Chitosan Nanofiber and Cellulose Nanofiber Blended Composite Applicable for Active Food Packaging

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Chitosan Nanofiber Preparation

2.3. Cellulose Nanofiber Preparation

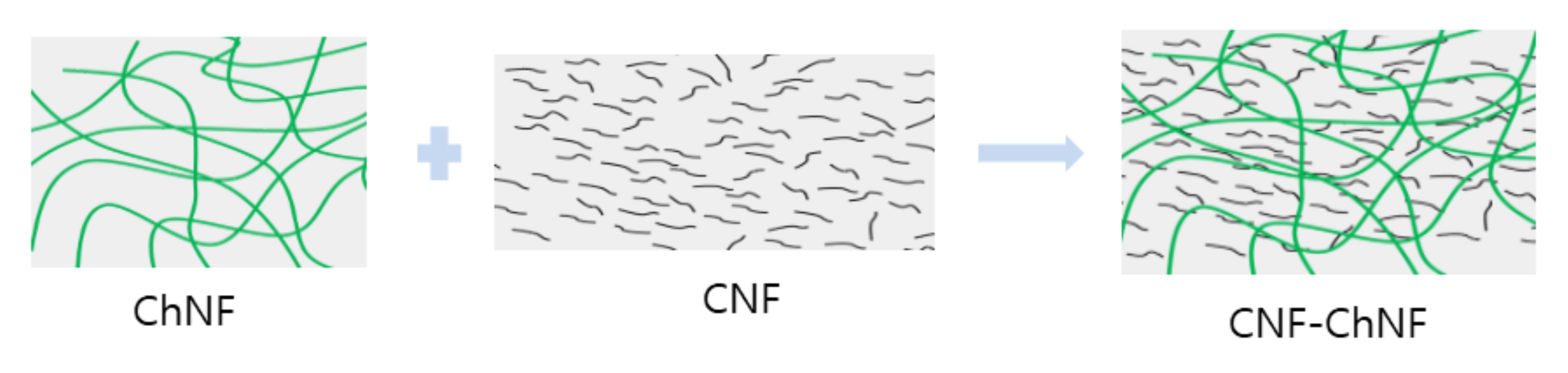

2.4. ChNF–CNF Composites Preparation

