Laser Thermochemical High-Contrast Recording on Thin Metal Films

Abstract

1. Introduction

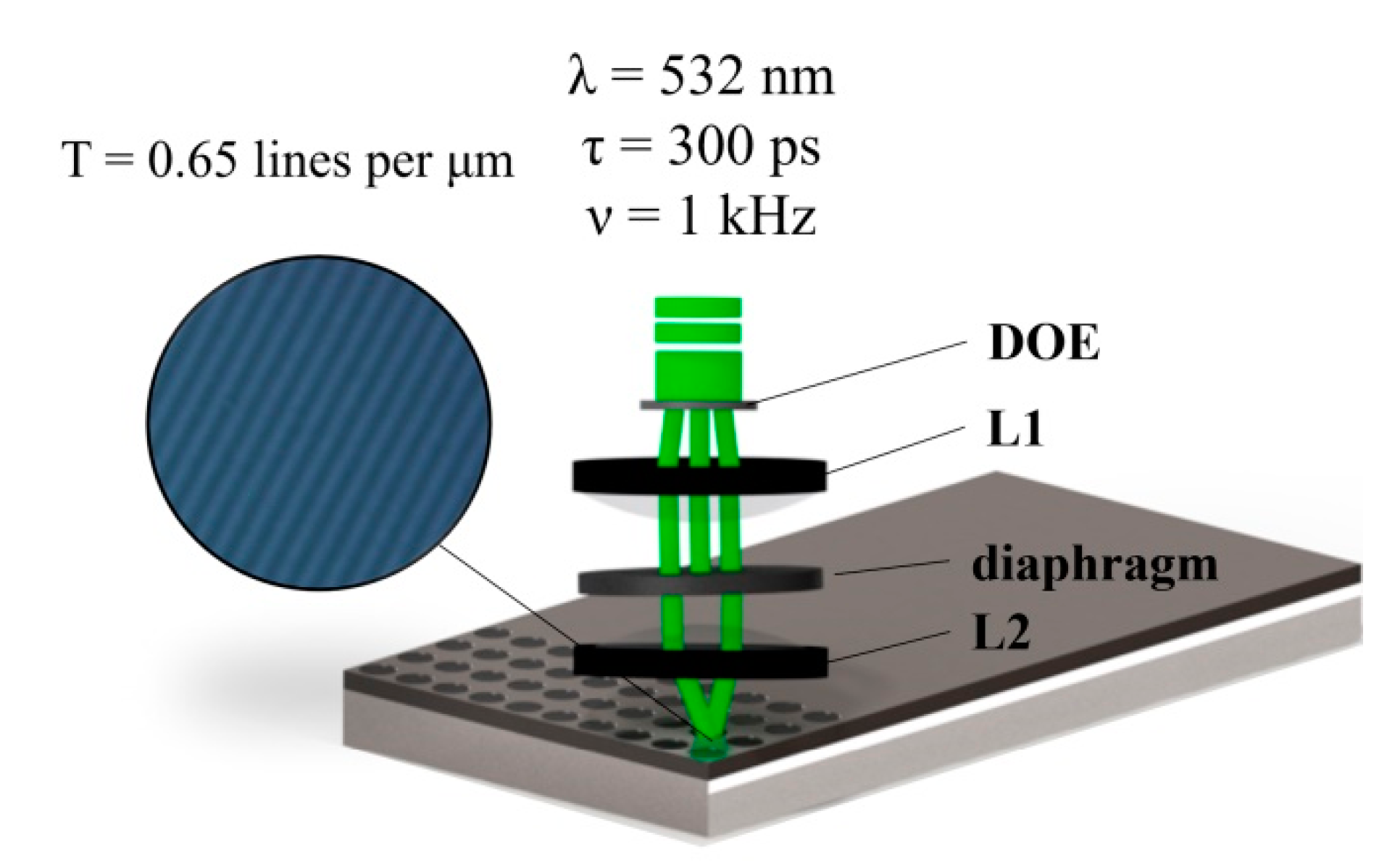

2. Laser Interference Patterning

2.1. Experimental Procedure

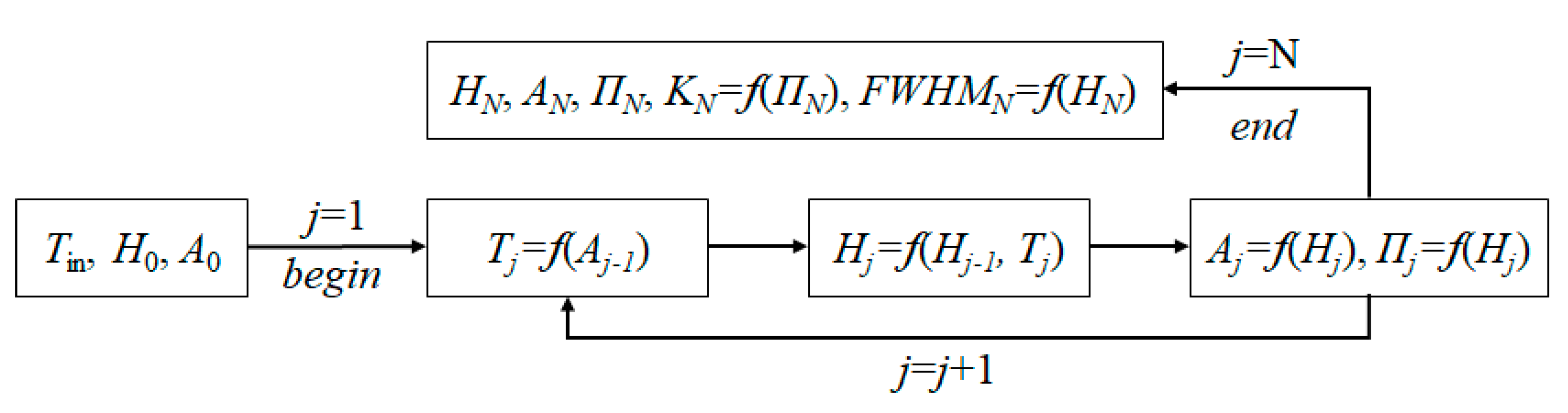

2.2. Setting the Simulation Problem

2.3. Simulation Procedure

3. Results and Discussion

