Efficient Removal of Hexavalent Chromium from an Aquatic System Using Nanoscale Zero-Valent Iron Supported by Ramie Biochar

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

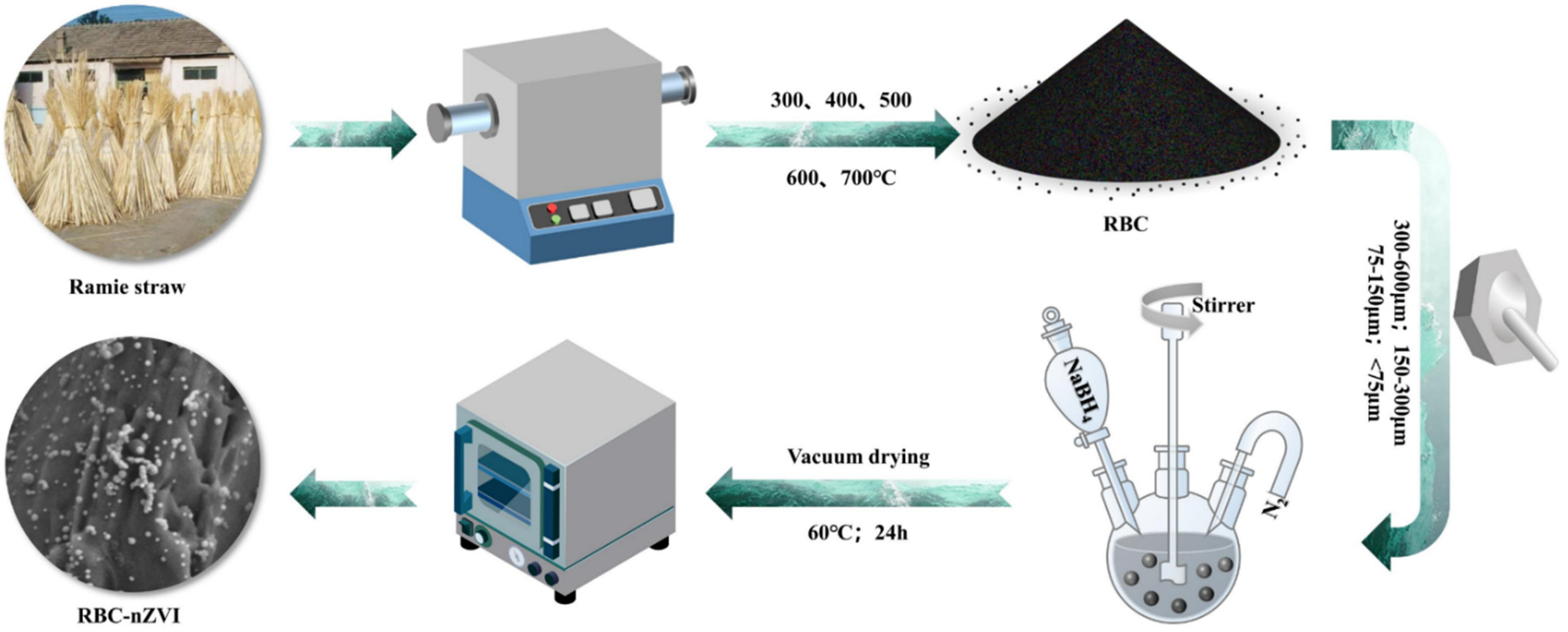

2.2. Preparation of Biochar

2.3. Preparation of nZVI

2.4. Preparation of RBC-nZVI

2.5. Characterization

2.6. Batch Experiments

2.6.1. Influence of Preparation Conditions

2.6.2. Influence of Environmental Factors

3. Results and Discussion

