A Content Review of Life Cycle Assessment of Nanomaterials: Current Practices, Challenges, and Future Prospects

Abstract

:Highlights

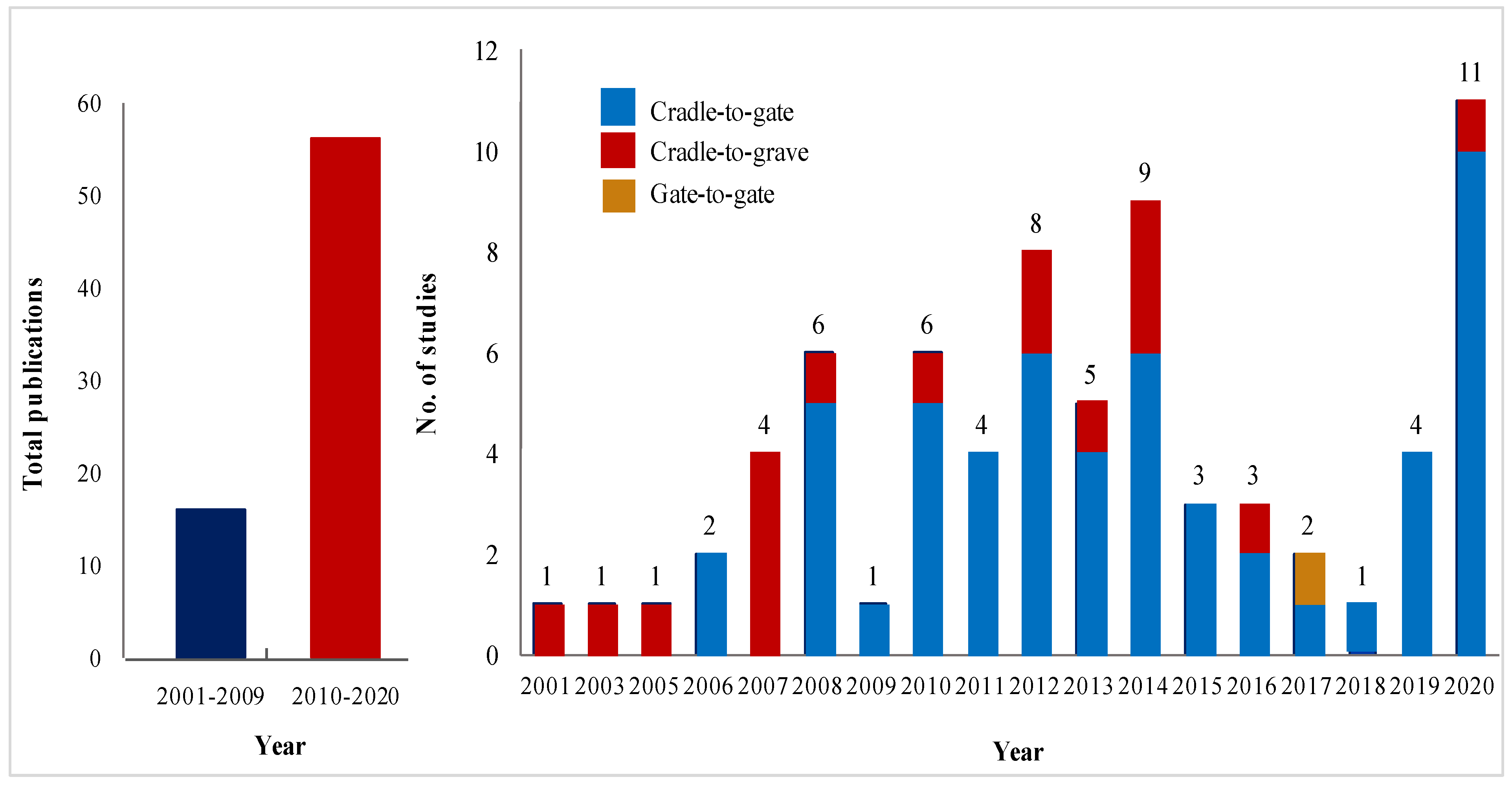

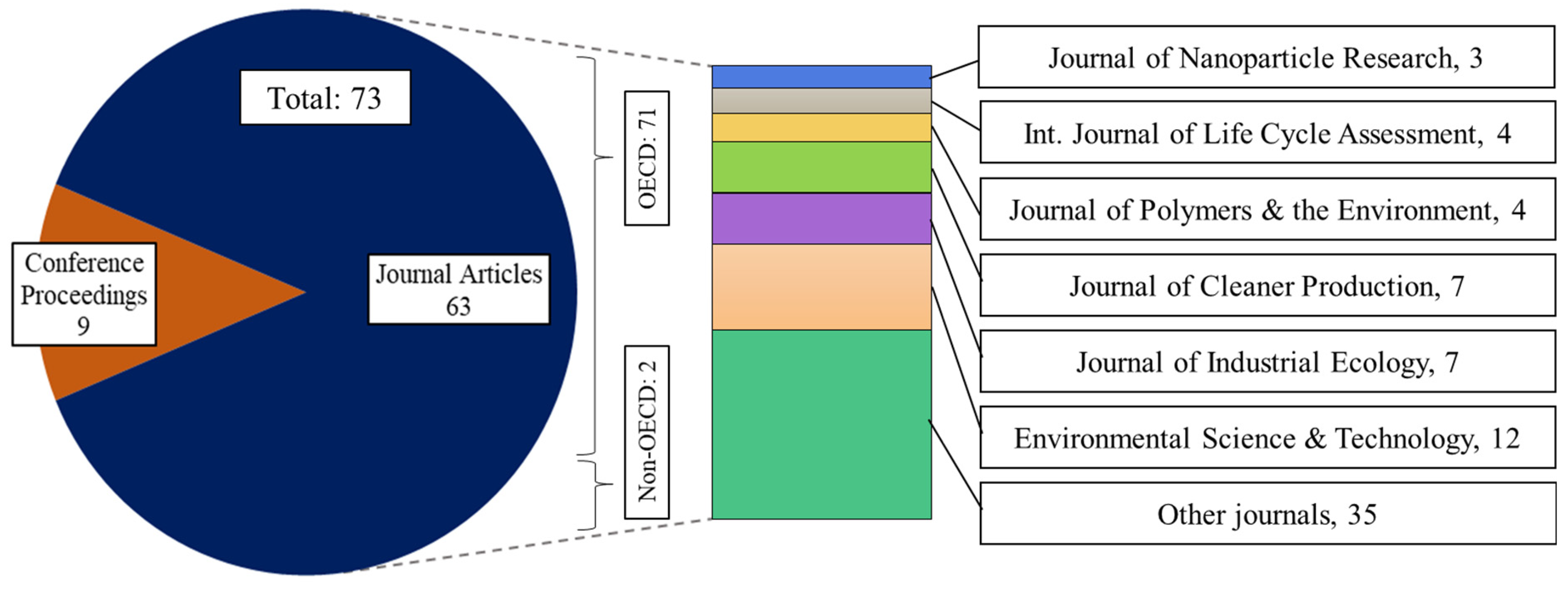

- A total of 71 studies on life cycle assessment of nanomaterials application were reviewed.

- Environmental performance and hotspot of nanomaterials were identified.

- Challenges and prospects for life cycle assessment of nanomaterials were discussed.

- Only five studies considered the exposure pathway of the nanomaterials.

- Of all the studies, 92% neglect the uncertainty analysis within the LCA.