3.1. Simulation Results

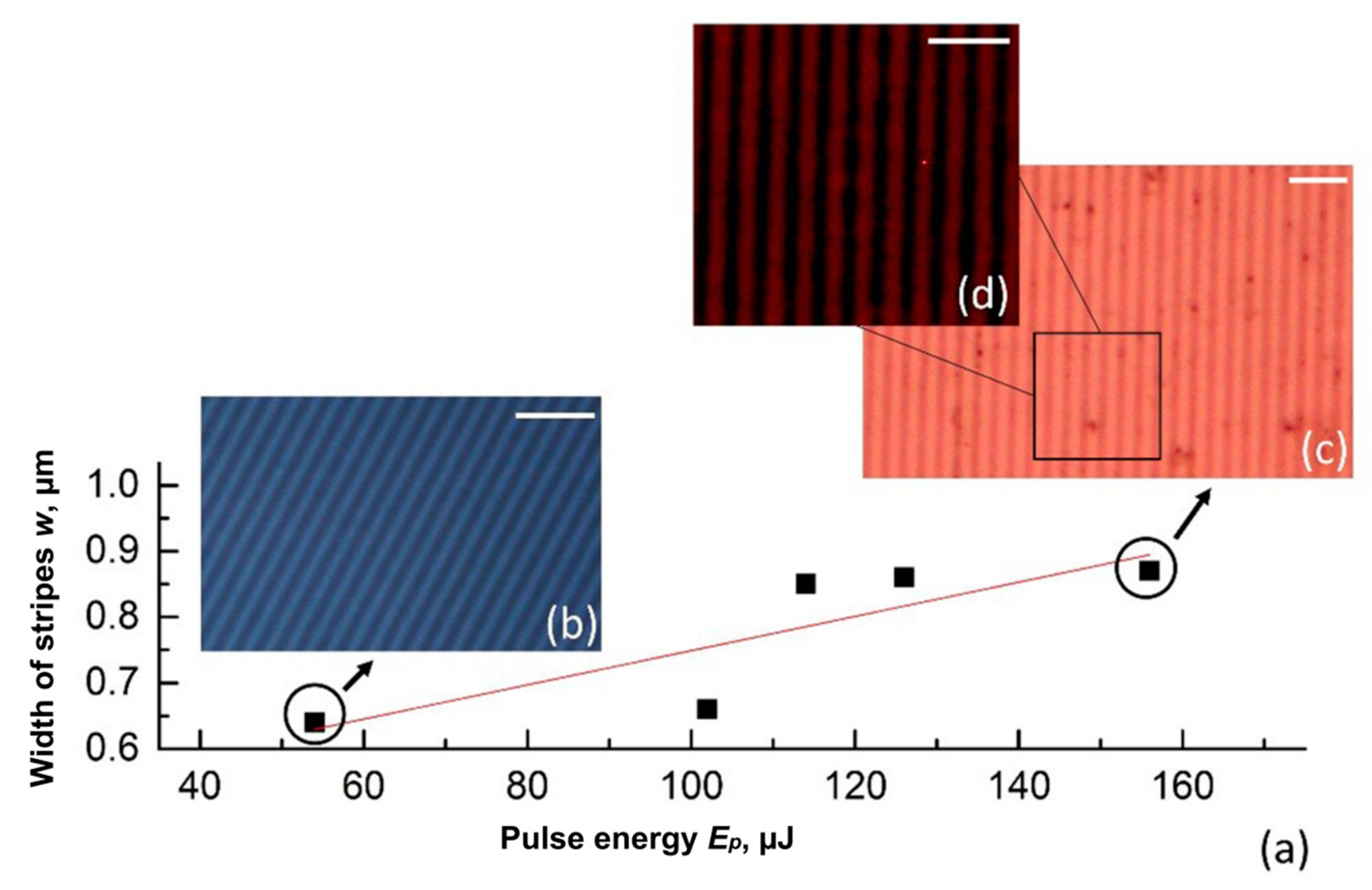

3.2. Experimental Results

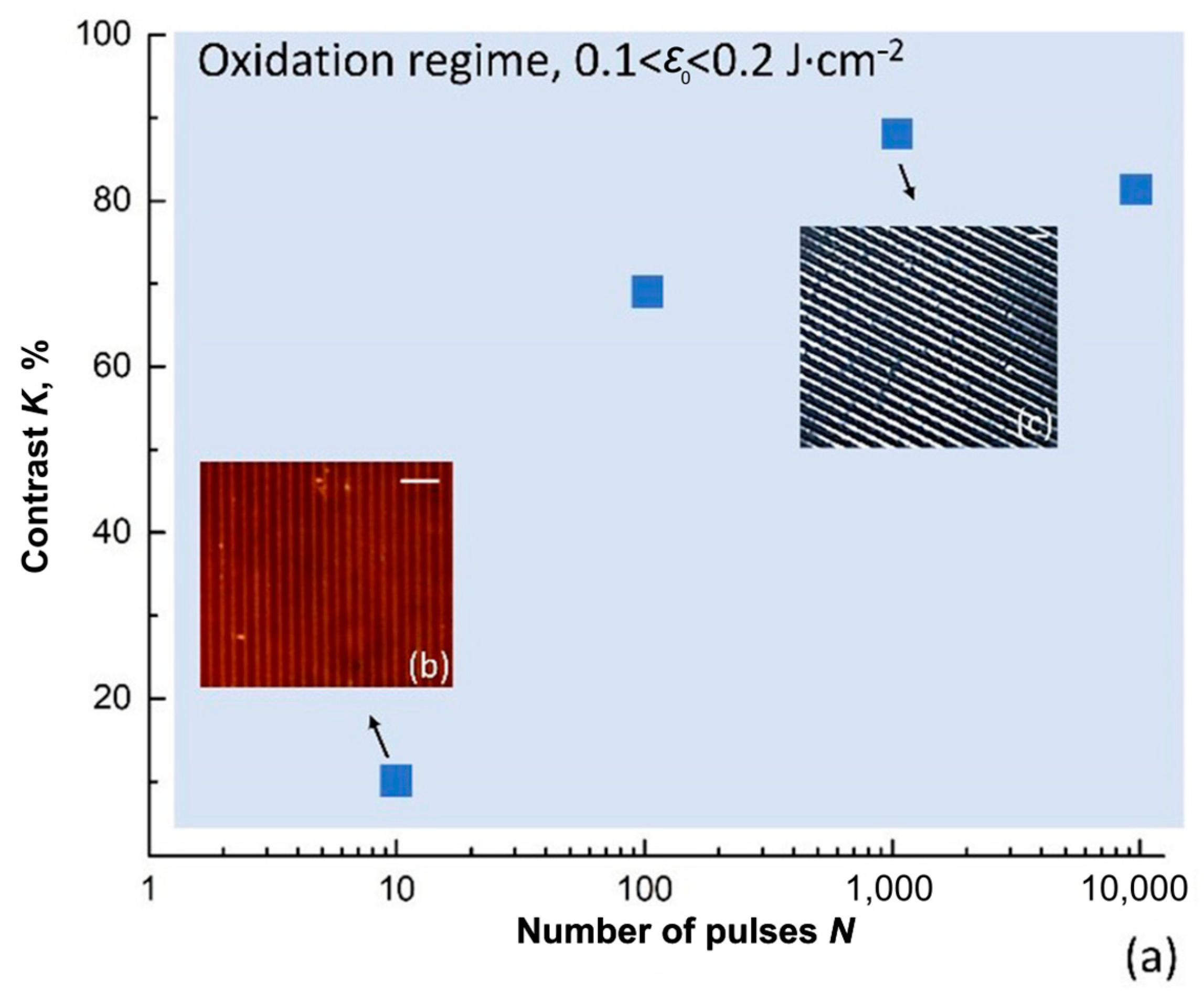

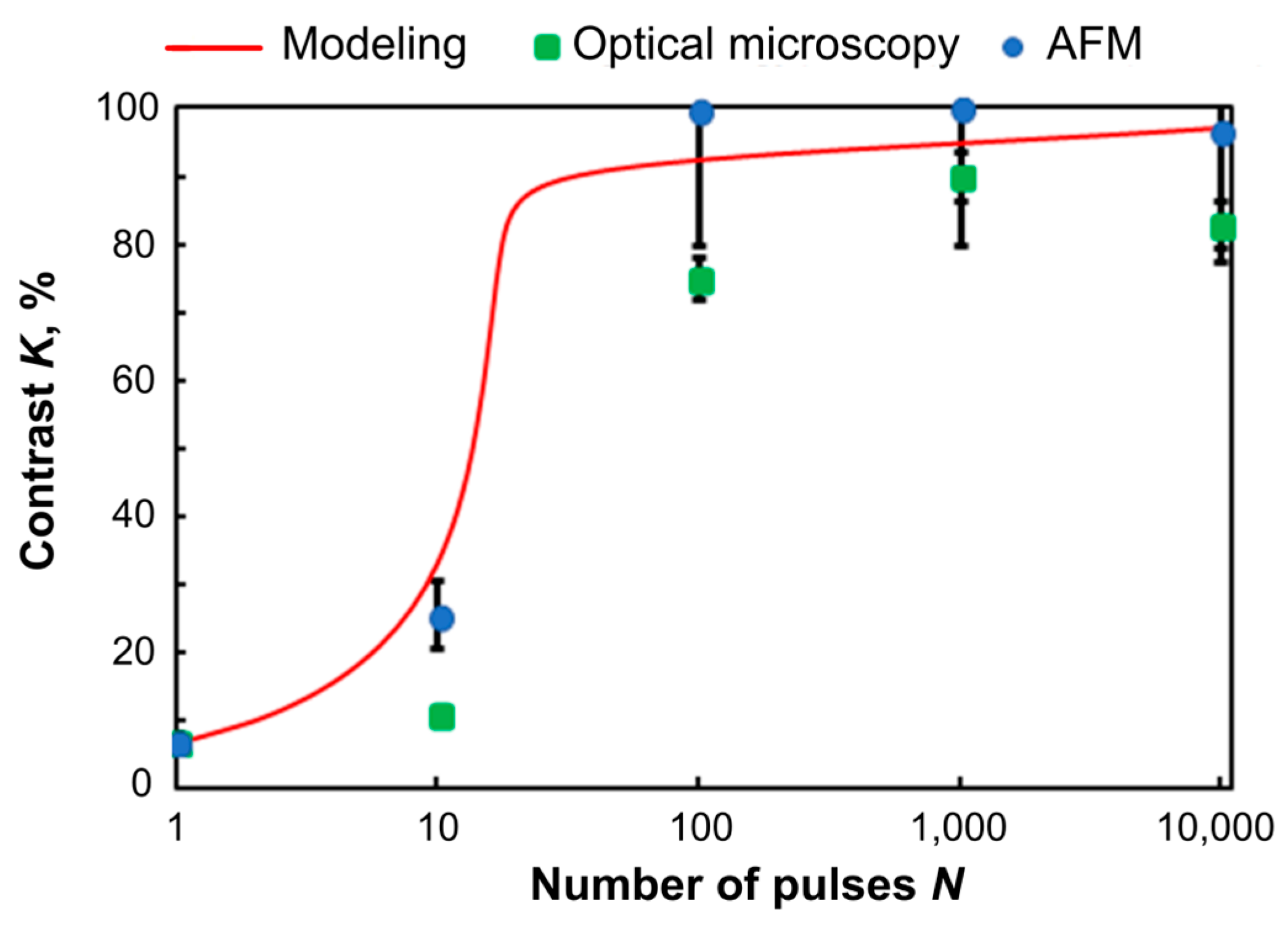

3.3. Contrast of Fabricated Structures

4. Influence of Various Parameters on the Laser Interference Patterning Performance: The Modeling Results

