Electrospinning of Nanofibrous Membrane and Its Applications in Air Filtration: A Review

Abstract

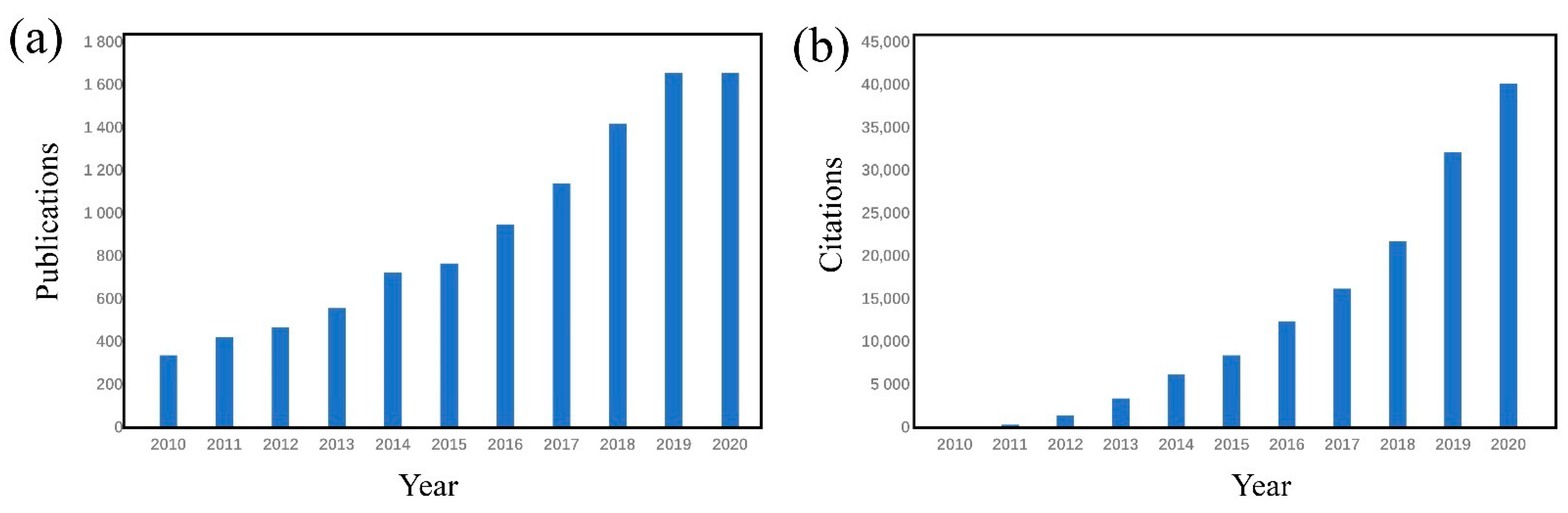

1. Introduction

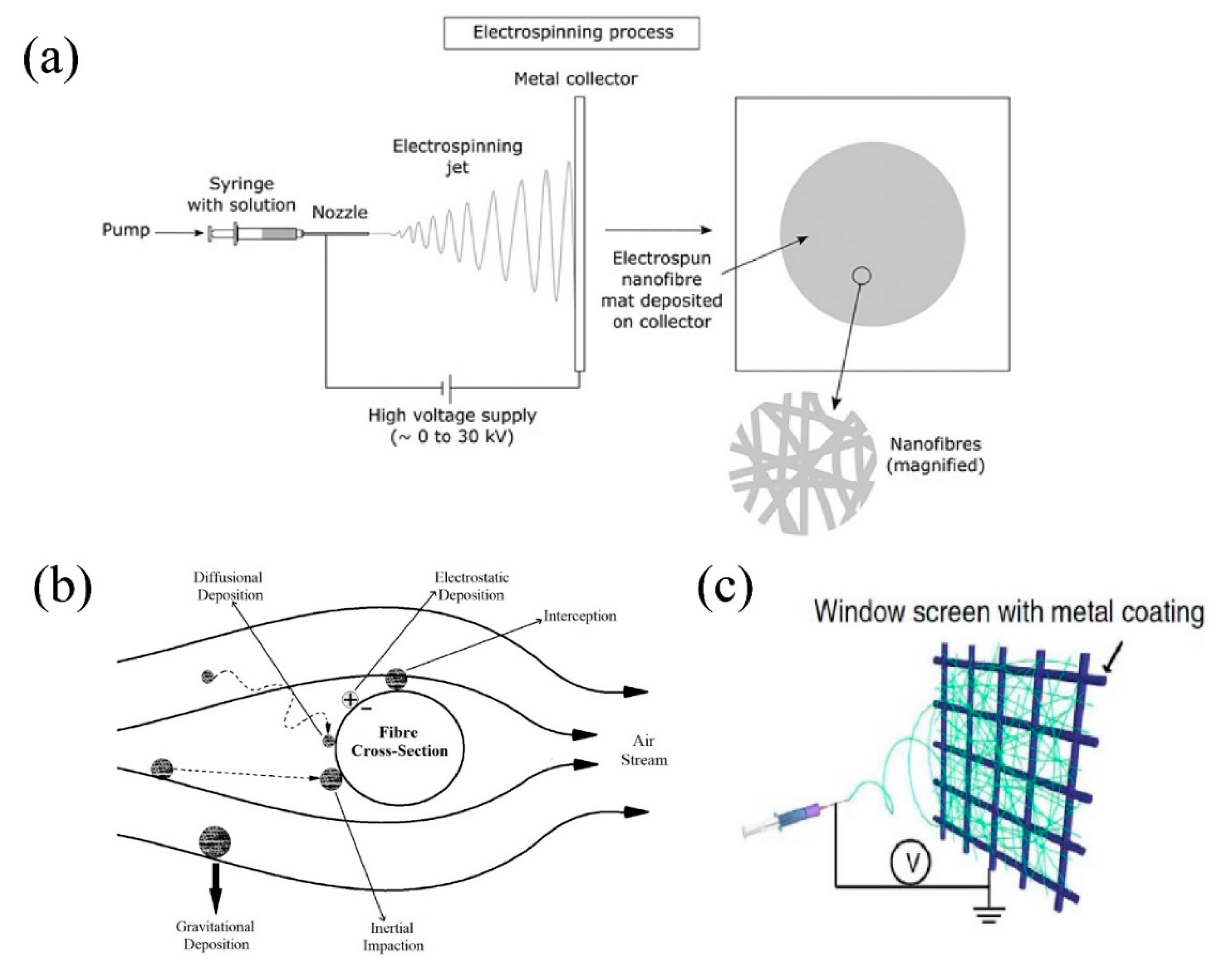

2. Electrospinning Techniques

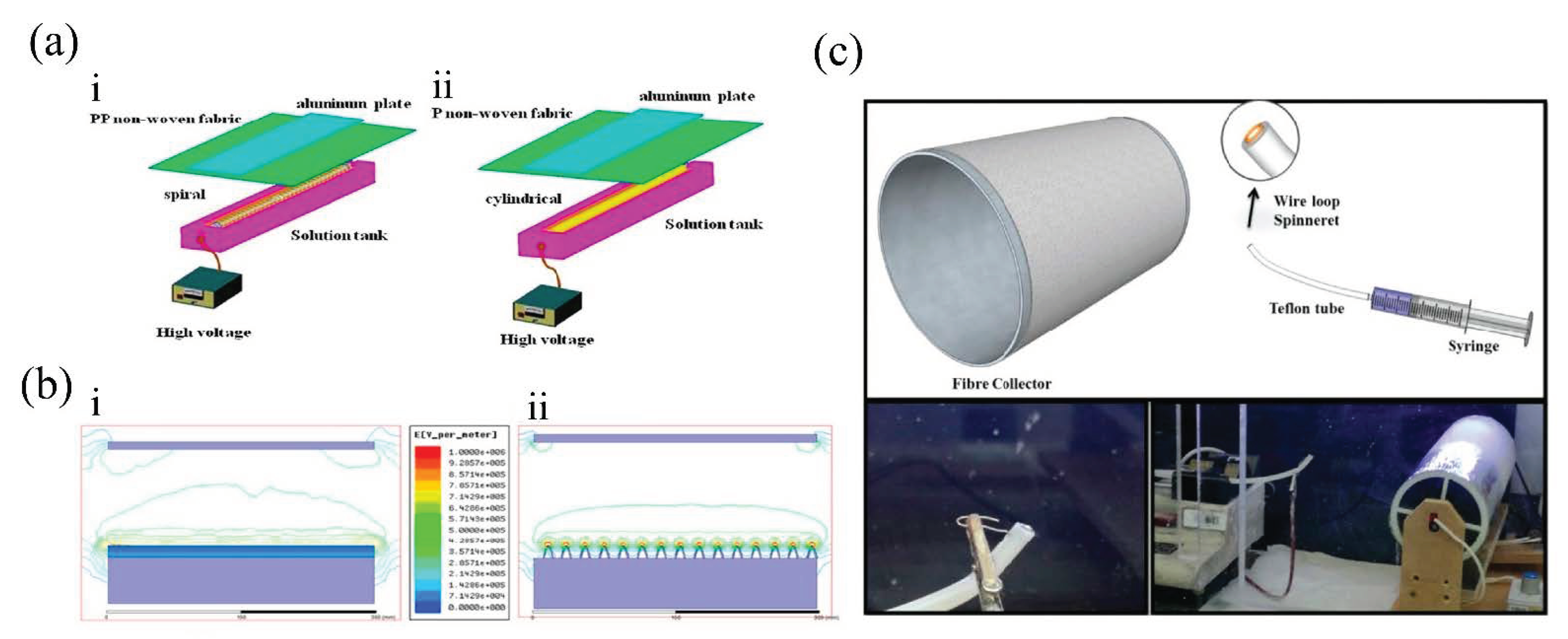

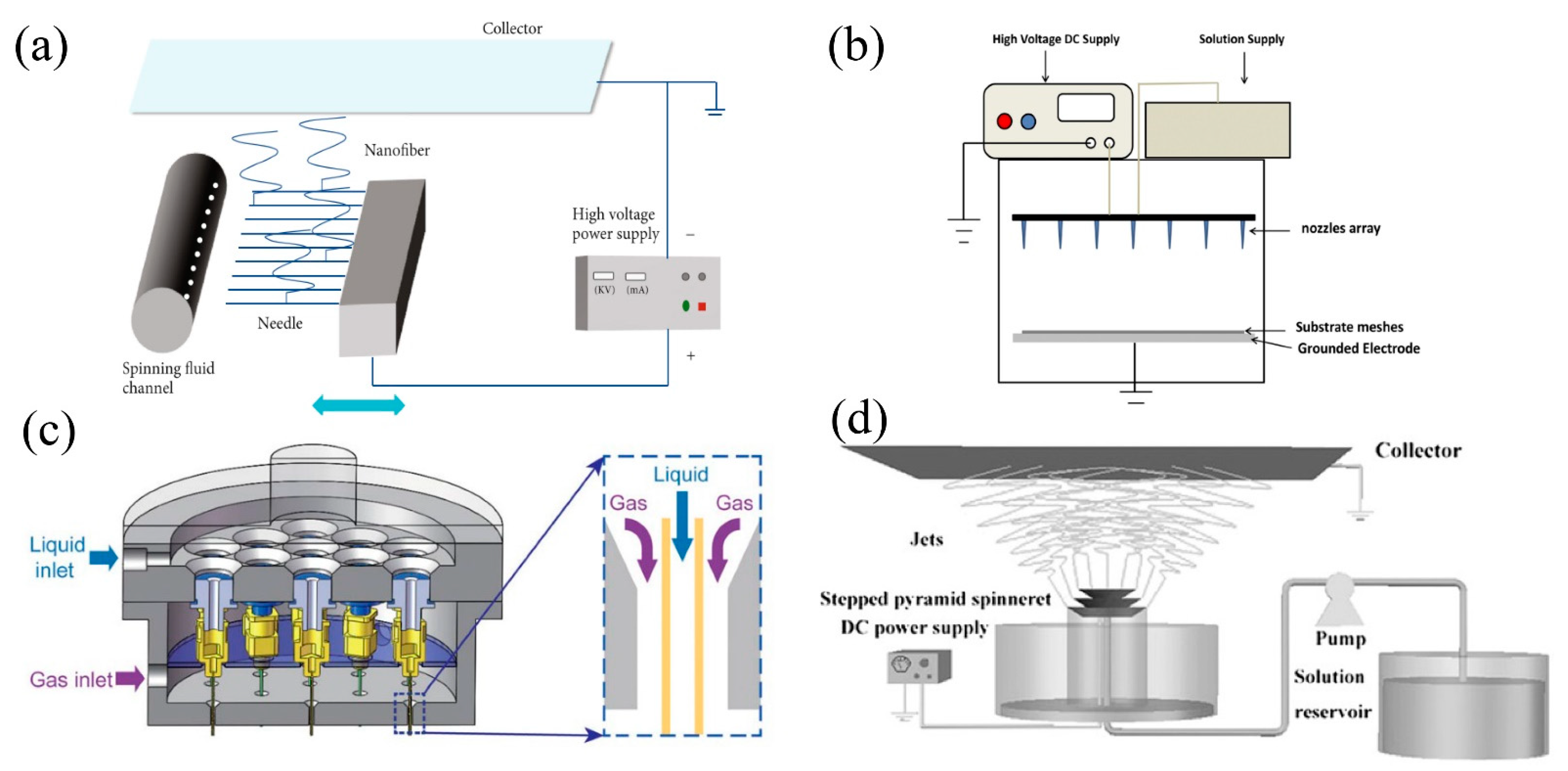

2.1. Needleless Electrospinning

2.2. Multi-Needle Electrospinning

