Molecular Dynamics Simulations and Theoretical Model for Engineering Tensile Properties of Single-and Multi-Walled Carbon Nanotubes

Abstract

1. Introduction

2. Molecular Dynamics Models and Computational Methods

3. Results and Discussion

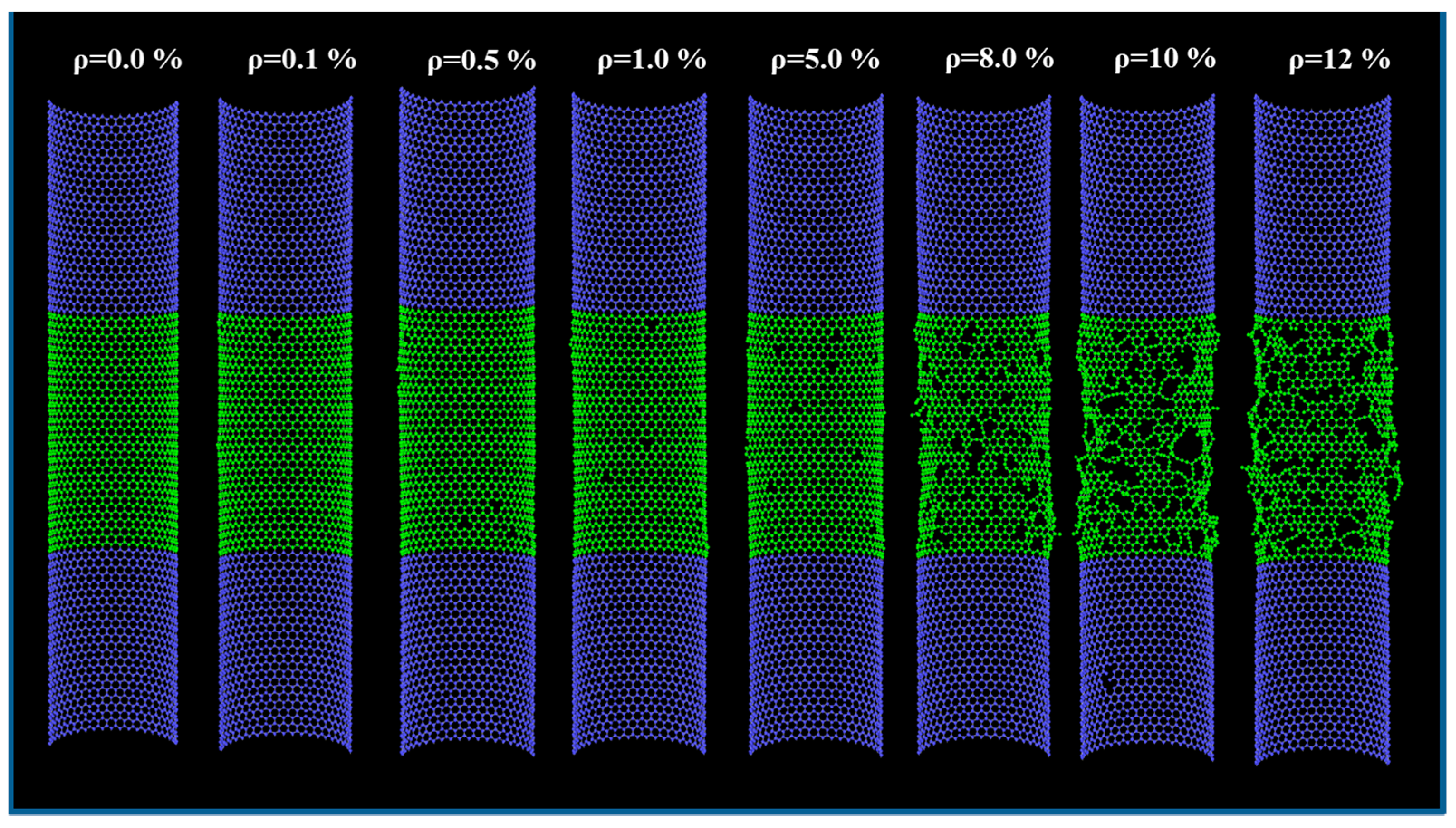

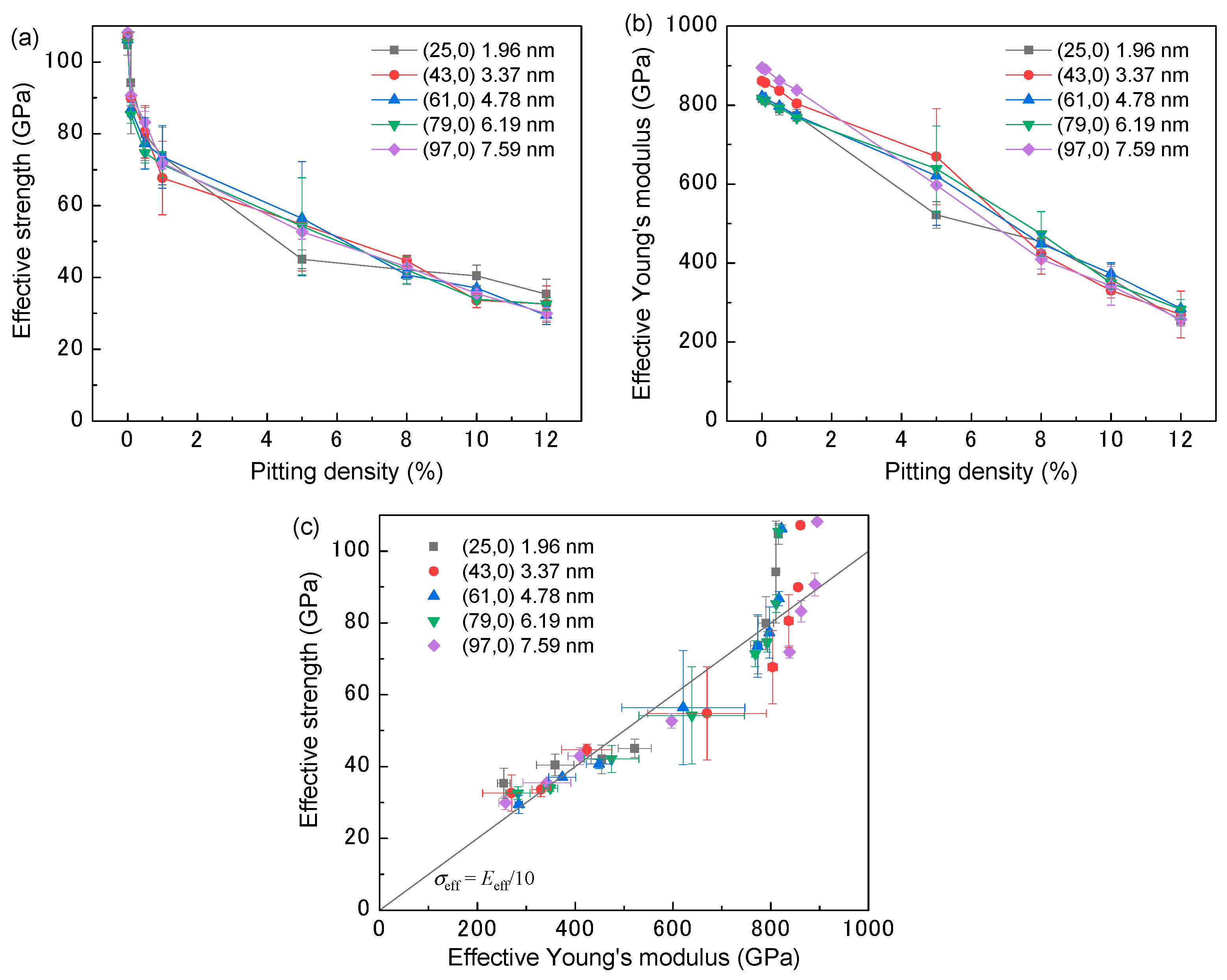

