Studies of Defect Structure in Epitaxial AlN/GaN Films Grown on (111) 3C-SiC

Abstract

1. Introduction

2. Materials and Methods

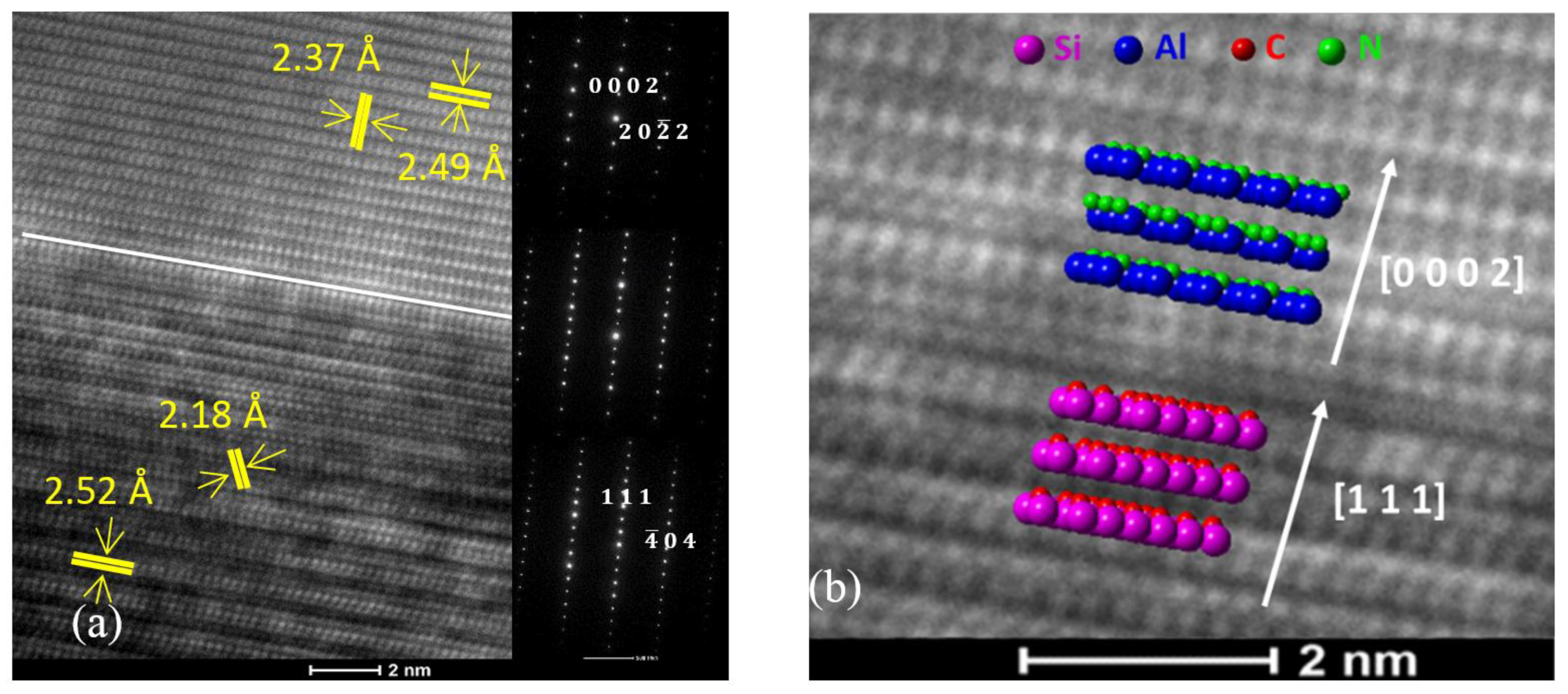

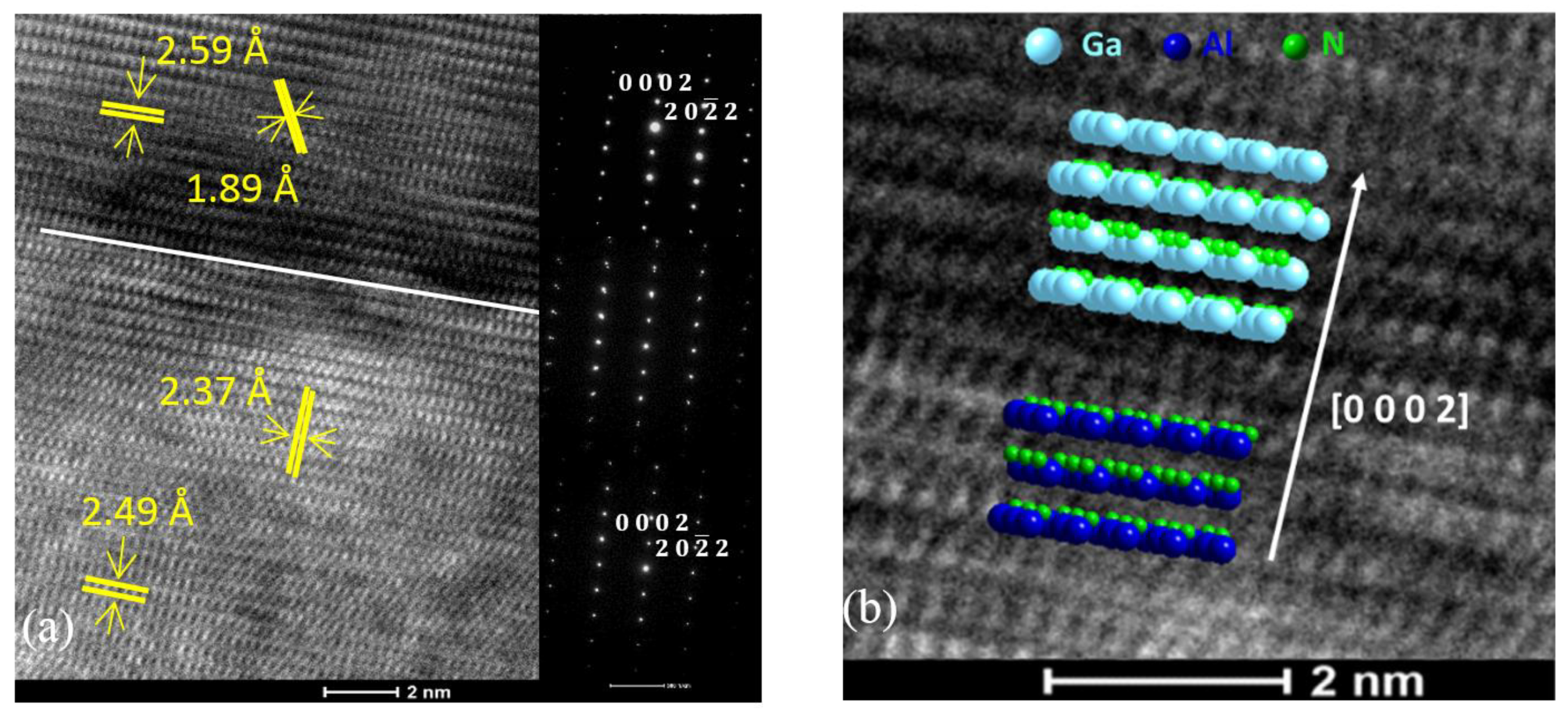

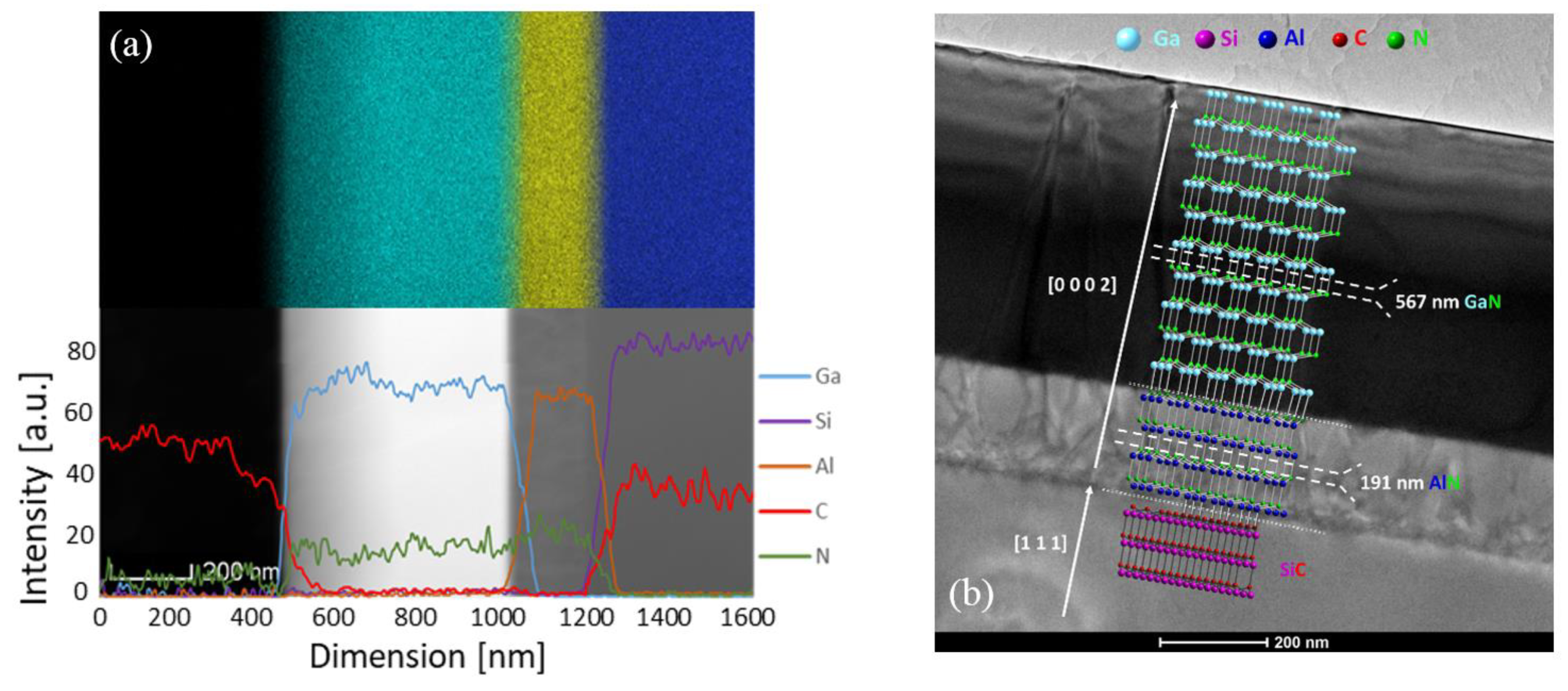

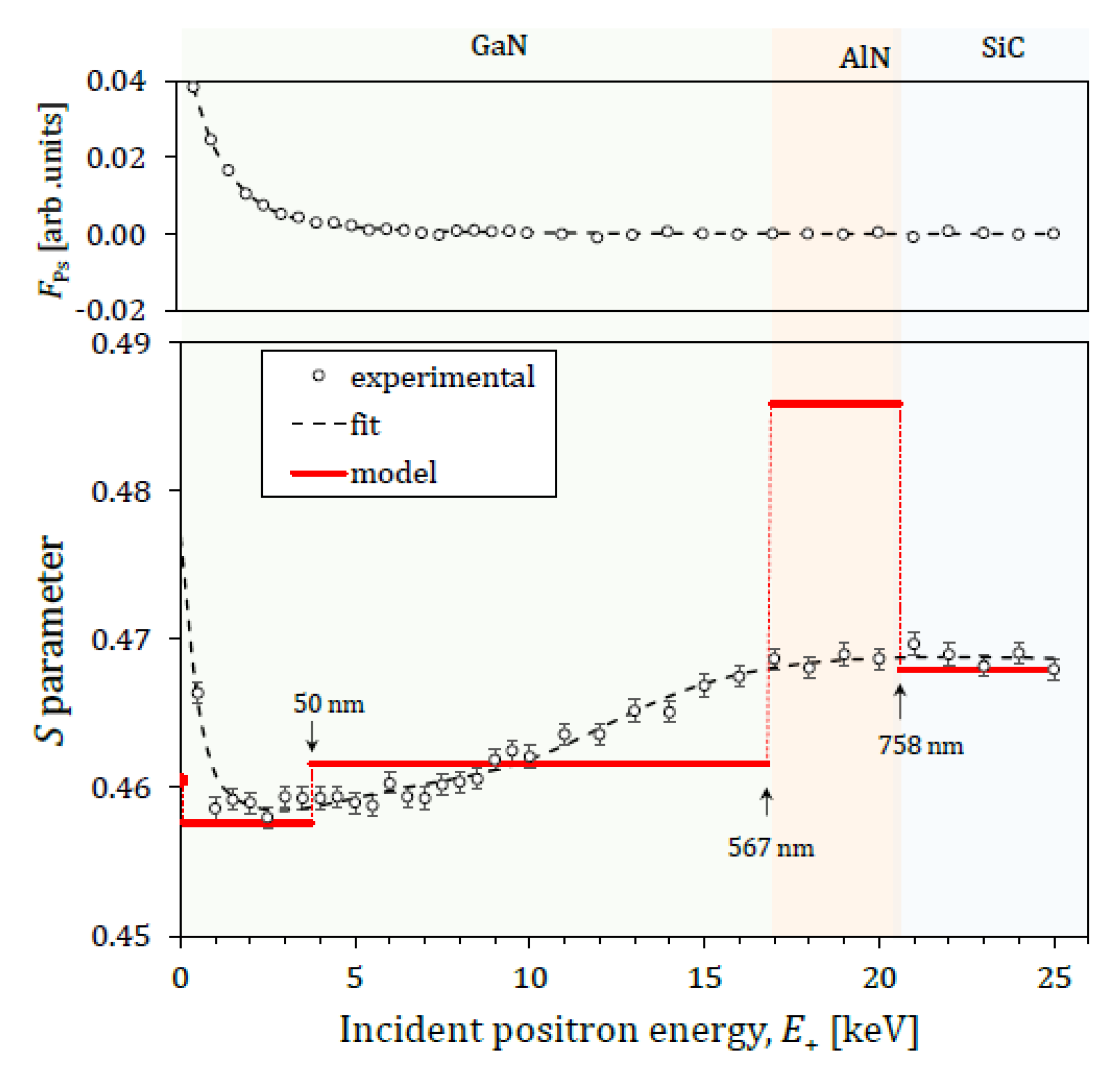

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, H.; Sun, Y.; Lin, D.; Zhang, R.; Zhang, C.; Pan, W. GaN nanofibers based on electrospinning: Facile synthesis, controlled assembly, precise doping, and application as high performance UV photodetector. Adv. Mater. 2009, 21, 227–231. [Google Scholar] [CrossRef]

- Hu, H.; Tang, B.; Wan, H.; Sun, H.; Zhou, S.; Dai, J.; Chen, C.; Liu, S.; Guo, L.J. Boosted ultraviolet electroluminescence of InGaN/AlGaN quantum structures grown on high-index contrast patterned sapphire with silica array. Nano Energy 2020, 69, 104427. [Google Scholar] [CrossRef]

- Hautakangas, S.; Makkonen, I.; Ranki, V.; Puska, M.J.; Saarinen, K.; Look, D.C. Direct evidence of impurity decoration of Ga vacancies in GaN from positron annihilation spectroscopy. Phys. Rev. B 2006, 73, 1–4. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, X.; Yan, H.; Chen, Z.; Liu, Y.; Liu, S. Highly efficient GaN-based high-power flip-chip light-emitting diodes. Opt. Express 2019, 27, A669. [Google Scholar] [CrossRef] [PubMed]

