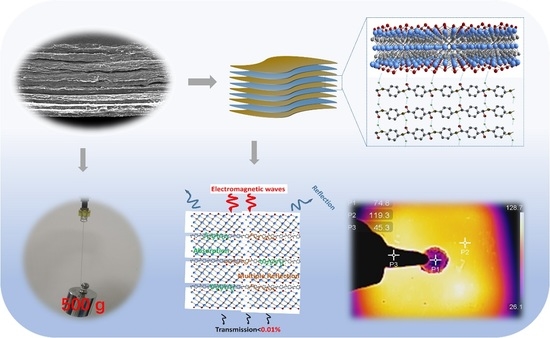

Mechanically Robust Flexible Multilayer Aramid Nanofibers and MXene Film for High-Performance Electromagnetic Interference Shielding and Thermal Insulation

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of ANF Dispersion

2.3. Preparation of MXene Nanosheet Suspension

2.4. Preparation of Multilayer-Structure ANF/MXene Films

2.5. Characterizations

3. Results and Discussion

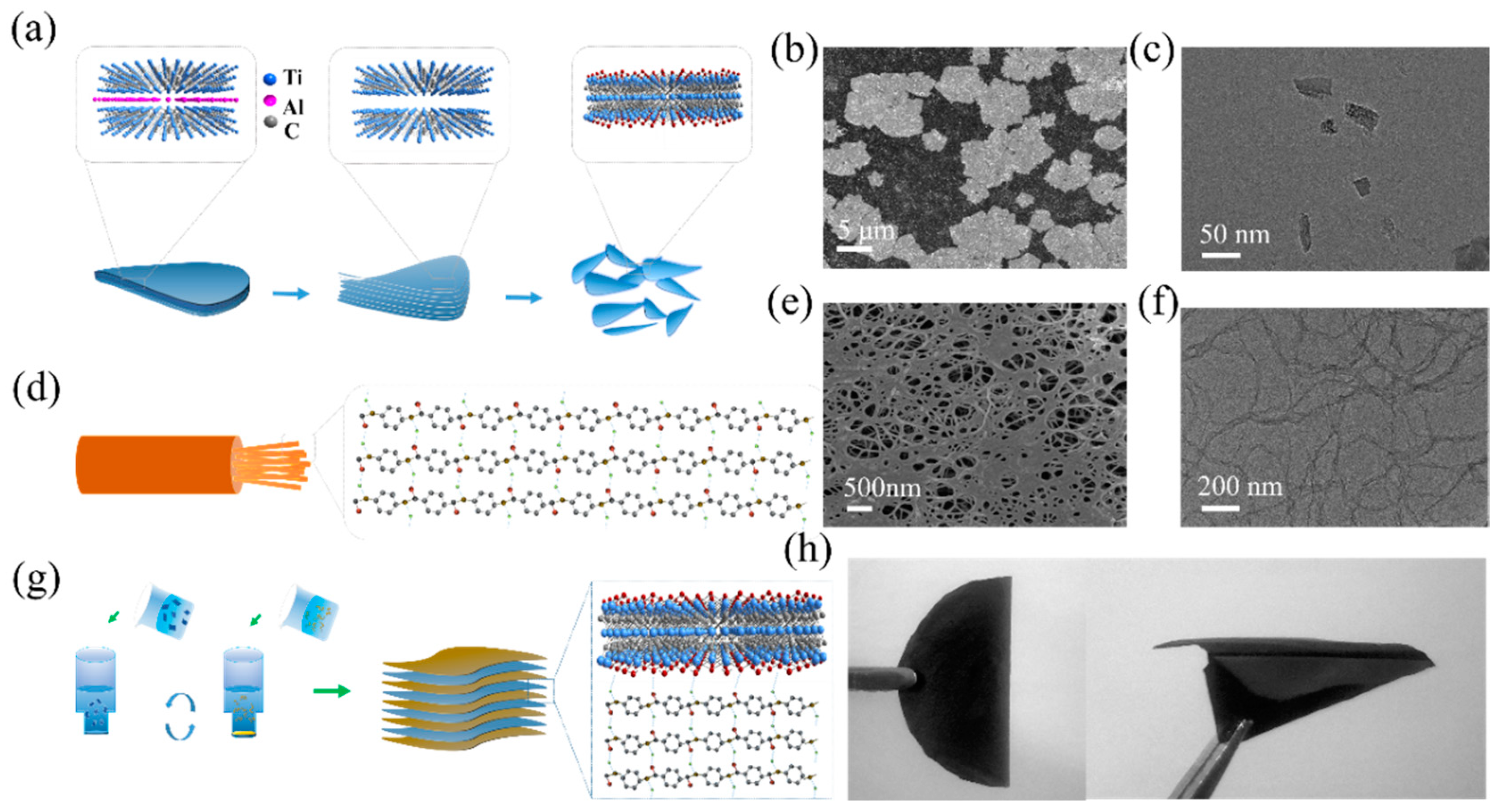

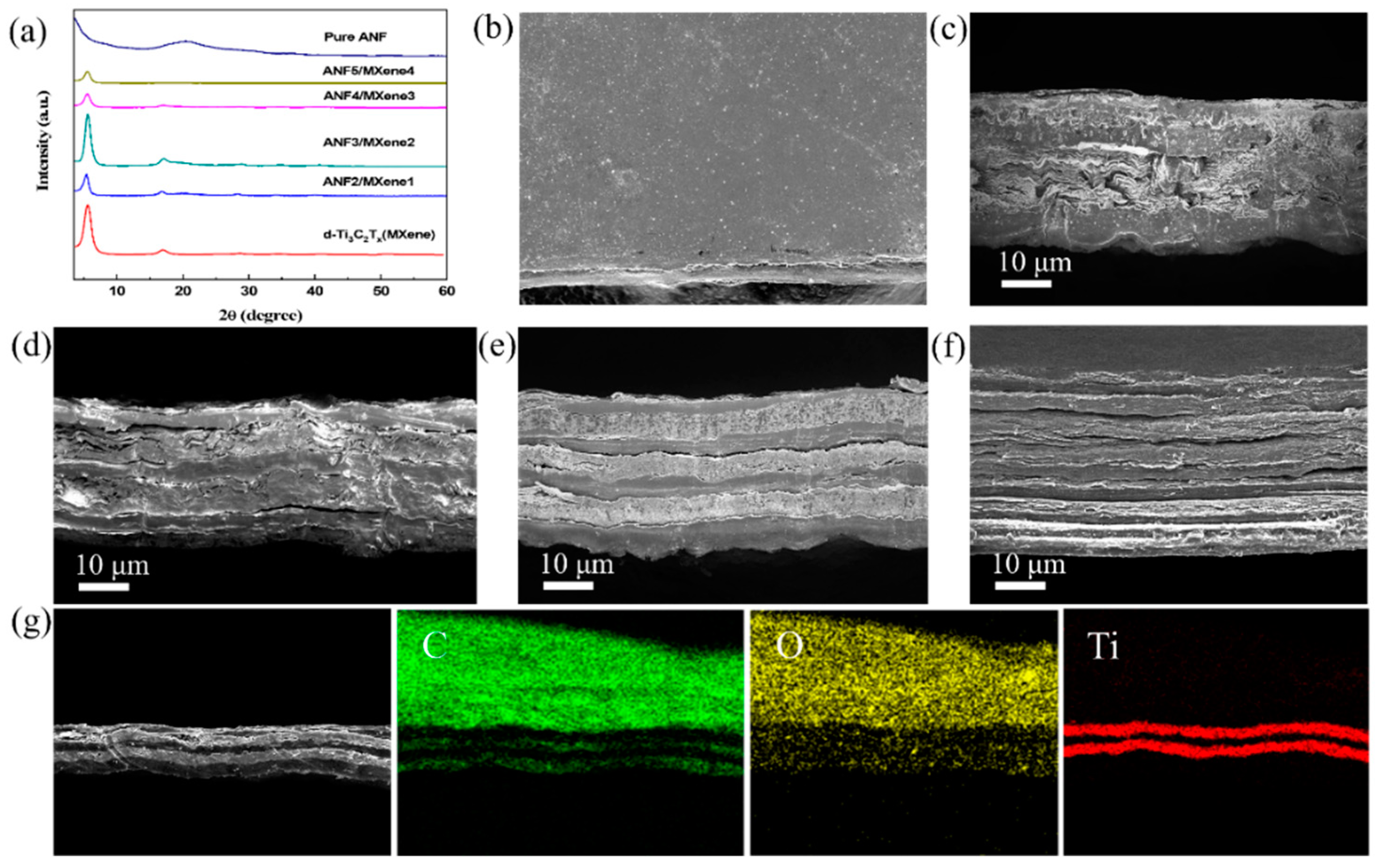

3.1. Microstructures of Alternating Laminated ANF/MXene Films

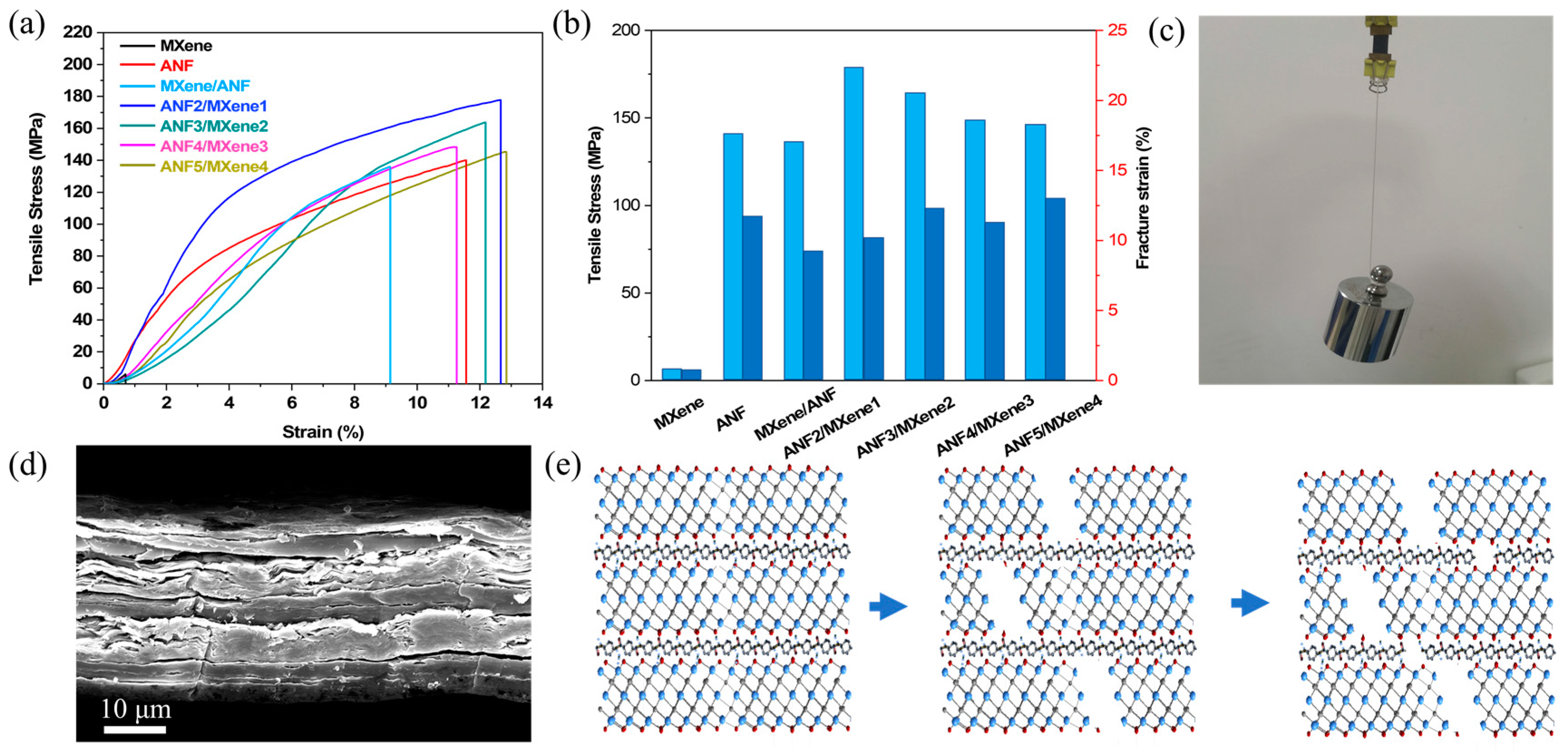