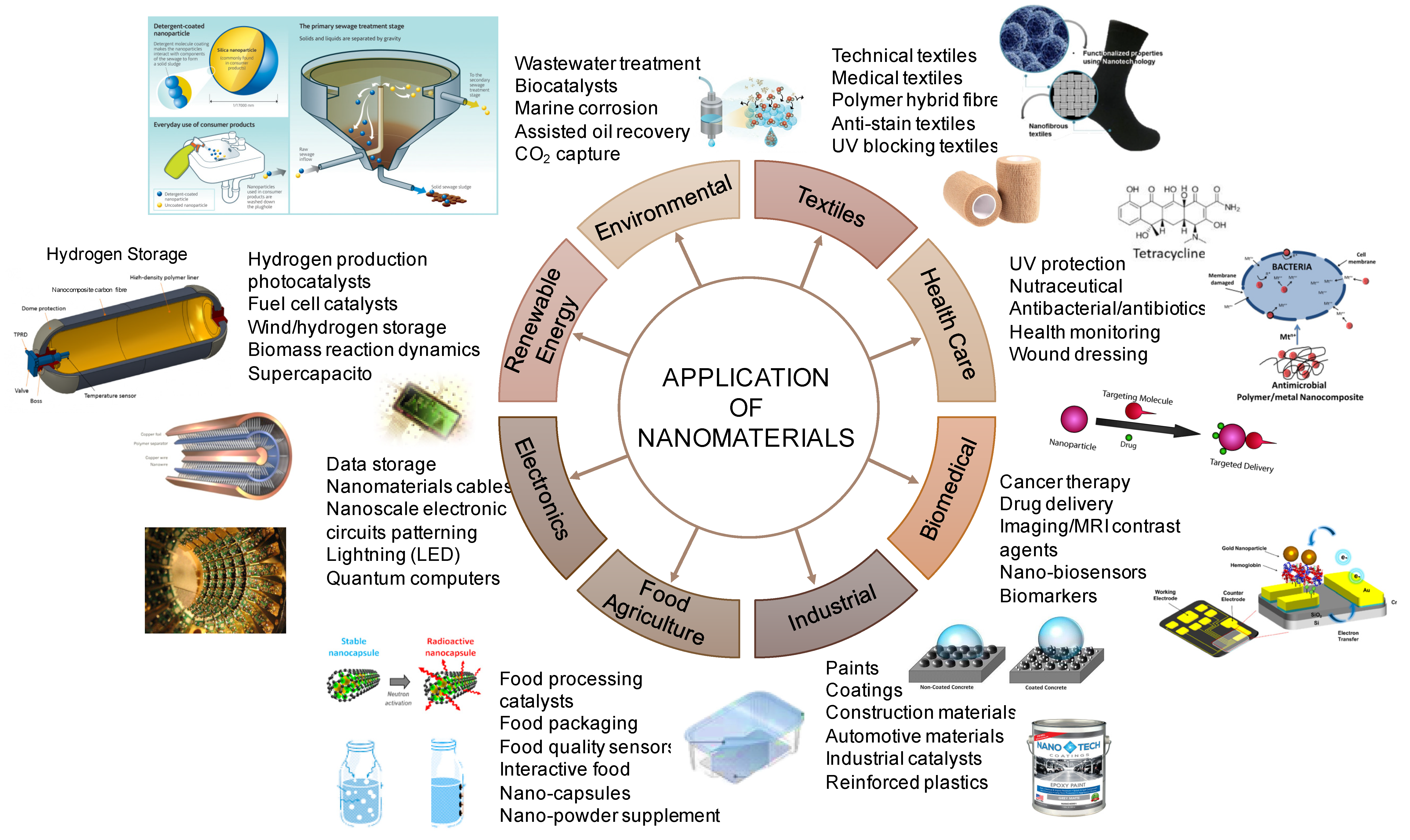

1. Introduction

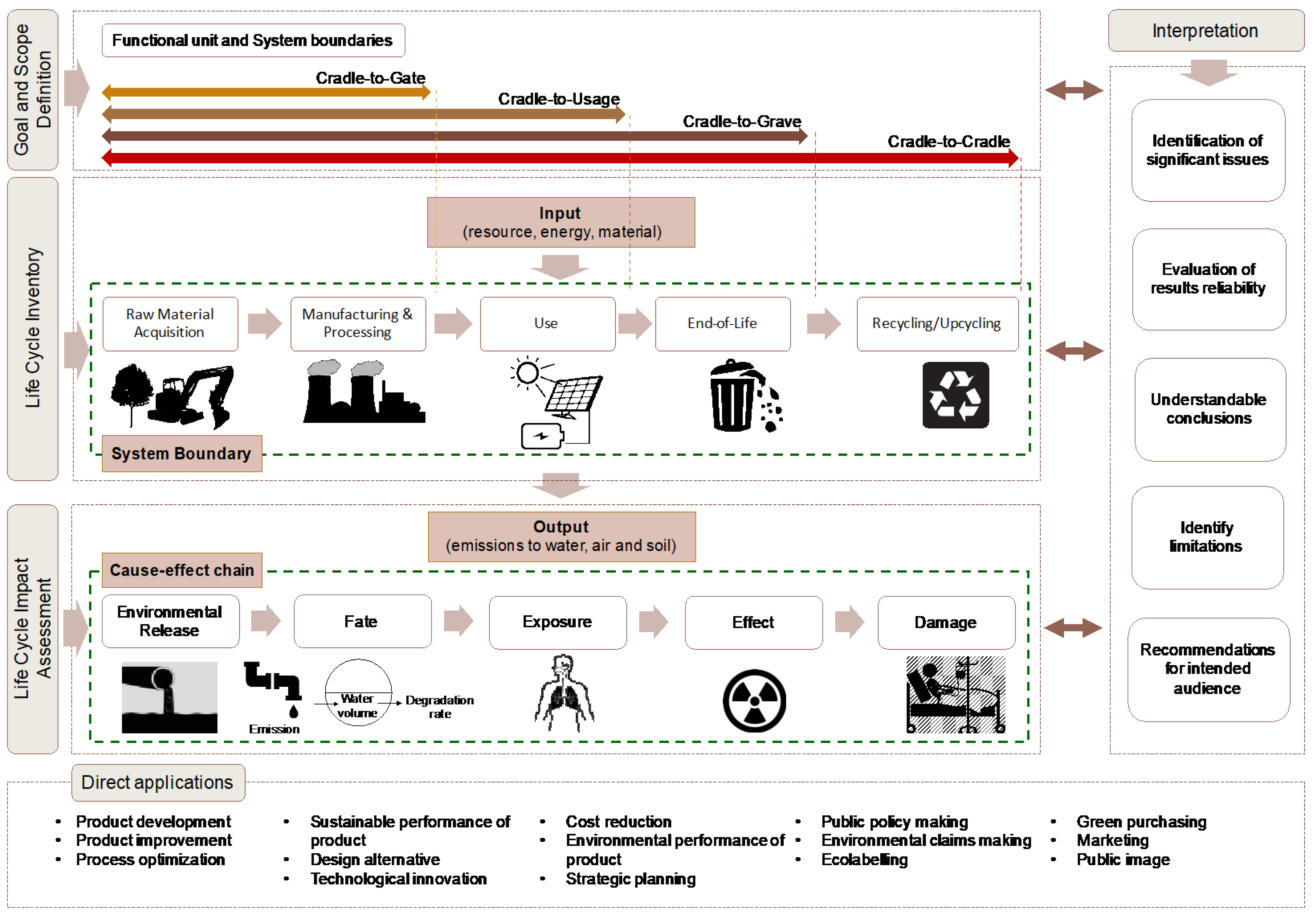

2. Life Cycle Assessment of Nanomaterials

2.1. Inclusion of Existing LCA Studies

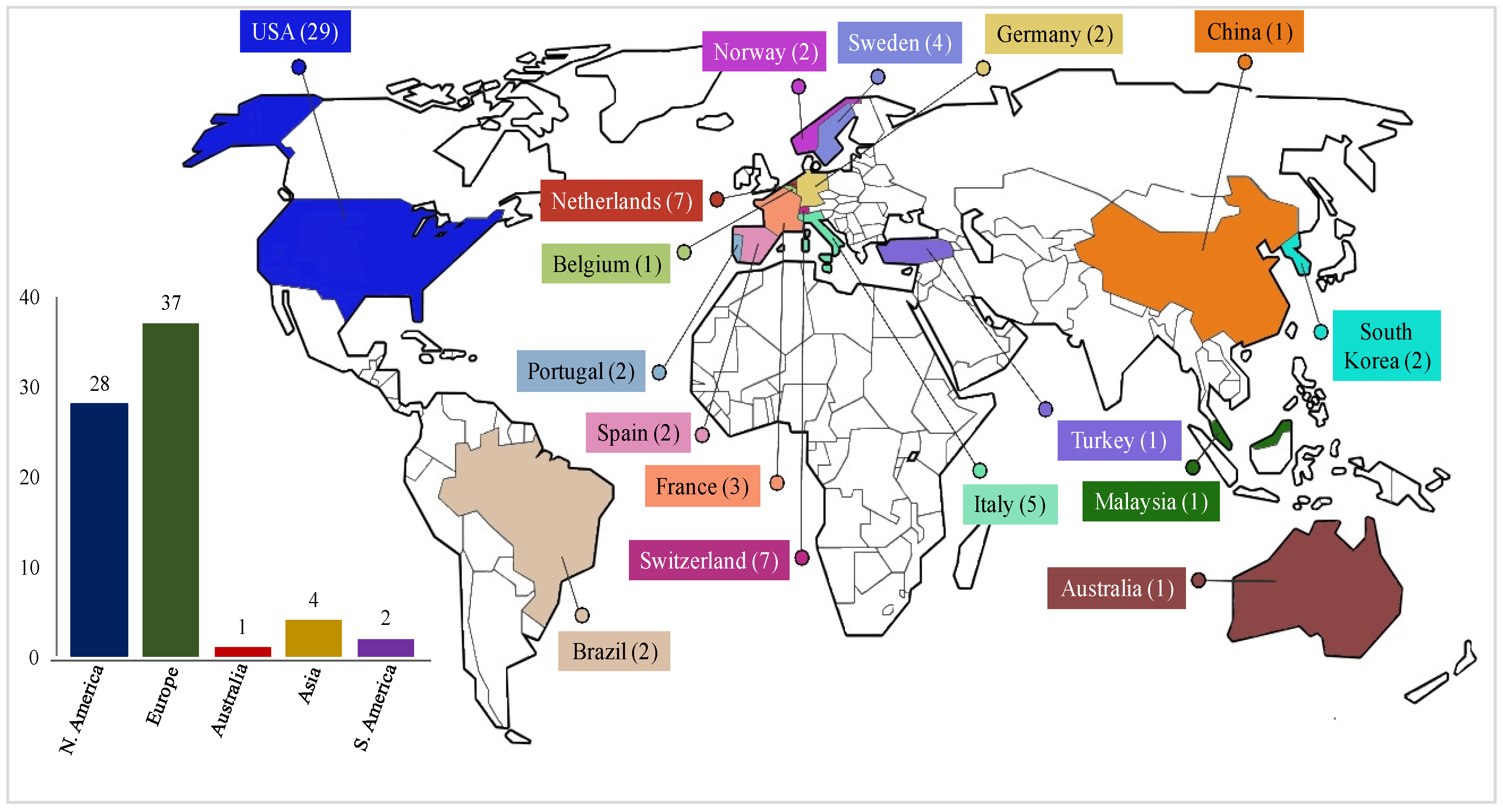

2.2. Research Subject and Geographical Distribution of LCA Studies

2.2.1. Functional Unit (FU)

2.2.2. System Boundaries

2.3. Life Cycle Inventory (LCI)

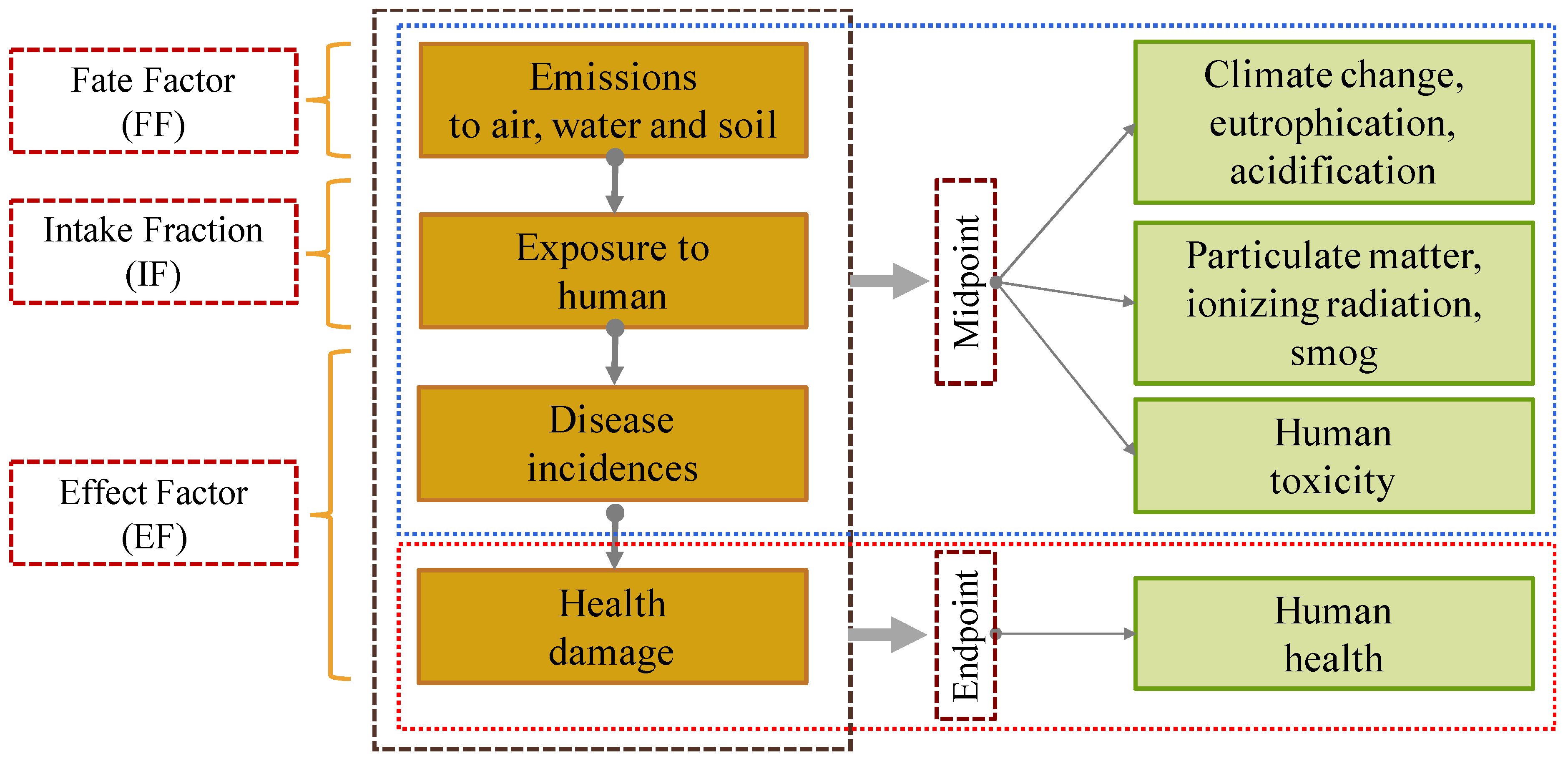

2.4. Life Cycle Impact Assessment (LCIA)

2.4.1. Fate Factor (FF)

2.4.2. Exposure Factor (XF)

2.4.3. Effect Factor (EF)

2.5. Interpretation

2.6. Advantages of Life Cycle Assessment Study

3. Limitations and Uncertainties in LCA Study

3.1. Limitation of Current LCA Studies on Nanomaterials

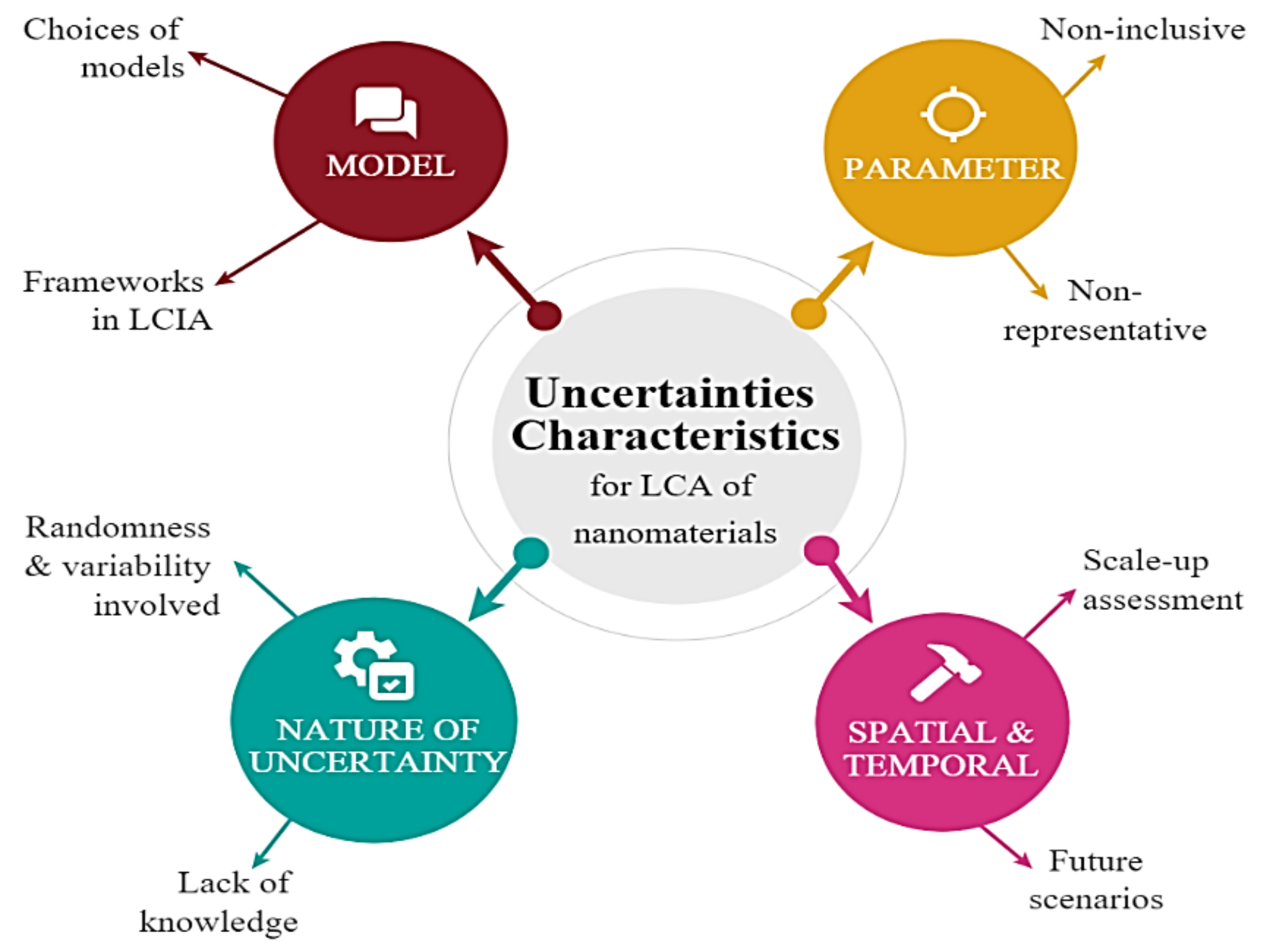

3.2. Uncertainty of LCA for Nanomaterials

4. Recommendations and Future Prospect of LCA for Nanomaterials

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, Z.; Han, S.; Zhou, S.; Feng, H.; Liu, Y.; Jia, G. Review of health safety aspects of titanium dioxide nanoparticles in food application. NanoImpact 2020, 18, 100224. [Google Scholar] [CrossRef]

- Huang, W.; Tao, F.; Li, F.; Mortimer, M.; Guo, L.-H. Antibacterial nanomaterials for environmental and consumer product applications. NanoImpact 2020, 20, 100268. [Google Scholar] [CrossRef]

- Weyell, P.; Kurland, H.D.; Hülser, T.; Grabow, J.; Müller, F.A.; Kralisch, D. Risk and life cycle assessment of nanoparticles for medical applications prepared using safe and benign-by-design gas-phase syntheses. Green Chem. 2020, 22, 814–827. [Google Scholar] [CrossRef] [Green Version]

- Arvidsson, R.; Hansen, S.F.; Baun, A. Influence of natural organic matter on the aquatic ecotoxicity of engineered nanoparticles: Recommendations for environmental risk assessment. NanoImpact 2020, 20, 100263. [Google Scholar] [CrossRef]