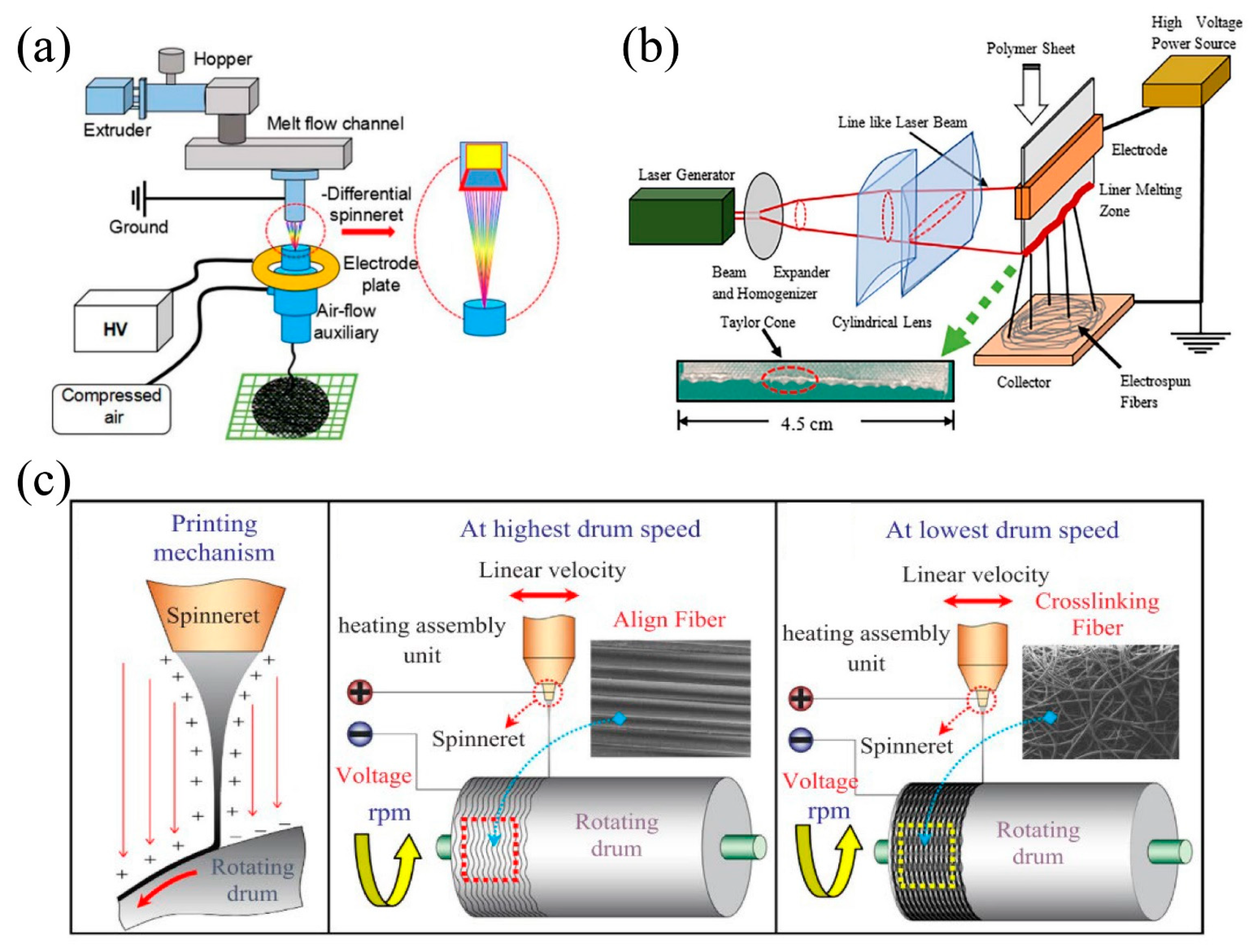

2.3. Solvent-Free Electrospinning

2.4. Discussion

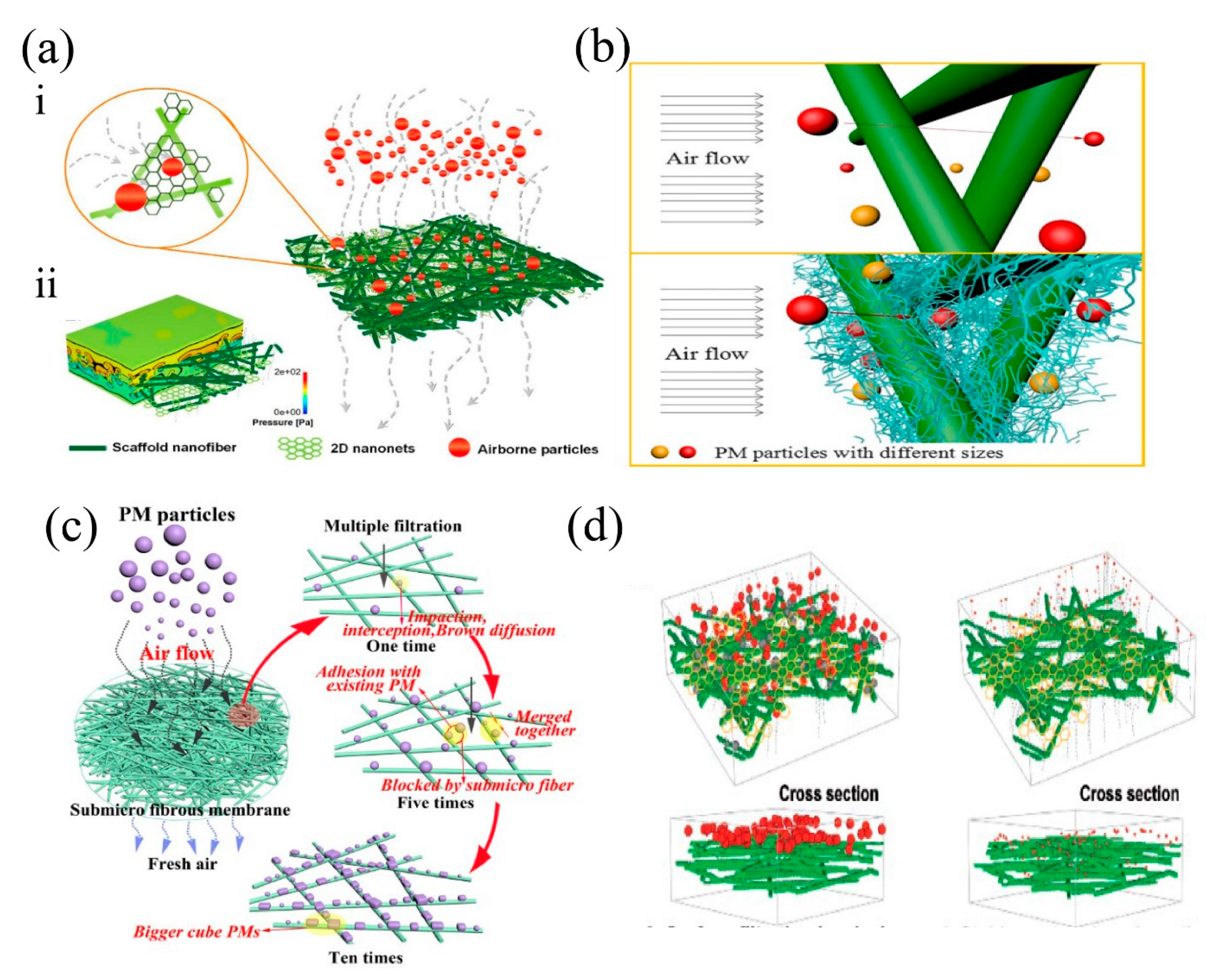

3. Structures of Membranes

3.1. Bead-on-String Structure

3.2. Multilayer Structure

3.3. Discussion

4. Characteristics of Membranes

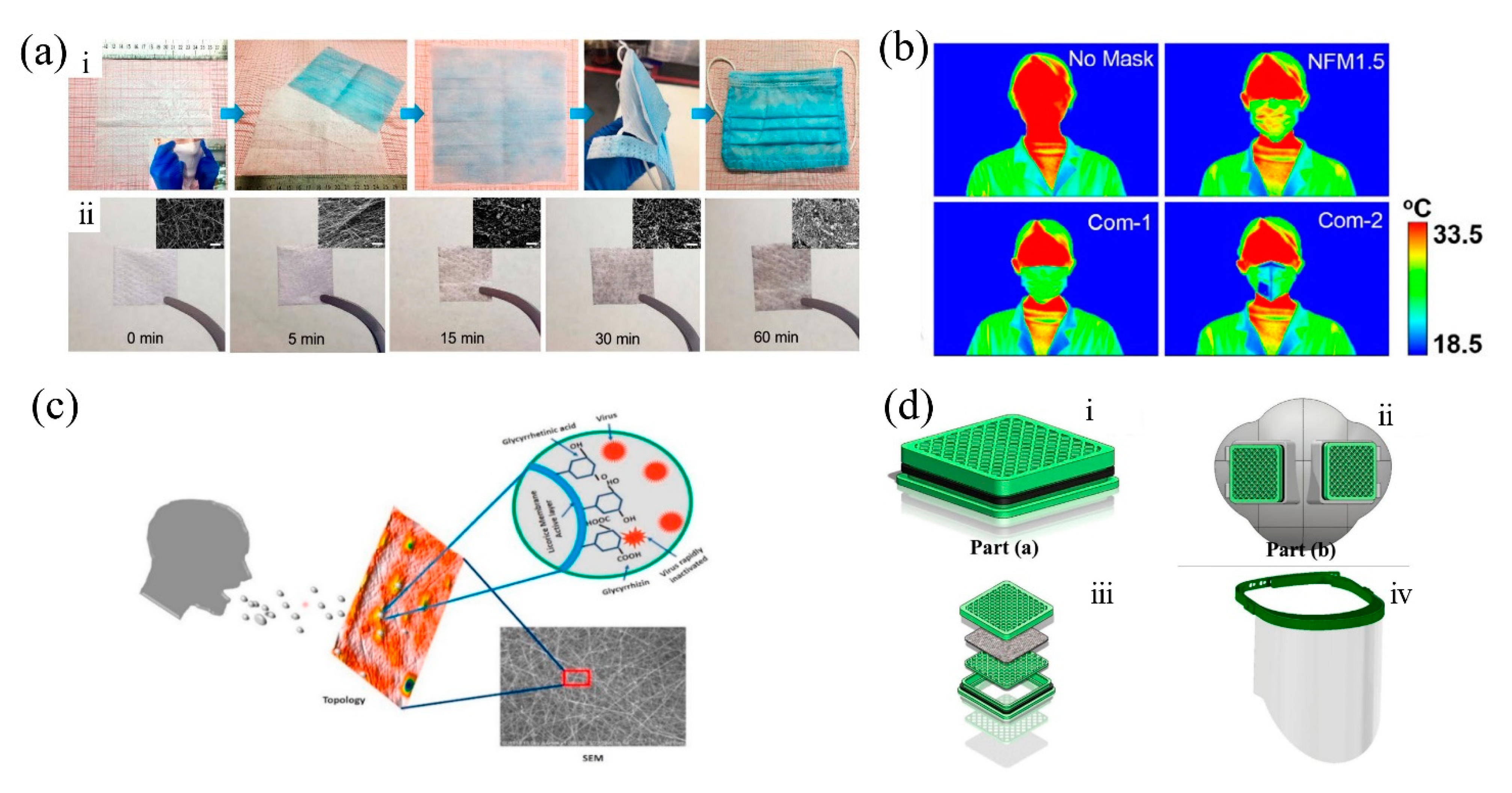

4.1. Enhanced Filtration Performance

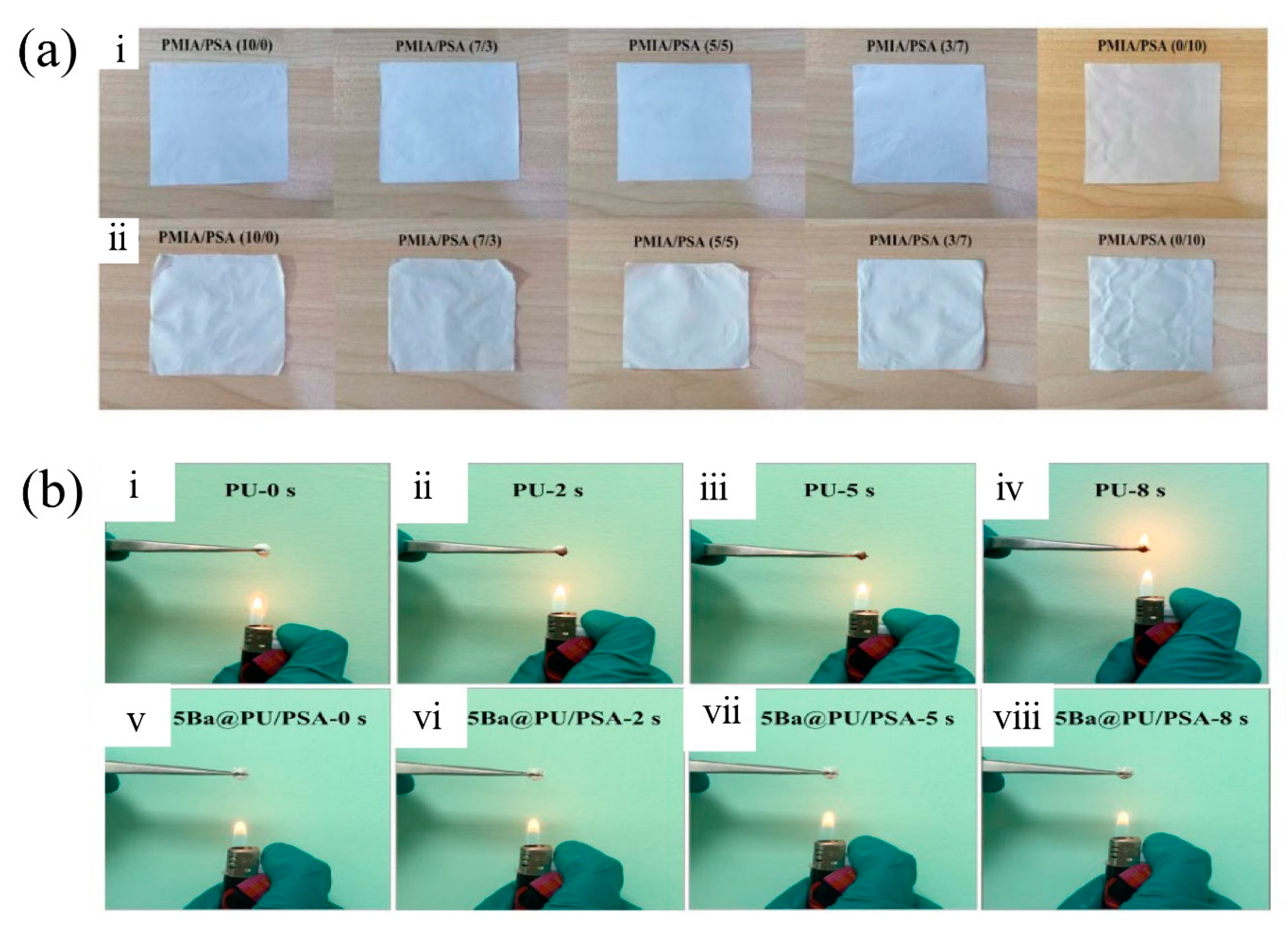

