Dielectric Properties and Spectral Characteristics of Photocatalytic Constant of TiO2 Nanoparticles Doped with Cobalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Samples

2.2. Composition and Phase Control

2.3. Photocatalytic Activity Measurements

2.4. Dielectric Constant Measurements

2.5. NMR Analysis and Magnetic Properties

3. Results

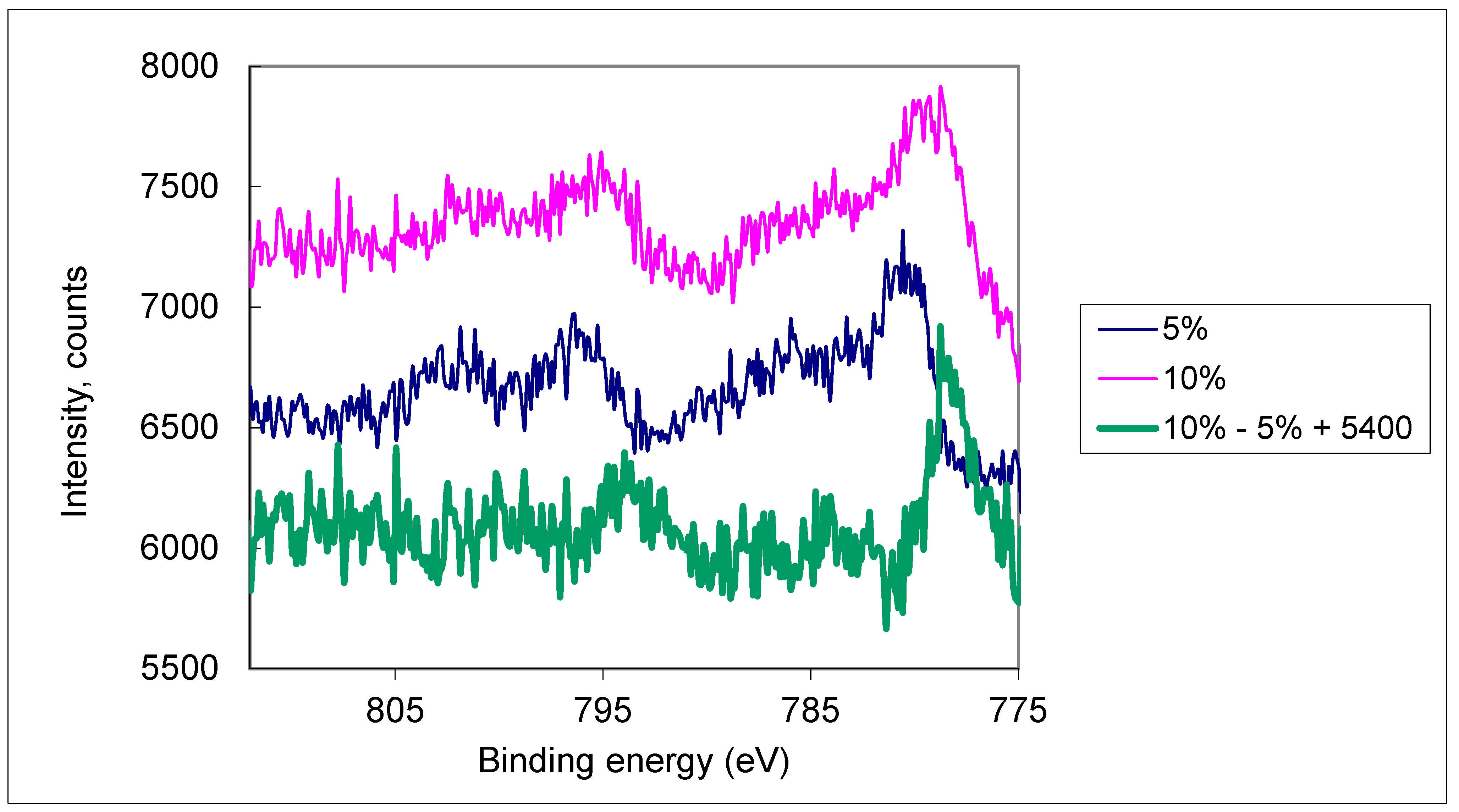

3.1. Composition Analysis by XPS and EDX

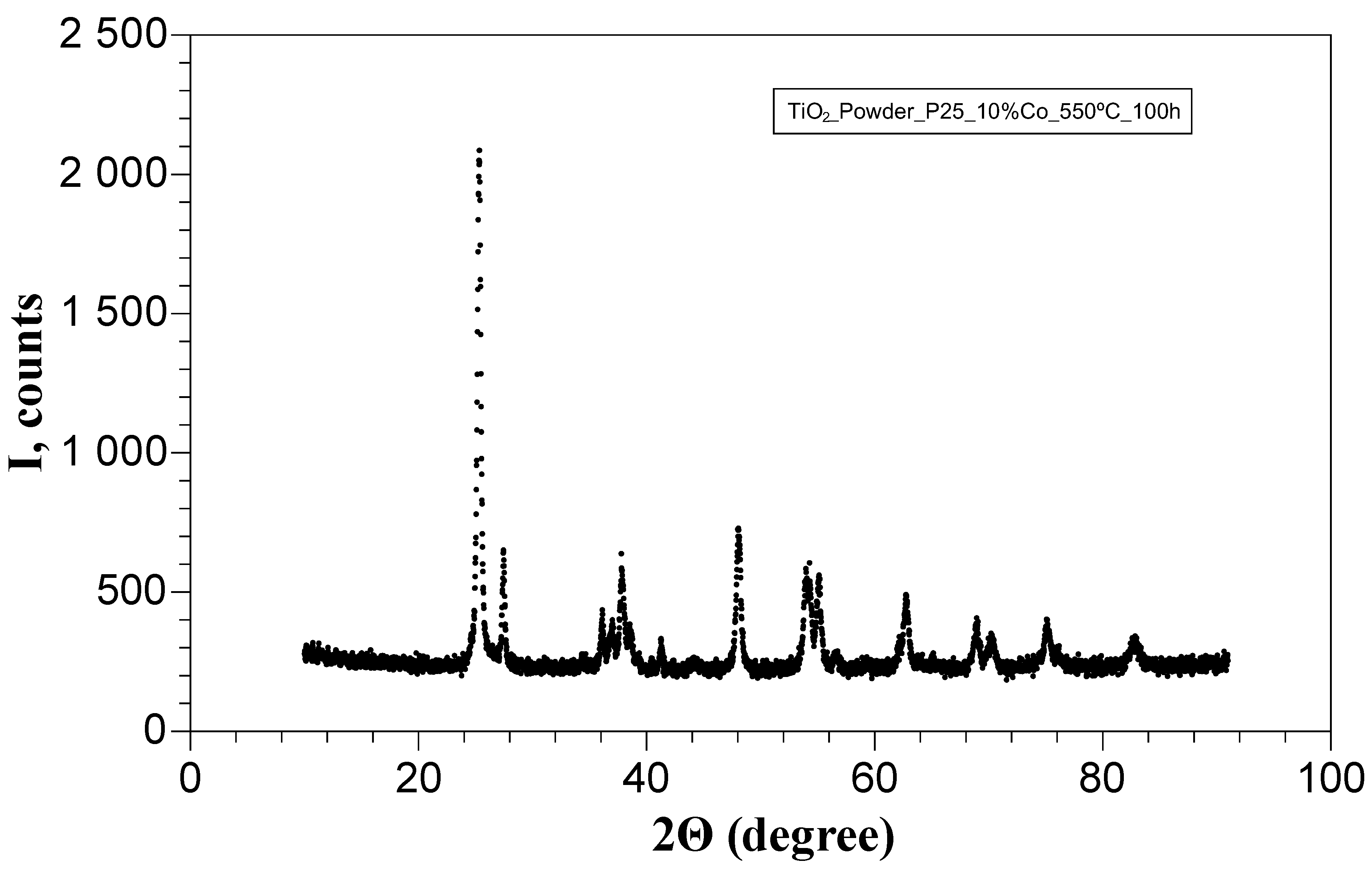

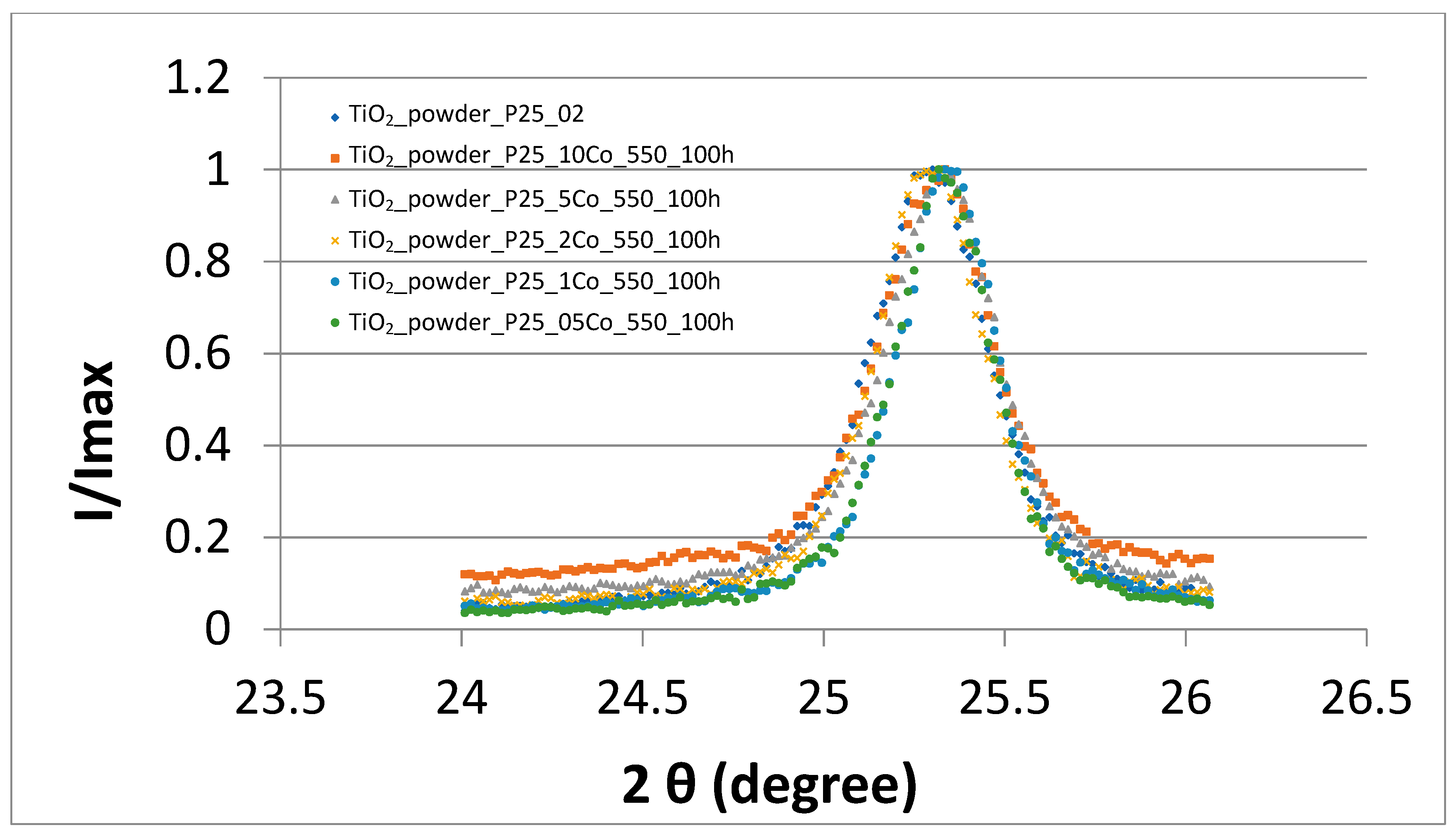

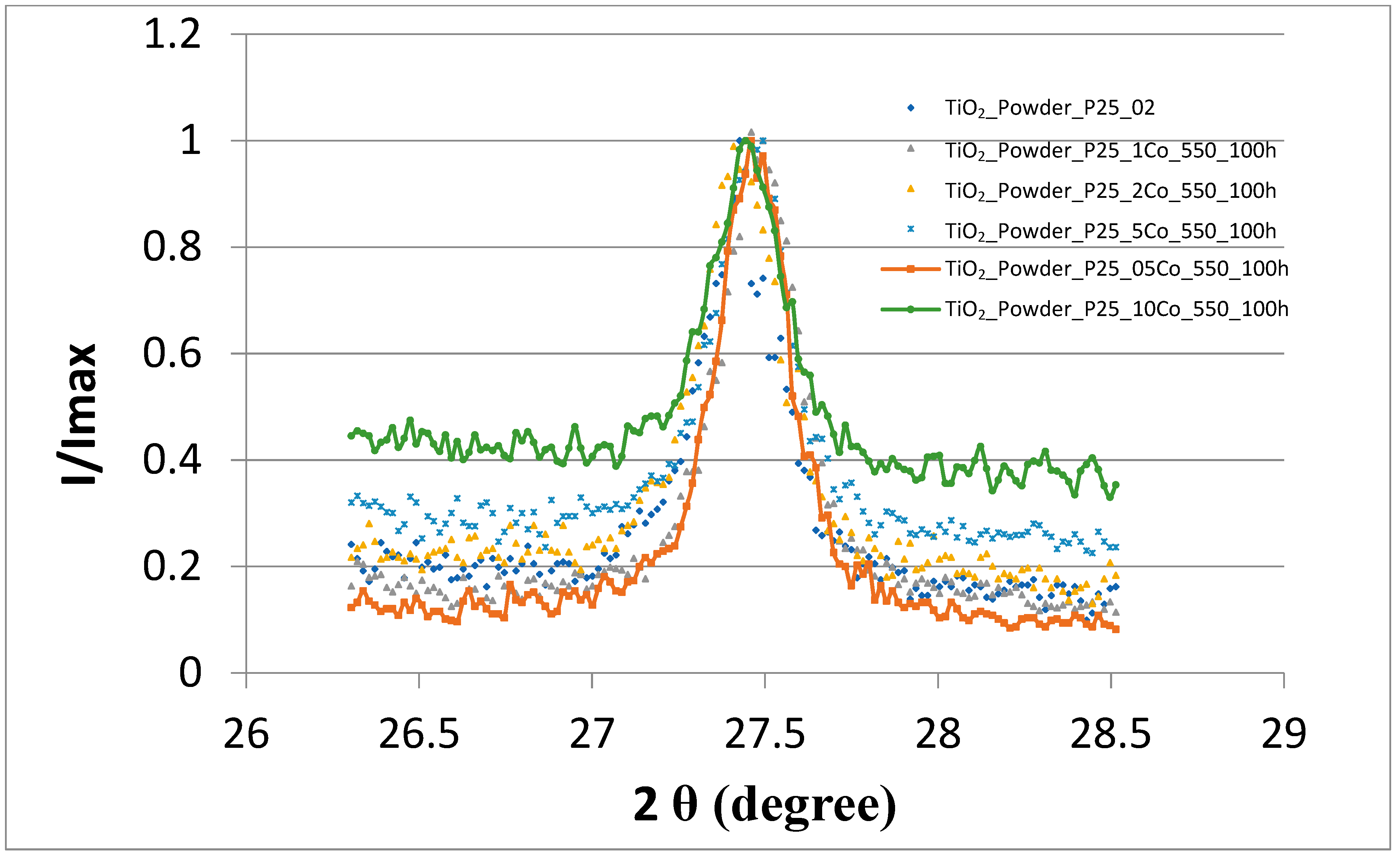

3.2. XRD Analysis of the Samples

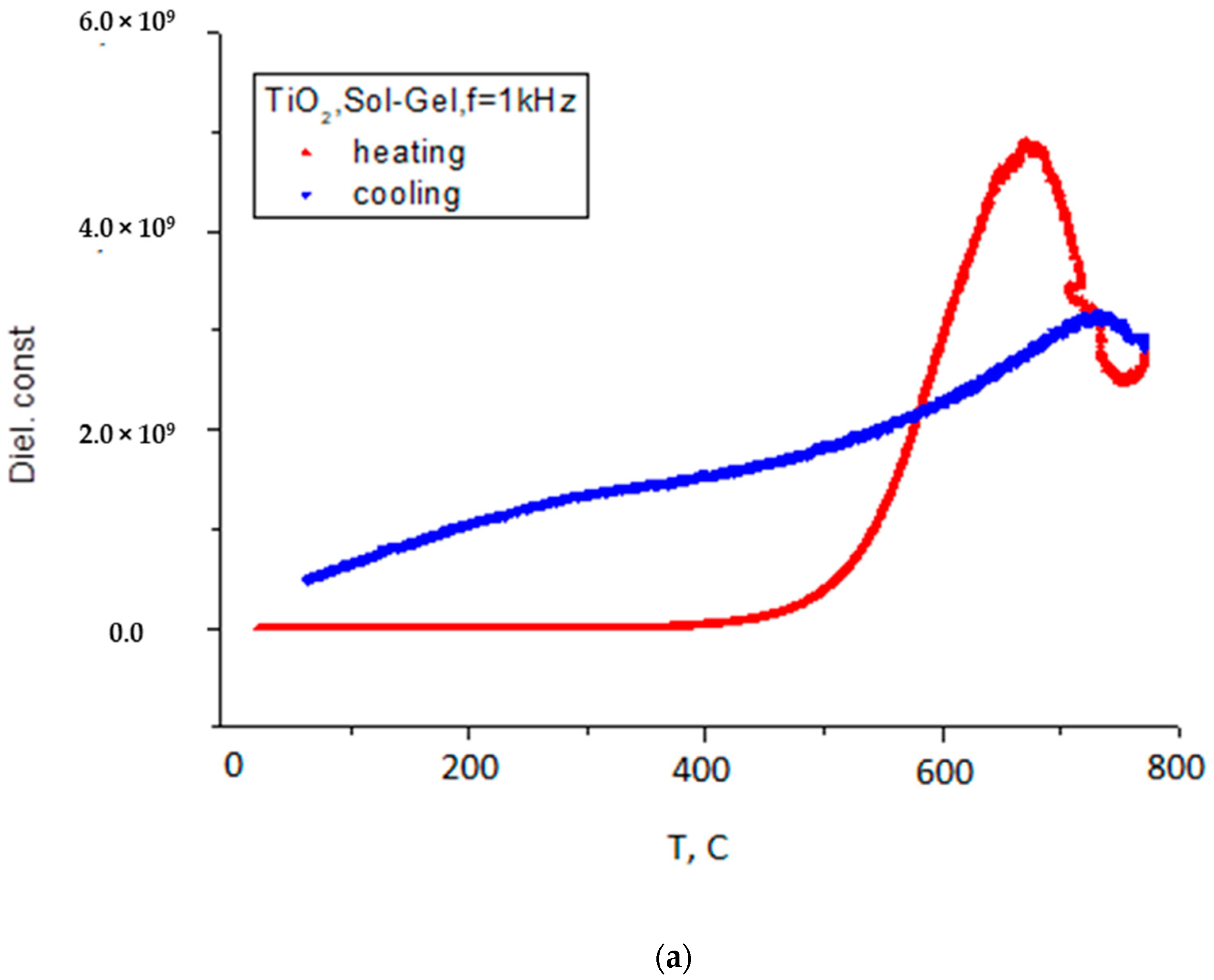

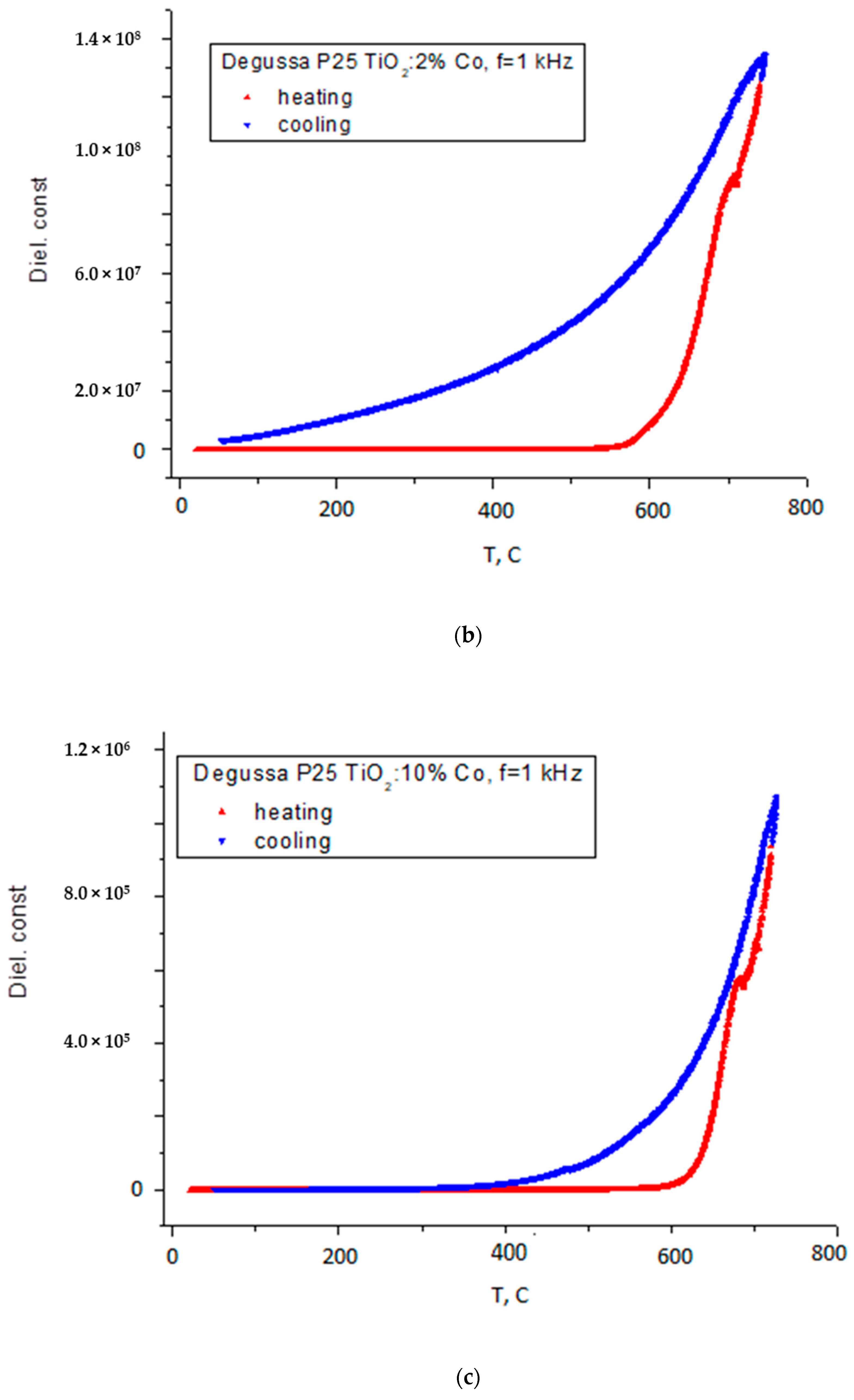

