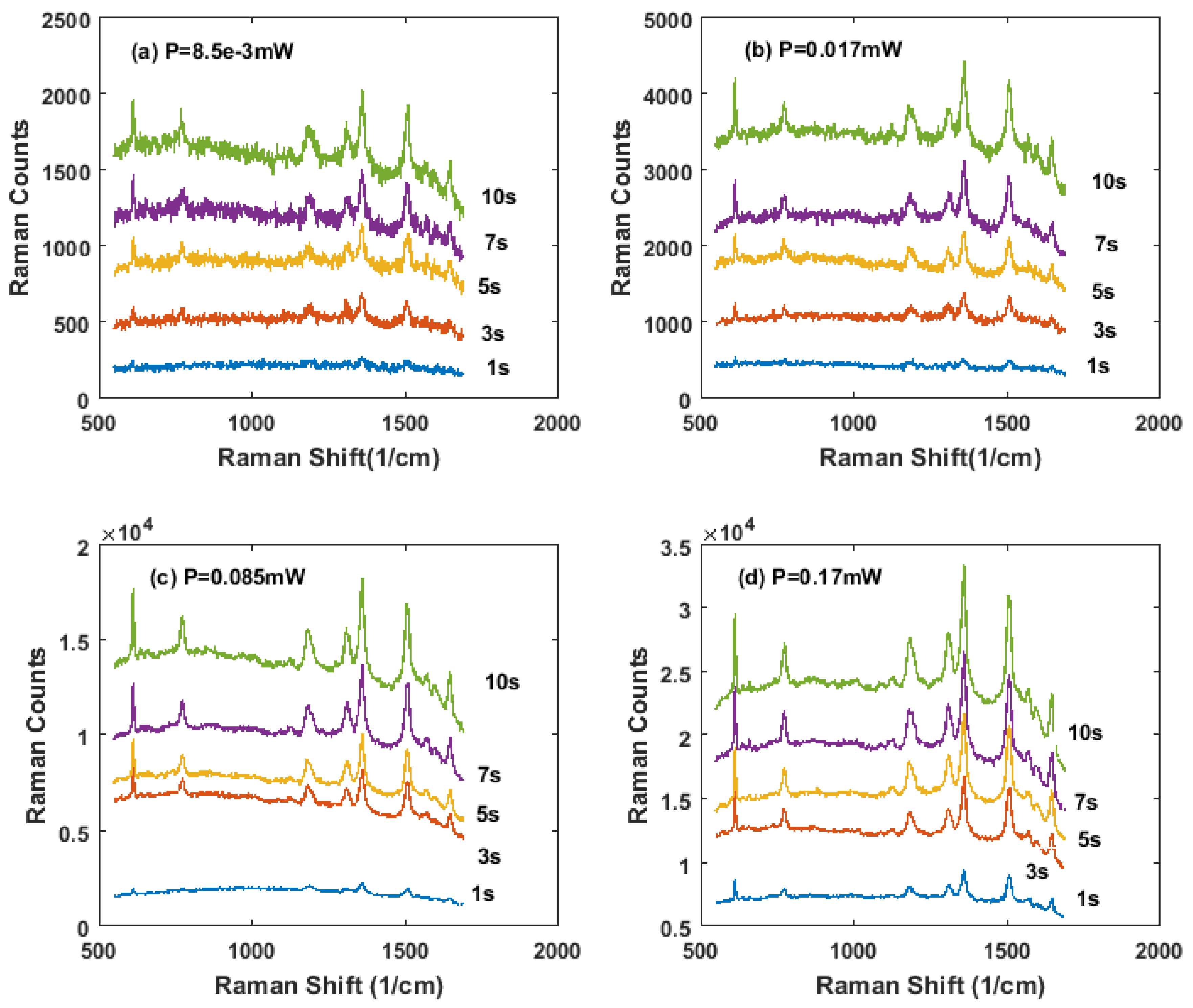

3.2. Raman Microscopy of R6G Molecules Adsorbed on AuNP/Si and AuNP/SiO2/Au/Sapphire Substrates

3.3. FDTD Simulation Results for Modeling AuNP/Si and AuNP/SiO2/Au/Sapphire

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Yang, Z.; Peng, B.; Cao, C.; Zhang, C.; You, H.; Xiong, Q.; Li, Z.; Fang, J. Highly Sensitive, Uniform, and Reproducible Surface-Enhanced Raman Spectroscopy from Hollow Au-Ag Alloy Nanourchins. Adv. Mater. 2014, 26, 2431–2439. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Tao, J.; Shen, Y.; Liang, G.; Liu, T.; Zhang, Y.; Wang, Q.J. A metal–dielectric–graphene sandwich for surface enhanced Raman spectroscopy. Nanoscale 2014, 6, 9925–9929. [Google Scholar] [CrossRef] [PubMed]

