High Transient-Thermal-Shock Resistant Nanochannel Tungsten Films

Abstract

:1. Introduction

2. Experiments

2.1. Material Preparation

2.2. ELMs-like Transient Thermal Load Tests

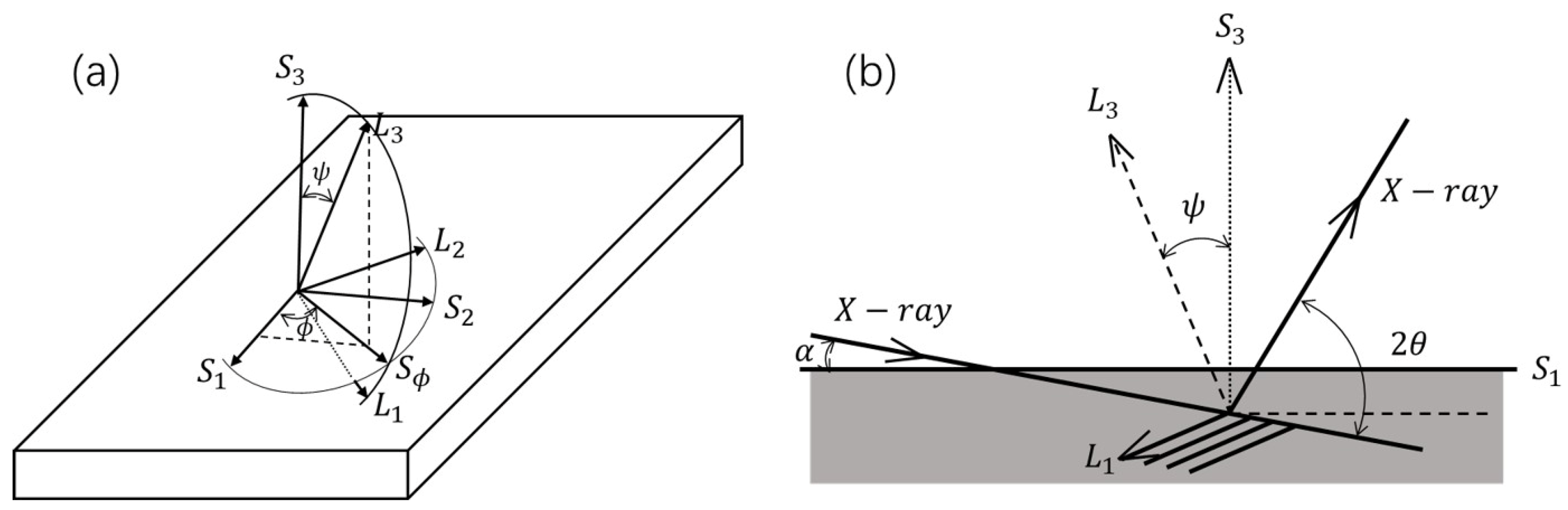

