Development of Monolithically Grown Coaxial GaInN/GaN Multiple Quantum Shell Nanowires by MOCVD

Abstract

1. Introduction

2. Experimental Growth

3. Results and Discussion

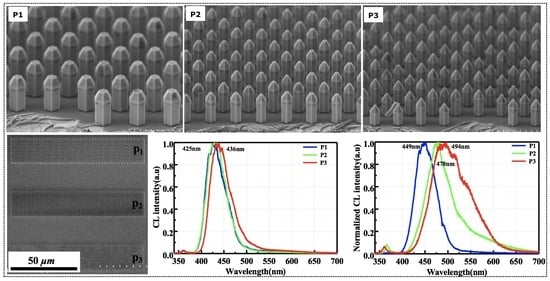

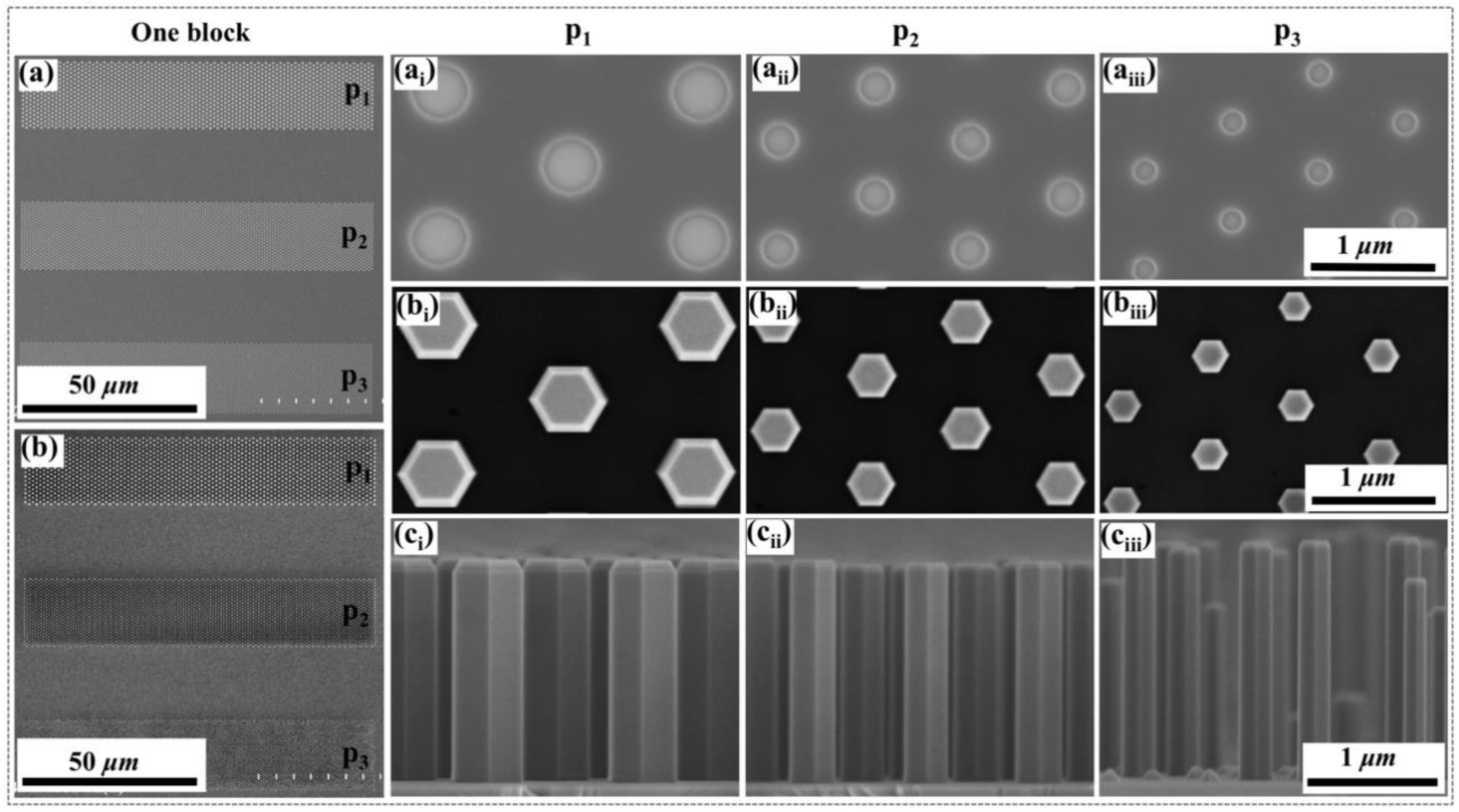

3.1. Morphology of the Monolithic Grown n-Core NWs

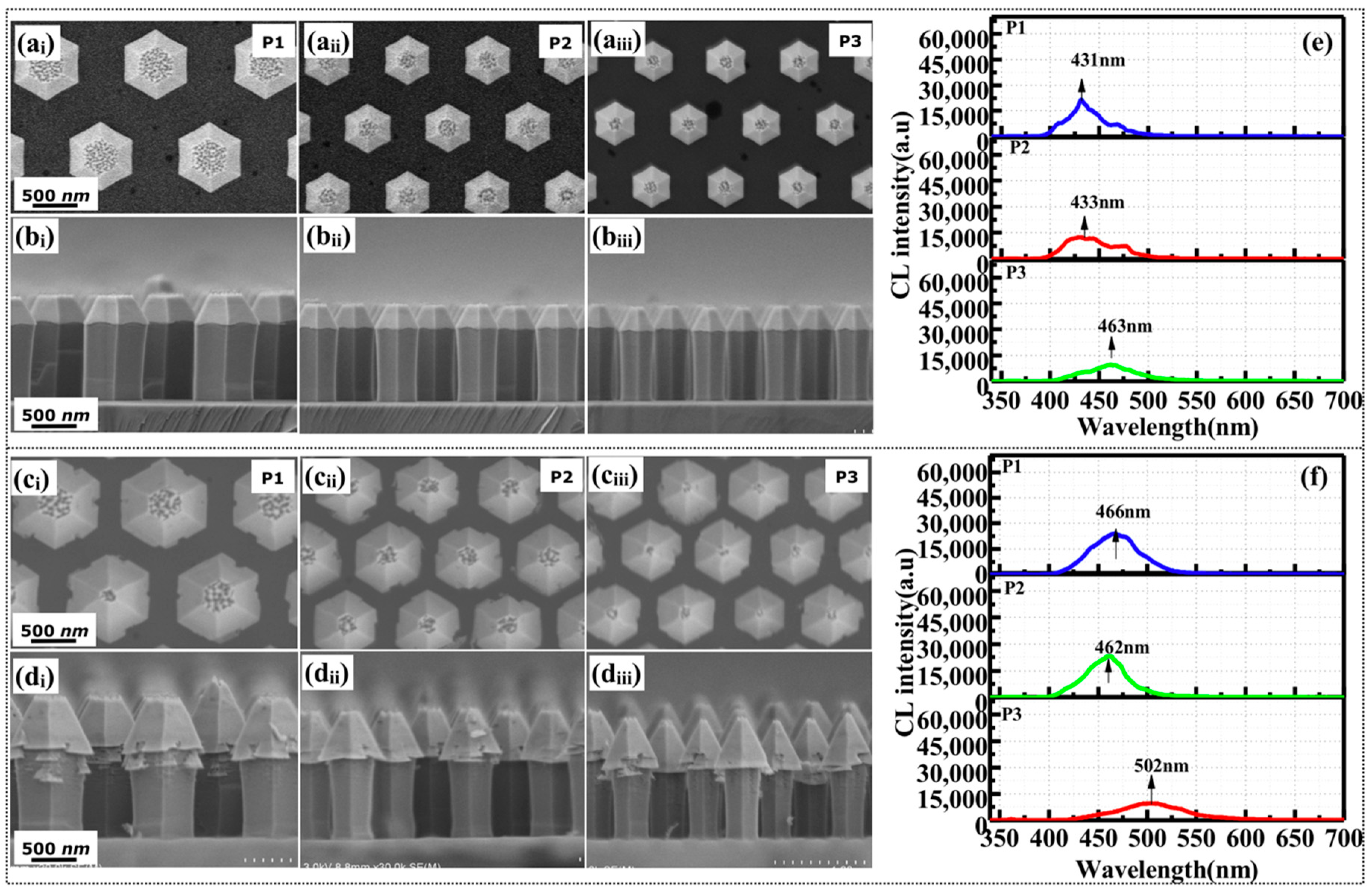

3.2. Effect of TEG Flow Rate on Emission Wavelength

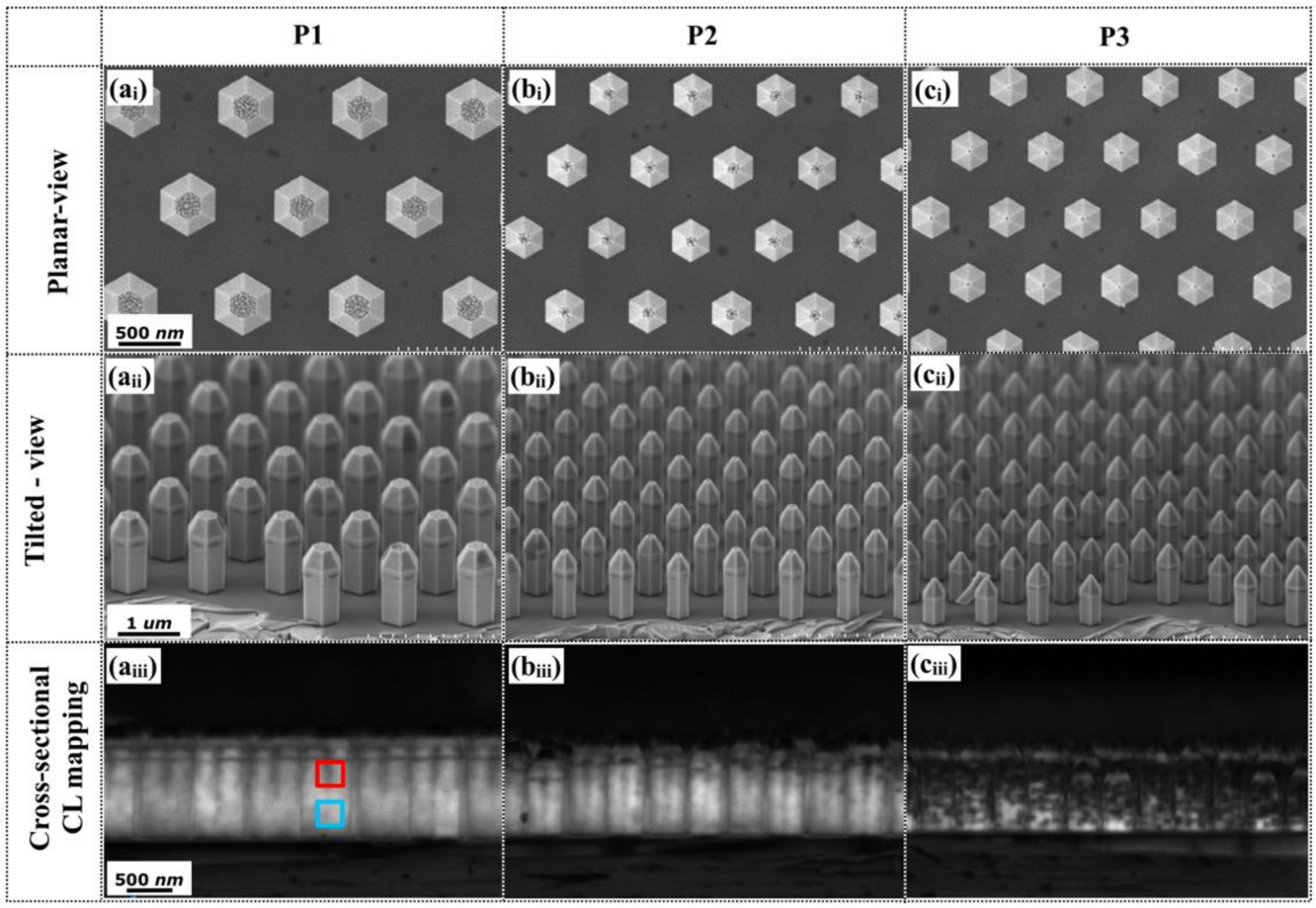

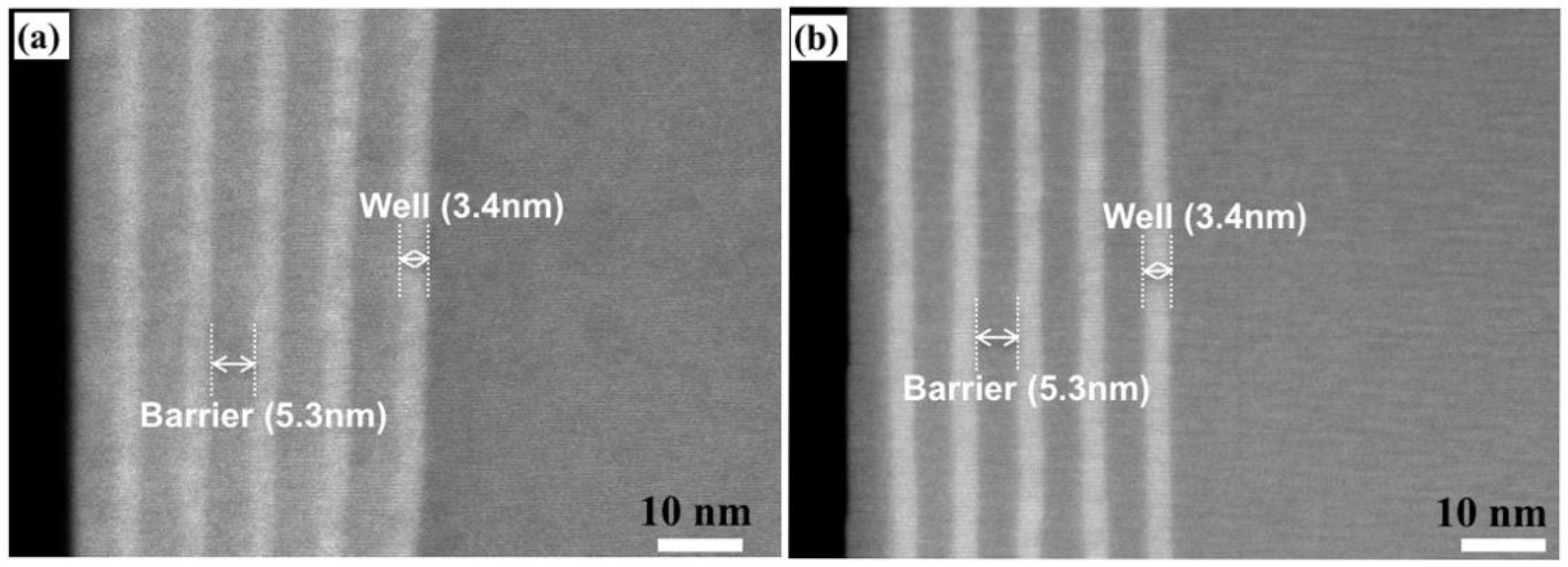

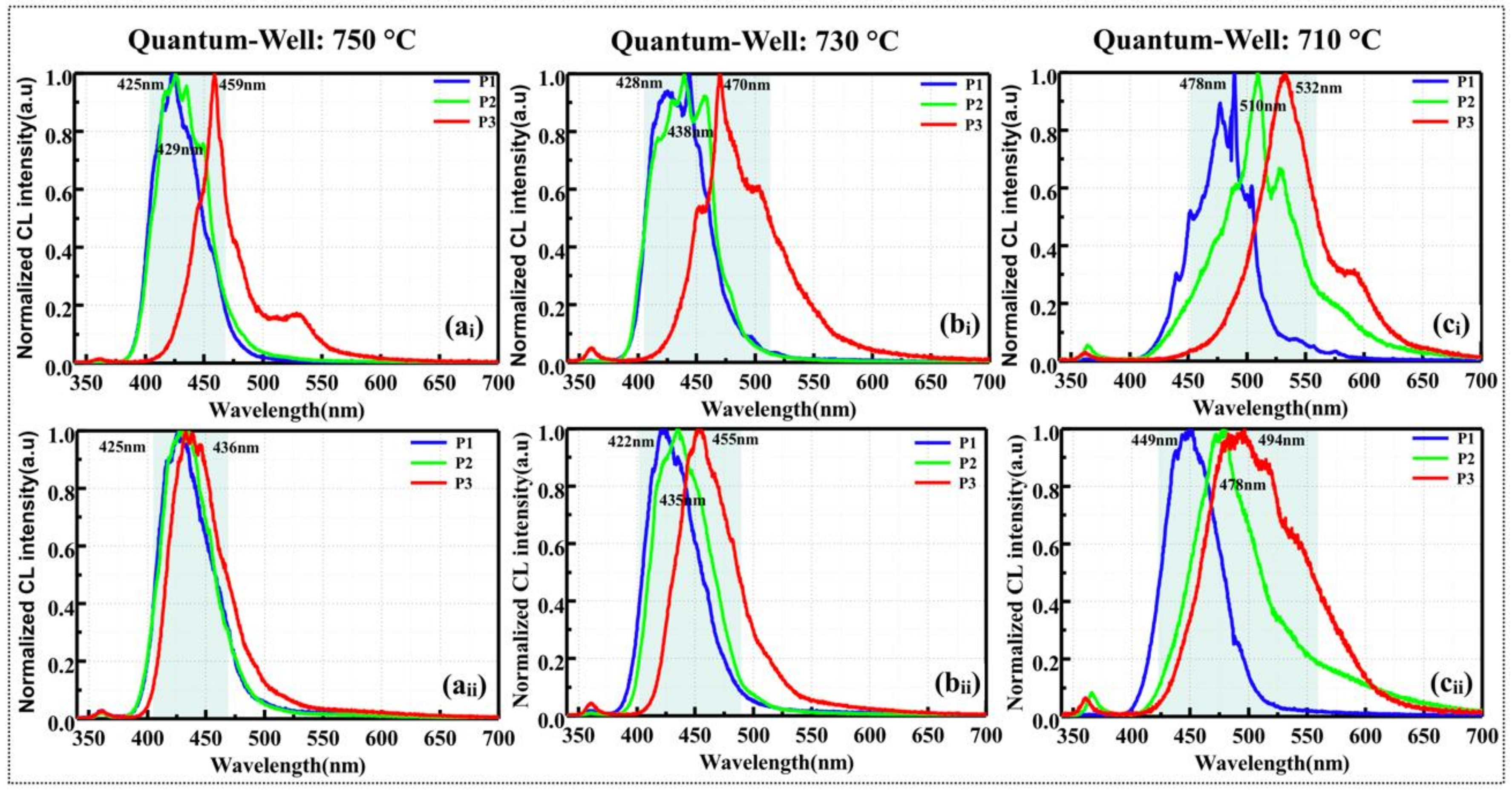

