Rapid Room-Temperature Preparation of Hierarchically Porous Metal–Organic Frameworks for Efficient Uranium Removal from Aqueous Solutions

Abstract

1. Introduction

2. Materials and Methods

2.1. Rapid Room-Temperature Preparation of Hierarchically Porous Cu-BTC

2.2. Material Characterization

2.3. Adsorption Experiments

3. Results and Discussion

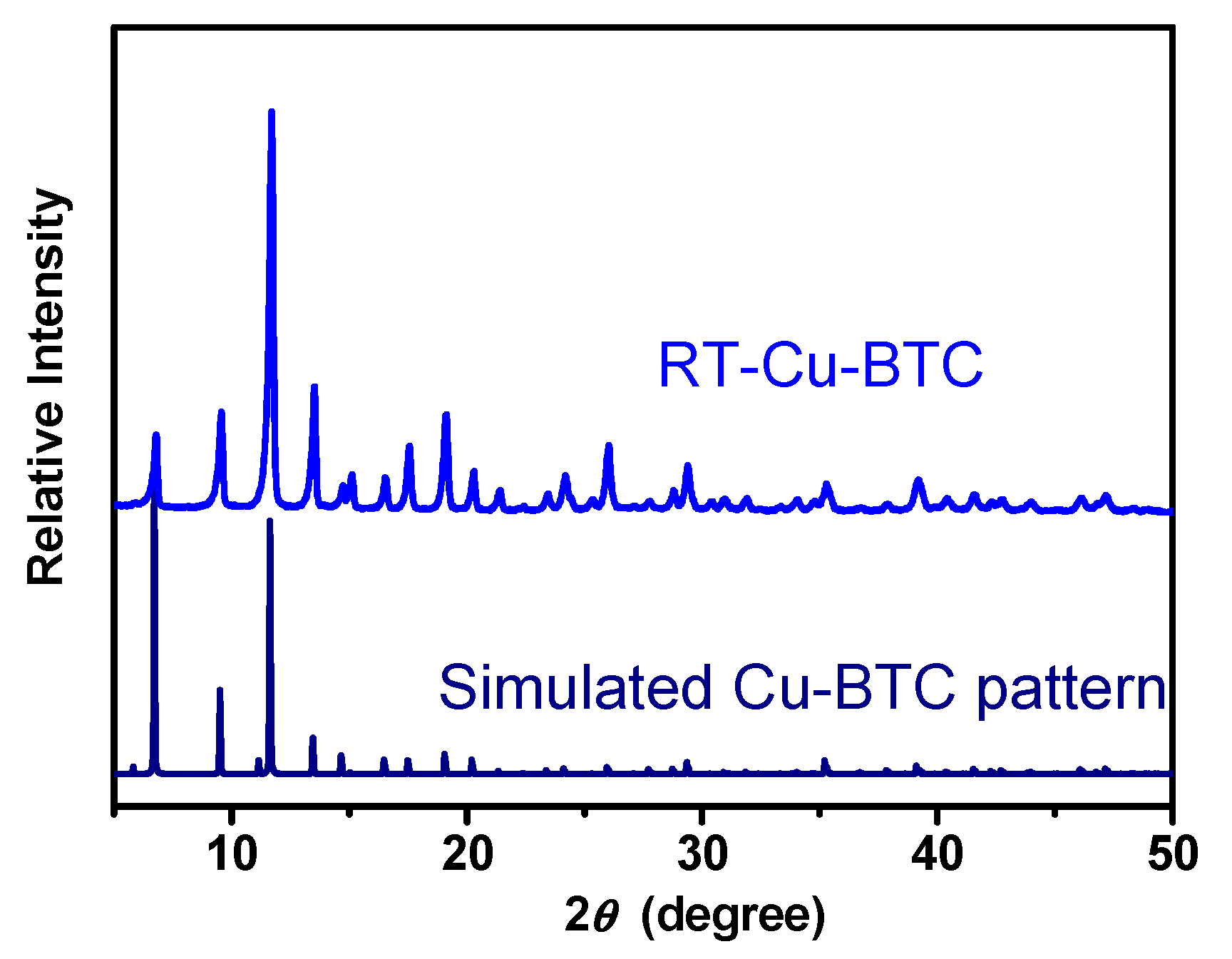

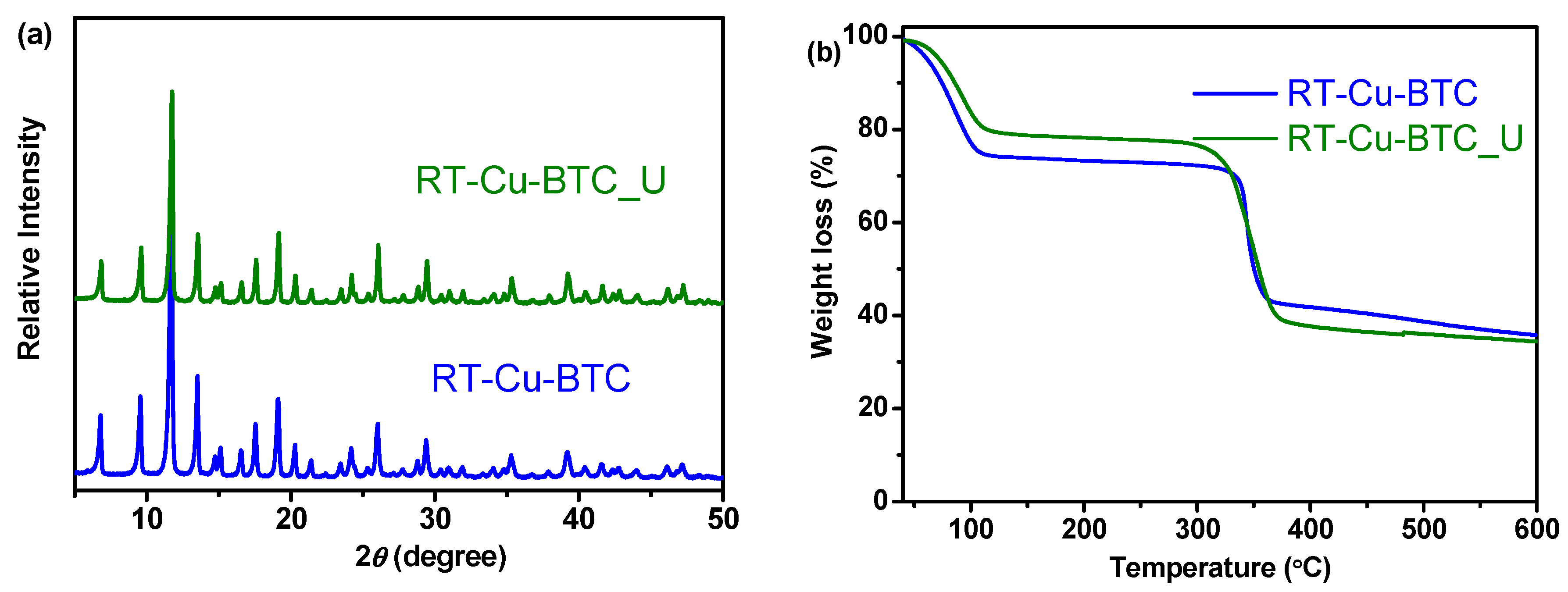

3.1. Crystal Structure Identification of RT-Cu-BTC

3.2. The Removal of Uranium (VI) by RT-Cu-BTC from Aqueous Solutions

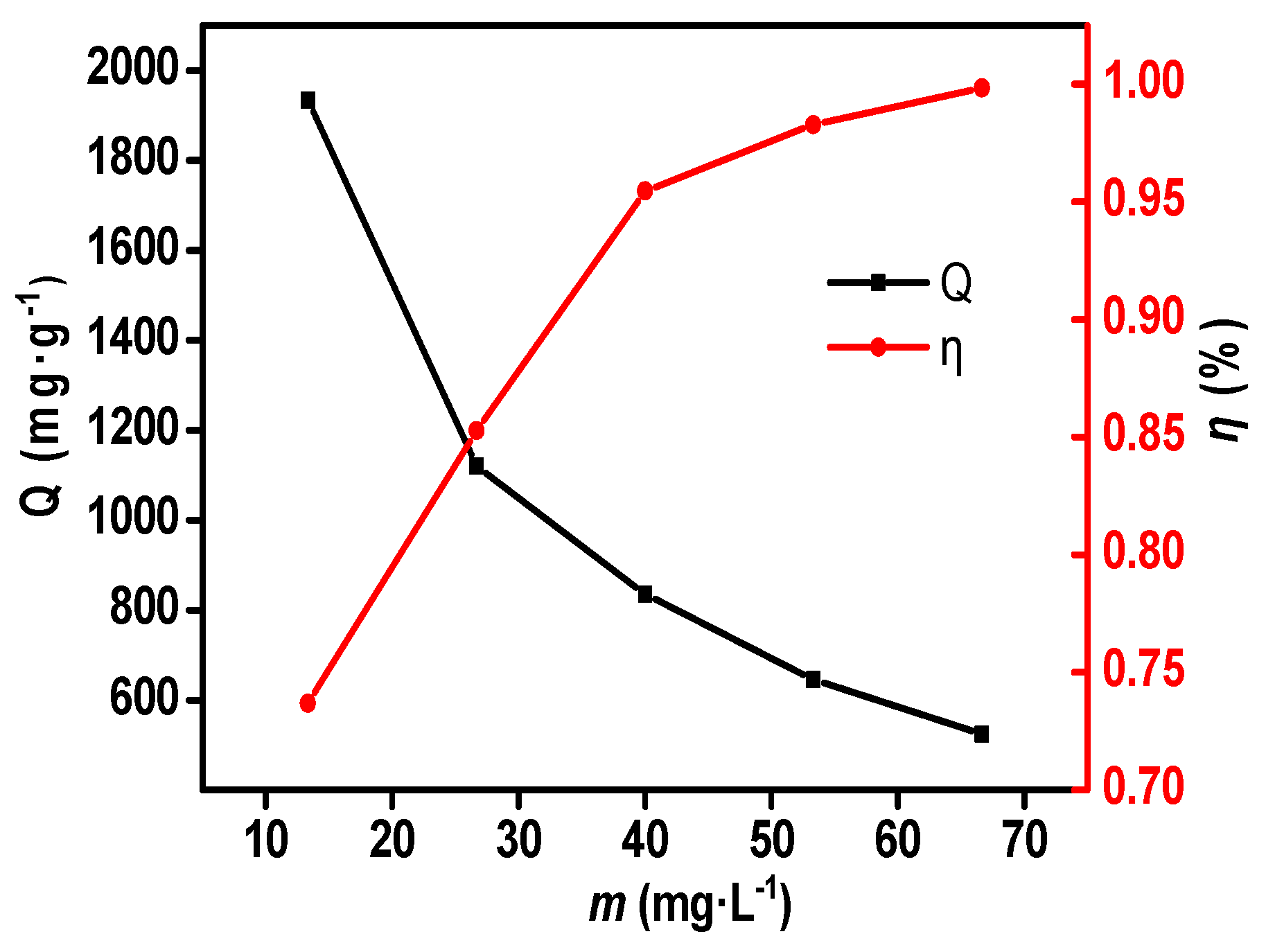

3.2.1. Effect of RT-Cu-BTC Dosage

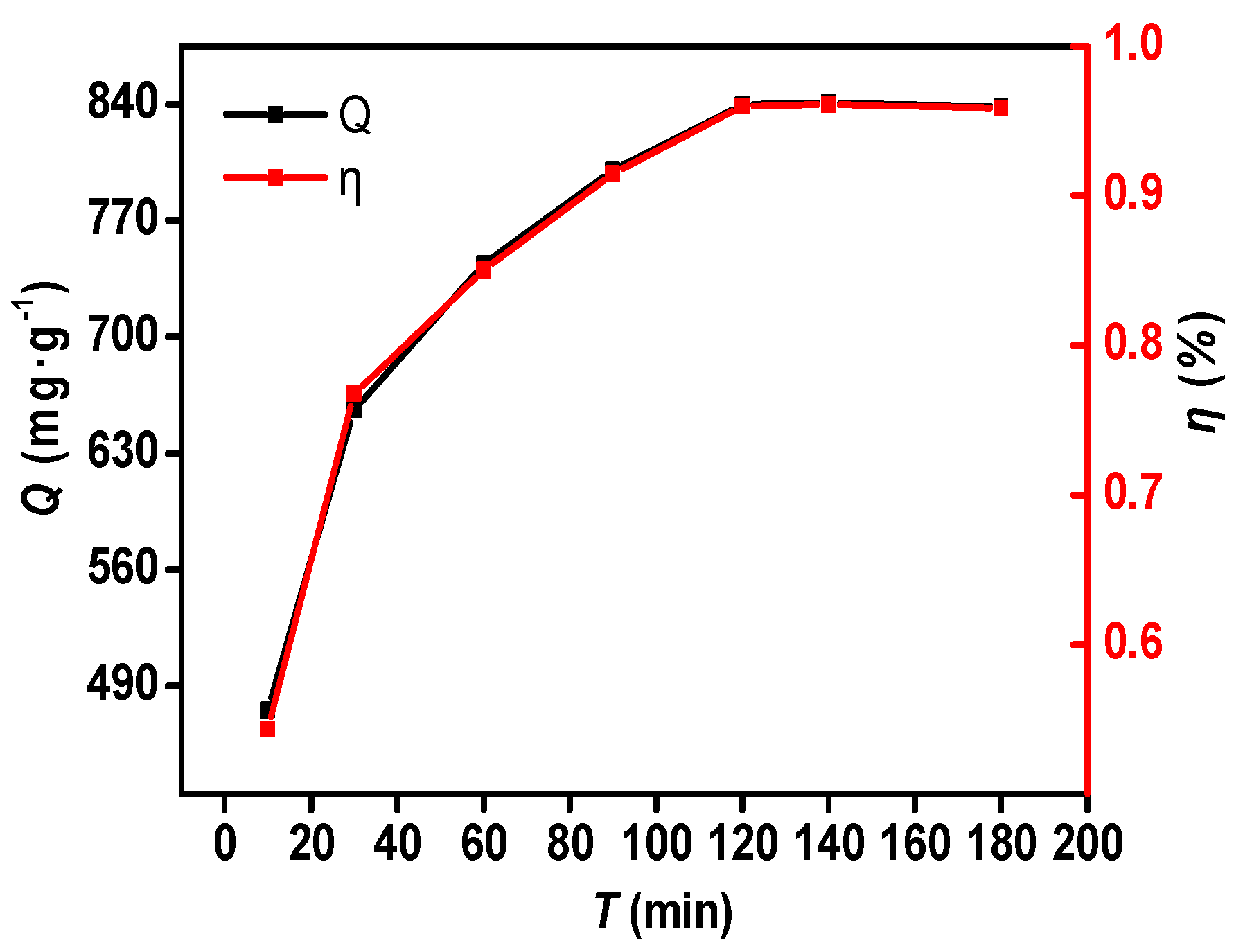

3.2.2. Effect of Contact Time

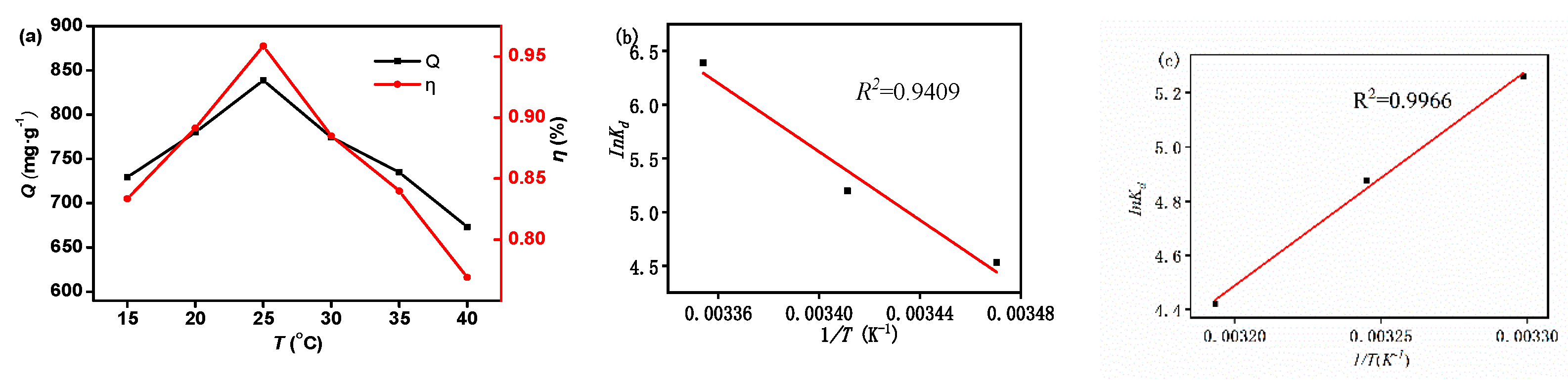

3.2.3. Effect of Temperature and Adsorption Thermodynamics

