Activated Carbon Blended with Reduced Graphene Oxide Nanoflakes for Capacitive Deionization

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

2.2.1. Graphene Oxide Synthesis

2.2.2. Reduced Graphene Oxide Synthesis

2.2.3. Fabrication of Activated Carbon and AC/RGO-x Electrodes

2.3. Physical Characterization

2.3.1. UV–VIS Spectrophotometry Measurement

2.3.2. FTIR Measurement

2.3.3. Electron Mobility Measurement

2.4. Electrochemical Characterization

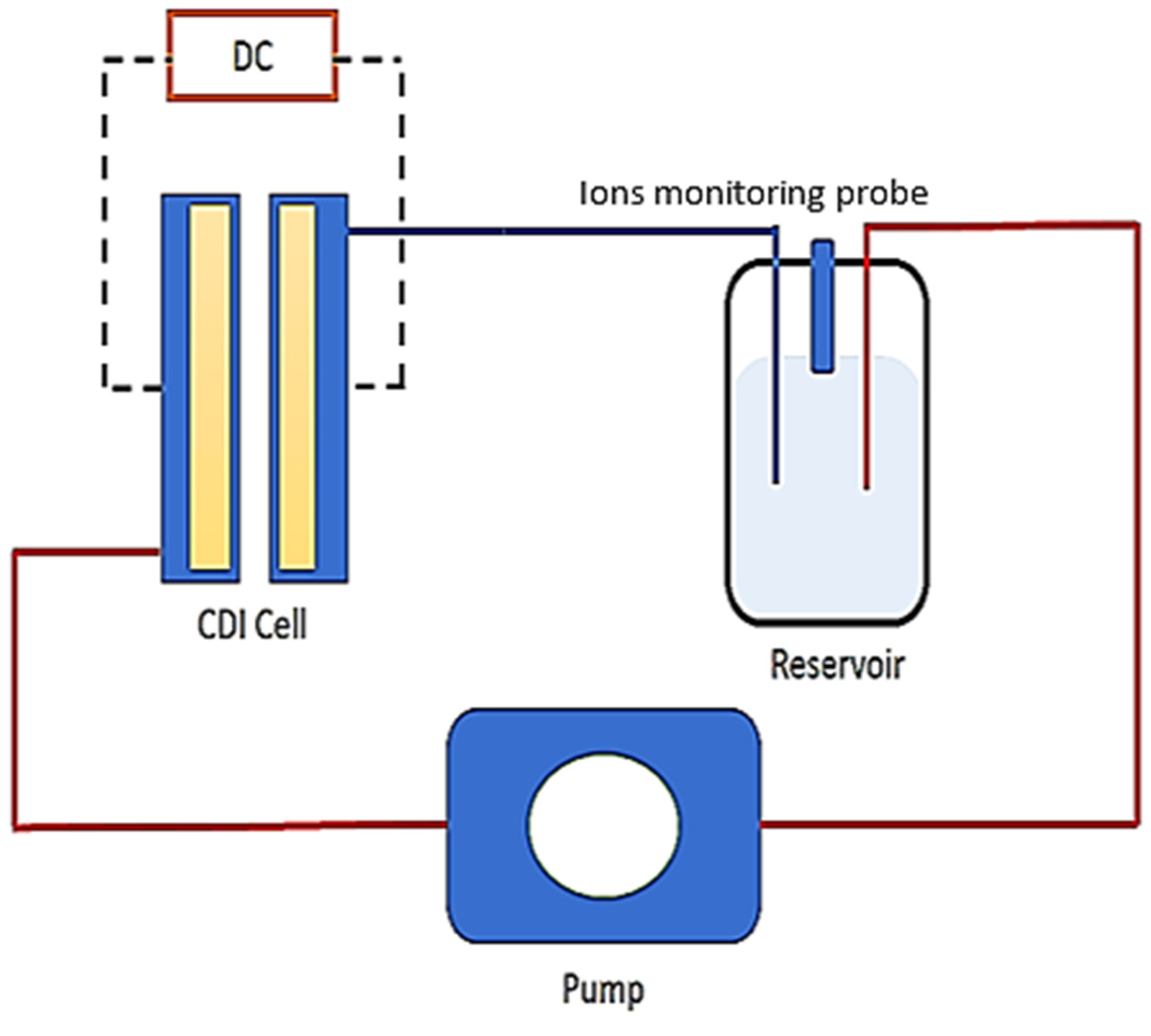

2.5. Capacitive Deionization Measurement

3. Results

3.1. Morphology Properties of Precursors

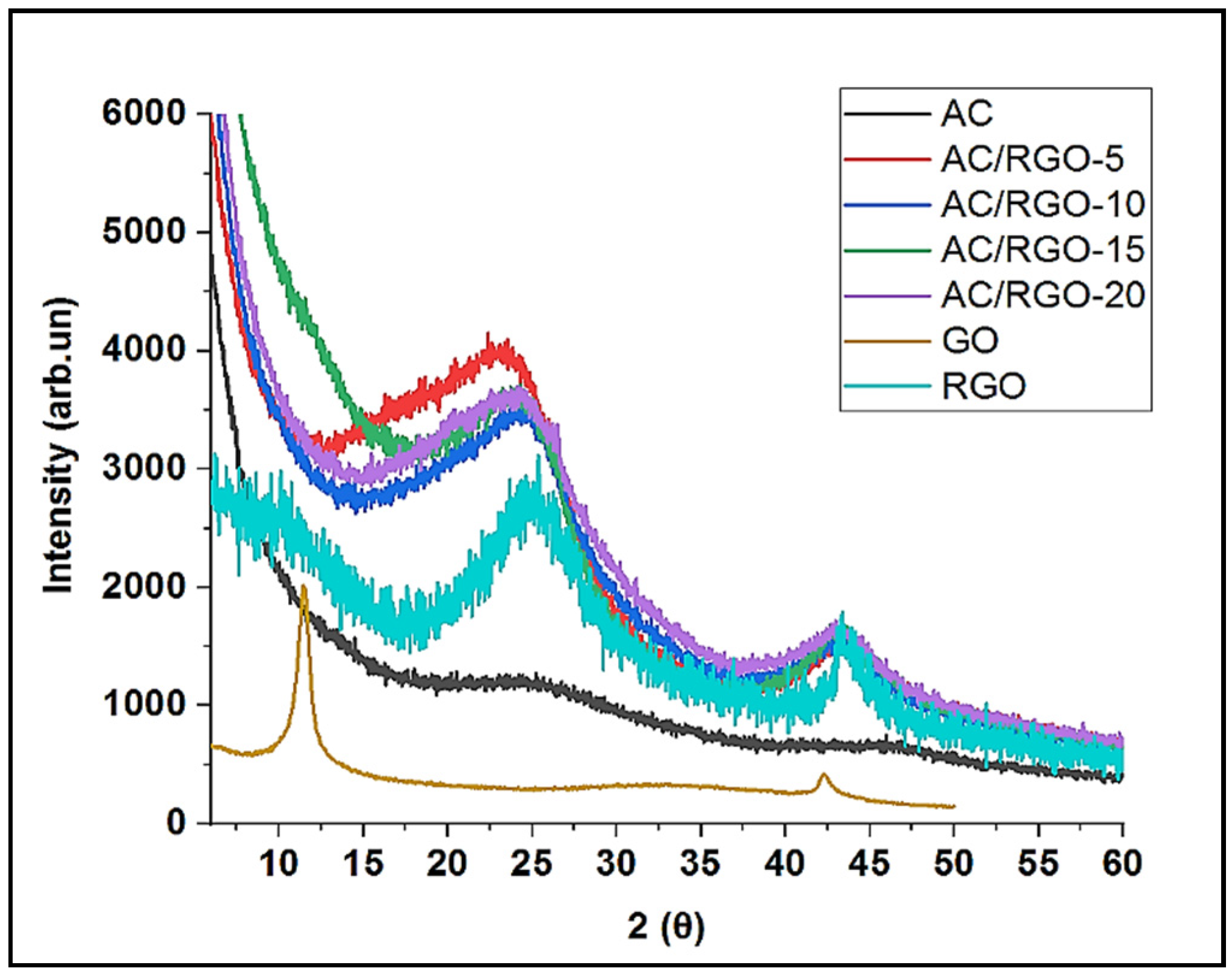

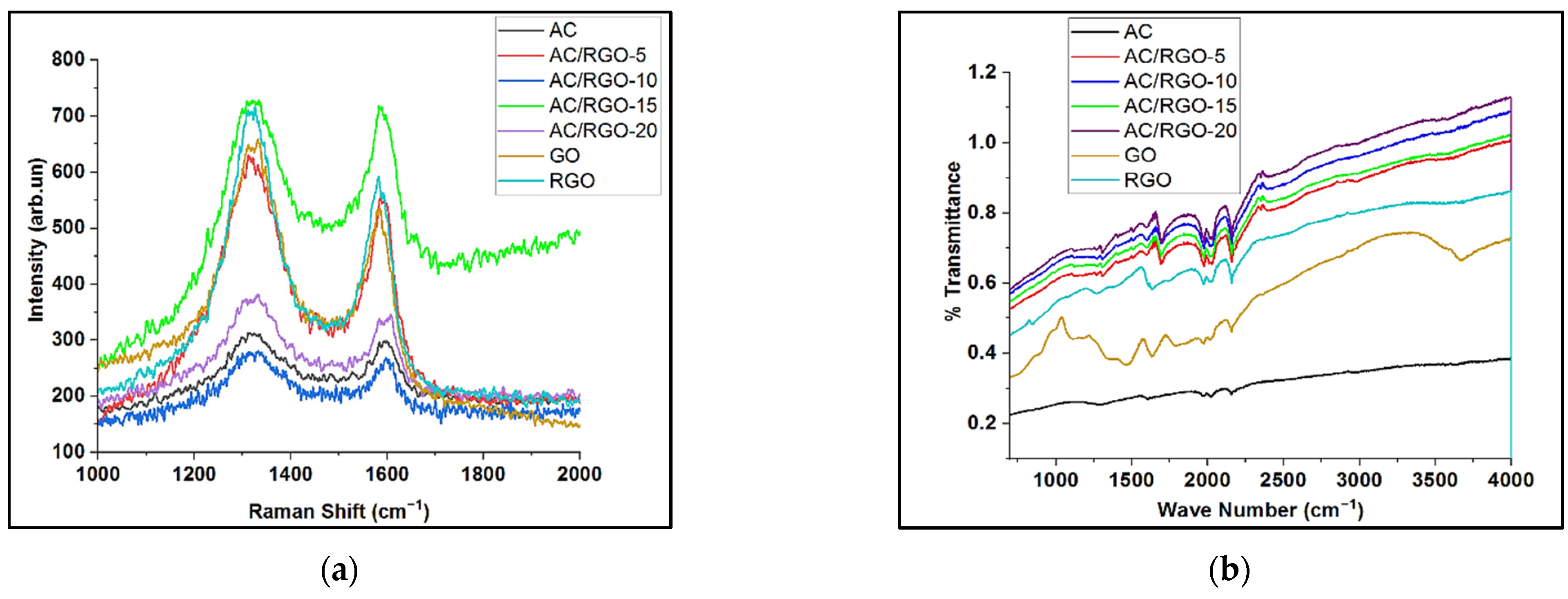

3.2. Structural Properties of Precursors

3.3. Textural Properties of Electrodes

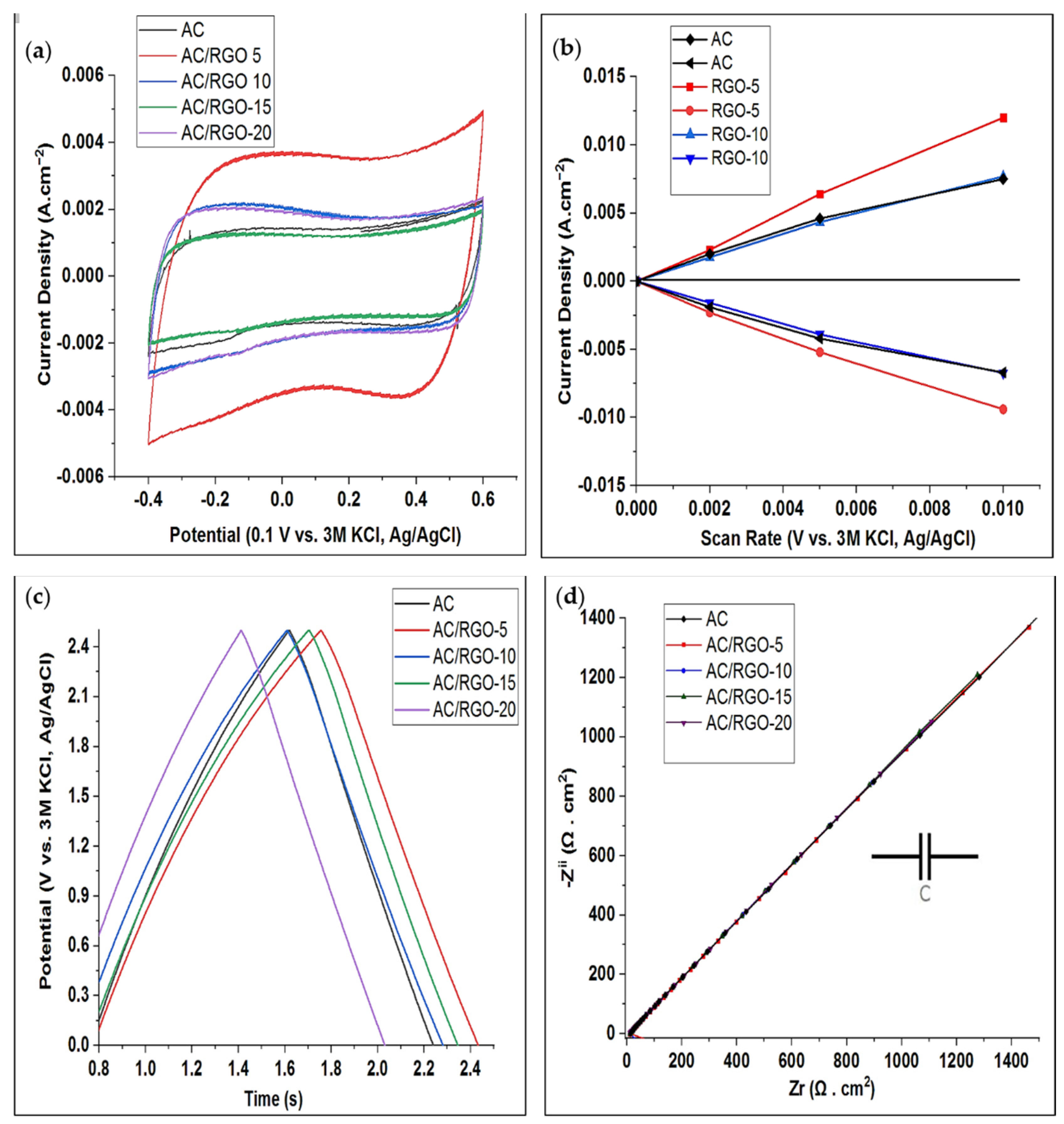

3.4. Electrochemical Property

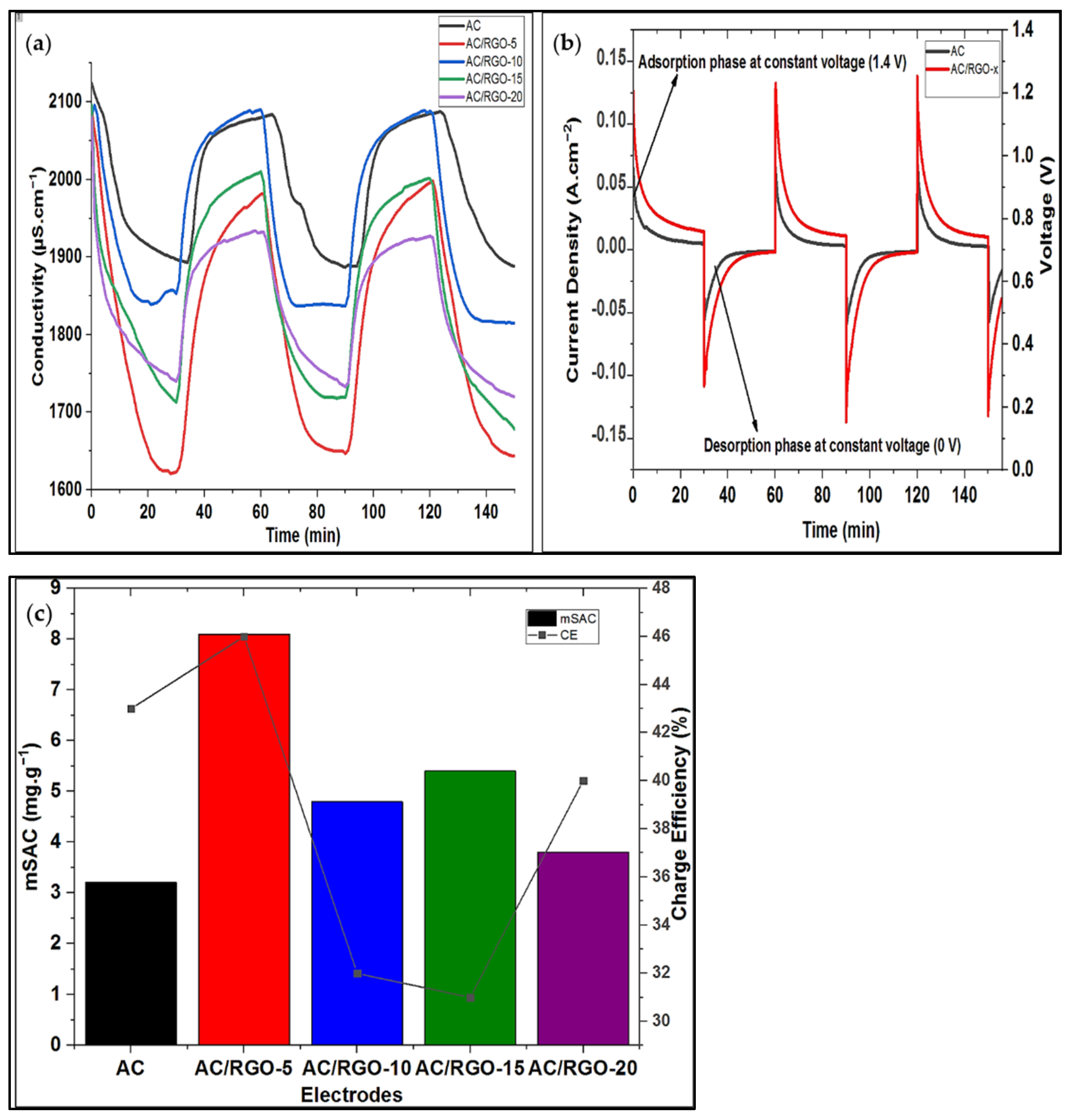