3.3. Improving Crystalline Quality by Raising the Growth Temperature of Quantum Barriers

3.4. Enhancing Emission Wavelength by Lowering the Growth Temperature of Quantum Wells

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kuykendall, T.R.; Schwartzberg, A.M.; Aloni, S. Gallium Nitride Nanowires and Heterostructures: Toward Color-Tunable and White-Light Sources. Adv. Mater. 2015, 27, 5805–5812. [Google Scholar] [CrossRef]

- Nami, M.; Stricklin, I.E.; Davico, K.M.; Mishkat-Ul-Masabih, S.; Rishinaramangalam, A.K.; Brueck, S.R.J.; Brener, I.; Feezell, D.F. Carrier Dynamics and Electro-Optical Characterization of High-Performance GaN/InGaN Core-Shell Nanowire Light-Emitting Diodes. Sci. Rep. 2018, 8, 501. [Google Scholar] [CrossRef] [PubMed]

- Cossu, G.; Khalid, A.M.; Choudhury, P.; Corsini, R.; Ciaramella, E. 34 Gbit/s visible optical wireless transmission based on RGB LED. Opt. Express 2012, 20, B501–B506. [Google Scholar] [CrossRef] [PubMed]

- Akasaki, I. Nobel Lecture: Fascinated journeys into blue light. Rev. Mod. Phys. 2015, 87, 1119–1131. [Google Scholar] [CrossRef]

