Gradient Microstructure Design in Stainless Steel: A Strategy for Uniting Strength-Ductility Synergy and Corrosion Resistance

Abstract

:1. Introduction

2. Experiments and Gradient Structure Preparation

3. Results and Discussion

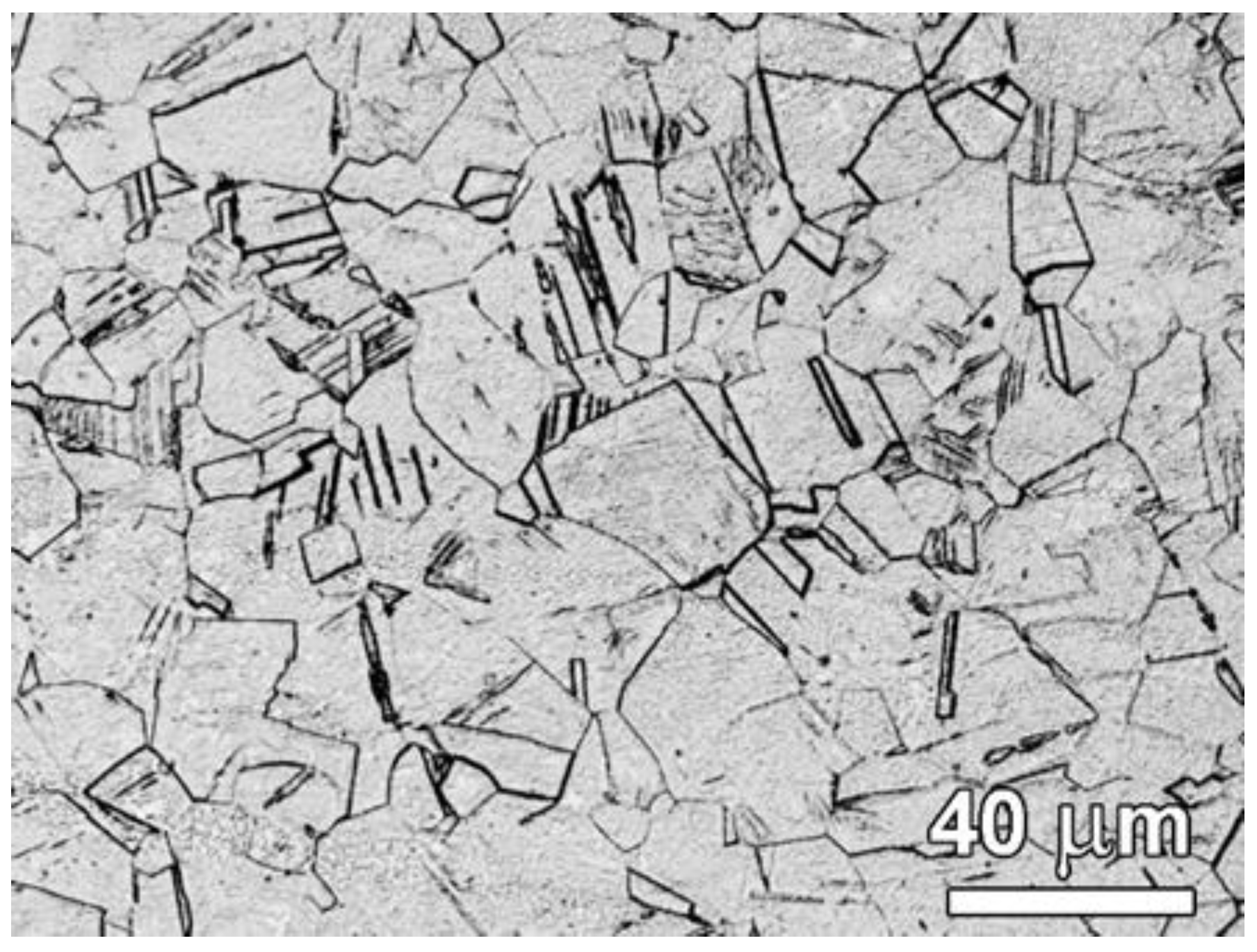

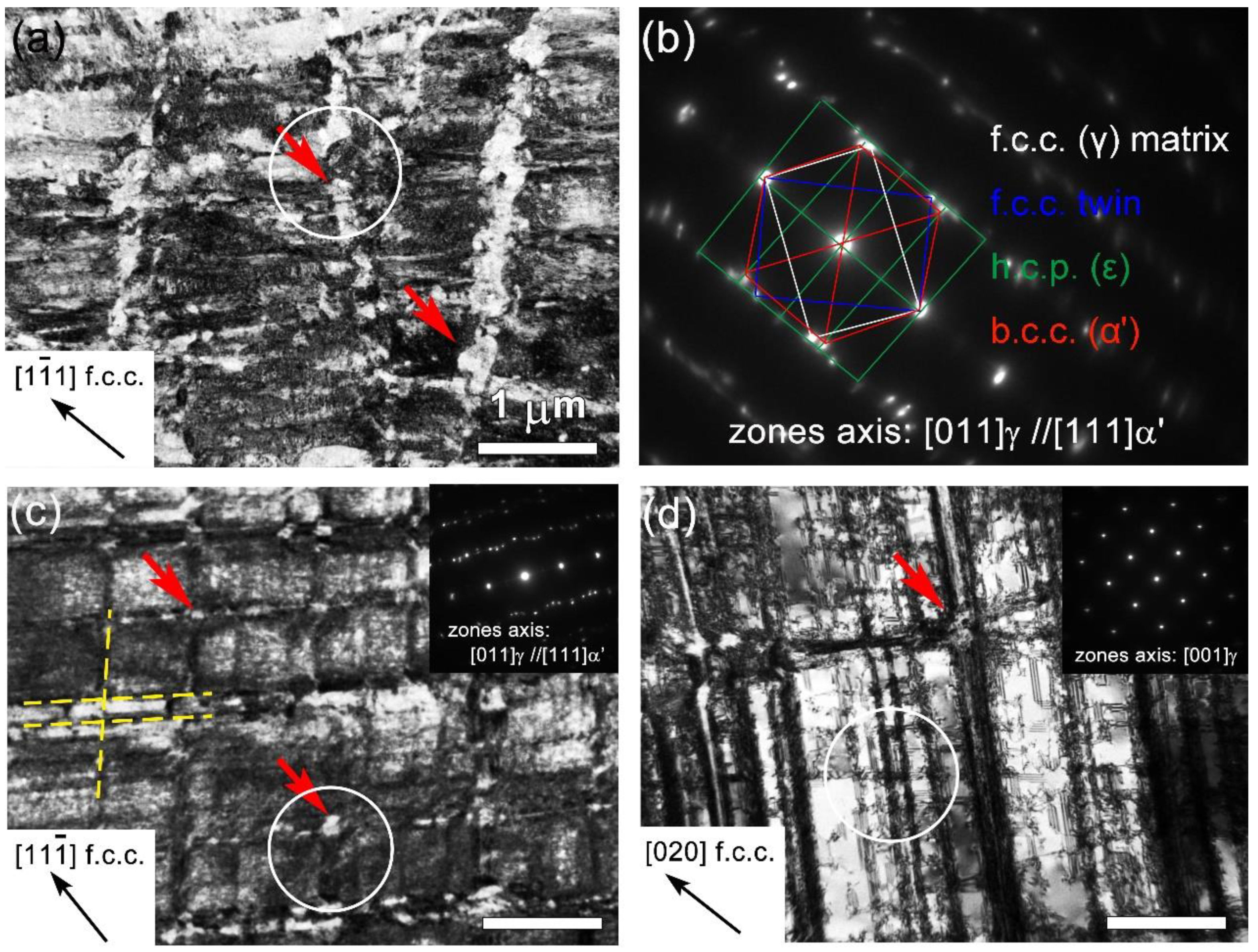

