MoS2 with Stable Photoluminescence Enhancement under Stretching via Plasmonic Surface Lattice Resonance

Abstract

:1. Introduction

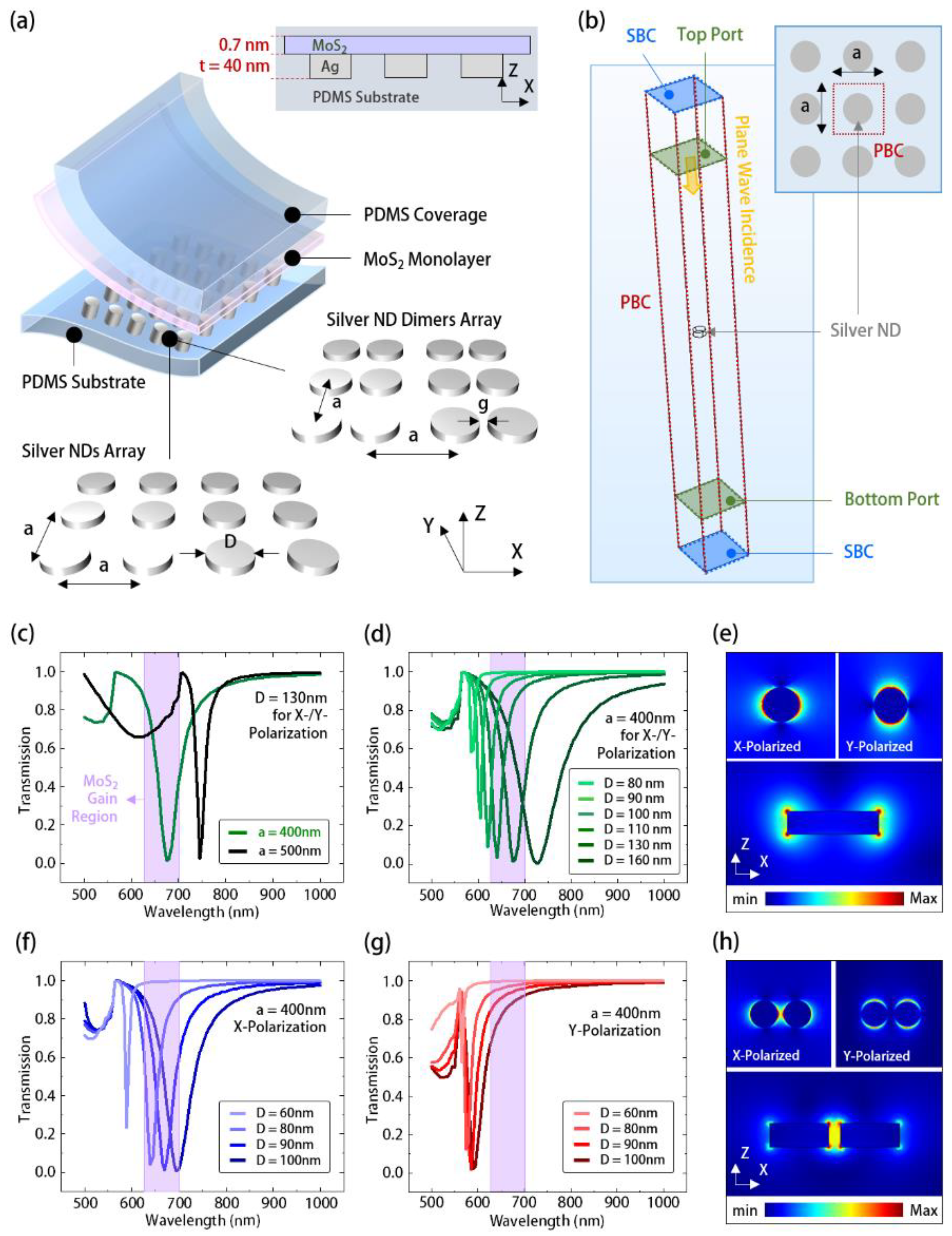

2. Design and Simulation

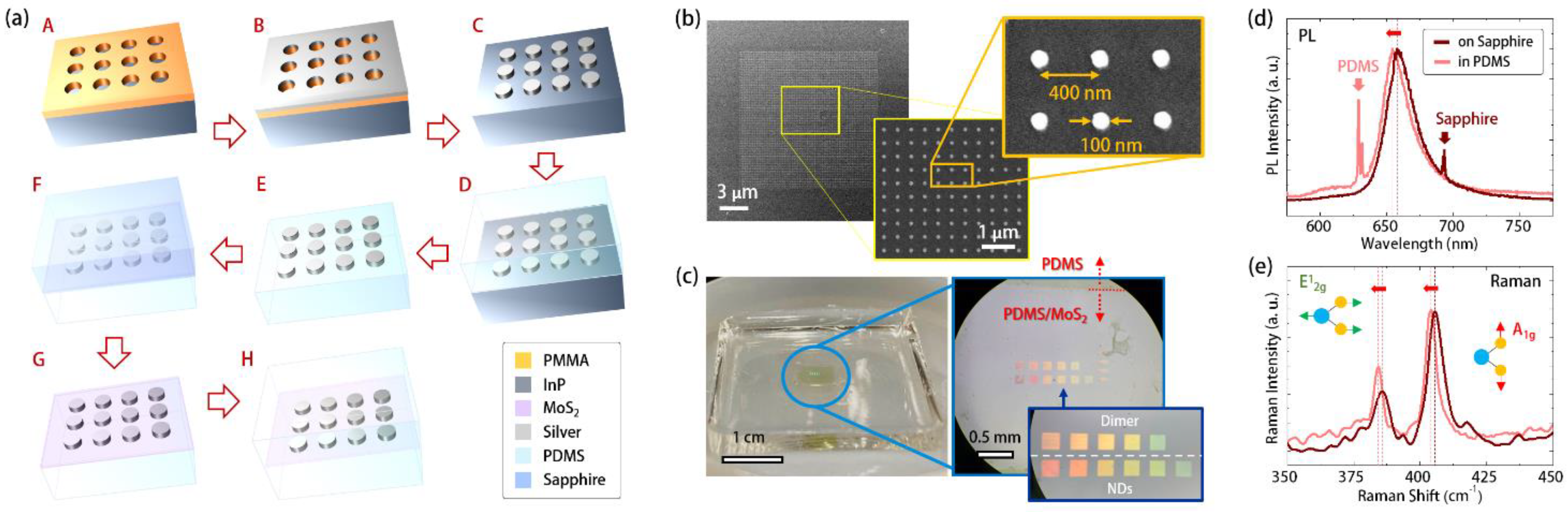

3. Manufacturing Process

4. Results and Discussions

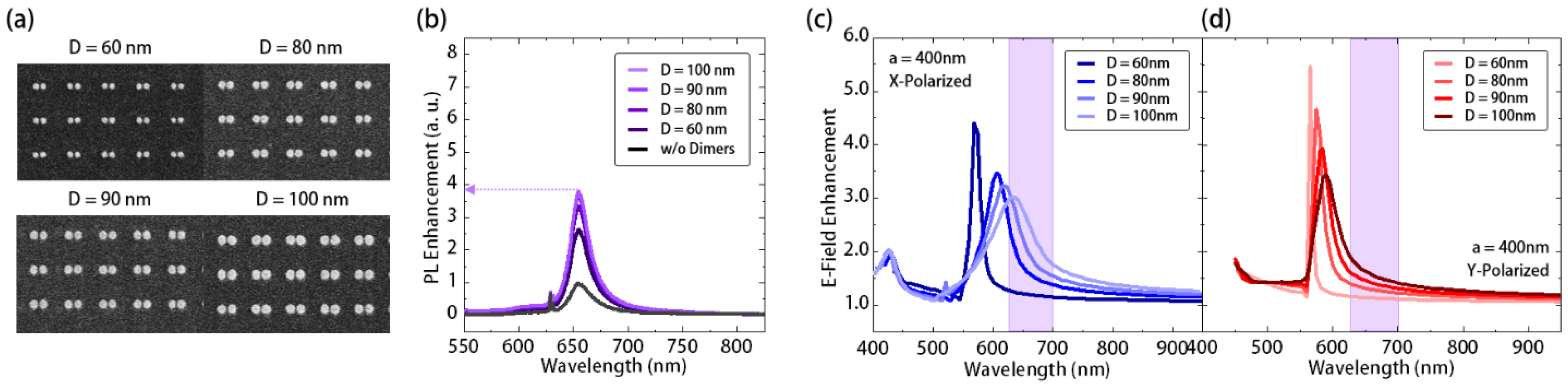

4.1. PL Enhancement of MoS2 via Silver ND and ND-Dimer Arrays in PDMS

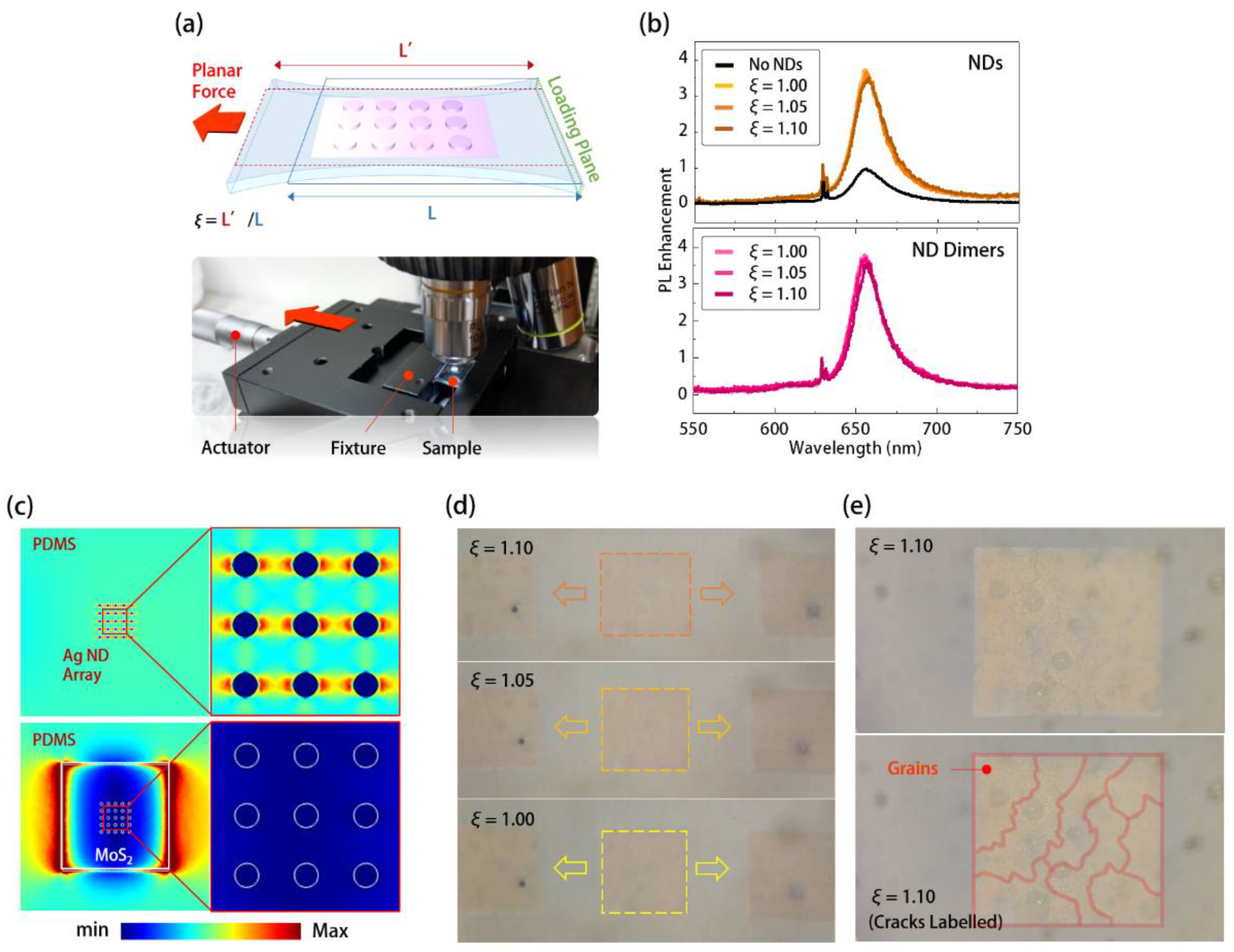

4.2. PL Enhancement of MoS2 with ND and ND-Dimer Arrays under Stretching

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Novoselov, A.K.S.; Fal’ko, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for grapheme. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef]

- Frank, I.W.; Tanenbaum, D.M.; Zande, A.M.; McEuen, P.L. Mechanical properties of suspended graphene sheets. J. Vac. Sci. Technol. B 2007, 25, 2558–2561. [Google Scholar] [CrossRef] [Green Version]