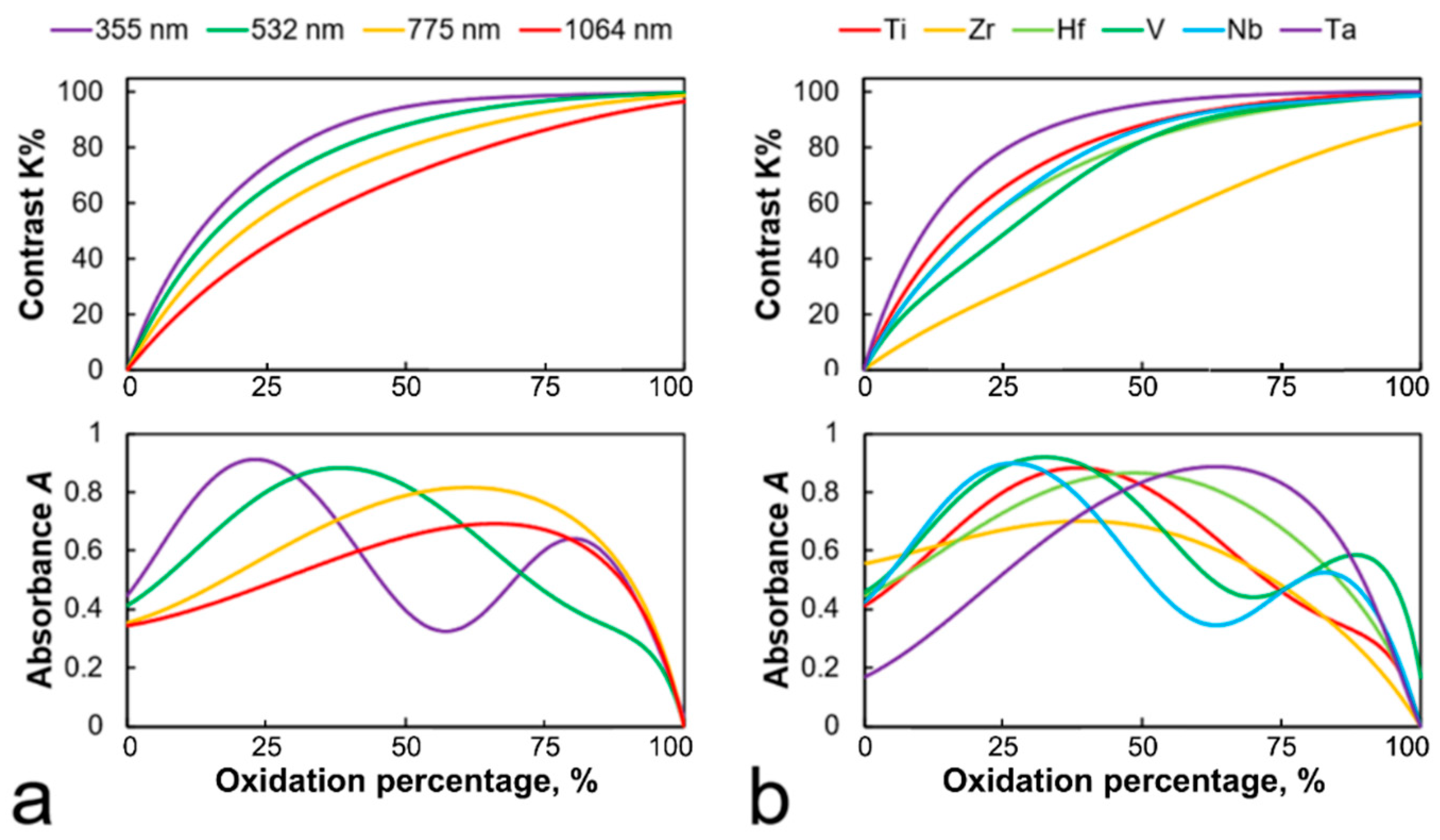

4.1. Absorbance

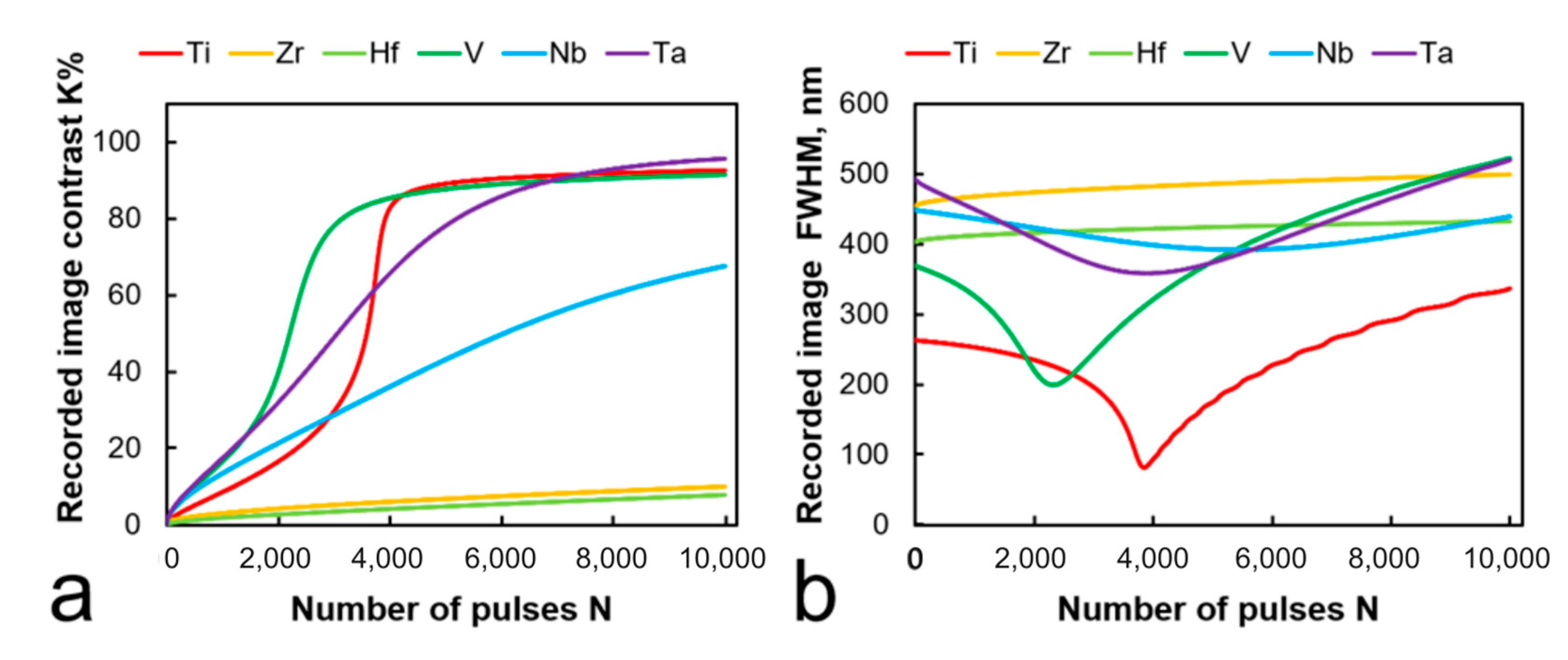

4.2. Number of Pulses

4.3. Laser Fluence

4.4. Initial Film Thickness

4.5. Laser Wavelength

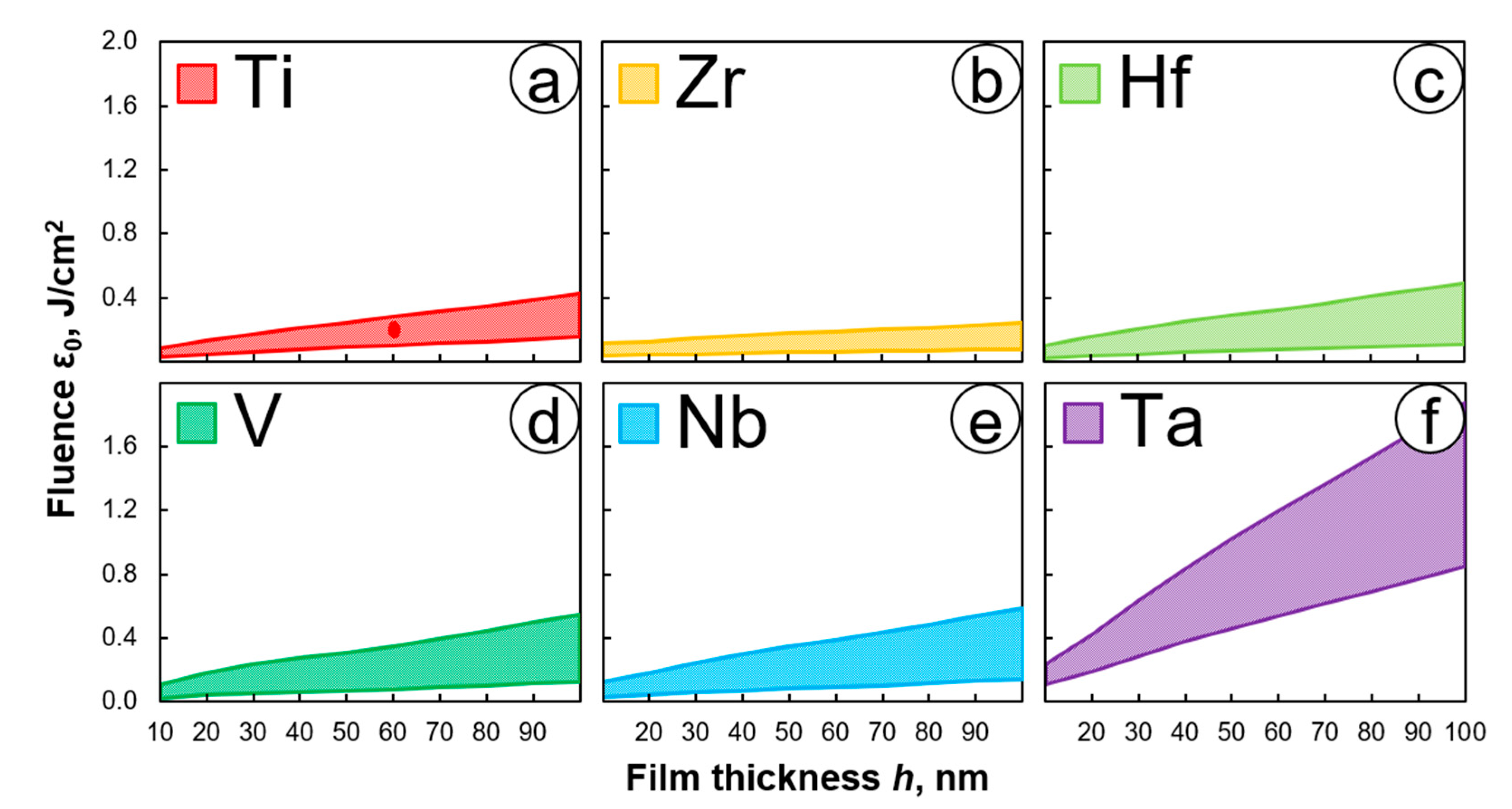

4.6. Film Material

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Properties | Symbol | Units | References | Ti | TiO2 | Zr | ZrO2 | Hf | HfO2 | V | V2O5 | Nb | Nb2O5 | Ta | Ta2O5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Density | ρ | kg/m3 | [48] | 4506 | 4260 | 6520 | 5680 | 13,300 | 9680 | 6000 | 3360 | 8570 | 4600 | 16,400 | 8240 |

| Heat capacity | c | J/(kg∙K) | [48] | 523 | 712 | 278 | 480 | 144 | 120 | 489 | 276.5 | 265 | 600 | 140 | 306 |

| Thermal conductivity | κ | W/(m∙K) | [48] | 21 | 10 | 22.7 | 2.2 | 23 | 1.1 | 30.7 | 1.5 | 53.7 | 1 | 57.5 | 0.4 |

| Thermal diffusivity (×10−) | a = κ/(ρc) | m2/s | 0.89 | 0.33 | 1.25 | 0.08 | 1.20 | 0.09 | 1.05 | 0.16 | 2.36 | 0.04 | 2.50 | 0.02 | |