3.5. Desalination Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Pendergast, M.M.; Hoek, E.M.V. A review of water treatment membrane nanotechnologies. Energy Environ. Sci. 2011, 4, 1946–1960. [Google Scholar] [CrossRef]

- Hamid, H.; Eskicioglu, C. Fate of estrogenic hormones in wastewater and sludge treatment: A review of properties and analytical detection techniques in sludge matrix. Water Res. 2012, 46, 5813–5833. [Google Scholar] [CrossRef] [PubMed]

- Anderson, M.A.; Cudero, A.L. Capacitive deionization as an electrochemical means of saving energy and delivering clean water. Comparison to present desalination practices: Will it compete? J. Palma Electrochim. Acta 2010, 55, 3845. [Google Scholar] [CrossRef]

- Zheng, X.; Chen, D.; Wang, Q.; Zhang, Z. Seawater desalination in China: Retrospect and prospect. J. Chem. Eng. 2014, 242, 404. [Google Scholar] [CrossRef]

- Porada, S.; Zhao, R.; van der Wal, A.; Presser, V.; Biesheuvel, P.M. Review on the science and technology of water desalination by capacitive deionization. Progr. Mater. Sci. 2013, 58, 1388–1442. [Google Scholar] [CrossRef]

- Noked, M.; Soffer, A.; Aurbach, D. The electrochemistry of activated carbonaceous materials: Past, present, and future. J. Solid State Electrochem. 2011, 15, 1563–1578. [Google Scholar] [CrossRef]

- Beidaghi, M.; Gogotsi, Y. Capacitive energy storage in micro-scale devices: Recent advances in design and fabrication of micro-supercapacitors. Energy Environ. Sci. 2014, 7, 867–884. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, X.S. Carbon-based materials as supercapacitor electrodes. Chem. Soc. Rev. 2009, 38, 2520–2531. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Dou, B.; Zheng, L.; Zhang, G.; Liu, Z.; Hao, Z. Effective desalination by capacitive deionization with functional graphene nanocomposite as novel electrode material. Desalination 2012, 299, 96–102. [Google Scholar] [CrossRef]

- Biswas, S.; Drzal, L.T. Multilayered Nanoarchitecture of Graphene Nanosheets and Polypyrrole Nanowires for High Performance Supercapacitor Electrodes. Chem. Mater. 2010, 22, 5667–5671. [Google Scholar] [CrossRef]

- Folaranmi, G.; Bechelany, M.; Sistat, P.; Cretin, M.; Zaviska, F. Towards Electrochemical Water Desalination Techniques: A Review on Capacitive Deionization, Membrane Capacitive Deionization and Flow Capacitive Deionization. Membranes 2020, 10, 96. [Google Scholar] [CrossRef] [PubMed]

- Chabot, V.; Higgins, D.; Yu, A.; Xiao, X.; Chen, Z.; Zhang, J. A review of graphene and graphene oxide sponge: Material synthesis and applications to energy and the environment. Energy Environ. Sci. 2014, 7, 1564–1596. [Google Scholar] [CrossRef]

- Li, H.; Zou, L.; Pan, L.; Sun, Z. Novel Graphene-Like Electrodes for Capacitive Deionization. Environ. Sci. Technol. 2010, 44, 8692–8697. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Lu, T.; Pan, L.; Zhang, Y.; Sun, Z. Electrosorption behavior of graphene in NaCl solutions. J. Mater. Chem. 2009, 19, 6773–6779. [Google Scholar] [CrossRef]

- Yao, W.; Hu, L.; Liu, D.; Wang, C.; Lee, C.S. Progress in the preparation and application of three-dimensional graphene-based porous nanocomposites. Nanoscale 2015, 7, 5563–5577. [Google Scholar]

- Böckenfeld, N.; Jeong, S.S.; Winter, M.; Passerini, S.; Balducci, A. Natural, cheap and environmentally friendly binder for supercapacitors. J. Power Sources 2013, 221, 14–20. [Google Scholar] [CrossRef]