3.1. SWCNTs (MD Simulations)

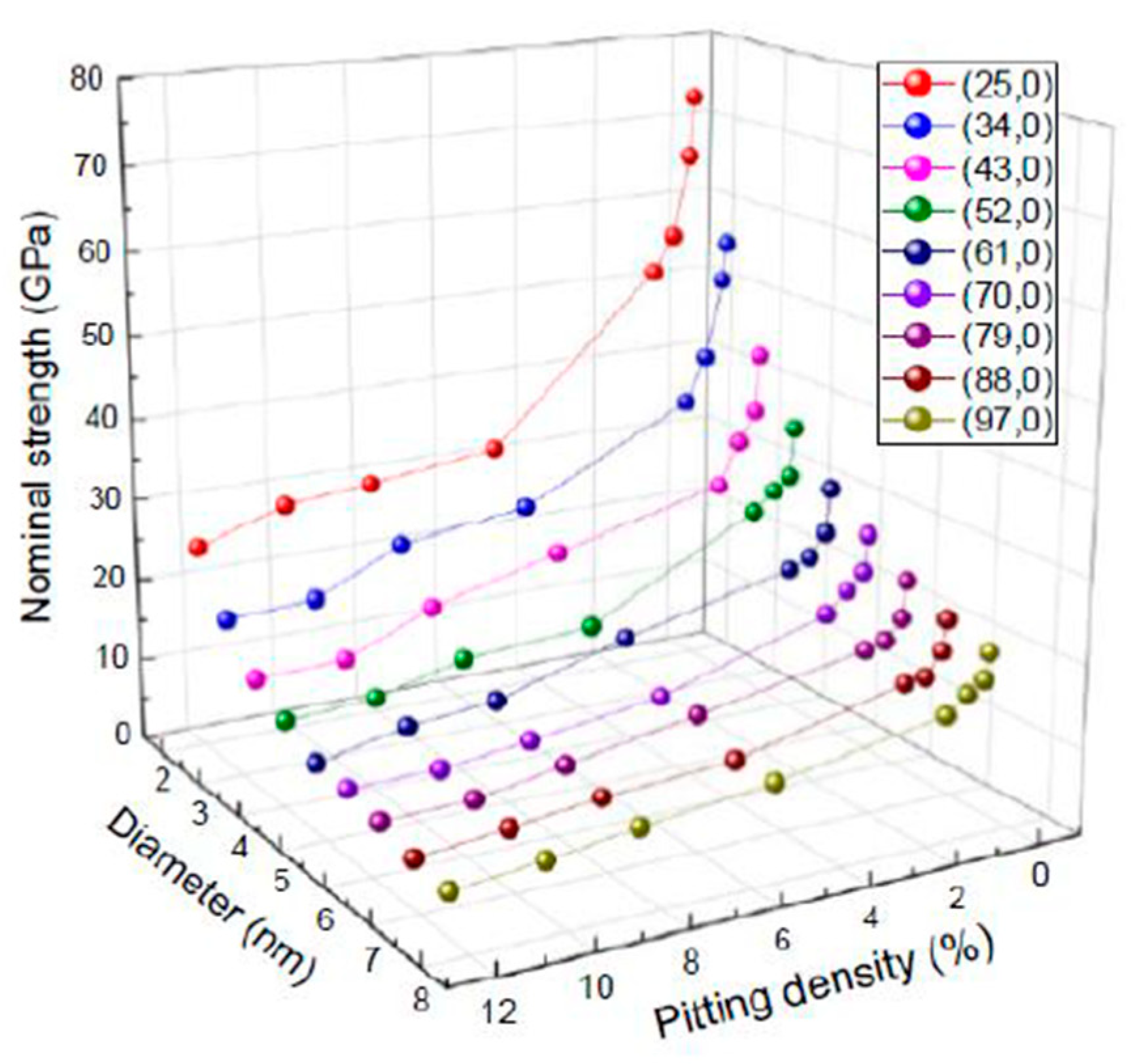

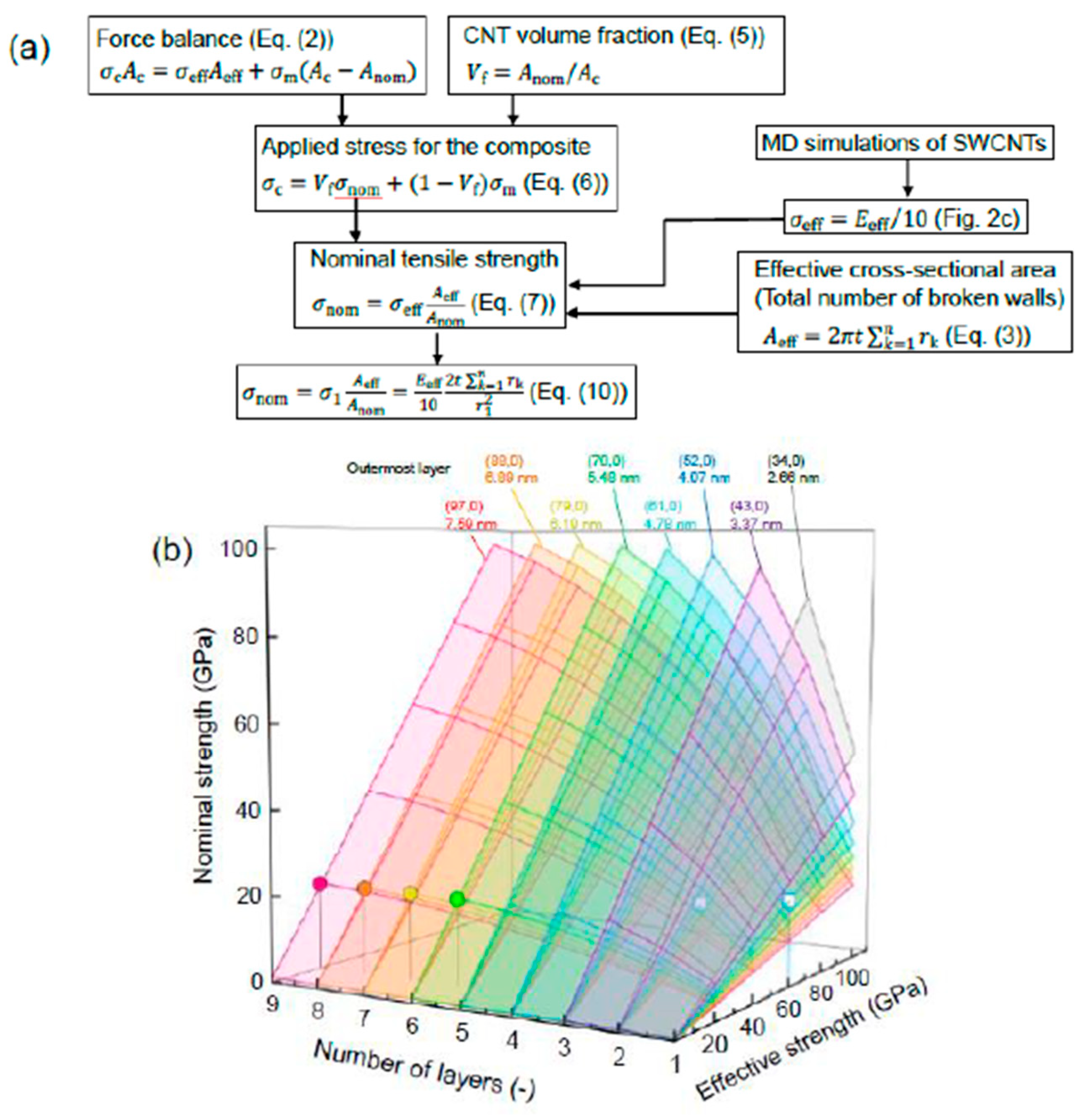

3.2. MWCNTs (Theoretical Calculations)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jiang, K.; Li, Q.; Fan, S. Spinning continuous carbon nanotube yarns. Nature 2002, 419, 801. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M. Multifunctional carbon nanotube yarns by downsizing an ancient technology. Science 2004, 306, 1358–1361. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, Q.; Tu, Y.; Li, Y.; Coulter, J.Y.; Zheng, L.; Zhao, Y.; Jia, Q.; Peterson, D.E.; Zhu, Y. Strong carbon-nanotube fibers spun from long carbon-nanotube arrays. Small 2007, 3, 244–248. [Google Scholar] [CrossRef]

- Inoue, Y.; Kakihata, K.; Hirono, Y.; Horie, T.; Ishida, A.; Mimura, H. One-step grown aligned bulk carbon nanotubes by chloride mediated chemical vapor deposition. Appl. Phys. Lett. 2008, 92, 213113. [Google Scholar] [CrossRef]