2.3. Residual Stress Measurement

2.4. Characterization Methods

3. Results and Discussion

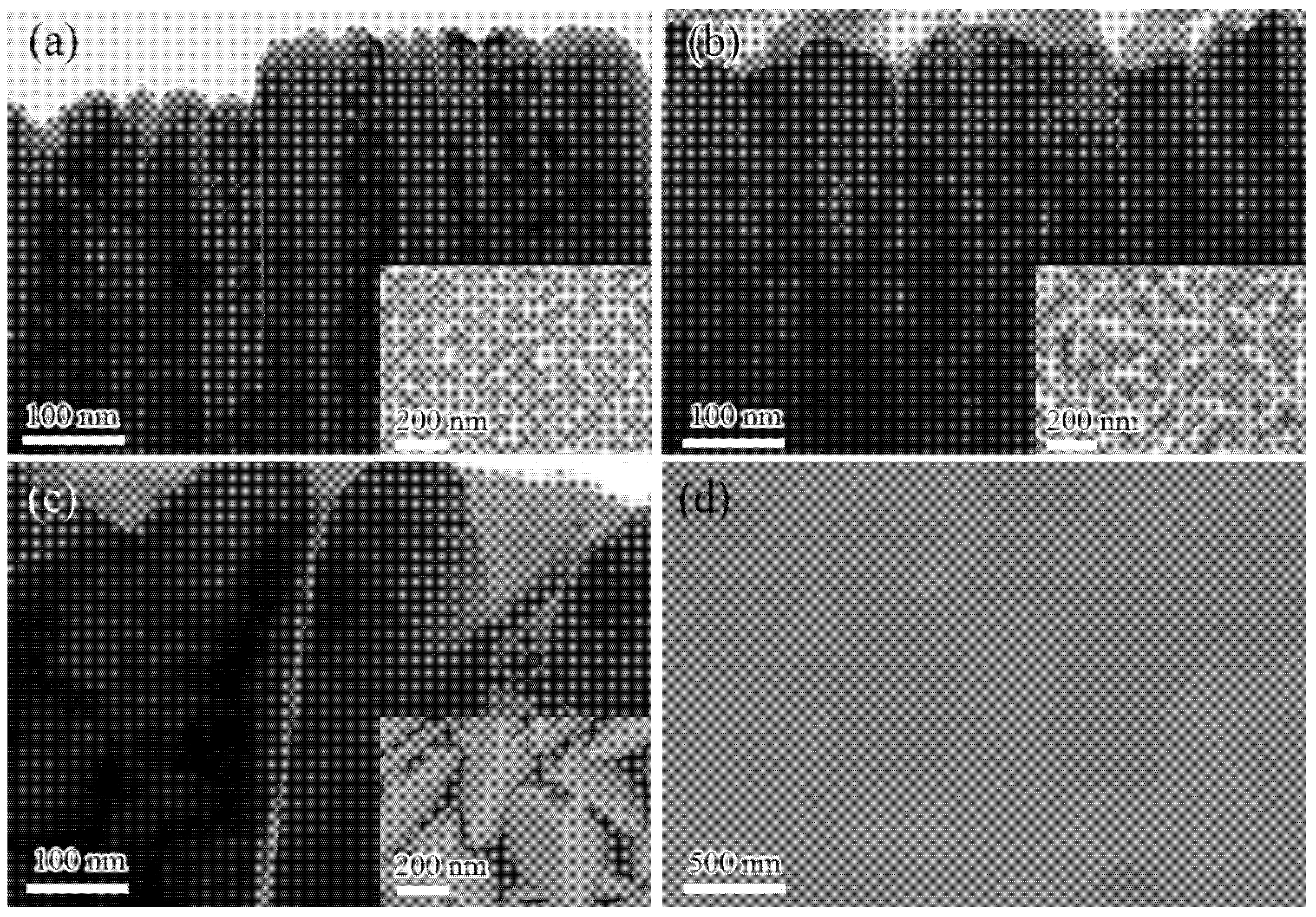

3.1. Microstructure of Nanochannel W Films

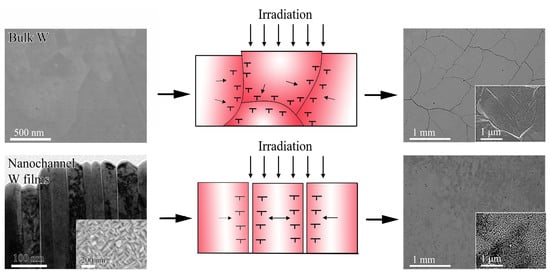