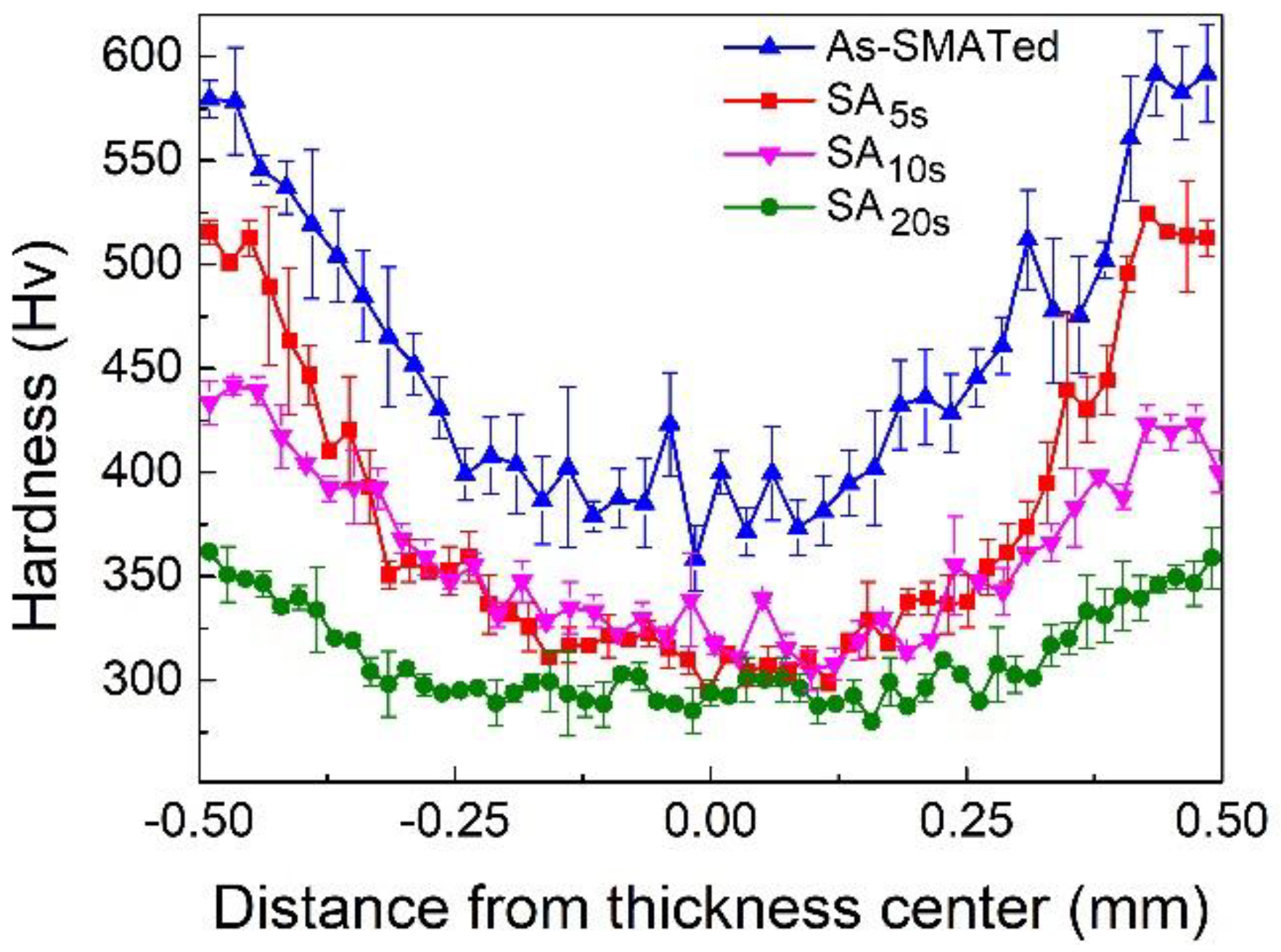

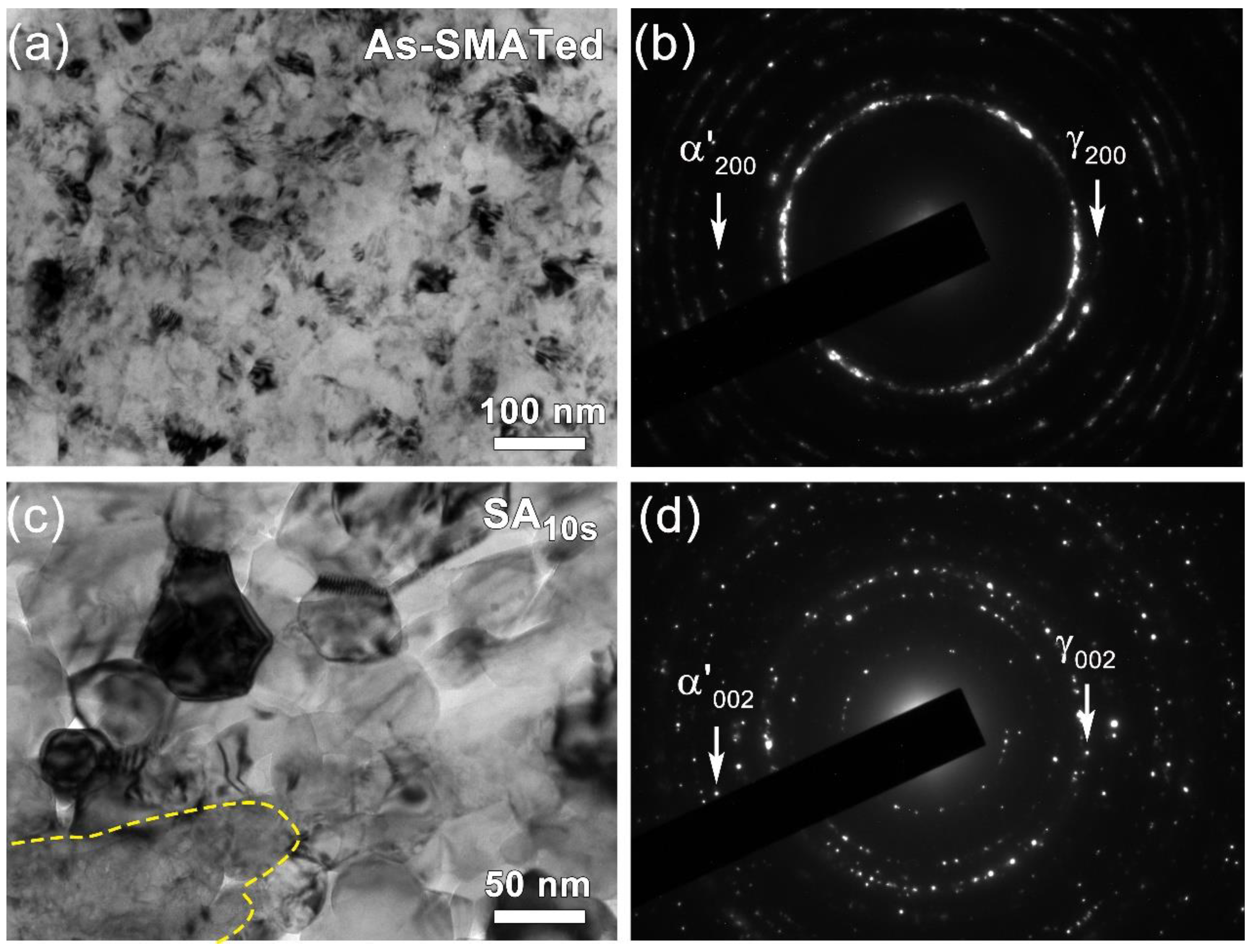

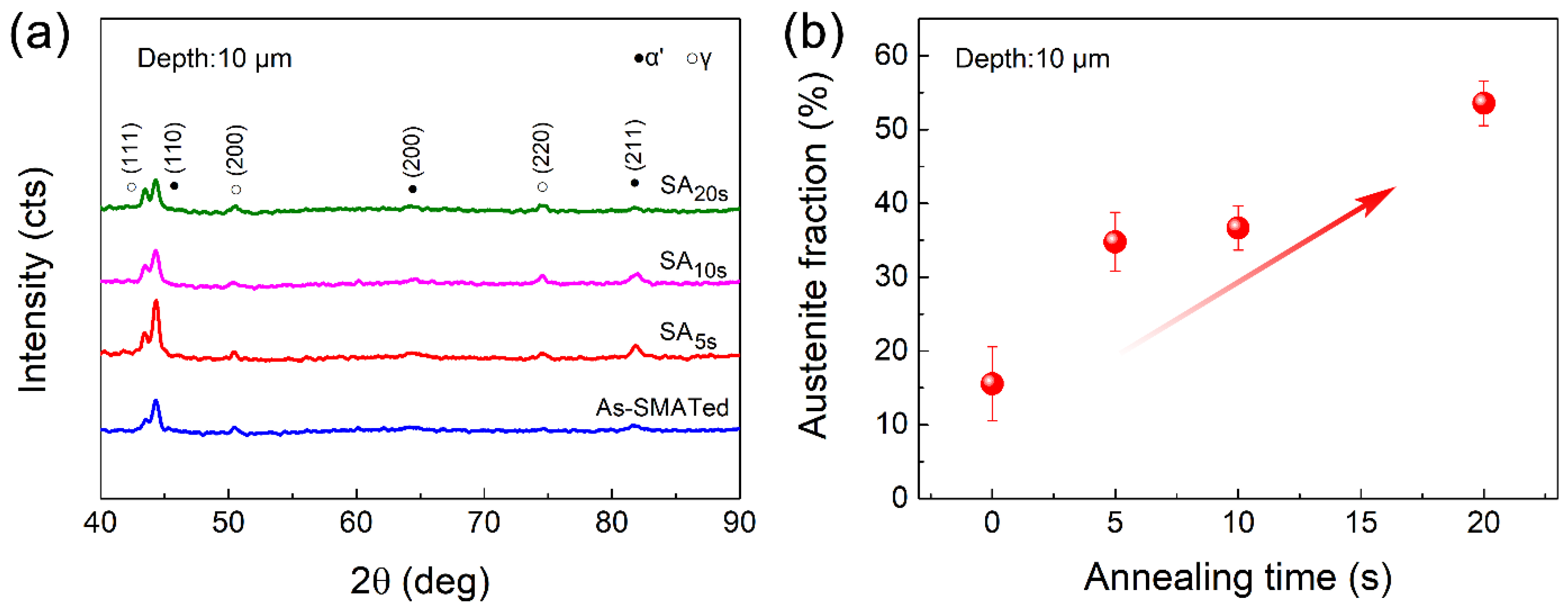

3.1. Gradient Structures

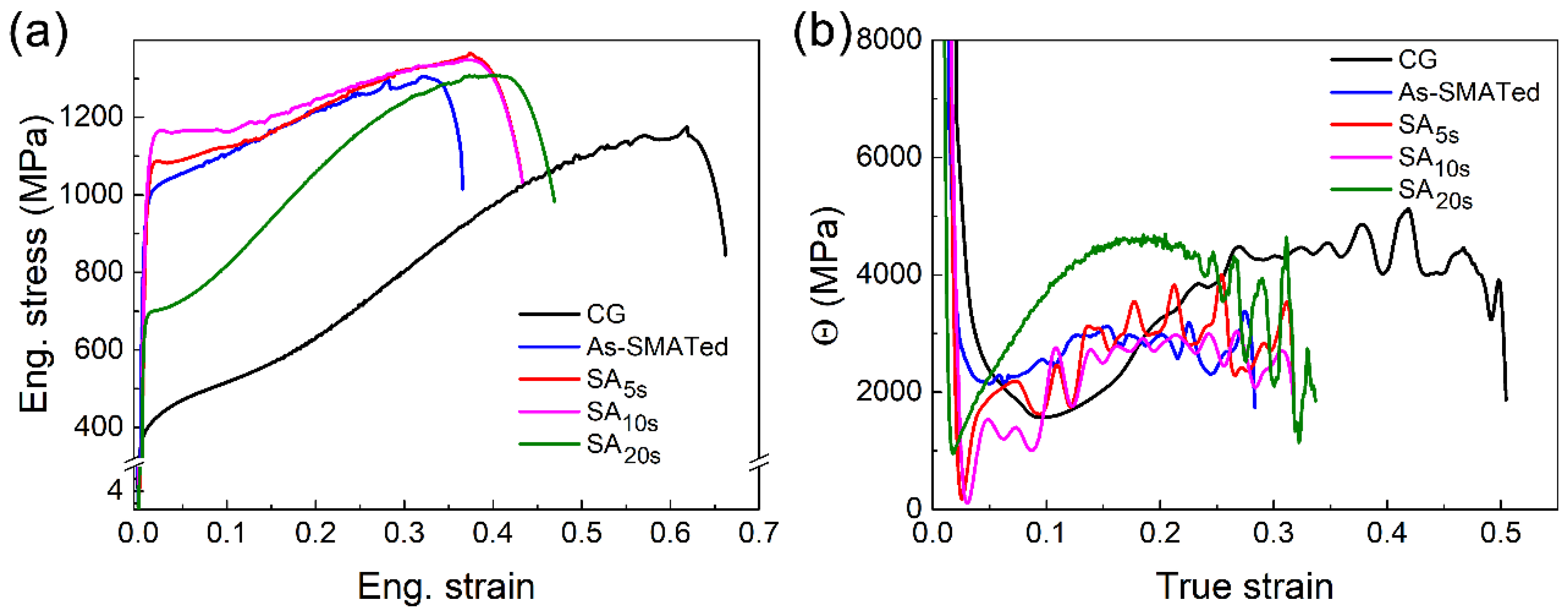

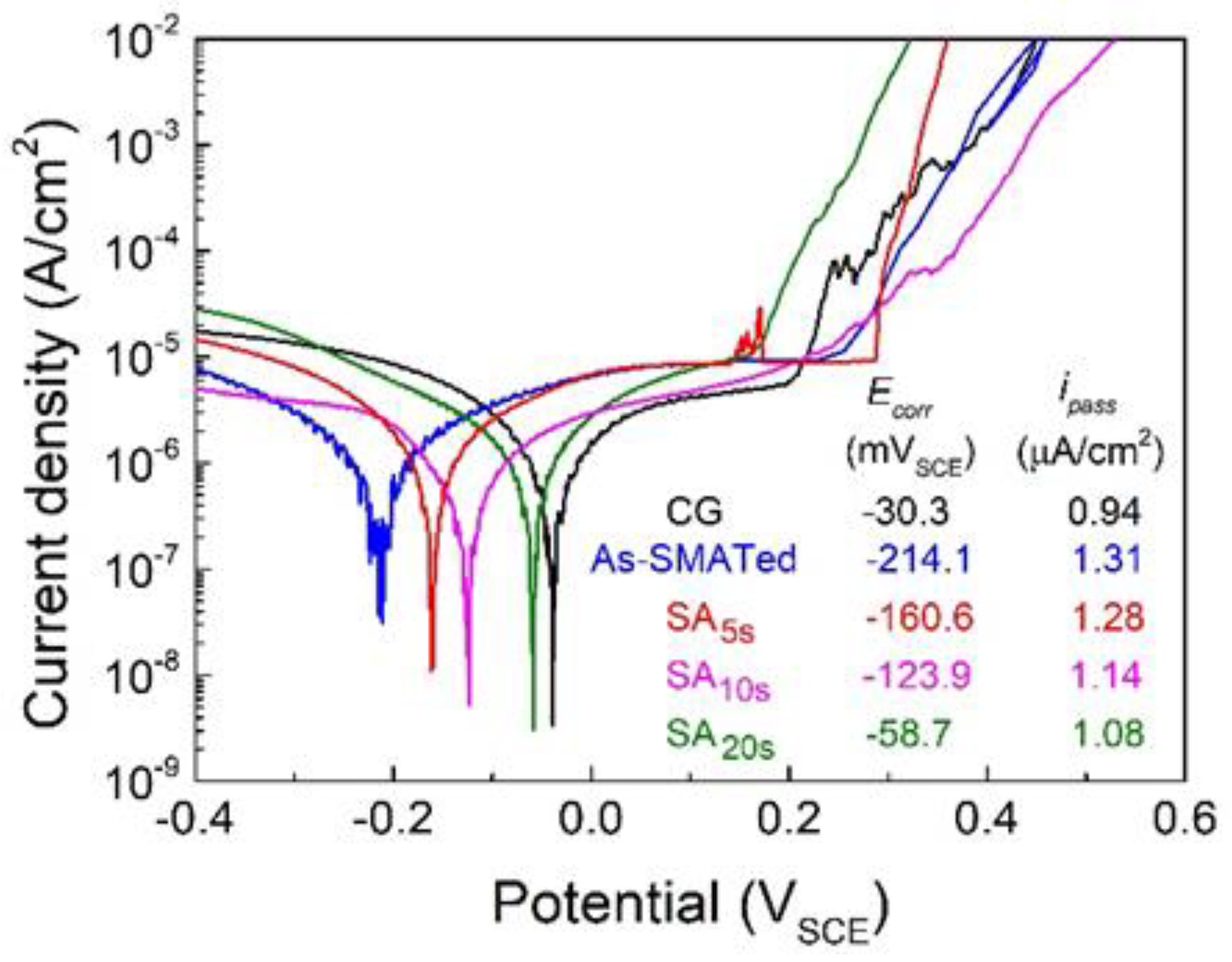

3.2. Improved Mechanical Responses and Corrosion Resistance

3.3. Physics behind the Mechanical Responses and Corrosion Resistance

4. Conclusions

- (i)

- The challenge can be overcome by designing gradient microstructure with partial austenitic nano-grains in the surface layer. Such gradient structure can be synthesized by a two-step route: conducting surface severe plastic deformation firstly to produce gradient structure, followed by high-temperature but short-time annealing to active partial reverse transformation in the surface layer.

- (ii)

- The as-processed gradient material is a 3D heterostructure with extra intra-layer heterogeneity in the surface layer, which produces extra back stress for high strength and extra HDI hardening for high ductility. The nano-sized microstructure with reduced dislocation density and martensite content in the surface layer is primarily responsible for the improved corrosion resistance.

