Twisting of a Pristine α-Fe Nanowire: From Wild Dislocation Avalanches to Mild Local Amorphization

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Two-Stage Plasticity in a Twisted Pristine α-Fe Nanowire

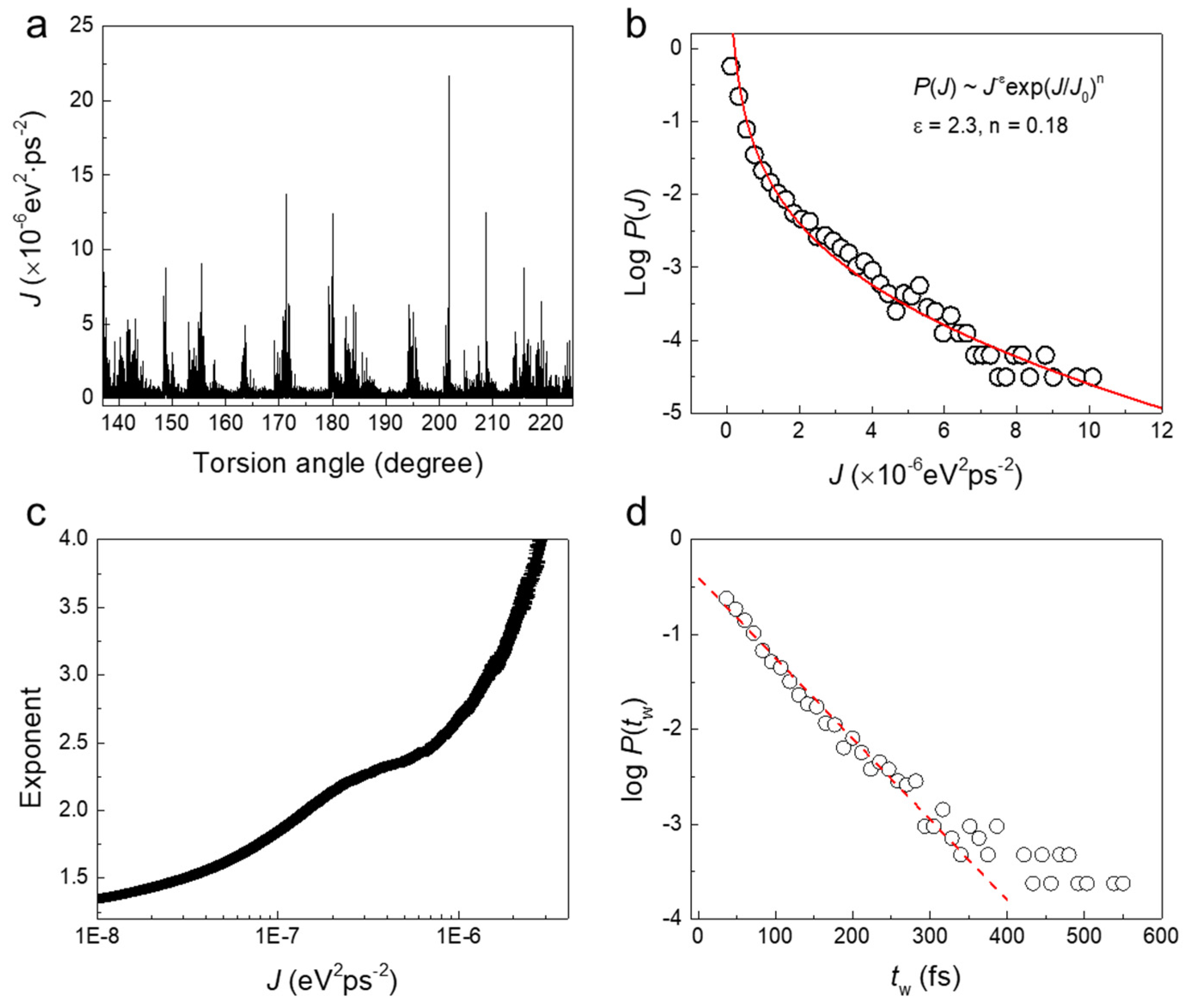

3.2. Mixed Wild Plasticity Induced by Dislocation Avalanches

3.3. Mild Plasticity Induced by Local Melting

4. Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, S.; Ding, X.; Li, J.; Ren, X.; Sun, J.; Ma, E. High-efficiency mechanical energy storage and retrieval using interfaces in nanowires. Nano Lett. 2010, 10, 1774–1779. [Google Scholar] [CrossRef]

- Li, S.; Ding, X.; Deng, J.; Lookman, T.; Li, J.; Ren, X.; Sun, J.; Saxena, A. Superelasticity in bcc nanowires by a reversible twinning mechanism. Phys. Rev. B 2010, 82, 205435. [Google Scholar] [CrossRef]

- Liang, W.; Zhou, M. Atomistic simulations reveal shape memory of fcc metal nanowires. Phys. Rev. B 2006, 73, 115409. [Google Scholar] [CrossRef]

- Park, H.S.; Gall, K.; Zimmerman, J.A. Shape memory and pseudoelasticity in metal nanowires. Phys. Rev. Lett. 2005, 95, 255504. [Google Scholar] [CrossRef] [PubMed]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Evoy, S.; Carr, D.W.; Sekaric, L.; Olkhovets, A.; Parpia, J.M.; Craighead, H.G. Nanofabrication and electrostatic operation of single-crystal silicon paddle oscillators. J. Appl. Phys. 1999, 86, 6072–6077. [Google Scholar] [CrossRef]