3.1. The Characterization of Biochar and Biochar-Supported nZVI

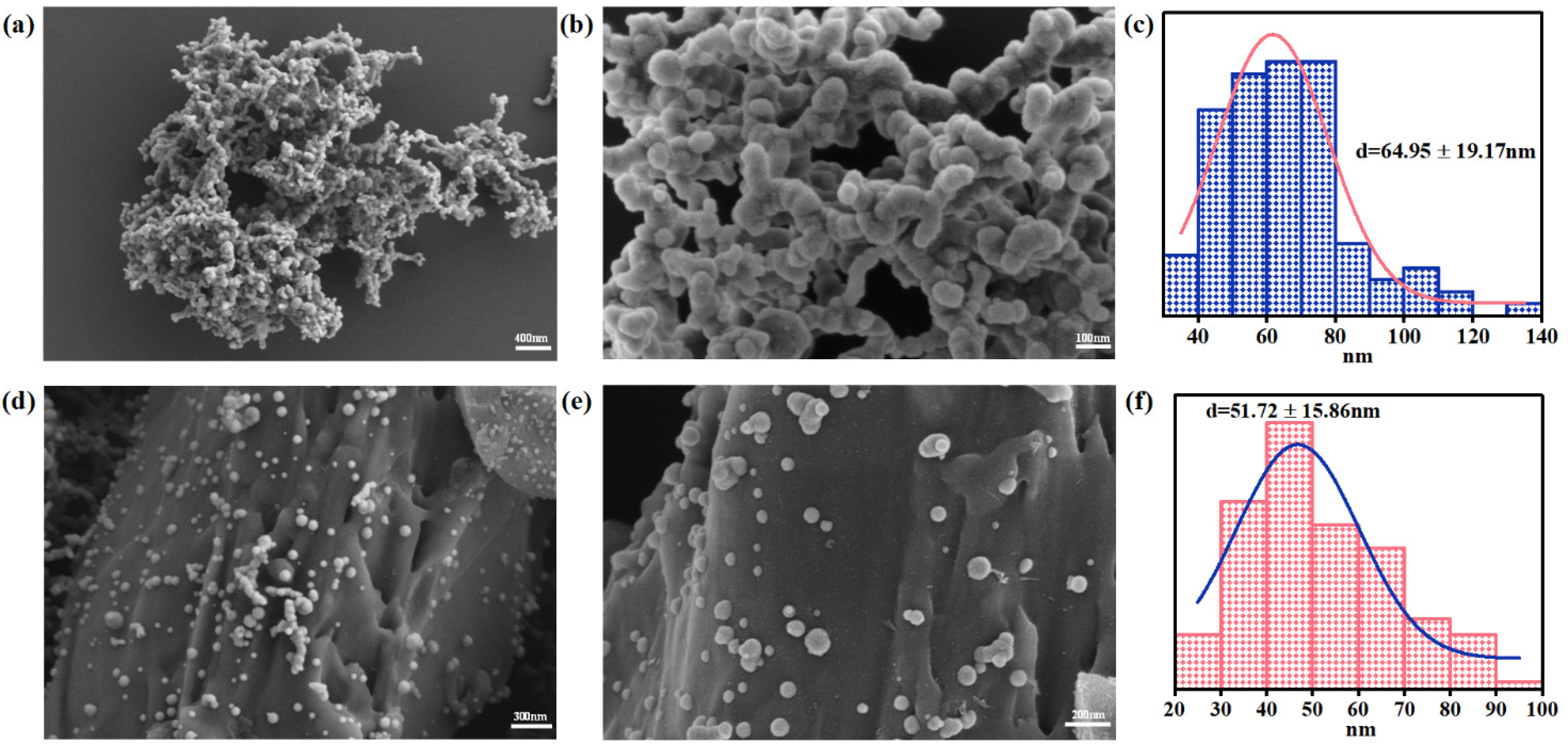

3.1.1. SEM

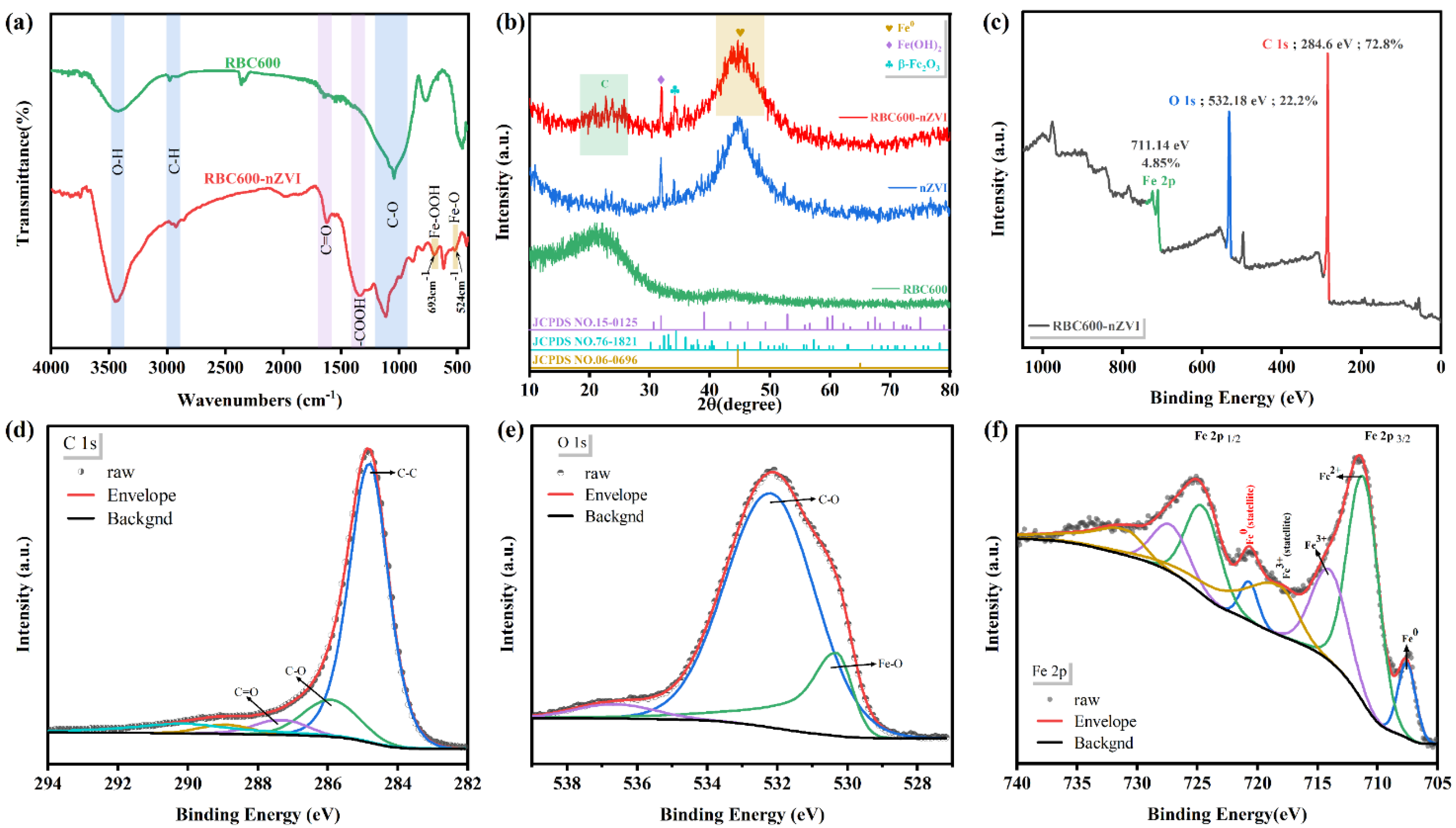

3.1.2. FTIR

3.1.3. XRD

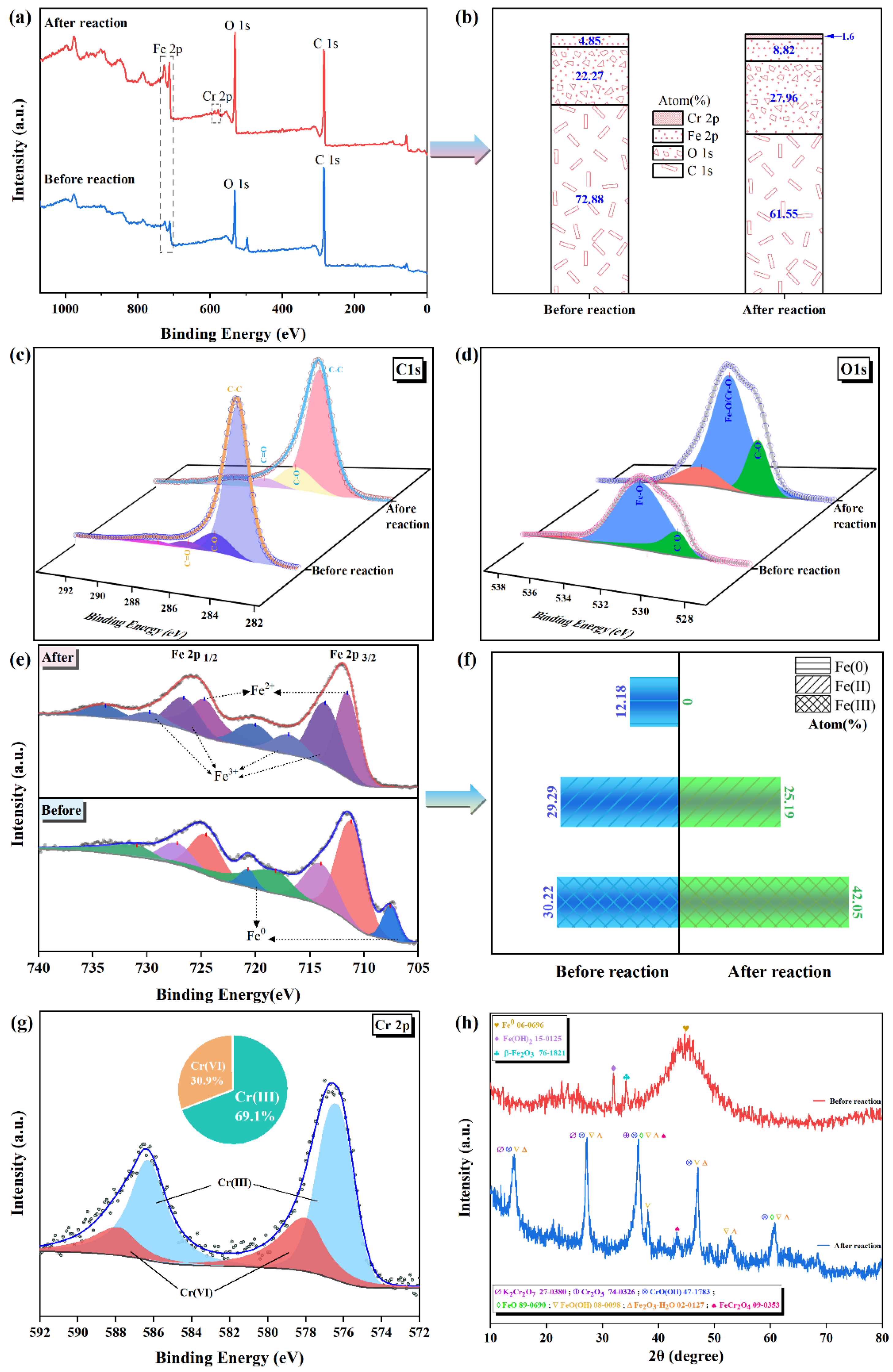

3.1.4. XPS

3.2. Removal of Cr(VI) by RBC

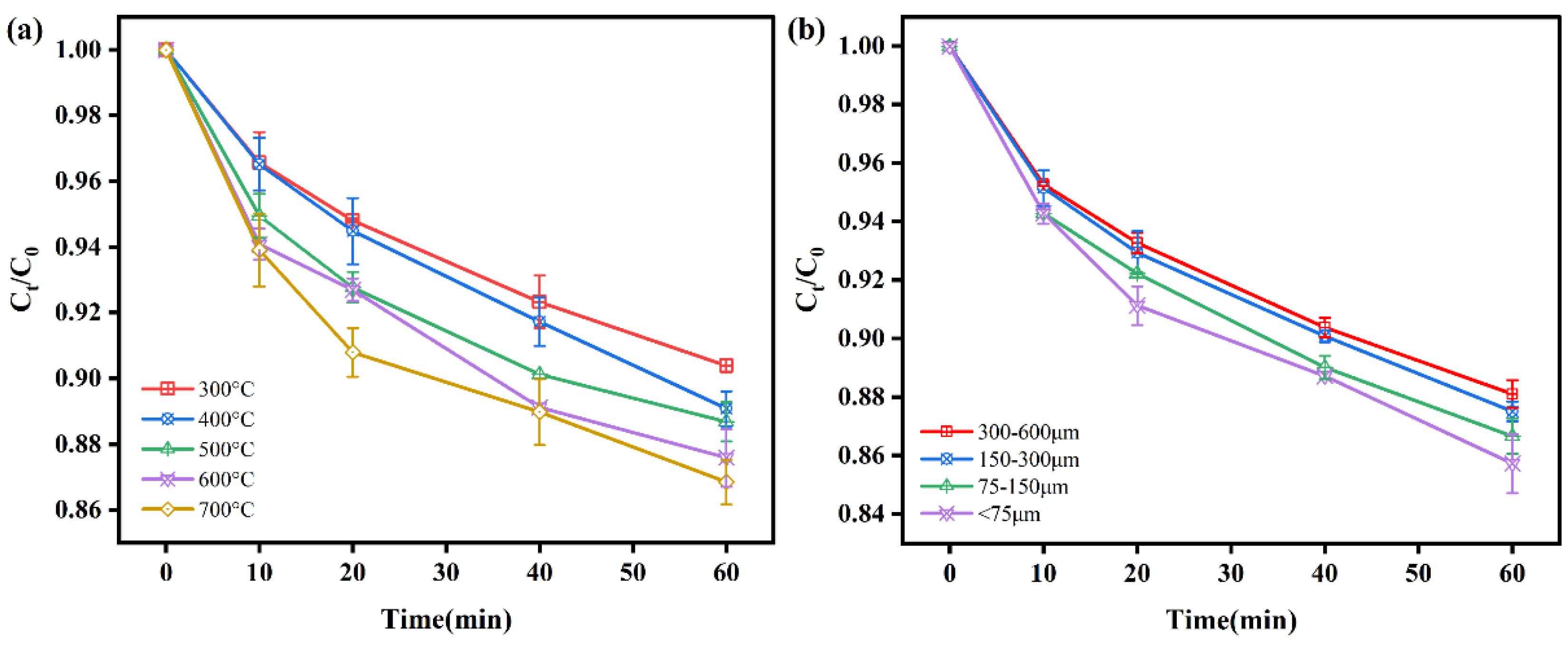

3.3. Effects of Preparation Conditions on Cr(VI) Removal

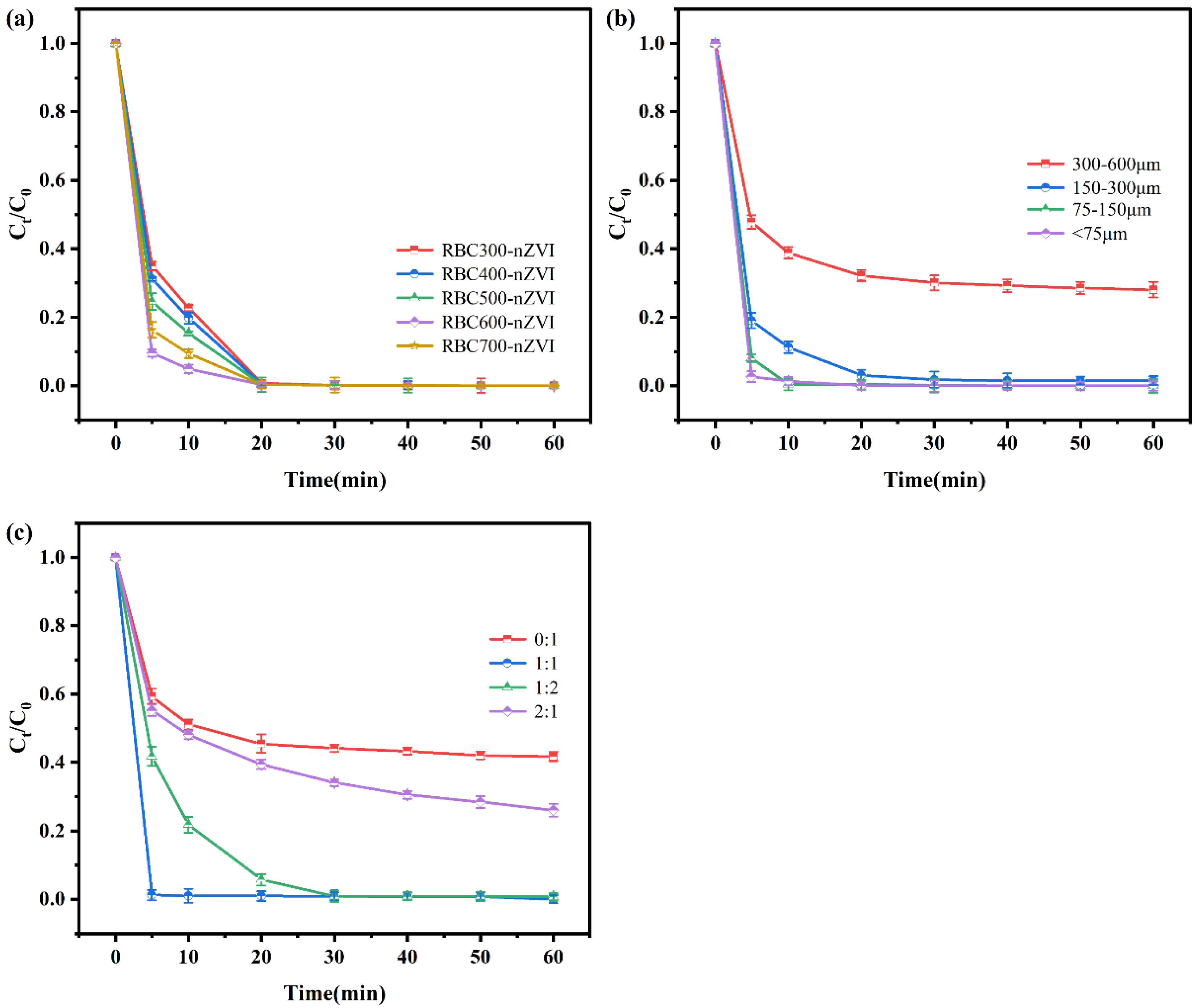

3.4. Effects of Physicochemical Factors on Cr(VI) Removal

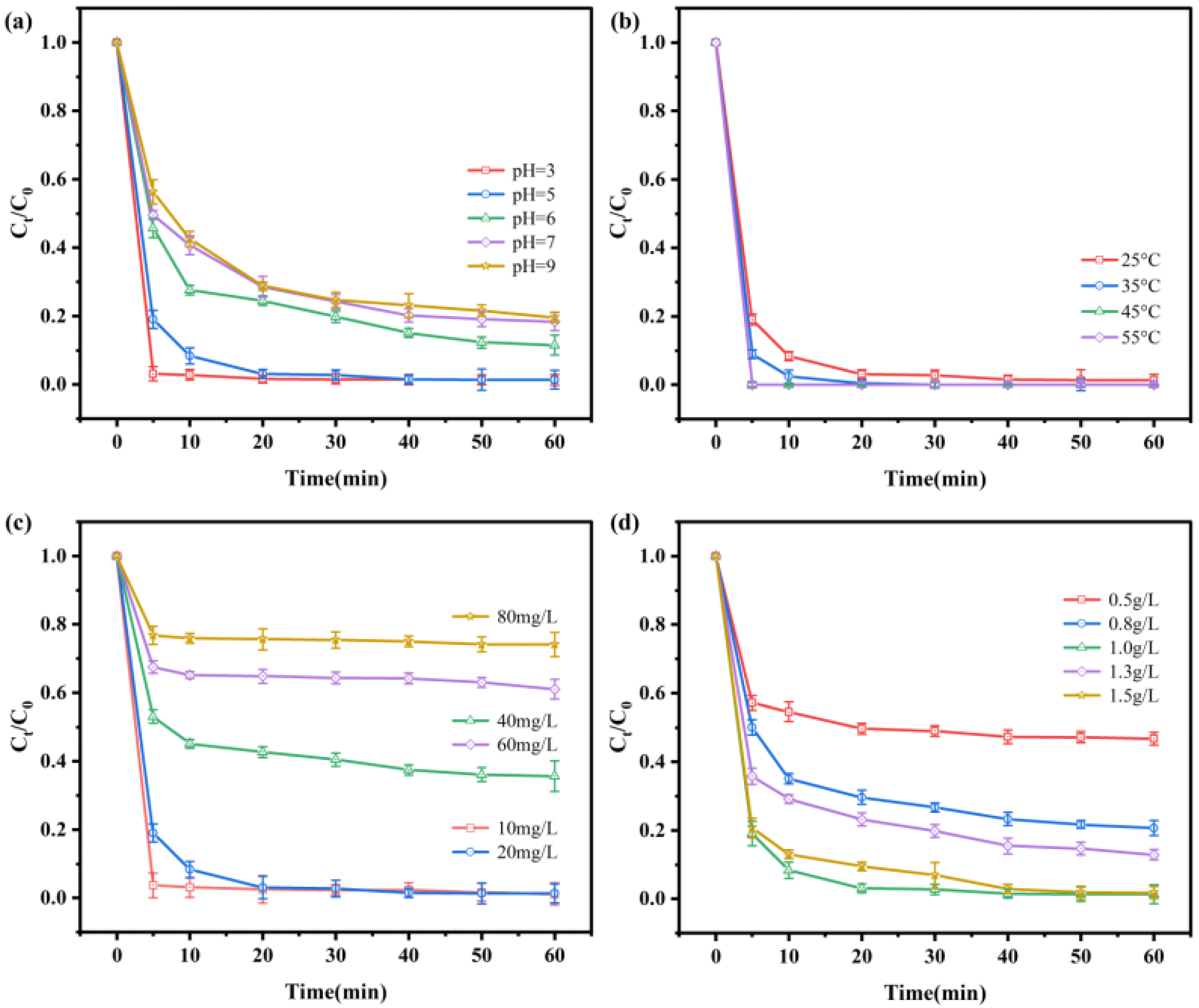