- Fang, J.; Du, S.; Lebedkin, S.; Li, Z.; Kruk, R.; Kappes, M.; Hahn, H. Gold Mesostructures with Tailored Surface Topography and Their Self-Assembly Arrays for Surface-Enhanced Raman Spectroscopy. Nano Lett. 2010, 10, 5006–5013. [Google Scholar] [CrossRef]

- Fleischmann, M.; Hendra, P.J.; McQuillan, A.J. Raman spectra of pyridine adsorbed at a silver electrode. Chem. Phys. Lett. 1974, 26, 163–166. [Google Scholar] [CrossRef]

- McQuillan, A.J. The discovery of surface-enhanced Raman scattering. Notes Rec. R. Soc. J. Hist. Sci. 2009, 63, 105–109. [Google Scholar] [CrossRef]

- Greeneltch, N.G.; Blaber, M.G.; Henry, A.-I.; Schatz, G.C.; Van Duyne, R.P. Immobilized Nanorod Assemblies: Fabrication and Understanding of Large Area Surface-Enhanced Raman Spectroscopy Substrates. Anal. Chem. 2013, 85, 2297–2303. [Google Scholar] [CrossRef]

- Lee, C.; Robertson, C.S.; Nguyen, A.H.; Kahraman, M.; Wachsmann-Hogiu, S. Thickness of a metallic film, in addition to its roughness, plays a significant role in SERS activity. Sci. Rep. 2015, 5, 11644. [Google Scholar] [CrossRef] [PubMed]

- Kreno, L.E.; Greeneltch, N.G.; Farha, O.K.; Hupp, J.T.; Van Duyne, R.P. SERS of molecules that do not adsorb on Ag surfaces: A metal–organic framework-based functionalization strategy. Analyst 2014, 139, 4073–4080. [Google Scholar] [CrossRef]

- Wang, D.; Zhu, W.; Best, M.D.; Camden, J.P.; Crozier, K.B. Wafer-scale metasurface for total power absorption, local field enhancement and single molecule Raman spectroscopy. Sci. Rep. 2013, 3, srep02867. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.; Zhang, H.; Liu, W.; Ge, J.; Wu, J.; Wang, S.; Wang, P. Surface-enhanced Raman scattering substrate based on cysteamine-modified gold nanoparticle aggregation for highly sensitive pentachlorophenol detection. RSC Adv. 2016, 6, 85285–85292. [Google Scholar] [CrossRef]

- Mevold, A.H.H.; Hsu, W.-W.; Hardiansyah, A.; Huang, L.-Y.; Yang, M.-C.; Liu, T.-Y.; Chan, T.-Y.; Wang, K.-S.; Su, Y.-A.; Jeng, R.-J.; et al. Fabrication of Gold Nanoparticles/Graphene-PDDA Nanohybrids for Bio-detection by SERS Nanotechnology. Nanoscale Res. Lett. 2015, 10, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Jin, Z.-M.; Gu, W.; Shi, X.-B.; Wang, Z.-K.; Jiang, Z.-Q.; Liao, L.-S. A Novel Route to Surface-Enhanced Raman Scattering: Ag Nanoparticles Embedded in the Nanogaps of a Ag Substrate. Adv. Opt. Mater. 2014, 2, 588–596. [Google Scholar] [CrossRef]

- Lee, P.C.; Meisel, D. Adsorption and surface-enhanced Raman of dyes on silver and gold sols. J. Phys. Chem. 1982, 86, 3391–3395. [Google Scholar] [CrossRef]

- Xu, W.; Ling, X.; Xiao, J.; Dresselhaus, M.S.; Kong, J.; Xu, H.; Liu, Z.; Zhang, J. Surface enhanced Raman spectroscopy on a flat graphene surface. Proc. Natl. Acad. Sci. USA 2012, 109, 9281–9286. [Google Scholar] [CrossRef] [PubMed]