- Guerra, F.D.; Attia, M.F.; Whitehead, D.C.; Alexis, F. Nanotechnology for Environmental Remediation: Materials and Applications. Molecules 2018, 23, 1760. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cucurachi, S.; Rocha, C.F.B. Nanotechnology in Eco-efficient Construction, 2nd ed.Materials, Processes and Application: Life-Cycle Assessment of Engineered Nanomaterials; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Leiden, The Netherlands, January 2019; pp. 815–846. [Google Scholar]

- Kim, J.; Rivera, J.L.; Meng, T.Y.; Laratte, B.; Chen, S. Review of life cycle assessment of nanomaterials in photovoltaics. Sol. Energy 2016, 133, 249–258. [Google Scholar] [CrossRef]

- Hanafiah, M.M.; Hashim, N.A.; Ahmed, S.; Ashraf, M.A. Removal of chromium from aqueous solutions using a palm kernel shell adsorbent. Desalination Water Treat. 2018, 118, 172–180. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, W.; Kang, X.; Zhang, C. Rapid and efficient recovery of silver with nanoscale zerovalent iron supported on high performance activated carbon derived from straw biomass. Environ. Pollut. 2019, 255, 113043. [Google Scholar] [CrossRef]

- Pallas, G.; Vijver, M.G.; Peijnenburg, W.J.G.M.; Guinée, J. Life cycle assessment of emerging technologies at the lab scale: The case of nanowire-based solar cells. J. Ind. Ecol. 2019, 24, 193–204. [Google Scholar] [CrossRef]

- Hischier, R.; Walser, T. Life cycle assessment of engineered nanomaterials: State of the art and strategies to overcome existing gaps. Sci. Total Environ. 2012, 425, 271–282. [Google Scholar] [CrossRef]

- Hischier, R.; Nowack, B.; Gottschalk, F.; Hincapie, I.; Steinfeldt, M.; Som, C. Life cycle assessment of façade coating systems containing manufactured nanomaterials. J. Nanopart. Res. 2015, 17, 68. [Google Scholar] [CrossRef]

- Salieri, B.; Turner, D.A.; Nowack, B.; Hischier, R. Life cycle assessment of manufactured nanomaterials: Where are we? NanoImpact 2018, 10, 108–120. [Google Scholar] [CrossRef]