- Alhabeb, M.; Beidaghi, M.; Van Aken, K.L.; Dyatkin, B.; Gogotsi, Y. High-density freestanding graphene/carbide-derived carbon film electrodes for electrochemical capacitors. Carbon 2017, 118, 642–649. [Google Scholar] [CrossRef]

- Liu, P.; Yan, T.; Shi, L.; Park, H.S.; Chen, X.; Zhao, Z.; Zhang, D. Graphene-based materials for capacitive deionization. J. Mater. Chem. A 2017, 5, 13907–13943. [Google Scholar] [CrossRef]

- Raluca, T.; Otto, T.B.; Loan, P.; Cosmin, L.; Simion, A.; Loan, B. Reduced graphene oxide today. J. Mater. Chem. C 2020, 8, 1198–1224. [Google Scholar]

- Zaid, M.H.M.; Abdullah, J.; Yusof, N.A.; Wasoh, H.; Sulaiman, Y.; Noh, M.F.M.; Issa, R. Reduced Graphene Oxide/TEMPO-Nanocellulose Nanohybrid-Based Electrochemical Biosensor for the Determination of Mycobacterium tuberculosis. J. Sens. 2020, 2020, 1–11. [Google Scholar] [CrossRef]

- Xiong, C.; Li, M.; Zhao, W.; Duan, C.; Ni, Y. Flexible N-Doped reduced graphene oxide/carbon Nanotube-MnO2 film as a Multifunctional Material for High-Performance supercapacitors, catalysts and sensors. J. Mater. 2020, 6, 523–531. [Google Scholar] [CrossRef]

- Faten Ermala, C.O.; Norhaniza, Y.; Javier, G.B.; Xiaolei, F.; Ahmad Fauzi, I. Electrospun Composites Made of Reduced Graphene Oxide and Polyacrylonitrile-Based Activated CarbonNanofibers (rGO/ACNF) for Enhanced CO2Adsorption. Polymers 2020, 12, 2117. [Google Scholar]

- Daniela, C.M.; Dmitry, V.K.; Jacob, M.B.; Alexander, S.; Zhengzong, S.; Alexander, S.; Lawrence, B.A.; Wei, L.; James, M.T. Improved Synthesis of Graphene Oxide. ACS Nano 2010, 4, 4806–4814. [Google Scholar]

- Fouda, A.; Assy, M.A.; El, E.G.; Yousf, N. Enhanced capacitance of thermally reduced hexagonal graphene oxide for high performance supercapacitor. Nanotub. Carbon Nanostruct. 2015, 23, 618–622. [Google Scholar] [CrossRef]

- Chen, D.; Feng, H.; Li, J. Graphene oxide: Preparation, functionalization, and electrochemical applications. Chem. Rev. 2012, 11, 6027–6053. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Miura, Y.; Macosko, C.W. Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem. Mater. 2010, 22, 3441–3450. [Google Scholar] [CrossRef]

- Murugan, A.V.; Muraliganth, T.; Manthiram, A. Rapid, facile microwave-solvothermal synthesis of graphene nanosheets and their polyaniline nanocomposites for energy strorage. Chem. Mater. 2009, 21, 5004–5006. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y. Synthesis of graphene based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Sreekanth, P.; Pranitha, S.; Priya, R.; Reji, P. White light Z-scan measurements of ultrafast optical nonlinearity in reduced graphene oxide nanosheets in the 400–700 nm region. Appl. Phys. Lett. 2015, 107, 051104. [Google Scholar]

- Malas, A.; Das, C.K.; Das, A.; Heinrich, G. Development of expanded graphite filled natural rubber vulcanizates in presence and absence of carbon black: Mechanical, thermal and morphological Properties. Mater. Des. 2012, 39, 410–417. [Google Scholar] [CrossRef]

- Piao, Y.; Chen, B. One pot synthesis and characterization of reduced graphene oxide—Gelatin nanocomposite hydrogel. RSC Adv. 2016, 6, 6171–6181. [Google Scholar] [CrossRef]

- Kil, H.-J.; Yun, K.; Yoo, M.-E.; Kim, S.; Park, J.-W. Solution-processed graphene oxide electrode for supercapacitors fabricated using low temperature thermal reduction. RSC Adv. 2020, 10, 22102–22211. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez, R.F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Ma, W.; Chang, Y.; Han, G.; Xiao, Y.; Fu, D.; Chang, Y. Capacitive Properties of the Binder-Free Electrode Prepared from Carbon Derived from Cotton and Reduced Graphene Oxide. Chin. J. Chem. 2017, 35, 1844–1852. [Google Scholar] [CrossRef]

- Choi, J.H.; Lee, C.; Cho, S.; Moon, G.D.; Chang, H.; Jang, H.D. High capacitance and energy density supercapacitor based on biomass-derived activated carbons with reduced graphene oxide binder. Carbon 2018, 132, 16–24. [Google Scholar] [CrossRef]