4.2. Thermal Stability

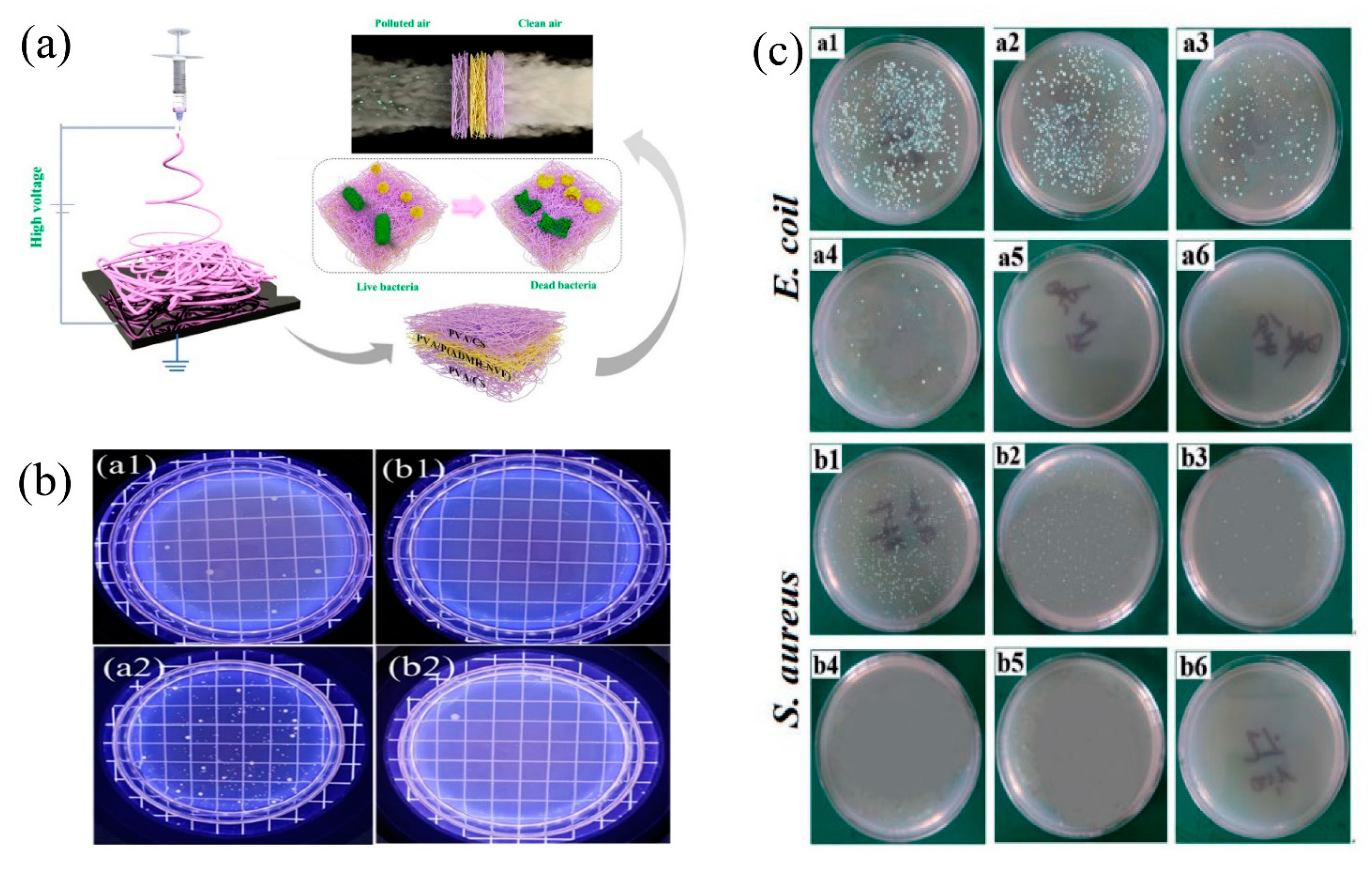

4.3. Antibacterial Function

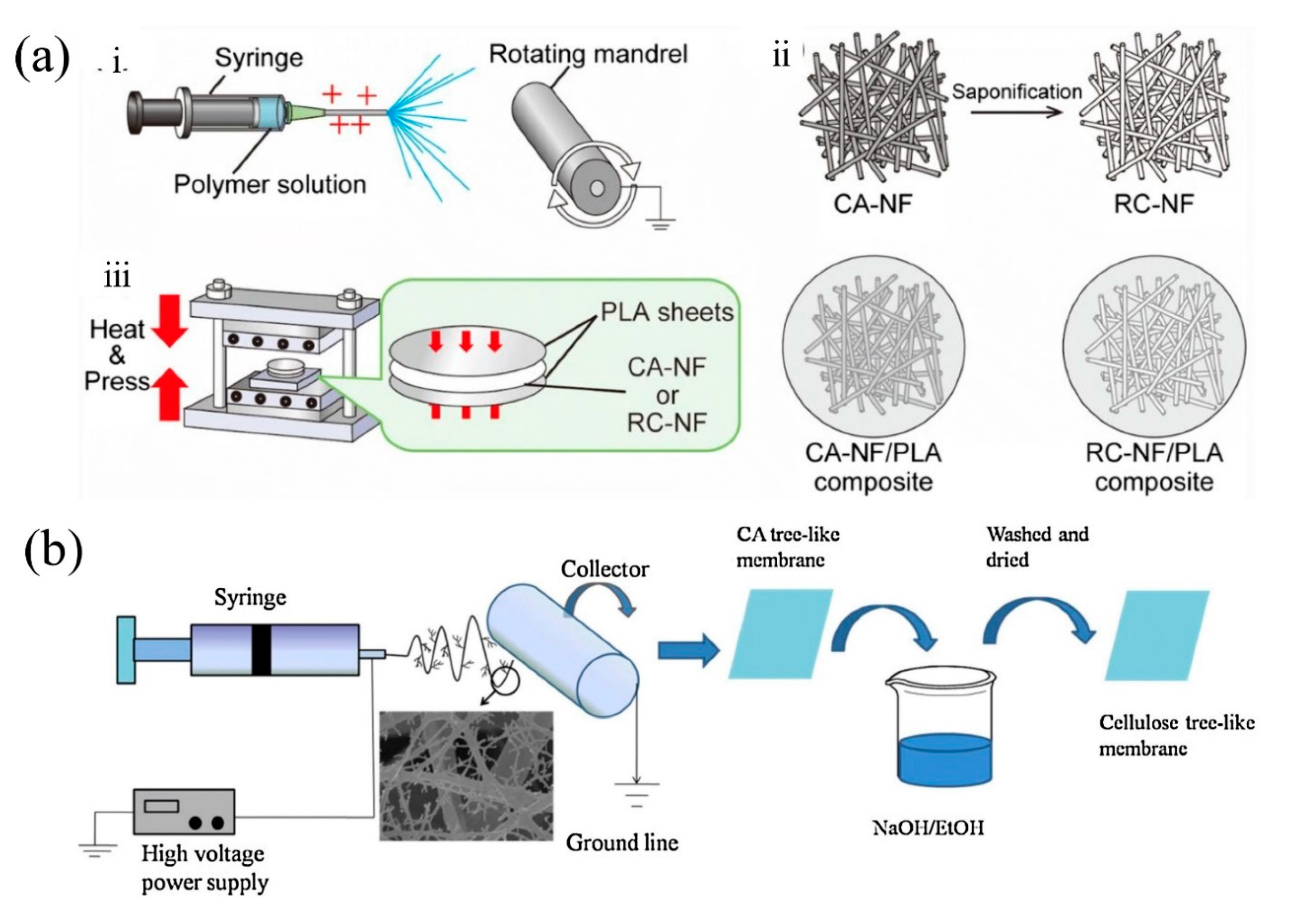

4.4. Environment-Friendliness and Biodegradability

4.5. Discussion

5. Applications in Air Filtration

5.1. Outdoor Protection

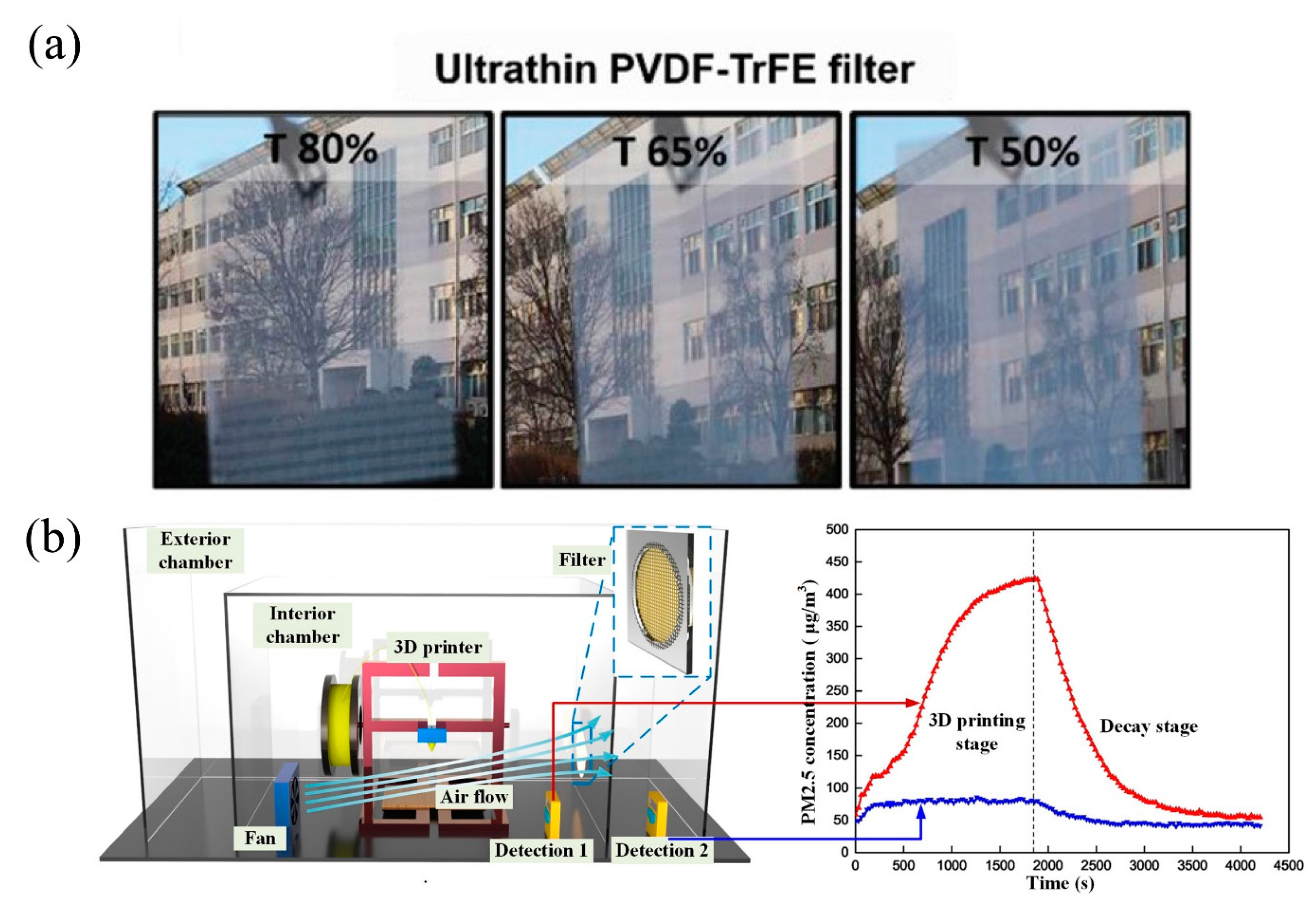

5.2. Indoor Protection

5.3. Discussion

6. Summary and Future Perspectives

6.1. Summary

- (1)

- Effective in protection against PM while maintaining good wearing comfort. Unique characteristics of electrospun membranes such as high porosity, low pressure drop, and different structures together allow air flow through the filter more easily, and the breathability and thermal comfort are therefore guaranteed, which are crucial factors of protective masks.