2.5. Characterizations

2.5.1. Morphology

2.5.2. FTIR Spectra

2.5.3. X-ray Diffraction (XRD)

2.5.4. Mechanical Properties

2.5.5. Thermogravimetric Analysis

2.5.6. Viscosity

2.5.7. UV–Transmittance

2.5.8. Hygroscopic Behaviors

2.5.9. Antioxidant Property

3. Results

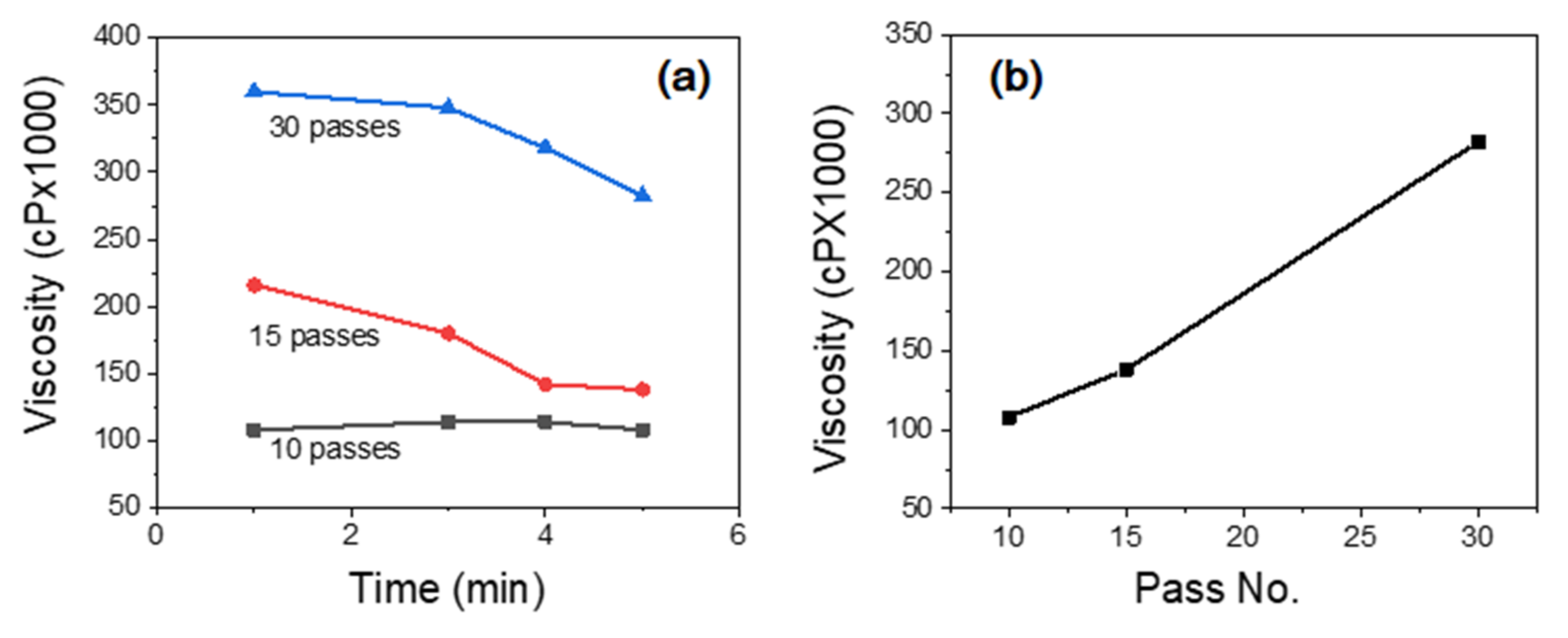

