High-Frequency Magnetoimpedance (MI) and Stress-MI in Amorphous Microwires with Different Anisotropies

Abstract

1. Introduction

2. Materials and Methods

2.1. Wire Samples

2.2. DC Magnetic Measurements

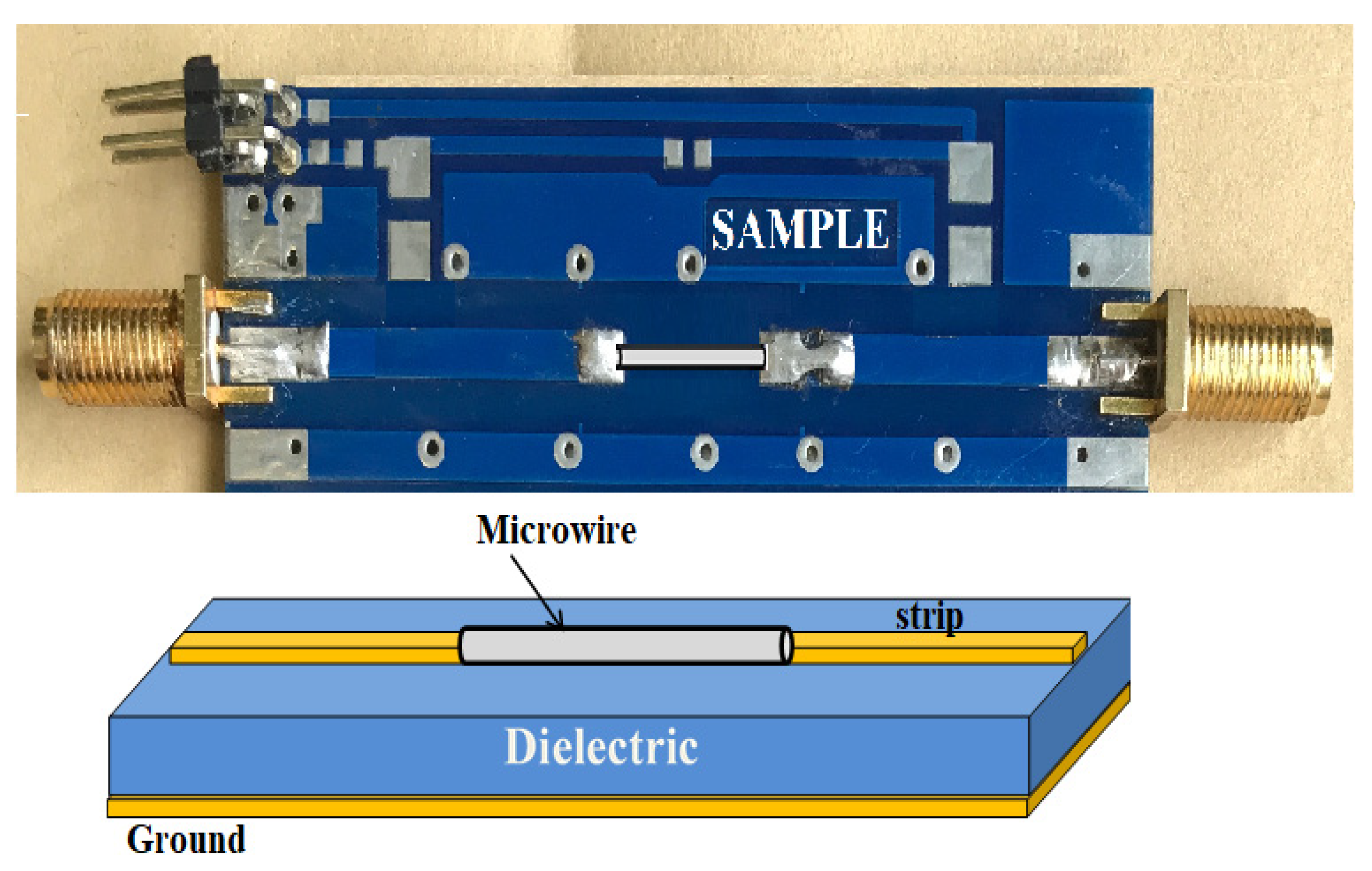

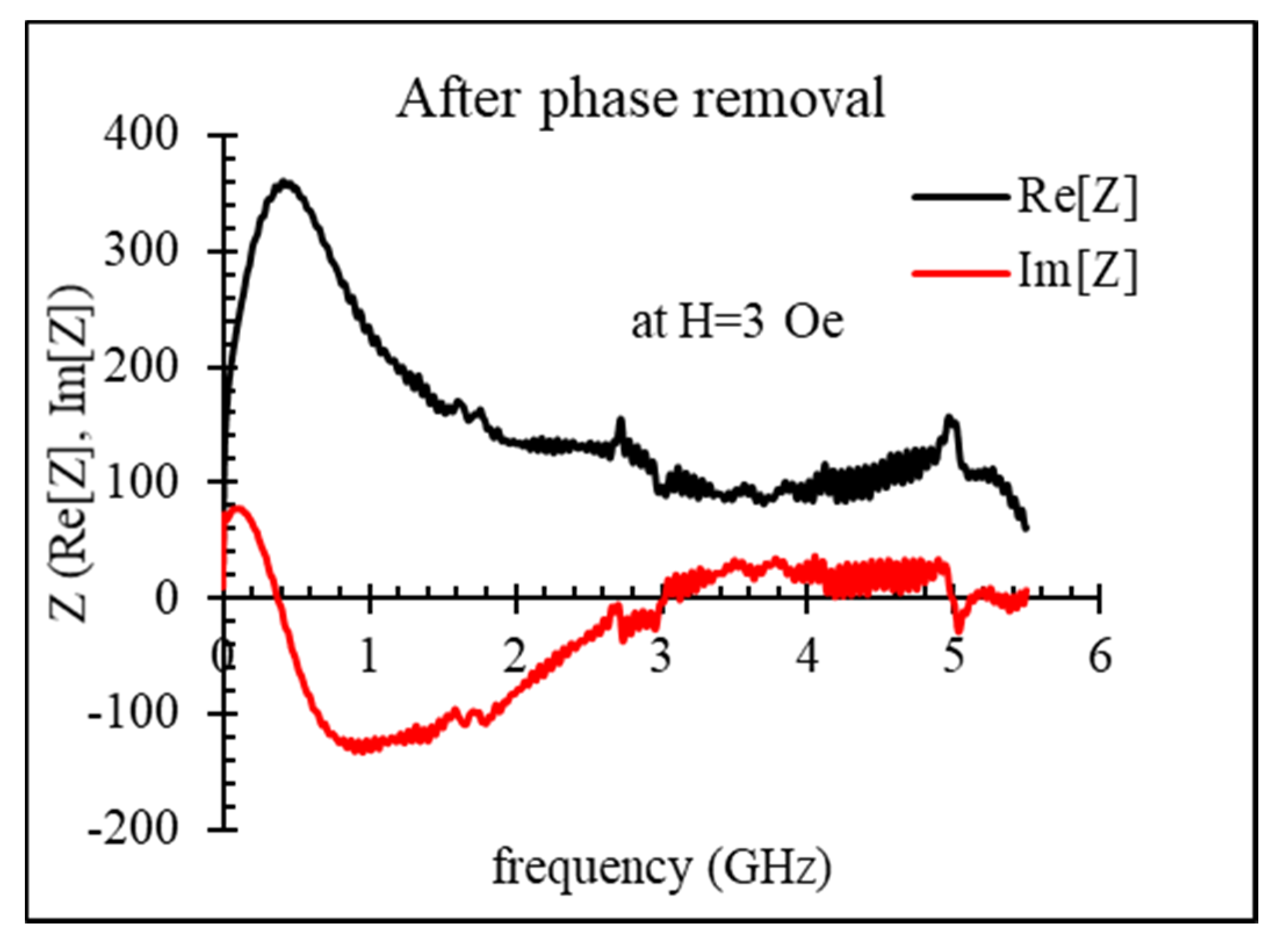

2.3. Impedance Measurements

3. Results and Discussions

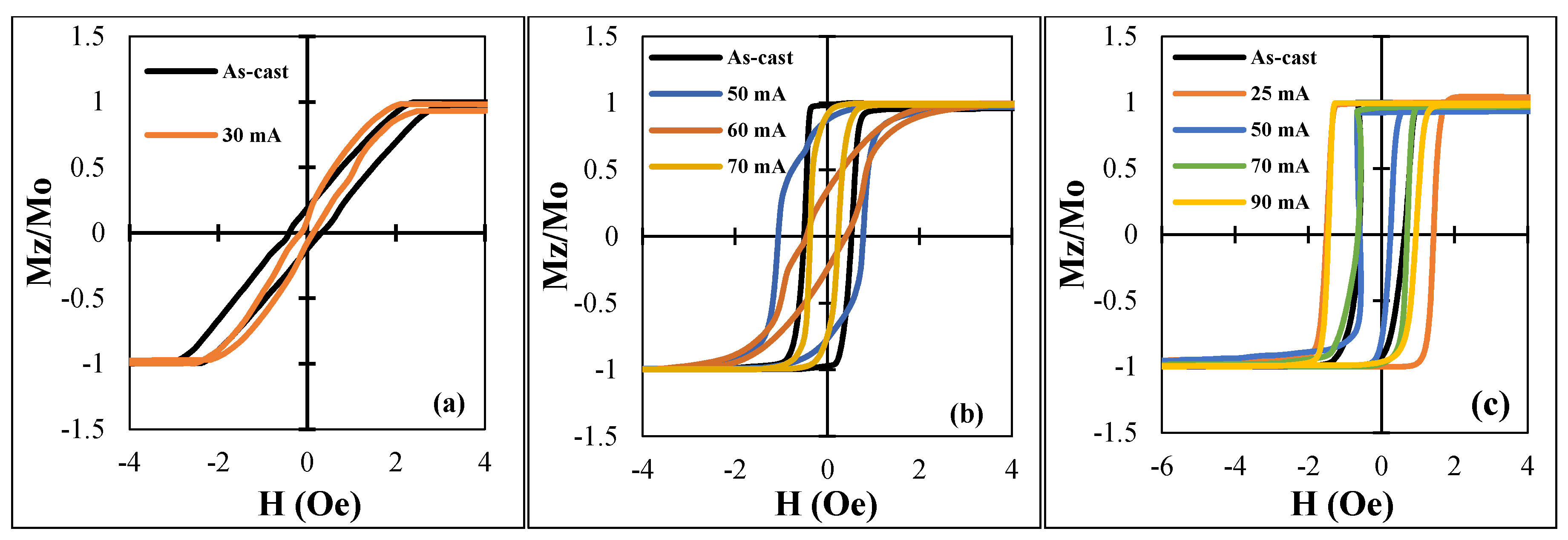

3.1. DC Properties

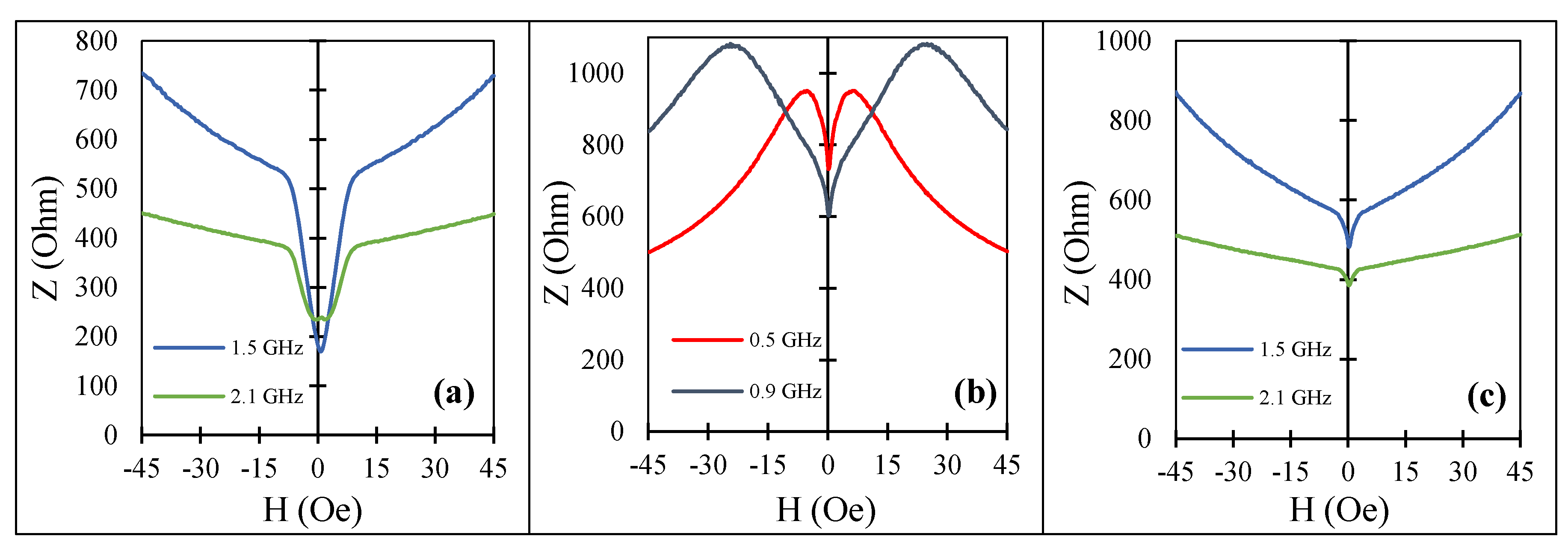

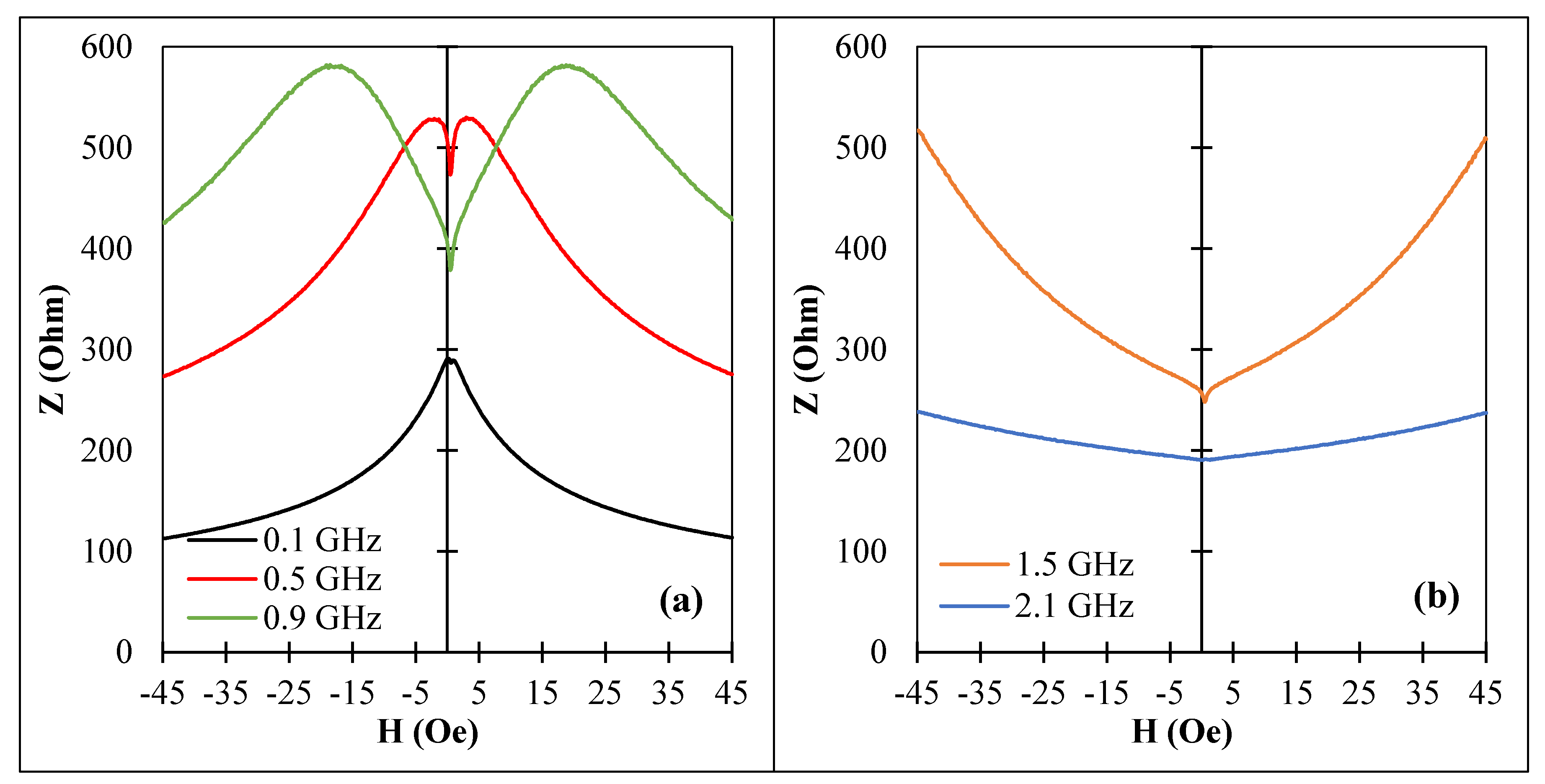

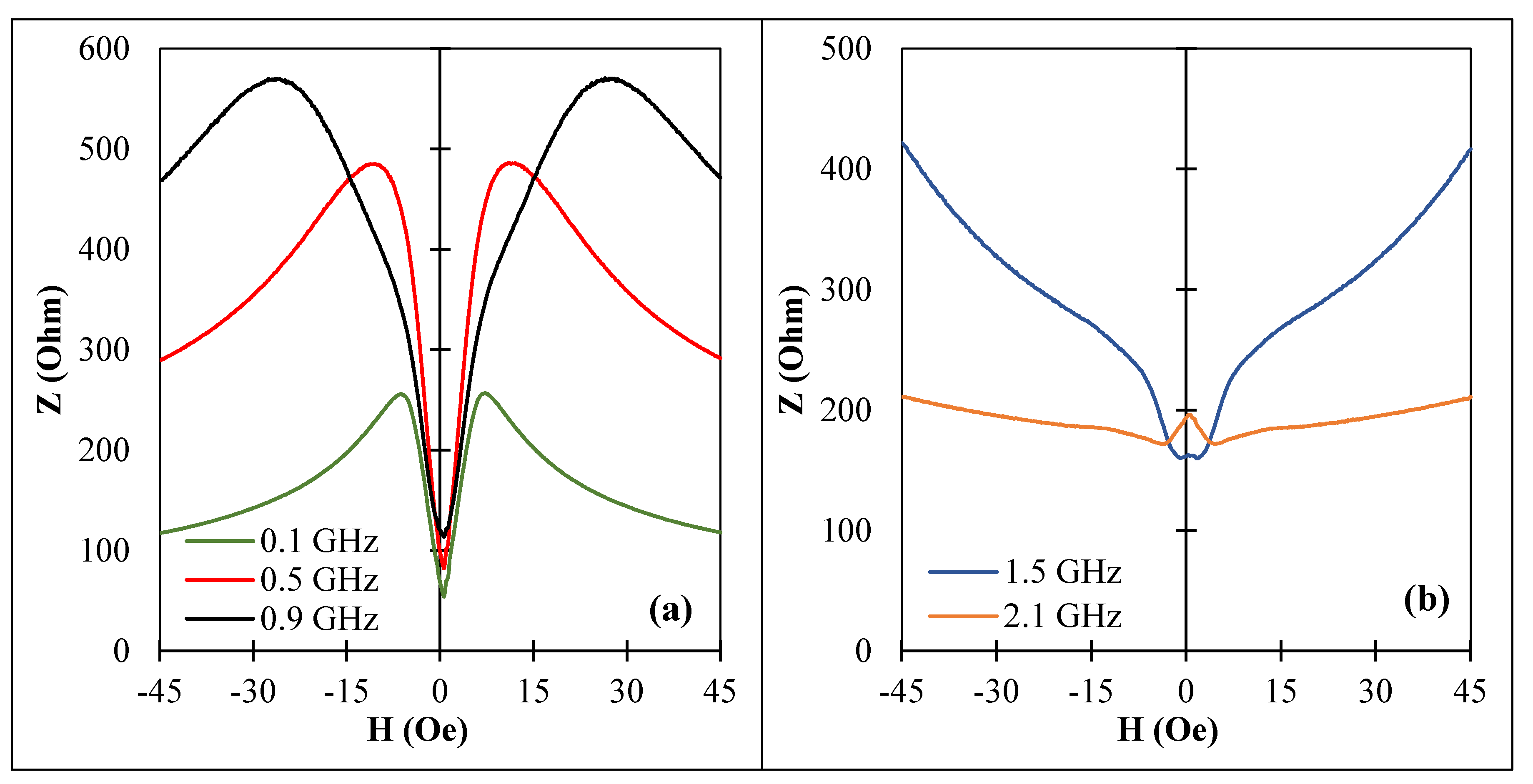

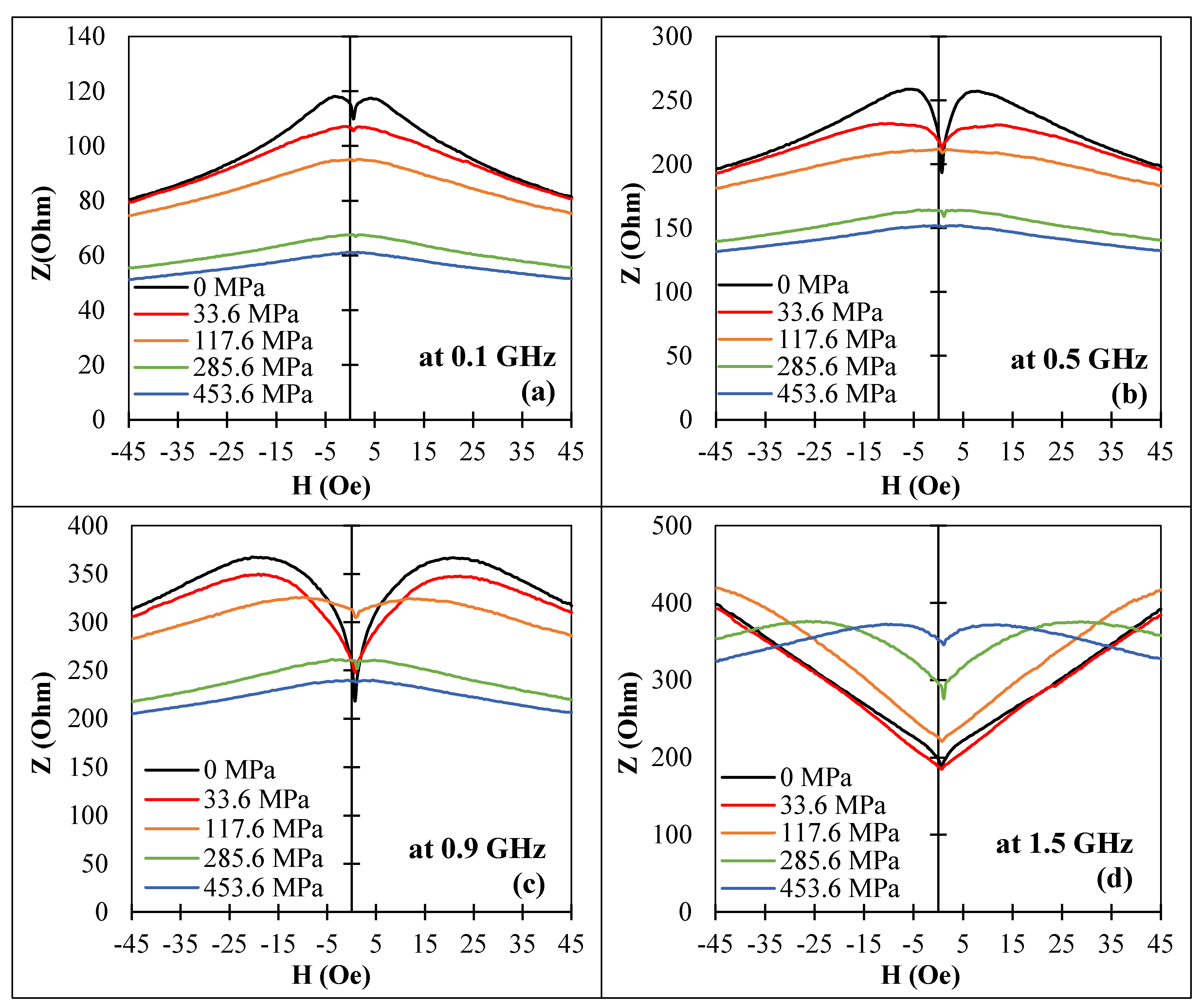

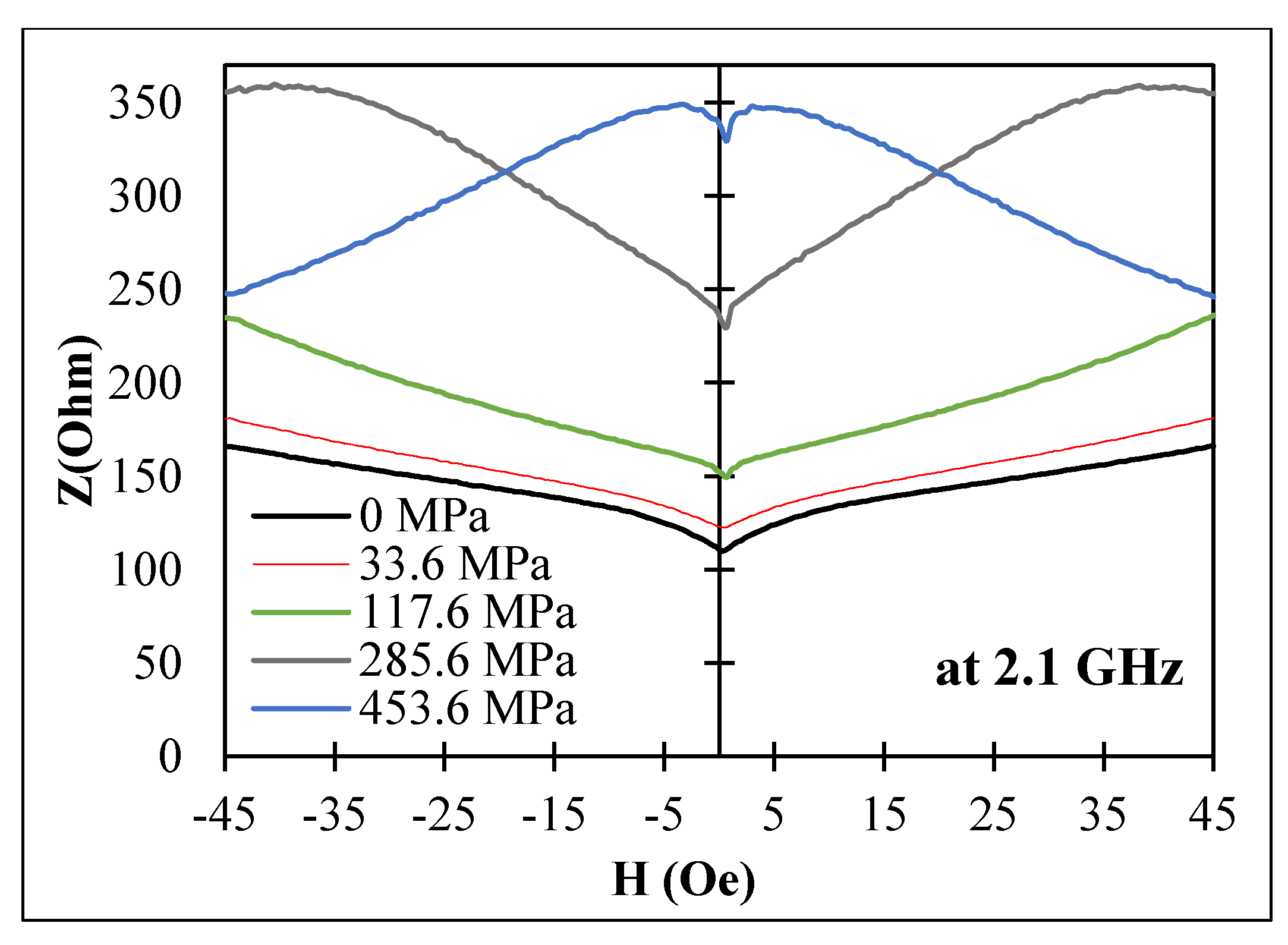

3.2. Impedance vs. Field at High Frequencies