- Ludin, N.A.; Mustafa, N.I.; Hanafiah, M.M.; Ibrahim, M.A.; Teridi, M.A.M.; Sepeai, S.; Zaharim, A.; Sopian, K. Prospects of life cycle assessment of renewable energy from solar photovoltaic technologies: A review. Renew. Sustain. Energy Rev. 2018, 96, 11–28. [Google Scholar] [CrossRef]

- Nizam, N.U.M.; Hanafiah, M.M.; Mahmoudi, E.; Halim, A.A.; Mohammad, A.W. The removal of anionic and cationic dyes from an aqueous solution using biomass-based activated carbon. Sci. Rep. 2021, 11, 8623. [Google Scholar] [CrossRef] [PubMed]

- Salieri, B.; Kaiser, J.-P.; Rösslein, M.; Nowack, B.; Hischier, R.; Wick, P. Relative potency factor approach enables the use of in vitro information for estimation of human effect factors for nanoparticle toxicity in life-cycle impact assessment. Nanotoxicology 2020, 14, 275–286. [Google Scholar] [CrossRef] [PubMed]

- Romeo, D.; Salieri, B.; Hischier, R.; Nowack, B.; Wick, P. An integrated pathway based on in vitro data for the human hazard assessment of nanomaterials. Environ. Int. 2020, 137, 105505. [Google Scholar] [CrossRef] [PubMed]

- Martins, F.; Machado, S.; Albergaria, T.; Delerue-Matos, C. LCA applied to nano scale zero valent iron synthesis. Int. J. Life Cycle Assess. 2017, 22, 707–714. [Google Scholar] [CrossRef] [Green Version]

- Aziz, N.I.H.A.; Hanafiah, M.M.; Gheewala, S.H. A review on life cycle assessment of biogas production: Challenges and future perspectives in Malaysia. Biomass Bioenergy 2019, 122, 361–374. [Google Scholar] [CrossRef]

- Woon, K.S.; Lo, I.M.; Chiu, S.L.; Yan, D.Y. Environmental assessment of food waste valorization in producing biogas for various types of energy use based on LCA approach. Waste Manag. 2016, 50, 290–299. [Google Scholar] [CrossRef]

- Temizel-Sekeryan, S.; Hicks, A.L. Global environmental impacts of silver nanoparticle production methods supported by life cycle assessment. Resour. Conserv. Recy. 2020, 156, 104676. [Google Scholar] [CrossRef]

- Ismail, H.; Hanafiah, M.M. An overview of LCA application in WEEE management: Current practices, progress and challenges. J. Clean. Prod. 2019, 232, 79–93. [Google Scholar] [CrossRef]

- Ismail, H.; Hanafiah, M.M. Discovering opportunities to meet the challenges of an effective waste electrical and electronic equipment recycling system in Malaysia. J. Clean. Prod. 2019, 238, 117927. [Google Scholar] [CrossRef]

- Chong, W.C.; Chung, Y.T.; Teow, Y.H.; Zain, M.M.; Mahmoudi, E.; Mohammad, A.W. Environmental impact of nanomaterials in composite membranes: Life cycle assessment of algal membrane photoreactor using polyvinylidene fluoride—Composite membrane. J. Clean. Prod. 2018, 202, 591–600. [Google Scholar] [CrossRef]

- Chiu, S.L.H.; Lo, I.M.C.; Woon, K.S.; Yan, D.Y.S. Sustainability evaluation and identification of waste management strategy for sewage sludge and food waste in Macau using life cycle assessment. Int. J. Life Cycle Assess. 2016, 21, 176–189. [Google Scholar] [CrossRef]

- Greijer, H.; Karlson, L.; Lindquist, S.-E.; Hagfeldt, A. Environmental aspects of electricity generation from a nanocrystalline dye sensitized solar cell system. Renew. Energy 2001, 23, 27–39. [Google Scholar] [CrossRef]

- Lloyd, S.M.; Lave, L.B. Life Cycle Economic and Environmental Implications of Using Nanocomposites in Automobiles. Environ. Sci. Technol. 2003, 37, 3458–3466. [Google Scholar] [CrossRef]

- Lloyd, S.M.; Lave, L.B.; Matthews, H.S. Life Cycle Benefits of Using Nanotechnology to Stabilize Platinum-Group Metal Particles in Automotive Catalysts. Environ. Sci. Technol. 2005, 39, 1384–1392. [Google Scholar] [CrossRef] [PubMed]

- Osterwalder, N.; Capello, C.; Hungerbühler, K.; Stark, W.J. Energy Consumption During Nanoparticle Production: How Economic Is Dry Synthesis? J. Nanopart. Res. 2006, 8, 1. [Google Scholar] [CrossRef] [Green Version]

- Isaacs, J.; Tanwani, A.; Healy, M. Environmental Assessment of SWNT Production. In Proceedings of the 2006 IEEE International Symposium on Electronics and the Environment, Scottsdale, AZ, USA, 8–11 May 2006; pp. 38–41. [Google Scholar]

- Roes, A.L.; Marsili, E.; Nieuwlaar, E.; Patel, M.K. Environmental and Cost Assessment of a Polypropylene Nanocomposite. J. Polym. Environ. 2007, 15, 212–226. [Google Scholar] [CrossRef] [Green Version]

- Pietrini, M.; Roes, L.; Patel, M.K.; Chiellini, E. Comparative Life Cycle Studies on Poly(3-hydroxybutyrate)-Based Composites as Potential Replacement for Conventional Petrochemical Plastics. Biomacromolecules 2007, 8, 2210–2218. [Google Scholar] [CrossRef] [Green Version]

- Köhler, A.R.; Som, C.; Helland, A.; Gottschalk, F. Studying the potential release of carbon nanotubes throughout the application life cycle. J. Clean. Prod. 2008, 16, 927–937. [Google Scholar] [CrossRef]

- Krishnan, N.; Boyd, S.; Somani, A.; Raoux, S.; Clark, D.; Dornfeld, D. A Hybrid Life Cycle Inventory of Nano-Scale Semiconductor Manufacturing. Environ. Sci. Technol. 2008, 42, 3069–3075. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Joshi, S. Can Nanotechnology Improve the Sustainability of Biobased Products? The Case of Layered Silicate Biopolymer Nanocomposites. J. Ind. Ecol. 2008, 12, 474–489. [Google Scholar]

- Khanna, V.; Bakshi, B.R.; Lee, L.J. Carbon Nanofiber Production: Life Cycle Energy Consumption and Environmental Impact. J. Ind. Ecol. 2008, 12, 394–410. [Google Scholar] [CrossRef]

- Kushnir, D.; Sandén, B.A. Energy Requirements of Carbon Nanoparticle Production. J. Ind. Ecol. 2008, 12, 360–375. [Google Scholar] [CrossRef]

- Healy, M.L.; Dahlben, L.J.; Isaacs, J.A. Environmental Assessment of Single-Walled Carbon Nanotube Processes. J. Ind. Ecol. 2008, 12, 376–393. [Google Scholar] [CrossRef]

- Khanna, V.; Bakshi, B.R. Carbon Nanofiber Polymer Composites: Evaluation of Life Cycle Energy Use. Environ. Sci. Technol. 2009, 43, 2078–2084. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.M. Quantification of the Environmental Benefits of Ultrafine/Nanotitanium Dioxide Photocatalyst Coatings for Concrete Pavement Using Hybrid Life-Cycle Assessment. J. Infrastruct. Syst. 2010, 16, 160–166. [Google Scholar] [CrossRef]

- Merugula, L.A.; Khanna, V.; Bakshi, B.R. Comparative life cycle assessment: Reinforcing wind turbine blades with carbon nanofibers. In Proceedings of the 2010 IEEE International Symposium on Sustainable Systems and Technology, Arlington, VA, USA, 17–19 May 2010; pp. 1–6. [Google Scholar]

- Moign, A.; Vardelle, A.; Themelis, N.; Legoux, J. Life cycle assessment of using powder and liquid precursors in plasma spraying: The case of yttria-stabilized zirconia. Surf. Coat. Technol. 2010, 205, 668–673. [Google Scholar] [CrossRef]

- Grubb, G.F.; Bakshi, B.R. Life Cycle of Titanium Dioxide Nanoparticle Production: Impact of Emissions and Use of Resources. J. Ind. Ecol. 2010, 15, 81–95. [Google Scholar] [CrossRef]

- Ganter, M.J.; Seager, T.P.; Schauerman, C.M.; Landi, B.J.; Raffaelle, R.P. A life-cycle energy analysis of single wall carbon nanotubes produced through laser vaporization. In Proceedings of the 2009 IEEE International Symposium on Sustainable Systems and Technology, Tempe, AZ, USA, 18–20 May 2009; pp. 1–4. [Google Scholar]

- Steinfeldt, M.; Gleich, A.V.; Petschow, U.; Pade, C.; Sprenger, R.-U. Environmental relief effects through nanotechnological processes and products. Abr. Version UBA 2010, 22, 2010. [Google Scholar]

- Şengül, H.; Theis, T.L. An environmental impact assessment of quantum dot photovoltaics (QDPV) from raw material acquisition through use. J. Clean. Prod. 2011, 19, 21–31. [Google Scholar] [CrossRef]

- Meyer, D.E.; Curran, M.A.; Gonzalez, M.A. An examination of silver nanoparticles in socks using screening-level life cycle assessment. J. Nanopart. Res. 2010, 13, 147–156. [Google Scholar] [CrossRef]

- Walser, T.; Demou, E.; Lang, D.J.; Hellweg, S. Prospective Environmental Life Cycle Assessment of Nanosilver T-Shirts. Environ. Sci. Technol. 2011, 45, 4570–4578. [Google Scholar] [CrossRef]

- Van Der Meulen, R.; Alsema, E. Life-cycle greenhouse gas effects of introducing nano-crystalline materials in thin-film silicon solar cells. Prog. Photovolt. Res. Appl. 2011, 19, 453–463. [Google Scholar] [CrossRef]

- Wender, B.A. Anticipatory Life Cycle Assessment of Single Wall Carbon Nanotube Anode Lithium-Ion Batteries; Center of Earth Systems Engineering and Management, Arizona State University: Tempe, AZ, USA, 2012. [Google Scholar]