3.2. Mechanical Properties of Multilayer-Structure ANF/MXene Films

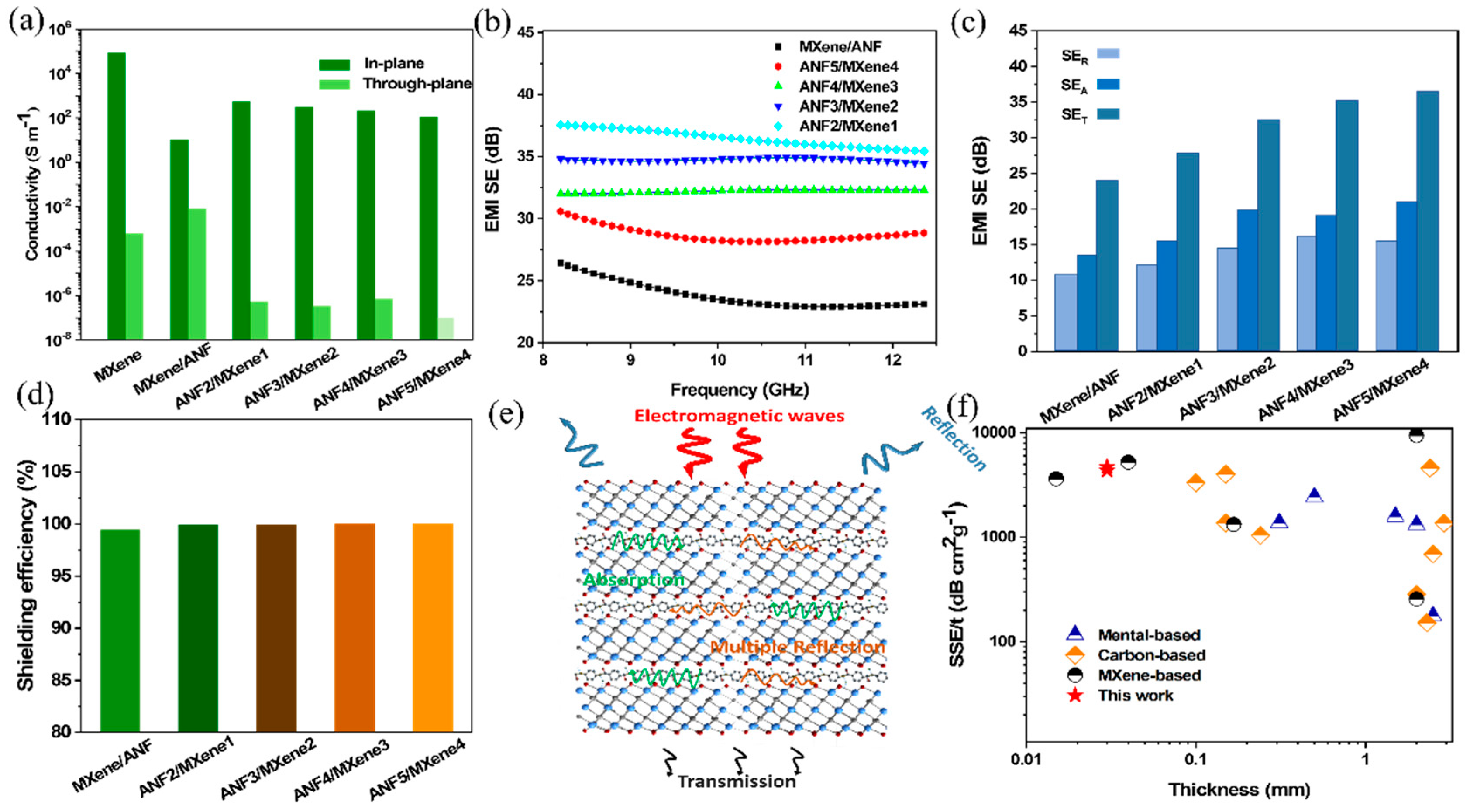

3.3. Electromagnetic Shielding Performances of Multilayer-Structure ANF/MXene Films

3.4. Thermal Insulation and Photothermal Conversion Performance of Alternating Laminated ANF/MXene Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Hong, S.M.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yun, T.; Kim, H.T.; Iqbal, A.; Cho, Y.S.; Lee, G.S.; Kim, M.; Kim, S.J.; Kim, D.; Gogotsi, Y.; Kim, S.O.; et al. Electromagnetic Interference Shielding: Electromagnetic Shielding of Monolayer MXene Assemblies. Adv. Mater. 2020, 32, 2070064. [Google Scholar] [CrossRef]