3.5. Removal Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Yu, L.; Wang, R.; Wang, Y.; Zhang, X. A novel cellulose hydrogel coating with nanoscale Fe0 for Cr(VI) adsorption and reduction. Sci. Total Environ. 2020, 726, 138625. [Google Scholar] [CrossRef]

- Jia, X.; Zhang, Y.; He, Z.; Chang, F.; Zhang, H.; Wågberg, T.; Hu, J. Mesopore-rich badam-shell biochar for efficient adsorption of Cr (VI) from aqueous solution. J. Environ. Chem. Eng. 2021, 9, 105634. [Google Scholar] [CrossRef]

- He, X.; Li, P. Surface water pollution in the middle Chinese Loess Plateau with special focus on hexavalent chromium (Cr 6+): Occurrence, sources and health risks. Expo. Health 2020, 12, 385–401. [Google Scholar] [CrossRef]

- Gan, Y.; Huang, X.; Li, S.; Liu, N.; Li, Y.C.; Freidenreich, A.; Wang, W.; Wang, R.; Dai, J. Source quantification and potential risk of mercury, cadmium, arsenic, lead, and chromium in farmland soils of Yellow River Delta. J. Clean. Prod. 2019, 221, 98–107. [Google Scholar] [CrossRef]

- Yang, C.; Ge, C.; Li, X.; Li, L.; Wang, B.; Lin, A.; Yang, W. Does soluble starch improve the removal of Cr(VI) by nZVI loaded on biochar? Ecotoxicol. Environ. Saf. 2021, 208, 111552. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.; Deng, J.; Xie, Y.; Zhang, C.; Jiang, Z.; Cheng, Y.; Hou, K.; Zeng, G. Stabilization of nanoscale zero-valent iron (nZVI) with modified biochar for Cr (VI) removal from aqueous solution. J. Hazard. Mater. 2017, 332, 79–86. [Google Scholar] [CrossRef]