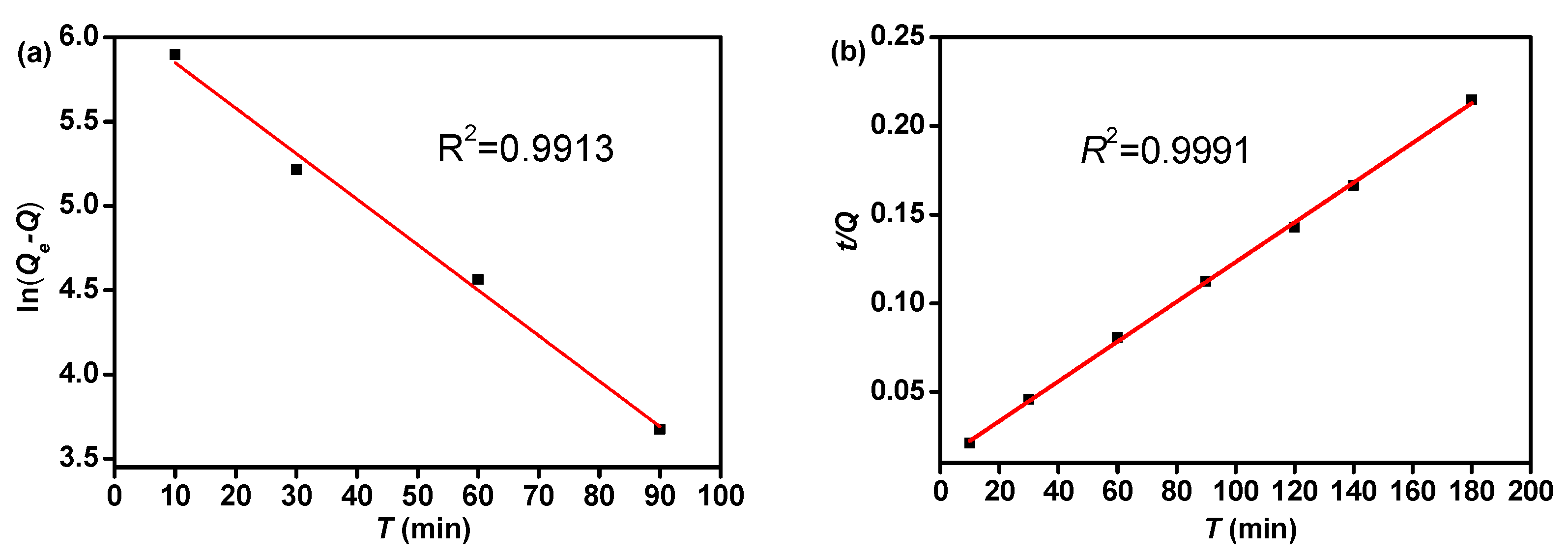

3.3. Adsorption Kinetics

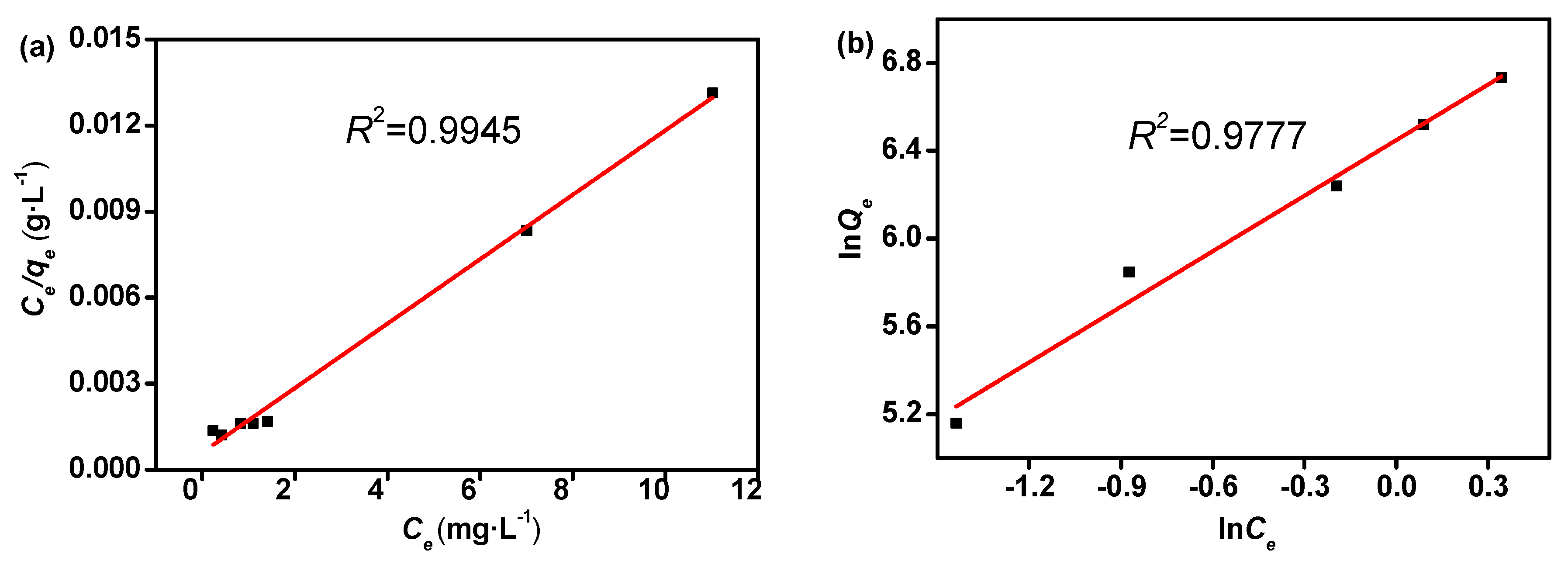

3.4. Adsorption Isotherms

3.5. Crystal Structure of RT-Cu-BTC after Adsorption of Uranium (VI)

3.6. A Possible Mechanism for Adsorption of Uranium (VI) by RT-Cu-BTC

3.7. The Enhanced Adsorption Capacity of Uranium (VI)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Diallo, M.S.; Kotte, M.R.; Cho, M. Mining Critical Metals and Elements from Seawater: Opportunities and Challenges. Environ. Sci. Technol. 2015, 49, 9390–9399. [Google Scholar] [CrossRef]

- Sun, Q.; Aguila, B.; Ma, S. Opportunities of Porous Organic Polymers for Radionuclide Sequestration. Trends Chem. 2019, 1, 292–303. [Google Scholar] [CrossRef]