- Yang, S.; Choi, J.; Yeo, J.G.; Jeon, S.I.; Park, H.R.; Kim, D.K. Flow-Electrode Capacitive Deionization Using an Aqueous Electrolyte with a High Salt Concentration. Environ. Sci. Technol. 2016, 50, 5892–5899. [Google Scholar] [CrossRef]

- Xu, Z.P.; Li, L.; Cheng, C.Y.; Ding, R.; Zhou, C. High capacitance electrode materials based on layered double hydroxides prepared by non-aqueous precipitation. Appl. Clay Sci. 2013, 74, 102–108. [Google Scholar] [CrossRef]

- Fang, B.; Binder, L. A Novel Carbon Electrode Material for Highly Improved EDLC Performance. J. Phys. Chem. B 2006, 110, 7877–7882. [Google Scholar] [CrossRef]

- Li, J.; Östling, M. Prevention of Graphene Restacking for Performance Boost of Supercapacitors—A Review. Crystals 2013, 3, 163–190. [Google Scholar] [CrossRef]

- Xu, L.; Li, Y.; Jia, M.; Zhao, Q.; Jin, X.; Yao, C. Synthesis and characterization of free-standing activated carbon/reduced graphene oxide film electrodes for flexible supercapacitors. RSC Adv. 2017, 7, 45066. [Google Scholar] [CrossRef]

- Dong, Q.; Wang, G.; Qian, B.; Hu, C.; Wang, Y.; Qiu, J. Electrospun composites made of reduced graphene Oxide and activated carbon nanofibers for Capacitive Deionization. Electrochim. Acta 2014, 137, 388–394. [Google Scholar] [CrossRef]

- Li, H.; Pan, L.; Nie, C.; Liu, Y.; Sun, Z. Reduced graphene oxide and activated carbon composites for capacitive deionization. J. Mater. Chem. 2012, 22, 15556. [Google Scholar] [CrossRef]

- Liu, X.; Chen, T.; Qiao, W.C.; Wang, Z.; Yu, L. Fabrication of graphene/activated carbon nanofiber composites for high performance capacitive deionization. J. Taiwan Inst. Chem. Eng. 2017, 72, 213–219. [Google Scholar] [CrossRef]

- Song, H.; Wu, Y.; Zhang, S.; Li, W.; Wang, B.; Wang, C.; Gao, J.; Li, A. Mesoporous generation-inspired ultrahigh capacitive deionization performance by sono-assembled activated carbon/inter-connected graphene network architecture. Electrochim. Acta 2016, 205, 161–169. [Google Scholar] [CrossRef]

- Fan, X.; Peng, W.; Li, Y.; Li, X.; Wang, S.; Zhang, G.; Zhang, F. Deoxygenation of Exfoliated Graphite Oxide under Alkaline Conditions: A Green Route to Graphene Preparation. Adv. Mater. 2008, 20, 4490–4493. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, X.; Lu, T.; Sun, Z.; Chua, D.H.C.; Pan, L. Nitrogen-doped electrospun reduced graphene oxide–carbon nanofiber composite for capacitive deionization. RSC Adv. 2015, 5, 34117–34124. [Google Scholar] [CrossRef]

- Wang, M.; Xu, X.; Tang, J.; Hou, S.; Shahriar, M.; Hossain, A.; Pan, L.; Yamauchi, Y. High performance capacitive deionization electrodes based on ultrathin nitrogen-doped carbon/graphene nano-sandwiches. Chem. Commun. 2017, 53, 10784–10787. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Wen, X.; Shi, L.; Yan, T.; Zhang, J. Enhanced capacitive deionization of graphene/mesoporous carbon composites. Nanoscale 2012, 4, 5440–5446. [Google Scholar] [CrossRef]

- Wang, H.; Shi, L.; Yan, T.; Zhang, J.; Zhong, Q.; Zhang, D. Reduced graphene oxide/highly porous carbon for capacitive deionization application. J. Mater. Chem. A 2014, 2, 4739–4750. [Google Scholar] [CrossRef]