- Liang, H.; Li, Z.; Wang, W.; Wu, Y.; Xu, H. Highly Surface-roughened “Flower-like” Silver Nanoparticles for Extremely Sensitive Substrates of Surface-enhanced Raman Scattering. Adv. Mater. 2009, 21, 4614–4618. [Google Scholar] [CrossRef]

- Wang, N.; Zhu, W.; Chu, Y.; Crozier, K.B. High Directivity Optical Antenna Substrates for Surface Enhanced Raman Scattering. Adv. Mater. 2012, 24, 4376–4380. [Google Scholar] [CrossRef]

- Wang, D.; Zhu, W.; Best, M.D.; Camden, J.; Crozier, K. Directional Raman Scattering from Single Molecules in the Feed Gaps of Optical Antennas. Nano Lett. 2013, 13, 2194–2198. [Google Scholar] [CrossRef] [PubMed]

- Kanipe, K.N.; Chidester, P.P.F.; Stucky, G.D.; Moskovits, M. Large Format Surface-Enhanced Raman Spectroscopy Substrate Optimized for Enhancement and Uniformity. ACS Nano 2016, 10, 7566–7571. [Google Scholar] [CrossRef]

- Gillibert, R.; Sarkar, M.; Bryche, J.-F.; Yasukuni, R.; Moreau, J.; Besbes, M.; Barbillon, G.; Bartenlian, B.; Canva, M.; De La Chapelle, M.L. Directional surface enhanced Raman scattering on gold nano-gratings. Nanotechnology 2016, 27, 115202. [Google Scholar] [CrossRef]

- Schmidt, M.S.; Hubner, J.; Boisen, A. Large area fabrication of leaning silicon nanopillars for surface enhanced Raman spectroscopy. Adv. Mater. 2012, 24, OP11–OP18. [Google Scholar] [CrossRef]

- Willets, K.A.; Van Duyne, R.P. Localized Surface Plasmon Resonance Spectroscopy and Sensing. Annu. Rev. Phys. Chem. 2007, 58, 267–297. [Google Scholar] [CrossRef]

- Fang, Y.; Seong, N.-H.; Dlott, D.D. Measurement of the Distribution of Site Enhancements in Surface-Enhanced Raman Scattering. Science 2008, 321, 388–392. [Google Scholar] [CrossRef]

- Xu, H.; Aizpurua, J.; Käll, M.; Apell, P. Electromagnetic contributions to single-molecule sensitivity in surface-enhanced Raman scattering. Phys. Rev. E 2000, 62, 4318–4324. [Google Scholar] [CrossRef]

- Xu, H.; Bjerneld, E.J.; Käll, M.; Börjesson, L. Spectroscopy of Single Hemoglobin Molecules by Surface Enhanced Raman Scattering. Phys. Rev. Lett. 1999, 83, 4357–4360. [Google Scholar] [CrossRef]

- Nie, S.; Emory, S.R. Probing Single Molecules and Single Nanoparticles by Surface-Enhanced Raman Scattering. Science 1997, 275, 1102–1106. [Google Scholar] [CrossRef] [PubMed]

- Sau, T.K.; Murphy, C. Room Temperature, High-Yield Synthesis of Multiple Shapes of Gold Nanoparticles in Aqueous Solution. J. Am. Chem. Soc. 2004, 126, 8648–8649. [Google Scholar] [CrossRef]

- Vecchio, G.; Galeone, A.; Brunetti, V.; Maiorano, G.; Sabella, S.; Cingolani, R.; Pompa, P.P. Concentration-Dependent, Size-Independent Toxicity of Citrate Capped AuNPs in Drosophila melanogaster. PLoS ONE 2012, 7, e29980. [Google Scholar] [CrossRef]

- Zhang, X.-D.; Wu, H.-Y.; Wu, D.; Wang, Y.-Y.; Chang, J.-H.; Zhai, Z.-B.; Meng, A.-M.; Liu, P.-X.; Zhang, L.-A.; Fan, F.-Y. Toxicologic effects of gold nanoparticles in vivo by different administration routes. Int. J. Nanomed. 2010, 5, 771–781. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Banaee, M.G.; Wang, D.; Chu, Y.; Crozier, K.B. Lithographically Fabricated Optical Antennas with Gaps Well Below 10 nm. Small 2011, 7, 1761–1766. [Google Scholar] [CrossRef]