| Melting temperature | Tm | K | [48] | 1941 | 2116 | 2128 | 2988 | 2506 | 3031 | 2183 | 963 | 2750 | 1785 | 3290 | 2145 |

| Molar mass | M | g/mol | [48] | 48 | 80 | 91 | 123 | 178.5 | 210.5 | 51 | 182 | 93 | 256.8 | 181 | 442 |

| Pilling-Bedworth ratio | υPB | [36] | 1.76 | 1.57 | 1.62 | 3.25 | 2.74 | 1.171 | |||||||

| Parabolic constant (×10−7) | B | m2/s | [35,46,49,50,51,52] | 330,000 | 0.0175 | 0.00535 | 15.6 | 0.159 | 0.0102 | ||||||

| Activation temperature | Ta | K | [35,46,49,50,51,52] | 33,000 | 12,890 | 18,117.8 | 19,124.4 | 13,346.2 | 12,761.6 | ||||||

| Refractive index (at 532 nm) | n | [53] | 2.48 | 2.45 | 2.33 | 2.17 | 2.48 | 2.12 | 3.92 | 1.88 | 2.22 | 2.37 | 1.14 | 2.16 | |

| Extinction coefficient (at 532 nm) | k | [53] | 3.35 | 0 | 1.5 | 0 | 3.04 | 0 | 3.13 | 0.05 | 3.12 | 0 | 4.72 | 0 | |

References

- Wang, E.; Shi, L.; Niu, J.; Hua, Y.; Li, H.; Zhu, X.; Ye, T. Multichannel Spatially Nonhomogeneous Focused Vector Vortex Beams for Quantum Experiments. Adv. Opt. Mater. 2019, 7, 1801415. [Google Scholar] [CrossRef]

- Veiko, V.P.; Korolkov, V.P.; Poleshchuk, A.G.; Sinev, D.A.; Shakhno, E.A. Laser technologies in micro-optics. Part 1. Fabrication of diffractive optical elements and photomasks with amplitude transmission. Optoelectron. Instrum. Data Process. 2017, 53, 474–483. [Google Scholar] [CrossRef]

- Devlin, R.C.; Ambrosio, A.; Rubin, N.A.; Mueller, J.B.; Capasso, F. Arbitrary spin-to–orbital angular momentum conversion of light. Science 2017, 358, 896–901. [Google Scholar] [CrossRef] [PubMed]

- Pavlov, D.; Syubaev, S.; Kuchmizhak, A.; Gurbatov, S.; Vitrik, O.; Modin, E.; Lapine, M. Direct laser printing of tunable IR resonant nanoantenna arrays. Appl. Surf. Sci. 2019, 469, 514–520. [Google Scholar] [CrossRef]

- Voisiat, B.; Bičiūnas, A.; Kašalynas, I.; Račiukaitis, G. Band-pass filters for THz spectral range fabricated by laser ablation. Appl. Phys. A 2011, 104, 953–958. [Google Scholar] [CrossRef]

- Lin, Y.; Yao, H.; Ju, X.; Chen, Y.; Zhong, S.; Wang, X. Free-standing double-layer terahertz band-pass filters fabricated by femtosecond laser micro-machining. Opt. Express 2017, 25, 25125–25134. [Google Scholar] [CrossRef]

- Demirhan, Y.; Alaboz, H.; Ozyuzer, L.; Nebioğlu, M.A.; Takan, T.; Altan, H.; Sabah, C. Metal mesh filters based on Ti, ITO and Cu thin films for terahertz waves. Opt. Quantum Electron. 2016, 48, 170. [Google Scholar] [CrossRef]

- Seniutinas, G.; Balčytis, A.; Reklaitis, I.; Chen, F.; Davis, J.; David, C.; Juodkazis, S. Tipping solutions: Emerging 3D nano-fabrication/-imaging technologies. Nanophotonics 2017, 6, 923–941. [Google Scholar] [CrossRef]

- Mezera, M.; Alamri, S.; Hendriks, W.A.; Hertwig, A.; Elert, A.M.; Bonse, J.; Kunze, T.; Lasagni, A.F.; Römer, G.-W.R. Hierarchical Micro-/Nano-Structures on Polycarbonate via UV Pulsed Laser Processing. Nanomaterials 2020, 10, 1184. [Google Scholar] [CrossRef]

- Yang, S.-N.; Liu, X.-Q.; Zheng, J.-X.; Lu, Y.-M.; Gao, B.-R. Periodic Microstructures Fabricated by Laser Interference with Subsequent Etching. Nanomaterials 2020, 10, 1313. [Google Scholar] [CrossRef]

- Hauschwitz, P.; Jochcová, D.; Jagdheesh, R.; Cimrman, M.; Brajer, J.; Rostohar, D.; Mocek, T.; Kopeček, J.; Lucianetti, A.; Smrž, M. Large-Beam Picosecond Interference Patterning of Metallic Substrates. Materials 2020, 13, 4676. [Google Scholar] [CrossRef] [PubMed]

- Blumenstein, A.; Garcia, M.E.; Rethfeld, B.; Simon, P.; Ihlemann, J.; Ivanov, D.S. Formation of Periodic Nanoridge Patterns by Ultrashort Single Pulse UV Laser Irradiation of Gold. Nanomaterials 2020, 10, 1998. [Google Scholar] [CrossRef] [PubMed]

- Böker, K.O.; Kleinwort, F.; Klein-Wiele, J.-H.; Simon, P.; Jäckle, K.; Taheri, S.; Lehmann, W.; Schilling, A.F. Laser Ablated Periodic Nanostructures on Titanium and Steel Implants Influence Adhesion and Osteogenic Differentiation of Mesenchymal Stem Cells. Materials 2020, 13, 3526. [Google Scholar] [CrossRef] [PubMed]

- Vercillo, V.; Tonnicchia, S.; Romano, J.-M.; García-Girón, A.; Aguilar-Morales, A.I.; Alamri, S.; Dimov, S.S.; Kunze, T.; Lasagni, A.F.; Bonaccurso, E. Design Rules for Laser-Treated Icephobic Metallic Surfaces for Aeronautic Applications. Adv. Funct. Mater. 2020, 30, 1910268. [Google Scholar] [CrossRef]