- Xiang, C.; Guo, R.; Lin, S.; Jiang, S.; Lan, J.; Wang, C.; Cui, C.; Xiao, H.; Zhang, Y. Lightweight and ultrathin TiO2-Ti3C2TX/graphene film with electromagnetic interference shielding. Chem. Eng. J. 2019, 360, 1158–1166. [Google Scholar] [CrossRef]

- Li, H.; Yuan, D.; Li, P.; He, C. High conductive and mechanical robust carbon nanotubes/waterborne polyurethane composite films for efficient electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2019, 121, 411–417. [Google Scholar] [CrossRef]

- Song, Q.; Ye, F.; Yin, X.; Li, W.; Li, H.; Liu, Y.; Li, K.; Xie, K.; Li, X.; Fu, Q.; et al. Carbon Nanotube-Multilayered Graphene Edge Plane Core-Shell Hybrid Foams for Ultrahigh-Performance Electromagnetic-Interference Shielding. Adv. Mater. 2017, 29, 1701583. [Google Scholar] [CrossRef]

- Weng, G.-M.; Li, J.; Alhabeb, M.; Karpovich, C.; Wang, H.; Lipton, J.; Maleski, K.; Kong, J.; Shaulsky, E.; Elimelech, M.; et al. Layer-by-Layer Assembly of Cross-Functional Semi-transparent MXene-Carbon Nanotubes Composite Films for Next-Generation Electromagnetic Interference Shielding. Adv. Funct. Mater. 2018, 28, 1803360. [Google Scholar] [CrossRef]