- Alqadami, A.A.; Naushad, M.; Alothman, Z.A.; Ghfar, A.A. Novel Metal-Organic Framework (MOF) Based Composite Material for the Sequestration of U(VI) and Th(IV) Metal Ions from Aqueous Environment. ACS Appl. Mater. Interfaces 2017, 9, 36026–36037. [Google Scholar] [CrossRef]

- Fu, F.; Xie, L.; Tang, B.; Wang, Q.; Jiang, S. Application of a novel strategy—Advanced Fenton-chemical precipitation to the treatment of strong stability chelated heavy metal containing wastewater. Chem. Eng. J. 2012, 189, 283–287. [Google Scholar] [CrossRef]

- Truong, H.T.; Nguyen, T.H.; Lee, M.S. Separation of molybdenum(VI), rhenium(VII), tungsten(VI), and vanadium(V) by solvent extraction. Hydrometallurgy 2017, 171, 298–305. [Google Scholar] [CrossRef]

- Sharma, G.; Thakur, B.; Naushad, M.; Al-Muhtaseb, A.a.H.; Kumar, A.; Sillanpaa, M.; Mola, G.T. Fabrication and characterization of sodium dodecyl sulphate@ironsilicophosphate nanocomposite: Ion exchange properties and selectivity for binary metal ions. Mater. Chem. Phys. 2017, 193, 129–139. [Google Scholar] [CrossRef]

