Narrow-Linewidth GaN-on-Si Laser Diode with Slot Gratings

Abstract

:1. Introduction

2. Experimental Section

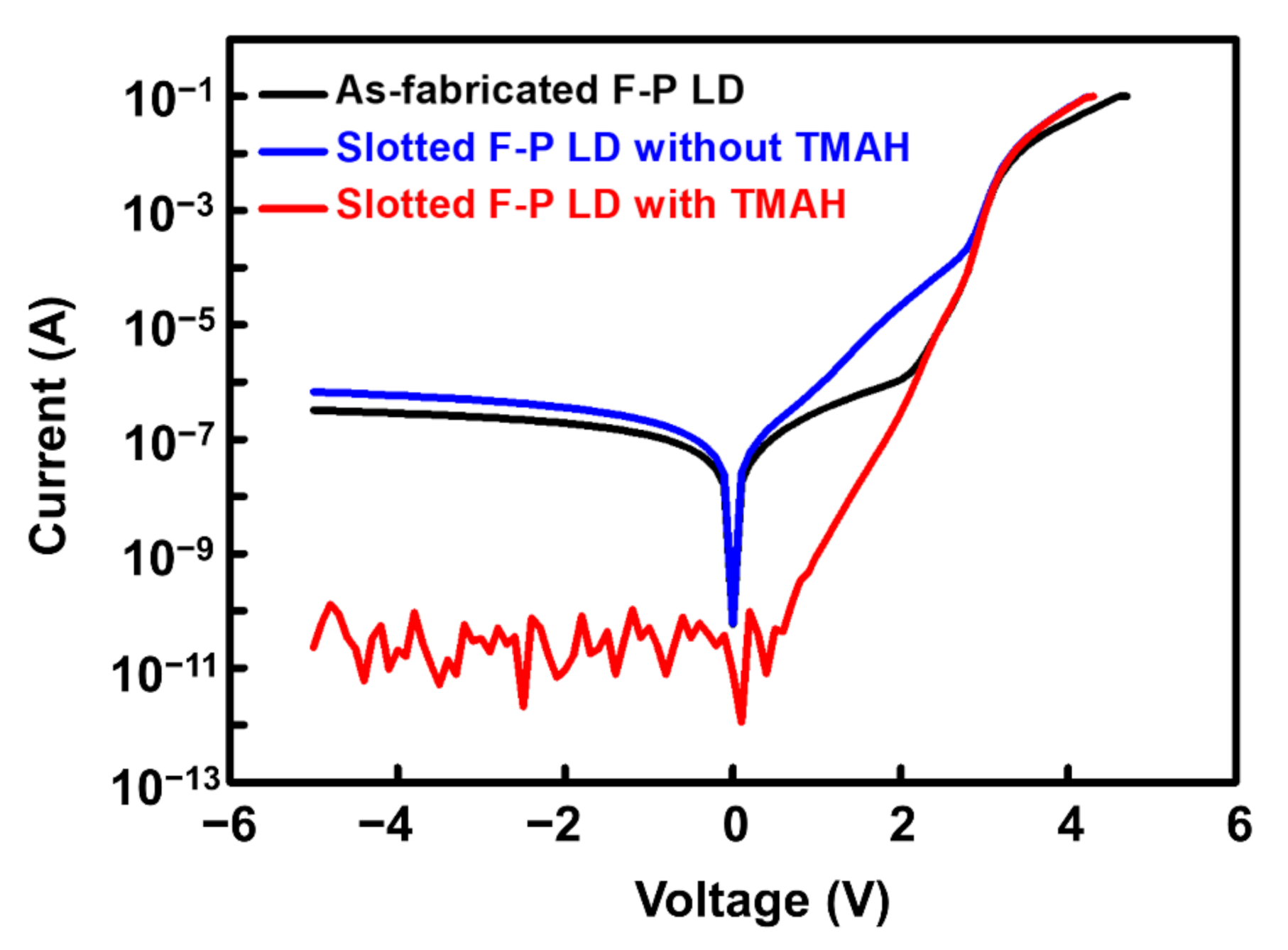

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Atabaki, A.H.; Moazeni, S.; Pavanello, F.; Gevorgyan, H.; Notaros, J.; Alloatti, L.; Wade, M.T.; Sun, C.; Kruger, S.A.; Meng, H.; et al. Integrating photonics with silicon nanoelectronics for the next generation of systems on a chip. Nature 2018, 556, 349–354. [Google Scholar] [CrossRef] [PubMed]

- Hirschman, K.D.; Tsybeskov, L.; Duttagupta, S.P.; Fauchet, P.M. Silicon-based visible light-emitting devices integrated into microelectronic circuits. Nature 1996, 384, 338–341. [Google Scholar] [CrossRef]