- (2)

- Relatively easy to fabricate, and large-scale production is possible. The most widely used single nozzle electrospinning is simple to set up and operate. Other electrospinning techniques such as needleless and multi-needle electrospinning can simultaneously produce multiple polymer jets, supporting the large-scale and fast-speed production of membrane filters.

- (3)

- Good versatility and adaptability to harsh conditions. With the introduction of different agents, various functions like thermal stability and antibacterial ability can be achieved. These diverse functions together with the notable filtration performance provide reliable protection even in harsh environments.

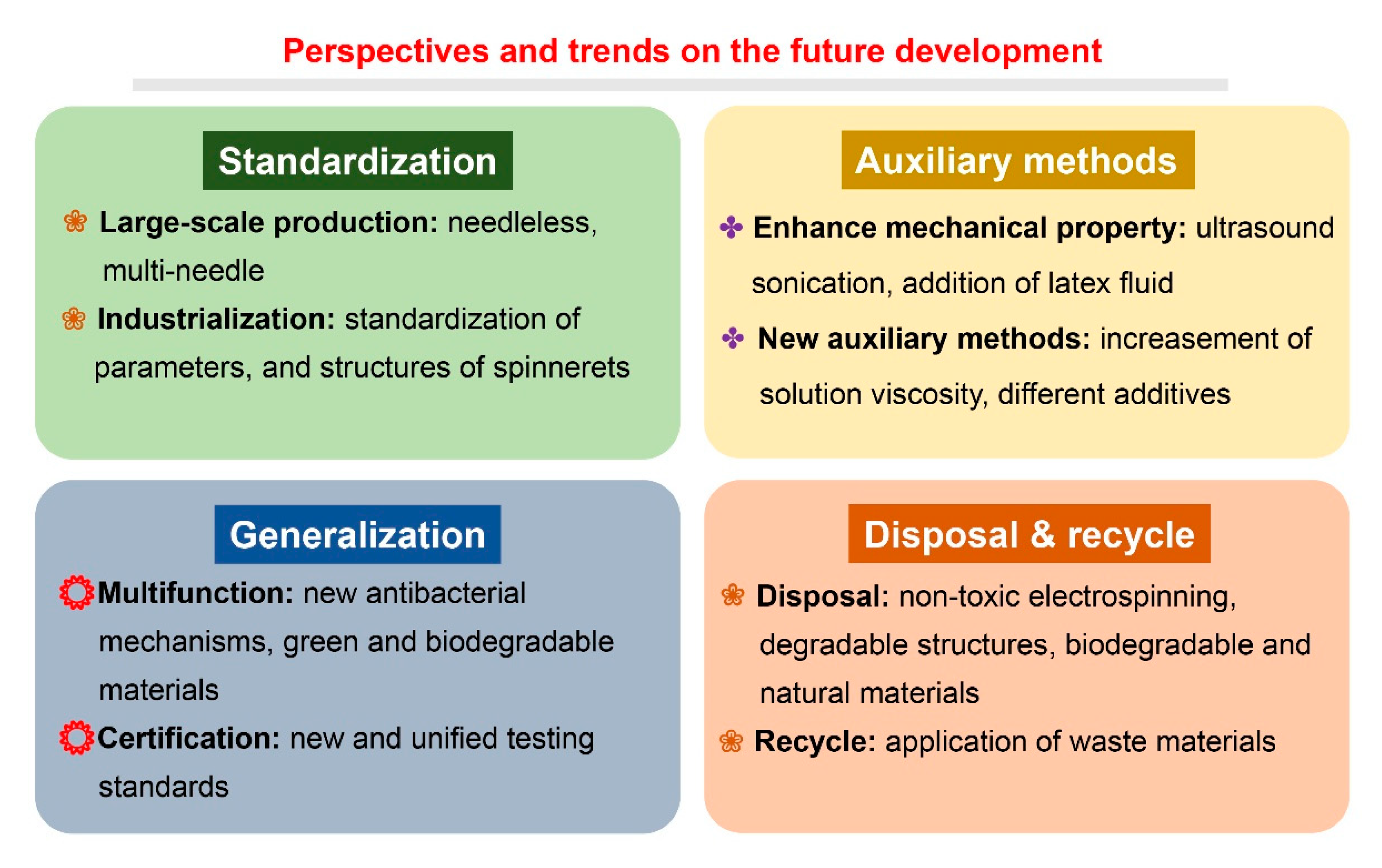

6.2. Future Perspectives

- (1)

- Standardization and industrialization of novel electrospinning techniques. As the solid foundation of broad applications, new electrospinning techniques need to be standardized to guarantee mass production. The electrospinning techniques introduced in this review, especially multi-needle and needleless electrospinning, are suitable for large-scale production of nanofibrous membranes. However, only a small number of electrospinning apparatus have achieved large-scale and fast-speed production of nanofibrous membranes, like the electrospinning equipment mentioned in the work of Liang et al. [102] and the actual realization of these novel electrospinning techniques on the large-scale production and industrialization is still very limited and is a major challenge due to the control difficulty, unstable quality, lack of standardized testing procedures, etc. The diameter of electrospun membranes is affected by a number of parameters, like nozzle distance, voltage strength, solution flow rate, collection speed, ambient temperature, solution concentration, etc. Changes of these parameters will finally result in the deviation of filtration performance. In the industrialization of the novel electrospinning techniques, parameters of these techniques require standardization to guarantee the fast-speed and large-scale production of nanofibrous membranes with the expected filtration performance. Moreover, because multi-needle and needleless electrospinning techniques both include specially designed spinnerets with unique structures, structure of the highest production rate and the corresponding design parameters of this structure need to be determined and standardized.

- (2)

- Auxiliary methods during the electrospinning process. Since the relatively weak mechanical property of membranes is a shared challenge faced by all types of electrospinning techniques, especially solution electrospinning, auxiliary methods that can enhance the mechanical property of nanofiber membranes are highly desirable. Ultrasound sonication prior to electrospinning process [103] and latex fluid as an additive to polymer solution [104] are two auxiliary methods that have been proved effective in the improvement of mechanical property. However, the related research is still rare. In the future, auxiliary mechanisms and methods, such as increasement of solution viscosity and introduction of different additives, need to be explored in both width and depth.

- (3)

- Generalization of multifunctional masks and filters. Nanofibrous membranes have already proven to be promising in the realization of various characteristics such as thermal stability, antibacterial function, environment-friendliness, and biodegradability. In these unique characteristics, antibacterial function is most crucial to shield humans from hazardous bacteria and viruses, therefore the advanced antibacterial masks and filters need to be generalized and put into actual use. The research of antibacterial mechanisms such as new additional agents and surface functionalization, awaits further development. Another problem is the certification procedure of these filtration products. Before putting into the market, the filtration membranes need to be tested and evaluated to meet the standards. For example, in EU, air filters are certificated according to ISO 16890 and EN1822:2019, which require stringent filtration tests. However, the testing procedures of the newly produced membranes corresponding with the standards are still lacking. In future research of these novel filters, standardized tests should be done following the experiments. With the gradual industrialization process of novel nanofibrous membranes, the unified test standards of these products need to be set to evaluate the characteristics of membranes more precisely.

- (4)

- Disposal and recycling of nanofibrous products. The inevitable problem of proper disposal and recycling of the electrospun air filtration membranes comes with the applications of these membranes. To meet the demand of environment-friendliness, research on the electrospun air filtration membranes is trending toward green, biodegradable, recyclable, and non-toxic materials. In the electrospinning techniques summarized in this review, the solvent-free electrospinning technique is bright in green and non-toxic production of nanofibrous membranes because it discards the toxic solvents. The structure of membranes should be designed as such to make it reusable and easily degradable. The spectrum of electrospinning materials needs to be expanded and reusable, green, and biodegradable materials deserve more focus.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yue, H.; He, C.; Huang, Q.; Yin, D.; Bryan, B.A. Stronger policy required to substantially reduce deaths from PM2.5 pollution in China. Nat. Commun. 2020, 11. [Google Scholar] [CrossRef]

- Downward, G.S.; van Nunen, E.J.H.M.; Kerckhoffs, J.; Vineis, P.; Brunekreef, B.; Boer, J.M.A.; Messier, K.P.; Roy, A.; Verschuren, W.M.M.; Van Der Schouw, Y.T.; et al. Long-term exposure to ultrafine particles and incidence of cardiovascular and cerebrovascular disease in a prospective study of a Dutch cohort. Environ. Health Perspect. 2018, 126. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Ruan, Z.; Wang, X.; Yang, Y.; Mason, T.G.; Lin, H.; Tian, L. Short-term and long-term exposures to fine particulate matter constituents and health: A systematic review and meta-analysis. Environ. Pollut. 2019, 247, 874–882. [Google Scholar] [CrossRef] [PubMed]

- Power, M.C.; Lamichhane, A.P.; Liao, D.; Xu, X.; Jack, C.R.; Gottesman, R.F.; Mosley, T.; Stewart, J.D.; Yanosky, J.D.; Whitsel, E.A. The association of long-term exposure to particulate matter air pollution with brain MRI findings: The ARIC study. Environ. Health Perspect. 2018, 126. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Fang, D.; Chen, B. Human health impact and economic effect for PM2.5 exposure in typical cities. Appl. Energy 2019, 249, 316–325. [Google Scholar] [CrossRef]

- Robert, B.; Nallathambi, G. A concise review on electrospun nanofibres/nanonets for filtration of gaseous and solid constituents (PM2.5) from polluted air. Colloids Interface Sci. Commun. 2020, 37, 100275. [Google Scholar] [CrossRef]

- Li, Y.; Yin, X.; Yu, J.; Ding, B. Electrospun nanofibers for high-performance air filtration. Compos. Commun. 2019, 15, 6–19. [Google Scholar] [CrossRef]