- Ferhat, M.; Kadouche, S.; Drouiche, N.; Messaoudi, K.; Messaoudi, B.; Lounici, H. Competitive adsorption of toxic metals on bentonite and use of chitosan as flocculent coagulant to speed up the settling of generated clay suspensions. Chemosphere 2016, 165, 87–93. [Google Scholar] [CrossRef]

- Sheng, D.; Zhu, L.; Dai, X.; Xu, C.; Li, P.; Pearce, C.I.; Xiao, C.; Chen, J.; Zhou, R.; Duan, T.; et al. Successful Decontamination of 99TcO4- in Groundwater at Legacy Nuclear Sites by a Cationic Metal-Organic Framework with Hydrophobic Pockets. Angew. Chem. 2019, 58, 4968–4972. [Google Scholar] [CrossRef]

- Visa, A.; Maranescu, B.; Lupa, L.; Crisan, L.; Borota, A. New Efficient Adsorbent Materials for the Removal of Cd(II) from Aqueous Solutions. Nanomaterials 2020, 10, 899. [Google Scholar] [CrossRef]

- Li, L.; Duan, Y.; Liao, S.; Ke, Q.; Qiao, Z.; Wei, Y. Adsorption and separation of propane/propylene on various ZIF-8 polymorphs: Insights from GCMC simulations and the ideal adsorbed solution theory (IAST). Chem. Eng. J. 2020, 386, 123945. [Google Scholar] [CrossRef]

- Duan, C.; Yu, Y.; Xiao, J.; Li, Y.; Yang, P.; Hu, F.; Xi, H. Recent advancements in metal-organic frameworks for green applications. Green Energy Environ. 2020. [Google Scholar] [CrossRef]

- Guillerm, V.; Kim, D.; Eubank, J.F.; Luebke, R.; Liu, X.; Adil, K.; Lah, M.S.; Eddaoudi, M. A supermolecular building approach for the design and construction of metal-organic frameworks. Chem. Soc. Rev. 2014, 43, 6141–6172. [Google Scholar] [CrossRef] [PubMed]