- Lv, D.; Zhou, J.; Cao, Z.; Xu, J.; Liu, Y.; Li, Y.; Yang, K.; Lou, Z.; Lou, L.; Xu, X. Mechanism and influence factors of chromium (VI) removal by sulfide-modified nanoscale zerovalent iron. Chemosphere 2019, 224, 306–315. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Wang, L.; Li, Z.; Tang, X.; He, M.; Yang, S.; Liu, X.; Xu, J. Simultaneous adsorption of Cd(II) and As(III) by a novel biochar-supported nanoscale zero-valent iron in aqueous systems. Sci. Total Environ. 2020, 708, 134823. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Li, X.; Xu, D.; Yang, W.; Bai, S. Application of nanoscale zero-valent iron in hexavalent chromium-contaminated soil: A review. Nanotechnol. Rev. 2020, 9, 736–750. [Google Scholar] [CrossRef]

- Hou, S.; Wu, B.; Peng, D.; Wang, Z.; Wang, Y.; Xu, H. Remediation performance and mechanism of hexavalent chromium in alkaline soil using multi-layer loaded nano-zero-valent iron. Environ. Pollut. 2019, 252, 553–561. [Google Scholar] [CrossRef]

- Li, P.; Yu, J.; Huangfu, Z.; Chang, J.; Zhong, C.; Ding, P. Applying modified biochar with nZVI/nFe3O4 to immobilize Pb in contaminated soil. Environ. Sci. Pollut. Res. 2020, 27, 24495–24506. [Google Scholar] [CrossRef] [PubMed]

- Wei, G.; Zhang, J.; Luo, J.; Xue, H.; Huang, D.; Cheng, Z.; Jiang, X. Nanoscale zero-valent iron supported on biochar for the highly efficient removal of nitrobenzene. Front. Environ. Sci. Eng. 2019, 13, 61. [Google Scholar] [CrossRef]

- Shaaban, M.; Van Zwieten, L.; Bashir, S.; Younas, A.; Núñez-Delgado, A.; Chhajro, M.A.; Kubar, K.A.; Ali, U.; Rana, M.S.; Mehmood, M.A.; et al. A concise review of biochar application to agricultural soils to improve soil conditions and fight pollution. J. Environ. Manag. 2018, 228, 429–440. [Google Scholar] [CrossRef]

- Lyu, H.; Tang, J.; Cui, M.; Gao, B.; Shen, B. Biochar/iron (BC/Fe) composites for soil and groundwater remediation: Synthesis, applications, and mechanisms. Chemosphere 2020, 246, 125609. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Song, Y.; Liu, S.; Ben, H.; Zhang, Y.; Zhou, C.; Han, G.; Ragauskas, A.J. A green degumming process of ramie. Ind. Crop. Prod. 2018, 120, 131–134. [Google Scholar] [CrossRef]

- Mu, L.; Cai, M.; Wang, Z.; Liu, J.; Liu, T.; Wanapat, M.; Huang, B. Assessment of ramie leaf (Boehmeria nivea L. gaud) as an animal feed supplement in PR China. Trop. Anim. Health Prod. 2020, 52, 115–121. [Google Scholar] [CrossRef]

- Chen, X.; Fan, G.; Li, H.; Li, Y.; Zhang, R.; Huang, Y.; Xu, X. Nanoscale zero-valent iron particles supported on sludge-based biochar for the removal of chromium (VI) from aqueous system. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.-D.; Ma, H.-T.; Lin, W.; Sun, P.; Zhang, L.-K.; Han, J.-H. Trametes suaveolens-derived biochar loaded on nanoscale zero-valent iron particles for the adsorption and reduction of Cr(VI). Int. J. Environ. Sci. Technol. 2021, 1–14. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiao, X.; Liu, N.; Lv, J.; Yang, Y. Enhanced removal of aqueous Cr(VI) by a green synthesized nanoscale zero-valent iron supported on oak wood biochar. Chemosphere 2020, 245, 125542. [Google Scholar] [CrossRef]

- Shu, Y.R.; Ji, B.; Cui, B.H.; Shi, Y.T.; Wang, J.; Hu, M.; Luo, S.; Guo, D. Almond Shell-Derived, Biochar-Supported, Nano-Zero-Valent Iron Composite for Aqueous Hexavalent Chromium Removal: Performance and Mechanisms. Nanomaterials 2020, 10, 198. [Google Scholar] [CrossRef] [Green Version]

- Ma, F.; Philippe, B.; Zhao, B.; Diao, J.; Li, J. Simultaneous adsorption and reduction of hexavalent chromium on biochar-supported nanoscale zero-valent iron (nZVI) in aqueous solution. Water Sci. Technol. 2020, 82, 1339–1349. [Google Scholar] [CrossRef] [PubMed]

- Khandelwal, N.; Behera, M.P.; Rajak, J.K.; Darbha, G.K. Biochar-nZVI nanocomposite: Optimization of grain size and Fe(0)loading, application and removal mechanism of anionic metal species from soft water, hard water and groundwater. Clean Technol. Environ. Policy 2020, 22, 1015–1024. [Google Scholar] [CrossRef]

- Fan, Z.; Zhang, Q.; Gao, B.; Li, M.; Liu, C.; Qiu, Y. Removal of hexavalent chromium by biochar supported nZVI composite: Batch and fixed-bed column evaluations, mechanisms, and secondary contamination prevention. Chemosphere 2019, 217, 85–94. [Google Scholar] [CrossRef]

- Diao, Z.H.; Du, J.J.; Jiang, D.; Kong, L.J.; Huo, W.Y.; Liu, C.M.; Wu, Q.H.; Xu, X.R. Insights into the simultaneous removal of Cr6+ and Pb2+ by a novel sewage sludge-derived biochar immobilized nanoscale zero valent iron: Coexistence effect and mechanism. Sci. Total. Environ. 2018, 642, 505–515. [Google Scholar] [CrossRef] [PubMed]