- (iii)

- Two advanced samples in 301 stainless steel are provided. The SA10s sample has a high yield strength of ~1200 MPa, a uniform elongation of ~32% and moderate corrosion resistance, which is suitable for high-strength applications. The SA20s sample has superior corrosion resistance and a moderate yield strength of ~700 MPa, which can be served in highly corrosive circumstances.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gupta, R.K.; Birbilis, N. The Influence of Nanocrystalline Structure and Processing Route on Corrosion of Stainless Steel: A Review. Corros. Sci. 2015, 92, 1–15. [Google Scholar] [CrossRef]

- Lei, Y.B.; Wang, Z.B.; Zhang, B.; Luo, Z.P.; Lu, J.; Lu, K. Enhanced Mechanical Properties and Corrosion Resistance of 316L Stainless Steel by Pre-Forming a Gradient Nanostructured Surface Layer and Annealing. Acta Mater. 2021, 208, 116773. [Google Scholar] [CrossRef]

- Wu, X.L.; Yang, M.X.; Yuan, F.P.; Chen, L.; Zhu, Y.T. Combining Gradient Structure and TRIP Effect to Produce Austenite Stainless Steel with High Strength and Ductility. Acta Mater. 2016, 112, 337–346. [Google Scholar] [CrossRef] [Green Version]

- Morris, J.W., Jr. Making Steel Strong and Cheap. Nat. Mater. 2017, 16, 787–789. [Google Scholar] [CrossRef]

- Ovid’ko, I.A.; Valiev, R.Z.; Zhu, Y.T. Review on Superior Strength and Enhanced Ductility of Metallic Nanomaterials. Prog. Mater. Sci. 2018, 94, 462–540. [Google Scholar] [CrossRef]

- Wang, Y.M.; Chen, M.W.; Zhou, F.H.; Ma, E. High Tensile Ductility in a Nanostructured Metal. Nature 2002, 419, 912–915. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.F.; Huang, C.X.; He, Q.; Guo, F.J.; Wang, M.S.; Song, L.Y.; Zhu, Y.T. Heterostructure Induced Dispersive Shear Bands in Heterostructured Cu. Scr. Mater. 2019, 170, 76–80. [Google Scholar] [CrossRef]

- Vajpai, S.K.; Ota, M.; Zhang, Z.; Ameyama, K. Three-Dimensionally Gradient Harmonic Structure Design: An Integrated Approach for High Performance Structural Materials. Mater. Res. Lett. 2016, 4, 191–197. [Google Scholar] [CrossRef]

- Park, H.K.; Ameyama, K.; Yoo, J.; Hwang, H.; Kim, H.S. Additional Hardening in Harmonic Structured Materials by Strain Partitioning and Back Stress. Mater. Res. Lett. 2018, 6, 261–267. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Z.; Zhou, H.F.; Lu, Q.H.; Gao, H.J.; Lu, L. Extra Strengthening and Work Hardening in Gradient Nanotwinned Metals. Science 2018, 362, eaau1925. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.L.; Jiang, P.; Chen, L.; Yuan, F.P.; Zhu, Y.T. Extraordinary Strain Hardening by Gradient Structure. Proc. Natl. Acad. Sci. USA 2014, 111, 7197–7201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, X.L.; Jiang, P.; Chen, L.; Zhang, J.F.; Yuan, F.P.; Zhu, Y.T. Synergetic Strengthening by Gradient Structure. Mater. Res. Lett. 2014, 2, 185–191. [Google Scholar] [CrossRef]

- Wang, Y.F.; Huang, C.X.; Li, Y.S.; Guo, F.J.; He, Q.; Wang, M.S.; Wu, X.L.; Scattergood, R.O.; Zhu, Y.T. Dense Dispersed Shear Bands in Gradient-Structured Ni. Int. J. Plast. 2020, 124, 186–198. [Google Scholar] [CrossRef]

- Wang, Y.F.; Huang, C.X.; Wang, M.S.; Li, Y.S.; Zhu, Y.T. Quantifying the Synergetic Strengthening in Gradient Material. Scr. Mater. 2018, 150, 22–25. [Google Scholar] [CrossRef]

- Wu, X.L.; Yang, M.X.; Yuan, F.P.; Wu, G.L.; Wei, Y.J.; Huang, X.X.; Zhu, Y.T. Heterogeneous Lamella Structure Unites Ultrafine-Grain Strength with Coarse-Grain Ductility. Proc. Natl. Acad. Sci. USA 2015, 112, 14501–14505. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J.S.; Cao, Y.; Gao, B.; Li, Y.S.; Zhu, Y.T. Superior Strength and Ductility of 316L Stainless Steel with Heterogeneous Lamella Structure. J. Mater. Sci. 2018, 53, 10442–10456. [Google Scholar] [CrossRef]

- Huang, C.X.; Wang, Y.F.; Ma, X.L.; Yin, S.; Höppel, H.W.; Göken, M.; Wu, X.L.; Gao, H.J.; Zhu, Y.T. Interface Affected Zone for Optimal Strength and Ductility in Heterogeneous Laminate. Mater. Today 2018, 21, 713–719. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.F.; Yang, M.X.; Ma, X.L.; Wang, M.S.; Yin, K.; Huang, A.H.; Huang, C.X. Improved Back Stress and Synergetic Strain Hardening in Coarse-Grain/Nanostructure Laminates. Mater. Sci. Eng. A 2018, 727, 113–118. [Google Scholar] [CrossRef] [Green Version]

- Huang, M.; Xu, C.; Fan, G.H.; Maawad, E.; Gan, W.M.; Geng, L.; Lin, F.X.; Tang, G.Z.; Wu, H.; Du, Y.; et al. Role of Layered Structure in Ductility Improvement of Layered Ti-Al Metal Composite. Acta Mater. 2018, 153, 235–249. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.S.; Zhang, Q.; Zhao, Y.H.; Zhu, Y.T. Gradient Structured Copper by Rotationally Accelerated Shot Peening. J. Mater. Sci. Technol. 2017, 33, 758–761. [Google Scholar] [CrossRef]