- Mubeen, S.; Zhang, S.; Kim, N.; Lee, S.; Kraemer, S.; Xu, H.; Moskovits, M. Plasmonic Properties of Gold Nanoparticles Separated from a Gold Mirror by an Ultrathin Oxide. Nano Lett. 2012, 12, 2088–2094. [Google Scholar] [CrossRef]

- Hakonen, A.; Svedendahl, M.; Ogier, R.; Yang, Z.-J.; Lodewijks, K.; Verre, R.; Shegai, T.; Andersson, P.O.; Käll, M. Dimer-on-mirror SERS substrates with attogram sensitivity fabricated by colloidal lithography. Nanoscale 2015, 7, 9405–9410. [Google Scholar] [CrossRef] [PubMed]

- Yue, Z.; Cai, B.; Wang, L.; Wang, X.; Gu, M. Intrinsically core-shell plasmonic dielectric nanostructures with ultrahigh refractive index. Sci. Adv. 2016, 2, e1501536. [Google Scholar] [CrossRef]

- Yue, Z.; Ren, H.; Wei, S.; Lin, J.; Gu, M. Angular-momentum nanometrology in an ultrathin plasmonic topological insulator film. Nat. Commun. 2018, 9, 1–7. [Google Scholar] [CrossRef]

- Lu, H.; Yue, Z.; Li, Y.; Zhang, Y.; Zhang, M.; Zeng, W.; Gan, X.; Mao, D.; Xiao, F.; Mei, T.; et al. Magnetic plasmon resonances in nanostructured topological insulators for strongly enhanced light–MoS2 interactions. Light. Sci. Appl. 2020, 9, 191. [Google Scholar] [CrossRef] [PubMed]

- Taflove, A.; Umashankar, K.R. Review of FDTD numerical modeling of electromagnetic wave scattering and radar cross section. Proc. IEEE 1989, 77, 682–699. [Google Scholar] [CrossRef]

- Berenger, J.P. A perfectly matched layer for the absorption of electromagnetic waves. J. Comput. Phys. 1994, 114, 185–200. [Google Scholar] [CrossRef]

- Palik, D. Handbook of Optical Constants of Solids; Academic Press: London, UK, 1985. [Google Scholar]

- Rumble, J. CRC Handbook of Chemistry and Physics; CRC Press: Boca Raton, FL, USA, 1985. [Google Scholar]

- Le Ru, E.C.; Etchegoin, P.G. Rigorous justification of the |E|4 enhancement factor in Surface Enhanced Raman Spectroscopy. Chem. Phys. Lett. 2006, 423, 63–66. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Tong, X.; Yang, Z.; Zhang, J.; Liu, B.; Chen, C.P. Improved Sensitivity of Surface-Enhanced Raman Scattering with Gold Nanoparticles-Insulator-Metal Sandwich Layers on Flat Sapphire Substrate. Nanomaterials 2021, 11, 2416. https://doi.org/10.3390/nano11092416

Li W, Tong X, Yang Z, Zhang J, Liu B, Chen CP. Improved Sensitivity of Surface-Enhanced Raman Scattering with Gold Nanoparticles-Insulator-Metal Sandwich Layers on Flat Sapphire Substrate. Nanomaterials. 2021; 11(9):2416. https://doi.org/10.3390/nano11092416

Chicago/Turabian StyleLi, Wenbing, Xin Tong, Zhuo Yang, Jiali Zhang, Bo Liu, and Chao Ping Chen. 2021. "Improved Sensitivity of Surface-Enhanced Raman Scattering with Gold Nanoparticles-Insulator-Metal Sandwich Layers on Flat Sapphire Substrate" Nanomaterials 11, no. 9: 2416. https://doi.org/10.3390/nano11092416

APA StyleLi, W., Tong, X., Yang, Z., Zhang, J., Liu, B., & Chen, C. P. (2021). Improved Sensitivity of Surface-Enhanced Raman Scattering with Gold Nanoparticles-Insulator-Metal Sandwich Layers on Flat Sapphire Substrate. Nanomaterials, 11(9), 2416. https://doi.org/10.3390/nano11092416