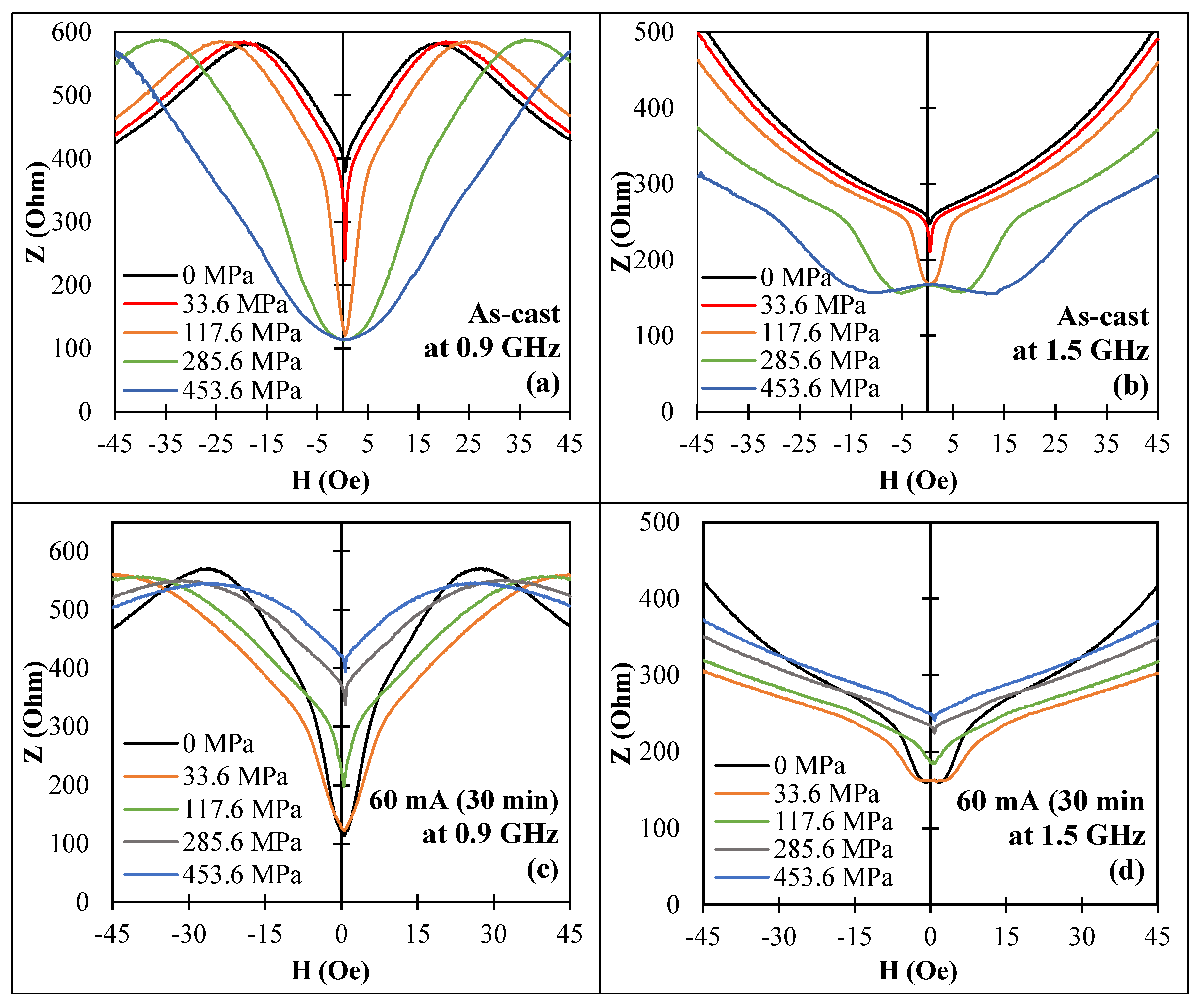

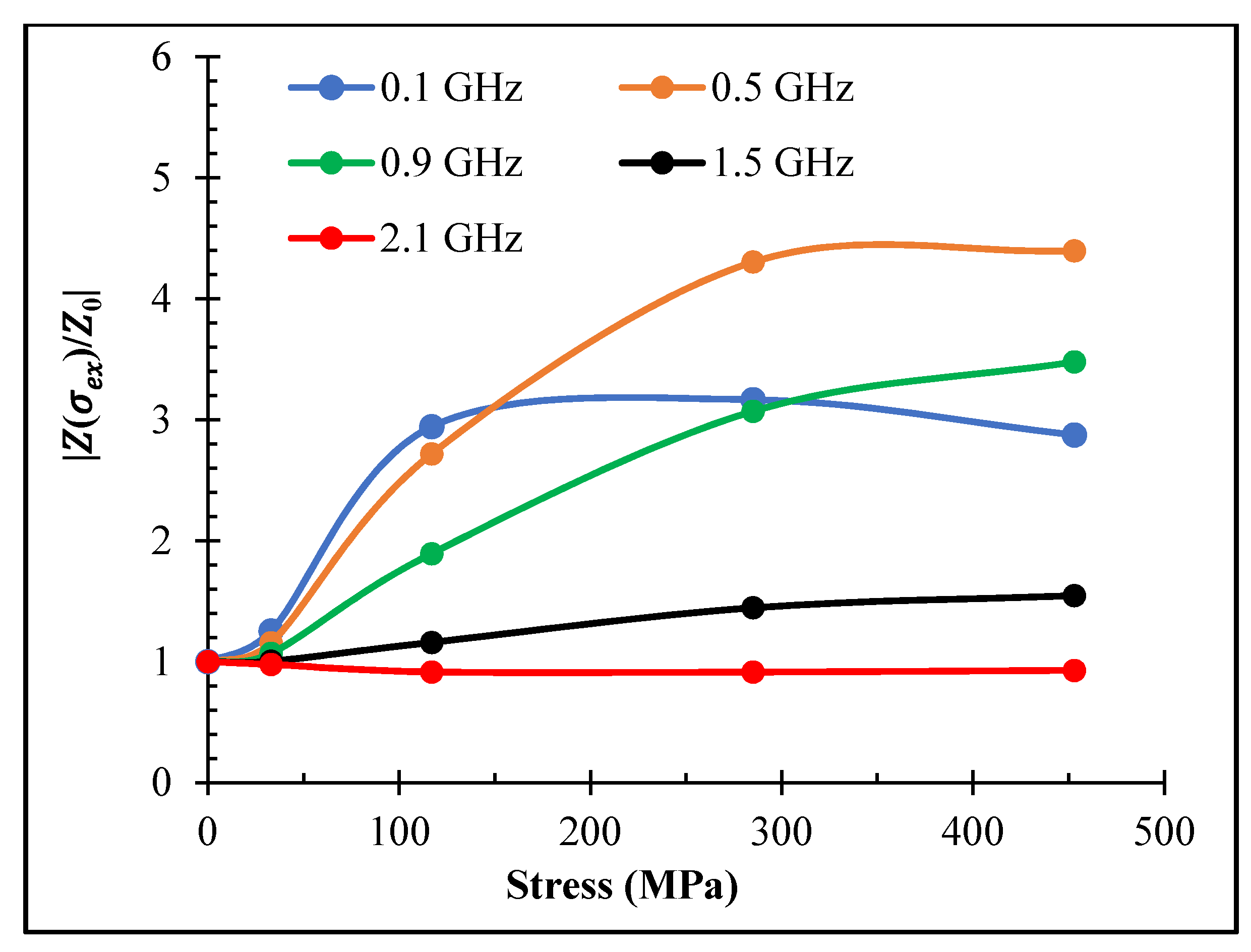

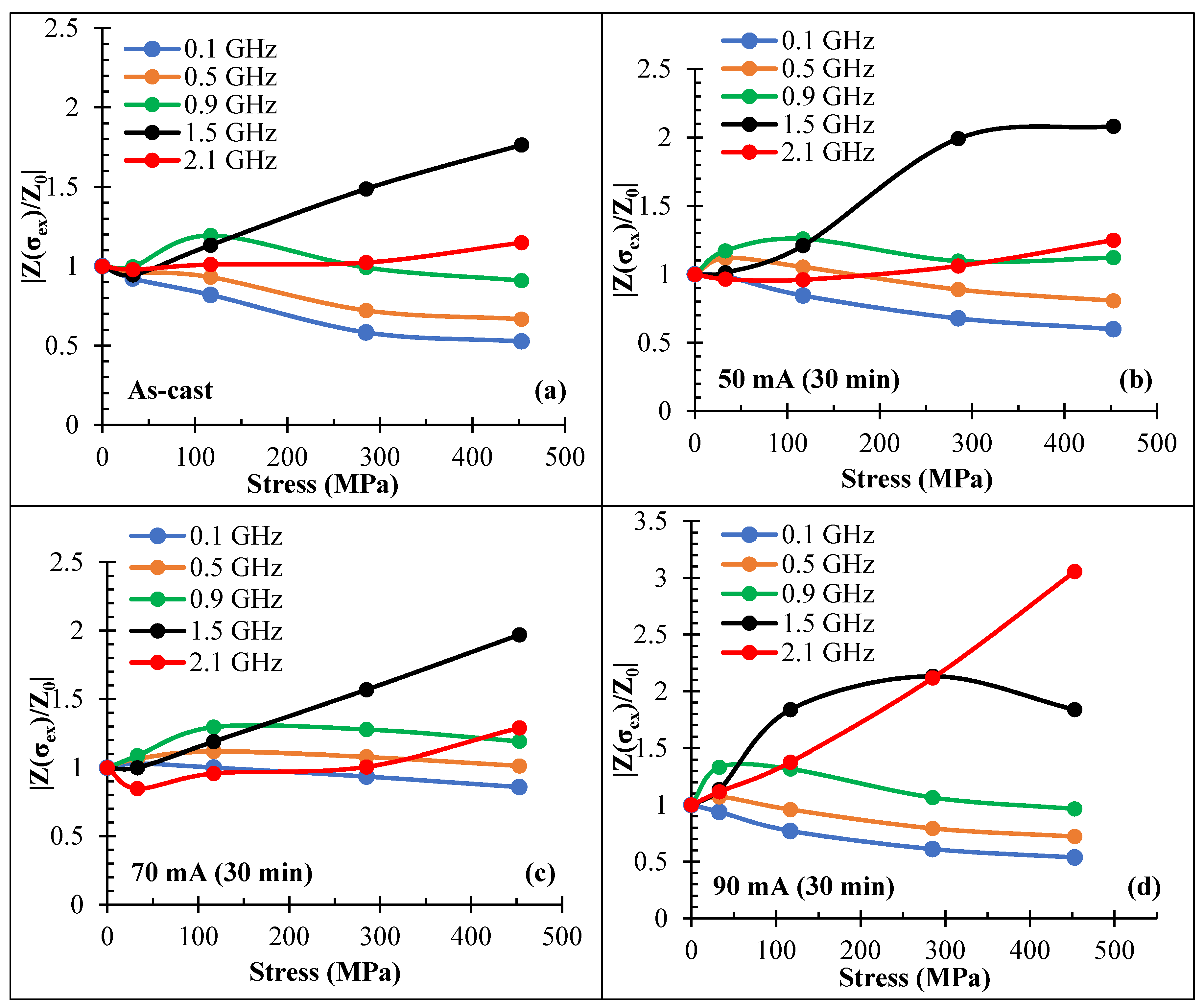

3.3. Effect of Tensile Stress on Impedance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vázquez, M.; Chiriac, H.; Zhukov, A.; Panina, L.; Uchiyama, T. On the state-of-the-art in magnetic microwires and expected trends for scientific and technological studies. Phys. Status Solidi Appl. Mater. Sci. 2011. [Google Scholar] [CrossRef]

- Zhukova, V.; Corte-Leon, P.; González-Legarreta, L.; Talaat, A.; Blanco, J.M.; Ipatov, M.; Olivera, J.; Zhukov, A. Review of Domain Wall Dynamics Engineering in Magnetic Microwires. Nanomaterials 2020, 10, 2407. [Google Scholar] [CrossRef]