- Duan, C.; Li, F.; Li, L.; Zhang, H.; Wang, X.; Xiao, J.; Xi, H. Hierarchically structured metal-organic frameworks assembled by hydroxy double salt-template synergy with high space-time yields. CrystEngComm 2018, 20, 1057–1064. [Google Scholar] [CrossRef]

- Arshad, M.; Du, H.; Javed, M.S.; Maqsood, A.; Ashraf, I.; Hussain, S.; Ma, W.; Ran, H. Fabrication, structure, and frequency-dependent electrical and dielectric properties of Sr-doped BaTiO3 ceramics. Ceram. Int. 2020, 46, 2238–2246. [Google Scholar] [CrossRef]

- Duan, C.; Li, F.; Yang, M.; Zhang, H.; Wu, Y.; Xi, H. Rapid Synthesis of Hierarchically Structured Multifunctional Metal-Organic Zeolites with Enhanced Volatile Organic Compounds Adsorption Capacity. Ind. Eng. Chem. Res. 2018, 57, 15385–15394. [Google Scholar] [CrossRef]

- Sun, Q.; Dai, Z.; Meng, X.; Xiao, F.-S. Porous polymer catalysts with hierarchical structures. Chem. Soc. Rev. 2015, 44, 6018–6034. [Google Scholar] [CrossRef]

- Duan, C.; Yu, Y.; Xiao, J.; Zhang, X.; Li, L.; Yang, P.; Wu, J.; Xi, H. Water-based routes for synthesis of metal-organic frameworks: A review. Sci. China Mater. 2020, 63, 667–685. [Google Scholar] [CrossRef]

- Duan, C.; Yu, Y.; Yang, P.; Zhang, X.; Li, F.; Li, L.; Xi, H. Engineering new defects in MIL-100 (Fe) via a mixed-ligand approach to effect enhanced volatile organic compound adsorption capacity. Ind. Eng. Chem. Res. 2019, 59, 774–782. [Google Scholar] [CrossRef]

- Wang, L.L.; Luo, F.; Dang, L.L.; Li, J.Q.; Wu, X.L.; Liu, S.J.; Luo, M.B. Ultrafast high-performance extraction of uranium from seawater without pretreatment using an acylamide- and carboxyl-functionalized metal-organic framework. J. Mater. Chem. A 2015, 3, 13724–13730. [Google Scholar] [CrossRef]

- Feng, Y.; Jiang, H.; Li, S.; Wang, J.; Jing, X.; Wang, Y.; Chen, M. Metal-organic frameworks HKUST-1 for liquid-phase adsorption of uranium. Colloids Surface. A Physicochem. Eng. Asp. 2013, 431, 87–92. [Google Scholar] [CrossRef]

- Luo, B.-C.; Yuan, L.-Y.; Chai, Z.-F.; Shi, W.-Q.; Tang, Q. U(VI) capture from aqueous solution by highly porous and stable MOFs: UiO-66 and its amine derivative. J. Radioanal. Nucl. Chem. 2016, 307, 269–276. [Google Scholar] [CrossRef]

- Cao, S.; Gody, G.; Zhao, W.; Perrier, S.; Peng, X.; Ducati, C.; Zhao, D.; Cheetham, A.K. Hierarchical bicontinuous porosity in metal-organic frameworks templated from functional block co-oligomer micelles. Chem. Sci. 2013, 4, 3573–3577. [Google Scholar] [CrossRef]

- Yang, W.; Bai, Z.-Q.; Shi, W.-Q.; Yuan, L.-Y.; Tian, T.; Chai, Z.-F.; Wang, H.; Sun, Z.-M. MOF-76: From a luminescent probe to highly efficient UVI sorption material. Chem. Commun. 2013, 49, 10415–10417. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Ke, G.; Yin, J.; Lei, W.; Yang, P. Synthesis of thiol-functionalized hydrotalcite and its application for adsorption of uranium (VI). J. Radioanal. Nucl. Chem. 2019, 319, 791–803. [Google Scholar] [CrossRef]

- Zhao, J.; Nunn, W.T.; Lemaire, P.C.; Lin, Y.; Dickey, M.D.; Oldham, C.J.; Walls, H.J.; Peterson, G.W.; Losego, M.D.; Parsons, G.N. Facile Conversion of Hydroxy Double Salts to Metal-Organic Frameworks Using Metal Oxide Particles and Atomic Layer Deposition Thin-Film Templates. J. Am. Chem. Soc. 2015, 137, 13756–13759. [Google Scholar] [CrossRef]

- Duan, C.; Zhang, H.; Yang, M.; Li, F.; Yu, Y.; Xiao, J.; Xi, H. Templated fabrication of hierarchically porous metal-organic frameworks and simulation of crystal growth. Nanoscale Adv. 2019, 1, 1062–1069. [Google Scholar] [CrossRef]

- Duan, C.; Li, F.; Luo, S.; Xiao, J.; Li, L.; Xi, H. Facile synthesis of hierarchical porous metal-organic frameworks with enhanced catalytic activity. Chem. Eng. J. 2018, 334, 1477–1483. [Google Scholar] [CrossRef]

- Duan, C.; Li, F.; Zhang, H.; Li, J.; Wang, X.; Xi, H. Template synthesis of hierarchical porous metal-organic frameworks with tunable porosity. RSC Adv. 2017, 7, 52245–52251. [Google Scholar] [CrossRef]

- Gao, X.; Wang, Y.; Ji, G.; Cui, R.; Liu, Z. One-pot synthesis of hierarchical-pore metal-organic frameworks for drug delivery and fluorescent imaging. CrystEngComm 2018, 20, 1087–1093. [Google Scholar] [CrossRef]