- Nakamura, S.; Senoh, M.; Iwasa, N.; Nagahama, S.-I. High-Brightness InGaN Blue, Green and Yellow Light-Emitting Diodes with Quantum Well Structures. Jpn. J. Appl. Phys. 1995, 34, L797–L799. [Google Scholar] [CrossRef]

- Amano, H. Nobel Lecture: Growth of GaN on sapphire via low-temperature deposited buffer layer and realization of p-type GaN by Mg doping followed by low-energy electron beam irradiation. Rev. Mod. Phys. 2015, 87, 1133. [Google Scholar] [CrossRef]

- Nakamura, S. Nobel Lecture: Background story of the invention of efficient blue InGaN light emitting diodes. Rev. Mod. Phys. 2015, 87, 1139–1151. [Google Scholar] [CrossRef]

- Akasaki, I.; Amano, H. Breakthroughs in Improving Crystal Quality of GaN and Invention of the p–n Junction Blue-Light-Emitting Diode. Jpn. J. Appl. Phys. 2006, 45, 9001–9010. [Google Scholar] [CrossRef]

- Ye, S.; Xiao, F.; Pan, Y.; Ma, Y.; Zhang, Q. Phosphors in phosphor-converted white light-emitting diodes: Recent advances in materials, techniques and properties. Mater. Sci. Eng. R Rep. 2010, 71, 1–34. [Google Scholar] [CrossRef]