- Hsieh, J.; Fang, W. A novel microelectrostatic torsional actuator. Sens. Actuators A Phys. 2000, 79, 64–70. [Google Scholar] [CrossRef]

- Da Fonseca, A.F.; Galvão, D.S. Mechanical properties of nanosprings. Phys. Rev. Lett. 2004, 92, 175502. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Li, S.; Ding, X.; Sun, J.; Salje, E.K.H. Interface driven pseudo-elasticity in α-Fe nanowires. Adv. Funct. Mater. 2016, 26, 760–767. [Google Scholar] [CrossRef]

- Yang, Y.; Li, S.; Ding, X.; Sun, J. Pseudoelasticity in twinned α-Fe nanowires under bending. Comput. Mater. Sci. 2020, 188, 110128. [Google Scholar] [CrossRef]

- Yang, Y.; Li, S.; Ding, X.; Sun, J.; Weiss, J.; Salje, E.K.H. Twisting of pre-twinned α-Fe nanowires: From mild to wild avalanche dynamics. Acta Mater. 2020, 195, 50–58. [Google Scholar] [CrossRef]

- Li, S.; Salje, E.K.H.; Sun, J.; Ding, X. Large recovery of six-fold twinned nanowires of α-Fe. Acta Mater. 2017, 125, 296–302. [Google Scholar] [CrossRef]

- Jin, S.; Bierman, M.J.; Morin, S.A. A New Twist on Nanowire Formation: Screw-Dislocation-Driven Growth of Nanowires and Nanotubes. J. Phys. Chem. Lett. 2010, 1, 1472–1480. [Google Scholar] [CrossRef]

- Ikeda, H.; Qi, Y.; Çagin, T.; Samwer, K.; Johnson, W.L.; Goddard, W.A. Strain Rate Induced Amorphization in Metallic Nanowires. Phys. Rev. Lett. 1999, 82, 2900–2903. [Google Scholar] [CrossRef]

- Li, S.; Pastewka, L.; Gumbsch, P. Glass formation by severe plastic deformation of crystalline Cu|Zr nano-layers. Acta Mater. 2019, 165, 577–586. [Google Scholar] [CrossRef]