- Alam, J.; Bran, C.; Chiriac, H.; Lupu, N.; Óvári, T.A.; Panina, L.V.; Rodionova, V.; Varga, R.; Vazquez, M.; Zhukov, A. Cylindrical micro and nanowires: Fabrication, properties and applications. J. Magn. Magn. Mater. 2020. [Google Scholar] [CrossRef]

- Baca, A.J.; Ahn, J.H.; Sun, Y.; Meitl, M.A.; Menard, E.; Kim, H.S.; Choi, W.M.; Kim, D.H.; Huang, Y.; Rogers, J.A. Semiconductor wires and ribbons for high-performance flexible electronics. Angew. Chem. Int. Ed. 2008. [Google Scholar] [CrossRef]

- Moya, A.; Archilla, D.; Navarro, E.; Hernando, A.; Marín, P. Scattering of microwaves by a passive array antenna based on amorphous ferromagnetic microwires for wireless sensors with biomedical applications. Sensors 2019, 19, 3060. [Google Scholar] [CrossRef]

- Qin, F.; Peng, H.X. Ferromagnetic microwires enabled multifunctional composite materials. Prog. Mater. Sci. 2013. [Google Scholar] [CrossRef]

- Mohri, K.; Uchiyama, T.; Shen, L.P.; Cai, C.M.; Panina, L.V. Amorphous wire and CMOS IC-based sensitive micro magnetic sensors (MI sensor and SI sensor) for intelligent measurements and controls. J. Magn. Magn. Mater. 2002. [Google Scholar] [CrossRef]

- Gudoshnikov, S.; Usov, N.; Nozdrin, A.; Ipatov, M.; Zhukov, A.; Zhukova, V. Highly sensitive magnetometer based on the off-diagonal GMI effect in Co-rich glass-coated microwire. Phys. Status Solidi Appl. Mater. Sci. 2014. [Google Scholar] [CrossRef]