- Neto, A.H.C.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The electronic properties of grapheme. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef] [Green Version]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef]

- Duong, D.L.; Yun, S.J.; Lee, Y.H. van der Waals Layered Materials: Opportunities and Challenges. ACS Nano 2017, 11, 11803–11830. [Google Scholar] [CrossRef]

- Chuang, H.J.; Chamlagain, B.; Koehler, M.; Perera, M.M.; Yan, J.; Mandrus, D.; Tománek, D.; Zhou, Z. Low-Resistance 2D/2D Ohmic Contacts: A Universal Approach to High-Performance WSe2, MoS2, and MoSe2 Transistors. Nano Lett. 2016, 16, 1896–1902. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Desai, S.B.; Madhvapathy, S.R.; Sachid, A.B.; Llinas, J.P.; Wang, Q.; Ahn, G.H.; Pitner, G.; Kim, M.J.; Bokor, J.; Hu, C.; et al. MoS2 transistors with 1-nanometer gate lengths. Science 2016, 354, 99–102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zheng, W.; Jiang, Y.; Hu, X.; Li, H.; Zeng, Z.; Wang, X.; Pan, A. Light Emission Properties of 2D Transition Metal Dichalcogenides: Fundamentals and Applications. Adv. Opt. Mater. 2018, 6, 1800420. [Google Scholar] [CrossRef]

- Lien, D.H.; Amani, M.; Desai, S.B.; Ahn, G.H.; Han, K.; He, J.H.; Ager, J.W., III; Wu, M.C.; Javey, A. Large-area and bright pulsed electroluminescence in monolayer semiconductors. Nat. Commun. 2018, 9, 1229. [Google Scholar] [CrossRef]

- Lohof, F.; Steinhoff, A.; Florian, M.; Lorke, M.; Erben, D.; Jahnke, F.; Gies, C. Prospects and Limitations of Transition Metal Dichalcogenide Laser Gain Materials. Nano Lett. 2019, 19, 210–217. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, C.; Wu, S.; Sanchez, A.M.; Peters, J.J.P.; Beanland, R.; Ross, J.S.; Rivera, P.; Yao, W.; Cobden, D.H.; Xu, X. Lateral heterojunctions within monolayer MoSe2–WSe2 semiconductors. Nat. Mater. 2014, 13, 1096–1101. [Google Scholar] [CrossRef]

- Nan, H.; Wang, Z.; Wang, W.; Liang, Z.; Lu, Y.; Chen, Q.; He, D.; Tan, P.; Miao, F.; Wang, X.; et al. Strong Photoluminescence Enhancement of MoS2 through Defect Engineering and Oxygen Bonding. ACS Nano 2014, 8, 5738–5745. [Google Scholar] [CrossRef] [Green Version]

- Noori, Y.J.; Cao, Y.; Roberts, J.; Woodhead, C.; Bernardo-Gavito, R.; Tovee, P.; Young, R.J. Photonic Crystals for Enhanced Light Extraction from 2D Materials. ACS Photonics 2016, 3, 2515–2520. [Google Scholar] [CrossRef] [Green Version]