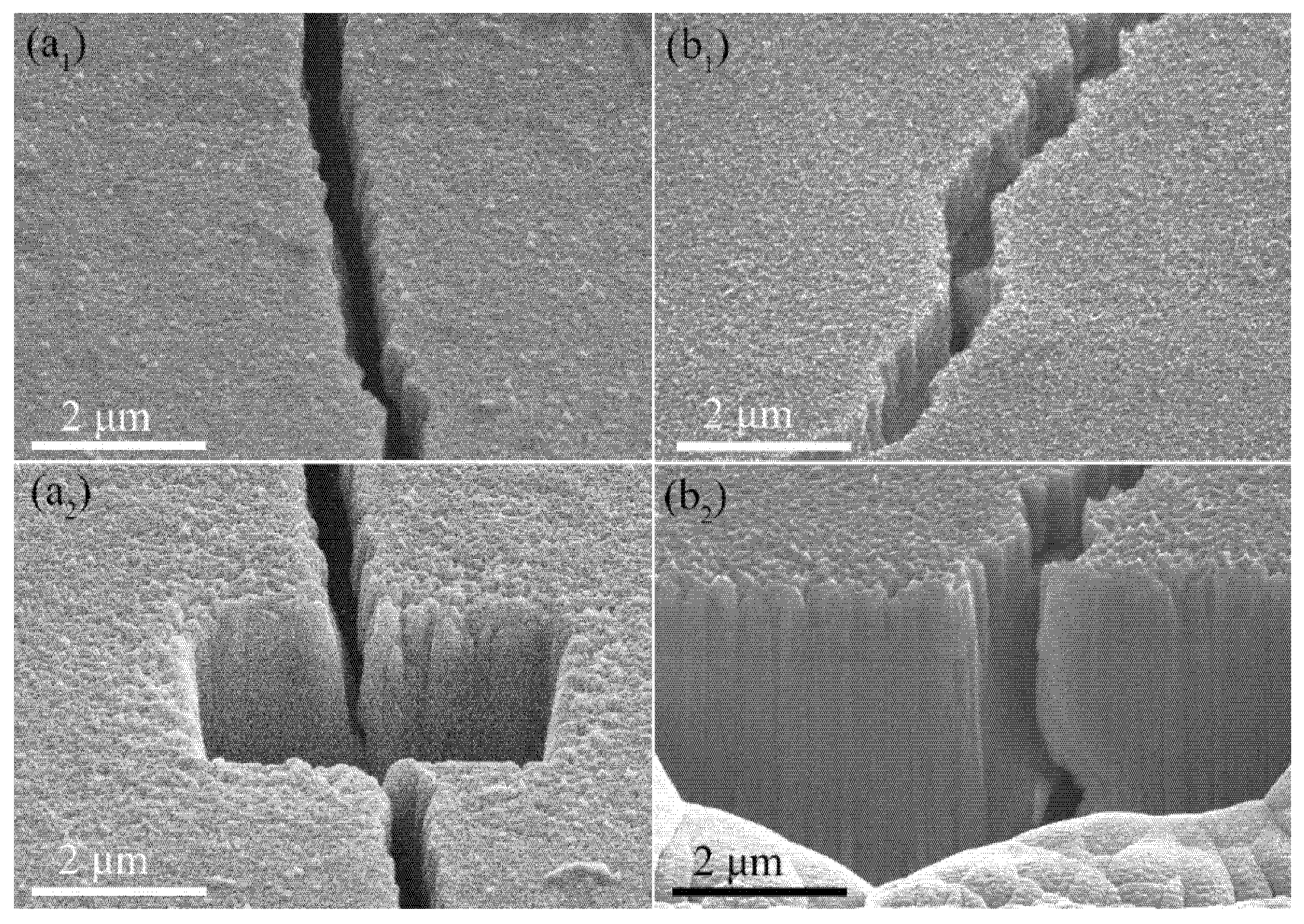

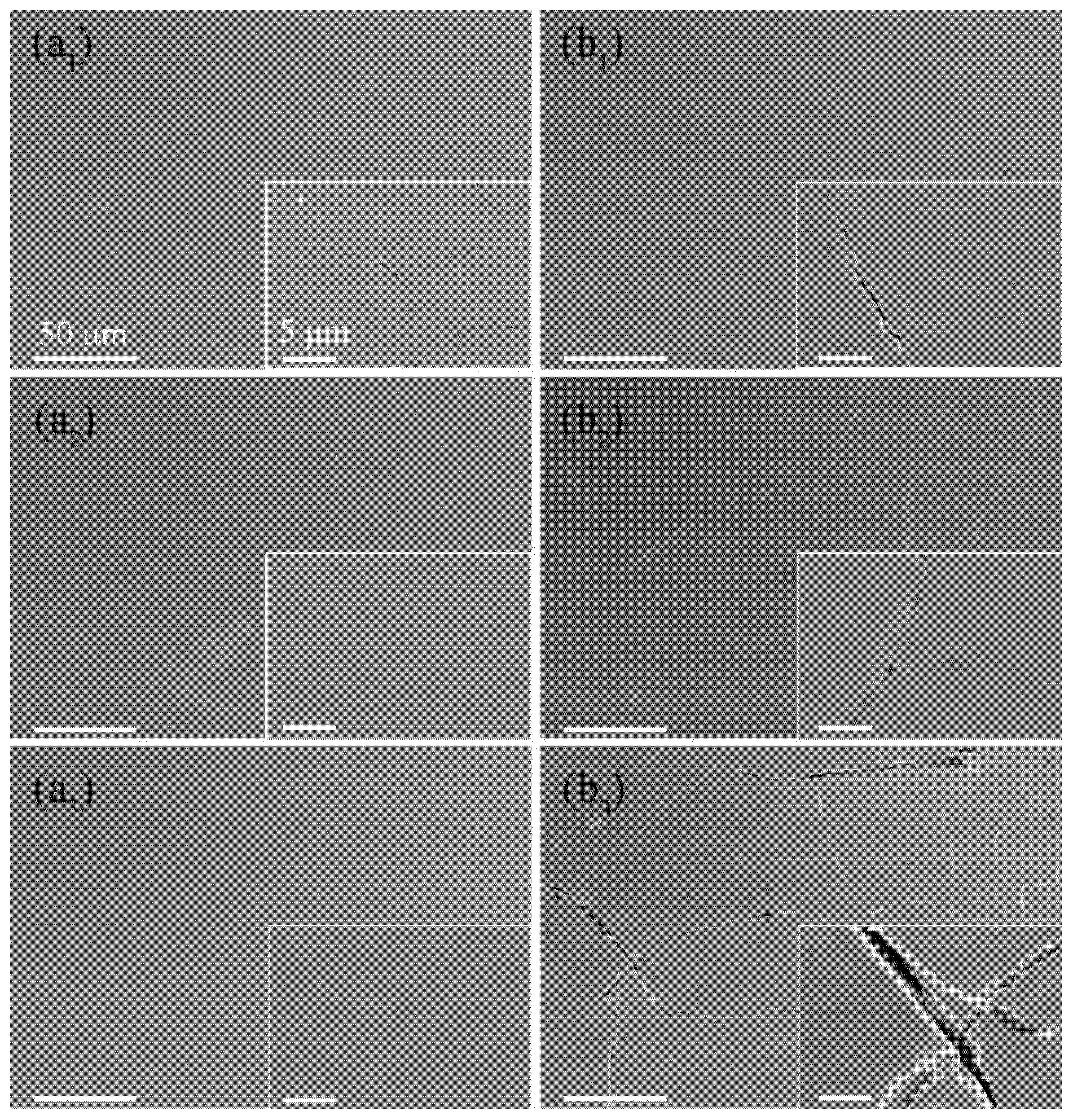

3.2. Damage Behavior under Pulsed Electron Beam Bombardment

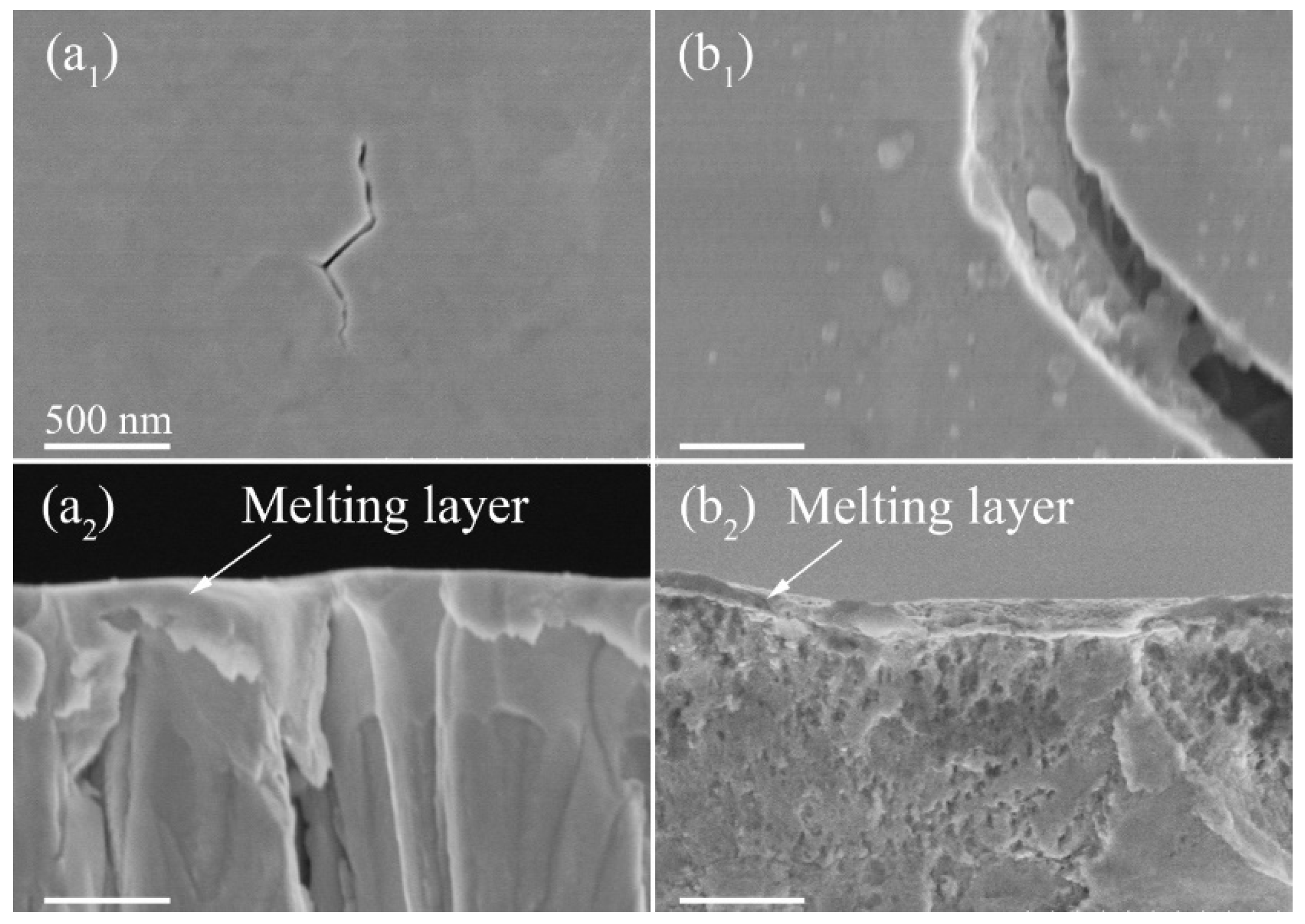

3.3. Damage Behavior under HIPIB Bombardment