- Baumann, R.; Milles, S.; Leupolt, B.; Kleber, S.; Dahms, J.; Lasagni, A.F. Tailored wetting of copper using precise nanosecond direct laser interference patterning. Opt. Lasers Eng. 2021, 137, 106364. [Google Scholar] [CrossRef]

- Müller, D.W.; Holtsch, A.; Lößlein, S.; Pauly, C.; Spengler, C.; Grandthyll, S.; Jacobs, K.; Mücklich, F.; Müller, F. In-Depth Investigation of Copper Surface Chemistry Modification by Ultrashort Pulsed Direct Laser Interference Patterning. Langmuir 2020, 36, 13415–13425. [Google Scholar] [CrossRef]

- Talbi, A.; Semmar, N.; Tabbal, M.; Connor, G.O.; Coddet, P.; Thomann, A.L.; Millon, E. Femtosecond laser irradiation of titanium oxide thin films: Accumulation effect under IR beam. Appl. Phys. A 2020, 126, 1–9. [Google Scholar] [CrossRef]

- Korolkov, V.P.; Sedukhin, A.G.; Mikerin, S.L. Technological and optical methods for increasing the spatial resolution of thermochemical laser writing on thin metal films. Opt. Quant. Electron. 2019, 51, 389. [Google Scholar] [CrossRef]

- Korolkov, V.P.; Sedukhin, A.G.; Belousov, D.A.; Shimansky, R.V.; Khomutov, V.N.; Mikerin, S.L.; Spesivtsev, E.V.; Kutz, R.I. Increasing the spatial resolution of direct laser writing of diffractive structures on thin films of titanium group metals. In Proceedings of the SPIE 11030, Holography: Advances and Modern Trends VI, Prague, Czech Republic, 1–4 April 2019. [Google Scholar] [CrossRef]

- Korolkov, V.P.; Mikerin, S.L.; Okotrub, K.A.; Sametov, A.R.; Malyshev, A.I. High-resolution laser fabrication of amplitude diffractive structures on thin metal films. In Proceedings of the SPIE 10823, Nanophotonics and Micro/Nano Optics IV, Beijing, China, 12–13 October 2018. [Google Scholar]

- Öktem, B.; Pavlov, I.; Ilday, S.; Kalaycıoğlu, H.; Rybak, A.; Yavaş, S.; Erdoğan, M.; Ilday, F.Ö. Nonlinear laser lithography for indefinitely large-area nanostructuring with femtosecond pulses. Nat. Photonics 2013, 7, 897–901. [Google Scholar] [CrossRef]

- Poleshchuk, A.G.; Churin, E.G.; Koronkevich, V.P.; Korolkov, V.P.; Kharissov, A.A.; Cherkashin, V.V.; Verhoglyad, A.G. Polar coordinate laser pattern generator for fabrication of diffractive optical elements with arbitrary structure. Appl. Opt. 1999, 38, 1295–1301. [Google Scholar] [CrossRef]

- Dostovalov, A.V.; Okotrub, K.A.; Bronnikov, K.A.; Terentyev, V.S.; Korolkov, V.P.; Babin, S.A. Influence of femtosecond laser pulse repetition rate on thermochemical laser-induced periodic surface structures formation by focused astigmatic Gaussian beam. Laser Phys. Lett. 2019, 16, 026003. [Google Scholar] [CrossRef]

- Veiko, V.P.; Shakhno, E.A.; Poleshchuk, A.G.; Korolkov, V.P.; Matyzhonok, V.N. Local laser oxidation of thin metal films: Ultra-resolution in theory and in practice. J. Laser Micro Nanoeng. 2008, 3, 201–205. [Google Scholar] [CrossRef]

- Wang, Y.; Miao, J.; Tian, Y.; Guo, C.; Zhang, J.; Ren, T.; Liu, Q. TiO2 micro-devices fabricated by laser direct writing. Opt. Express 2011, 19, 17390–17395. [Google Scholar] [CrossRef] [PubMed]

- Dostovalov, A.V.; Korolkov, V.P.; Babin, S.A. Formation of thermochemical laser-induced periodic surface structures on Ti films by a femtosecond IR Gaussian beam: Regimes, limiting factors, and optical properties. Appl. Phys. B 2017, 123, 30. [Google Scholar] [CrossRef]

- Sinev, D.A.; Yuzhakova, D.S.; Moskvin, M.K.; Veiko, V.P. Formation of the Submicron Oxidative LIPSS on Thin Titanium Films during Nanosecond Laser Recording. Nanomaterials 2020, 10, 2161. [Google Scholar] [CrossRef]

- Veiko, V.; Yarchuk, M.; Zakoldaev, R.; Gedvilas, M.; Račiukaitis, G.; Kuzivanov, M. Picosecond laser registration of interference pattern by oxidation of thin Cr films. Appl. Surf. Sci. 2017, 404, 63–66. [Google Scholar] [CrossRef]

- Gedvilas, M.; Voisiat, B.; Indrišiūnas, S.; Račiukaitis, G.; Veiko, V.; Zakoldaev, R. Thermo-chemical microstructuring of thin metal films using multi-beam interference by short (nano-& picosecond) laser pulses. Thin Solid Film. 2017, 634, 134–140. [Google Scholar]

- Kostyuk, G.K.; Zakoldaev, R.A.; Koval, V.V.; Sergeev, M.M.; Rymkevich, V.S. Laser microplasma as a tool to fabricate phase grating applied for laser beam splitting. Opt. Lasers Eng. 2017, 92, 63–69. [Google Scholar] [CrossRef]

- Shakhno, E.A.; Sinev, D.A.; Kulazhkin, A.M. Features of laser oxidation of thin films of titanium. J. Opt. Technol. 2014, 81, 298–302. [Google Scholar] [CrossRef]

- Shakhno, E.A.; Nguen, Q.D. Dynamics of the laser heating and oxidation of thin metallic films, allowing for absorptivity variation. J. Opt. Technol. 2016, 83, 219–223. [Google Scholar] [CrossRef]