- Wen, X.; Zhang, D.; Yan, T.; Zhang, J.; Shi, L. Three-dimensional graphene-based hierarchically porous carbon composites prepared by a dual-template strategy for capacitive deionization. J. Mater. Chem. A 2013, 1, 12334–12344. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, W.; Li, X.; Zhu, J.; Wang, H.; Zhang, L. Design and fabrication of a graphene/carbon nanotubes/activated carbon hybrid and its application for capacitive deionization. RSC Adv. 2016, 6, 5817–5823. [Google Scholar] [CrossRef]

| Sample | Vt (cm3g−1) | SBET (m2g−1) | VMESO (cm3g−1) |

|---|---|---|---|

| Pure AC | 0.82 | 1031.03 | 0.55 |

| AC electrode | 0.46 | 474.62 | 0.40 |

| GO | 0.01 | 5.48 | 0.01 |

| RGO | 0.03 | 16.37 | 0.06 |

| AC/RGO-5 | 0.41 | 374.37 | 0.30 |

| AC/RGO-10 | 0.43 | 473.42 | 0.38 |

| AC/RGO-15 | 0.40 | 434.12 | 0.33 |

| AC/RGO-20 | 0.45 | 480.73 | 0.39 |

| AC | AC/RGO-5 | AC/RGO-10 | AC/RGO-15 | AC/RGO-20 | |

|---|---|---|---|---|---|

| CDL (F cm−2) | 0.29 | 0.89 | 0.74 | 0.49 | 0.65 |

| CSpecific (F g−1) | 32 | 74 | 48 | 29 | 50 |

| mSAC (mg g−1) | SAC (mg cm−1) | ASAR (mg g−1 min−1) | CE (%) | |

|---|---|---|---|---|

| AC | 3.20 | 0.08 | 0.10 | 43 |

| AC/RGO-5 | 8.10 | 0.23 | 0.27 | 46 |

| AC/RGO-10 | 4.80 | 0.14 | 0.16 | 32 |

| AC/RGO-15 | 5.40 | 0.17 | 0.18 | 31 |

| AC/RGO-20 | 6.46 | 0.11 | 0.13 | 40 |

| Electrode Material | Synthesis Method | Applied Voltage ΔE (V) | [NaCl]° (mg L−1) | CSpecific (F g−1) | mSAC (mg g−1) | Ref |

|---|---|---|---|---|---|---|

| AC/RGO | Vacuum filtration process and *Th.T under N2 | - | 207 | - | [40] | |

| CNFs/RGO | Electrospinning and *Th.T under CO2 | 0.4–1.60 | 400 | 256 | 7.20 | [41] |

| OAC/RGO | Oxidation/simple doping and *Th.T under N2 | 1.2–2.0 | 25 | 181 | 0.81 | [42] |

| CNF/RGO | Electrospinning and *Th.T under N2 | 2.0 | 400 | 108 | 2.99 | [43] |

| AC/FRGO | Sono-assembly and *Th.T under N2 | 1.80 | 117 | 27.9 | 12.58 | [44] |

| NRGO-CNFs | Electrospinning and *Th.T under N2 | 1.20 | 100 | 337.85 | 3.91 | [46] |

| RGO-CNFs | Electrospinning and *Th.T under N2 | 1.20 | - | 264.32 | 3.60 | [46] |

| NC/RGO | Polymer templated method and *Th.T under N2 | 1.2 | 589 | 137.26 | 17.52 | [47] |

| RGO/MC | Polymer templated method and *Th.T under N2 | 2.0 | 40 | 52.15 | 0.73 | [48] |

| RGO/HCS | - | 1.6 | - | - | 2.3 | [49] |

| RGO/HPC | Dual template strategy and *Th.T under N2 | 1.2 | 25 | 80.34 | 6.18 | [50] |

| RGO/CNTs/AC | Chemical mixing method | 1.2 | - | 93.50 | 2.30 | [51] |

| AC/RGO-5 | Simple chemical method without *Th.T | 1.4 | 1200 | 74 | 8.10 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Folaranmi, G.; Bechelany, M.; Sistat, P.; Cretin, M.; Zaviska, F. Activated Carbon Blended with Reduced Graphene Oxide Nanoflakes for Capacitive Deionization. Nanomaterials 2021, 11, 1090. https://doi.org/10.3390/nano11051090

Folaranmi G, Bechelany M, Sistat P, Cretin M, Zaviska F. Activated Carbon Blended with Reduced Graphene Oxide Nanoflakes for Capacitive Deionization. Nanomaterials. 2021; 11(5):1090. https://doi.org/10.3390/nano11051090

Chicago/Turabian StyleFolaranmi, Gbenro, Mikhael Bechelany, Philippe Sistat, Marc Cretin, and Francois Zaviska. 2021. "Activated Carbon Blended with Reduced Graphene Oxide Nanoflakes for Capacitive Deionization" Nanomaterials 11, no. 5: 1090. https://doi.org/10.3390/nano11051090

APA StyleFolaranmi, G., Bechelany, M., Sistat, P., Cretin, M., & Zaviska, F. (2021). Activated Carbon Blended with Reduced Graphene Oxide Nanoflakes for Capacitive Deionization. Nanomaterials, 11(5), 1090. https://doi.org/10.3390/nano11051090