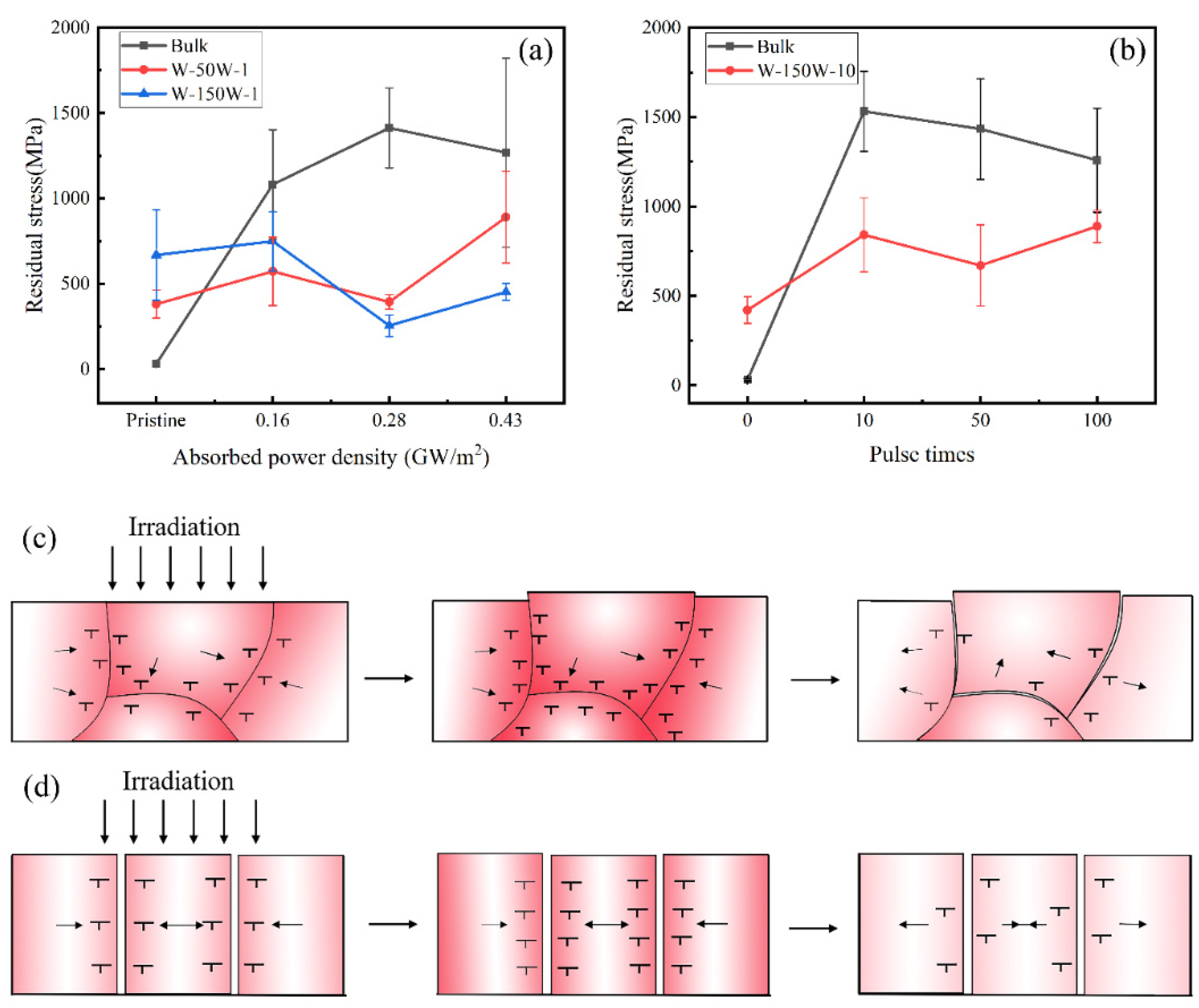

3.4. Evolutions of Stress under Irradiation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Loarte, A.; Saibene, G.; Sartori, R.; Campbell, D.; Becoulet, M.; Horton, L.; Eich, T.; Herrmann, A.; Matthews, G.; Asakura, N.; et al. Characteristics of type I ELM energy and particle losses in existing devices and their extrapolation to ITER. Plasma Phys. Control. Fusion 2003, 45, 1549–1569. [Google Scholar] [CrossRef] [Green Version]