- Qian, L.; Zhang, W.; Yan, J.; Han, L.; Chen, Y.; Ouyang, D.; Chen, M. Nanoscale zero-valent iron supported by biochars produced at different temperatures: Synthesis mechanism and effect on Cr(VI) removal. Environ. Pollut. 2017, 223, 153–160. [Google Scholar] [CrossRef]

- Shang, J.G.; Zong, M.Z.; Yu, Y.; Kong, X.R.; Du, Q.; Liao, Q.J.H. Removal of chromium (VI) from water using nanoscale zerovalent iron particles supported on herb-residue biochar. J. Environ. Manag. 2017, 197, 331–337. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.H.; Wu, M.F.; Tang, T.T.; Xing, Q.J.; Peng, C.Q.; Li, F.; Liu, H.; Luo, X.B.; Zou, J.P.; Min, X.B.; et al. Mechanism investigation of anoxic Cr(VI) removal by nano zero-valent iron based on XPS analysis in time scale. Chem. Eng. J. 2018, 335, 945–953. [Google Scholar] [CrossRef]

- Su, H.; Fang, Z.; Tsang, P.E.; Fang, J.; Zhao, D. Stabilisation of nanoscale zero-valent iron with biochar for enhanced transport and in-situ remediation of hexavalent chromium in soil. Environ. Pollut. 2016, 214, 94–100. [Google Scholar] [CrossRef]

- Chen, G.-Q.; Zhang, W.-J.; Zeng, G.-M.; Huang, J.-H.; Wang, L.; Shen, G.-L. Surface-modified Phanerochaete chrysosporium as a biosorbent for Cr(VI)-contaminated wastewater. J. Hazard. Mater. 2011, 186, 2138–2143. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, L.; Wang, R.; Wang, Y.; Zhang, X. Microwave catalytic activities of supported perovskite catalysts MOx/LaCo0. 5Cu0. 5O3@ CM (M = Mg, Al) for salicylic acid degradation. J. Colloid Interface Sci. 2020, 564, 392–405. [Google Scholar] [CrossRef]

- Bhatti, Z.A.; Qureshi, K.; Maitlo, G.; Ahmed, S. Study of PAN fiber and iron ore adsorbents for arsenic removal. Civ. Eng. J. 2020, 6, 548–562. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.; Zhuang, W.-Q.; De Costa, Y.; Xia, S. Potential effects of suspended TiO2 nanoparticles on activated sludge floc properties in membrane bioreactors. Chemosphere 2019, 223, 148–156. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W.; Chen, M. Progress in the preparation and application of modified biochar for improved contaminant removal from water and wastewater. Bioresour. Technol. 2016, 214, 836–851. [Google Scholar] [CrossRef] [PubMed]

- Wan, Z.; Cho, D.-W.; Tsang, D.C.; Li, M.; Sun, T.; Verpoort, F. Concurrent adsorption and micro-electrolysis of Cr(VI) by nanoscale zerovalent iron/biochar/Ca-alginate composite. Environ. Pollut. 2019, 247, 410–420. [Google Scholar] [CrossRef]

- Dickinson, M.; Scott, T.B.; Crane, R.A.; Riba, O.; Barnes, R.J.; Hughes, G.M. The effects of vacuum annealing on the structure and surface chemistry of iron:nickel alloy nanoparticles. J. Nanoparticle Res. 2010, 12, 2081–2092. [Google Scholar] [CrossRef]

- Mu, Y.; Jia, F.L.; Ai, Z.H.; Zhang, L.Z. Iron oxide shell mediated environmental remediation properties of nano zero-valent iron. Environ. Sci. Nano 2017, 4, 27–45. [Google Scholar] [CrossRef]

- Bae, S.; Collins, R.N.; Waite, T.D.; Hanna, K. Advances in Surface Passivation of Nanoscale Zerovalent Iron: A Critical Review. Environ. Sci. Technol. 2018, 52, 12010–12025. [Google Scholar] [CrossRef]

- Li, M.; Shang, H.; Li, H.; Hong, Y.; Ling, C.; Wei, K.; Zhou, B.; Mao, C.; Ai, Z.; Zhang, L. Kirkendall Effect Boosts Phosphorylated nZVI for Efficient Heavy Metal Wastewater Treatment. Angew. Chem. Int. Ed. 2021, 60, 17115–17122. [Google Scholar] [CrossRef]

- Lv, X.S.; Qin, X.F.; Wang, K.F.; Peng, Y.Y.; Wang, P.; Jiang, G.M. Nanoscale zero valent iron supported on MgAl-LDH-decorated reduced graphene oxide: Enhanced performance in Cr(VI) removal, mechanism and regeneration. J. Hazard. Mater. 2019, 373, 176–186. [Google Scholar] [CrossRef]

- Wu, L.M.; Liao, L.B.; Lv, G.C.; Qin, F.X.; He, Y.J.; Wang, X.Y. Micro-electrolysis of Cr (VI) in the nanoscale zero-valent iron loaded activated carbon. J. Hazard. Mater. 2013, 254, 277–283. [Google Scholar] [CrossRef]

- Cheng, Y.J.; Dong, H.R.; Hao, T.W. CaCO3 coated nanoscale zero-valent iron (nZVI) for the removal of chromium(VI) in aqueous solution. Sep. Purif. Technol. 2021, 257, 117967. [Google Scholar] [CrossRef]

- Szabó, M.; Kalmár, J.; Ditrói, T.; Bellér, G.; Lente, G.; Simic, N.; Fábián, I. Equilibria and kinetics of chromium(VI) speciation in aqueous solution—A comprehensive study from pH 2 to 11. Inorganica Chim. Acta 2018, 472, 295–301. [Google Scholar] [CrossRef]

- Li, J.; Fana, M.J.; Li, M.; Liu, X. Cr(VI) removal from groundwater using double surfactant-modified nanoscale zero-valent iron (nZVI): Effects of materials in different status. Sci. Total Environ. 2020, 717, 137112. [Google Scholar] [CrossRef]

