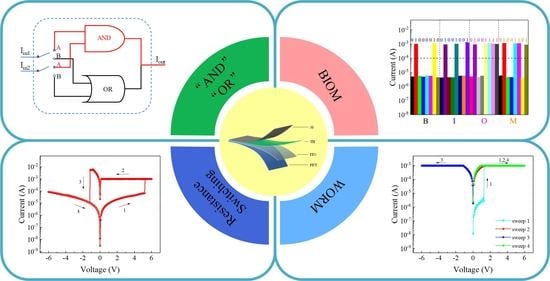

Flexible Nonvolatile Bioresistive Random Access Memory with an Adjustable Memory Mode Capable of Realizing Logic Functions

Abstract

:1. Introduction

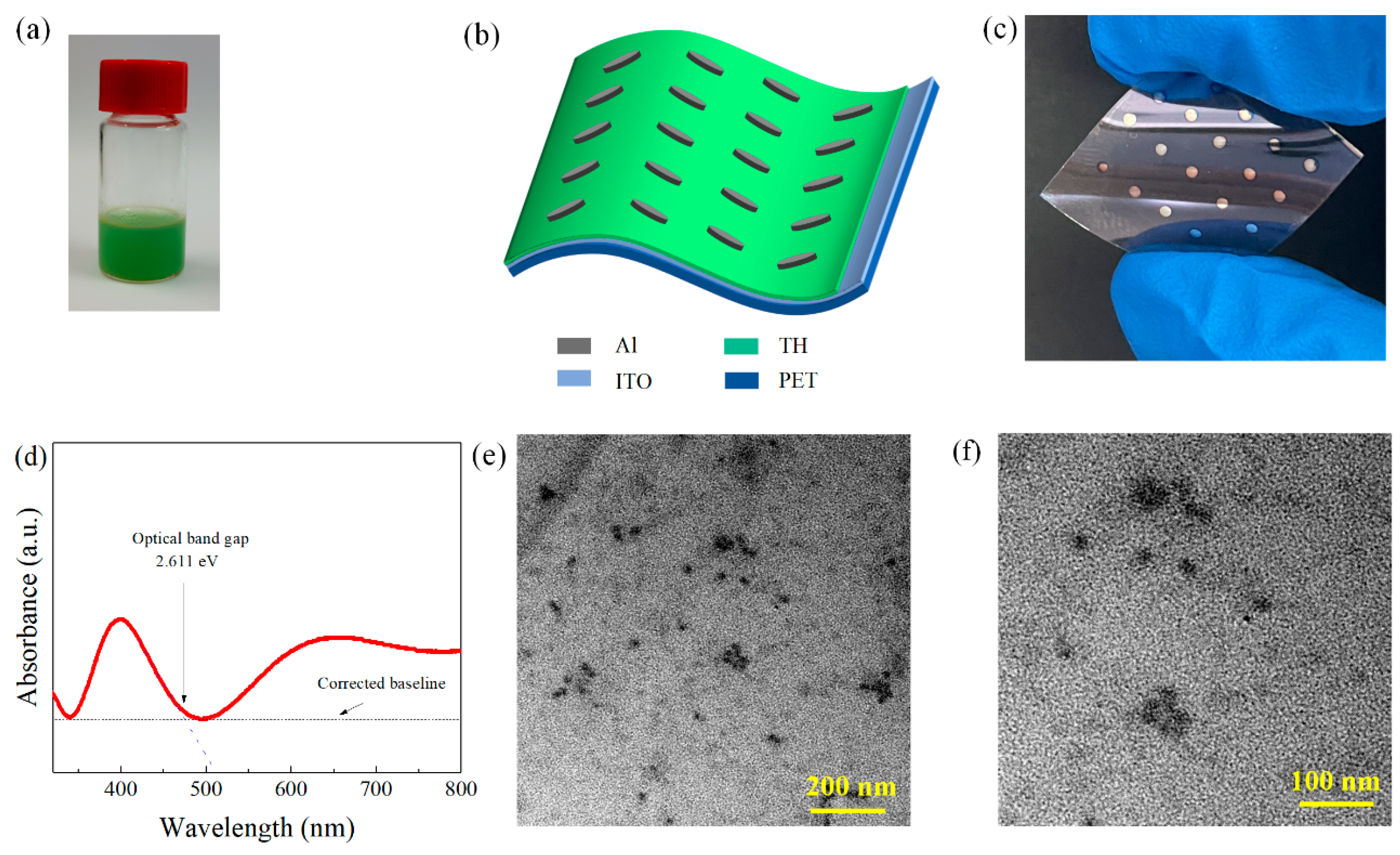

2. Materials and Methods

2.1. Device Fabrication

2.2. Characterization

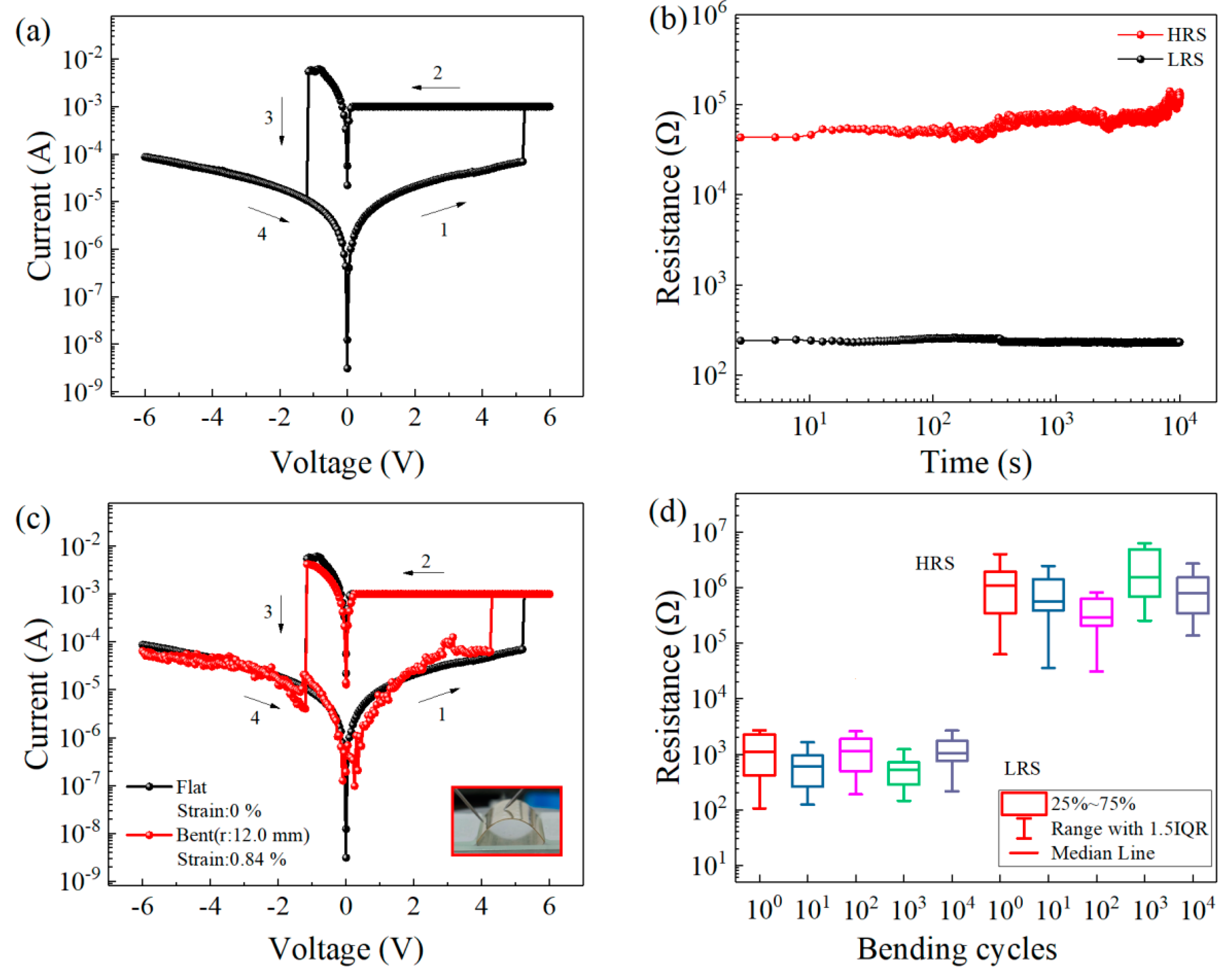

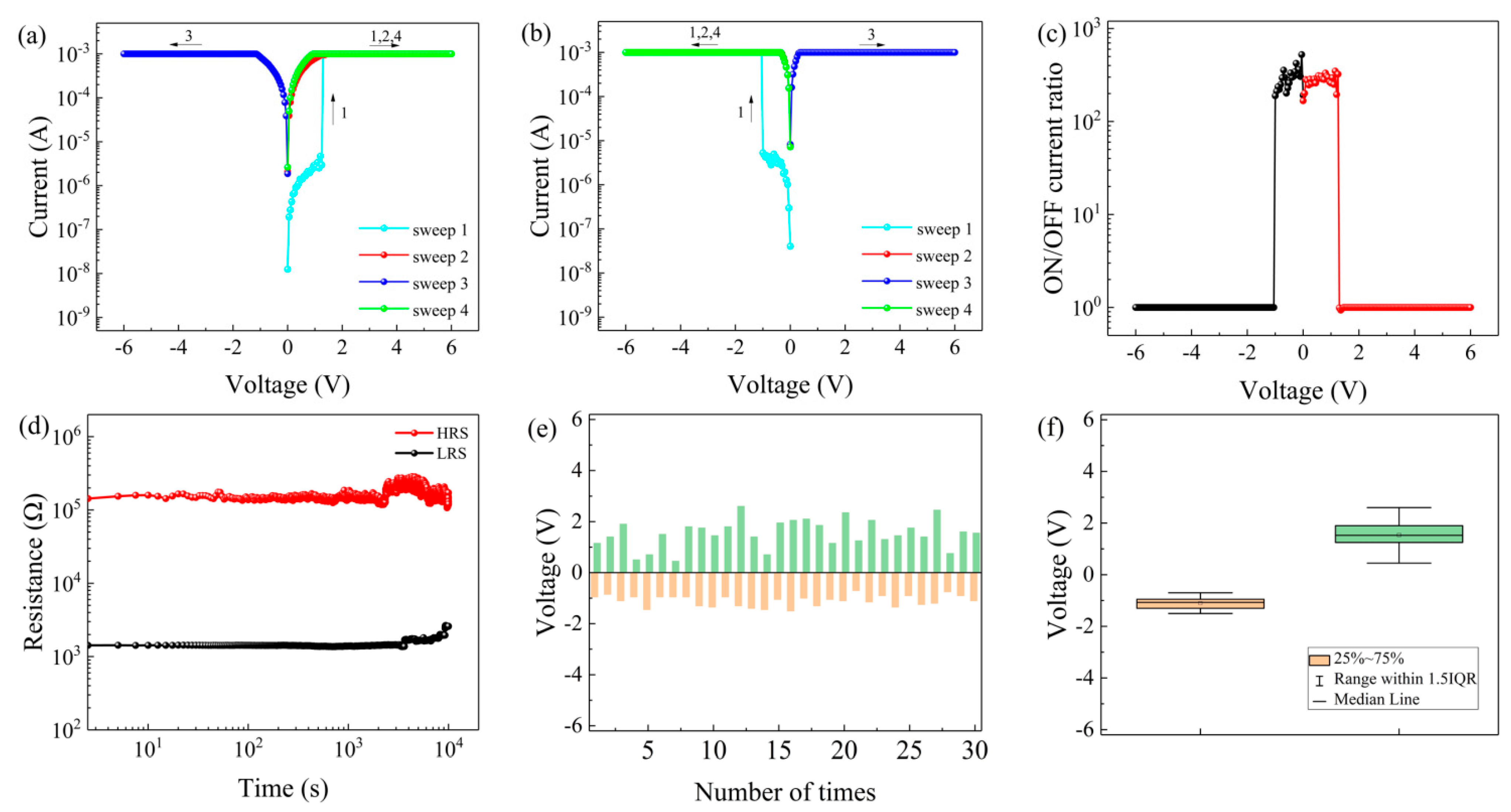

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zidan, M.A.; Strachan, J.P.; Lu, W.D. The future of electronics based on memristive systems. Nat. Electron. 2018, 1, 22–29. [Google Scholar] [CrossRef]

- Dong, X.F.; Zhao, Y.; Zheng, T.T.; Li, X.; Li, Y. Coexistence of Bipolar Resistive Switching and the Negative Differential Resistance Effect from a Kesterite Memristor. J. Phys. Chem. C 2020, 125, 923–930. [Google Scholar] [CrossRef]