- Linke, J.; Escourbiac, F.; Mazul, I.; Nygren, R.; Rödig, M.; Schlosser, J.; Suzuki, S. High heat flux testing of plasma facing materials and components—Status and perspectives for ITER related activities. J. Nucl. Mater. 2007, 367–370, 1422–1431. [Google Scholar] [CrossRef]

- Pitts, R.; Carpentier, S.; Escourbiac, F.; Hirai, T.; Komarov, V.; Kukushkin, A.; Lisgo, S.; Loarte, A.; Merola, M.; Mitteau, R.; et al. Physics basis and design of the ITER plasma-facing components. J. Nucl. Mater. 2011, 415, S957–S964. [Google Scholar] [CrossRef]

- Hu, J.S.; Sun, Z.; Guo, H.Y.; Li, J.G.; Wan, B.N.; Wang, H.Q.; Ding, S.Y.; Xu, G.S.; Liang, Y.F.; Mansfield, D.K.; et al. New steady-state quiescent high-confinement plasma in an experimental advanced superconducting tokamak. Phys. Rev. Lett. 2015, 114, 055001. [Google Scholar] [CrossRef]

- Bazylev, B.; Janeschitz, G.; Landman, I.; Loarte, A.; Federici, G.; Merola, M.; Zhitlukhin, A.; Podkovyrov, V.; Klimov, N.; Linke, J.; et al. Experimental validation of 3D simulations of tungsten melt erosion under ITER-like transient loads. J. Nucl. Mater. 2009, 390–391, 810–813. [Google Scholar] [CrossRef]

- Linke, J.; Loewenhoff, T.; Massaut, V.; Pintsuk, G.; Ritz, G.F.; Rödig, M.; Schmidt, A.; Thomser, C.; Uytdenhouwen, I.; Vasechko, V.; et al. Performance of different tungsten grades under transient thermal loads. Nucl. Fusion 2011, 51, 073017. [Google Scholar] [CrossRef] [Green Version]

- Lian, Y.; Liu, X.; Cheng, Z.; Wang, J.; Song, J.; Yu, Y.; Chen, J. Thermal shock performance of CVD tungsten coating at elevated temperatures. J. Nucl. Mater. 2014, 455, 371–375. [Google Scholar] [CrossRef]

- Sinclair, G.; Tripathi, J.K.; Diwakar, P.K.; Hassanein, A. Melt layer erosion during ELM-like heat loading on molybdenum as an alternative plasma-facing material. Sci. Rep. 2017, 7, 12273. [Google Scholar] [CrossRef] [Green Version]

- Zan, X.; Yan, J.; Sun, H.; Wang, K.; Lian, Y.; Tan, X.; Luo, L.; Liu, X.; Wu, Y. Surface damage during transient thermal load of 50% thickness reduced W-2% (Vol.) Y2O3 sheet with different recrystallization volume fraction. Int. J. Refract. Met. Hard Mater. 2020, 88, 105197. [Google Scholar] [CrossRef]

- Sinclair, G.; Tripathi, J.K.; Hassanein, A. Erosion dynamics of tungsten fuzz during ELM-like heat loading. J. Appl. Phys. 2018, 123, 133302. [Google Scholar] [CrossRef]

- Smid, I.; Akiba, M.; Vieider, G.; Plöchl, L. Development of tungsten armor and bonding to copper for plasma-interactive components. J. Nucl. Mater. 1998, 258, 160–172. [Google Scholar] [CrossRef]

- Davis, J.; Barabash, V.; Makhankov, A.; Plöchl, L.; Slattery, K. Assessment of tungsten for use in the ITER plasma facing components. J. Nucl. Mater. 1998, 258–263, 308–312. [Google Scholar] [CrossRef]

- Neu, R.; Dux, R.; Kallenbach, A.; Pütterich, T.; Balden, M.; Fuchs, J.; Herrmann, A.; Maggi, C.; O’Mullane, M.; Pugno, R.; et al. Tungsten: An option for divertor and main chamber plasma facing components in future fusion devices. Nucl. Fusion 2005, 45, 209–218. [Google Scholar] [CrossRef]