- Dorenbos, P. The 5d level positions of the trivalent lanthanides in inorganic compounds. J. Lumin. 2000, 91, 155–176. [Google Scholar] [CrossRef]

- Bando, K.; Noguchi, Y.; Sakano, K.; Shimizu, Y. Development and application of high-brightness white LEDs. Tech. Digest Phosphor Res. Soc. 264th Meeting Tokyo 1996, 11, 5–14. [Google Scholar]

- Wang, Y.; Zhu, G.; Xin, S.; Wang, Q.; Li, Y.; Wu, Q.; Wang, C.; Wang, X.; Ding, X.; Geng, W. Recent development in rare earth doped phosphors for white light emitting diodes. J. Rare Earths 2015, 33, 1–12. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, X.; Hao, Z.; Luo, Y.; Wang, X.; Zhang, J. Enriching red emission of Y3Al5O12: Ce3+ by codoping Pr3+ and Cr3+ for improving color rendering of white LEDs. Opt. Express 2010, 18, 25177–25182. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Kim, Y.-S. Energy transfer-based spectral properties of Tb-, Pr-, or Sm-codoped YAG:Ce nanocrystalline phosphors. J. Lumin. 2008, 128, 1570–1576. [Google Scholar] [CrossRef]

- Jang, H.S.; Bin Im, W.; Lee, D.C.; Jeon, D.Y.; Kim, S.S. Enhancement of red spectral emission intensity of Y3Al5O12:Ce3+ phosphor via Pr co-doping and Tb substitution for the application to white LEDs. J. Lumin. 2007, 126, 371–377. [Google Scholar] [CrossRef]

- Sommer, C.; Hartmann, P.; Pachler, P.; Hoschopf, H.; Wenzl, F.P. White light quality of phosphor converted light-emitting diodes: A phosphor materials perspective of view. J. Alloys Compd. 2012, 520, 146–152. [Google Scholar] [CrossRef]

- Takeuchi, T.; Sota, S.; Katsuragawa, M.; Komori, M.; Takeuchi, H.; Amano, H.; Akasaki, I. Quantum-Confined Stark Effect due to Piezoelectric Fields in GaInN Strained Quantum Wells. Jpn. J. Appl. Phys. 1997, 36, L382–L385. [Google Scholar] [CrossRef]

- Ramesh, V.; Kikuchi, A.; Kishino, K.; Funato, M.; Kawakami, Y. Strain relaxation effect by nanotexturing InGaN/GaN multiple quantum well. J. Appl. Phys. 2010, 107, 114303. [Google Scholar] [CrossRef]

- Chung, K.; Sui, J.; Demory, B.; Ku, P.-C. Color mixing from monolithically integrated InGaN-based light-emitting diodes by local strain engineering. Appl. Phys. Lett. 2017, 111, 041101. [Google Scholar] [CrossRef]

- Chung, K.; Sui, J.; Demory, B.; Teng, C.-H.; Ku, P.-C. Monolithic integration of individually addressable light-emitting diode color pixels. Appl. Phys. Lett. 2017, 110, 111103. [Google Scholar] [CrossRef]

- Feng, C.; Huang, J.-A.; Choi, H.W. Monolithic Broadband InGaN Light-Emitting Diode. ACS Photonics 2016, 3, 1294–1300. [Google Scholar] [CrossRef]

- Keller, S.; Schaake, C.; Fichtenbaum, N.A.; Neufeld, C.J.; Wu, Y.; McGroddy, K.; David, A.; DenBaars, S.P.; Weisbuch, C.; Speck, J.S.; et al. Optical and structural properties of GaN nanopillar and nanostripe arrays with embedded InGaN∕GaN multi-quantum wells. J. Appl. Phys. 2006, 100, 054314. [Google Scholar] [CrossRef]

- Kapoor, A.; Guan, N.; Vallo, M.; Messanvi, A.; Mancini, L.; Gautier, E.; Bougerol, C.; Gayral, B.; Julien, F.H.; Vurpillot, F.; et al. Green Electroluminescence from Radial m-Plane InGaN Quantum Wells Grown on GaN Wire Sidewalls by Metal–Organic Vapor Phase Epitaxy. ACS Photonics 2018, 5, 4330–4337. [Google Scholar] [CrossRef]