- Lu, K.; Lu, J. Nanostructured Surface Layer on Metallic Materials Induced by Surface Mechanical Attrition Treatment. Mater. Sci. Eng. A 2004, 375–377, 38–45. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.L.; Zhu, Y.T. Heterogeneous Materials: A New Class of Materials with Unprecedented Mechanical Properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Wu, X.L. Perspective on Hetero-Deformation Induced (HDI) Hardening and Back Stress. Mater. Res. Lett. 2019, 7, 393–398. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.T.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.J.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Muhrabi, H.; Ritchie, R.O.; et al. Heterostructured Materials: Superior Properties from Hetero-Zone Interaction. Mater. Res. Lett. 2021, 9, 1–31. [Google Scholar] [CrossRef]

- Wang, Y.F.; Wang, M.S.; Fang, X.T.; Guo, F.J.; Liu, H.Q.; Scattergood, R.O.; Huang, C.X.; Zhu, Y.T. Extra Strengthening in a Coarse/Ultrafine Grained Laminate: Role of Gradient Interfaces. Int. J. Plast. 2019, 123, 196–207. [Google Scholar] [CrossRef]

- Wan, T.; Cheng, Z.; Bu, L.F.; Lu, L. Work Hardening Discrepancy Designing to Strengthening Gradient Nanotwinned Cu. Scr. Mater. 2021, 201, 113975. [Google Scholar] [CrossRef]

- He, Q.; Wang, Y.F.; Wang, M.S.; Guo, F.J.; Wen, Y.; Huang, C.X. Improving Strength-Ductility Synergy in 301 Stainless Steel by Combining Gradient Structure and TRIP Effect. Mater. Sci. Eng. A 2020, 780, 139146. [Google Scholar] [CrossRef]

- Qin, S.; Yang, M.X.; Yuan, F.P.; Wu, X.L. Simultaneous Improvement of Yield Strength and Ductility at Cryogenic Temperature by Gradient Structure in 304 Stainless Steel. Nanomaterials 2021, 11, 1856. [Google Scholar] [CrossRef]

- Lei, Y.B.; Xu, J.L.; Wang, Z.B. Controllable Martensite Transformation and Strain-Controlled Fatigue Behavior of a Gradient Nanostructured Austenite Stainless Steel. Nanomaterials 2021, 11, 1870. [Google Scholar] [CrossRef]

- Han, X.L.; Li, C.J.; Chen, C.H.; Zhang, X.D.; Zhang, H.W. Fabrication of Low Roughness Gradient Nanostructured Inner Surface on an AISI 304 Stainless Steel Pipe via Ultra-Sonic Rolling Treatment (USRT). Nanomaterials 2021, 11, 1769. [Google Scholar] [CrossRef] [PubMed]

- Chen, A.Y.; Wang, C.; Jiang, J.G.; Ruan, H.H.; Lu, J. Microstructure Evolution and Mechanical Properties of Austenite Stainless Steel with Gradient Twinned Structure by Surface Mechanical Attrition Treatment. Nanomaterials 2021, 11, 1624. [Google Scholar] [CrossRef]

- Chen, X.D.; Li, Y.S.; Zhu, Y.T.; Bai, Y.K.; Yang, B. Improved Corrosion Resistance of 316LN Stainless Steel Performed by Rotationally Accelerated Shot Peening. Appl. Surf. Sci. 2019, 481, 1305–1312. [Google Scholar] [CrossRef]

- Jinlong, L.; Hongyun, L. The Effects of Grain Refinement and Deformation on Corrosion Resistance of Passive Film Formed on the Surface of 304 Stainless Steels. Mater. Res. Bull. 2015, 70, 896–907. [Google Scholar] [CrossRef]

- Balusamy, T.; Sankara Narayanan, T.S.N.; Ravichandran, K.; Park, I.S.; Lee, M.H. Influence of Surface Mechanical Attrition Treatment (SMAT) on the Corrosion Behaviour of AISI 304 Stainless Steel. Corros. Sci. 2013, 74, 332–344. [Google Scholar] [CrossRef]

- Li, N.N.; Shi, S.Q.; Luo, J.L.; Lu, J.; Wang, N. Effects of Surface Nanocrystallization on the Corrosion Behaviors of 316L and Alloy 690. Surf. Coat. Technol. 2017, 309, 227–231. [Google Scholar] [CrossRef]

- Zhang, H.W.; Hei, Z.K.; Liu, G.; Lu, J.; Lu, K. Formation of Nanostructured Surface Layer on AISI 304 Stainless Steel by Means of Surface Mechanical Attrition Treatment. Acta Mater. 2003, 51, 1871–1881. [Google Scholar] [CrossRef]

- Liu, X.C.; Zhang, H.W.; Lu, K. Formation of Nano-Laminated Structure in Nickel by Means of Surface Mechanical Grinding Treatment. Acta Mater. 2015, 96, 24–36. [Google Scholar] [CrossRef]

- Zhu, L.L.; Ruan, H.H.; Chen, A.Y.; Guo, X.; Lu, J. Microstructures-Based Constitutive Analysis for Mechanical Properties of Gradient-Nanostructured 304 Stainless Steels. Acta Mater. 2017, 128, 375–390. [Google Scholar] [CrossRef]