- Anand, S.; Pauline, S. Electromagnetic Interference Shielding Properties of BaCo2Fe16O27 Nanoplatelets and RGO Reinforced PVDF Polymer Composite Flexible Films. Adv. Mater. Interfaces 2020, 8, 2001810. [Google Scholar] [CrossRef]

- Lan, C.; Li, C.; Hu, J.; Yang, S.; Qiu, Y.; Ma, Y. High-Loading Carbon Nanotube/Polymer Nanocomposite Fabric Coatings Obtained by Capillarity-Assisted “Excess Assembly” for Electromagnetic Interference Shielding. Adv. Mater. Interfaces 2018, 5, 1800116. [Google Scholar] [CrossRef]

- Liang, C.; Qiu, H.; Han, Y.; Gu, H.; Song, P.; Wang, L.; Kong, J.; Cao, D.; Gu, J. Superior electromagnetic interference shielding 3D graphene nanoplatelets/reduced graphene oxide foam/epoxy nanocomposites with high thermal conductivity. J. Mater. Chem. C 2019, 7, 2725–2733. [Google Scholar] [CrossRef]

- Ma, Z.; Kang, S.; Ma, J.; Shao, L.; Zhang, Y.; Liu, C.; Wei, A.; Xiang, X.; Wei, L.; Gu, J. Ultraflexible and Mechanically Strong Double-Layered Aramid Nanofiber–Ti3C2Tx MXene/Silver Nanowire Nanocomposite Papers for High-Performance Electromagnetic Interference Shielding. ACS Nano 2020, 14, 8368–8382. [Google Scholar] [CrossRef]

- Jia, L.-C.; Yan, D.-X.; Liu, X.; Ma, R.; Wu, H.-Y.; Li, Z.-M. Highly Efficient and Reliable Transparent Electromagnetic Interference Shielding Film. ACS Appl. Mater. Interfaces 2018, 10, 11941–11949. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.Y.; Lee, T.-W.; Lee, S.-E.; Lim, J.; Jeong, Y.G. Silver nanowire/carbon nanotube/cellulose hybrid papers for electrically conductive and electromagnetic interference shielding elements. Compos. Sci. Technol. 2017, 150, 45–53. [Google Scholar] [CrossRef]

- Shen, B.; Li, Y.; Zhai, W.; Zheng, W. Compressible Graphene-Coated Polymer Foams with Ultralow Density for Adjustable Electromagnetic Interference (EMI) Shielding. ACS Appl. Mater. Interfaces 2016, 8, 8050–8057. [Google Scholar] [CrossRef]

- Lu, D.; Mo, Z.; Liang, B.; Yang, L.; He, Z.; Zhu, H.; Tang, Z.; Gui, X. Flexible, lightweight carbon nanotube sponges and composites for high-performance electromagnetic interference shielding. Carbon 2018, 133, 457–463. [Google Scholar] [CrossRef]

- Hantanasirisakul, K.; Gogotsi, Y. Electronic and Optical Properties of 2D Transition Metal Carbides and Nitrides (MXenes). Adv. Mater. 2018, 30, 1804779. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional Nanocrystals Produced by Exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef] [Green Version]

- Cao, M.-S.; Cai, Y.-Z.; He, P.; Shu, J.-C.; Cao, W.-Q.; Yuan, J. 2D MXenes: Electromagnetic property for microwave absorption and electromagnetic interference shielding. Chem. Eng. J. 2019, 359, 1265–1302. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, Y.; Xie, Z.; Wang, D.; Yuan, Y.; Kang, H.; Su, B.; Cheng, Z.; Liu, Y. Modified MXene/Holey Graphene Films for Advanced Supercapacitor Electrodes with Superior Energy Storage. Adv. Sci. 2018, 5, 1800750. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Hao, J.; Liu, R.; He, H.; Wang, Y.; Liang, G.; Liu, Y.; Yuan, G.; Guo, Z. Interfacing MXene flakes on fiber fabric as an ultrafast electron transport layer for high performance textile electrodes. Energy Storage Mater. 2020, 33, 62–70. [Google Scholar] [CrossRef]