- Galfsky, T.; Sun, Z.; Considine, C.R.; Chou, C.T.; Ko, W.C.; Lee, Y.H.; Narimanov, E.E.; Menon, V.M. Broadband Enhancement of Spontaneous Emission in Two-Dimensional Semiconductors Using Photonic Hypercrystals. Nano Lett. 2016, 16, 4940–4945. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Choi, S.; Wang, D.; Naylor, C.H.; Johnson, A.T.C.; Cubukcu, E. Unidirectional Doubly Enhanced MoS2 Emission via Photonic Fano Resonances. Nano Lett. 2017, 17, 6715–6720. [Google Scholar] [CrossRef]

- Wu, S.; Buckley, S.; Schaibley, J.R.; Feng, L.; Yan, J.; Mandrus, D.G.; Hatami, F.; Yao, W.; Vučković, J.; Majumdar, A.; et al. Monolayer semiconductor nanocavity lasers with ultralow thresholds. Nature 2015, 520, 69–72. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Zhang, J.; Huang, D.; Sun, H.; Fan, F.; Feng, J.; Wang, Z.; Ning, C.Z. Room-temperature continuous-wave lasing from monolayer molybdenum ditelluride integrated with a silicon nanobeam cavity. Nat. Nanotechnol. 2017, 12, 987–992. [Google Scholar] [CrossRef] [Green Version]

- Ge, X.; Minkov, M.; Fan, S.; Li, X.; Zhou, W. Laterally confined photonic crystal surface emitting laser incorporating monolayer tungsten disulfide. NPJ 2D Mater. Appl. 2019, 3, 16. [Google Scholar] [CrossRef] [Green Version]

- Butun, S.; Tongay, S.; Aydin, K. Enhanced Light Emission from Large-Area Monolayer MoS2 Using Plasmonic Nanodisc Arrays. Nano Lett. 2015, 15, 2700–2704. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.; Park, J.; Han, G.H.; Ee, H.S.; Naylor, C.H.; Liu, W.; Johnson, A.T.C.; Agarwal, R. Enhancement in Monolayer MoS2 Integrated with Plasmonic Nanoantenna Array. Nano Lett. 2015, 15, 3646–3653. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Ji, Q.; Chu, S.; Zhang, Y.; Li, Y.; Gong, Q.; Liu, K.; Shi, K. Tuning the photo-response in monolayer MoS2 by plasmonic nano-antenna. Sci. Rep. 2016, 6, 23626. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Dong, Z.; Gu, Y.; Chang, Y.H.; Zhang, L.; Li, L.J.; Zhao, W.; Eda, G.; Zhang, W.; Grinblat, G.; et al. Giant photoluminescence enhancement in tungsten-diselenide–gold plasmonic hybrid structures. Nat. Commun. 2016, 7, 11283. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.H.; Lee, H.S.; An, G.H.; Lee, J.; Oh, H.M.; Choi, J.; Lee, Y.H. Dielectric Nanowire Hybrids for Plasmon-Enhanced Light–Matter Interaction in 2D Semiconductors. ACS Nano 2020, 14, 11985–11994. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Dong, Z.; Zhu, H.; Jin, L.; Chiu, M.H.; Li, L.J.; Xu, Q.H.; Eda, G.; Maier, S.A.; Wee, A.T.S.; et al. Selectively Plasmon-Enhanced Second-Harmonic Generation from Monolayer Tungsten Diselenide on Flexible Substrates. ACS Nano 2018, 12, 1859–1867. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maier, S.A. Plasmonics: Fundamentals and Applications; Springer: New York, NY, USA, 2007. [Google Scholar]