- Zhou, L.; Shang, C.; Liu, Z.; Huang, G.; Adesina, A.A. Selective adsorption of uranium(VI) from aqueous solutions using the ion-imprinted magnetic chitosan resins. J. Colloid Interface Sci. 2012, 366, 165–172. [Google Scholar] [CrossRef]

- Sen, T.K.; Sarzali, M.V. Removal of cadmium metal ion (Cd2+) from its aqueous solution by aluminium oxide (Al2O3): A kinetic and equilibrium study. Chem. Eng. J. 2008, 142, 256–262. [Google Scholar] [CrossRef]

- Zhu, L.; Shi, X.; Song, L.; Sun, Y.; Chen, S.; Wu, W. Mesoporous silica (KIT-6) derivatized with hydroxyquinoline functionalities as a selective adsorbent of uranium(VI). J. Radioanal. Nucl. Chem. 2016, 308, 381–392. [Google Scholar] [CrossRef]

- Li, R.; Che, R.; Liu, Q.; Su, S.; Li, Z.; Zhang, H.; Liu, J.; Liu, L.; Wang, J. Hierarchically structured layered-double-hydroxides derived by ZIF-67 for uranium recovery from simulated seawater. J. Hazard. Mater. 2017, 338, 167–176. [Google Scholar] [CrossRef] [PubMed]

- Gupta, V.K.; Jain, C.K.; Ali, I.; Sharma, M.; Saini, V.K. Removal of cadmium and nickel from wastewater using bagasse fly ash—A sugar industry waste. Water Res. 2003, 37, 4038–4044. [Google Scholar]

- Thompson, C.V.; Spaepen, F. On the approximation of the free energy change on crystallization. Acta Metall. 1979, 27, 1855–1859. [Google Scholar] [CrossRef]

- Mathias, P.M.; O’Connell, J.P. The Gibbs-Helmholtz Equation and the Thermodynamic Consistency of Chemical Absorption Data. Ind. Eng. Chem. Res. 2012, 51, 5090–5097. [Google Scholar] [CrossRef]

- Asnin, L.D.; Stepanova, M.V. Van’t Hoff analysis in chiral chromatography. J. Sep. Sci. 2018, 41, 1319–1337. [Google Scholar] [CrossRef]

- Mi, F.-L.; Wu, S.-J.; Chen, Y.-C. Combination of carboxymethyl chitosan-coated magnetic nanoparticles and chitosan-citrate complex gel beads as a novel magnetic adsorbent. Carbohyd. Polym. 2015, 131, 255–263. [Google Scholar] [CrossRef]

- Ho, Y.S.; McKay, G. Pseudo-second order model for sorption processes. Process. Biochem. 1999, 34, 451–465. [Google Scholar] [CrossRef]

- Li, S.; Bai, H.; Wang, J.; Jing, X.; Liu, Q.; Zhang, M.; Chen, R.; Liu, L.; Jiao, C. In situ grown of nano-hydroxyapatite on magnetic CaAl-layered double hydroxides and its application in uranium removal. Chem. Eng. J. 2012, 193, 372–380. [Google Scholar] [CrossRef]

- Song, L.L.; Chen, C.; Luo, F.; Huang, S.Y.; Wang, L.L.; Zhang, N. Isoreticular MOFs functionalized in the pore wall by different organic groups for high-performance removal of uranyl ions. J. Radioanal. Nucl. Chem. 2016, 310, 317–327. [Google Scholar] [CrossRef]

- Prestipino, C.; Regli, L.; Vitillo, J.G.; Bonino, F.; Damin, A.; Lamberti, C.; Zecchina, A.; Solari, P.; Kongshaug, K.; Bordiga, S. Local structure of framework Cu(II) in HKUST-1 metallorganic framework: Spectroscopic characterization upon activation and interaction with adsorbates. Chem. Mater. 2006, 18, 1337–1346. [Google Scholar] [CrossRef]

- Awual, M.R. A novel facial composite adsorbent for enhanced copper(II) detection and removal from wastewater. Chem. Eng. J. 2015, 266, 368–375. [Google Scholar] [CrossRef]

- Awual, M.R. Novel ligand functionalized composite material for efficient copper(II) capturing from wastewater sample. Compos. Part B Eng. 2019, 172, 387–396. [Google Scholar] [CrossRef]

- Choi, S.-H.; Nho, Y.C. Adsorption of UO2+2 by polyethylene adsorbents with amidoxime, carboxyl, and amidoxime/carboxyl group. Radiat. Phys. Chem. 2000, 57, 187–193. [Google Scholar] [CrossRef]

- Castillo, J.M.; Vlugt, T.J.H.; Calero, S. Understanding Water Adsorption in Cu-BTC Metal-Organic Frameworks. J. Phys. Chem. C 2008, 112, 15934–15939. [Google Scholar] [CrossRef]

- Guo, X.; Xiong, X.-G.; Li, C.; Gong, H.; Huai, P.; Hu, J.; Jin, C.; Huang, L.; Wu, G. DFT investigations of uranium complexation with amidoxime-, carboxyl- and mixed amidoxime/carboxyl-based host architectures for sequestering uranium from seawater. Inorg. Chim. Acta 2016, 441, 117–125. [Google Scholar] [CrossRef]