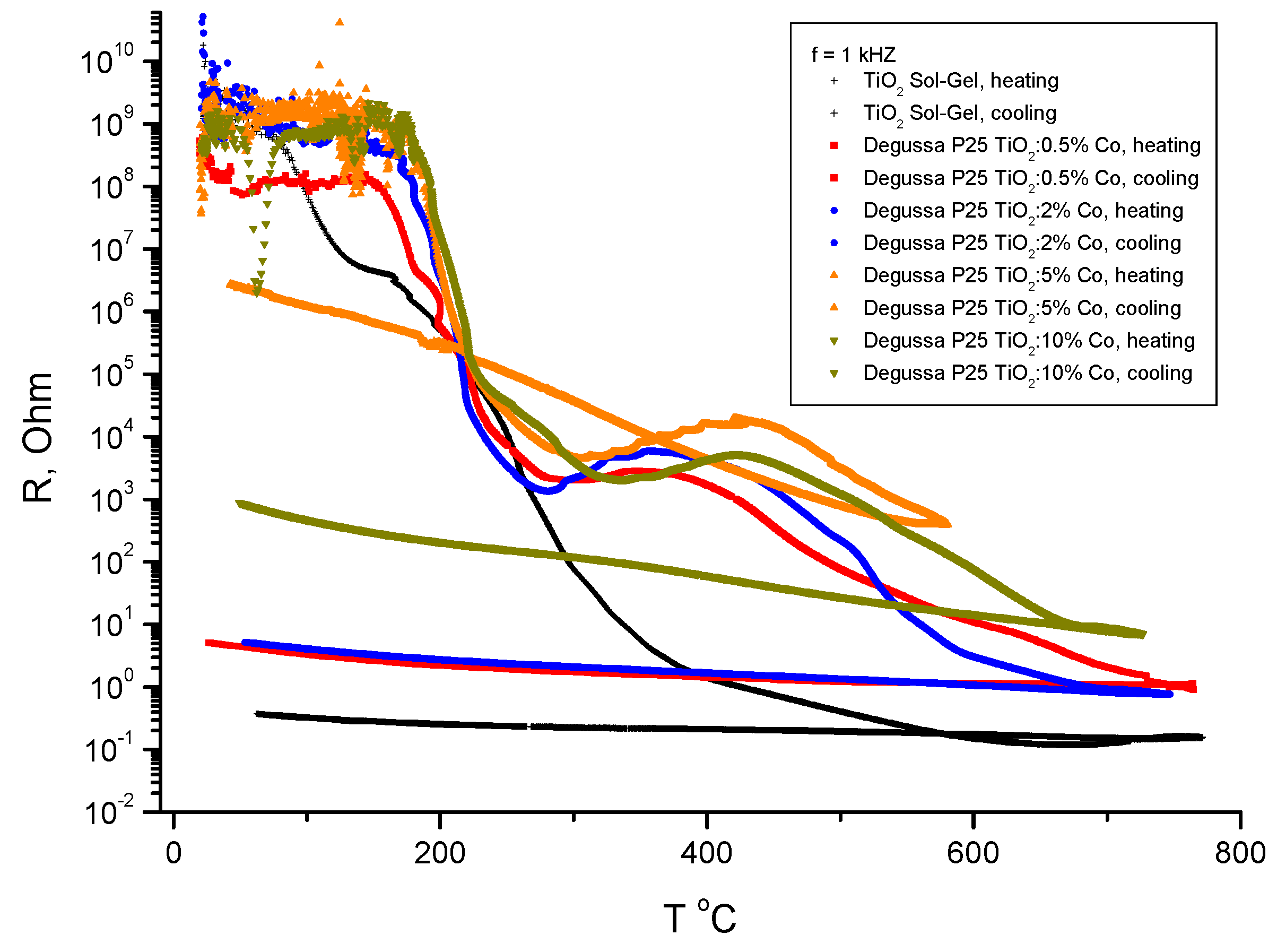

3.3. Dielectric Properties

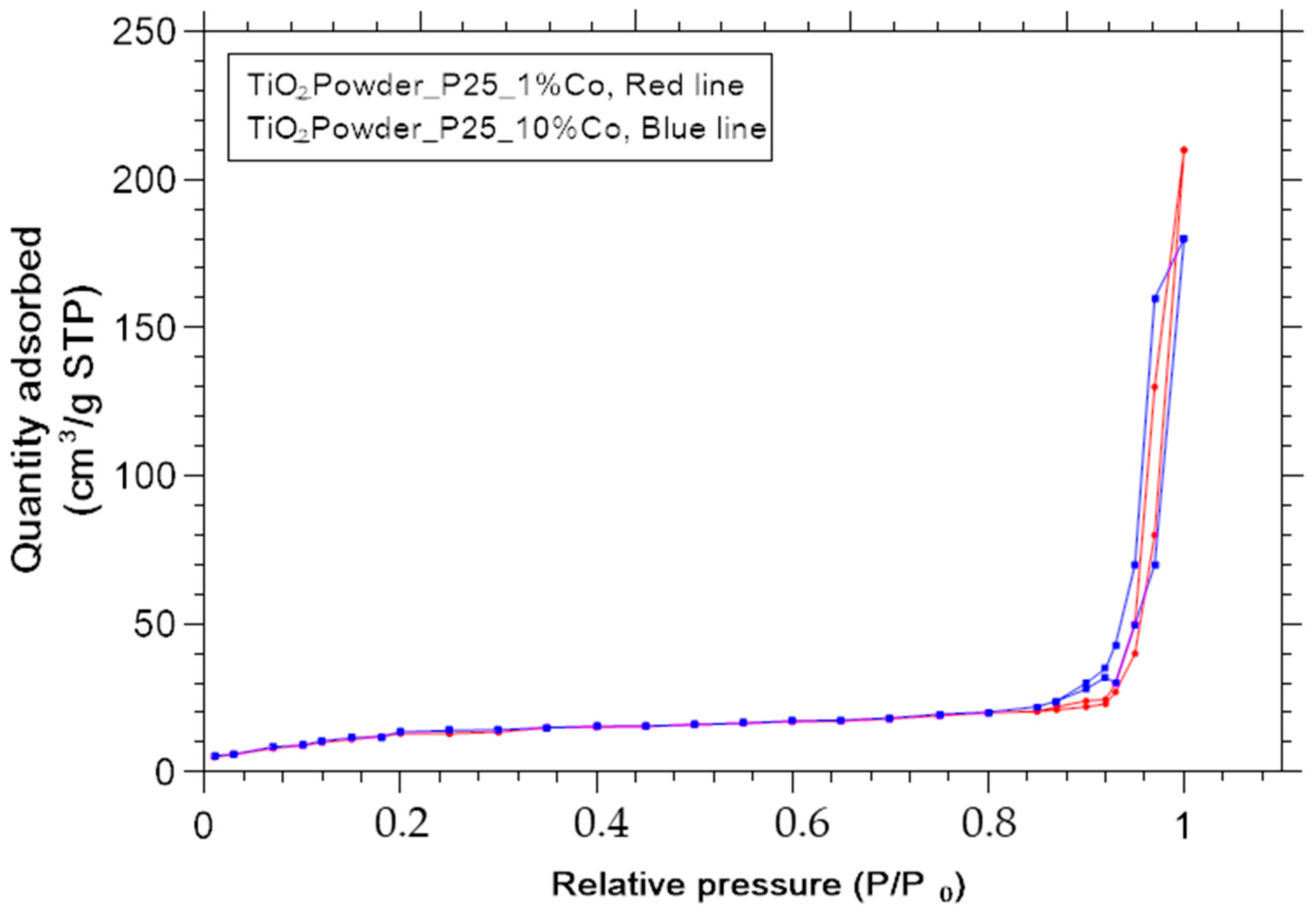

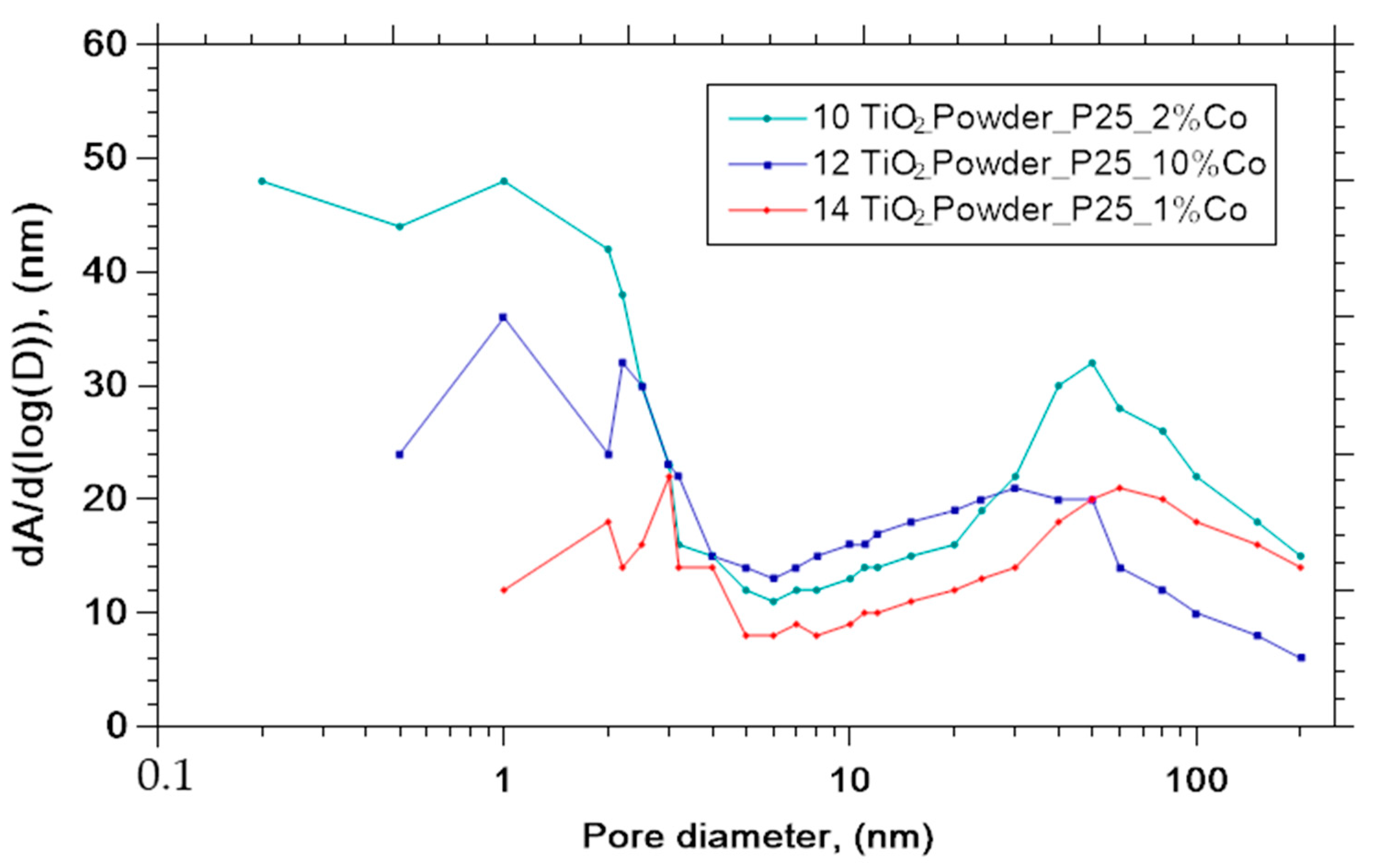

3.4. Effective BET Surface Area

3.5. Photocatalytic Activity

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Matsumoto, Y.; Murakami, M.; Shono, T.; Hasegawa, T.; Fukumura, T.; Kawasaki, M.; Ahmet, P.; Chikyow, T.; Koshihara, S.; Koinuma, H. Room-temperature ferromagnetism in transparent transition metal-doped titanium dioxide. Science 2001, 291, 854–856. [Google Scholar] [CrossRef]

- Chambers, S.A. A potential role in spintronic. Mater. Today 2002, 5, 34–39. [Google Scholar] [CrossRef]