- Becker, R.; Orowan, E. Sudden expansion of zinc crystals. Z. Phys. 1932, 79, 566–572. [Google Scholar] [CrossRef]

- Miguel, M.C.; Vespignani, A.; Zapperi, S.; Weiss, J.; Grasso, J.-R. Intermittent dislocation flow in viscoplastic deformation. Nature 2001, 410, 667. [Google Scholar] [CrossRef] [PubMed]

- Weiss, J.; Marsan, D. Three-dimensional mapping of dislocation avalanches: Clustering and space/time coupling. Science 2003, 299, 89–92. [Google Scholar] [CrossRef] [PubMed]

- Weiss, J.; Miguel, M.C. Dislocation avalanche correlations. Mater. Sci. Eng. A 2004, 387, 292–296. [Google Scholar] [CrossRef]

- Weiss, J.; Rhouma, W.B.; Richeton, T.; Dechanel, S.; Louchet, F.; Truskinovsky, L. From mild to wild fluctuations in crystal plasticity. Phys. Rev. Lett. 2015, 114, 105504. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Salman, O.U.; Zhang, J.; Liu, G.; Weiss, J.; Truskinovsky, L.; Sun, J. Taming intermittent plasticity at small scales. Acta Mater. 2017, 128, 351–364. [Google Scholar] [CrossRef]

- Mendelev, M.I.; Han, S.; Srolovitz, D.J.; Ackland, G.J.; Sun, D.; Asta, M. Development of new interatomic potentials appropriate for crystalline and liquid iron. Philos. Mag. 2003, 83, 3977–3994. [Google Scholar] [CrossRef]

- Daw, M.S.; Baskes, M.I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 1984, 29, 6443. [Google Scholar] [CrossRef]

- Nosé, S. A unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 1984, 81, 511–519. [Google Scholar] [CrossRef]

- Hoover, W.G. Canonical dynamics: Equilibrium phase-space distributions. Phys. Rev. A 1985, 31, 1695. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Li, J. AtomEye: An efficient atomistic configuration viewer. Modell. Simul. Mater. Sci. Eng. 2003, 11, 173. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Stukowski, A.; Albe, K. Dislocation detection algorithm for atomistic simulations. Modell. Simul. Mater. Sci. Eng. 2010, 18, 025016. [Google Scholar] [CrossRef]

- Rycroft, C.H.; Grest, G.S.; Landry, J.W.; Bazant, M.Z. Analysis of granular flow in a pebble-bed nuclear reactor. Phys. Rev. E 2006, 74, 021306. [Google Scholar] [CrossRef]

- Liu, F.; Huang, G.; Ganguly, B. Plasma excitation dependence on voltage slew rates in 10–200 Torr argon–nitrogen gas mixture DBD. Plasma Sources Sci. Technol. 2010, 19, 045017. [Google Scholar] [CrossRef]

- He, X.; Ding, X.; Sun, J.; Salje, E.K.H. Parabolic temporal profiles of non-spanning avalanches and their importance for ferroic switching. Appl. Phys. Lett. 2016, 108, 072904. [Google Scholar] [CrossRef]

- Salje, E.K.H.; Dahmen, K.A. Crackling Noise in Disordered Materials. Annu. Rev. Condens. Matter. Phys. 2014, 5, 233–254. [Google Scholar] [CrossRef]

- Kelchner, C.L.; Plimpton, S.J.; Hamilton, J.C. Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 1998, 58, 11085. [Google Scholar] [CrossRef]

- Blumm, J.; Henderson, J.B. Measurement of the volumetric expansion and bulk density of metals in the solid and molten regions. High Temp. High Press. 2000, 32, 109–114. [Google Scholar] [CrossRef]

- Baró, J.; Corral, Á.; Illa, X.; Planes, A.; Salje, E.K.H.; Schranz, W.; Soto-Parra, D.E.; Vives, E. Statistical similarity between the compression of a porous material and earthquakes. Phys. Rev. Lett. 2013, 110, 088702. [Google Scholar] [CrossRef] [PubMed]