- Liliental-Weber, Z.; Tomaszewicz, T.; Zakharov, D.; Jasinski, J.; O’Keefe, M.A. Atomic structure of defects in GaN:Mg grown with Ga polarity. Phys. Rev. Lett. 2004, 93, 206102. [Google Scholar] [CrossRef]

- Uedono, A.; Sakurai, H.; Narita, T.; Sierakowski, K.; Bockowski, M.; Suda, J.; Ishibashi, S.; Chichibu, S.F.; Kachi, T. Behaviors of vacancy-type defects in Mg-implanted GaN during ultra-high-pressure annealing studied by using a monoenergetic positron beam. In Proceedings of the Gallium Nitride Materials and Devices XVI; Morkoç, H., Fujioka, H., Schwarz, U.T., Eds.; SPIE: Washington, DC, USA, 2021; Volume 11686, p. 48. [Google Scholar]

- Lin, M.E.; Sverdlov, B.; Zhou, G.L.; Morkoç, H. A comparative study of GaN epilayers grown on sapphire and SiC substrates by plasma-assisted molecular-beam epitaxy. Appl. Phys. Lett. 1993, 62, 3479–3481. [Google Scholar] [CrossRef]

- Li, B.; Peng, D.; Li, J.; Kang, L.; Zhang, T.; Zhang, Z.; Jin, S.; Cao, X.; Liu, J.; Wu, L.; et al. Magnetic and structural properties of Fe-implanted GaN at room temperature. Vacuum 2021, 184, 109909. [Google Scholar] [CrossRef]

- Tang, B.; Hu, H.; Wan, H.; Zhao, J.; Gong, L.; Lei, Y.; Zhao, Q.; Zhou, S. Growth of high-quality AlN films on sapphire substrate by introducing voids through growth-mode modification. Appl. Surf. Sci. 2020, 518, 146218. [Google Scholar] [CrossRef]

- Richter, E.; Hennig, C.; Weyers, M.; Habel, F.; Tsay, J.D.; Liu, W.Y.; Brückner, P.; Scholz, F.; Makarov, Y.; Segal, A.; et al. Reactor and growth process optimization for growth of thick GaN layers on sapphire substrates by HVPE. J. Cryst. Growth 2005, 277, 6–12. [Google Scholar] [CrossRef]

- Takeuchi, T.; Amano, H.; Hiramatsu, K.; Sawaki, N.; Akasaki, I. Growth of single crystalline GaN film on Si substrate using 3C-SiC as an intermediate layer. J. Cryst. Growth 1991, 115, 634–638. [Google Scholar] [CrossRef]

- Romanitan, C.; Mihalache, I.; Tutunaru, O.; Pachiu, C. Effect of the lattice mismatch on threading dislocations in heteroepitaxial GaN layers revealed by X-ray diffraction. J. Alloys Compd. 2021, 858, 157723. [Google Scholar] [CrossRef]

- Ene, V.L.; Dinescu, D.; Zai, I.; Djourelov, N.; Vasile, B.S.; Serban, A.B.; Leca, V.; Andronescu, E. Study of Edge and Screw Dislocation Density in GaN/Al2O3 Heterostructure. Materials 2019, 12, 4205. [Google Scholar] [CrossRef] [PubMed]

- Ene, V.-L.; Dinescu, D.; Djourelov, N.; Zai, I.; Vasile, B.S.; Serban, A.B.; Leca, V.; Andronescu, E. Defect Structure Determination of GaN Films in GaN/AlN/Si Heterostructures by HR-TEM, XRD, and Slow Positrons Experiments. Nanomaterials 2020, 10, 197. [Google Scholar] [CrossRef]