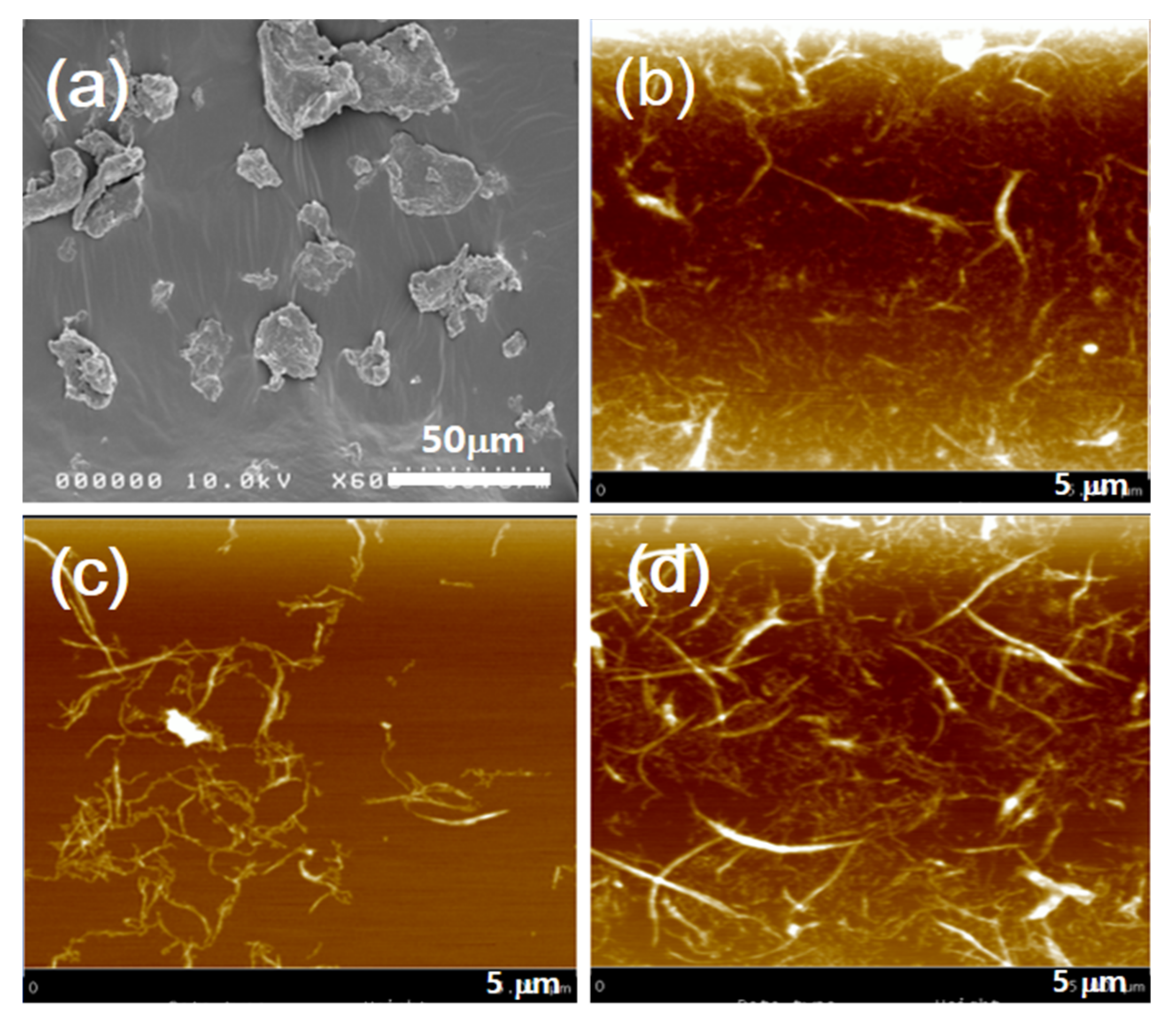

3.1. Chitosan Nanofibers

3.2. ChNF–CNF Composites

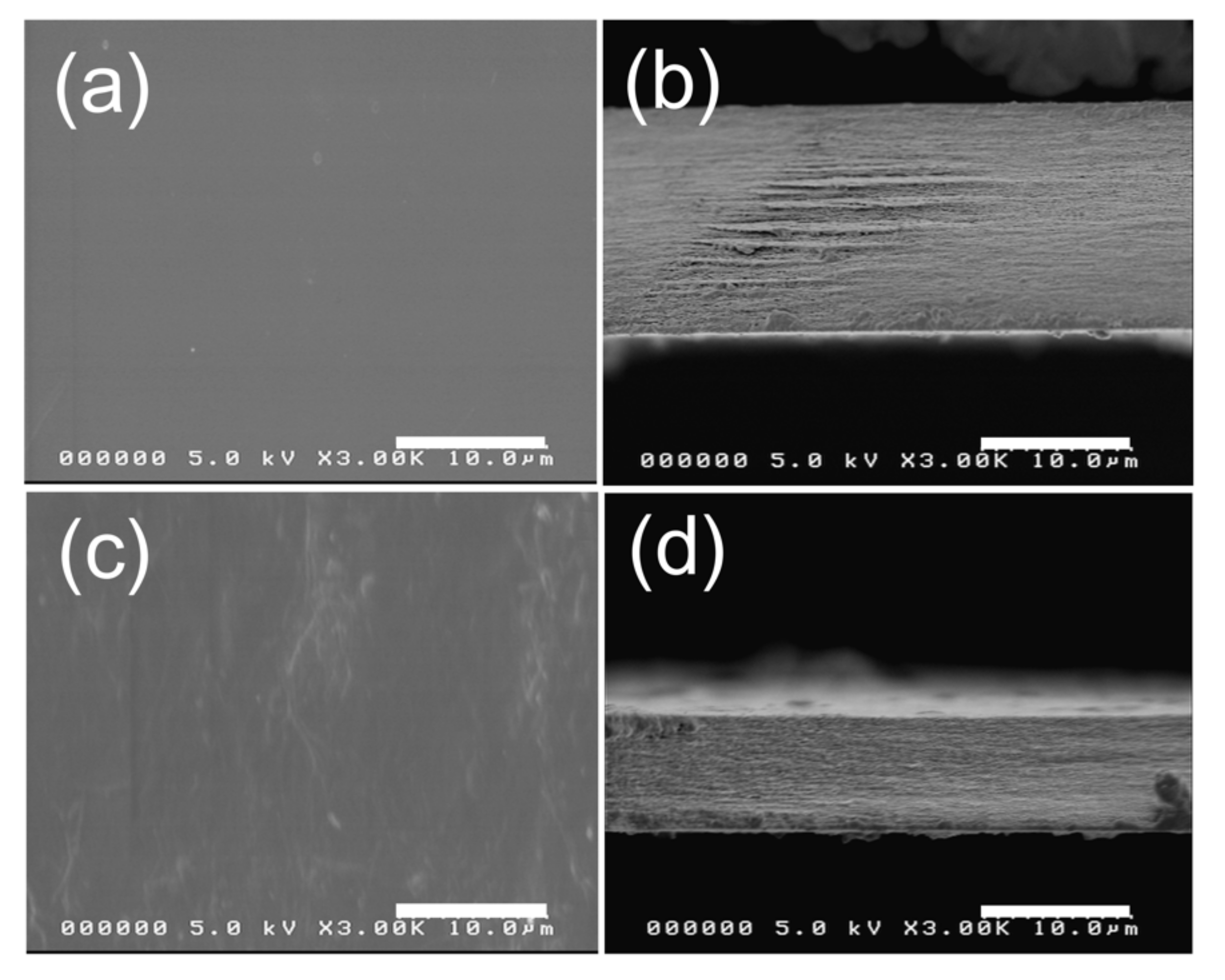

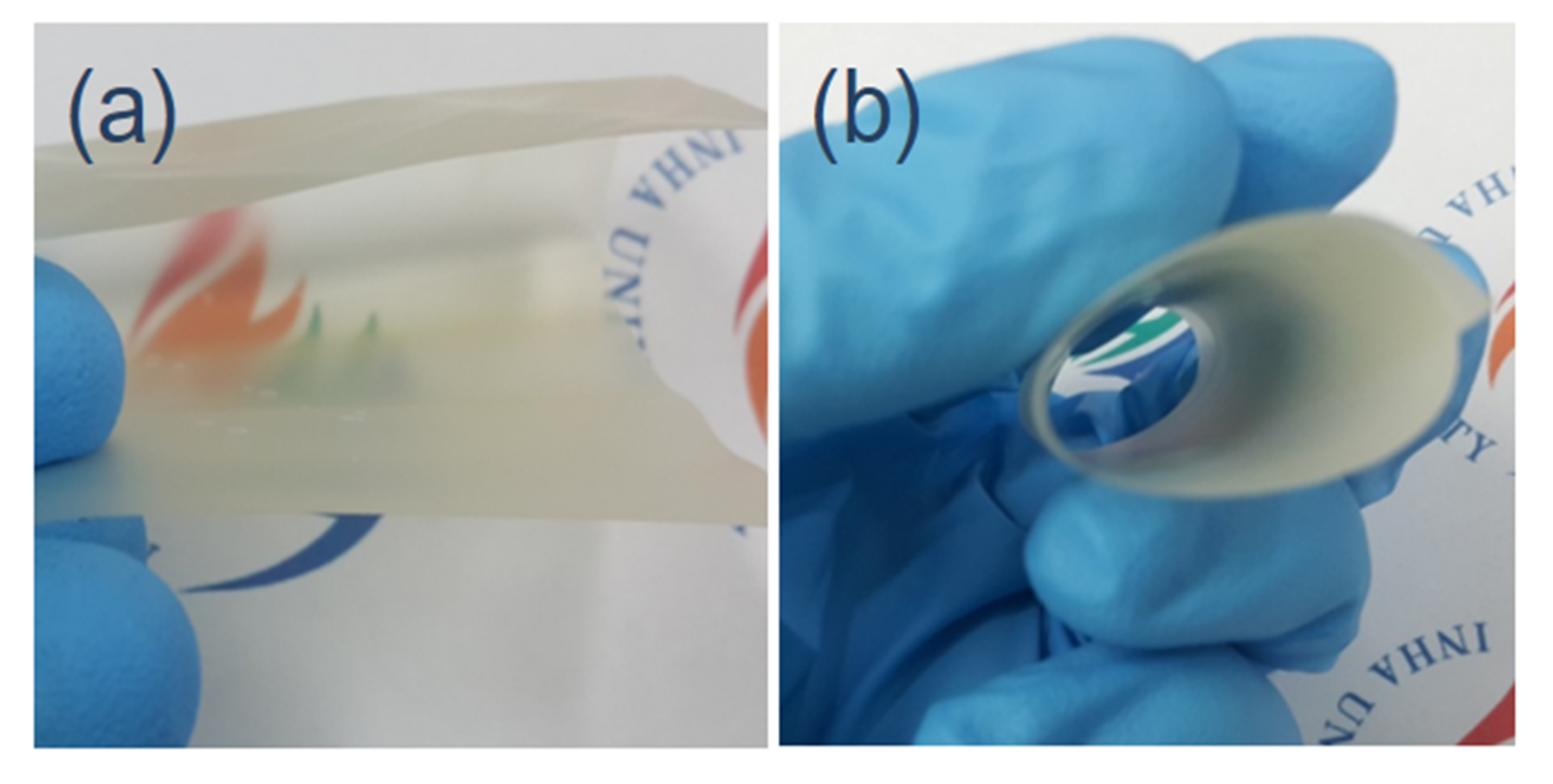

3.2.1. Morphologies

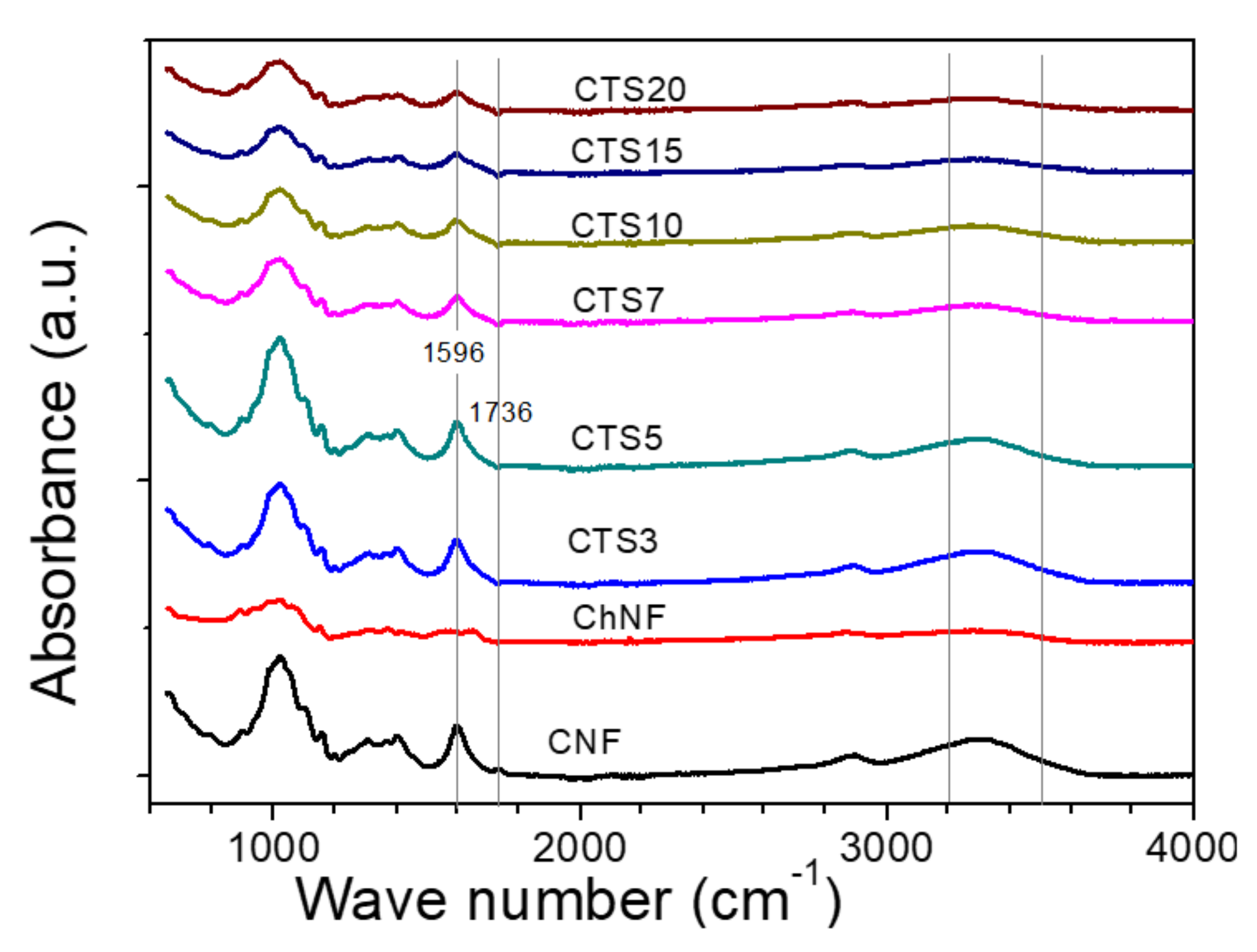

3.2.2. FTIR

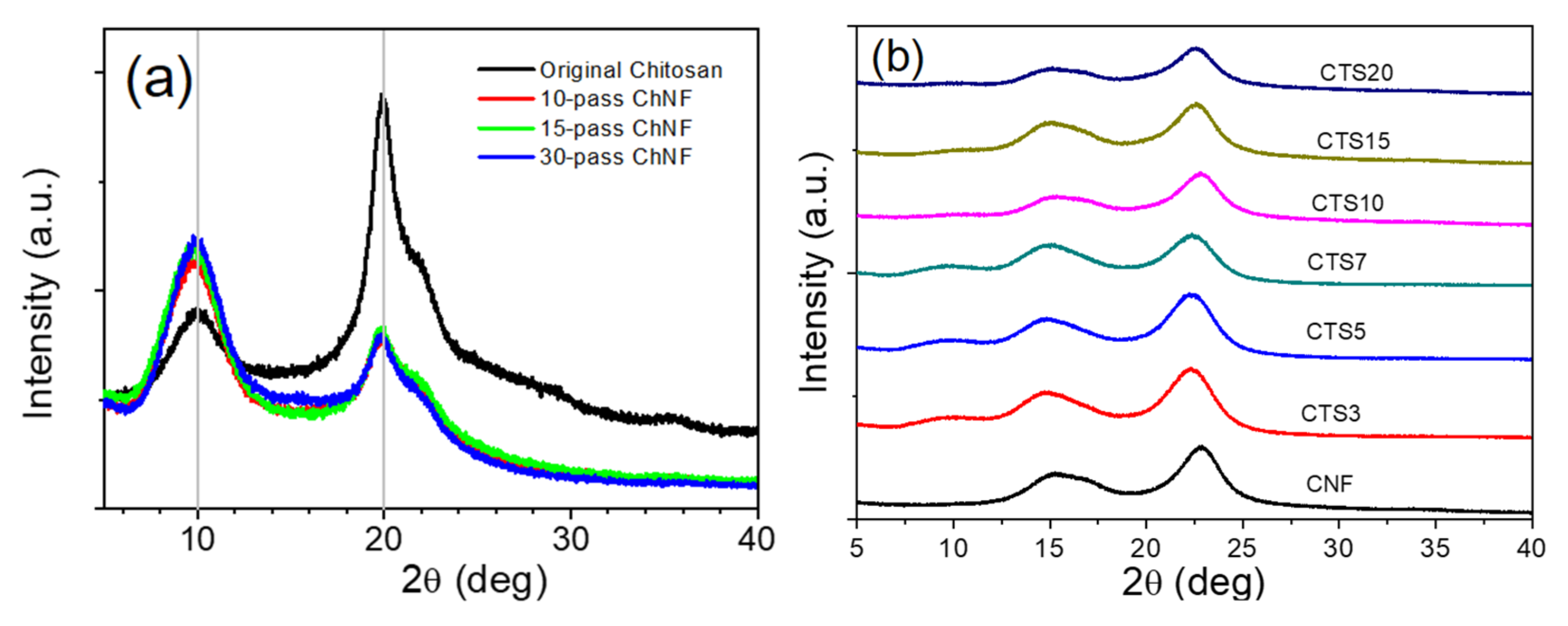

3.2.3. Crystallinity Index