- Ra, Y.-H.; Navamathavan, R.; Park, J.-H.; Lee, C.-R. Coaxial InxGa1–xN/GaN Multiple Quantum Well Nanowire Arrays on Si(111) Substrate for High-Performance Light-Emitting Diodes. Nano Lett. 2013, 13, 3506–3516. [Google Scholar] [CrossRef] [PubMed]

- Lim, W.; Kum, H.; Choi, Y.-J.; Sim, S.-H.; Yeon, J.-H.; Kim, J.-S.; Seong, H.-K.; Cha, N.-G.; Park, Y.-S.; Yoo, G.; et al. SiO2 nanohole arrays with high aspect ratio for InGaN/GaN nanorod-based phosphor-free white light-emitting-diodes. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2016, 34, 042204. [Google Scholar] [CrossRef]

- Robin, Y.; Bae, S.Y.; Shubina, T.V.; Pristovsek, M.; Evropeitsev, E.A.; Kirilenko, D.A.; Davydov, V.Y.; Smirnov, A.N.; Toropov, A.A.; Jmerik, V.N.; et al. Insight into the performance of multi-color InGaN/GaN nanorod light emitting diodes. Sci. Rep. 2018, 8, 7311. [Google Scholar] [CrossRef]

- Albert, S.; Bengoechea-Encabo, A.; Garcia, M.A.S.; Calleja, E.; Jahn, U. Selective area growth and characterization of InGaN nanocolumns for phosphor-free white light emission. J. Appl. Phys. 2013, 113, 114306. [Google Scholar] [CrossRef]

- Sim, Y.C.; Lim, S.-H.; Yoo, Y.-S.; Jang, M.-H.; Choi, S.; Yeo, H.-S.; Woo, K.Y.; Lee, S.; Song, H.G.; Cho, Y.-H. Three-dimensional GaN dodecagonal ring structures for highly efficient phosphor-free warm white light-emitting diodes. Nanoscale 2018, 10, 4686–4695. [Google Scholar] [CrossRef]

- Ra, Y.-H.; Lee, C.-R. Core–Shell Tunnel Junction Nanowire White-Light-Emitting Diode. Nano Lett. 2020, 20, 4162–4168. [Google Scholar] [CrossRef]

- Sekiguchi, H.; Kishino, K.; Kikuchi, A. Emission color control from blue to red with nanocolumn diameter of InGaN/GaN nanocolumn arrays grown on same substrate. Appl. Phys. Lett. 2010, 96, 231104. [Google Scholar] [CrossRef]

- Kishino, K.; Nagashima, K.; Yamano, K. Monolithic Integration of InGaN-Based Nanocolumn Light-Emitting Diodes with Different Emission Colors. Appl. Phys. Express 2013, 6, 012101. [Google Scholar] [CrossRef]

- Hammersley, S.; Kappers, M.; Massabuau, F.C.-P.; Sahonta, S.-L.; Dawson, P.; Oliver, R.A.; Humphreys, C.J. Effects of quantum well growth temperature on the recombination efficiency of InGaN/GaN multiple quantum wells that emit in the green and blue spectral regions. Appl. Phys. Lett. 2015, 107, 132106. [Google Scholar] [CrossRef]

- Otsuki, S.; Jinno, D.; Daicho, H.; Kamiyama, S.; Iwaya, M.; Takeuchi, T.; Akasaki, I. Optical and structural characterization of GaInN/GaN multiple quantum wells grown on nonpolar a-plane GaN templates by metalorganic vapor phase epitaxy. Jpn. J. Appl. Phys. 2019, 58, SC1054. [Google Scholar] [CrossRef]

- Lu, W.; Goto, N.; Murakami, H.; Sone, N.; Iida, K.; Terazawa, M.; Han, D.-P.; Iwaya, M.; Tekeuchi, T.; Kamiyama, S.; et al. Controlled synthesis of nonpolar GaInN/GaN multiple-quantum-shells on GaN nanowires by metal-organic chemical vapour deposition. Appl. Surf. Sci. 2020, 509, 145271. [Google Scholar] [CrossRef]

- Kamiyama, S.; Lu, W.; Takeuchi, T.; Iwaya, M.; Akasaki, I. Growth and Characterization of Core-Shell Structures Consisting of GaN Nanowire Core and GaInN/GaN Multi-Quantum Shell. ECS J. Solid State Sci. Technol. 2020, 9, 015007. [Google Scholar] [CrossRef]