- Mu, F.; Cheng, Z.; Shi, J.; Shin, S.; Xu, B.; Shiomi, J.; Graham, S.; Suga, T. High Thermal Boundary Conductance across Bonded Heterogeneous GaN–SiC Interfaces. ACS Appl. Mater. Interfaces 2019, 11, 33428–33434. [Google Scholar] [CrossRef]

- Saha, S.; Kumar, D.; Sharma, C.K.; Singh, V.K.; Channagiri, S.; Sridhara Rao, D.V. Microstructural Characterization of GaN Grown on SiC. Microsc. Microanal. 2019, 25, 1–11. [Google Scholar] [CrossRef]

- Kukushkin, S.A.; Osipov, A.V.; Bessolov, V.N.; Medvedev, B.K.; Nevolin, V.K.; Tcarik, K.A. Substrates for epitaxy of Gallium Nitride:new materials and techniques. Rev. Adv. Mater. Sci. 2008, 17, 1–32. [Google Scholar]

- Liu, L.; Edgar, J.H. Substrates for gallium nitride epitaxy. Mater. Sci. Eng. R Rep. 2002, 37, 61–127. [Google Scholar] [CrossRef]

- Davis, R.F.; Bishop, S.M.; Mita, S.; Collazo, R.; Reitmeier, Z.J.; Sitar, Z. Epitaxial Growth of Gallium Nitride; AIP: New York, NY, USA, 2007; Volume 916, pp. 520–540. [Google Scholar]

- Fritze, S.; Drechsel, P.; Stauss, P.; Rode, P.; Markurt, T.; Schulz, T.; Albrecht, M.; Blsing, J.; Dadgar, A.; Krost, A. Role of low-temperature AlGaN interlayers in thick GaN on silicon by metalorganic vapor phase epitaxy. J. Appl. Phys. 2012, 111, 124505. [Google Scholar] [CrossRef]

- Peng, C.X.; Weng, H.M.; Zhu, C.F.; Ye, B.J.; Zhou, X.Y.; Han, R.D.; Fong, W.K.; Surya, C. Influence of GaN polarity and intermediate-temperature buffer layers on strain relaxation and defects. Phys. B Condens. Matter 2007, 391, 6–11. [Google Scholar] [CrossRef]

- Jarndal, A.; Arivazhagan, L.; Nirmal, D. On the performance of GaN-on-Silicon, Silicon-Carbide, and Diamond substrates. Int. J. RF Microw. Comput. Eng. 2020, 30, e22196. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Palmer, D.C. CrystalMaker; Begbroke: Oxfordshire, UK, 2014. [Google Scholar]

- Lahrèche, H.; Vennéguès, P.; Tottereau, O.; Laügt, M.; Lorenzini, P.; Leroux, M.; Beaumont, B.; Gibart, P. Optimisation of AlN and GaN growth by metalorganic vapour-phase epitaxy (MOVPE) on Si(111). J. Cryst. Growth 2000, 217, 13–25. [Google Scholar] [CrossRef]

- Kaganer, V.M.; Brandt, O.; Trampert, A.; Ploog, K.H. X-ray diffraction peak profiles from threading dislocations in GaN epitaxial films. Phys. Rev. B Condens. Matter Mater. Phys. 2005, 72, 045423. [Google Scholar] [CrossRef]

- Romanitan, C.; Gavrila, R.; Danila, M. Comparative study of threading dislocations in GaN epitaxial layers by nondestructive methods. Mater. Sci. Semicond. Process. 2017, 57, 32–38. [Google Scholar] [CrossRef]

- GREEN, J.; LEE, J. Positrons in Solids. In Positronium Chemistry; Hautojärvi, P., Ed.; Topics in Current Physics; Springer: Berlin/Heidelberg, Germany, 1964; Volume 12, pp. 35–42. ISBN 978-3-642-81318-4. [Google Scholar]

- Uedono, A.; Ishibashi, S.; Oshima, N.; Suzuki, R. Positron annihilation spectroscopy on nitride-based semiconductors. Jpn. J. Appl. Phys. 2013, 52, 08JJ02. [Google Scholar] [CrossRef]