- LeCorre, D.; Hohenthal, C.; Dufresne, A.; Bras, J. Comparative Sustainability Assessment of Starch Nanocrystals. J. Polym. Environ. 2013, 21, 71–80. [Google Scholar] [CrossRef]

- Weil, M.; Dura, H.; Shimon, B.; Baumann, M.; Zimmermann, B.; Ziemann, S.; Lei, C.; Markoulidis, F.; Lekakou, T.; Decker, M. Ecological assessment of nano-enabled supercapacitors for automotive applications. IOP Conf. Ser. Mater. Sci. Eng. 2012, 40, 012013. [Google Scholar] [CrossRef] [Green Version]

- Manda, B.K.; Blok, K.; Patel, M.K. Innovations in papermaking: An LCA of printing and writing paper from conventional and high yield pulp. Sci. Total Environ. 2012, 439, 307–320. [Google Scholar] [CrossRef]

- De Figueirêdo, M.C.B.; de Freitas Rosa, M.; Ugaya, C.M.L.; de Souza Filho, M.d.S.M.; da Silva Braid, A.C.C.; de Melo, L.F.L. Life cycle assessment of cellulose nanowhiskers. J. Clean. Prod. 2012, 35, 130–139. [Google Scholar] [CrossRef]

- Eckelman, M.J.; Mauter, M.S.; Isaacs, J.A.; Elimelech, M. New Perspectives on Nanomaterial Aquatic Ecotoxicity: Production Impacts Exceed Direct Exposure Impacts for Carbon Nanotubes. Environ. Sci. Technol. 2012, 46, 2902–2910. [Google Scholar] [CrossRef]

- Deorsola, F.; Russo, N.; Blengini, G.; Fino, D. Synthesis, characterization and environmental assessment of nanosized MoS2 particles for lubricants applications. Chem. Eng. J. 2012, 195–196, 1–6. [Google Scholar] [CrossRef]

- Anctil, A.; Fthenakis, V. Life Cycle Assessment of Organic Photovoltaics. Third Generation: Photovoltaics; IntechOpen: London, UK, 2012; pp. 91–110. [Google Scholar]

- Dahlben, L.J.; Eckelman, M.J.; Hakimian, A.; Somu, S.; Isaacs, J. Environmental Life Cycle Assessment of a Carbon Nanotube-Enabled Semiconductor Device. Environ. Sci. Technol. 2013, 47, 8471–8478. [Google Scholar] [CrossRef] [PubMed]

- Babaizadeh, H.; Hassan, M. Life cycle assessment of nano-sized titanium dioxide coating on residential windows. Constr. Build. Mater. 2013, 40, 314–321. [Google Scholar] [CrossRef]

- Keller, A.A.; McFerran, S.; Lazareva, A.; Suh, S. Global life cycle releases of engineered nanomaterials. J. Nanopart. Res. 2013, 15, 1692. [Google Scholar] [CrossRef]

- Gao, T.; Jelle, B.P.; Sandberg, L.I.C.; Gustavsen, A. Monodisperse Hollow Silica Nanospheres for Nano Insulation Materials: Synthesis, Characterization, and Life Cycle Assessment. ACS Appl. Mater. Interfaces 2013, 5, 761–767. [Google Scholar] [CrossRef]

- Li, Q.; McGinnis, S.; Sydnor, C.; Wong, A.; Renneckar, S. Nanocellulose Life Cycle Assessment. ACS Sustain. Chem. Eng. 2013, 1, 919–928. [Google Scholar] [CrossRef]

- Pourzahedi, L.; Eckelman, M.J. Environmental Life Cycle Assessment of Nanosilver-Enabled Bandages. Environ. Sci. Technol. 2015, 49, 361–368. [Google Scholar] [CrossRef]

- Upadhyayula, V.K.K.; Meyer, D.E.; Curran, M.A.; Gonzalez, M.A. Evaluating the Environmental Impacts of a Nano-Enhanced Field Emission Display Using Life Cycle Assessment: A Screening-Level Study. Environ. Sci. Technol. 2014, 48, 1194–1205. [Google Scholar] [CrossRef]

- Gu, H.; Reiner, R.; Bergman, R.; Rudie, A. LCA Study for Pilot Scale Production of Cellulose Nano Crystals (Cnc) from Wood Pulp. October 2015. In Proceedings of the LCA XV Conference, Vancouver, BC, Canada, 6–8 October 2015; pp. 33–42. [Google Scholar]

- Pati, P.; Mcginnis, S.; Vikesland, P.J. Life Cycle Assessment of “Green” Nanoparticle Synthesis Methods. Environ. Eng. Sci. 2014, 31, 410–420. [Google Scholar] [CrossRef]

- Pizza, A.; Metz, R.; Hassanzadeh, M.; Bantignies, J.-L. Life cycle assessment of nanocomposites made of thermally conductive graphite nanoplatelets. Int. J. Life Cycle Assess. 2014, 19, 1226–1237. [Google Scholar] [CrossRef]

- Gilbertson, L.M.; Busnaina, A.A.; Isaacs, J.; Zimmerman, J.; Eckelman, M.J. Life Cycle Impacts and Benefits of a Carbon Nanotube-Enabled Chemical Gas Sensor. Environ. Sci. Technol. 2014, 48, 11360–11368. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Garcia, G.; Zimmermann, B.; Weil, M. Nanotoxicity and Life Cycle Assessment: First attempt towards the determination of characterization factors for carbon nanotubes. IOP Conf. Ser. Mater. Sci. Eng. 2014, 64, 012029. [Google Scholar] [CrossRef]

- Arvidsson, R.; Kushnir, D.; Sandén, B.A.; Molander, S. Prospective Life Cycle Assessment of Graphene Production by Ultrasonication and Chemical Reduction. Environ. Sci. Technol. 2014, 48, 4529–4536. [Google Scholar] [CrossRef] [PubMed]

- Gao, T.; Sandberg, L.I.C.; Jelle, B.P. Nano Insulation Materials: Synthesis and Life Cycle Assessment. Procedia CIRP 2014, 15, 490–495. [Google Scholar] [CrossRef] [Green Version]

- Barton, L.E.; Auffan, M.; Olivi, L.; Bottero, J.-Y.; Wiesner, M.R. Heteroaggregation, transformation and fate of CeO2 nanoparticles in wastewater treatment. Environ. Pollut. 2015, 203, 122–129. [Google Scholar] [CrossRef] [PubMed]

- Arvidsson, R.; Nguyen, D.; Svanström, M. Life Cycle Assessment of Cellulose Nanofibrils Production by Mechanical Treatment and Two Different Pretreatment Processes. Environ. Sci. Technol. 2015, 49, 6881–6890. [Google Scholar] [CrossRef] [PubMed]

- Bobba, S.; Deorsola, F.A.; Blengini, G.A.; Fino, D. LCA of tungsten disulphide (WS2) nano-particles synthesis: State of art and from-cradle-to-gate LCA. J. Clean. Prod. 2016, 139, 1478–1484. [Google Scholar] [CrossRef]

- Deng, Y.; Li, J.; Qiu, M.; Yang, F.; Zhang, J.; Yuan, C. Deriving characterization factors on freshwater ecotoxicity of graphene oxide nanomaterial for life cycle impact assessment. Int. J. Life Cycle Assess. 2017, 22, 222–236. [Google Scholar] [CrossRef]

- Pourzahedi, L. Environmental impact assessment of nanoparticles and nano-enabled products using LCA frameworks. In The Department of Civil and Environmental Engineering; Northeastern University Library: Boston, MA, USA, 2021. [Google Scholar]

- Chappell, M.A.; Shih, W.S.; Bledsoe, J.K.; Cox, C.; Janzen, D.; Gibbons, S.; Patel, R.; Kennedy, A.J.; Brame, J.; Brondum, M.; et al. Environmental life cycle assessment for a carbon nanotube-based printed electronic sensor platform. Adv. Mater. 2017, 1, 345–347. [Google Scholar]

- Sackey, S.; Lee, D.-E.; Kim, B.-S. Life Cycle Assessment for the Production Phase of Nano-Silica-Modified Asphalt Mixtures. Appl. Sci. 2019, 9, 1315. [Google Scholar] [CrossRef] [Green Version]

- Bartolozzi, I.; Daddi, T.; Punta, C.; Fiorati, A.; Iraldo, F. Life cycle assessment of emerging environmental technologies in the early stage of development: A case study on nanostructured materials. J. Ind. Ecol. 2019, 24, 101–115. [Google Scholar] [CrossRef]

- Visentin, C.; da Silva Trentin, A.W.; Braun, A.B.; Thomé, A. Nano Scale Zero Valent Iron Production Methods Applied to Contaminated Sites Remediation: An Overview of Production and Environmental Aspects. J. Hazard. Mater. 2021, 410, 124614. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Wu, F.; Gong, Y. Oxidation and adsorption of antimony(iii) from surface water using novel Al2O3-supported Fe–Mn binary oxide nanoparticles: Effectiveness, dynamic quantitative mechanisms, and life cycle analysis. Environ. Sci. Nano 2020, 7, 3047–3061. [Google Scholar] [CrossRef]

- Feijoo, S.; González-Rodríguez, J.; Fernández, L.; Vázquez-Vázquez, C.; Feijoo, G.; Moreira, M.T. Fenton and Photo-Fenton Nanocatalysts Revisited from the Perspective of Life Cycle Assessment. Catalysts 2019, 10, 23. [Google Scholar] [CrossRef] [Green Version]

- Gunasekara, C.; Sandanayake, M.; Zhou, Z.; Law, D.W.; Setunge, S. Effect of nano-silica addition into high volume fly ash–hydrated lime blended concrete. Constr. Build. Mater. 2020, 253, 119205. [Google Scholar] [CrossRef]

- Huseien, G.F.; Hamzah, H.K.; Sam, A.R.M.; Khalid, N.H.A.; Shah, K.W.; Deogrescu, D.P.; Mirza, J. Alkali-activated mortars blended with glass bottle waste nano powder: Environmental benefit and sustainability. J. Clean. Prod. 2020, 243, 118636. [Google Scholar] [CrossRef]