- Zhao, P.; Gu, H.; Mi, H.; Rao, C.; Fu, J.; Turng, L. sheng Fabrication of scaffolds in tissue engineering: A review. Front. Mech. Eng. 2018, 13, 107–119. [Google Scholar] [CrossRef]

- Gao, Q.; Gu, H.; Zhao, P.; Zhang, C.; Cao, M.; Fu, J.; He, Y. Fabrication of electrospun nanofibrous scaffolds with 3D controllable geometric shapes. Mater. Des. 2018, 157, 159–169. [Google Scholar] [CrossRef]

- Huang, Z.M.; Zhang, Y.Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Shou, D.; Ye, L.; Fan, J. Gas transport properties of electrospun polymer nanofibers. Polymer 2014, 55, 3149–3155. [Google Scholar] [CrossRef]

- Bao, L.; Seki, K.; Niinuma, H.; Otani, Y.; Balgis, R.; Ogi, T.; Gradon, L.; Okuyama, K. Verification of slip flow in nanofiber filter media through pressure drop measurement at low-pressure conditions. Sep. Purif. Technol. 2016, 159, 100–107. [Google Scholar] [CrossRef]

- Xin, Y.; Reneker, D.H. Garland formation process in electrospinning. Polymer 2012, 53, 3629–3635. [Google Scholar] [CrossRef]

- Ahmed, F.E.; Lalia, B.S.; Hashaikeh, R. A review on electrospinning for membrane fabrication: Challenges and applications. Desalination 2015, 356, 15–30. [Google Scholar] [CrossRef]

- SalehHudin, H.S.; Mohamad, E.N.; Mahadi, W.N.L.; Muhammad Afifi, A. Multiple-jet electrospinning methods for nanofiber processing: A review. Mater. Manuf. Process. 2018, 33, 479–498. [Google Scholar] [CrossRef]

- Liu, C.; Hsu, P.C.; Lee, H.W.; Ye, M.; Zheng, G.; Liu, N.; Li, W.; Cui, Y. Transparent air filter for high-efficiency PM 2.5 capture. Nat. Commun. 2015, 6, 1–9. [Google Scholar] [CrossRef]

- Rasouli, R.; Barhoum, A.; Bechelany, M.; Dufresne, A. Nanofibers for Biomedical and Healthcare Applications. Macromol. Biosci. 2019, 19, 1–27. [Google Scholar] [CrossRef]

- Barhoum, A.; Pal, K.; Rahier, H.; Uludag, H.; Kim, I.S.; Bechelany, M. Nanofibers as new-generation materials: From spinning and nano-spinning fabrication techniques to emerging applications. Appl. Mater. Today 2019, 17, 1–35. [Google Scholar] [CrossRef]

- Zhu, M.; Han, J.; Wang, F.; Shao, W.; Xiong, R.; Zhang, Q.; Pan, H.; Yang, Y.; Samal, S.K.; Zhang, F.; et al. Electrospun Nanofibers Membranes for Effective Air Filtration. Macromol. Mater. Eng. 2017, 302, 1–27. [Google Scholar] [CrossRef]

- Lian, H.; Meng, Z. Melt electrospinning vs. solution electrospinning: A comparative study of drug-loaded poly (ε-caprolactone) fibres. Mater. Sci. Eng. C 2017, 74, 117–123. [Google Scholar] [CrossRef] [PubMed]

- Muerza-Cascante, M.L.; Haylock, D.; Hutmacher, D.W.; Dalton, P.D. Melt electrospinning and its technologization in tissue engineering. Tissue Eng.—Part B Rev. 2015, 21, 187–202. [Google Scholar] [CrossRef] [PubMed]

- Ng, J.J.; Supaphol, P. Rotating-disk electrospinning: Needleless electrospinning of poly(caprolactone), poly(lactic acid) and poly(vinyl alcohol) nanofiber mats with controlled morphology. J. Polym. Res. 2018, 25. [Google Scholar] [CrossRef]

- Yan, S.; Yu, Y.; Ma, R.; Fang, J. The formation of ultrafine polyamide 6 nanofiber membranes with needleless electrospinning for air filtration. Polym. Adv. Technol. 2019, 30, 1635–1643. [Google Scholar] [CrossRef]

- Moon, S.; Park, K.; Seo, E.; Lee, K.J. Mass Production of Functional Amine–Conjugated PAN Nanofiber Mat via Syringeless Electrospinning and CVD. Macromol. Mater. Eng. 2018, 303, 1–8. [Google Scholar] [CrossRef]

- Jahan, I.; Wang, L.; Wang, X. Needleless Electrospinning from a Tube with an Embedded Wire Loop. Macromol. Mater. Eng. 2019, 304. [Google Scholar] [CrossRef]

- Zhou, M.; Hu, M.; Quan, Z.; Zhang, H.; Qin, X.; Wang, R.; Yu, J. Polyacrylonitrile/polyimide composite sub-micro fibrous membranes for precise filtration of PM0.26 pollutants. J. Colloid Interface Sci. 2020, 578, 195–206. [Google Scholar] [CrossRef] [PubMed]

- Wan, L.Y. Bubble Electrospinning and Bubble-Spun Nanofibers. Recent Pat. Nanotechnol. 2019, 14, 10–13. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Dong, A.; He, J. Innovation of critical bubble electrospinning and its mechanism. Polymers 2020, 12, 304. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Wu, X.F.; Ding, Y.; Yu, M.; Zhao, Y.; Jiang, L.; Xuan, C.; Sun, C. Needleless emulsion electrospinning for scalable fabrication of core-shell nanofibers. J. Appl. Polym. Sci. 2014, 131, 1–9. [Google Scholar] [CrossRef]

- Bhattacharyya, I.; Molaro, M.C.; Braatz, R.D.; Rutledge, G.C. Free surface electrospinning of aqueous polymer solutions from a wire electrode. Chem. Eng. J. 2016, 289, 203–211. [Google Scholar] [CrossRef]

- Thoppey, N.M.; Bochinski, J.R.; Clarke, L.I.; Gorga, R.E. Unconfined fluid electrospun into high quality nanofibers from a plate edge. Polymer 2010, 51, 4928–4936. [Google Scholar] [CrossRef]

- Thoppey, N.M.; Gorga, R.E.; Clarke, L.I.; Bochinski, J.R. Control of the electric field-polymer solution interaction by utilizing ultra-conductive fluids. Polymer 2014, 55, 6390–6398. [Google Scholar] [CrossRef]

- Pokorny, P.; Kostakova, E.; Sanetrnik, F.; Mikes, P.; Chvojka, J.; Kalous, T.; Bilek, M.; Pejchar, K.; Valtera, J.; Lukas, D. Effective AC needleless and collectorless electrospinning for yarn production. Phys. Chem. Chem. Phys. 2014, 16, 26816–26822. [Google Scholar] [CrossRef]

- Ali, U.; Niu, H.; Aslam, S.; Jabbar, A.; Rajput, A.W.; Lin, T. Needleless electrospinning using sprocket wheel disk spinneret. J. Mater. Sci. 2017, 52, 7567–7577. [Google Scholar] [CrossRef]

- Xu, Y.; Li, X.; Xiang, H.F.; Zhang, Q.Q.; Wang, X.X.; Yu, M.; Hao, L.Y.; Long, Y.Z. Large-Scale Preparation of Polymer Nanofibers for Air Filtration by a New Multineedle Electrospinning Device. J. Nanomater. 2020, 2020. [Google Scholar] [CrossRef]

- Jiang, R.; Yan, T.; Wang, Y.Q.; Pan, Z.J. The preparation of PA6/CS-NPs nanofiber filaments with excellent antibacterial activity via a one-step multineedle electrospinning method with liquid bath circling system. J. Appl. Polym. Sci. 2020, 137, 1–12. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Zhu, Z.; Chen, R.; Chen, X.; Zeng, J.; Xu, G.; Wei, C.; Zhang, Q.; Bai, J.; et al. Fabrication of nanofiber filters for electret air conditioning filter via a multi-needle electrospinning. AIP Adv. 2020, 10. [Google Scholar] [CrossRef]

- Zhu, Z.; Wu, P.; Wang, Z.; Xu, G.; Wang, H.; Chen, X.; Wang, R.; Huang, W.; Chen, R.; Chen, X.; et al. Optimization of electric field uniformity of multi-needle electrospinning nozzle. AIP Adv. 2019, 9. [Google Scholar] [CrossRef]

- Zheng, G.; Jiang, J.; Chen, D.; Liu, J.; Liu, Y.; Zheng, J.; Wang, X.; Li, W. Multinozzle high efficiency electrospinning with the constraint of sheath gas. J. Appl. Polym. Sci. 2019, 136, 1–12. [Google Scholar] [CrossRef]

- Yu, M.; Dong, R.H.; Yan, X.; Yu, G.F.; You, M.H.; Ning, X.; Long, Y.Z. Recent Advances in Needleless Electrospinning of Ultrathin Fibers: From Academia to Industrial Production. Macromol. Mater. Eng. 2017, 302, 1–19. [Google Scholar] [CrossRef]

- Morikawa, K.; Green, M.; Naraghi, M. A Novel Approach for Melt Electrospinning of Polymer Fibers. Procedia Manuf. 2018, 26, 205–208. [Google Scholar] [CrossRef]

- Qin, Y.; Cheng, L.; Zhang, Y.; Chen, X.; Wang, X.; He, X.; Yang, W.; An, Y.; Li, H. Efficient preparation of poly(lactic acid) nanofibers by melt differential electrospinning with addition of acetyl tributyl citrate. J. Appl. Polym. Sci. 2018, 135, 42–45. [Google Scholar] [CrossRef]

- Zakaria, M.; Nakane, K. Fabrication of Polypropylene Nanofibers from Polypropylene/Polyvinyl Butyral Blend Films Using Laser-Assisted Melt-Electrospinning. Polym. Eng. Sci. 2020, 60, 362–370. [Google Scholar] [CrossRef]

- Buivydiene, D.; Krugly, E.; Ciuzas, D.; Tichonovas, M.; Kliucininkas, L.; Martuzevicius, D. Formation and characterisation of air filter material printed by melt electrospinning. J. Aerosol Sci. 2019, 131, 48–63. [Google Scholar] [CrossRef]