- Liu, K.; Sun, Y.; Chen, L.; Feng, C.; Feng, X.; Jiang, K.; Zhao, Y.; Fan, S. Controlled Growth of super-aligned carbon nanotube arrays for spinning continuous unidirectional sheets with tunable physical properties. Nano Lett. 2008, 8, 700–705. [Google Scholar] [CrossRef] [PubMed]

- Iijima, T.; Oshima, H.; Hayashi, Y.; Suryavanshi, U.B.; Hayashi, A.; Tanemura, M. In-situ observation of carbon nanotube fiber spinning from vertically aligned carbon nanotube forest. Diam. Relat. Mater. 2012, 24, 158–160. [Google Scholar] [CrossRef]

- Inoue, Y.; Hayashi, K.; Karita, M.; Nakano, T.; Shimamura, Y.; Shirasu, K.; Yamamoto, G.; Hashida, T. Study on the mechanical and electrical properties of twisted CNT yarns fabricated from CNTs with various diameters. Carbon 2021, 176, 400–410. [Google Scholar] [CrossRef]

- Shimamura, Y.; Oshima, K.; Tohgo, K.; Fujii, T.; Shirasu, K.; Yamamoto, G.; Hashida, T.; Goto, K.; Ogasawara, T.; Naito, K.; et al. Tensile mechanical properties of carbon nanotube/epoxy composite fabricated by pultrusion of carbon nanotube spun yarn preform. Compos. Part A Appl. Sci. Manuf. 2014, 62, 32–38. [Google Scholar] [CrossRef]

- Zhang, S.; Mielke, S.L.; Khare, R.; Troya, D.; Ruoff, R.S.; Schatz, G.C.; Belytschko, T. Mechanics of defects in carbon nanotubes: Atomistic and multiscale simulations. Phys. Rev. B 2005, 71, 115403. [Google Scholar] [CrossRef]

- Tserpes, K.; Papanikos, P. The effect of Stone–Wales defect on the tensile behavior and fracture of single-walled carbon nanotubes. Compos. Struct. 2007, 79, 581–589. [Google Scholar] [CrossRef]

- Suenaga, K.; Wakabayashi, H.; Koshino, M.; Sato, Y.; Urita, K.; Iijima, S. Imaging active topological defects in carbon nanotubes. Nat. Nanotechnol. 2007, 2, 358–360. [Google Scholar] [CrossRef]

- Shirasu, K.; Yamamoto, G.; Hashida, T. How do the mechanical properties of carbon nanotubes increase? An experimental evaluation and modeling of the engineering tensile strength of individual carbon nanotubes. Mater. Res. Express 2019, 6, 055047. [Google Scholar] [CrossRef]

- Xiao, J.; Gama, B.; Gillespie, J. An analytical molecular structural mechanics model for the mechanical properties of carbon nanotubes. Int. J. Solids Struct. 2005, 42, 3075–3092. [Google Scholar] [CrossRef]

- Byrne, E.M.; McCarthy, M.A.; Xia, Z.; Curtin, W.A. Multiwall nanotubes can be stronger than single wall nanotubes and implications for nanocomposite design. Phys. Rev. Lett. 2009, 103, 045502. [Google Scholar] [CrossRef]

- Xia, Z.H.; Guduru, P.R.; Curtin, W.A. Enhancing mechanical properties of multiwall carbon nanotubes via sp 3 interwall bridging. Phys. Rev. Lett. 2007, 98, 245501. [Google Scholar] [CrossRef] [PubMed]

- Fonseca, A.F.; Borders, T.; Baughman, R.H.; Cho, K. Load transfer between cross-linked walls of a carbon nanotube. Phys. Rev. B 2010, 81, 045429. [Google Scholar] [CrossRef]

- Xiang, Y.; Shimoyama, K.; Shirasu, K.; Yamamoto, G. Machine learning-assisted high-throughput molecular dynamics simulation of high-mechanical performance carbon nanotube structure. Nanomaterials 2020, 10, 2459. [Google Scholar] [CrossRef]

- Olander, D.R.; Siekhaus, W.J.; Jones, R.; Schwarz, J.A. Reactions of modulated molecular beams with pyrolytic graphite. I. oxidation of the basal plane. J. Chem. Phys. 1972, 57, 408–420. [Google Scholar] [CrossRef]