- Gogoi, K.K.; Chowdhury, A. Performance Enhancement of Solution Processed Organic Memories by Exploiting Synergistic Organic-Inorganic Hybrid Composites. J. Phys. Chem. C 2019, 124, 1108–1120. [Google Scholar] [CrossRef]

- Lv, Z.; Zhou, Y.; Han, S.-T.; Roy, V. From biomaterial-based data storage to bio-inspired artificial synapse. Mater. Today 2018, 21, 537–552. [Google Scholar] [CrossRef]

- Zhang, L.; Gong, T.; Wang, H.; Guo, Z.; Zhang, H. Memristive devices based on emerging two-dimensional materials beyond graphene. Nanoscale 2019, 11, 12413–12435. [Google Scholar] [CrossRef] [PubMed]

- Hwang, B.; Lee, J.-S. Recent Advances in Memory Devices with Hybrid Materials. Adv. Electron. Mater. 2019, 5, 1800519. [Google Scholar] [CrossRef] [Green Version]

- Rehman, S.; Khan, M.F.; Rahmani, M.K.; Kim, H.; Patil, H.; Khan, S.A.; Kang, M.H.; Kim, D.K. Neuro-Transistor Based on UV-Treated Charge Trapping in MoTe2 for Artificial Synaptic Features. Nanomaterials 2020, 10, 2326. [Google Scholar] [CrossRef] [PubMed]

- Mahata, C.; Kang, M.; Kim, S. Multi-Level Analog Resistive Switching Characteristics in Tri-Layer HfO2/Al2O3/HfO2 Based Memristor on ITO Electrode. Nanomaterials 2020, 10, 2069. [Google Scholar] [CrossRef]

- Huang, Y.; Shen, Z.; Wu, Y.; Wang, X.; Zhang, S.; Shi, X.; Zeng, H. Amorphous ZnO based resistive random access memory. RSC Adv. 2016, 6, 17867–17872. [Google Scholar] [CrossRef]

- Li, L.; Chang, K.-C.; Lin, X.; Lai, Y.-C.; Zhang, R.; Kuo, T.-P. Variable-temperature activation energy extraction to clarify the physical and chemical mechanisms of the resistive switching process. Nanoscale 2020, 12, 15721–15724. [Google Scholar] [CrossRef]

- Cho, H.; Kim, S. Short-Term Memory Dynamics of TiN/Ti/TiO2/SiOx/Si Resistive Random Access Memory. Nanomaterials 2020, 10, 1821. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.; Zhang, B.; Cao, Y.; Chen, Y. Solution-processable poly (N-vinylcarbazole)-covalently grafted MoS2 nanosheets for nonvolatile rewritable memory devices. Nanoscale 2017, 9, 2449–2456. [Google Scholar] [CrossRef]