- Lu, W.; Sone, N.; Goto, N.; Iida, K.; Suzuki, A.; Han, D.-P.; Iwaya, M.; Tekeuchi, T.; Kamiyama, S.; Akasaki, I. Effect of AlGaN undershell on the cathodoluminescence properties of coaxial GaInN/GaN multiple-quantum-shells nanowires. Nanoscale 2019, 11, 18746–18757. [Google Scholar] [CrossRef]

- Ueda, M.; Hayashi, K.; Kondou, T.; Funato, M.; Kawakami, Y.; Narukawa, Y.; Mukai, T. Mechanisms of metalorganic vapor phase epitaxy of InGaN quantum wells on GaN microfacet structures. Phys. Status Solidi (C) 2007, 4, 2826–2829. [Google Scholar] [CrossRef]

- Bosi, M.; Fornari, R. A study of Indium incorporation efficiency in InGaN grown by MOVPE. J. Cryst. Growth 2004, 265, 434–439. [Google Scholar] [CrossRef]

- Goto, N.; Lu, W.; Murakami, H.; Terazawa, M.; Uzuhashi, J.; Ohkubo, T.; Hono, K.; Kamiyama, S.; Takeuchi, T.; Iwaya, M.; et al. Characterizations of GaN nanowires and GaInN/GaN multi-quantum shells grown by MOVPE. Jpn. J. Appl. Phys. 2020, 59, SGGE05. [Google Scholar] [CrossRef]

| Sample Name | Pattern | Pitch (nm) | Diameter (nm) | Height (µm) | TEG Flow Rate (sccm) | Barrier Growth Temperature (°C) | Well Growth Temperature (°C) |

|---|---|---|---|---|---|---|---|

| a | pa1 | 400 | 1200 | 1.4 | 30 | 750 | 750 |

| pa2 | 230 | 880 | 1.2 | ||||

| pa3 | 150 | 800 | 1.2 | ||||

| b | pb2 | 400 | 1200 | 1.6 | 60 | 750 | 750 |

| pb2 | 230 | 880 | 1.5 | ||||

| pb3 | 150 | 800 | 1.3 | ||||

| c | pc1 | 400 | 1200 | 1.6 | 60 | 800 | 750 |

| pc2 | 230 | 880 | 1.3 | ||||

| pc3 | 150 | 800 | 1.3 | ||||

| d | pd1 | 400 | 1200 | 1.1 | 30 | 800 | 750 |

| pd2 | 230 | 880 | 0.9 | ||||

| pd3 | 150 | 800 | 0.9 | ||||

| e | pe1 | 400 | 1200 | 1.4 | 30 | 800 | 730 |

| pe2 | 230 | 880 | 1.2 | ||||

| pe3 | 150 | 800 | 1.0 | ||||

| f | Pf1 | 400 | 1200 | 1.4 | 30 | 800 | 710 |

| Pf2 | 230 | 880 | 1.1 | ||||

| Pf3 | 150 | 800 | 1.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ito, K.; Lu, W.; Sone, N.; Miyamoto, Y.; Okuda, R.; Iwaya, M.; Tekeuchi, T.; Kamiyama, S.; Akasaki, I. Development of Monolithically Grown Coaxial GaInN/GaN Multiple Quantum Shell Nanowires by MOCVD. Nanomaterials 2020, 10, 1354. https://doi.org/10.3390/nano10071354

Ito K, Lu W, Sone N, Miyamoto Y, Okuda R, Iwaya M, Tekeuchi T, Kamiyama S, Akasaki I. Development of Monolithically Grown Coaxial GaInN/GaN Multiple Quantum Shell Nanowires by MOCVD. Nanomaterials. 2020; 10(7):1354. https://doi.org/10.3390/nano10071354

Chicago/Turabian StyleIto, Kazuma, Weifang Lu, Naoki Sone, Yoshiya Miyamoto, Renji Okuda, Motoaki Iwaya, Tetsuya Tekeuchi, Satoshi Kamiyama, and Isamu Akasaki. 2020. "Development of Monolithically Grown Coaxial GaInN/GaN Multiple Quantum Shell Nanowires by MOCVD" Nanomaterials 10, no. 7: 1354. https://doi.org/10.3390/nano10071354

APA StyleIto, K., Lu, W., Sone, N., Miyamoto, Y., Okuda, R., Iwaya, M., Tekeuchi, T., Kamiyama, S., & Akasaki, I. (2020). Development of Monolithically Grown Coaxial GaInN/GaN Multiple Quantum Shell Nanowires by MOCVD. Nanomaterials, 10(7), 1354. https://doi.org/10.3390/nano10071354