- Lee, S.-G.; Shim, K.-T.; Lee, Y.-H. Preparation and Characterization of lead zirconate titanate heterolayered thin films on Pt/Ti/SiO2/Si Substrate by Sol–Gel Method. Jpn. J. Appl. Phys. 1999, 38, 217–218. [Google Scholar] [CrossRef]

- Solís-Fernández, P.; Paredes, J.I.; Cosío, A.; Martínez-Alonso, A.; Tascón, J.M.D. A comparison between physically and chemically driven etching in the oxidation of graphite surfaces. J. Colloid Interface Sci. 2010, 344, 451–459. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, Y.H.; Hwang, Y.G.; Hahn, J.R.; Kang, H. Defect-induced oxidation of graphite. Phys. Rev. Lett. 1999, 82, 217–220. [Google Scholar] [CrossRef]

- Shirasu, K.; Tamaki, I.; Miyazaki, T.; Yamamoto, G.; Bekarevich, R.; Hirahara, K.; Shimamura, Y.; Inoue, Y.; Hashida, T. Key factors limiting carbon nanotube strength: Structural characterization and mechanical properties of multi-walled carbon nanotubes. Mech. Eng. J. 2017, 4, 17–00029. [Google Scholar] [CrossRef][Green Version]

- Mielke, S.L.; Zhang, S.; Khare, R.; Ruoff, R.S.; Belytschko, T.; Schatz, G.C. The effects of extensive pitting on the mechanical properties of carbon nanotubes. Chem. Phys. Lett. 2007, 446, 128–132. [Google Scholar] [CrossRef]

- Mielke, S.L.; Troya, D.; Zhang, S.; Li, J.-L.; Xiao, S.; Car, R.; Ruoff, R.S.; Schatz, G.C.; Belytschko, T. The role of vacancy defects and holes in the fracture of carbon nanotubes. Chem. Phys. Lett. 2004, 390, 413–420. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stuart, S.J.; Tutein, A.B.; Harrison, J.A. A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 2000, 112, 6472–6486. [Google Scholar] [CrossRef]

- Yamamoto, G.; Shirasu, K.; Nozaka, Y.; Sato, Y.; Takagi, T.; Hashida, T. Structure–property relationships in thermally-annealed multi-walled carbon nanotubes. Carbon 2014, 66, 219–226. [Google Scholar] [CrossRef]

- Jeng, Y.-R.; Tsai, P.-C.; Fang, T.-H. Effects of temperature and vacancy defects on tensile deformation of single-walled carbon nanotubes. J. Phys. Chem. Solids 2004, 65, 1849–1856. [Google Scholar] [CrossRef]

- Peng, B.; LoCascio, M.A.; Zapol, P.; Li, S.; Mielke, S.L.; Schatz, G.C.; Espinosa, H.D. Measurements of near-ultimate strength for multiwalled carbon nanotubes and irradiation-induced crosslinking improvements. Nat. Nanotechnol. 2008, 3, 626–631. [Google Scholar] [CrossRef]

- Naito, K.; Tanaka, Y.; Yang, J.-M.; Kagawa, Y. Tensile properties of ultrahigh strength PAN-based, ultrahigh modulus pitch-based and high ductility pitch-based carbon fibers. Carbon 2008, 46, 189–195. [Google Scholar] [CrossRef]

- Shirasu, K.; Goto, K.; Naito, K. Microstructure-elastic property relationships in carbon fibers: A nanoindentation study. Compos. Part B Eng. 2020, 200, 108342. [Google Scholar] [CrossRef]

- Orowan, E. Fracture and strength of solids. Rep. Prog. Phys. 1949, 12, 185–232. [Google Scholar] [CrossRef]

- Zhang, B.; Zhao, L.; Cheng, Y.; Golberg, D.; Wang, M.-S. Reversible tuning of individual carbon nanotube mechanical properties via defect engineering. Nano Lett. 2016, 16, 5221–5227. [Google Scholar] [CrossRef]

- Behler, K.; Osswald, S.; Ye, H.; Dimovski, S.; Gogotsi, Y. Effect of thermal treatment on the structure of multi-walled carbon nanotubes. J. Nanoparticle Res. 2006, 8, 615–625. [Google Scholar] [CrossRef]