- Nataf, G.F.; Castillo-Villa, P.O.; Baró, J.; Illa, X.; Vives, E.; Planes, A.; Salje, E.K.H. Avalanches in compressed porous Si O 2-based materials. Phys. Rev. E 2014, 90, 022405. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.; Lookman, T.; Zhao, Z.; Saxena, A.; Sun, J.; Salje, E.K.H. Dynamically strained ferroelastics: Statistical behavior in elastic and plastic regimes. Phys. Rev. B 2013, 87, 094109. [Google Scholar] [CrossRef]

- Salje, E.K.H.; Planes, A.; Vives, E. Analysis of crackling noise using the maximum-likelihood method: Power-law mixing and exponential damping. Phys. Rev. E 2017, 96, 042122. [Google Scholar] [CrossRef] [PubMed]

- Galvanetto, U.; Bishop, S.R. Stick-slip vibrations of a two degree-of-freedom geophysical fault model. Int. J. Mech. Sci. 1994, 36, 683–698. [Google Scholar] [CrossRef]

- Bar Sinai, Y.; Brener, E.A.; Bouchbinder, E. Slow rupture of frictional interfaces. Geophys. Res. Lett. 2012, 39, L03308. [Google Scholar] [CrossRef]

- Wang, W.; Wang, C.; Yang, T.; Chen, D. A friction interface model for multi-material interactions in a Eulerian framework. J. Comput. Phys. 2021, 433, 110057. [Google Scholar] [CrossRef]

- Lu, Y.; Song, J.; Huang, J.Y.; Lou, J. Surface dislocation nucleation mediated deformation and ultrahigh strength in sub-10-nm gold nanowires. Nano Res. 2011, 4, 1261–1267. [Google Scholar] [CrossRef]

- Qin, Q.; Yin, S.; Cheng, G.; Li, X.; Chang, T.-H.; Richter, G.; Zhu, Y.; Gao, H. Recoverable plasticity in penta-twinned metallic nanowires governed by dislocation nucleation and retraction. Nat. Commun. 2015, 6, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Yue, Y.; Liu, P.; Deng, Q.; Ma, E.; Zhang, Z.; Han, X. Quantitative evidence of crossover toward partial dislocation mediated plasticity in copper single crystalline nanowires. Nano Lett. 2012, 12, 4045–4049. [Google Scholar] [CrossRef]

- Cheng, G.; Yin, S.; Li, C.; Chang, T.-H.; Richter, G.; Gao, H.; Zhu, Y. In-situ TEM study of dislocation interaction with twin boundary and retraction in twinned metallic nanowires. Acta Mater. 2020, 196, 304–312. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Ding, X.; Sun, J.; Salje, E.K.H. Twisting of a Pristine α-Fe Nanowire: From Wild Dislocation Avalanches to Mild Local Amorphization. Nanomaterials 2021, 11, 1602. https://doi.org/10.3390/nano11061602

Yang Y, Ding X, Sun J, Salje EKH. Twisting of a Pristine α-Fe Nanowire: From Wild Dislocation Avalanches to Mild Local Amorphization. Nanomaterials. 2021; 11(6):1602. https://doi.org/10.3390/nano11061602

Chicago/Turabian StyleYang, Yang, Xiangdong Ding, Jun Sun, and Ekhard K. H. Salje. 2021. "Twisting of a Pristine α-Fe Nanowire: From Wild Dislocation Avalanches to Mild Local Amorphization" Nanomaterials 11, no. 6: 1602. https://doi.org/10.3390/nano11061602

APA StyleYang, Y., Ding, X., Sun, J., & Salje, E. K. H. (2021). Twisting of a Pristine α-Fe Nanowire: From Wild Dislocation Avalanches to Mild Local Amorphization. Nanomaterials, 11(6), 1602. https://doi.org/10.3390/nano11061602