- Li, C.; Zhu, D.; Li, X.; Wang, B.; Chen, J. Thermal–stress analysis on the crack formation of tungsten during fusion relevant transient heat loads. Nucl. Mater. Energy 2017, 13, 68–73. [Google Scholar] [CrossRef]

- Pestchanyi, S.; Garkusha, I.; Landman, I. Simulation of residual thermostress in tungsten after repetitive ELM-like heat loads. Fusion Eng. Des. 2011, 86, 1681–1684. [Google Scholar] [CrossRef]

- Hirai, T.; Pintsuk, G. Thermo-mechanical calculations on operation temperature limits of tungsten as plasma facing material. Fusion Eng. Des. 2007, 82, 389–393. [Google Scholar] [CrossRef]

- Wirtz, M.; Linke, J.; Loewenhoff, T.; Pintsuk, G.; Uytdenhouwen, I. Transient heat load challenges for plasma-facing materials during long-term operation. Nucl. Mater. Energy 2017, 12, 148–155. [Google Scholar] [CrossRef]

- Zhang, X.; Hattar, K.; Chen, Y.; Shao, L.; Li, J.; Sun, C.; Yu, K.; Li, N.; Taheri, M.L.; Wang, H.; et al. Radiation damage in nanostructured materials. Prog. Mater. Sci. 2018, 96, 217–321. [Google Scholar] [CrossRef]

- Ackland, G. Controlling Radiation Damage. Science 2010, 327, 1587–1588. [Google Scholar] [CrossRef]

- Tang, J.; Wei, G.; Cai, X.; Hu, S.; Shen, T.; Cheng, T.; Yin, R.; Zhang, J.; Ruan, X.; Yang, B.; et al. Smart 3D Network Nanocomposites Collect Irradiation-Induced “Trash”. Matter 2020, 3, 1631–1645. [Google Scholar] [CrossRef]

- Qin, W.; Ren, F.; Doerner, R.P.; Wei, G.; Lv, Y.; Chang, S.; Tang, M.; Deng, H.; Jiang, C.; Wang, Y. Nanochannel structures in W enhance radiation tolerance. Acta Mater. 2018, 153, 147–155. [Google Scholar] [CrossRef]

- Qin, W.; Ren, F.; Zhang, J.; Dong, X.; Feng, Y.; Wang, H.; Tang, J.; Cai, G.; Wang, Y.; Jiang, C.; et al. Helium retention in krypton ion pre-irradiated nanochannel W film. Nucl. Fusion 2017, 58, 026021. [Google Scholar] [CrossRef]

- Lian, Y.; Liu, X.; Xu, Z.; Song, J.; Yu, Y. Preparation and properties of CVD-W coated W/Cu FGM mock-ups. Fusion Eng. Des. 2013, 88, 1694–1698. [Google Scholar] [CrossRef]

- Mei, X.; Zhang, X.; Liu, X.; Wang, Y. Effect on structure and mechanical property of tungsten irradiated by high intensity pulsed ion beam. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2017, 406, 697–702. [Google Scholar] [CrossRef]

- Remnev, G.; Uglov, V.; Shymanski, V.; Pavlov, S.; Kuleshov, A. Formation of nanoscale carbon structures in the surface layer of metals under the impact of high intensity ion beam. Appl. Surf. Sci. 2014, 310, 204–209. [Google Scholar] [CrossRef]

- Remnev, G.; Isakov, I.; Opekounov, M.; Kotlyarevsky, G.; Kutuzov, V.; Lopatin, V.; Matvienko, V.; Ovsyannikov, M.; Potyomkin, A.; Tarbokov, V. High-power ion beam sources for industrial application. Surf. Coat. Technol. 1997, 96, 103–109. [Google Scholar] [CrossRef]

- Pushkarev, A.I.; Isakova, Y.I. A gigawatt power pulsed ion beam generator for industrial applications. Surf. Coat. Technol. 2012, 228, S382–S384. [Google Scholar] [CrossRef]

- Noyan, I.C.; Cohen, J.B. Determination of Strain and Stress Fields by Diffraction Methods. In Residual Stress; Springer: New York, NY, USA, 1987; pp. 117–163. [Google Scholar] [CrossRef]

- Ma, C.-H.; Huang, J.-H.; Chen, H. Residual stress measurement in textured thin film by grazing-incidence X-ray diffraction. Thin Solid Films 2002, 418, 73–78. [Google Scholar] [CrossRef]

- Skrzypek, S.J.; Baczmański, A.; Ratuszek, W.; Kusior, E. New approach to stress analysis based on grazing-incidence X-ray diffraction. J. Appl. Crystallogr. 2001, 34, 427–435. [Google Scholar] [CrossRef]