- Elumeeva, K.V.; Kuznetsov, V.L.; Ischenko, A.V.; Smajda, R.; Spina, M.; Forró, L.; Magrez, A. Reinforcement of CVD grown multi-walled carbon nanotubes by high temperature annealing. AIP Adv. 2013, 3, 112101. [Google Scholar] [CrossRef]

- Chen, J.; Shan, J.; Tsukada, T.; Munekane, F.; Kuno, A.; Matsuo, M.; Hayashi, T.; Kim, Y.; Endo, M. The structural evolution of thin multi-walled carbon nanotubes during isothermal annealing. Carbon 2007, 45, 274–280. [Google Scholar] [CrossRef]

- Hada, M.; Makino, K.; Inoue, H.; Hasegawa, T.; Masuda, H.; Suzuki, H.; Shirasu, K.; Nakagawa, T.; Seki, T.; Matsuo, J.; et al. Phonon transport probed at carbon nanotube yarn/sheet boundaries by ultrafast structural dynamics. Carbon 2020, 170, 165–173. [Google Scholar] [CrossRef]

- Su, C.-Y.; Xu, Y.; Zhang, W.; Zhao, J.; Liu, A.; Tang, X.; Tsai, C.-H.; Huang, Y.; Li, L.-J. Highly efficient restoration of graphitic structure in graphene oxide using alcohol vapors. ACS Nano 2010, 4, 5285–5292. [Google Scholar] [CrossRef]

- Grimm, S.; Schweiger, M.; Eigler, S.; Zaumseil, J. High-quality reduced graphene oxide by CVD-assisted annealing. J. Phys. Chem. C 2016, 120, 3036–3041. [Google Scholar] [CrossRef]

- Ohata, Y.; Long, D.; Qiao, W.; Ling, L.; Nakabayashi, K.; Miyawaki, J.; Mochida, I.; Yoon, S.-H. Dimensional control of tubular-type carbon nanofibers via pyrolytic carbon coating. J. Mater. Sci. 2017, 52, 5165–5178. [Google Scholar] [CrossRef]

- Kuznetsov, V.L.; Bokova-Sirosh, S.N.; Moseenkov, S.I.; Ishchenko, A.V.; Krasnikov, D.V.; Kazakova, M.A.; Romanenko, A.I.; Tkachev, E.N.; Obraztsova, E.D. Raman spectra for characterization of defective CVD multi-walled carbon nanotubes. Phys. Status Solidi 2014, 251, 2444–2450. [Google Scholar] [CrossRef]

- Shirasu, K.; Asaoka, M.; Miyazaki, T.; Yamamoto, G.; Hashida, T. Stack-coating of multishell carbon layers templated with carbon nanotubes. Mater. Today Commun. 2019, 21, 100608. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shirasu, K.; Kitayama, S.; Liu, F.; Yamamoto, G.; Hashida, T. Molecular Dynamics Simulations and Theoretical Model for Engineering Tensile Properties of Single-and Multi-Walled Carbon Nanotubes. Nanomaterials 2021, 11, 795. https://doi.org/10.3390/nano11030795

Shirasu K, Kitayama S, Liu F, Yamamoto G, Hashida T. Molecular Dynamics Simulations and Theoretical Model for Engineering Tensile Properties of Single-and Multi-Walled Carbon Nanotubes. Nanomaterials. 2021; 11(3):795. https://doi.org/10.3390/nano11030795

Chicago/Turabian StyleShirasu, Keiichi, Shunsuke Kitayama, Fan Liu, Go Yamamoto, and Toshiyuki Hashida. 2021. "Molecular Dynamics Simulations and Theoretical Model for Engineering Tensile Properties of Single-and Multi-Walled Carbon Nanotubes" Nanomaterials 11, no. 3: 795. https://doi.org/10.3390/nano11030795

APA StyleShirasu, K., Kitayama, S., Liu, F., Yamamoto, G., & Hashida, T. (2021). Molecular Dynamics Simulations and Theoretical Model for Engineering Tensile Properties of Single-and Multi-Walled Carbon Nanotubes. Nanomaterials, 11(3), 795. https://doi.org/10.3390/nano11030795