- Hochberg, M.; Baehr-Jones, T. Towards fabless silicon photonics. Nat. Photonics 2010, 4, 492–494. [Google Scholar] [CrossRef]

- Jalali, B.; Fathpour, S. Silicon photonics. J. Lightwave Technol. 2006, 24, 4600–4615. [Google Scholar] [CrossRef]

- Soref, R. The past, present, and future of silicon pho-tonics. IEEE J. Sel. Top. Quant. 2006, 12, 1678–1687. [Google Scholar] [CrossRef]

- Lipson, M. Guiding, modulating, and emitting light on Silicon-challenges and opportunities. J. Lightwave Technol. 2005, 23, 4222–4238. [Google Scholar] [CrossRef]

- Liang, D.; Bowers, J.E. Recent progress in lasers on silicon. Nat. Photonics 2010, 4, 511–517. [Google Scholar] [CrossRef]

- Jain, S.C.; Willander, M.; Narayan, J.; Overstraeten, R.V. III-nitrides: Growth, characterization, and properties. J. Appl. Phys. 2000, 87, 965–1006. [Google Scholar] [CrossRef] [Green Version]

- Pimputkar, S.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. Prospects for LED lighting. Nat. Photonics 2009, 3, 179–181. [Google Scholar] [CrossRef]

- Hardy, M.T.; Feezell, D.F.; DenBaars, S.P.; Nakamura, S. Group III-nitride lasers: A materials perspective. Mater. Today 2011, 14, 408–415. [Google Scholar] [CrossRef]

- Lang, X.; Jia, P.; Chen, Y.; Qin, L.; Liang, L.; Chen, C.; Wang, Y.; Shan, X.; Ning, Y.; Wang, L. Advances in narrow linewidth diode lasers. Sci. China Inf. Sci. 2019, 62, 61401. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Zhu, B.; Shi, Z.; Wang, J.; Li, X.; Gao, X.; Yuan, J.; Li, Y.; Jiang, Y.; Wang, Y. Multi-dimensional spatial light communication made with on-chip InGaN photonic integration. Opt. Mater. 2017, 66, 659–663. [Google Scholar] [CrossRef]

- Hazari, A.; Aiello, A.; Ng, T.; Ooi, B.S.; Bhattacharya, P. III-nitride disk-in-nanowire 1.2 μm monolithic diode laser on (001) silicon. Appl. Phys. Lett. 2015, 107, 191107. [Google Scholar] [CrossRef] [Green Version]

- Hazari, A.; Bhattacharya, A.; Frost, T.; Zhao, S.; Baten, M.Z.; Mi, Z.; Bhattacharya, P. Optical constants of InxGa1−xN (0 ≤ x ≤ 0.73) in the visible and near-infrared wavelength regimes. Opt. Lett. 2015, 40, 3304–3307. [Google Scholar] [CrossRef]

- Rumbaugh, L.K.; Dunn, K.J.; Bollt, E.M.; Cochenour, B.; Jemison, W.D.; Hou, W.W.; Arnone, R.A. An underwater chaotic lidar sensor based on synchronized blue laser diodes. Proc. SPIE 2016, 9827, 98270I. [Google Scholar]

- Wu, T.; Chi, Y.; Wang, H.; Tsai, C.; Lin, G. Blue laser diode enables underwater communication at 12.4 Gbps. Sci. Rep. 2017, 7, 40480. [Google Scholar] [CrossRef]

- Holguin-Lerma, J.A.; Kong, M.; Alkhazragi, O.; Sun, X.; Ng, T.K.; Ooi, B.S. 480-nm distributed-feedback InGaN laser diode for 10.5-Gbit/s visible-light communication. Opt. Lett. 2020, 45, 742–745. [Google Scholar] [CrossRef]

- Chi, Y.; Hsieh, D.; Tsai, C.; Chen, H.; Kuo, H.; Lin, G. 450-nm GaN laser diode enables high-speed visible light communication with 9-Gbps QAM-OFDM. Opt. Express 2015, 23, 13051. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Di Gaetano, E.; Watson, S.; McBrearty, E.; Sorel, M.; Paul, D.J. Sub-megahertz linewidth 780.24 nm distributed feedback laser for 87Rb applications. Opt. Lett. 2020, 45, 3529–3532. [Google Scholar] [CrossRef] [PubMed]

- Dube, P.; Madej, A.A.; Bernard, J.E.; Shiner, A.D. High-resolution spectroscopy of the 88Sr+ single ion optical frequency standard. Proc. SPIE 2007, 6673, 667305. [Google Scholar]