- Liu, J.; Zeng, F.; Yin, J.; Sun, Y.; Wan, Q.; Yin, S.; Wang, Y.; Pan, F. Implementing a Type of Synaptic Coupling between Excitatory and Inhibitory Cells by Using Pt/Poly(3,4-ethylenedioxythiophene): Polystyrenesulfonate/HfOx/Pt Memristive Structure. J. Phys. Chem. C 2020, 124, 4843–4851. [Google Scholar] [CrossRef]

- Cheng, X.-F.; Hou, X.; Qian, W.-H.; He, J.-H.; Xu, Q.-F.; Li, H.; Li, N.-J.; Chen, D.-Y.; Lu, J.-M. Poly(3,4-ethylenedioxythiophene)–Poly(styrenesulfonate) Interlayer Insertion Enables Organic Quaternary Memory. ACS Appl. Mater. Interfaces 2017, 9, 27847–27852. [Google Scholar] [CrossRef] [PubMed]

- Mamo, M.A.; Sustaita, A.O.; Coville, N.J.; Hümmelgen, I.A. Polymer composite of poly (vinyl phenol)-reduced graphene oxide reduced by vitamin C in low energy consuming write-once–read-many times memory devices. Org. Electron. 2013, 14, 175–181. [Google Scholar] [CrossRef]

- Das, U.; Das, D.; Paul, B.; Rabha, T.; Pattanayak, S.; Kanjilal, A.; Bhattacharjee, S.; Sarkar, P.; Roy, A. Induced Vacancy-Assisted Filamentary Resistive Switching Device Based on RbPbI3–x Cl x Perovskite for RRAM Application. ACS Appl. Mater. Interfaces 2020, 12, 41718–41727. [Google Scholar] [CrossRef]

- Wan, T.; Qu, B.; Du, H.; Lin, X.; Lin, Q.; Wang, D.-W.; Cazorla, C.; Li, S.; Liu, S.; Chu, D. Digital to analog resistive switching transition induced by graphene buffer layer in strontium titanate based devices. J. Colloid Interface Sci. 2018, 512, 767–774. [Google Scholar] [CrossRef]

- Ku, B.; Koo, B.; Sokolov, A.S.; Min, J.K.; Choi, C. Two-terminal artificial synapse with hybrid organic–inorganic perovskite (CH3NH3)PbI3 and low operating power energy (47 fJ/μm2). J. Alloys Compd. 2020, 833, 155064. [Google Scholar] [CrossRef]

- Yang, J.M.; Kim, S.G.; Seo, J.Y.; Cuhadar, C.; Son, D.Y.; Lee, D.; Park, N.G. 1D hexagonal HC (NH2)2PbI3 for multilevel resistive switching nonvolatile memory. Adv. Electron. Mater. 2018, 4, 1800190. [Google Scholar] [CrossRef]

- Garg, A.; Onuchic, J.N.; Ambegaokar, V. Effect of friction on electron transfer in biomolecules. J. Chem. Phys. 1985, 83, 4491–4503. [Google Scholar] [CrossRef]

- Lee, T.; Chen, Y. Organic resistive nonvolatile memory materials. MRS Bull. 2012, 37, 144–149. [Google Scholar] [CrossRef]

- Kim, H.-D.; Yun, M.J.; Lee, J.H.; Kim, K.H.; Kim, T.G. Transparent multi-level resistive switching phenomena observed in ITO/RGO/ITO memory cells by the sol-gel dip-coating method. Sci. Rep. 2014, 4, 1–6. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, H.-L.; Kim, M.-H.; Lee, S.-H. Control of conductive filament growth in flexible organic memristor by polymer alignment. Org. Electron. 2020, 87, 105927. [Google Scholar] [CrossRef]

- Sokolov, A.S.; Jeon, Y.-R.; Ku, B.; Choi, C. Ar ion plasma surface modification on the heterostructured TaOx/InGaZnO thin films for flexible memristor synapse. J. Alloys Compd. 2020, 822, 153625. [Google Scholar] [CrossRef]