- Herrmann, J.M. Heterogeneous photocatalysis: Fundamental and applications to the removal of various types of aqueous pollutants. Catal. Today 1999, 53, 115–129. [Google Scholar] [CrossRef]

- Van Santen, R.A.; Tranca, I.; Hensen, E.J.M. Theory of surface chemistry and reactivity of reducible oxides. Catal. Today 2015, 244, 63–84. [Google Scholar] [CrossRef]

- Pang, L.-X.; Wang, H.; Zhou, D.; Yao, X. Low-temperature sintering and microwave dielectric properties of TiO2-based LTCC materials. J. Mater. Sci. 2010, 21, 1285–1292. [Google Scholar] [CrossRef]

- Crippa, M.; Bianchi, A.; Cristofori, D.; D’Arienzo, M.; Merletti, F.; Morazzoni, F.; Scotti, R.; Simonutti, R. High dielectric constant rutile-polystyrene composite with enhanced percolative threshold. J. Mater. Chem. C 2013, 1, 484–492. [Google Scholar] [CrossRef]

- Huang, X.; Pu, Z.; Tong, L.; Wang, Z.; Liu, X. Preparation and dielectric properties of surface modified TiO2/PEN composite films with high thermal stability and flexibility. J. Mater. Sci. 2012, 23, 2089–2097. [Google Scholar] [CrossRef]

- Leedahl, B.; Zatsepin, D.A.; Boukhanov, D.W.; Green, R.J.; McLeod, J.A.; Kim, S.S.; Kurmaev, E.Z.; Zhidkov, I.S.; Gavrilov, N.V.; Cholakh, S.O.; et al. Structural defects induced by Fe-ion implantation in TiO2. J. Appl. Phys. 2014, 117, 053711. [Google Scholar] [CrossRef] [Green Version]