3.2.4. Mechanical Properties

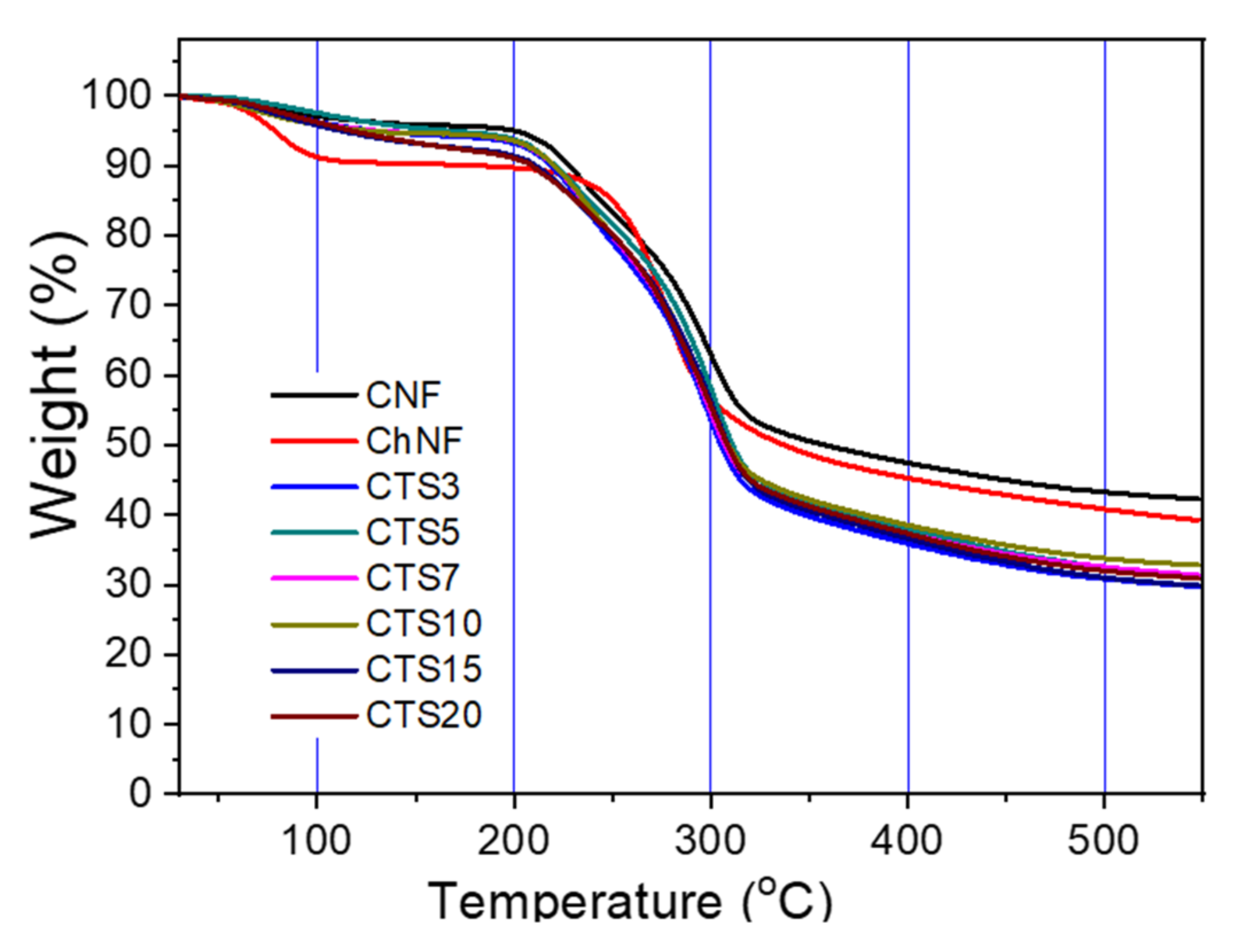

3.2.5. Thermal Stability

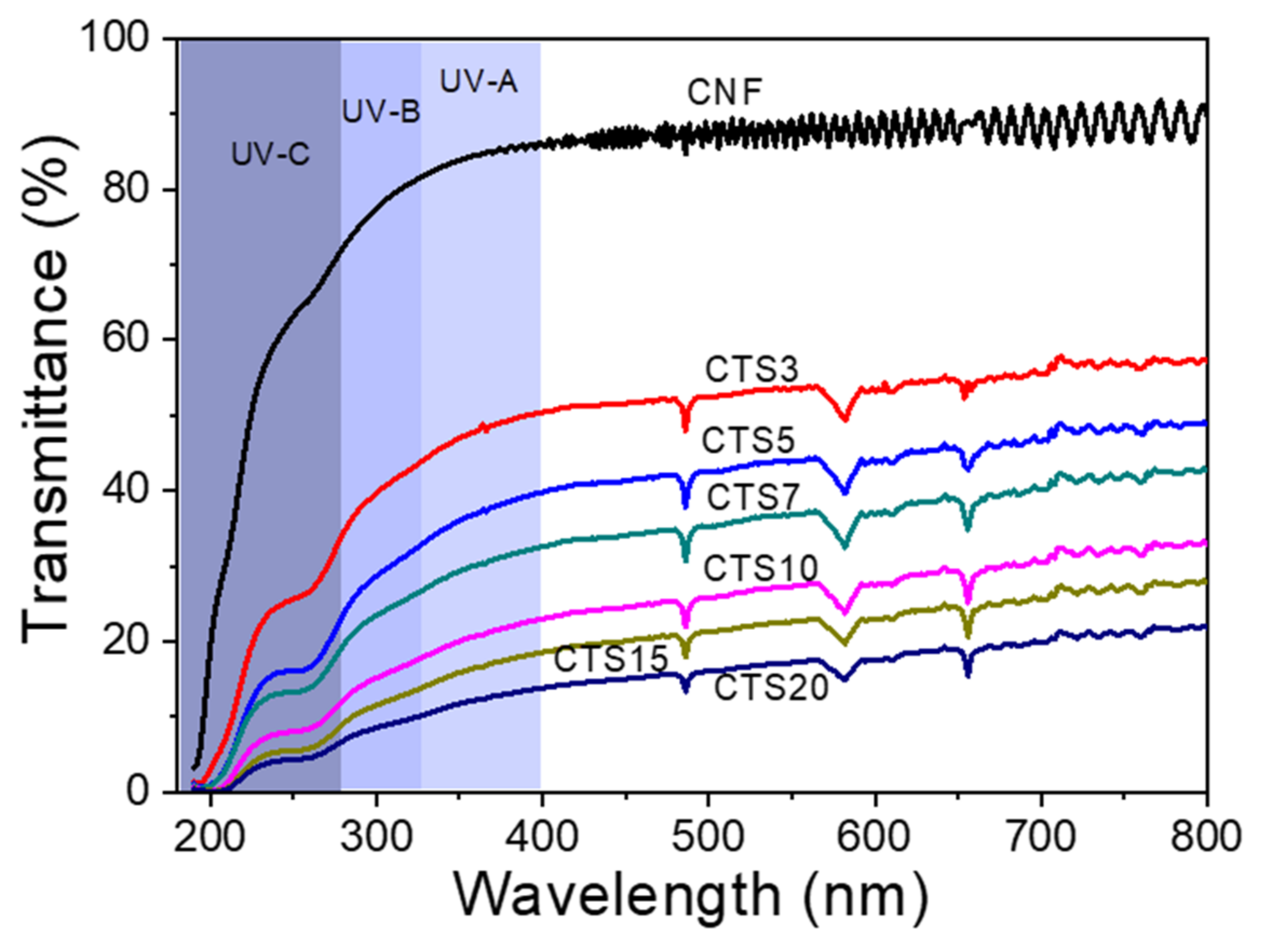

3.2.6. UV Transmittance

3.2.7. Hygroscopic Behaviors

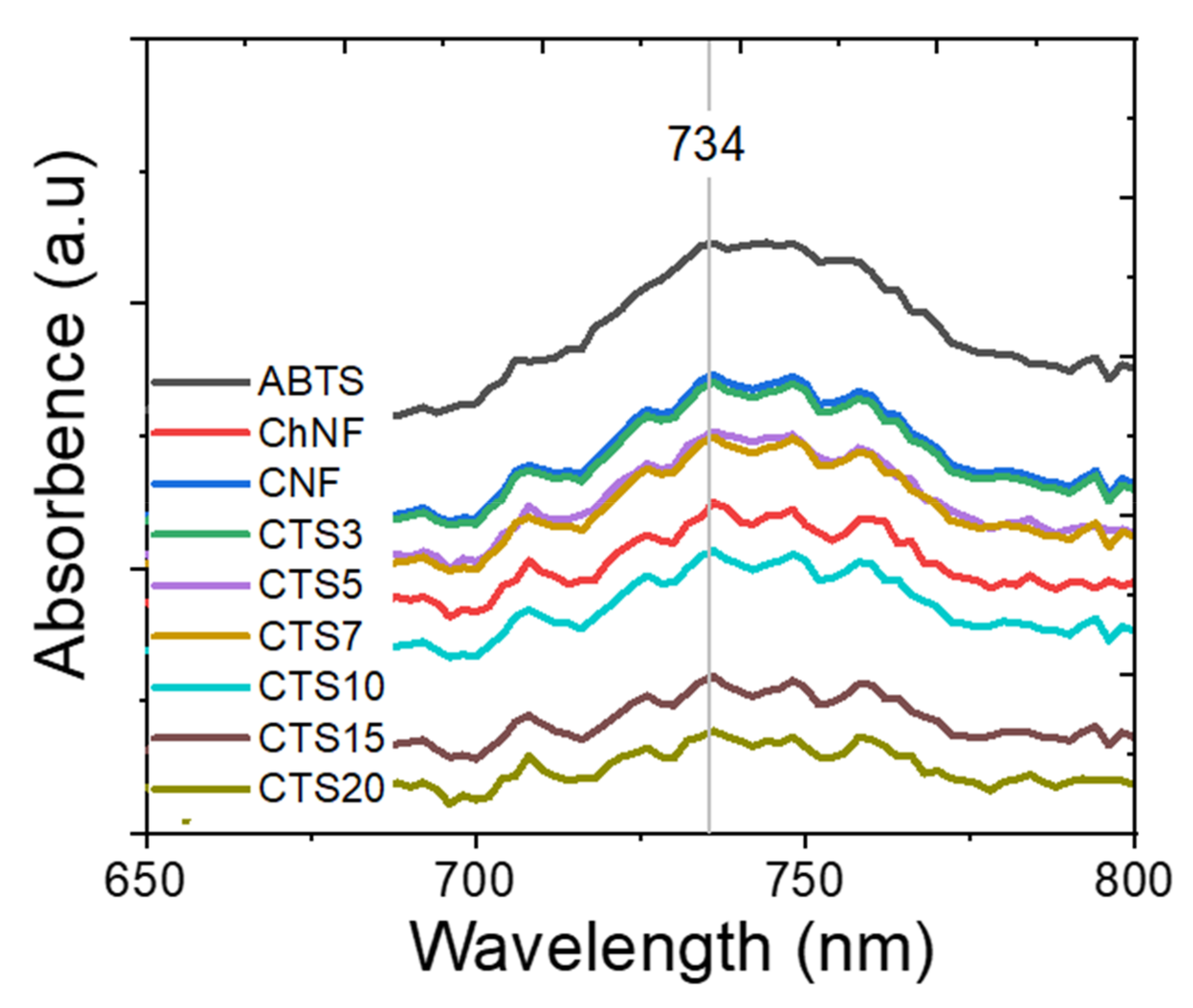

3.2.8. Antioxidant Property

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The Next Generation of Sustainable Food Packaging to Preserve Our Environment in a Circular Economy Context. Front. Nutr. 2018, 5, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Hirano, S.; Zhang, M.; Chung, B.G.; Kim, S.K. The N-acylation of chitosan fibre and the N-deacetylation of chitin fibre and chitin-cellulose blended fibre at a solid state. Carbohyd. Polym. 2000, 41, 175–179. [Google Scholar] [CrossRef]

- Yadav, S.; Mehrotra, G.K.; Dutta, P.K. Chitosan based ZnO nanoparticles loaded gallic-acid films for active food packaging. Food Chem. 2020, 334, 127605. [Google Scholar] [CrossRef] [PubMed]