- Stanczyk, S.; Kafar, A.; Grzanka, S.; Sarzynski, M.; Mroczynski, R.; Najda, S.; Suski, T.; Perlin, P. 450 nm (Al,In)GaN optical amplifier with double ‘j-shape’ waveguide for master oscillator power amplifier systems. Opt. Express 2018, 26, 7351. [Google Scholar] [CrossRef] [PubMed]

- Hofstetter, D.; Thornton, R.L.; Romano, L.T.; Bour, D.P.; Kneissl, M.; Donaldson, R.M. Room-temperature pulsed operation of an electrically injected InGaN/GaN multi-quantum well distributed feedback laser. Appl. Phys. Lett. 1998, 73, 2158–2160. [Google Scholar] [CrossRef]

- Masui, S.; Tsukayama, K.; Yanamoto, T.; Kozaki, T.; Nagahama, S.; Mukai, T. First-order AlInGaN 405 nm distributed feedback laser diodes by current injection. Jpn. J. Appl. Phys. 2006, 45, L749–L751. [Google Scholar] [CrossRef]

- Kang, J.H.; Martens, M.; Wenzel, H.; Hoffmann, V.; John, W.; Einfeldt, S.; Wernicke, T.; Kneissl, M. Optically pumped DFB lasers based on GaN using 10th-order laterally coupled surface gratings. IEEE Photonics Technol. Lett. 2017, 29, 138–141. [Google Scholar] [CrossRef]

- Kang, J.H.; Wenzel, H.; Freier, E.; Hoffmann, V.; Brox, O.; Fricke, J.; Sulmoni, L.; Matalla, M.; Stoelmacker, C.; Kneissl, M.; et al. Continuous-wave operation of DFB laser diodes based on GaN using 10th-order laterally coupled surface gratings. Opt. Lett. 2020, 45, 935–938. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Cohen, D.A.; Chan, P.; Wong, M.S.; Mehari, S.; Becerra, D.L.; Nakamura, S.; DenBaars, S.P. Continuous-wave operation of a semipolar InGaN distributed-feedback blue laser diode with a first-order indium tin oxide surface grating. Opt. Lett. 2019, 44, 3106–3109. [Google Scholar] [CrossRef]

- Deng, Z.; Li, J.; Liao, M.; Xie, W.; Luo, S. InGaN/GaN distributed feedback laser diodes with surface gratings and sidewall gratings. Micromachines 2019, 10, 699. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Slight, T.J.; Odedina, O.; Meredith, W.; Docherty, K.E.; Kelly, A.E. InGaN/GaN distributed feedback laser diodes with deeply etched sidewall gratings. IEEE Photonics Technol. Lett. 2016, 28, 2886–2888. [Google Scholar] [CrossRef]

- Xie, W.; Li, J.; Liao, M.; Deng, Z.; Wang, W.; Sun, S. Narrow linewidth distributed Bragg reflectors based on InGaN/GaN laser. Micromachines 2019, 10, 529. [Google Scholar] [CrossRef] [Green Version]

- Holguín-Lerma, J.A.; Ng, T.K.; Ooi, B.S. Narrow-line InGaN/GaN green laser diode with high-order distributed-feedback surface grating. Appl. Phys. Express 2019, 12, 42007. [Google Scholar] [CrossRef]

- Slight, T.J.; Stanczyk, S.; Watson, S.; Yadav, A.; Grzanka, S.; Rafailov, E.; Perlin, P.; Najda, S.P.; Leszczyński, M.; Gwyn, S.; et al. Continuous-wave operation of (Al,In)GaN distributed-feedback laser diodes with high-order notched gratings. Appl. Phys. Express 2018, 11, 112701. [Google Scholar] [CrossRef]

- Sun, W.; Lu, Q.; Guo, W.; Wallace, M.; Bello, F.; Donegan, J.F. Analysis of High-Order Slotted Surface Gratings by the 2D Finite-Difference Time-Domain Method. J. Lightwave Technol. 2017, 35, 96–102. [Google Scholar] [CrossRef]

- Lu, Q.Y.; Guo, W.H.; Phelan, R.; Byrne, D.; Donegan, J.F.; Lambkin, P.; Corbett, B. Analysis of Slot Characteristics in Slotted Single-Mode Semiconductor Lasers Using the 2D Scattering Matrix Method. IEEE Photonics Technol. Lett. 2006, 18, 2605–2607. [Google Scholar] [CrossRef] [Green Version]

- Kakanakova-Georgieva, A.; Gueorguiev, G.K.; Sangiovanni, D.G.; Suwannaharn, N.; Ivanov, I.G.; Cora, I.; Pécz, B.; Nicotra, G.; Giannazzo, F. Nanoscale phenomena ruling deposition and intercalation of AlN at the graphene/SiC interface. Nanoscale 2020, 12, 19470–19476. [Google Scholar] [CrossRef] [PubMed]