- Raveau, B.; Motin Seikh, M.d. Cobalt Oxides: From Crystal Chemistry to Physics; Wiley–VCH: Weinheim, Germany, 2012. [Google Scholar]

- Mariano JF, M.L.; Bessergenev, V.G.; Lourenço, J.P.; Hantusch, M.; Burkel, E.; Botelho do Rego, A.M.; Rajnak, M.; Timko, M.; Kopcansky, P. Structural and magnetic properties of P25 TiO2 nanoparticles Nanoparticles Doped by Co. J. Magn. Magn. Mater. 2020, 501, 166442. [Google Scholar] [CrossRef]

- Diebold, U. The surface science of titanium dioxide. Surf. Sci. Rep. 2003, 48, 53–229. [Google Scholar] [CrossRef]

- Astruc, D. Nanoparticles and Catalysis; Wiley–VCH: Weinheim, Germany, 2008. [Google Scholar]

- Carpenter, M.A.; Mathus, S.; Kolmakov, A. Metal Oxide Nanomaterials for Chemical Sensors; Springer: New York, NY, USA, 2013. [Google Scholar]

- Ganduglia-Pirovano, M.V.; Hofmann, A.; Sauer, J. Oxygen vacancies in transition metal and rare earth oxides: Current state of understanding and remaining challenges. Surf. Sci. Rep. 2007, 62, 219–270. [Google Scholar] [CrossRef]

- Etacheri, V.; Di Valentin, C.; Schneider, J.; Bahnemannd, D.; Pillai, S.C. Visible-light activation of TiO2 photocatalysts: Advances in theory and experiments. J. Photochem. Photobiol. C Photochem. Rev. 2015, 25, 1–29. [Google Scholar] [CrossRef] [Green Version]