- Carboni, M.; Abney, C.W.; Liu, S.; Lin, W. Highly porous and stable metal-organic frameworks for uranium extraction. Chem. Sci. 2013, 4, 2396–2402. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Z.; Li, Y.; Bai, Z.; Liu, W.; Wang, Y.; Xu, X.; Xiao, C.; Sheng, D.; Diwu, J.; et al. Umbellate Distortions of the Uranyl Coordination Environment Result in a Stable and Porous Polycatenated Framework That Can Effectively Remove Cesium from Aqueous Solutions. J. Am. Chem. Soc. 2015, 137, 6144–6147. [Google Scholar] [CrossRef]

- Bai, Z.-Q.; Yuan, L.-Y.; Zhu, L.; Liu, Z.-R.; Chu, S.-Q.; Zheng, L.-R.; Zhang, J.; Chai, Z.-F.; Shi, W.-Q. Introduction of amino groups into acid-resistant MOFs for enhanced U(vi) sorption. J. Mater. Chem. A 2015, 3, 525–534. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, L.L.; Gong, L.L.; Feng, X.F.; Luo, M.B.; Luo, F. Coumarin-modified microporous-mesoporous Zn-MOF-74 showing ultra-high uptake capacity and photo-switched storage/release of UVI ions. J. Hazard. Mater. 2016, 311, 30–36. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.-G.; Yang, K.; Shan, R.-R.; Yan, T.; Wei, J.; Yu, S.-J.; Yu, H.-Q.; Du, B. Kinetic, isotherm and thermodynamic investigations of phosphate adsorption onto core-shell Fe3O4@LDHs composites with easy magnetic separation assistance. J. Colloid Interface Sci. 2015, 448, 508–516. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yuan, L.; Yuan, Y.; Lan, J.; Li, Z.; Feng, Y.; Zhao, Y.; Chai, Z.; Shi, W. A high efficient sorption of U(VI) from aqueous solution using amino-functionalized SBA-15. J. Radioanal. Nucl. Chem. 2012, 292, 803–810. [Google Scholar] [CrossRef]

| ΔH [KJ·mol−1] | ΔS [J·mol−1·K−1] | ΔG [KJ·mol−1] | ||

|---|---|---|---|---|

| 288.15 K | 293.15 K | 298.15 K | ||

| 132.329 | 496.17 | −10.643 | −13.123 | −15.604 |

| Pseudo-First-Order | Pseudo-Second-Order | qe (exp) [mg·g−1] | ||||

|---|---|---|---|---|---|---|

| K1 [min−1] | qe [mg·g−1] | R2 | K2 [g·mg−1·min−1] | qe [mg·g−1] | R2 | |

| −0.027 | 454.45 | 0.9913 | 0.0001 | 1000 | 0.9991 | 839.7 |

| T (°C) | Langmuir | Freundlich | ||||

|---|---|---|---|---|---|---|

| Qm [mg·g−1] | KL [L·mg−1] | R2 | KF [mg1−n·Ln·g−1] | n | R2 | |

| 25 | 892.9 | 1.86 | 0.9945 | 631.4 | 1.19 | 0.9777 |

| No | Adsorbent | Temperature [K] | Uranium Capacity [mg·g−1] | Ref. |

|---|---|---|---|---|

| 1 | MIL-101 | 298 | 20 | [50] |

| 2 | MIL-101-NH2 | 298 | 90 | [50] |

| 3 | MIL-101-ED | 298 | 200 | [50] |

| 4 | MIL-101-DETA | 298 | 350 | [50] |

| 5 | Zn-MOF | 298 | 115 | [19] |

| 6 | UIO-66 | - | 109.9 | [21] |

| 7 | UIO-66-NH2 | - | 114.9 | [21] |

| 8 | UIO-68 | 295 | 217 | [48] |

| 9 | Zn-MOF-74 | 298 | 360 | [51] |

| 10 | MOF-76 | 288 | 300 | [23] |

| 11 | Cu-BTC | 298 | 744 | [20] |

| 12 | Fe3O4@Zn–Al–LDHs | - | 36.9 | [52] |

| 13 | SBA-15 | 298 | 409 | [53] |

| 14 | RT-Cu-BTC | 298 | 839.7 | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, C.; Zhang, Y.; Li, J.; Kang, L.; Xie, Y.; Qiao, W.; Zhu, C.; Luo, H. Rapid Room-Temperature Preparation of Hierarchically Porous Metal–Organic Frameworks for Efficient Uranium Removal from Aqueous Solutions. Nanomaterials 2020, 10, 1539. https://doi.org/10.3390/nano10081539

Duan C, Zhang Y, Li J, Kang L, Xie Y, Qiao W, Zhu C, Luo H. Rapid Room-Temperature Preparation of Hierarchically Porous Metal–Organic Frameworks for Efficient Uranium Removal from Aqueous Solutions. Nanomaterials. 2020; 10(8):1539. https://doi.org/10.3390/nano10081539

Chicago/Turabian StyleDuan, Chongxiong, Yi Zhang, Jiexin Li, Le Kang, Yawei Xie, Wenxiong Qiao, Chunxia Zhu, and Haochuan Luo. 2020. "Rapid Room-Temperature Preparation of Hierarchically Porous Metal–Organic Frameworks for Efficient Uranium Removal from Aqueous Solutions" Nanomaterials 10, no. 8: 1539. https://doi.org/10.3390/nano10081539

APA StyleDuan, C., Zhang, Y., Li, J., Kang, L., Xie, Y., Qiao, W., Zhu, C., & Luo, H. (2020). Rapid Room-Temperature Preparation of Hierarchically Porous Metal–Organic Frameworks for Efficient Uranium Removal from Aqueous Solutions. Nanomaterials, 10(8), 1539. https://doi.org/10.3390/nano10081539