- Chortos, A.; Liu, J.; Bao, Z. Pursuing prosthetic electronic skin. Nat. Mater. 2016, 15, 937–950. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.Y.; Lee, H.R.; Park, C.H.; Han, S.G.; Oh, J.H. Organic transistor-based chemical sensors for wearable bioelectronics. Acc. Chem. Res. 2018, 51, 2829–2838. [Google Scholar] [CrossRef]

- Torres-Costa, V.; Mäkilä, E.; Granroth, S.; Kukk, E.; Salonen, J. Synaptic and fast switching memristance in porous silicon-based structures. Nanomaterials 2019, 9, 825. [Google Scholar] [CrossRef] [Green Version]

- Jeong, D.S.; Kim, I.; Ziegler, M.; Kohlstedt, H. Towards artificial neurons and synapses: A materials point of view. RSC Adv. 2013, 3, 3169–3183. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, M.; Iqbal, S.; Kang, H.; Park, J.-Y.; Seo, H. Highly transparent solid-state artificial synapse based on oxide memristor. Appl. Surf. Sci. 2021, 536, 147738. [Google Scholar] [CrossRef]

- Zhu, S.; Zhou, G.; Yuan, W.; Mao, S.; Yang, F.; Fu, G.; Sun, B. Non-zero-crossing current-voltage hysteresis behavior induced by capacitive effects in bio-memristor. J. Colloid Interface Sci. 2020, 560, 565–571. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.; Wen, D. Devices with Tuneable Resistance Switching Characteristics Based on a Multilayer Structure of Graphene Oxide and Egg Albumen. Nanomaterials 2020, 10, 1491. [Google Scholar] [CrossRef]

- Murgunde, B.K.; Rabinal, M.K. Solution processed bilayer junction of silk fibroin and semiconductor quantum dots as multilevel memristor devices. Org. Electron. 2017, 48, 276–284. [Google Scholar] [CrossRef]

- Kook, G.; Jeong, S.; Kim, S.H.; Kim, M.K.; Lee, S.; Cho, I.-J.; Choi, N.; Lee, H.J. Wafer-scale multilayer fabrication for silk fibroin-based microelectronics. ACS Appl. Mater. Interfaces 2018, 11, 115–124. [Google Scholar] [CrossRef]

- Abbas, Y.; Dugasani, S.R.; Raza, M.T.; Jeon, Y.-R.; Park, S.H.; Choi, C. The observation of resistive switching characteristics using transparent and biocompatible Cu2+-doped salmon DNA composite thin film. Nanotechnology 2019, 30, 335203. [Google Scholar] [CrossRef]

- Qin, S.; Dong, R.; Yan, X.; Du, Q. A reproducible write–(read)n–erase and multilevel bio-memristor based on DNA molecule—ScienceDirect. Org. Electron. 2015, 22, 147–153. [Google Scholar] [CrossRef]

- Yuan, W.; Yan, X.; Dong, R. Organic memristive devices based on silver nanoparticles and DNA. Org. Electron. 2014, 15, 3476–3481. [Google Scholar] [CrossRef]

- Lee, T.; Yagati, A.K.; Pi, F.; Sharma, A.; Choi, J.W.; Guo, P. Construction of RNA–Quantum Dot Chimera for Nanoscale Resistive Biomemory Application. ACS Nano 2015, 9, 6675–6682. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hosseini, N.R.; Lee, J.S. Resistive Switching Memory Based on Bioinspired Natural Solid Polymer Electrolytes. ACS Nano 2015, 9, 419–426. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.C.; Yu, H.C.; Huang, C.Y.; Chung, W.L.; Wu, S.L.; Su, Y.K. Nonvolatile Bio-Memristor Fabricated with Egg Albumen Film. Sci. Rep. 2015, 5, 10022. [Google Scholar] [CrossRef] [Green Version]