- Willets, K.A.; Van Duyne, R.P. Localized Surface Plasmon Resonance Spectroscopy and Sensing. Annu. Rev. Phys. Chem. 2007, 58, 267–297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kravets, V.G.; Kabashin, A.V.; Barnes, W.L.; Grigorenko, A.N. Plasmonic Surface Lattice Resonances: A Review of Properties and Applications. Chem. Rev. 2018, 118, 5912–5951. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Zhu, X.; Dong, J.; Ding, Y.; Xiao, S. 2D materials integrated with metallic nanostructures: Fundamentals and optoelectronic applications. Nanophotonics 2020, 9, 1877–1900. [Google Scholar] [CrossRef]

- Rakić, A.D.; Djurišić, A.B.; Elazar, J.M.; Majewski, M.L. Optical properties of metallic films for vertical-cavity optoelectronic devices. Appl. Opt. 1998, 37, 5271–5283. [Google Scholar] [CrossRef]

- Babar, S.; Weaver, J.H. Optical constants of Cu, Ag, and Au revisited. Appl. Opt. 2015, 54, 477–481. [Google Scholar] [CrossRef]

- Chang, K.H.; Cheng, J.S.; Lu, T.W.; Lee, P.T. Engineering surface lattice resonance of elliptical gold nanodisk array for enhanced strain sensing. Opt. Express 2018, 26, 33215–33225. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.R.; Chang, X.R.; Wu, C.H.; Lin, S.Y. The Growth Mechanism of Transition Metal Dichalcogenides by Using Sulfurization of Pre-Deposited Transition Metals and the 2D Crystal Hetero-Structure Establishment. Sci. Rep. 2017, 7, 42146. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Okogbue, E.; Kim, J.H.; Ko, T.J.; Chung, H.S.; Krishnaprasad, A.; Flores, J.C.; Nehate, S.; Kaium, M.G.; Park, J.B.; Lee, S.J.; et al. Centimeter-Scale Periodically Corrugated Few-Layer 2D MoS2 with Tensile Stretch-Driven Tunable Multifunctionalities. ACS Appl. Mater. Interfaces 2018, 10, 30623–30630. [Google Scholar] [CrossRef]

- Wang, X.; Kang, K.; Chen, S.; Du, R.; Yang, E.H. Location-specific growth and transfer of arrayed MoS2 monolayers with controllable size. 2D Mater. 2017, 4, 025093. [Google Scholar] [CrossRef]

- Palacios, E.; Park, S.; Lauhon, L.; Aydin, K. Identifying Excitation and Emission Rate Contributions to Plasmon-Enhanced Photoluminescence from Monolayer MoS2 Using a Tapered Gold Nanoantenna. ACS Photonics 2017, 4, 1602–1606. [Google Scholar] [CrossRef]

- Hu, S.M.J. Film-edge-induced stress in substrates. Appl. Phys. 1979, 50, 4661. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiang, Y.-J.; Lu, T.-W.; Huang, P.-R.; Lin, S.-Y.; Lee, P.-T. MoS2 with Stable Photoluminescence Enhancement under Stretching via Plasmonic Surface Lattice Resonance. Nanomaterials 2021, 11, 1698. https://doi.org/10.3390/nano11071698

Chiang Y-J, Lu T-W, Huang P-R, Lin S-Y, Lee P-T. MoS2 with Stable Photoluminescence Enhancement under Stretching via Plasmonic Surface Lattice Resonance. Nanomaterials. 2021; 11(7):1698. https://doi.org/10.3390/nano11071698

Chicago/Turabian StyleChiang, Yen-Ju, Tsan-Wen Lu, Pin-Ruei Huang, Shih-Yen Lin, and Po-Tsung Lee. 2021. "MoS2 with Stable Photoluminescence Enhancement under Stretching via Plasmonic Surface Lattice Resonance" Nanomaterials 11, no. 7: 1698. https://doi.org/10.3390/nano11071698

APA StyleChiang, Y.-J., Lu, T.-W., Huang, P.-R., Lin, S.-Y., & Lee, P.-T. (2021). MoS2 with Stable Photoluminescence Enhancement under Stretching via Plasmonic Surface Lattice Resonance. Nanomaterials, 11(7), 1698. https://doi.org/10.3390/nano11071698