- Sarwar, Z.; Krugly, E.; Danilovas, P.P.; Ciuzas, D.; Kauneliene, V.; Martuzevicius, D. Fabrication and characterization of PEBA fibers by melt and solution electrospinning. J. Mater. Res. Technol. 2019, 8, 6074–6085. [Google Scholar] [CrossRef]

- Sarwar, Z.; Yousef, S.; Tatariants, M.; Krugly, E.; Čiužas, D.; Danilovas, P.P.; Baltusnikas, A.; Martuzevicius, D. Fibrous PEBA-graphene nanocomposite filaments and membranes fabricated by extrusion and additive manufacturing. Eur. Polym. J. 2019, 121. [Google Scholar] [CrossRef]

- Li, T.; Fan, Y.; Cen, X.; Wang, Y.; Shiu, B.; Ren, H.; Peng, H.; Jiang, Q.; Lou, C.; Lin, J. Polypropylene/Polyvinyl Alcohol/Metal-Organic Framework-Based Melt-Blown Electrospun Composite Membranes for Highly E ffi cient Filtration of PM 2.5. Nanomaterials 2020, 8, 1–17. [Google Scholar]

- Kadam, V.V.; Wang, L.; Padhye, R. Electrospun nanofibre materials to filter air pollutants—A review. J. Ind. Text. 2018, 47, 2253–2280. [Google Scholar] [CrossRef]

- Korycka, P.; Mirek, A.; Kramek-Romanowska, K.; Grzeczkowicz, M.; Lewinska, D. Effect of electrospinning process variables on the size of polymer fibers and bead-on-string structures established with a 23 factorial design. Beilstein J. Nanotechnol. 2018, 9, 2466–2478. [Google Scholar] [CrossRef]

- Rasouli, M.; Pirsalami, S.; Zebarjad, S.M. Study on the formation and structural evolution of bead-on-string in electrospun polysulfone mats. Polym. Int. 2020, 69, 822–832. [Google Scholar] [CrossRef]

- Cao, Q.; Meng, X.; Tan, S.; Xin, Z.; Turng, L.S.; Li, J.; Yao, Z.; Zhai, Z.; Duan, R. Electrospun bead-in-string fibrous membrane prepared from polysilsesquioxane-immobilising poly(lactic acid) with low filtration resistance for air filtration. J. Polym. Res. 2019, 27. [Google Scholar] [CrossRef]

- Huang, J.J.; Tian, Y.; Wang, R.; Tian, M.; Liao, Y. Fabrication of bead-on-string polyacrylonitrile nanofibrous air filters with superior filtration efficiency and ultralow pressure drop. Sep. Purif. Technol. 2020, 237. [Google Scholar] [CrossRef]

- Li, J.; Zhang, D.; Yang, T.; Yang, S.; Yang, X.; Zhu, H. Nanofibrous membrane of graphene oxide-in-polyacrylonitrile composite with low filtration resistance for the effective capture of PM2.5. J. Memb. Sci. 2018, 551, 85–92. [Google Scholar] [CrossRef]

- Kadam, V.; Kyratzis, I.L.; Truong, Y.B.; Schutz, J.; Wang, L.; Padhye, R. Electrospun bilayer nanomembrane with hierarchical placement of bead-on-string and fibers for low resistance respiratory air filtration. Sep. Purif. Technol. 2019, 224, 247–254. [Google Scholar] [CrossRef]

- Zhang, L.; Li, L.; Wang, L.; Nie, J.; Ma, G. Multilayer electrospun nanofibrous membranes with antibacterial property for air filtration. Appl. Surf. Sci. 2020, 515. [Google Scholar] [CrossRef]

- Yang, Y.; He, R.; Cheng, Y.; Wang, N. Multilayer-structured fibrous membrane with directional moisture transportability and thermal radiation for high-performance air filtration. E-Polymers 2020, 20, 282–291. [Google Scholar] [CrossRef]

- Roche, R.; Yalcinkaya, F. Incorporation of PVDF nanofibre multilayers into functional structure for filtration applications. Nanomaterials 2018, 8. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Ma, X.Y.D.; Ang, J.; Zeng, Z.; Ng, B.F.; Wan, M.P.; Wong, S.C.; Lu, X. Polymer/MOF-derived multilayer fibrous membranes for moisture-wicking and efficient capturing both fine and ultrafine airborne particles. Sep. Purif. Technol. 2020, 235. [Google Scholar] [CrossRef]

- Xiong, J.; Zhou, M.; Zhang, H.; Quan, Z.; Wang, R.; Qin, X. Sandwich-structured fibrous membranes with low filtration resistance for effective PM2.5 capture via one-step needleless electrospinning. Mater. Res. Express 2019, 6. [Google Scholar] [CrossRef]

- Lv, D.; Zhu, M.; Jiang, Z.; Jiang, S.; Zhang, Q.; Xiong, R.; Huang, C. Green Electrospun Nanofibers and Their Application in Air Filtration. Macromol. Mater. Eng. 2018, 303, 1–18. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Yin, X.; Li, Z.; Yu, J.; Ding, B. Tailoring mechanically robust poly(m-phenylene isophthalamide) nanofiber/nets for ultrathin high-efficiency air filter. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef]

- Nakata, K.; Kim, S.H.; Ohkoshi, Y.; Gotoh, Y.; Nagura, M. Electrospinning of poly (ether sulfone) and evaluation of the filtration efficiency. J. Fiber Sci. Technol. 2007, 63, 307–312. [Google Scholar] [CrossRef][Green Version]

- Zuo, F.; Zhang, S.; Liu, H.; Fong, H.; Yin, X.; Yu, J.; Ding, B. Free-Standing Polyurethane Nanofiber/Nets Air Filters for Effective PM Capture. Small 2017, 13, 1–11. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Zuo, F.; Yin, X.; Yu, J.; Ding, B. A Controlled Design of Ripple-Like Polyamide-6 Nanofiber/Nets Membrane for High-Efficiency Air Filter. Small 2017, 13, 1–10. [Google Scholar] [CrossRef]

- Zhong, L.; Wang, T.; Liu, L.; Du, W.; Wang, S. Ultra-fine SiO2 nanofilament-based PMIA: A double network membrane for efficient filtration of PM particles. Sep. Purif. Technol. 2018, 202, 357–364. [Google Scholar] [CrossRef]

- Guo, Y.; He, W.; Liu, J. Electrospinning polyethylene terephthalate/SiO2 nanofiber composite needle felt for enhanced filtration performance. J. Appl. Polym. Sci. 2020, 137, 1–11. [Google Scholar] [CrossRef]

- Ruan, D.; Qin, L.; Chen, R.; Xu, G.; Su, Z.; Cheng, J.; Xie, S.; Cheng, F.; Ko, F. Transparent PAN:TiO2 and PAN-co-PMA:TiO2 Nanofiber Composite Membranes with High Efficiency in Particulate Matter Pollutants Filtration. Nanoscale Res. Lett. 2020, 15. [Google Scholar] [CrossRef]

- Lee, M.; Ojha, G.P.; Oh, H.J.; Kim, T.; Kim, H.Y. Copper//terbium dual metal organic frameworks incorporated side-by-side electrospun nanofibrous membrane: A novel tactics for an efficient adsorption of particulate matter and luminescence property. J. Colloid Interface Sci. 2020, 578, 155–163. [Google Scholar] [CrossRef]

- Tian, X.; Zhang, F.; Xin, B.; Liu, Y.; Gao, W.; Wang, C.; Zheng, Y. Electrospun meta-aramid/polysulfone-amide nanocomposite membranes for the filtration of industrial PM2.5 particles. Nanotechnology 2020, 31. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Pu, Y.; Zhang, Y.; Liu, X.; Li, J.; Yuan, D.; Ning, X. Multifunctional composite membrane based on BaTiO3@PU/PSA nanofibers for high-efficiency PM2.5 removal. J. Hazard. Mater. 2020, 391. [Google Scholar] [CrossRef] [PubMed]

- Hao, Z.; Wu, J.; Wang, C.; Liu, J. Electrospun Polyimide/Metal-Organic Framework Nanofibrous Membrane with Superior Thermal Stability for Efficient PM 2.5 Capture. ACS Appl. Mater. Interfaces 2019, 11, 11904–11909. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, Y.; Cao, G. Preparation of a polyacrylonitrile/polyurethane nanofibrous membrane with antibacterial function and measurement of its air filtration performance. Indoor Built Environ. 2019, 28, 1038–1048. [Google Scholar] [CrossRef]

- Bortolassi, A.C.C.; Nagarajan, S.; de Araújo Lima, B.; Guerra, V.G.; Aguiar, M.L.; Huon, V.; Soussan, L.; Cornu, D.; Miele, P.; Bechelany, M. Efficient nanoparticles removal and bactericidal action of electrospun nanofibers membranes for air filtration. Mater. Sci. Eng. C 2019, 102, 718–729. [Google Scholar] [CrossRef] [PubMed]

- Bortolassi, A.C.C.; Guerra, V.G.; Aguiar, M.L.; Soussan, L.; Cornu, D.; Miele, P.; Bechelany, M. Composites based on nanoparticle and pan electrospun nanofiber membranes for air filtration and bacterial removal. Nanomaterials 2019, 9. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Li, M.; Shao, W.; Yue, W.; Hu, B.; Weng, K.; Chen, Y.; Liao, X.; He, J. Preparation of a polyurethane electret nanofiber membrane and its air-filtration performance. J. Colloid Interface Sci. 2019, 557, 318–327. [Google Scholar] [CrossRef]

- Zhu, M.; Hua, D.; Pan, H.; Wang, F.; Manshian, B.; Soenen, S.J.; Xiong, R.; Huang, C. Green electrospun and crosslinked poly(vinyl alcohol)/poly(acrylic acid) composite membranes for antibacterial effective air filtration. J. Colloid Interface Sci. 2018, 511, 411–423. [Google Scholar] [CrossRef]

- Bazbouz, M.B.; Taylor, M.; Baker, D.; Ries, M.E.; Goswami, P. Dry-jet wet electrospinning of native cellulose microfibers with macroporous structures from ionic liquids. J. Appl. Polym. Sci. 2019, 136. [Google Scholar] [CrossRef]

- Kurokawa, N.; Hotta, A. Regenerated cellulose nanofibers fabricated through electrospinning and saponification of cellulose acetate as reinforcement of polylactide composites. Cellulose 2019, 26, 7797–7808. [Google Scholar] [CrossRef]