- Dolabdjian, C.; Ménard, D. Giant magneto-impedance (GMI) magnetometers. In Smart Sensors, Measurement and Instrumentation; Springer: Cham, Switzarland, 2017. [Google Scholar] [CrossRef]

- Uchiyama, T.; Takiya, T. Development of precise off-diagonal magnetoimpedance gradiometer for magnetocardiography. AIP Adv. 2017. [Google Scholar] [CrossRef]

- Zhukova, V.; Corte-Leon, P.; Ipatov, M.; Blanco, J.M.; Gonzalez-Legarreta, L.; Zhukov, A. Development of magnetic microwires for magnetic sensor applications. Sensors 2019, 19, 4767. [Google Scholar] [CrossRef] [PubMed]

- Makhnovskiy, D.P.; Panina, L.V.; Mapps, D.J. Field-dependent surface impedance tensor in amorphous wires with two types of magnetic anisotropy: Helical and circumferential. Phys. Rev. B Condens. Matter Mater. Phys. 2001. [Google Scholar] [CrossRef]

- Panina, L.V.; Makhnovskiy, D.P.; Morchenko, A.T.; Kostishin, V.G. Tunable permeability of magnetic wires at microwaves. J. Magn. Magn. Mater. 2015. [Google Scholar] [CrossRef]

- Ciureanu, P.; Britel, M.; Ménard, D.; Yelon, A.; Akyel, C.; Rouabhi, M.; Cochrane, R.W.; Rudkowski, P.; Ström-Olsen, J.O. High frequency behavior of soft magnetic wires using the giant magnetoimpedance effect. J. Appl. Phys. 1998, 83, 6563–6565. [Google Scholar] [CrossRef]

- Da Silva, R.B.; De Andrade, A.M.H.; Severino, A.M.; Schelp, L.F.; Sommer, R.L. Giant magnetoimpedance in glass-covered amorphous microwires at microwave frequencies. J. Appl. Phys. 2002. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Y.; Estevez, D.; Qin, F.; Wang, H.; Zheng, X.; Makhnovskiy, D.; Peng, H. Novel broadband measurement technique on PCB cells for the field- And stress-dependent impedance in ferromagnetic wires. Meas. Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Kraus, L.; Knobel, M.; Kane, S.N.; Chiriac, H. Influence of Joule heating on magnetostriction and giant magnetoimpedance effect in a glass covered CoFeSiB microwire. J. Appl. Phys. 1999. [Google Scholar] [CrossRef]