- Nan, J.; Guo, X.; Xiao, J.; Li, X.; Chen, W.; Wu, W.; Liu, H.; Wang, Y.; Wu, M.; Wang, G. Nanoengineering of 2D MXene-Based Materials for Energy Storage Applications. Small 2019, 17, 1902085. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Zhou, Z. MXene-based materials for electrochemical energy storage. J. Energy Chem. 2018, 27, 73–85. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.-W.; Zhang, H.-B.; Liu, J.; Zhao, S.; Xie, X.; Liu, L.; Yang, R.; Koratkar, N.; Yu, Z.-Z. Multifunctional and Water-Resistant MXene-Decorated Polyester Textiles with Outstanding Electromagnetic Interference Shielding and Joule Heating Performances. Adv. Funct. Mater. 2018, 29, 1806819. [Google Scholar] [CrossRef]

- Jiang, Q.; Wu, C.; Wang, Z.; Wang, A.C.; He, J.-H.; Wang, Z.L.; Alshareef, H.N. MXene electrochemical microsupercapacitor integrated with triboelectric nanogenerator as a wearable self-charging power unit. Nano Energy 2018, 45, 266–272. [Google Scholar] [CrossRef] [Green Version]

- Liang, C.; Qiu, H.; Song, P.; Shi, X.; Kong, J.; Gu, J. Ultra-light MXene aerogel/wood-derived porous carbon composites with wall-like “mortar/brick” structures for electromagnetic interference shielding. Sci. Bull. 2020, 65, 616–622. [Google Scholar] [CrossRef] [Green Version]

- Natu, V.; Hart, J.L.; Sokol, M.; Chiang, H.; Taheri, M.L.; Barsoum, M.W. Edge Capping of 2D-MXene Sheets with Polyanionic Salts To Mitigate Oxidation in Aqueous Colloidal Suspensions. Angew. Chem. 2019, 131, 12785–12790. [Google Scholar] [CrossRef]

- Jia, X.; Shen, B.; Zhang, L.; Zheng, W. Corrigendum to “Construction of compressible Polymer/MXene composite foams for high-performance absorption-dominated electromagnetic shielding with ultra-low reflectivity”. Carbon 2021, 173, 932–940. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Q.; Xu, P.; Feng, Y.; Ma, J.; Liu, C.; Shen, C. Asymmetric Sandwich Structural Cellulose-based Film with Self-supported MXene and AgNW Layers for Flexible Electromagnetic Interference Shielding and Thermal Management. Nanoscale 2021, 13, 2378–2388. [Google Scholar] [CrossRef]

- Xu, H.; Yin, X.; Li, X.; Li, M.; Liang, S.; Zhang, L.; Cheng, L. Lightweight Ti2CTx MXene/Poly(vinyl alcohol) Composite Foams for Electromagnetic Wave Shielding with Absorption-Dominated Feature. ACS Appl. Mater. Interfaces 2019, 11, 10198–10207. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, H.-B.; Luo, J.-Q.; Wang, Q.-W.; Xu, B.; Hong, S.; Yu, Z.-Z. Highly Electrically Conductive Three-Dimensional Ti3C2Tx MXene/Reduced Graphene Oxide Hybrid Aerogels with Excellent Electromagnetic Interference Shielding Performances. ACS Nano 2018, 12, 11193–11202. [Google Scholar] [CrossRef] [PubMed]

- Monastyreckis, G.; Mishnaevsky, L.; Hatter, C.B.; Aniskevich, A.; Gogotsi, Y.; Zeleniakiene, D. Micromechanical modeling of MXene-polymer composites. Carbon 2020, 162, 402–409. [Google Scholar] [CrossRef]

- Lee, G.S.; Yun, T.; Kim, H.; Kim, I.H.; Choi, J.; Lee, S.H.; Lee, H.J.; Hwang, H.S.; Kim, J.G.; Kim, D.; et al. Mussel Inspired Highly Aligned Ti3C2Tx MXene Film with Synergistic Enhancement of Mechanical Strength and Ambient Stability. ACS Nano 2020, 14, 11722–11732. [Google Scholar] [CrossRef] [PubMed]

- Sun, R.; Zhang, H.-B.; Liu, J.; Xie, X.; Yang, R.; Li, Y.; Hong, S.; Yu, Z.-Z. Highly Conductive Transition Metal Carbide/Carbonitride(MXene)@polystyrene Nanocomposites Fabricated by Electrostatic Assembly for Highly Efficient Electromagnetic Interference Shielding. Adv. Funct. Mater. 2017, 27, 1702807. [Google Scholar] [CrossRef]

- Huang, J.; Wang, T.; Su, Y.; Ding, Y.; Tu, C.; Li, W. Hydrophobic MXene/Hydroxyethyl Cellulose/Silicone Resin Composites with Electromagnetic Interference Shielding. Adv. Mater. Interfaces 2021, 8, 2100186. [Google Scholar] [CrossRef]