- Welzel, U.; Ligot, J.; Lamparter, P.; Vermeulen, A.C.; Mittemeijer, E.J. Stress analysis of polycrystalline thin films and surface regions by X-ray diffraction. J. Appl. Crystallogr. 2005, 38, 1–29. [Google Scholar] [CrossRef]

- Marciszko, M.; Baczmański, A.; Braham, C.; Wróbel, M.; Wroński, S.; Cios, G. Stress measurements by multi-reflection grazing-incidence X-ray diffraction method (MGIXD) using different radiation wavelengths and different incident angles. Acta Mater. 2017, 123, 157–166. [Google Scholar] [CrossRef]

- Hirai, T.; Pintsuk, G.; Linke, J.; Batilliot, M. Cracking failure study of ITER-reference tungsten grade under single pulse thermal shock loads at elevated temperatures. J. Nucl. Mater. 2009, 390, 751–754. [Google Scholar] [CrossRef]

- Wirtz, M.; Cempura, G.; Linke, J.; Pintsuk, G.; Uytdenhouwen, I. Thermal shock response of deformed and recrystallised tungsten. Fusion Eng. Des. 2013, 88, 1768–1772. [Google Scholar] [CrossRef]

- A Makhlaj, V.; E Garkusha, I.; Malykhin, S.V.; Pugachov, A.T.; Landman, I.; Linke, J.; Pestchanyi, S.; Chebotarev, V.V.; I Tereshin, V. Residual stresses in tungsten under exposures with ITER ELM-like plasma loads. Phys. Scr. 2009, 2009, 014060. [Google Scholar] [CrossRef]

- Schiller, S.; Heisig, U.; Panzer, S. Electron Beam Technology; Wiley: New York, NY, USA, 1982. [Google Scholar]

- Wu, D.; Lei, M.; Zhu, X.; Gong, Y. Numerical Study on the Ablation Effects of Tungsten Irradiated by High-intensity Pulsed Ion Beam. Phys. Procedia 2011, 22, 246–251. [Google Scholar] [CrossRef] [Green Version]

- Singh, C.K.; Ilango, S.; Polaki, S.R.; Dash, S.; Tyagi, A.K. On the evolution of residual stress at different substrate temperatures in sputter-deposited polycrystalline Mo thin films by X-ray diffraction. Mater. Res. Express 2014, 1, 036401. [Google Scholar] [CrossRef]

- Li, M.; Werner, E.; You, J.-H. Cracking behavior of tungsten armor under ELM-like thermal shock loads: A computational study. Nucl. Mater. Energy 2015, 2, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Furumoto, T.; Ueda, T.; Aziz, M.S.A.; Hosokawa, A.; Tanaka, R. Study on Reduction of Residual Stress Induced during Rapid Tooling Process: Influence of Heating Conditions on Residual Stress. Key Eng. Mater. 2010, 447–448, 785–789. [Google Scholar] [CrossRef] [Green Version]

- Cancellieri, C.; Moszner, F.; Chiodi, M.; Yoon, S.; Janczak-Rusch, J.; Jeurgens, L.P. The effect of thermal treatment on the stress state and evolving microstructure of Cu/W nano-multilayers. J. Appl. Phys. 2016, 120, 195107. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, T.; Qin, W.; Lian, Y.; Liu, X.; Tang, J.; Cai, G.; Zhang, S.; Le, X.; Jiang, C.; Ren, F. High Transient-Thermal-Shock Resistant Nanochannel Tungsten Films. Nanomaterials 2021, 11, 2663. https://doi.org/10.3390/nano11102663

Cheng T, Qin W, Lian Y, Liu X, Tang J, Cai G, Zhang S, Le X, Jiang C, Ren F. High Transient-Thermal-Shock Resistant Nanochannel Tungsten Films. Nanomaterials. 2021; 11(10):2663. https://doi.org/10.3390/nano11102663

Chicago/Turabian StyleCheng, Tao, Wenjing Qin, Youyun Lian, Xiang Liu, Jun Tang, Guangxu Cai, Shijian Zhang, Xiaoyun Le, Changzhong Jiang, and Feng Ren. 2021. "High Transient-Thermal-Shock Resistant Nanochannel Tungsten Films" Nanomaterials 11, no. 10: 2663. https://doi.org/10.3390/nano11102663

APA StyleCheng, T., Qin, W., Lian, Y., Liu, X., Tang, J., Cai, G., Zhang, S., Le, X., Jiang, C., & Ren, F. (2021). High Transient-Thermal-Shock Resistant Nanochannel Tungsten Films. Nanomaterials, 11(10), 2663. https://doi.org/10.3390/nano11102663