- Liu, J.S.; Cao, F.Y.; Xing, D.W.; Zhang, L.Y.; Qin, F.X.; Peng, H.X.; Xue, X.; Sun, J.F. Enhancing GMI properties of melt-extracted Co-based amorphous wires by twin-zone Joule annealing. J. Alloys Compd. 2012. [Google Scholar] [CrossRef]

- Zhukov, A.; Talaat, A.; Ipatov, M.; Blanco, J.M.; Zhukova, V. Tailoring of magnetic properties and GMI effect of Co-rich amorphous microwires by heat treatment. J. Alloys Compd. 2014. [Google Scholar] [CrossRef]

- Thiabgoh, O.; Shen, H.; Eggers, T.; Galati, A.; Jiang, S.; Liu, J.S.; Li, Z.; Sun, J.F.; Srikanth, H.; Phan, M.H. Enhanced high-frequency magneto-impedance response of melt-extracted Co69.25Fe4.25Si13B13.5 microwires subject to Joule annealing. J. Sci. Adv. Mater. Devices 2016. [Google Scholar] [CrossRef]

- Nematov, M.G.; Baraban, I.; Yudanov, N.A.; Rodionova, V.; Qin, F.X.; Peng, H.X.; Panina, L.V. Evolution of the magnetic anisotropy and magnetostriction in Co-based amorphous alloys microwires due to current annealing and stress-sensory applications. J. Alloys Compd. 2020. [Google Scholar] [CrossRef]

- Panina, L.V.; Sandacci, S.I.; Makhnovskiy, D.P. Stress effect on magnetoimpedance in amorphous wires at gigahertz frequencies and application to stress-tunable microwave composite materials. J. Appl. Phys. 2005. [Google Scholar] [CrossRef]

- Adenot, A.L.; Acher, O.; Pain, D.; Duverger, F.; Malliavin, M.J.; Damiani, D.; Taffary, T. Broadband permeability measurement of ferromagnetic thin films or microwires by a coaxial line perturbation method. J. Appl. Phys. 2000. [Google Scholar] [CrossRef]

- Melo, L.G.C.; Ciureanu, P.; Yelon, A. Permeability deduced from impedance measurements at microwave frequencies. J. Magn. Magn. Mater. 2002. [Google Scholar] [CrossRef]

- Rumiantsev, A.; Ridler, N. VNA calibration. IEEE Microw. Mag. 2008. [Google Scholar] [CrossRef]

- Kilinc, M.; Garcia, C.; Eginligil, M.; Wang, J.; Huang, W. De-embedding zero-field signal in high-frequency magneto-impedance measurements of soft ferromagnetic materials. J. Magn. Magn. Mater. 2019. [Google Scholar] [CrossRef]

- Chiriac, H.; Corodeanu, S.; Lostun, M.; Stoian, G.; Ababei, G.; Óvári, T.A. Rapidly solidified amorphous nanowires. J. Appl. Phys. 2011. [Google Scholar] [CrossRef]

- Baranov, S.A.; Larin, V.S.; Torcunov, A.V. Technology, preparation and properties of the cast glass-coated magnetic microwires. Crystals 2017, 7, 136. [Google Scholar] [CrossRef]

- Nematov, M.G.; Salem, M.M.; Adam, A.M.; Ahmad, M.; Yudanov, N.A.; Panina, L.V.; Morchenko, A.T. Effect of Stress on Magnetic Properties of Annealed Glass-Coated Co71Fe5B11Si10Cr3 Amorphous Microwires. IEEE Trans. Magn. 2017. [Google Scholar] [CrossRef]

- Dzhumazoda, A.; Panina, L.V.; Nematov, M.G.; Ukhasov, A.A.; Yudanov, N.A.; Morchenko, A.T.; Qin, F.X. Temperature-stable magnetoimpedance (MI) of current-annealed Co-based amorphous microwires. J. Magn. Magn. Mater. 2019. [Google Scholar] [CrossRef]

- Zhukov, A.; Churyukanova, M.; Kaloshkin, S.; Sudarchikova, V.; Gudoshnikov, S.; Ipatov, M.; Talaat, A.; Blanco, J.M.; Zhukova, V. Magnetostriction of Co-Fe-based amorphous soft magnetic microwires. In Energy Technology 2015: Carbon Dioxide Management and Other Technologies; Springer: Cham, Switzarland, 2016. [Google Scholar] [CrossRef]

- Kostitsyna, E.V.; Gudoshnikov, S.A.; Popova, A.V.; Petrzhik, M.I.; Tarasov, V.P.; Usov, N.A.; Ignatov, A.S. Mechanical properties and internal quenching stresses in Co-rich amorphous ferromagnetic microwires. J. Alloys Compd. 2017. [Google Scholar] [CrossRef]

- Fitzpatrick, J. Error models for system measurement. Microw. J. 1978, 21, 63–66. [Google Scholar]

- Salem, M.M.; Nematov, M.G.; Uddin, A.; Panina, L.V.; Churyukanova, M.N.; Marchenko, A.T. CoFe-microwires with stress-dependent magnetostriction as embedded sensing elements. J. Phys. Conf. Ser. 2017. [Google Scholar] [CrossRef]

- Herzer, G. Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 2013. [Google Scholar] [CrossRef]

- Vázquez, M.; González, J.; Hernando, A. Induced magnetic anisotropy and change of the magnetostriction by current annealing in Co-based amorphous alloys. J. Magn. Magn. Mater. 1986. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alam, J.; Nematov, M.; Yudanov, N.; Podgornaya, S.; Panina, L. High-Frequency Magnetoimpedance (MI) and Stress-MI in Amorphous Microwires with Different Anisotropies. Nanomaterials 2021, 11, 1208. https://doi.org/10.3390/nano11051208

Alam J, Nematov M, Yudanov N, Podgornaya S, Panina L. High-Frequency Magnetoimpedance (MI) and Stress-MI in Amorphous Microwires with Different Anisotropies. Nanomaterials. 2021; 11(5):1208. https://doi.org/10.3390/nano11051208

Chicago/Turabian StyleAlam, Junaid, Makhsudsho Nematov, Nikolay Yudanov, Svetlana Podgornaya, and Larissa Panina. 2021. "High-Frequency Magnetoimpedance (MI) and Stress-MI in Amorphous Microwires with Different Anisotropies" Nanomaterials 11, no. 5: 1208. https://doi.org/10.3390/nano11051208

APA StyleAlam, J., Nematov, M., Yudanov, N., Podgornaya, S., & Panina, L. (2021). High-Frequency Magnetoimpedance (MI) and Stress-MI in Amorphous Microwires with Different Anisotropies. Nanomaterials, 11(5), 1208. https://doi.org/10.3390/nano11051208