- Cao, W.-T.; Chen, F.-F.; Zhu, Y.-J.; Zhang, Y.-G.; Jiang, Y.-Y.; Ma, M.-G.; Chen, F. Binary Strengthening and Toughening of MXene/Cellulose Nanofiber Composite Paper with Nacre-Inspired Structure and Superior Electromagnetic Interference Shielding Properties. ACS Nano 2018, 12, 4583–4593. [Google Scholar] [CrossRef]

- Sun, Y.; Ding, R.; Hong, S.Y.; Lee, J.; Seo, Y.-K.; Nam, J.-D.; Suhr, J. MXene-xanthan nanocomposite films with layered microstructure for electromagnetic interference shielding and Joule heating. Chem. Eng. J. 2021, 410, 128348. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, Z.; Li, Y.; Han, G.; Feng, Y.; Wang, B.; Zhang, D.; Ma, J.; Liu, C. Flexible, Robust, and Multifunctional Electromagnetic Interference Shielding Film with Alternating Cellulose Nanofiber and MXene Layers. ACS Appl. Mater. Interfaces 2020, 12, 4895–4905. [Google Scholar] [CrossRef]

- Naeimirad, M.; Zadhoush, A.; Neisiany, R.E.; Ramakrishna, S.; Salimian, S.; Leal, A.A. Influence of microfluidic flow rates on the propagation of nano/microcracks in liquid core and hollow fibers. Theor. Appl. Fract. Mech. 2018, 96, 83–89. [Google Scholar] [CrossRef]

- Esmaeely Neisiany, R.; Nouri Khorasani, S.; Kong Yoong Lee, J.; Razavi, J.; Enayati, M.S.; Naeimirad, M.; Berto, F.; Ramakrishna, S. Core-shell nanofibers for developing self-healing materials: Recent progress and future directions. Mater. Des. Process. Commun. 2019, 3, 90. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.; Cao, K.; Sui, L.; Qi, Y.; Zhu, J.; Waas, A.; Arruda, E.M.; Kieffer, J.; Thouless, M.D.; Kotov, N.A. Dispersions of Aramid Nanofibers: A New Nanoscale Building Block. ACS Nano 2011, 5, 6945–6954. [Google Scholar] [CrossRef] [Green Version]

- Yang, B.; Wang, L.; Zhang, M.; Luo, J.; Ding, X. Timesaving, High-Efficiency Approaches To Fabricate Aramid Nanofibers. ACS Nano 2019, 13, 7886–7897. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, F.; Huang, Y. Facile and simple fabrication of strong, transparent and flexible aramid nanofibers/bacterial cellulose nanocomposite membranes. Compos. Sci. Technol. 2018, 159, 70–76. [Google Scholar] [CrossRef]

- Xie, C.; He, L.; Shi, Y.; Guo, Z.-X.; Qiu, T.; Tuo, X. From Monomers to a Lasagna-like Aerogel Monolith: An Assembling Strategy for Aramid Nanofibers. ACS Nano 2019, 13, 7811–7824. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.; Zhao, Y.; Ruan, K.; Liu, X.; Zhang, J.; Guo, Y.; Yang, X.; Kong, J.; Gu, J. Highly Thermal Conductivities, Excellent Mechanical Robustness and Flexibility, and Outstanding Thermal Stabilities of Aramid Nanofiber Composite Papers with Nacre-Mimetic Layered Structures. ACS Appl. Mater. Interfaces 2019, 12, 1677–1686. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Zhang, M.; Lu, Z.; Tan, J.; Luo, J.; Song, S.; Ding, X.; Wang, L.; Lu, P.; Zhang, Q. Comparative study of aramid nanofiber (ANF) and cellulose nanofiber (CNF). Carbohydr. Polym. 2019, 208, 372–381. [Google Scholar] [CrossRef]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for Synthesis and Processing of Two-Dimensional Titanium Carbide (Ti3C2Tx MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar] [CrossRef]

- Yang, B.; Wang, L.; Zhang, M.; Luo, J.; Lu, Z.; Ding, X. Fabrication, Applications, and Prospects of Aramid Nanofiber. Adv. Funct. Mater. 2020, 30, 2000186. [Google Scholar] [CrossRef]

- Raagulan, K.; Kim, B.M.; Chai, K.Y. Recent Advancement of Electromagnetic Interference (EMI) Shielding of Two Dimensional (2D) MXene and Graphene Aerogel Composites. Nanomaterials 2020, 10, 702. [Google Scholar] [CrossRef] [Green Version]

- Lei, C.; Zhang, Y.; Liu, D.; Wu, K.; Fu, Q. Metal-Level Robust, Folding Endurance, and Highly Temperature-Stable MXene-Based Film with Engineered Aramid Nanofiber for Extreme-Condition Electromagnetic Interference Shielding Applications. ACS Appl. Mater. Interfaces 2020, 12, 26485–26495. [Google Scholar] [CrossRef]