- Yong, J.; Hassan, B.; Liang, Y.; Ganesan, K.; Rajasekharan, R.; Evans, R.; Egan, G.; Kavehei, O.; Li, J.; Chana, G. A Silk Fibroin Bio-Transient Solution Processable Memristor. Sci. Rep. 2017, 7, 14731. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Sun, B.; Fu, G.; Li, T.; Zhu, S.; Zheng, L.; Mao, S.; Kan, X.; Lei, M.; Chen, Y. A nonvolatile organic resistive switching memory based on lotus leaves. Chem. Phys. 2019, 516, 168–174. [Google Scholar] [CrossRef]

- Raeis-Hosseini, N.; Lee, J.-S. Controlling the resistive switching behavior in starch-based flexible biomemristors. ACS Appl. Mater. Interfaces 2016, 8, 7326–7332. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, X.; Wang, Z.; Xu, H.; Hu, J.; Ma, J.; Liu, Y. Biodegradable natural pectin-based flexible multilevel resistive switching memory for transient electronics. Small 2019, 15, 1803970. [Google Scholar] [CrossRef]

- Gogurla, N.; Mondal, S.P.; Sinha, A.K.; Katiyar, A.K.; Ray, S.K. Transparent and flexible resistive switching memory devices with a very high ON/OFF ratio using gold nanoparticles embedded in a silk protein matrix. Nanotechnology 2013, 24, 345202. [Google Scholar] [CrossRef]

- Hou, Y.; Zhang, Y.; Gong, J.; Tian, S.; Li, J.; Dong, Z.; Guo, C.; Peng, L.; Zhao, P.; Xia, Q. Comparative proteomics analysis of silkworm hemolymph during the stages of metamorphosis via liquid chromatography and mass spectrometry. Proteomics 2016, 16, 1421–1431. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y.; Yang, Y.; Lee, S.K.; Ruan, G.; Kim, T.W.; Fei, H.; Lee, S.H.; Kim, D.Y.; Yoon, J.; Tour, J.M. Flexible Nanoporous WO3-x Nonvolatile Memory Device. ACS Nano 2016, 10, 7598–7603. [Google Scholar] [CrossRef] [PubMed]

- C, Y.-Y.; W, Y.-C. Effects of fluoride on changes of calcium, copper and iron level in the important organs of silkworm larvae (Bombyx mori L.). Sericologia 1998, 38, 69–83. [Google Scholar]