- Zhang, K.; Li, Z.; Kang, W.; Deng, N.; Yan, J.; Ju, J.; Liu, Y.; Cheng, B. Preparation and characterization of tree-like cellulose nanofiber membranes via the electrospinning method. Carbohydr. Polym. 2018, 183, 62–69. [Google Scholar] [CrossRef]

- Ahne, J.; Li, Q.; Croiset, E.; Tan, Z. Electrospun cellulose acetate nanofibers for airborne nanoparticle filtration. Text. Res. J. 2019, 89, 3137–3149. [Google Scholar] [CrossRef]

- Zhu, M.; Xiong, R.; Huang, C. Bio-based and photocrosslinked electrospun antibacterial nanofibrous membranes for air filtration. Carbohydr. Polym. 2019, 205, 55–62. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Fan, J.; Xu, R.; Zhang, L.; Zhong, S.; Wang, W.; Yu, D. Quaternary ammonium chitosan/polyvinyl alcohol composites prepared by electrospinning with high antibacterial properties and filtration efficiency. J. Mater. Sci. 2019, 54, 12522–12532. [Google Scholar] [CrossRef]

- Huang, X.; Jiao, T.; Liu, Q.; Zhang, L.; Zhou, J.; Li, B.; Peng, Q. Hierarchical electrospun nanofibers treated by solvent vapor annealing as air filtration mat for high-efficiency PM2.5 capture. Sci. China Mater. 2019, 62, 423–436. [Google Scholar] [CrossRef]

- Wang, N.; Cai, M.; Yang, X.; Yang, Y. Electret nanofibrous membrane with enhanced filtration performance and wearing comfortability for face mask. J. Colloid Interface Sci. 2018, 530, 695–703. [Google Scholar] [CrossRef]

- Šišková, A.O.; Frajová, J.; Nosko, M. Recycling of poly(ethylene terephthalate) by electrospinning to enhanced the filtration efficiency. Mater. Lett. 2020, 278, 2–4. [Google Scholar] [CrossRef]

- Huang, C.; Liu, Y.; Li, Z.; Li, R.; Ren, X.; Huang, T.S. N-halamine antibacterial nanofibrous mats based on polyacrylonitrile and N-halamine for protective face masks. J. Eng. Fiber. Fabr. 2019, 14, 1558925019843222. [Google Scholar] [CrossRef]

- Hashmi, M.; Ullah, S.; Kim, I.S. Copper oxide (CuO) loaded polyacrylonitrile (PAN) nanofiber membranes for antimicrobial breath mask applications. Curr. Res. Biotechnol. 2019, 1, 1–10. [Google Scholar] [CrossRef]

- Liu, G.; Nie, J.; Han, C.; Jiang, T.; Yang, Z.; Pang, Y.; Xu, L.; Guo, T.; Bu, T.; Zhang, C.; et al. Self-Powered Electrostatic Adsorption Face Mask Based on a Triboelectric Nanogenerator. ACS Appl. Mater. Interfaces 2018, 10, 7126–7133. [Google Scholar] [CrossRef]

- Tang, Z.; Kong, N.; Zhang, X.; Liu, Y.; Hu, P.; Mou, S.; Liljeström, P.; Shi, J.; Tan, W.; Kim, J.S.; et al. A materials-science perspective on tackling COVID-19. Nat. Rev. Mater. 2020, 5, 847–860. [Google Scholar] [CrossRef]

- Xu, J.; Xiao, X.; Zhang, W.; Xu, R.; Kim, S.C.; Cui, Y.; Howard, T.T.; Wu, E. Air-Filtering Masks for Respiratory Protection from PM2.5 and Pandemic Pathogens. One Earth 2020, 3, 574–589. [Google Scholar] [CrossRef]

- Sivri, Ç. Improvement of protective and comfort properties of face masks using superabsorbent polymer containing nanofibers. Int. J. Cloth. Sci. Technol. 2018, 30, 668–686. [Google Scholar] [CrossRef]

- Ahmed, M.K.; Afifi, M.; Uskoković, V. Protecting healthcare workers during COVID-19 pandemic with nanotechnology: A protocol for a new device from Egypt. J. Infect. Public Health 2020, 13, 1243–1246. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, M.A.; Shuvho, M.B.A.; Shahid, M.A.; Haque, A.K.M.M.; Kashem, M.A.; Lam, S.S.; Ong, H.C.; Uddin, M.A.; Mofijur, M. Prospect of biobased antiviral face mask to limit the coronavirus outbreak. Environ. Res. 2021, 192, 110294. [Google Scholar] [CrossRef]

- He, H.; Gao, M.; Illés, B.; Molnar, K. 3D Printed and electrospun, transparent, hierarchical polylactic acid mask nanoporous filter. Int. J. Bioprinting 2020, 6. [Google Scholar] [CrossRef]

- Khanzada, H.; Salam, A.; Hassan, T.; Munir, M.U.; Pasha, K.; Hassan, N. Fabrication of Promising Antimicrobial Aloe Vera/PVA Electrospun Nanofibers for Protective Clothing. Materials 2020, 13, 3884. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Liu, C.; Hsu, P.C.; Liu, K.; Zhang, R.; Liu, Y.; Cui, Y. Roll-to-Roll Transfer of Electrospun Nanofiber Film for High-Efficiency Transparent Air Filter. Nano Lett. 2016, 16, 1270–1275. [Google Scholar] [CrossRef]

- Cai, R.R.; Zhang, L.Z.; Yu, C.W. Advanced electrospun filters to protect building environments from pollution. Indoor Built Environ. 2019, 28, 147–151. [Google Scholar] [CrossRef]

- Han, K.S.; Lee, S.; Kim, M.; Park, P.; Lee, M.H.; Nah, J. Electrically Activated Ultrathin PVDF-TrFE Air Filter for High-Efficiency PM1.0 Filtration. Adv. Funct. Mater. 2019, 29, 1–7. [Google Scholar] [CrossRef]

- Gobi, N.; Vijayalakshmi, E.; Robert, B.; Srinivasan, N.R. Development of PAN nano fibrous filter hybridized by SiO2 nanoparticles electret for high efficiency air filtration. J. Polym. Mater. 2019, 35, 317–328. [Google Scholar] [CrossRef]

- Rao, C.; Gu, F.; Zhao, P.; Sharmin, N.; Gu, H.; Fu, J. Capturing PM2.5 Emissions from 3D Printing via Nanofiber-based Air Filter. Sci. Rep. 2017, 7, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Cao, M.; Gu, F.; Rao, C.; Fu, J.; Zhao, P. Improving the electrospinning process of fabricating nanofibrous membranes to filter PM2.5. Sci. Total. Environ. 2019, 666, 1011–1021. [Google Scholar] [CrossRef]

- Liang, W.; Xu, Y.; Li, X.; Wang, X.X.; Zhang, H.D.; Yu, M.; Ramakrishna, S.; Long, Y.Z. Transparent Polyurethane Nanofiber Air Filter for High-Efficiency PM2.5 Capture. Nanoscale Res. Lett. 2019, 14. [Google Scholar] [CrossRef] [PubMed]

- Serôdio, R.; Schickert, S.L.; Costa-Pinto, A.R.; Dias, J.R.; Granja, P.L.; Yang, F.; Oliveira, A.L. Ultrasound sonication prior to electrospinning tailors silk fibroin/PEO membranes for periodontal regeneration. Mater. Sci. Eng. C 2019, 98, 969–981. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.-J.; Chen, C.; Zhou, H.; He, J.-H. Fabrication of Latex-based Nanofibers by Electrospinning. Recent Pat. Nanotechnol. 2019, 13, 202–205. [Google Scholar] [CrossRef] [PubMed]

| Spinneret Design | Mechanisms | Refs. |

|---|---|---|

| Bubble | Under the effect of applied electric force and air pressure, polymer jets break the surface tension and are formed from bubbles on the liquid surface, then drawn toward the grounded collector. | [27,28] |

| Wire/coil | There are two ways of solution delivery: jets emerge from droplets formed on the wired spinneret through capillary effect, or splashed out by the rotating spinneret in the solution tank. | [29,30] |

| Disk of plate | Strong electric field is generated on the sharp edges of plate, disk or bowl, and therefore solution jets are formed there. Plates can be stacked into a waterfall composition. | [31,32] |

| Cylindrical | The cylindrical spinneret is either rotating or stationary. The rotating cylinder is first coated with solution, then generates jets under the applied electric field. The stationary cylinder is a vertically set rod, with solution provided by a syringe. | [33] |

| Tube with embedded wire loop | The jets are generated from the wire loop fixed on one end of the tube, with solution fed through the tube. | [25] |

| Sprocket wheel | The pivoting sprocket wheel is half immersed in solution tank. All the teeth dip in the solution and move to the top position, then the solution jets are formed on the edges of the teeth. | [34] |

| Single Needle | Needleless | Multi-Needle | Solvent-Free | |

|---|---|---|---|---|

| Pros |

|

|

|

|

| Cons |

|

|

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, C.; Zhao, P.; Xie, J.; Dong, S.; Liu, J.; Rao, C.; Fu, J. Electrospinning of Nanofibrous Membrane and Its Applications in Air Filtration: A Review. Nanomaterials 2021, 11, 1501. https://doi.org/10.3390/nano11061501

Lyu C, Zhao P, Xie J, Dong S, Liu J, Rao C, Fu J. Electrospinning of Nanofibrous Membrane and Its Applications in Air Filtration: A Review. Nanomaterials. 2021; 11(6):1501. https://doi.org/10.3390/nano11061501

Chicago/Turabian StyleLyu, Chenxin, Peng Zhao, Jun Xie, Shuyuan Dong, Jiawei Liu, Chengchen Rao, and Jianzhong Fu. 2021. "Electrospinning of Nanofibrous Membrane and Its Applications in Air Filtration: A Review" Nanomaterials 11, no. 6: 1501. https://doi.org/10.3390/nano11061501

APA StyleLyu, C., Zhao, P., Xie, J., Dong, S., Liu, J., Rao, C., & Fu, J. (2021). Electrospinning of Nanofibrous Membrane and Its Applications in Air Filtration: A Review. Nanomaterials, 11(6), 1501. https://doi.org/10.3390/nano11061501