- Tian, W.; VahidMohammadi, A.; Reid, M.S.; Wang, Z.; Ouyang, L.; Erlandsson, J.; Pettersson, T.; Wågberg, L.; Beidaghi, M.; Hamedi, M.M. MXene Nanocomposites: Multifunctional Nanocomposites with High Strength and Capacitance Using 2D MXene and 1D Nanocellulose (Adv. Mater. 41/2019). Adv. Mater. 2019, 31, 1970290. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Chen, Q.; Li, P.; Zhou, A.; Cao, X.; Hu, Q. Corrigendum to “Preparation, mechanical and anti-friction performance of MXene/polymer composites”. Mater. Des. 2016, 92, 682–689. [Google Scholar] [CrossRef]

- Cao, W.; Ma, C.; Tan, S.; Ma, M.; Wan, P.; Chen, F. Ultrathin and Flexible CNTs/MXene/Cellulose Nanofibrils Composite Paper for Electromagnetic Interference Shielding. Nano-Micro Lett. 2019, 11, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Chung, D.D.L. Electromagnetic interference shielding effectiveness of carbon materials. Carbon 2001, 39, 279–285. [Google Scholar] [CrossRef]

- Wen, B.; Cao, M.; Lu, M.; Cao, W.; Shi, H.; Liu, J.; Wang, X.; Jin, H.; Fang, X.; Wang, W.; et al. Reduced Graphene Oxides: Light-Weight and High-Efficiency Electromagnetic Interference Shielding at Elevated Temperatures. Adv. Mater. 2014, 26, 3484–3489. [Google Scholar] [CrossRef]

- Liang, L.; Li, Q.; Yan, X.; Feng, Y.; Wang, Y.; Zhang, H.-B.; Zhou, X.; Liu, C.; Shen, C.; Xie, X. Multifunctional Magnetic Ti3C2Tx MXene/Graphene Aerogel with Superior Electromagnetic Wave Absorption Performance. ACS Nano 2021, 15, 6622–6632. [Google Scholar] [CrossRef] [PubMed]

- Naguib, M.; Mashtalir, O.; Carle, J.; Presser, V.; Lu, J.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional Transition Metal Carbides. ACS Nano 2012, 6, 1322–1331. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Zhang, L.; Shi, L.; Wang, P. MXene Ti3C2: An Effective 2D Light-to-Heat Conversion Material. ACS Nano 2017, 11, 3752–3759. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Zhang, M.; Yang, B.; Tan, J.; Ding, X. Highly Compressible, Thermally Stable, Light-Weight, and Robust Aramid Nanofibers/Ti3AlC2 MXene Composite Aerogel for Sensitive Pressure Sensor. ACS Nano 2020, 14, 10633–10647. [Google Scholar] [CrossRef] [PubMed]

- Zhou, B.; Su, M.; Yang, D.; Han, G.; Feng, Y.; Wang, B.; Ma, J.; Ma, J.; Liu, C.; Shen, C. Flexible MXene/Silver Nanowire-Based Transparent Conductive Film with Electromagnetic Interference Shielding and Electro-Photo-Thermal Performance. ACS Appl. Mater. Interfaces 2020, 12, 40859–40869. [Google Scholar] [CrossRef]

- Cheng, Z.; Hong, D.; Dai, Y.; Jiang, C.; Meng, C.; Luo, L.; Liu, X. Highly improved UV resistance and composite interfacial properties of aramid fiber via iron (III) coordination. Appl. Surf. Sci. 2018, 434, 473–480. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Yu, J.; Bai, D.; Liu, H.; Li, L. Mechanically Robust Flexible Multilayer Aramid Nanofibers and MXene Film for High-Performance Electromagnetic Interference Shielding and Thermal Insulation. Nanomaterials 2021, 11, 3041. https://doi.org/10.3390/nano11113041

Zhou J, Yu J, Bai D, Liu H, Li L. Mechanically Robust Flexible Multilayer Aramid Nanofibers and MXene Film for High-Performance Electromagnetic Interference Shielding and Thermal Insulation. Nanomaterials. 2021; 11(11):3041. https://doi.org/10.3390/nano11113041

Chicago/Turabian StyleZhou, Jun, Junsheng Yu, Dongyu Bai, Huili Liu, and Lu Li. 2021. "Mechanically Robust Flexible Multilayer Aramid Nanofibers and MXene Film for High-Performance Electromagnetic Interference Shielding and Thermal Insulation" Nanomaterials 11, no. 11: 3041. https://doi.org/10.3390/nano11113041