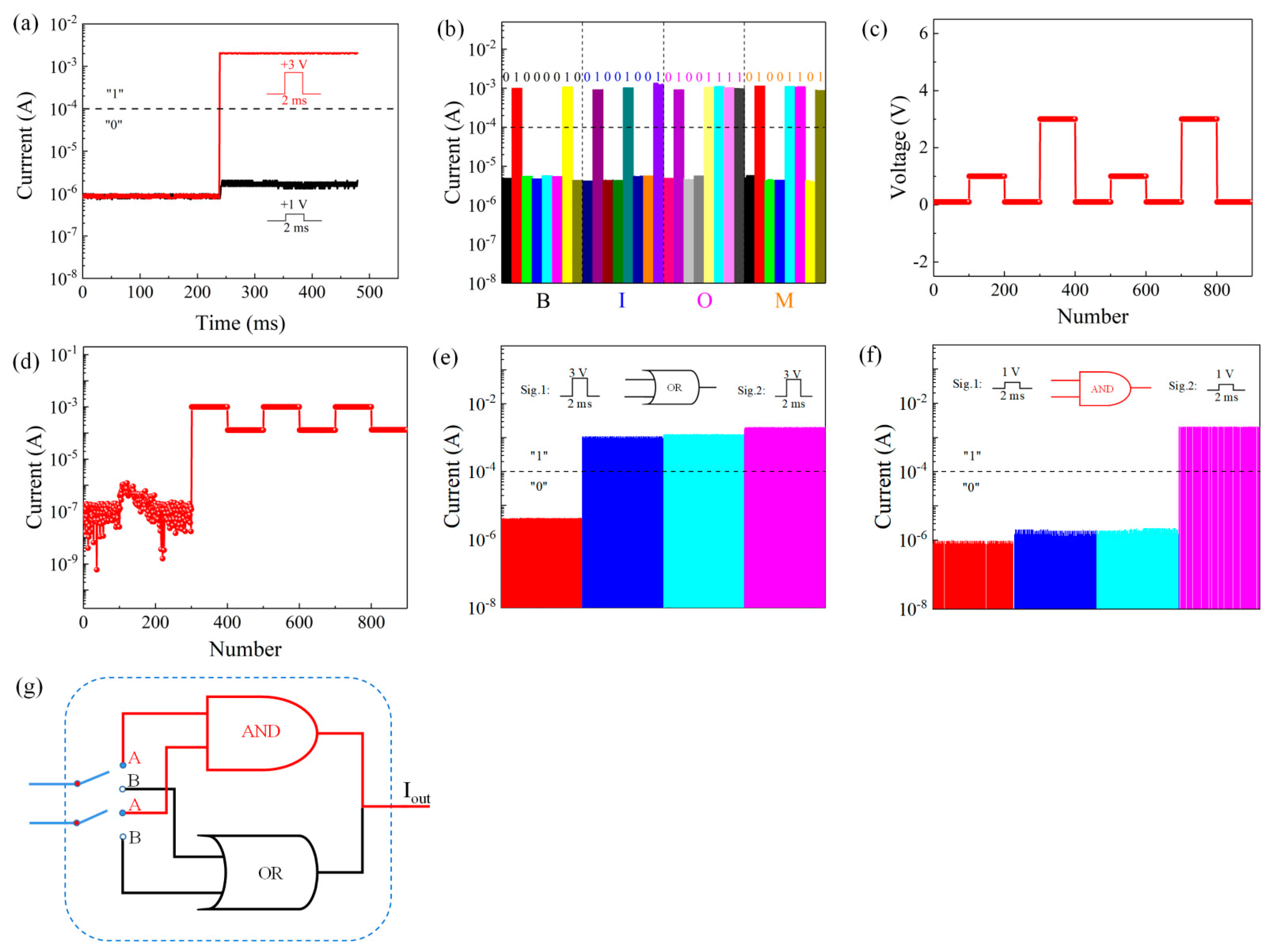

| Sig.1 | Sig.2 | Out |

|---|---|---|

| 0 | 0 | 0 |

| 0 | 1 | 1 |

| 1 | 0 | 1 |

| 1 | 1 | 1 |

| Sig.1 | Sig.2 | Out |

|---|---|---|

| 0 | 0 | 0 |

| 0 | 1 | 0 |

| 1 | 0 | 0 |

| 1 | 1 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Zhang, Y.; Wen, D. Flexible Nonvolatile Bioresistive Random Access Memory with an Adjustable Memory Mode Capable of Realizing Logic Functions. Nanomaterials 2021, 11, 1973. https://doi.org/10.3390/nano11081973

Wang L, Zhang Y, Wen D. Flexible Nonvolatile Bioresistive Random Access Memory with an Adjustable Memory Mode Capable of Realizing Logic Functions. Nanomaterials. 2021; 11(8):1973. https://doi.org/10.3390/nano11081973

Chicago/Turabian StyleWang, Lu, Yukai Zhang, and Dianzhong Wen. 2021. "Flexible Nonvolatile Bioresistive Random Access Memory with an Adjustable Memory Mode Capable of Realizing Logic Functions" Nanomaterials 11, no. 8: 1973. https://doi.org/10.3390/nano11081973

APA StyleWang, L., Zhang, Y., & Wen, D. (2021). Flexible Nonvolatile Bioresistive Random Access Memory with an Adjustable Memory Mode Capable of Realizing Logic Functions. Nanomaterials, 11(8), 1973. https://doi.org/10.3390/nano11081973