- Mujtaba, M.; Morsi, R.E.; Kerch, G.; Elsabee, M.Z.; Kaya, M.; Labidi, J.; Khawar, K.M. Current advancements in chitosan-based film production for food technology: A review. Int. J. Biol. Macromol. 2019, 121, 889–904. [Google Scholar] [CrossRef] [PubMed]

- Rinaudo, M. Chitin and chitosan: Properties and applications. Prog. Polym. Sci. 2006, 31, 603–632. [Google Scholar] [CrossRef]

- Ravi Kuma, M.N.V. A review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27. [Google Scholar] [CrossRef]

- Kittur, F.S.; Kumar, K.R.; Tharanathan, R.N. Functional packaging properties of chitosan films. Z Lebensm Unters Forsch A 1997, 206, 44–47. [Google Scholar] [CrossRef]

- Shahidi, F.; Arachchi, J.K.V.; Jeon, Y.J. Food applications of chitin and chitosan. Trends Food Sci. Technol. 1999, 10, 37–51. [Google Scholar] [CrossRef]

- Tripathi, S.; Mehrotra, G.K.; Dutta, P.K. Chitosan based antimicrobial films for food packaging applications. Euro. Polym. 2008, 93, 1–7. [Google Scholar] [CrossRef]

- Elghaouth, A.; Ponnampalam, R.; Castaigne, F.; Arul, J. Chitosan coating to extend the storage life of Tomatoes. Hortscience 1992, 27, 1016–1018. [Google Scholar]

- Cheah, L.H.; Page, B.B.C.; Shepherd, R. Chitosan coating for inhibition of sclerotinia rot of carrots. New Zeal. J. Crop. Hot. 1997, 25, 89–92. [Google Scholar] [CrossRef]

- Simpson, B.K.; Gagne, N.; Ashie, I.N.A.; Noroozi, E. Utilization of chitosan for preservation of raw shrimo (Pandalus borealis). Food Biotechnol. 1997, 11, 25–44. [Google Scholar] [CrossRef]

- Jianglian, D.; Shaoying, Z. Application of chitosan based coating in fruit and vegetable preservation: A Review. Food Process. Technol. 2013, 4, 1–4. [Google Scholar] [CrossRef]

- Arkoun, M.; Daigle, F.; Heuzey, M.C.; Aji, A. Antibacterial electrospun chitosan-based nanofibers: A bacterial membrane perforator. Food Sci. Nutr. 2017, 5, 865–874. [Google Scholar] [CrossRef] [PubMed]

- Dutta, A.K.; Kawamoto, N.; Sugino, G.; Izawa, H.; Morimoto, M.; Saimoto, H.; Ifuku, S. Simple preparation of chitosan nanofibers from dry chitosan powder by the Star Burst System. Carbohyd. Polym. 2013, 97, 363–367. [Google Scholar] [CrossRef] [PubMed]

- Ifuku, S. Chitin and chitosan nanofibers: Preparation and chemical modifications. Molecules 2014, 19, 18367–18380. [Google Scholar] [CrossRef] [PubMed]

- Min, L.L.; Zhong, L.B.; Zheng, Y.M.; Liu, Q.; Yuan, Z.H.; Yang, L.M. Functionalized chitosan electrospun nanofiber for effective removal of trace arsenate from water. Sci. Rep. 2016, 6, 32480. [Google Scholar] [CrossRef]

- Jayakumar, R.; Prabaharan, M.; Nair, S.V.; Tamura, H. Novel chitin and chitosan nanofibers in biomedical applications. Biotechnol. Adv. 2010, 28, 142–150. [Google Scholar] [CrossRef]

- Aruma, K.; Ifuku, S.; Osaka, T.; Okamoto, Y.; Minamil, S. Preparation and biomedical applications of chitin and chitosan nanofibers. J. Biomed. Nanotech. 2014, 10, 2891–2920. [Google Scholar] [CrossRef]

- Ali, F.A.A.; Haider, S.; Al-Mảy, W.A.; Al-zeghaye, Y. Fabrication of chitosan nanofibers membrane and its treatment. 2013. Available online: www.jeaconf.org/UploadedFiles/.../a2a3a6d5-6810-4b3e-93a0-09140c4740c4.pdf (accessed on 4 September 2020).

- Bacakova, L.; Pajorova, J.; Bacakova, M.; Skogberg, A.; Kallio, P.; Kolarova, K.; Svorcik, V. Versatile Application of Nanocellulose: From Industry to Skin Tissue Engineering and Wound Healing. Nanomaterials 2019, 9, 164. [Google Scholar] [CrossRef]

- Ferrer, A.; Pal, L.; Hubbe, M. Nanocellulose in packaging: Advances in barrier layer technologies. Ind. Crop. Prod. 2017, 95, 574–582. [Google Scholar] [CrossRef]

- Future Markets. The Global Market for Cellulose Nanofibers to 2027. Future Markets Inc.: Edinburgh, UK, 2018. [Google Scholar]

- Isogai, A.; Kato, Y. Preparation of Polyuronic Acid from Cellulose by TEMPO-mediated Oxidation. Cellulose 1998, 5, 153. [Google Scholar] [CrossRef]

- Saito, T.; Kimura, S.; Nishiyama, Y.; Isogai, A. Cellulose nanofiber prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 2007, 8, 2485–2491. [Google Scholar] [CrossRef] [PubMed]

- Noorbakhsh-Soltani, S.M.; Zerafat, M.M.; Sabbaghi, S. A comparative study of gelatin and starch-based nano-composite films modified by nano-cellulose and chitosan for food packaging applications. Carbohyd. Polym. 2018, 189, 48–55. [Google Scholar] [CrossRef]

- Fernandes, S.C.M.; Freire, C.S.R.; Silvestre, A.J.D.; Neto, C.P.; Gandini, A.; Berglund, L.A.; Salmen, L. Transparent chitosan films reinforced with a high content of nanofibrillated cellulose. Carbohyd. Polym. 2010, 81, 394–401. [Google Scholar] [CrossRef]