- Bessergenev, V. High–temperature anomalies of dielectric constant in TiO2 thin films. Mater. Res. Bull. 2009, 44, 1722–1728. [Google Scholar] [CrossRef]

- Hanaor, D.A.H.; Sorrell, C.C. Review of the anatase to rutile phase transformation. J. Mater. Sci. 2011, 46, 855–874. [Google Scholar] [CrossRef] [Green Version]

- MHussein NAssadi Dorian, A.H.H.a.n.a.o.r. The effect of copper doping on photocatalytic activity of (101) planes of anatase TiO2: A theretical study. Appl. Surf. Sci. 2016, 387, 682–689. [Google Scholar]

- Esmail, D.; Hussein, N.M.; Assadi, K.K.; Nao, T.; Mohamed, E.; Naoki, F.; Osamu, T.; Abe, R.; Otami, B.; Ide, Y. Insitu blue titania via band shape engineering for exceptional solar H2 production in rutile TiO2. Appl. Catal. B Environ. 2021, 297, 120380–120405. [Google Scholar]

- Garbout, A.; Bouattor, S.; Botelho do Rego, A.M.; Ferraria, A.M.; Kolsi, A.W. Synthesis, Raman and X-ray diffraction investigations of rubidium-doped Gd1.8Ti2O6.7 pyrochlore oxide via a sol–gel process. J. Cryst. Growth 2007, 304, 374–382. [Google Scholar] [CrossRef]

- Rodriguez-Carvajal, J. An Introduction to the Program FullProf 2000; Laboratorie Léon Brillouin (CEA–CNRS): CEA/Saclay, France, 2000. [Google Scholar]

- McCusker, L.B.; Von Dreele, R.B.; Cox, D.E.; Louer, D.; Scardi, P. Rietveld refinement guidelines. J. Appl. Crystallogr. 1999, 32, 36–50. [Google Scholar] [CrossRef] [Green Version]

- Bessergenev, V.G.; Mateus, M.C.; Botelho do Rego, A.M.; Hantusch, M.; Burkel, E. An improvement of photocatalytic activity of TiO2 Degussa P25 powder. Appl. Catal. A Gen. 2015, 500, 40–50. [Google Scholar] [CrossRef] [Green Version]

- Kaushik, A.; Dalela, B.; Kumar, S.; Alvi, P.A.; Dalela, S. Role of Co doping on structural, optical and magnetic properties of TiO2. J. Alloys Compd. 2013, 552, 274–278. [Google Scholar] [CrossRef]

- Cross, L.E. Relaxor ferroelectrics. Ferroelectrics 1987, 76, 241–267. [Google Scholar] [CrossRef]

- Leofanti, G.; Padovan, M.; Tozzola, G.; Venturelli, B. Surface area and pore texture of catalysts. Catal. Today 1998, 41, 207–219. [Google Scholar] [CrossRef]

- Sing, K. The use of nitrogen adsorption for the characterization of porous materials. Colloids Surf. A Physicochem. Eng. Asp. 2001, 187, 3–9. [Google Scholar] [CrossRef]

- Udalov, O.G.; Beloborodov, I.S. Competition of the coulomb and hopping-based exchange interactions in granular magnets. Phys. Rev. B 2017, 95, 045427–045439. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Liu, L.; Yu, P.Y.; Mao, S.S. Increasing solar adsorption for photocatalysis with black Hydro-genated titanium dioxide nanocrystals. Science 2011, 331, 746–750. [Google Scholar] [CrossRef]

| TiO2:Co | XPS | EDX | |

|---|---|---|---|

| Co (%) | Co/Ti | Co/Ti | Co/Ti |

| 0.5 | 0.005 | 0.032 | 0.033 |

| 1 | 0.01 | 0.119 | 0.042 |

| 2 | 0.02 | 0.115 | 0.059 |

| 5 | 0.05 | 0.144 | 0.128 |

| 10 | 0.1 | 0.211 | 0.213 |

| Sample Prepared at 550 °C | Samples Annealed in Air at 800 °C, 24 h | Samples Heated in Vacuum up to 750 °C | ||||

|---|---|---|---|---|---|---|

| Samples Ti1−xCoxO2 %, of Co | Anatase %, of Fraction | Rutile %, of Fraction | Rutile %, of Fraction | CoTiO3 %, of Fraction | Rutile %, of Fraction | CoTiO3 %, of Fraction |

| 0 | 83.3 | 16.7 | 100 | 0 | ||

| 0.5 | 72.6 | 27.4 | 99.4 | 0.6 | ||

| 1 | 75.6 | 24.4 | 99.2 | 0.8 | ||

| 2 | 78.0 | 22.0 | 97.0 | 3.0 | ||

| 5 | 80.1 | 19.9 | 91.3 | 8.7 | ||

| 10 | 83.0 | 17.0 | 82.5 | 17.5 | 86.7 | 13.3 |

| Co Content, % | BET Surface Area (SA), m2/g | SA Error, m2/g | Pore Volume, cm3/g | Pore Volume Error, cm3/g | Pore Area, m2/g |