- Zhou, S.; Li, Y.; Chen, J.; Liu, Z.; Wang, Z.; Na, P. Enhanced Cr(vi) removal from aqueous solutions using Ni/Fe bimetallic nanoparticles: Characterization, kinetics and mechanism. RSC Adv. 2014, 4, 50699–50707. [Google Scholar] [CrossRef]

- Qiu, Y.; Zhang, Q.; Gao, B.; Li, M.; Fan, Z.X.; Sang, W.J.; Hao, H.; Wei, X. Removal mechanisms of Cr(VI) and Cr(III) by biochar supported nanosized zero-valent iron: Synergy of adsorption, reduction and transformation. Environ. Pollut. 2020, 265, 115018. [Google Scholar] [CrossRef]

- Chang, D.Y.; Chen, T.H.; Liu, H.B.; Xi, Y.F.; Qing, C.S.; Xie, Q.Q. A new approach to prepare ZVI and its application in removal of Cr(VI) from aqueous solution. Chem. Eng. J. 2014, 244, 264–272. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.Y.; Zhao, L.; Tan, X.; Liu, S.J.; Li, J.J.; Qi, Y.; Mao, G.Z. Effects of physicochemical factors on Cr(VI) removal from leachate by zero-valent iron and alpha-Fe2O3 nanoparticles. Water Sci. Technol. 2010, 61, 2759–2767. [Google Scholar] [CrossRef]

- Zhou, M.; Yang, X.; Sun, R.; Wang, X.; Yin, W.; Wang, S.; Wang, J. The contribution of lignocellulosic constituents to Cr(VI) reduction capacity of biochar-supported zerovalent iron. Chemosphere 2021, 263, 127871. [Google Scholar] [CrossRef]

- Qian, L.; Shang, X.; Zhang, B.; Zhang, W.; Su, A.; Chen, Y.; Ouyang, D.; Han, L.; Yan, J.; Chen, M. Enhanced removal of Cr (VI) by silicon rich biochar-supported nanoscale zero-valent iron. Chemosphere 2019, 215, 739–745. [Google Scholar] [CrossRef] [PubMed]

- Du, J.; Bao, J.; Lu, C.; Werner, D. Reductive sequestration of chromate by hierarchical FeS@ Fe0 particles. Water Res. 2016, 102, 73–81. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Biomass | Conditions | Removal Performance | Ref. |

|---|---|---|---|

| Sewage sludge and sunflower seed shells | pH = 3; Cr(VI) = 50 mg L−1; Dosage = 1.0 g L−1; Reaction time: 90 min | 95.00% | [17] |

| Trametes suaveolens | pH = 2; Cr(VI) = 50 mg L−1; Dosage = 5.0 g L−1; Reaction time: 90 min | 100% | [18] |

| Oak wood | pH = 2; Cr(VI) = 50 mg L−1; Dosage = 0.04 g; Reaction time: 12 h | 99.9% | [19] |

| Almond shell | pH = 2; Cr(VI) = 10 mg L−1; Dosage = 0.08 g; Reaction time: 60 min | 99.8% | [20] |

| Flax straw | pH = 3; Cr(VI) = 100 mg L−1; Dosage = 0.05 g; Reaction time: 24 h | 186.99 mg/g | [21] |

| Woody biomass of Prosopis juliflora | pH neutral; Cr(VI) = 10 mg L−1; Dosage = 0.02 g; Reaction time: 18 h | 16.30 mg/g | [22] |

| Sewage sludge | pH = 4; Cr(VI) = 50 mg L−1; Dosage = 0.05 g; Reaction time: 24 h | 31.53 mg/g | [23] |

| Sewage sludge and the starch | pH = 4; Cr(VI) = 30 mg L−1; Dosage = 1.5 g L−1; | 98.8% | [24] |

| Rice straw | pH = 4; Cr(VI) = 20 mg L−1; Dosage = 0.05 g; Reaction time: 24 h | 40.0 mg/g; | [25] |

| Cornstalk | pH = 5; Cr(VI) = 10 mg L−1; Dosage = 0.2 g L−1; Reaction time: 4 h | 17.8 mg/g | [6] |

| Herb-residue | pH = 2; Cr(VI) = 20 mg L−1; Dosage = 0.2 g L−1; Reaction time: 4 h | 98.71% | [26] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, X.; Shaaban, M.; Yang, J.; Cai, Y.; Wang, B.; Peng, Q.-A. Efficient Removal of Hexavalent Chromium from an Aquatic System Using Nanoscale Zero-Valent Iron Supported by Ramie Biochar. Nanomaterials 2021, 11, 2698. https://doi.org/10.3390/nano11102698

Tan X, Shaaban M, Yang J, Cai Y, Wang B, Peng Q-A. Efficient Removal of Hexavalent Chromium from an Aquatic System Using Nanoscale Zero-Valent Iron Supported by Ramie Biochar. Nanomaterials. 2021; 11(10):2698. https://doi.org/10.3390/nano11102698

Chicago/Turabian StyleTan, Xiangpeng, Muhammad Shaaban, Jianwei Yang, Yajun Cai, Buyun Wang, and Qi-An Peng. 2021. "Efficient Removal of Hexavalent Chromium from an Aquatic System Using Nanoscale Zero-Valent Iron Supported by Ramie Biochar" Nanomaterials 11, no. 10: 2698. https://doi.org/10.3390/nano11102698

APA StyleTan, X., Shaaban, M., Yang, J., Cai, Y., Wang, B., & Peng, Q.-A. (2021). Efficient Removal of Hexavalent Chromium from an Aquatic System Using Nanoscale Zero-Valent Iron Supported by Ramie Biochar. Nanomaterials, 11(10), 2698. https://doi.org/10.3390/nano11102698