- Uedono, A.; Ishibashi, S.; Ohdaira, T.; Suzuki, R. Point defects in group-III nitride semiconductors studied by positron annihilation. J. Cryst. Growth 2009, 311, 3075–3079. [Google Scholar] [CrossRef]

- Van Veen, A.; Schut, H.; de Vries, J.; Hakvoort, R.A.; Ijpma, M.R. Analysis of positron profiling data by means of “VEPFIT”. AIP Conf. Proc. 1991, 218, 171–198. [Google Scholar]

- Uedono, A.; Itoh, H.; Ohshima, T.; Aoki, Y.; Yoshikawa, M.; Nashiyama, I.; Okumura, H.; Yoshida, S.; Moriya, T.; Kawano, T.; et al. Defects in ion-implanted 3C-SiC probed by a monoenergetic positron beam. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 1996, 35, 5986–5990. [Google Scholar] [CrossRef]

- Krause-Rehberg, R.; Leipner, H.S. Positron Annihilation in Semiconductors-Defect Studies, 1st ed.; Springer: Berlin/Heidelberg, Germany, 1999; ISBN 978-3-540-64371-5. [Google Scholar]

| Sample | GaN/SiC | S | χ2 = 1.18 |

|---|---|---|---|

| Layer/Sublayer | Leff [nm] | d [nm] | |

| GaN1 GaN2 | 13.0 ± 0.4 75 ± 20 | 0.4576 ± 0.0004 0.4615 ± 0.0004 | 50 517 |

| AlN | 25 ± 18 | 0.4813 ± 0.0027 | 191 |

| SiC | 184 | 0.4680 ± 0.0008 | - |

| Sample | dGaN [nm] | L [nm] | Leff [nm] | ||||

|---|---|---|---|---|---|---|---|

| GaN1 | GaN2 | ||||||

| GaN/Al2O3 [18] | 189 | 7.49 × 1010 | 36 | 155 | 229 | 12.4 ± 0.4 | 56 ± 4 |

| GaN300/Si [17] | 350 | 4.37 × 1011 | 15 | 27 | 107 | 14.3 ± 0.5 | 22 ± 6 |

| GaN700/Si [17] | 690 | 2.35 × 1011 | 21 | 41 | 220 | 13.1 ± 0.4 | 43 ± 6 |

| GaN/SiC | 567 | 1.47 × 1010 | 82 | 171 | 288 | 13.0 ± 0.4 | 78 ± 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serban, A.B.; Ene, V.L.; Dinescu, D.; Zai, I.; Djourelov, N.; Vasile, B.S.; Leca, V. Studies of Defect Structure in Epitaxial AlN/GaN Films Grown on (111) 3C-SiC. Nanomaterials 2021, 11, 1299. https://doi.org/10.3390/nano11051299

Serban AB, Ene VL, Dinescu D, Zai I, Djourelov N, Vasile BS, Leca V. Studies of Defect Structure in Epitaxial AlN/GaN Films Grown on (111) 3C-SiC. Nanomaterials. 2021; 11(5):1299. https://doi.org/10.3390/nano11051299

Chicago/Turabian StyleSerban, Andreea Bianca, Vladimir Lucian Ene, Doru Dinescu, Iulia Zai, Nikolay Djourelov, Bogdan Stefan Vasile, and Victor Leca. 2021. "Studies of Defect Structure in Epitaxial AlN/GaN Films Grown on (111) 3C-SiC" Nanomaterials 11, no. 5: 1299. https://doi.org/10.3390/nano11051299

APA StyleSerban, A. B., Ene, V. L., Dinescu, D., Zai, I., Djourelov, N., Vasile, B. S., & Leca, V. (2021). Studies of Defect Structure in Epitaxial AlN/GaN Films Grown on (111) 3C-SiC. Nanomaterials, 11(5), 1299. https://doi.org/10.3390/nano11051299