- Shakhno, E.A.; Nguyen, K.Z. Study of the resolution of direct recording of submicron structures on titanium films using millisecond laser pulses. J. Opt. Technol. 2019, 86, 251–254. [Google Scholar] [CrossRef]

- Veiko, V.P.; Zakoldaev, R.A.; Shakhno, E.A.; Sinev, D.A.; Nguyen, Z.K.; Baranov, A.V. Thermochemical writing with high spatial resolution on Ti films utilising picosecond laser. Opt. Mater. Express 2019, 9, 2729–2737. [Google Scholar] [CrossRef]

- Libenson, M.N. Laser-Induced Optical and Thermal Processes in Condensed Matter and Their Mutual Influence; Nauka Publ.: St. Petersburg, Russia, 2007. [Google Scholar]

- Korb, L.J.; Olson, D.L. Corrosion in petroleum production operation. In Metals Handbook; ASM International: Novelty, OH, USA, 1987; Volume 13, pp. 121–172. [Google Scholar]

- Born, M.; Wolf, E. Principles of Optics, 7th ed.; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Veiko, V.P.; Shakhno, E.A.; Yakovlev, E.B. Effective time of thermal action of ultrashort laser pulses on dielectrics. Quantum Electron. 2014, 44, 322–324. (In Russian) [Google Scholar] [CrossRef]

- Gorbunov, A.A.; Eichler, H.; Pompe, W.; Huey, B. Lateral self-limitation in the laser-induced oxidation of ultrathin metal films. Appl. Phys. Lett. 1996, 69, 2816–2818. [Google Scholar] [CrossRef]

- Lakshmi, N.; Yoo, H.I.; Martin, M. Oxidation kinetics of zirconium examined by in situ X-ray diffraction. J. Electrochem. Soc. 2013, 160, 136–141. [Google Scholar] [CrossRef]

- Marks, R.F.; Pollak, R.A.; Avouris, P.; Lin, C.T.; Théfaine, Y.J. Laser-pulsed plasma chemistry: Laser-initiated plasma oxidation of niobium. J. Chem. Phys. 1983, 78, 4270–4276. [Google Scholar] [CrossRef]

- Marks, R.F.; Pollak, R.A. Laser-pulsed thermal chemistry: UV laser-activated oxidation of niobium. J. Chem. Phys. 1984, 81, 1019–1023. [Google Scholar] [CrossRef]

- Atanassova, E.; Aygun, G.; Turan, R.; Babeva, T. Structural and optical characteristics of tantalum oxide grown by pulsed Nd: YAG laser oxidation. J. Vac. Sci. Technol. A Vac. Surf. Film. 2006, 24, 206–211. [Google Scholar] [CrossRef][Green Version]

- Aygun, G.; Turan, R. Electrical and dielectrical properties of tantalum oxide films grown by Nd: YAG laser assisted oxidation. Thin Solid Film. 2008, 517, 994–999. [Google Scholar] [CrossRef]

- Ursu, I.; Nanu, L.; Dinescu, M.; Hening, A.; Mihailescu, I.N.; Nistor, L.C. Vanadium oxidation as a result of cw CO2 laser irradiation in atmospheric air. Appl. Phys. A 1984, 35, 103–108. [Google Scholar] [CrossRef]

- Kofstad, P.; Espevik, S. Kinetic study of high-temperature oxidation of hafnium. J. Less Common Met. 1967, 12, 382–394. [Google Scholar] [CrossRef]

- Voitovich, V.B.; Lavrenko, V.A.; Golovko, E.I.; Adejev, V.M. The effect of purity on the high-temperature oxidation of hafnium. Oxid. Met. 1994, 42, 249–263. [Google Scholar] [CrossRef]

- Efunda.com. Available online: https://www.efunda.com/materials/materials_home/materials.cfm (accessed on 30 September 2020).

- Koneska, Z.; Stoevska-Gogovska, D.; Manojlovic, R.; Mickovski, J. The oxidation kinetics of zirconium in the temperature range 773–1173 K. In Proceedings of the Materials of 5th Congress of the Society of Metallurgists of Macedonia, Ohrid, North Macedonia, 17–20 September 2008. [Google Scholar]

- Mukherjee, A.; Wach, S.P. Kinetics of the oxidation of vanadium in the temperature range 350–950 °C. J. Less Common Met. 1983, 92, 289–300. [Google Scholar] [CrossRef]

- Clenny, J.T.; Rosa, C.J. Oxidation kinetics of niobium in the temperature range of 873 to 1083 K. Metall. Trans. A 1980, 11, 1385–1389. [Google Scholar] [CrossRef]

- Bali, K.; Nánai, L. Laser light induced oxidation of tantalum in air. Spectrochim. Acta Part A Mol. Spectrosc. 1990, 46, 499–502. [Google Scholar] [CrossRef]

- Refractiveindex.info. Available online: https://refractiveindex.info/ (accessed on 30 September 2020).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shakhno, E.A.; Nguyen, Q.D.; Sinev, D.A.; Matvienko, E.V.; Zakoldaev, R.A.; Veiko, V.P. Laser Thermochemical High-Contrast Recording on Thin Metal Films. Nanomaterials 2021, 11, 67. https://doi.org/10.3390/nano11010067

Shakhno EA, Nguyen QD, Sinev DA, Matvienko EV, Zakoldaev RA, Veiko VP. Laser Thermochemical High-Contrast Recording on Thin Metal Films. Nanomaterials. 2021; 11(1):67. https://doi.org/10.3390/nano11010067

Chicago/Turabian StyleShakhno, Elena A., Quang D. Nguyen, Dmitry A. Sinev, Elizaveta V. Matvienko, Roman A. Zakoldaev, and Vadim P. Veiko. 2021. "Laser Thermochemical High-Contrast Recording on Thin Metal Films" Nanomaterials 11, no. 1: 67. https://doi.org/10.3390/nano11010067

APA StyleShakhno, E. A., Nguyen, Q. D., Sinev, D. A., Matvienko, E. V., Zakoldaev, R. A., & Veiko, V. P. (2021). Laser Thermochemical High-Contrast Recording on Thin Metal Films. Nanomaterials, 11(1), 67. https://doi.org/10.3390/nano11010067