- Pacheco, J.M.; Gueorguiev, G.K.; Martins, J.L. First-principles study of the possibility of condensed phases of endohedral silicon cage clusters. Phys. Rev. B 2002, 66, 334011–334013. [Google Scholar] [CrossRef]

- Sun, Y.; Zhou, K.; Sun, Q.; Liu, J.; Feng, M.; Li, Z.; Zhou, Y.; Zhang, L.; Li, D.; Zhang, S.; et al. Room-temperature continuous-wave electrically injected InGaN-based laser directly grown on Si. Nat. Photonics 2016, 10, 595–599. [Google Scholar] [CrossRef]

- Sun, Y.; Zhou, K.; Feng, M.; Li, Z.; Zhou, Y.; Sun, Q.; Liu, J.; Zhang, L.; Li, D.; Sun, X.; et al. Room-temperature continuous-wave electrically pumped InGaN/GaN quantum well blue laser diode directly grown on Si. Light Sci. Appl. 2018, 7, 13. [Google Scholar] [CrossRef]

- Shi, K.; Smyth, F.; Reid, D.; Roycroft, B.; Corbett, B.; Peters, F.H.; Barry, L.P. Characterization of a tunable three-section slotted Fabry-Perot laser for advanced modulation format optical transmission. Opt. Commun. 2011, 284, 1616–1621. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; He, J. Single-Electrode Controlled Four-Section Coupled-Cavity Tunable Laser. IEEE Photonics Technol. Lett. 2013, 25, 1340–1343. [Google Scholar] [CrossRef]

- Jin, J.; Wang, L.; Yu, T.; Wang, Y.; He, J.J. Widely wavelength switchable V-coupled-cavity semiconductor laser with approximately 40 dB side-mode suppression ratio. Opt. Lett. 2011, 36, 4230–4232. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumakura, K.; Makimoto, T.; Kobayashi, N.; Hashizume, T.; Fukui, T.; Hasegawa, H. Minority carrier diffusion length in GaN: Dislocation density and doping concentration dependence. Appl. Phys. Lett. 2005, 86, 52105. [Google Scholar] [CrossRef] [Green Version]

- Modak, S.; Chernyak, L.; Xian, M.; Ren, F.; Pearton, S.J.; Khodorov, S.; Lubomirsky, I.; Ruzin, A.; Dashevsky, Z. Impact of electron injection on carrier transport and recombination in unintentionally doped GaN. J. Appl. Phys. 2020, 128, 85702. [Google Scholar] [CrossRef]

- Slight, T.J.; Yadav, A.; Odedina, O.; Meredith, W.; Docherty, K.E.; Rafailov, E.; Kelly, A.E. InGaN/GaN Laser Diodes with High Order Notched Gratings. IEEE Photonics Technol. Lett. 2017, 29, 2020–2022. [Google Scholar] [CrossRef]

- He, J.; Feng, M.; Zhong, Y.; Wang, J.; Zhou, R.; Gao, H.; Zhou, Y.; Sun, Q.; Liu, J.; Huang, Y.; et al. On-wafer fabrication of cavity mirrors for InGaN-based laser diode grown on Si. Sci. Rep. 2018, 8, 7922. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; Feng, M.; Liu, J.; Fan, S.; Sun, X.; Sun, Q.; Zhang, S.; Liu, T.; Kong, Y.; Huang, Z.; et al. Narrow-Linewidth GaN-on-Si Laser Diode with Slot Gratings. Nanomaterials 2021, 11, 3092. https://doi.org/10.3390/nano11113092

Tang Y, Feng M, Liu J, Fan S, Sun X, Sun Q, Zhang S, Liu T, Kong Y, Huang Z, et al. Narrow-Linewidth GaN-on-Si Laser Diode with Slot Gratings. Nanomaterials. 2021; 11(11):3092. https://doi.org/10.3390/nano11113092

Chicago/Turabian StyleTang, Yongjun, Meixin Feng, Jianxun Liu, Shizhao Fan, Xiujian Sun, Qian Sun, Shuming Zhang, Tong Liu, Yaping Kong, Zengli Huang, and et al. 2021. "Narrow-Linewidth GaN-on-Si Laser Diode with Slot Gratings" Nanomaterials 11, no. 11: 3092. https://doi.org/10.3390/nano11113092

APA StyleTang, Y., Feng, M., Liu, J., Fan, S., Sun, X., Sun, Q., Zhang, S., Liu, T., Kong, Y., Huang, Z., Ikeda, M., & Yang, H. (2021). Narrow-Linewidth GaN-on-Si Laser Diode with Slot Gratings. Nanomaterials, 11(11), 3092. https://doi.org/10.3390/nano11113092