- Ingrao, C.; Vesce, E.; Evola, R.S.; Rebba, E.; Arcidiacono, C.; Martra, G.; Beltramo, R. Chemistry behind leather: Life Cycle Assessment of nano-hydroxyapatite preparation on the lab-scale for fireproofing applications. J. Clean. Prod. 2021, 279, 123837. [Google Scholar] [CrossRef]

- Lee, J.; Ryu, K.H.; Ha, H.Y.; Jung, K.-D.; Lee, J.H. Techno-economic and environmental evaluation of nano calcium carbonate production utilizing the steel slag. J. CO2 Util. 2020, 37, 113–121. [Google Scholar] [CrossRef]

- Petrakli, F.; Gkika, A.; Bonou, A.; Karayannis, P.; Koumoulos, E.; Semitekolos, D.; Trompeta, A.-F.; Rocha, N.; Santos, R.; Simmonds, G.; et al. End-of-Life Recycling Options of (Nano)Enhanced CFRP Composite Prototypes Waste—A Life Cycle Perspective. Polymer 2020, 12, 2129. [Google Scholar] [CrossRef]

- Rodrigues, N.P.; Scott-Fordsmand, J.J.; Amorim, M.J. Novel understanding of toxicity in a life cycle perspective–The mechanisms that lead to population effect–The case of Ag (nano) materials. Environ. Pollut. 2020, 262, 114277. [Google Scholar] [CrossRef] [PubMed]

- Rossi, F.; Parisi, M.L.; Maranghi, S.; Basosi, R.; Sinicropi, A. Environmental analysis of a nano-grid: A Life Cycle Assessment. Sci. Total Environ. 2020, 700, 134814. [Google Scholar] [CrossRef] [PubMed]

- Mullen, E.; Morris, M. Green Nanofabrication Opportunities in the Semiconductor Industry: A Life Cycle Perspective. Nanomaterials 2021, 11, 1085. [Google Scholar] [CrossRef] [PubMed]

- Park, W.-J.; Kim, T.; Roh, S.; Kim, R. Analysis of Life Cycle Environmental Impact of Recycled Aggregate. Appl. Sci. 2019, 9, 1021. [Google Scholar] [CrossRef] [Green Version]

- Miseljic, M.; Olsen, S.I. Life-cycle assessment of engineered nanomaterials: A literature review of assessment status. J. Nanopart. Res. 2014, 16, 2427. [Google Scholar] [CrossRef]

- Hischier, R.; Salieri, B.; Pini, M. Most important factors of variability and uncertainty in an LCA study of nanomaterials—Findings from a case study with nano titanium dioxide. NanoImpact 2017, 7, 17–26. [Google Scholar] [CrossRef]

- Bjørn, A.; Hauschild, M.Z. Cradle to Cradle and LCA. In Life Cycle Assessment; Springer: Cham, Switzerland, 2018; pp. 605–631. [Google Scholar]

- Moloi, M.S.; Lehutso, R.F.; Erasmus, M.; Oberholster, P.J.; Thwala, M. Aquatic Environment Exposure and Toxicity of Engineered Nanomaterials Released from Nano-Enabled Products: Current Status and Data Needs. Nanomaterials 2021, 11, 2868. [Google Scholar] [CrossRef] [PubMed]

- Phuang, Z.X.; Woon, K.S.; Wong, K.J.; Liew, P.Y.; Hanafiah, M.M. Unlocking the Environmental Hotspots of Palm Biodiesel Upstream Production in Malaysia via Life Cycle Assessment. Energy 2021, 232, 121206. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Zijp, M.; Van Zelm, R. ReCiPe 2017: A harmonized life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2016, 22, 138–147. [Google Scholar] [CrossRef]

- Aziz, N.I.H.A.; Hanafiah, M.M. Life cycle analysis of biogas production from anaerobic digestion of palm oil mill effluent. Renew. Energy 2020, 145, 847–857. [Google Scholar] [CrossRef]

- Gavankar, S.; Suh, S.; Keller, A.A. Life Cycle Assessment of Engineered Nanomaterials, in Health and Environmental Safety of Nanomaterials: Polymer Nancomposites and Other Materials Containing Nanoparticles; Njuguna, J., Pielichowski, K., Zhu, H., Eds.; Woodhead Publishing: Cambridge, UK, 2014; pp. 112–129. [Google Scholar]

- Steinfeldt, M. Environmental Exposure to Engineered Nanomaterial from Four Applications: Nanotio2 in Paint, NanoZnO in Glass Coatings, MWCNT in Epoxy Plates, and Nanocellulose as a Paper Additive; Project Report of the Work Package 4 of the Nanosustain Project; Nanosustain Project: Bremen, Germany, 2013. [Google Scholar]

- Salieri, B.; Hischier, R.; Quik, J.T.; Jolliet, O. Fate modelling of nanoparticle releases in LCA: An integrative approach towards “USEtox4Nano”. J. Clean. Prod. 2019, 206, 701–712. [Google Scholar] [CrossRef]

- Boldrin, A.; Hansen, S.F.; Baun, A.; Hartmann, N.B.; Astrup, T.F. Environmental exposure assessment framework for nanoparticles in solid waste. J. Nanopart. Res. 2014, 16, 2394. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mitrano, D.; Nowack, B. The need for a life-cycle based aging paradigm for nanomaterials: Importance of real-world test systems to identify realistic particle transformations. Nanotechnology 2017, 28, 072001. [Google Scholar] [CrossRef]

- Seabra, A.B.; Paula, A.J.; de Lima, R.; Alves, O.L.; Durán, N. Nanotoxicity of Graphene and Graphene Oxide. Chem. Res. Toxicol. 2014, 27, 159–168. [Google Scholar] [CrossRef]

- Hanafiah, M.M.; Hendriks, A.J.; Huijbregts, M.A.J. Comparing the ecological footprint with the biodiversity footprint of products. J. Clean. Prod. 2012, 37, 107–114. [Google Scholar] [CrossRef]

- Hanafiah, M.M.; Huijbregts, M.A.J.; Hendriks, J. The influence of nutrients and non-CO2 greenhouse gas emissions on the ecological footprint of products. Sustainability 2010, 2, 963–979. [Google Scholar] [CrossRef] [Green Version]

- Hanafiah, M.M.; Leuven, R.S.E.W.; Sommerwerk, N.; Tockner, K.; Huijbregts, M.A.J. Including the introduction of exotic species in life cycle impact assessment: The case of inland shipping. Environ. Sci. Technol. 2013, 47, 13934–13940. [Google Scholar] [CrossRef] [PubMed]

- Parsons, S.; Murphy, R.; Lee, J.; Sims, G. Uncertainty communication in the environmental life cycle assessment of carbon nanotubes. Int. J. Nanotechnol. 2015, 12, 620. [Google Scholar] [CrossRef] [Green Version]

- Lacirignola, M.; Blanc, P.; Girard, R.; Perez-Lopez, P.; Blanc, I. LCA of emerging technologies: Addressing high uncertainty on inputs’ variability when performing global sensitivity analysis. Sci. Total Environ. 2017, 578, 268–280. [Google Scholar] [CrossRef]

- Walser, T.; Gottschalk, F. Stochastic fate analysis of engineered nanoparticles in incineration plants. J. Clean. Prod. 2014, 80, 241–251. [Google Scholar] [CrossRef]

- Beloin-Saint-Pierre, D.; Turner, D.A.; Salieri, B.; Haarman, A.; Hischier, R. How suitable is LCA for nanotechnology assessment? Overview of current methodological pitfalls and potential solutions: 65th LCA Discussion Forum, Swiss Federal Institute of Technology, Zürich, May 24, 2017. Int. J. Life Cycle Assess. 2017, 23, 191–196. [Google Scholar] [CrossRef]

- Igos, E.; Benetto, E.; Meyer, R.; Baustert, P.; Othoniel, B. How to treat uncertainties in life cycle assessment studies? Int. J. Life Cycle Assess. 2019, 24, 794–807. [Google Scholar] [CrossRef]

- Gilbertson, L.M.; Wender, B.A.; Zimmerman, J.B.; Eckelman, M.J. Coordinating modeling and experimental research of engineered nanomaterials to improve life cycle assessment studies. Environ. Sci. Nano 2015, 2, 669–682. [Google Scholar] [CrossRef]

- Inshakova, E.; Inshakov, O. World market for nanomaterials: Structure and trends. MATEC Web Conf. 2017, 129, 02013. [Google Scholar] [CrossRef]

- Jakovljevic, M.; Sugahara, T.; Timofeyev, Y.; Rancic, N. Predictors of (in)efficiencies of Healthcare Expenditure Among the Leading Asian Economies—Comparison of OECD and Non-OECD Nations. Health Policy 2020, 13, 2261–2280. [Google Scholar] [CrossRef] [PubMed]