|---|---|---|---|---|---|

| 0, Degussa P25 | 41.27 | 1.3 | |||

| 0, P25 Annealed at 550 °C in air | 44.9 | 1.3 | |||

| 0 | 28.9 | 1.3 | 0.231 | 0.01 | 25.82 |

| 0.5 | 31 | 1.3 | 0.273 | 0.011 | 30.91 |

| 1 | 31.5 | 1.3 | 0.325 | 0.014 | 27.10 |

| 2 | 38 | 1.6 | 0.420 | 0.017 | 42.94 |

| 5 | 35.5 | 1.5 | 0.307 | 0.013 | 34.68 |

| 10 | 31.5 | 1.3 | 0.270 | 0.011 | 33.98 |

| S1 | 6.4 | 0.1 | 0.01 | 0.01 | 6.8 |

| S2 | 73.5 | 1.1 | 0.08 | 0.09 | 75.4 |

| S3 | 8.6 | 0.12 | 0.07 | 0.01 | 9.8 |

| Composition | k, h−1 | kA/g, (h × g)−1 | kAS/m2, (h × m2)−1 |

|---|---|---|---|

| Direct degradation | 0.058 | ||

| Degussa P25 (Rutile) | 0.1228 | ||

| Degussa P25 | 1.53 | 71.49 | 1.732 |

| Degussa P25:0.5%Co | 0.2664 | 24.07 | 0.776 |

| Degussa P25:1%Co | 0.21 | 18.97 | 0.700 |

| Degussa P25:2%Co | 0.2441 | 20.39 | 0.537 |

| Degussa P25:10%Co | 0.0846 | 0.69 | 0.022 |

| S1 | 0.39 | 35.24 | 5.5 |

| S2 | 0.15 | 13.55 | 0.17 |

| S3 | 0.19 | 17.17 | 1.99 |

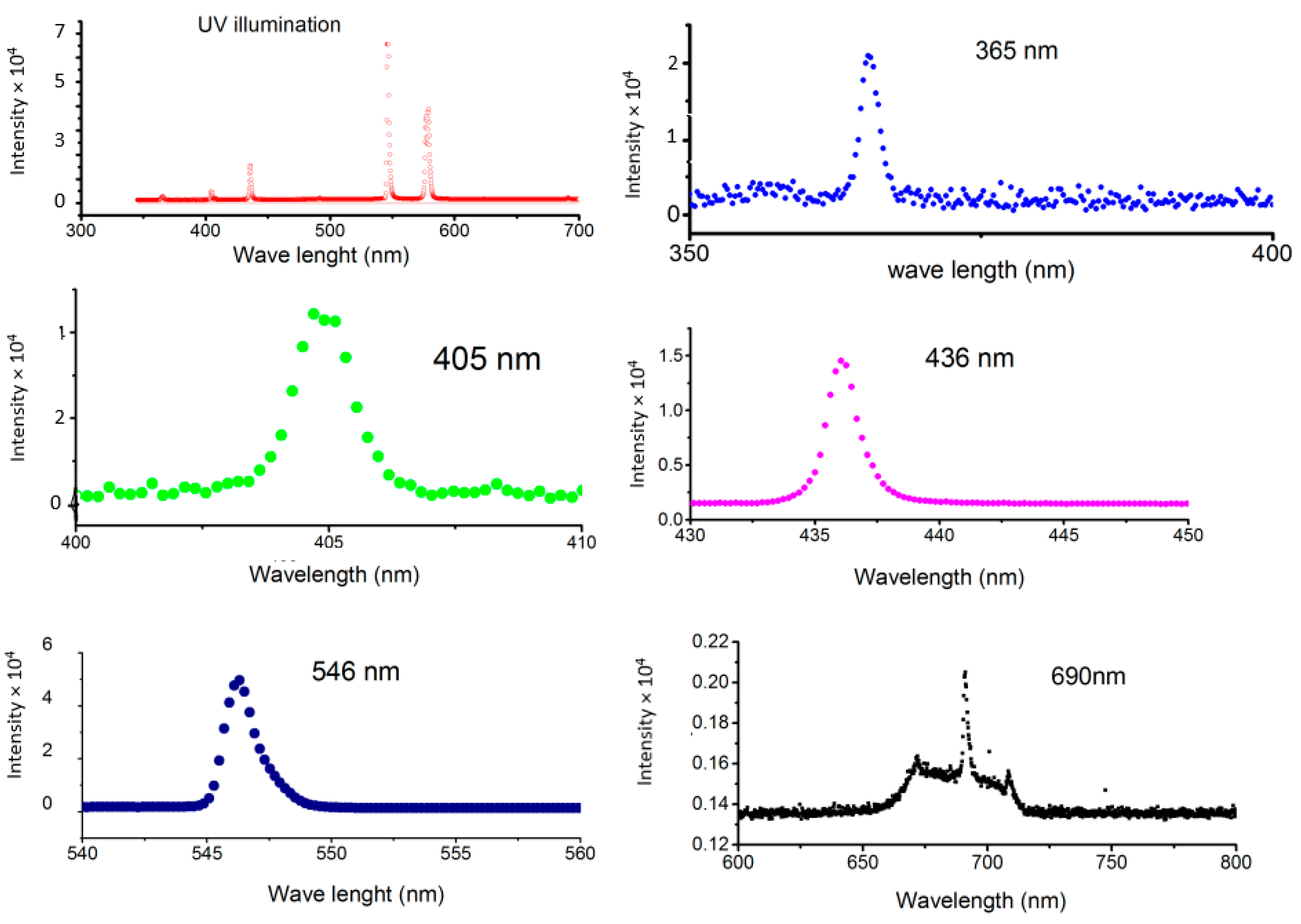

| Wavelength | 365 nm | 405 nm | 436 nm | 546 nm | 690 nm |

|---|---|---|---|---|---|

| P25 Degussa | 885 | 250 | 12.1 | 2.97 | 420 |

| P25:1%Co | 117 | 76.8 | 12.1 | 1.99 | 245 |

| P25:2%Co | 110 | 327 | 8.31 | 0.83 | 271 |

| P25:5%Co | 175 | 683 | 104 | 4.05 | 245 |

| P25:10%Co | 462 | 65 | 9.1 | 1.2 | 17 |

| S1 | 72.9 | 42.3 | 7.67 | 2.35 | 16.6 |

| S2 | 45.8 | 21.1 | 12.6 | 2.87 | 21.01 |

| S3 | 188 | 53.8 | 7.03 | 0.88 | 15.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bessergenev, V.G.; Mariano, J.F.; Mateus, M.C.; Lourenço, J.P.; Ahmed, A.; Hantusch, M.; Burkel, E.; Botelho do Rego, A.M. Dielectric Properties and Spectral Characteristics of Photocatalytic Constant of TiO2 Nanoparticles Doped with Cobalt. Nanomaterials 2021, 11, 2519. https://doi.org/10.3390/nano11102519

Bessergenev VG, Mariano JF, Mateus MC, Lourenço JP, Ahmed A, Hantusch M, Burkel E, Botelho do Rego AM. Dielectric Properties and Spectral Characteristics of Photocatalytic Constant of TiO2 Nanoparticles Doped with Cobalt. Nanomaterials. 2021; 11(10):2519. https://doi.org/10.3390/nano11102519

Chicago/Turabian StyleBessergenev, Valentin G., José F. Mariano, Maria Conceição Mateus, João P. Lourenço, Adwaa Ahmed, Martin Hantusch, Eberhard Burkel, and Ana Maria Botelho do Rego. 2021. "Dielectric Properties and Spectral Characteristics of Photocatalytic Constant of TiO2 Nanoparticles Doped with Cobalt" Nanomaterials 11, no. 10: 2519. https://doi.org/10.3390/nano11102519

APA StyleBessergenev, V. G., Mariano, J. F., Mateus, M. C., Lourenço, J. P., Ahmed, A., Hantusch, M., Burkel, E., & Botelho do Rego, A. M. (2021). Dielectric Properties and Spectral Characteristics of Photocatalytic Constant of TiO2 Nanoparticles Doped with Cobalt. Nanomaterials, 11(10), 2519. https://doi.org/10.3390/nano11102519