- Wang, Y.F.; Guo, F.J.; He, Q.; Song, L.Y.; Wang, M.S.; Huang, A.H.; Li, Y.S.; Huang, C.X. Synergetic Deformation-Induced Extraordinary Softening and Hardening in Gradient Copper. Mater. Sci. Eng. A 2019, 752, 217–222. [Google Scholar] [CrossRef]

- Hasan, M.N.; Liu, Y.F.; An, X.H.; Gu, J.; Song, M.; Cao, Y.; Li, Y.S.; Zhu, Y.T.; Liao, X.Z. Simultaneously Enhancing Strength and Ductility of a High-Entropy Alloy via Gradient Hierarchical Microstructures. Int. J. Plast. 2019, 123, 178–195. [Google Scholar] [CrossRef]

- Wang, Y.F.; Huang, C.X.; Fang, X.T.; Höppel, H.W.; Göken, M.; Zhu, Y.T. Hetero-Deformation Induced (HDI) Hardening Does Not Increase Linearly with Strain Gradient. Scr. Mater. 2020, 174, 19–23. [Google Scholar] [CrossRef]

- Mordyuk, B.N.; Prokopenko, G.I.; Vasylyev, M.A.; Iefimov, M.O. Effect of Structure Evolution Induced by Ultrasonic Peening on the Corrosion Behavior of AISI-321 Stainless Steel. Mater. Sci. Eng. A 2007, 458, 253–261. [Google Scholar] [CrossRef]

- Elayaperumal, K.; De, P.K.; Balachandra, J. Passivity of Type 304 Stainless Steel–Effect of Plastic Deformation. Corrosion 1972, 28, 269–273. [Google Scholar] [CrossRef]

- Yin, S.B.; Li, D.Y.; Bouchard, R. Effects of the Strain Rate of Prior Deformation on the Wear–Corrosion Synergy of Carbon Steel. Wear 2007, 263, 801–807. [Google Scholar] [CrossRef]

- Trethewey, K.R.; Wenman, M.; Chard-Tuckey, P.; Roebuck, B. Correlation of Meso- and Micro-Scale Hardness Measurements with the Pitting of Plastically-Deformed Type 304L Stainless Steel. Corros. Sci. 2008, 50, 1132–1141. [Google Scholar] [CrossRef]

- Yang, M.X.; Pan, Y.; Yuan, F.P.; Zhu, Y.T.; Wu, X.L. Back Stress Strengthening and Strain Hardening in Gradient Structure. Mater. Res. Lett. 2016, 4, 145–151. [Google Scholar] [CrossRef]

- Zhou, H.; Huang, C.X.; Sha, X.C.; Xiao, L.R.; Ma, X.L.; Höppel, H.W.; Göken, M.; Wu, X.L.; Ameyama, K.; Han, X.D.; et al. In-Situ Observation of Dislocation Dynamics near Heterostructured Interfaces. Mater. Res. Lett. 2019, 7, 376–382. [Google Scholar] [CrossRef] [Green Version]

- Mughrabi, H. Dual Role of Deformation-Induced Geometrically Necessary Dislocations with Respect to Lattice Plane Misorientations and/or Long-Range Internal Stresses. Acta Mater. 2006, 54, 3417–3427. [Google Scholar] [CrossRef]

- Wang, Y.F.; Zhu, Y.T.; Wu, X.L.; Wei, Y.G.; Huang, C.X. Inter-Zone Constraint Modifies the Stress-Strain Response of the Constituent Layer in Gradient Structure. Sci. China Mater. 2021, 1–10. [Google Scholar] [CrossRef]

- Wang, Y.F.; Huang, C.X.; Li, Z.K.; Fang, X.T.; Wang, M.S.; He, Q.; Guo, F.J.; Zhu, Y.T. Shear Band Stability and Uniform Elongation of Gradient Structured Material: Role of Lateral Constraint. Extrem. Mech. Lett. 2020, 37, 100686. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Q.; Wei, W.; Wang, M.-S.; Guo, F.-J.; Zhai, Y.; Wang, Y.-F.; Huang, C.-X. Gradient Microstructure Design in Stainless Steel: A Strategy for Uniting Strength-Ductility Synergy and Corrosion Resistance. Nanomaterials 2021, 11, 2356. https://doi.org/10.3390/nano11092356

He Q, Wei W, Wang M-S, Guo F-J, Zhai Y, Wang Y-F, Huang C-X. Gradient Microstructure Design in Stainless Steel: A Strategy for Uniting Strength-Ductility Synergy and Corrosion Resistance. Nanomaterials. 2021; 11(9):2356. https://doi.org/10.3390/nano11092356

Chicago/Turabian StyleHe, Qiong, Wei Wei, Ming-Sai Wang, Feng-Jiao Guo, Yu Zhai, Yan-Fei Wang, and Chong-Xiang Huang. 2021. "Gradient Microstructure Design in Stainless Steel: A Strategy for Uniting Strength-Ductility Synergy and Corrosion Resistance" Nanomaterials 11, no. 9: 2356. https://doi.org/10.3390/nano11092356

APA StyleHe, Q., Wei, W., Wang, M.-S., Guo, F.-J., Zhai, Y., Wang, Y.-F., & Huang, C.-X. (2021). Gradient Microstructure Design in Stainless Steel: A Strategy for Uniting Strength-Ductility Synergy and Corrosion Resistance. Nanomaterials, 11(9), 2356. https://doi.org/10.3390/nano11092356