- Milea, D.; Azmi, S.; Reginald, P.; Verpillat, P.; Francois, C. A review of accessibility of administrative healthcare databases in the Asia-Pacific region. J. Mark. Access Health Policy 2015, 3, 28076. [Google Scholar] [CrossRef]

| No. | Reference | Type of Nanomaterials | Method/Software | Impact Categories | System Boundaries | Functional Unit | Impact Assessment | |

|---|---|---|---|---|---|---|---|---|

| Mid-Point | Endpoint | |||||||

| 1. | [26] | Nanocrystalline | Ecoindicator 95, Environmental Priority Strategies (EPS), Eco Sweden, Eco Netherlands and Environmental Design of Industrial Products (EDIP)/SimaPro | Greenhouse gases (GHG) emissions, air emissions, electricity generation | Cradle-to-grave | 1 kWh electricity | O | O |

| 2. | [27] | Nanoclay polymer composites | Economic Input-Output Life Cycle Assessment (EIO-LCA) through Economic Input-Output (EIO) model/GaBi 4 | Projected fuel savings, Carbon Dioxide (CO2) reduction, economic inputs and outputs, GHG emissions, toxic releases | Cradle-to-grave | 16.9 million light-duty vehicles, 210 million vehicles on the road | O | O |

| 3. | [28] | Nanoscale platinum-group metal particles | EIO-LCA through EIO model/GaBi 4 | Economic inputs and outputs, economic purchases, emissions of conventional pollutants and greenhouse gases, RCRA hazardous waste, toxic releases | Cradle-to-gate | Projected motor vehicles in the US between 2005 and 2030 | O | O |

| 4. | [29] | Various oxide nanoparticles | Not stated - Ecoinvent | Energy consumption, CO2 emissions | Cradle-to-gate | 1 kg | O | X |

| 5. | [30] | Single-walled carbon nanotubes | EPS 2000/SimaPro | Human health, production capacity, abiotic resources, biodiversity | Cradle-to-gate | 1 g | O | X |

| 6. | [31] | Nanoclay polypropylene layered silicate nanocomposite packaging film | Not stated/SimaPro Derived from the latter: energy and material data from the pilot plant | Non-renewable energy use (NREU), GHG emissions | Cradle-to-grave | 1000 bags | O | X |

| 7. | [31] | Nanoclay polypropylene layered silicate nanocomposite agricultural film | Not stated/SimaPro Derived from the latter energy and material data from the pilot plant | GHG emissions | Cradle-to-grave | Coverage of 650 m3 | O | X |

| 8. | [31] | Nanoclay polypropylene layered silicate nanocomposite automotive panels | Not stated/SimaPro Derived from the latter energy and material data from the pilot plant | NREU, GHG emissions, abiotic depletion, ozone layer depletion, photochemical oxidant formation, acidification, eutrophication | Cradle-to-grave | Internal panel of low-weight family car over 150,000 km operation | O | X |

| 9. | [32] | Nanoscaled organophilic montmorillonite in PHB fillers | Not stated PlasticsEurope LCA database used | GHG emissions and NREU | Cradle-to-grave | 17-inch CRT monitor | O | O |

| 10. | [33] | Single-walled carbon nanotubes | Not stated | Human exposure | Cradle-to-grave | 1 kg | O | X |

| 11. | [34] | Nanoscale semiconductor fabrication and manufacturing | EIO-LCA through EIO model/SimaPro Primary data used | Economic inputs and outputs, GHG emissions (uncertainty included) | Cradle-to-gate | 1 wafer with 300 mm diameter | O | X |

| 12. | [35] | Nanoclay biopolymer composites | Not stated Ecobilan’s Data for Environmental Analysis and Management (DEAM)™ LCA database used | Energy demand and GHG emissions, non-renewable energy savings | Cradle-to-gate | 1 kg | O | X |

| 13. | [36] | Carbon nanofibers | Not stated/SimaPro Industrial data of the United States (US) economy for the 20th century and US LCI database used | Energy analysis, GHG emissions, human toxicity potential (sensitivity analysis included) | Cradle-to-gate | 1 kg | O | O |

| 14. | [37] | Fullerenes and single-walled carbon nanotubes | Not stated PlasticsEurope, LCA database used | Energy consumption, carbon yield | Cradle-to-gate | 1 kg | O | O |

| 15. | [38] | Single-walled carbon nanotubes | Not stated/SimaPro HiPco model inventory used | Climate change, airborne inorganics, acidification | Cradle-to-gate | 1 g | O | O |

| 16. | [39] | Carbon nanofibers—Polymer nanocomposites | Not stated PlasticsEurope, LCA databases used | GHG emissions and impact (toxicity impact included) | Cradle-to-gate | Midsize car over 150,000 miles of operation | O | O |

| 17. | [40] | Nanotitanium dioxide photocatalyst coatings for concrete pavement | EIO-LCA/SimaPro | Economic inputs and outputs, acidification, eutrophication, criteria air pollutants, smog formation | Cradle-to-gate | 1 km lane of pavement | O | X |

| 18. | [41] | Vapor-grown carbon nanofibers, polymer nanocomposites | Collected from values reported in literature and LCA software/SimaPro | Energy consumption (sensitivity and uncertainty analysis included) | Cradle-to-grave | 1 kWh electricity generated | O | X |

| 19. | [42] | Yttria-stabilized zirconia, nanostructured coating | EDIP 2003/SimaPro Ecoinvent database used | Ozone depletion potentials, GHG emissions, eutrophication, human toxicity, ecotoxicity, hazardous waste, slags/ashes, bulk waste, radioactive waste, resources | Cradle-to-gate | 1 micrometer thick area of 1 m2 surface | O | O |

| 20. | [43] | Titanium dioxide nanoparticles | Eco-indicator 99/SimaPro | Carcinogen, climate change, GHG emissions, radiation, ozone layer, acidification, land use, airborne organics and inorganics, (uncertainty analysis included) | Cradle-to-gate | 1 kg | O | O |

| 21. | [44] | Single-walled carbon nanotube | EIO-LCA through EIO model/SimaPro | Economic inputs and outputs | Cradle-to-gate | 1 kg | O | X |

| 22. | [45] | Nanoelectronics, multi-walled carbon nanotube | Chain Management by Life cycle assessment (CML)/Umberto Ecoinvent database used | Energy consumption | Cradle-to-gate | 1 kg | O | X |

| 23. | [46] | Quantum dot photovoltaics | Impact 2002+/SimaPro Ecoinvent database used | Energy consumptions, lower GHG emissions, SOx, NOx emissions | Cradle-to-gate | 1 kg | O | O |

| 24. | [47] | Silver nanoparticles | Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI) 2.0 v-3.01 and EIO-LCA model/SimaPro | Economic inputs and outputs, GHG emissions, acidification, carcinogens, euthrophication, ozone depletion, ecotoxicity | Cradle-to-gate | 1 mg | O | O |

| 25. | [48] | Nanosilver t-shirts | USES-LCA/SimaPro Ecoinvent database used | GHG emissions, freshwater toxicity, waterborne emissions (sensitivity and uncertainty analysis included) | Cradle-to-gate | 1 kg | O | X |

| 26. | [49] | Nano-crystalline materials in thin-film silicon solar cells | Not stated/Simapro Ecoinvent database used | Climate change, ozone depletion, GHG emissions, acidification, ecotoxicity, human toxicity (toxicity impact included) | Cradle-to-gate | 1 m2 of module area and 1 kWh | O | X |

| 27. | [50] | Single-walled carbon nanotubes | EIO-LCA model /SimaPro HiPco data used | Economic inputs and outputs, energy consumption | Cradle-to-gate | 1 kWh | O | X |

| 28. | [51] | Starch nanocrystals | TRACI 2 and Ecoindicator 99/SimaPro | GHG emissions, acidification, climate change, radiation, ozone layer, ecotoxicity, land use, respiratory organics and inorganics | Cradle-to-gate | 1 kg and 10,000 m2 of packaging material | O | O |

| 29. | [52] | Black carbon and activated carbon with single-walled and multi-walled carbon nanotubes | Primary data in laboratory-scale study/not stated | Energy consumption | Cradle-to-gate | 1 MJ/kg | O | X |

| 30. | [53] | Nanoparticles coated recovered fiber paper | ReCiPe, Building for Environmental and Economic Sustainability (BEES), Life Cycle Cost (LCC) and TRACI/SimaPro Ecoinvent and BEES databases used | Energy consumption, NREU, renewable energy use (REU), GHG emissions | Cradle-to-grave | 1 tonne | O | O |

| 31. | [54] | Cellulose nanowhiskers | ReCiPe/SimaPro Ecoinvent database used | Climate change, water depletion, eutrophication, human toxicity | Cradle-to-gate | 1 g of cellulose nanowhiskers | O | X |

| 32. | [55] | Carbon nanotubes | USEtox model/SimaPro | Ecotoxicity (uncertainty analysis included) | Cradle-to-gate | 1 kg of carbon nanotubes | O | X |

| 33. | [56] | Molybdenum sulfide (MoS2) nanoparticles | Not stated/SimaPro Ecoinvent database used | Energy consumption, GHG emissions | Cradle-to-gate | 1 g of MoS2 nanoparticles | O | O |

| 34. | [57] | Organic photovoltaics from nanomaterials | Not stated/SimaPro Ecoinvent database used | GHG emissions, energy consumption, acidification, ozone depletion potential, human toxicity, ecotoxicity | Cradle-to-grave | 1 kg | O | O |

| 35. | [58] | Carbon nanotubes | TRACI and primary data/SimaPro Ecoinvent database used | GHG emissions, acidification, GHG emissions, eutrophication, ozone depletion, smog formation, ecotoxicity, human health, respiratory effects | Cradle-to-gate | 1 unit of Si wafer with a surface area of 45 cm2 and 4 g mass | O | X |

| 36. | [59] | Nano-sized titanium dioxide coatings | BEES 4.0 model/BEES software | Acidification, eutrophication, air pollutants and smog formation potential, GHG emissions, fossil fuel depletion, water intake, human health, ecological toxicity | Cradle-to-gate | 1 m2 of titanium dioxide-coated glass | O | X |

| 37. | [60] | Nano-coated wooden claddings | ReCiPe, Europe Ecolabel (EU-Ecolabel) /SimaPro 7.3 Ecoinvent database used | Air emissions, water emissions | Cradle-to-grave | 0.01 m2 of coated exterior wooden cladding | O | O |

| 38. | [61] | Hollow silica nanospheres, nano insulation materials | Primary data in laboratory-scale study/not stated | Energy consumption | Cradle-to-gate | 1 g of hollow silica nanospheres | O | X |

| 39. | [62] | Nanocellulose | Eco-Indicator 99/SimaPro | Energy consumption, carcinogens, human health respiratory organics and inorganics climate change, GHG emissions, radiation, ozone layer, ecotoxicity, acidification, eutrophication, land use resources | Cradle-to-gate | 10 g equivalent dry mass of the end product nanocellulose | O | X |

| 40. | [63] | Silver nanoparticles bandages | TRACI/SimaPro Ecoinvent database used | Ozone depletion, GHG emissions, smog formation, respiratory effects, water and soil quality impacts, acidification, eutrophication, human health, ecotoxicity | Cradle-to-grave | 1 g | O | O |

| 41. | [64] | Carbon nanotubes field emission displays (CNT-FEDs) | TRACI, USEtox/SimaPro Ecoinvent and National Renewable Energy Laboratory (NREL) US LCI database used | GHG emissions, acidification, human health, carcinogens and noncarcinogens. respiratory effects, eutrophication, ozone depletion, ecotoxicity, fossil fuel depletion, ecotoxicity | Cradle-to-grave | 10,000 viewing hours | O | O |