- Hai, L.V.; Zhai, L.; Kim, H.C.; Kim, J.W.; Choi, E.S.; Kim, J. Cellulose nanofibers isolated by TEMPO-oxidation and aqueous counter collision methods. Carbohyd. Polym. 2018, 191, 65–70. [Google Scholar]

- Sohofi, N.; Tavanai, H.; Morshed, M.; Abdolmaeki, A. Electrospinning of 100% Carboxymethyl Chitosan Nanofibers. J. Eng. Fiber. Fabr. 2014, 9, 87–92. [Google Scholar] [CrossRef]

- Pillai, C.K.S.; Sharma, C.P. Electrospinning of chitin and chitosan nannofibers. Trends Biomater. Artif. Organs 2009, 22, 179–201. [Google Scholar]

- Fadaie, M.; Mirzaei, E. Nanofibrillated chitosan/Polycaprolactonebionanocompsoite scaffold with improved tensile strength and cellular behavior. Nanomed. J. 2018, 5, 77–89. [Google Scholar]

- Hassan, A.E.; Hassan, M.L.; Abo-zeid, R.E.; El-wkil, N.A. Novel nanofibrillated cellulose/chitosan nanoparticles nanocomposites films and their use for paper coating. Ind. Crop. Prod. 2016, 93, 219–226. [Google Scholar] [CrossRef]

- Zhai, L.; Kim, H.C.; Kim, J.W.; Kim, J. Simple centrifugal fractionation to reduce the size distribution of cellulose nanofibers. Sci. Rep. 2020, 10, 11744. [Google Scholar] [CrossRef] [PubMed]

- Kondo, T.; Kose, R.; Naito, H.; Kasai, W. Aqueous counter collision using paired water jets as a novel means of preparing bio-nanofibers. Carbohyd. Polym. 2014, 112, 284–290. [Google Scholar] [CrossRef] [PubMed]

- Kafy, A.; Kim, H.C.; Zhai, L.; Kim, J.W.; Hai, L.V.; Kang, T.J.; Kim, J. Cellulose long fibers fabricated from cellulose nanofibers and its strong and tough characteristics. Sci. Rep. 2017, 7, 17683. [Google Scholar] [CrossRef] [PubMed]

- ASTM. Standard Test Methods for Water Vapor Transmission of Materials. E96-95. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/E96-95.htm (accessed on 4 September 2020).

- Cao, T.L.; Yang, S.Y.; Song, K.B. Development of burdock root Inulin/Chitosan Blend films Containing Oregano and Thyme Essential oils. Int. J. Mol. Sci. 2017, 19, 31. [Google Scholar]

- Al Sagheer, F.A.; Al-Sughayer, M.A.; Muslim, S.; Elsabee, M.Z. Extraction and characterization of chitin and chitosan from marine sources in Arabian Gulf. Carbohyd. Polym. 2009, 77, 410–419. [Google Scholar] [CrossRef]

- Tamer, T.M.; Valachova, K.; Mohyeldin, M.S.; Soltes, L. Free radial scavenger activity of chitosan and its aminated derivative. J. Appl. Pharm. Sci. 2016, 6, 195–201. [Google Scholar] [CrossRef]

- Yen, M.T.; Yang, J.H.; Mau, J.L. Antioxidant properties of chitosan from crab shells. Carbohyd. Polym. 2008, 74, 840–844. [Google Scholar] [CrossRef]

| Samples | Young’s Modulus (GPa) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|

| CNF | 16.9 + 2.6 | 111.7 + 57 | 174.5 + 56.0 | 2.02 |

| CTS3 | 13.9 + 2.1 | 100.2 + 23 | 183.1 + 60.8 | 2.06 |

| CTS5 | 15.2 + 4.0 | 124.6 + 17 | 197.5 + 32.0 | 2.46 |

| CTS7 | 13.2 + 0.5 | 136.2 + 80 | 216.5 + 95.7 | 2.85 |

| CTS10 | 12.9 + 0.9 | 149.0 + 20 | 224.0 + 27.0 | 4.17 |

| CTS15 | 13.5 + 2.3 | 131.8 + 23 | 198.0 + 31.4 | 3.40 |

| CTS20 | 15.8 + 2.7 | 104.4 + 22 | 157.1 + 30.5 | 1.79 |

| ChNF * | 7.3 + 0.70 | 87.5 + 26.8 | 133.4 + 17.9 | 3.69 |

| Sample | Water Vapor Transmission Rate (g /m2.day) | Water Contact Angle (°) |

|---|---|---|

| CNF | 164.98 + 3.09 | 47 |

| CTS3 | 164.69 + 1.85 | 47 |

| CTS5 | 167.33 + 5.32 | 45 |

| CTS7 | 171.18 + 0.89 | 45 |

| CTS10 | 175.29 + 1.08 | 41 |

| CTS15 | 173.45 + 0.67 | 41 |

| CTS20 | 173.04 + 6.06 | 38 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hai, L.V.; Zhai, L.; Kim, H.C.; Panicker, P.S.; Pham, D.H.; Kim, J. Chitosan Nanofiber and Cellulose Nanofiber Blended Composite Applicable for Active Food Packaging. Nanomaterials 2020, 10, 1752. https://doi.org/10.3390/nano10091752

Hai LV, Zhai L, Kim HC, Panicker PS, Pham DH, Kim J. Chitosan Nanofiber and Cellulose Nanofiber Blended Composite Applicable for Active Food Packaging. Nanomaterials. 2020; 10(9):1752. https://doi.org/10.3390/nano10091752

Chicago/Turabian StyleHai, Le Van, Lindong Zhai, Hyun Chan Kim, Pooja S. Panicker, Duc Hoa Pham, and Jaehwan Kim. 2020. "Chitosan Nanofiber and Cellulose Nanofiber Blended Composite Applicable for Active Food Packaging" Nanomaterials 10, no. 9: 1752. https://doi.org/10.3390/nano10091752

APA StyleHai, L. V., Zhai, L., Kim, H. C., Panicker, P. S., Pham, D. H., & Kim, J. (2020). Chitosan Nanofiber and Cellulose Nanofiber Blended Composite Applicable for Active Food Packaging. Nanomaterials, 10(9), 1752. https://doi.org/10.3390/nano10091752