| 42. | [65] | Cellulose nanocrystals/cellulose nanofibrils from wood pulp | TRACI and primary data of pilot-scale production/SimaPro Ecoinvent database used | Energy consumption, GHG emissions, ozone depletion, acidification, eutrophication, human health, ecotoxicity, fossil fuel depletion | Cradle-to-gate | 1 kg of cellulose nanocrystals | O | X |

| 43. | [66] | Gold nanoparticles (AuNP) | Not stated/SimaPro Ecoinvent database used | Energy consumption, climate change, metal depletion, agricultural land occupation, freshwater ecotoxicity | Cradle-to-gate | 1 mg of AuNP | O | O |

| 44. | [67] | Graphite nanoplatelets (GnP) | ReCiPe, USEtox, EDIP,CML/SimaPro Ecoinvent database used | Energy consumption | Cradle-to-grave | 1 kg of epoxy composite loaded with 0.058 kg of GnP | O | O |

| 45. | [68] | Carbon nanotube-enabled chemical gas sensor | ReCiPe and TRACI 2/SimaPro Ecoinvent database used | GHG emissions, acidification, eutrophication, ozone depletion, smog formation, human health impacts from carcinogenic, noncarcinogenic, respiratory disease, ecotoxicity | Cradle-to-gate | 1 g per chip | O | O |

| 46. | [69] | Single-walled carbon nanotubes, multi-walled carbon nanotubes | USEtox model/Microsoft Excel | Human toxicity, freshwater ecotoxicity | Cradle-to-gate | 1 nm | O | X |

| 47. | [70] | Nanomaterials from graphene | USEtox model/not stated | Energy use, water use, human toxicity, ecotoxicity, (sensitivity analysis included) | Cradle-to-gate | 1 kg of graphene in solution | O | X |

| 48. | [71] | Nano insulation materials consisting of hollow silica nanospheres | Not stated Primary data in laboratory-scale study used | Energy consumption | Cradle-to-gate | 1 g | O | X |

| 49. | [72] | Cerium Dioxide (CeO2) nanoparticles | Monte Carlo/mathematical modeling software | Toxicity and uncertainty analysis | Cradle-to-gate | 1 tonne | X | O |

| 50. | [73] | Cellulose nanofibrils from wood pulp | ReCiPe /not stated Ecoinvent database used | Energy use, climate change, acidification, water use (sensitivity analysis included) | Cradle-to-gate | 1 kg | O | X |

| 51. | [12] | Titanium dioxide, silver and silica nanoparticles in facade coatings/paints | ReCiPe and USEtox/Open LCA tool Ecoinvent database used | GHG emissions, freshwater eutrophication, fossil fuel depletion, acidification, ecotoxicity, human toxicity, human health, resource availability | Cradle-to-gate | 1 square meter of (indoor or outdoor) wall during 80 years | O | O |

| 52. | [74] | Tungsten disulphide nanoparticles | ReCiPe, CML and primary data collection from an industrial process/SimaPro Ecoinvent database used | Energy resources, GHG emission, acidification, euthrophication, human toxicity | Cradle-to-gate | 1 g | O | X |

| 53. | [75] | Graphene oxide nanomaterial | USEtox and ReCiPe/SimaPro | Freshwater ecotoxicity (sensitivity analysis included) | Cradle-to-gate | 1 kg | O | X |

| 54. | [76] | Silver nanoparticles | TRACI and USEtox model/SimaPro | Ozone depletion, GHG emissions, photochemical smog formation, acidification, eutrophication, carcinogens, air pollutants, ecotoxicity, fossil fuel depletion | Cradle-to-grave | 1 kg | O | O |

| 55. | [77] | Printed electronic temperature sensor composed of specialized carbon nanotube | IMPACT 2002+ model/Simapro Ecoinvent database used | Carcinogens, respiratory organics and inorganics, ionizing radiation, ozone layer depletion, ecotoxicity, GHG emissions, land occupation, NRE, mineral extraction | Gate-to-gate | 2400 sensors/day | - | O |

| 56. | [18] | Nano-scale zero valent iron | IMPACT 2002+/SimaPro Ecoinvent database used | Climate change, ecosystem quality, human health, resources | Cradle-to-gate | 1 g | O | X |

| 57. | [13] | Nano-titanium dioxide | USEtox/SimpleBox4Nano | GHG emissions, freshwater eutrophication, fossil fuel depletion, acidification, ecotoxicity, human toxicity, human health | Cradle-to-gate | 1 nm | O | X |

| 58. | [78] | Nano-silica-modified asphalt mixtures | TRACI/Open LCA tool—Ecoinvent database used | Ecotoxicity, carcinogens, GHG emissions, ozone depletion, acidification, eutrophication, respiratory effects | Cradle-to-gate | 1000 kg production of nano-silica-modified asphalt mixtures | O | X |

| 59. | [79] | Cellulose nano-sponges | International Reference Life Cycle Data System (ILCD) 2011 Midpoint+/SimaPro Ecoinvent database used | Climate change, ozone depletion, human toxicity, GHG emissions, particulate matter, ionizing radiation, photochemical ozone formation, acidification, eutrophication, freshwater ecotoxicity, water resource depletion, renewable resource depletion | Cradle-to-gate | 1 kg of cellulose nanosponge | O | X |

| 60. | [10] | Nano-wire based solar cells | Primary data in laboratory-scale/SimaPro Ecoinvent database used | Land use, eutrophication, acidification, GHG emissions, photochemical oxidation, climate change, ecotoxicity, ozone depletion, human toxicity | Cradle-to-gate | 1 kWh of electricity production | O | X |

| 61. | [80] | Nano-scale zero-valent iron | IMPACT 2002+/Simapro Ecoinvent database used | Energy consumption, human health, atmospheric emissions | Cradle-to-gate | 1 kg | O | X |

| 62. | [81] | Binary oxides nanoparticles | TRACI 2.1/SimaPro Ecoinvent and US Life Cycle Inventory used | Ozone depletion, GHG emissions, smog, acidification, eutrophication, carcinogenic and noncarcinogenic, respiratory effects, ecotoxicity, fossil fuel depletion | Cradle-to-gate | 1 kg | O | X |

| 63. | [82] | Photo-Fenton catalysts with combinations of magnetite nanoparticles semiconductor | IMPACT and ReCiPe/SimaPro Ecoinvent database used | Climate change, ozone depletion, acidification, eutrophication, toxicity, fossil depletion | Cradle-to-gate | 1 kg | O | X |

| 64. | [83] | Fly ash hydrated lime blended concrete nanosilica | Not stated/SimaPro Ecoinvent database used | GHG emissions, acidification, photochemical oxidant formation impact | Cradle-to-gate | kg/m3 | O | X |

| 65. | [84] | Nano-powder in glass bottle wastes | Not stated Primary data in laboratory-scale study used | CO2 emission, energy consumption, fuel consumption | Cradle-to-gate | 1 m3 | O | X |

| 66. | [85] | Nano-hydroxyapatite | IMPACT/SimaPro | GHG emissions, non-renewable energy, respiratory inorganics, human health, climate change, resources, ecosystem quality | Cradle-to-gate | 10 g | O | O |

| 67. | [86] | Nano calcium carbonate | Not stated/SimaPro Ecoinvent database used | GHG emissions, CO2 emissions (sensitivity analysis included) | Cradle-to-gate | 1 g | O | X |

| 68. | [87] | Nano-enhanced carbon fiber-reinforced polymer | ILCD Midpoint +/SimaPro Ecoinvent database used | Human toxicity, respiratory effects, ionizing radiation, photochemical oxidation, climate change, ozone depletion, GHG emissions, human health, ecotoxicity, acidification, eutrophication, land occupation, water consumption, NRE, mineral extraction, water turbined | Cradle-to-gate | 1 product piece | O | X |

| 69. | [88] | Silver nanomaterials | TRAP (Toxicity Relationship Analysis Program)/REST-MSC tool | Water and soil emissions | Cradle-to-gate | mg/kg | O | X |

| 70. | [17] | Engineered nanomaterials | In vivo No-Observed-Adverse-Effect Level (NOAEL), Lowest-Observed-Adverse-Effect Level (LOAEL), EC50 or ED50 (Effective Dose/Dosage) methods/not stated | Human health, human toxicity | Cradle-to-gate | 1 kg | O | X |

| 71. | [89] | Nano-grid | ReCiPe/OpenLCA tool Ecoinvent database used | Ecotoxicity, human health, resources (sensitivity analysis included) | Cradle-to-grave | 1 MWh | O | X |

| No. | Limitations | Uncertainties | Possible Approaches/Recommendations |

|---|---|---|---|

| 1. | Scarcity of knowledge: End-of-life stages. Potential of emissions from various waste management processes. | Uncertainties in outputs, final emissions, and interpretation stage. |

|

| 2. | Inadequate data on LCI. | Uncertainties in process inputs, outputs, and final emissions. |

|

| 3. | Lack of characterization factors in LCIA. | Uncertainties in fate, exposure, and effect factors. |

|

| 4. | Invalid assumptions in the interpretation stage. | Uncertainties in results being irrelevant and unclear conclusions if interpreted out of context. |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nizam, N.U.M.; Hanafiah, M.M.; Woon, K.S. A Content Review of Life Cycle Assessment of Nanomaterials: Current Practices, Challenges, and Future Prospects. Nanomaterials 2021, 11, 3324. https://doi.org/10.3390/nano11123324

Nizam NUM, Hanafiah MM, Woon KS. A Content Review of Life Cycle Assessment of Nanomaterials: Current Practices, Challenges, and Future Prospects. Nanomaterials. 2021; 11(12):3324. https://doi.org/10.3390/nano11123324

Chicago/Turabian StyleNizam, Nurul Umairah M., Marlia M. Hanafiah, and Kok Sin Woon. 2021. "A Content Review of Life Cycle Assessment of Nanomaterials: Current Practices, Challenges, and Future Prospects" Nanomaterials 11, no. 12: 3324. https://doi.org/10.3390/nano11123324

APA StyleNizam, N. U. M., Hanafiah, M. M., & Woon, K. S. (2021). A Content Review of Life Cycle Assessment of Nanomaterials: Current Practices, Challenges, and Future Prospects. Nanomaterials, 11(12), 3324. https://doi.org/10.3390/nano11123324